BERGES ACP SLV 6000 User Manual

BERGES

BERGES

Operating manual

SLV

ACP

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

Program Code Summary (Level 1 and 2)

·Level 1 – accesses only basic operator parameters.

·Level 2 – accesses all parameters in Level 1 and Level 2.

·Level 3 – accesses all parameters in Level 1, Level 2 and Level 3.

For more information consult Section 5 and publication “ACP 6000 – Option”.

|

|

|

|

|

|

|

|

|

|

|

PARAMETER |

DESCRIPTION |

DATA RANGE |

FACTORY |

ACCESS |

SEE |

CUSTOMER |

|

|

|

NUMBER |

NAME |

|

|

SETTING |

LEVEL |

PAGE |

SETTING |

|

|

|

|

|

|

|

|

|

||

|

01 |

MODEL |

Model Number |

0–65000 |

(1) |

1 |

47 |

|

|

|

02 |

RVLVL |

Software Revision |

0–640 |

(1) |

2 |

47 |

|

|

|

03 |

IRAT |

Rated Current |

2–200 A |

(1) |

2 |

47 |

|

|

|

05 |

SERNO |

Serial Number |

0–65000 |

|

2 |

47 |

|

|

|

06 |

REP |

Repair Date |

0–65000 |

|

2 |

47 |

|

|

|

07 |

FLT3 |

Last Fault |

– |

|

1 |

48 |

|

|

|

08 |

FLT2 |

2nd Fault |

– |

|

2 |

48 |

|

|

|

09 |

FLT1 |

1st Fault |

– |

|

2 |

48 |

|

|

|

12 |

FOUT |

Output Frequency |

0–400 Hz |

|

1 |

48 |

|

|

|

13 |

VOUT |

Output Voltage |

0–100% |

|

1 |

48 |

|

|

|

14 |

IOUT |

Output Current |

0–650 A |

|

1 |

48 |

|

|

|

15 |

LOAD |

Drive Load |

0–200% |

|

1 |

48 |

|

|

|

16 |

TORQ |

Load Torque |

0–200% |

|

1 |

48 |

|

|

|

17 |

TEMP |

Inverter Temp |

2–105 °C |

|

1 |

48 |

|

|

|

18 |

TIME1 |

Total Run Time |

0–65000 h |

|

2 |

48 |

|

|

|

19 |

TIME2 |

Power On Hours |

0–65000 h |

|

2 |

48 |

|

|

|

1B |

FLUX |

Magnetizing Current |

0–100% |

|

2 |

48 |

|

|

|

21 |

MODE |

Input Mode |

0–36 |

13 |

1 |

49 |

|

|

|

24 |

FSEL |

Reference Select |

0–19 |

0 |

2 |

49 |

|

|

|

27 |

TLSEL |

Torque Limit Select |

0–6 |

0 |

2 |

51 |

|

|

|

31 |

FMIN |

Minimum Frequency |

0.01–400.00 Hz |

0.00 Hz |

1 |

51 |

|

|

|

32 |

FMAX |

Maximum Frequency |

20.00–400.00 Hz |

50.00 Hz |

1 |

51 |

|

|

|

33 |

F2 |

Preset Frequency 2 (Jog) |

0.00–400.00 Hz |

5.00 Hz |

1 |

51 |

|

|

|

34 |

F3 |

Preset Frequency 3 |

0.00–400.00 Hz |

20.00 Hz |

2 |

51 |

|

|

|

35 |

F4 |

Preset Frequency 4 |

0.00–400.00 Hz |

40.00 Hz |

2 |

51 |

|

|

|

36 |

F5 |

Preset Frequency 5 |

0.00–400.00 Hz |

60.00 Hz (2) |

2 |

51 |

|

|

|

37 |

F6 |

Preset Frequency 6 |

0.00–400.00 Hz |

0.00 Hz (2) |

2 |

51 |

|

|

|

38 |

F7 |

Preset Frequency 7 |

0.00–400.00 Hz |

0.00 Hz (2) |

2 |

51 |

|

|

|

39 |

FTL |

Minimum Frequency in Torque Limit |

0.00–400.00 Hz |

10.00 Hz |

2 |

52 |

|

|

|

41 |

RSEL |

Ramp Selector |

0–7 |

0 |

2 |

52 |

|

|

|

42 |

ACC1 |

Acceleration Ramp 1 |

0.10–600.00 s |

3.00 s |

1 |

52 |

|

|

|

43 |

DEC1 |

Deceleration Ramp 1 |

0.10–600.00 s |

3.00 s |

1 |

52 |

|

|

|

44 |

ACC2 |

Acceleration Ramp 2 |

0.10–600.00 s |

1.00 s |

2 |

52 |

|

|

|

45 |

DEC2 |

Deceleration Ramp 2 |

0.10–600.00 s |

1.00 s |

2 |

52 |

|

|

|

46 |

DECTL |

Torque Limit Response Time |

0.10–30.00 s |

1.00 s |

2 |

53 |

|

|

|

47 |

DCBRK |

DC Brake Time |

0.00–5.00 s |

0.20 s |

2 |

53 |

|

|

|

48 |

DCVLT |

DC Brake Voltage |

0.00–15.00% |

(1) |

2 |

53 |

|

|

|

|

|

|

|

|

|

|

|

|

(1)Default value is model dependant.

(2)Parameter adjustable while the drive is in the run mode.

30.10.97 |

Operating manual |

05_GB |

ACP 6000SLV — 0.75–55 |

|

BERGES |

Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126 |

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

PARAMETER |

|

DESCRIPTION |

DATA RANGE |

FACTORY |

ACCESS |

SEE |

CUSTOMER |

|

|

|

NUMBER |

NAME |

|

|

|

SETTING |

LEVEL |

PAGE |

SETTING |

|

|

|

|

|

|

|

|

|

|

||

|

51 |

VSEL |

V/Hz Characteristic Selector |

0–6 |

0 |

2 |

53 |

|

|

|

|

52 |

BOOST |

|

Torque Boost |

0.00–20.00% |

(1) |

1 |

54 |

|

|

|

53 |

FKNEE |

|

V/Hz Knee Frequency |

26.00–640.00 Hz |

50.00 Hz |

2 |

54 |

|

|

|

54 |

SKBND |

Skip Frequency Hysteresis Band |

0.20–20.00 Hz |

1.00 Hz |

2 |

54 |

|

|

|

|

55 |

SK1 |

|

Skip Frequency 1 |

0.00–400.00 Hz |

0.00 Hz |

2 |

54 |

|

|

|

56 |

SK2 |

|

Skip Frequency 2 |

0.00–400.00 Hz |

0.00 Hz |

2 |

54 |

|

|

|

57 |

SK3 |

|

Skip Frequency 3 |

0.00–400.00 Hz |

0.00 Hz |

2 |

54 |

|

|

|

58 |

SK4 |

|

Skip Frequency 4 |

0.00–400.00 Hz |

0.00 Hz |

2 |

54 |

|

|

|

59 |

MVOLT |

|

Rated Motor Voltage |

370–480 V |

400 V |

2 |

55 |

|

|

|

5B |

IMAG |

Rated Magnetizing Current |

15.00–80.00% |

0.00% |

2 |

55 |

|

|

|

|

61 |

LTLF |

|

Load Torque Limit FWD |

5–200% |

150% |

2 |

56 |

|

|

|

62 |

LTLR |

|

Load Torque Limit REV |

5–200% |

150% |

2 |

56 |

|

|

|

63 |

RTLF |

Regenerative Torque Limit FWD |

5–110% |

80% |

2 |

56 |

|

|

|

|

64 |

RTLR |

Regenerative Torque Limit REV |

5–110% |

80% |

2 |

56 |

|

|

|

|

65 |

SLIP |

|

Slip Compensation |

0.00–10.00% |

0.00% |

1 |

56 |

|

|

|

66 |

STAB |

|

Current Stability |

0–6 |

2 |

2 |

56 |

|

|

|

67 |

TOL |

|

Timed Overload Trip Point |

0–100% |

0% |

1 |

57 |

|

|

|

68 |

NRST |

|

Restart Number |

0–8 |

0 |

2 |

57 |

|

|

|

69 |

DRST |

|

Restart Delay |

0.00–60.00 s |

0.00 s |

2 |

58 |

|

|

|

6A |

TOLC |

Timed Overload Characteristic |

0–7 |

0 |

2 |

58 |

|

|

|

|

70 |

MCAL |

|

Meter Calibration |

0–255 |

Set to |

1 |

58 |

|

|

|

|

|

|

|

|

10 VDC (2) |

|

|

|

|

|

71 |

METER |

|

Analog Meter Output |

0–8 |

1 |

1 |

58 |

|

|

|

72 |

ST1 |

|

Auxiliary Output 1 |

0–11 |

6 |

2 |

59 |

|

|

|

73 |

ST2 |

|

Auxiliary Output 2 |

0–11 |

3 |

2 |

59 |

|

|

|

74 |

ST3 |

|

Auxiliary Output 3 |

0–11 |

7 |

2 |

59 |

|

|

|

75 |

STR |

|

Auxiliary Relay (Fault) |

0–11 |

1 |

1 |

59 |

|

|

|

77 |

MOL |

Motor Overload Input Function |

0–1 |

0 |

2 |

60 |

|

|

|

|

81 |

PRGNO |

|

Special Program Number |

0–65000 |

0 |

2 |

61 |

|

|

|

82 |

START |

|

Inverter Start Options |

0–7 |

0 |

2 |

62 |

|

|

|

83 |

PWM |

Carrier Frequency Selector |

0–8 |

1 |

2 |

62 |

|

|

|

|

84 |

DISP |

|

Display Option Full Setting |

0–65000 |

0 |

2 |

63 |

|

|

|

85 |

UNITS |

|

Display Units |

6-digit |

RPM 1 |

2 |

63 |

|

|

|

86 |

LANG |

|

Display Language |

0–3 |

0 |

2 |

64 |

|

|

|

87 |

ACODE |

|

Security Access Code |

0–999 |

0 |

2 |

64 |

|

|

|

88 |

FRO |

Frequency Reference Output |

0–1 |

0 |

2 |

65 |

|

|

|

|

A2 |

RATIO |

|

Master Slave Speed Ratio |

0.00–200.00% |

100.00% (2) |

2 |

65 |

|

|

|

B1 |

OPTNO |

|

Option Board Number |

0–6 |

0 |

2 |

65 |

|

|

|

Cx |

CNTLx |

|

Event Control (1–9) |

Binary (8) |

0 (3) |

2 |

|

|

|

|

Ex |

ECNTx |

|

Event Counts (1–9) |

0–65535 |

0 (3) |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

NOTES:

Level 1 Parameters shown shaded.

See Section 5 for parameters accessible in Level 3 (SIO control).

(1)Default value is model dependant.

(2)Parameter adjustable while the drive is in the run mode.

(3)Consult BERGES for specific implementation instructions.

Operating manual |

30.10.97 |

ACP 6000SLV — 0.75–55 |

05_GB |

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

30.10.97 |

Operating manual |

05_GB |

ACP 6000SLV — 0.75–55 |

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

Operating manual |

30.10.97 |

ACP 6000SLV — 0.75–55 |

05_GB |

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

Table of contents

|

|

|

Page |

1 |

General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . 2 |

|

|

1.0 |

Safety and operating instructions for drive converters . . . . . . . . . . . . . . . . . . . . |

. . 2 |

|

1.1 |

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 5 |

|

1.2 |

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 5 |

|

1.3 |

Control Identification Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 5 |

|

1.4 |

ACP Series Control Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . 6 |

|

1.5 |

ACP Inverter Input/Output Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 10 |

|

1.6 |

AC Inverter Fundamentals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 10 |

|

1.7 |

Description of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 11 |

2 Installation and enclosure dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 12 |

||

|

2.1 |

General Rules for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 12 |

|

2.2 |

Dimensional Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 14 |

|

2.3 |

Input AC Line Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 22 |

|

2.3.1 |

Mains power connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 23 |

|

2.3.2 |

Motor connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 24 |

|

2.3.3 |

EMC Ordinance (EMC Directive, 89/336 EEC) . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 24 |

|

2.3.4 |

Using mains filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 26 |

|

2.3.5 |

Interference suppression measures/EMC (electromagnetic compatibility) . . . . . |

. 26 |

|

2.4 |

Line Fuse or Circuit Breaker Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 28 |

|

2.5 |

Wiring Practices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 28 |

|

2.6 |

Reducing Current Surges and Voltage Transients . . . . . . . . . . . . . . . . . . . . . . . |

. 29 |

|

2.7 |

Function and Use of Terminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 30 |

|

2.8 |

Environmental Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 33 |

3 Control Functions and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 35 |

||

|

3.1 |

General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 35 |

|

3.2 |

Digital Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 35 |

|

3.3 |

Operation Mode (STOP and RUN modes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 36 |

|

3.4 |

Program Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 37 |

|

3.5 |

Status (LED) Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 37 |

|

3.6 |

Description of Displays (Operating Display) . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 38 |

|

3.7 |

Operating Tips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 41 |

|

3.8 |

Quick-Start – Running the Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 42 |

|

3.9 |

Programming Flowchart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 44 |

4 Level 1 and 2 Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 45 |

||

|

4.1 |

Program Code Summary (Level 1 and 2) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 45 |

|

4.2 |

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 47 |

|

4.3 |

Parameter Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 47 |

5 |

Level 3 parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 66 |

|

|

5.1 |

Program Code Summary (Level 3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 66 |

|

5.2 |

Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 66 |

|

5.3 |

Parameter Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 67 |

6 |

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 72 |

|

|

6.1 |

Connection Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 72 |

|

6.2 |

Options and Accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 74 |

|

6.3 |

Application Hints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 75 |

7 |

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 77 |

|

|

7.1 |

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 77 |

|

7.2 |

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 78 |

|

7.3 |

Maintenance and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. 80 |

30.10.97 |

Operating manual |

1 |

05_GB |

ACP 6000SLV — 0.75–55 |

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

1 General information

Explanation of symbols and notes

Work safety symbol

You will find this symbol next to all work safety notes in this operating manual if there is a risk of injury or death for persons involved. Pay attention to these notes and observe particular caution in such cases. Also pass on all work safety instructions to other users.

Voltage warning

This symbol is shown wherever particular caution is necessary owing to occurring or applied voltages (e.g. DC voltages up to 650 V) and where special precautionary measures have to be taken. The inverter must always be isolated from the mains when working on it.

|

Caution note |

|

This note is shown in all parts of this operating manual to which particular attention must be |

ATTENTION! |

|

|

paid to ensure that the guidelines, specifications, notes and the correct sequence of work |

|

|

|

will be obeyed and to prevent damage or destruction of the inverter and/or systems. |

1.0Safety and operating instructions for drive converters

1. General

In operation, drive converters, depending on their degree of protection, may have live, unisolated, and possibly also moving or rotating parts, as well as hot surfaces.

In case of inadmissible removal of the required covers, of improper use, wrong installation or maloperation, there is the danger of serious personal injury and damage to property.

For further information, see documentation.

All operations serving transport, installation and commissioning as well as maintenance are to be carried out by skilled technical personnel (Observe IEC 364 or CENELEC HD 384 or DIN VDE 0100 and IEC 664 or DIN/VDE 0110 and national accident prevention rules!).

For the purposes of these basic safety instructions, “skilled technical personnel” means persons who are familiar with the installation, mounting, commissioning and operation of the product and have the qualifications needed for the performance of their functions.

We draw attention to the fact that no liability can be assumed for damage and malfunctions resulting from failure to observe the operating manual.

Technical amendments of illustrations and data given in this operating manual are reserved in the interest of improving the unit and its functions.

2. Intended use

The application of the drive converter described in this operating manual exclusively serves the purpose of continuously variable speed control of three-phase motors.

Drive converters are components designed for inclusion in electrical installations or machinery.

The drive converters are designed for installation in a switchgear cabinet (applies only to units of protection class IP 00/IP 21) and for permanent connection.

The operator of the system is solely liable for damage resulting from improper use of the drive converter.

2 |

Operating manual |

30.10.97 |

ACP 6000SLV — 0.75–55 |

05_GB |

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

Only items expressly approved by BERGES (e.g. mains filter, choke, external braking choppers and braking resistors etc.) may be used as accessories.

The installer of the system is liable for any damage resulting from the use of accessories that have not been approved expressly by BERGES. Please consult us in case of doubt.

In case of installation in machinery, commissioning of the drive converters (i.e. the starting of normal operation) is prohibited until the machinery has been proved to conform to the provisions of the directive 89/392/EEC (Machinery Safety Directive – MSD). Account is to be taken of EN 60204.

Commissioning (i.e. the starting of normal operation) is admissible only where conformity with the EMC directive (89/336/EEC) has been established.

The drive converters meet the requirements of the low-voltage directive 73/23/EEC. They are subject to the harmonized standards of the series prEN 50178/DIN VDE 0160 in conjunction with EN 60439-1/DIN VDE 0660, part 500, and EN 60146/DIN VDE 0558.

The technical data as well as information concerning the supply conditions shall be taken from the rating plate and from the documentation and shall be strictly observed.

3. Transport, storage

The instructions for transport, storage and proper use shall be complied with.

Damage established after delivery must be notified to the transport company immediately. Where necessary, the supplier must also be notified before the damaged drive converter is put into operation.

The climatic conditions shall be in conformity with prEN 50178.

4. Installation

The installation and cooling of the appliances shall be in accordance with the specifications in the pertinent documentation.

The drive converters shall be protected against excessive strains. In particular, no components must be bent or isolating distances altered in the course of transportation or handling. No contact shall be made with electronic components and contacts.

Drive converters contain electrostatic sensitive components which are liable to damage through improper use. Electric components must not be mechanically damaged or destroyed (potential health risks).

5. Electrical connection

When working on live drive converters, the applicable national accident prevention rules (e.g. VBG 4) must be complied with.

The electrical installation shall be carried out in accordance with the relevant requirements (e.g. cross-sectional areas of conductors, fusing, PE connection). For further information, see documentation.

Instructions for the installation in accordance with EMC requirements, like screening, earthing, location of filters and wiring, are contained in the drive converter documentation. They must always be complied with, also for drive converters bearing a CE marking. Observance of the limit values required by EMC law is the responsibility of the manufacturer of the installation or machine.

6. Operation

The components of the power section and certain elements of the control section are connected to the voltage mains when the drive converter is connected to the mains voltage.

Touching these components involves mortal danger!

Always isolate the drive converter from the mains supply before performing any work on the electrical or mechanical part of the system.

30.10.97 |

Operating manual |

3 |

05_GB |

ACP 6000SLV — 0.75–55 |

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

Isolate the drive converter from the mains before removing the terminal cover or the housing (e.g. by removing or deactivating on-site fuses or by deactivating a master switch isolating all poles etc.).

After disconnection of the drive converters from the voltage supply, live appliance parts and power terminals must not be touched immediately because of possibly energized capacitors. In this respect, the corresponding signs and markings on the drive converter must be respected. After switching off the mains voltage, wait for at least 5 minutes before beginning work on or in the drive converter. Dangerous voltages are still present as long as the “BUS CHG” lamp is still lit. In the event of malfunctions, the discharge time of 5 minutes may be exceeded substantially.

The drive converter contains protective facilities that deactivate it in the event of malfunctions, whereby the motor is de-energized and comes to a standstill (so-called “coasting” of the motor is possible depending on the rotating mass of the type of drive involved). Standstill of the motor can, however, also be produced by mechanical blockage. Voltage fluctuations, and particularly mains power failures, may also lead to deactivation. In certain circumstances, the drive may start up automatically once the cause of the fault has been remedied. As a result of this, certain systems may be damaged or destroyed and there may be a risk for operators working on the system. Installations which include drive converters shall be equipped with additional control and protective devices in accordance with the relevant applicable safety requirements, e.g. Act respecting technical equipment, accident prevention rules etc. Changes to the drive converters by means of the operating software are admissible.

The motor may be stopped during operation by disabling it or by deactivating the setpoint, whereby the drive converter and motor may remain live. If inadvertent startup of the motor must be excluded to protect operating personnel, electronic interlocking by disabling the motor or by deactivating the setpoint is inadequate. This is why the drive converter must be isolated from the mains voltage.

During operation, all covers and doors shall be kept closed.

Measuring instruments must be connected and disconnected only in de-energized condition.

Unauthorized conversions or modifications on or in the drive converter and its components and accessories will render all warranty claims void.

When installing an option board, observe the installation specification valid for this board.

Please contact BERGES if conversions or modifications are necessary, particularly if electrical components are involved.

7. Maintenance and servicing

The manufacturer’s documentation shall be followed.

KEEP SAFETY INSTRUCTIONS IN A SAFE PLACE!

Before you read on, please check whether technical changes are attached in the annex to this operating manual!

4 |

Operating manual |

30.10.97 |

ACP 6000SLV — 0.75–55 |

05_GB |

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

1.1Preface

|

This manual contains the specifications, installation instructions, description of operation and |

|

troubleshooting procedure for the ACP 6000 AC inverter. Before installing the drive, read this |

|

manual carefully to ensure correct installation and maximum performance. The information |

|

contained in this manual is current for versions fitted with drive software series 4.43 (02-RVLVL). |

|

Display Language |

|

With the parameter 86-LANG you can select the display language, see page 64. |

HINT! |

|

|

|

1.2Inspection

A.Upon receipt of the product, unpack the AC inverter and carefully inspect for any damage sustained in transit (depression in the enclosure, damage to parts, missing parts).

B.Next remove the AC Inverter cover, if supplied, and inspect for any loose screws, nuts or connectors.

C.Read the technical data plate and verify the correct power size for the application and note the input voltage and current required for the inverter.

D.If the inverter is to be stored for a long period of time, repack the inverter and store in a clean dry place, free from direct sunlight or corrosive fumes, and in a location where the ambient temperature will not be less than -20 °C nor more than 60 °C.

1.3Control Identification Number

Asystematic numbering system is used to define all models by input voltage rating, power rating, and enclosure type. This model number appears both on the shipping carton label and the technical data label on the enclosure. A model number code is also accessible in the Level 1 programming mode (Refer page 47, 01-MODEL).

ACP 6007-5A |

|

|

|

|

|

|

ACP |

|

6 |

|

007-5 |

|

A |

||||

BERGES inverter type: |

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|||||||||

Input volts: |

6 |

= 400 V AC |

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

460 V AC |

|

|

|

|

|

||||||||||

|

|

|

|||||||||||||||

KW: |

007-5 |

= 7.5 kW |

|

|

|

|

|

||||||||||

|

|

|

|

|

|||||||||||||

Housing: |

A |

= IP 00 |

|

|

|

||||||||||||

|

|

||||||||||||||||

C = IP 21/IP 54

Example Control Identification Number

30.10.97 |

Operating manual |

5 |

05_GB |

ACP 6000SLV — 0.75–55 |

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

The different power ratings available and code for each rating are as follows:

CODE |

KW |

PS |

3 ´ 400 V |

6000-7 |

0.75 |

1.0 |

X |

6001-5 |

1.5 |

2.0 |

X |

6002-2 |

2.2 |

3.0 |

X |

6003-0 |

3.0 |

4.0 |

X |

6004-0 |

4.0 |

5.0 |

X |

6005-5 |

5.5 |

7.5 |

X |

6007-5 |

7.5 |

10.0 |

X |

6011-0 |

11.0 |

15.0 |

X |

6015-0 |

15.0 |

20.0 |

X |

6022-0 |

22.0 |

30.0 |

X |

6030-0 |

30.0 |

40.0 |

X |

6037-0 |

37.0 |

50.0 |

X |

6045-0 |

45.0 |

60.0 |

X |

6055-0 |

55.0 |

75.0 |

X |

|

|

|

|

Table 1.3

1.4ACP Series Control Specifications

|

|

|

|

|

|

|

|

MODEL SERIES |

ACP 6000 |

SEE |

|

|

|

|

|

PAGE |

|

|

Applicable |

Horsepower (PS) |

1–75. |

– |

|

|

Motor Output |

|

|

|

|

|

Kilowatt (kW) |

0.75–55. |

10 |

|

|

|

|

|

|||

|

Inverter Output |

Capacity (kVA) |

1.5–135.0. |

10 |

|

|

Ratings |

|

|

|

|

|

Continuous Amps (A) |

2–121. |

10 |

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

Output Voltage |

3 ´ 7.0–460 VAC. |

– |

|

|

|

(Source limited) |

|

|

|

|

|

|

|

|

|

|

|

Frequency Range |

Programmable 0.1–400 Hz. |

51, 62 |

|

|

|

|

|

|

|

|

|

Overload Capacity at |

150% for 60 Seconds; |

57, 58 |

|

|

|

40 °C Ambient |

120% for 90 Seconds. |

|

|

|

|

|

|

|

|

|

|

Running Torque |

More than 100% (Programmable) + autoboost. |

54 |

|

|

|

|

|

|

|

|

|

Efficiency at Rated |

Greater than 95%. |

– |

|

|

|

Outputs |

|

|

|

|

Inverter Input |

Input Voltage |

±10% at 400–460 V. |

10, 22 |

|

|

Ratings |

(3Æ inputs all 3-wire) |

|

|

|

|

|

|

|

|

|

|

|

Input Current at |

2.2–152.8 A. |

10 |

|

|

|

Maximum Rated Output |

|

|

|

|

|

(AC amperes) |

|

|

|

|

|

|

|

|

|

|

|

KVA at 50/60 Hz |

1.8–122.0. |

10 |

|

|

|

|

|

|

|

|

|

Input Frequency |

50/60 Hz ±10%. |

– |

|

|

|

|

|

|

|

|

|

Phase Imbalance |

2% maximum. |

22 |

|

|

Control |

Control System |

Sine weighted Pulse Width Modulation with |

– |

|

|

Specifications |

|

Application Specific Integrated Circuit. |

|

|

|

|

|

|

|

|

|

|

Frequency Range |

4000:1; 0.1–400 Hz (Programmable). |

51, 62 |

|

|

|

|

|

|

|

6 |

Operating manual |

30.10.97 |

ACP 6000SLV — 0.75–55 |

05_GB |

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

|

|

|

|

|

|

|

|

MODEL SERIES |

ACP 6000 |

SEE |

|

|

|

|

|

PAGE |

|

|

Control |

Frequency Command |

0–10 VDC or 0–2 VDC (100 kW), |

30, 49 |

|

|

Specifications |

Selections |

4–20 mA (237 W), |

|

|

|

|

|

0–1 kHz or 0–10 kHz pulse train, |

|

|

|

|

|

Ext. Potentiometer, |

|

|

|

|

|

Digital Keypad, |

|

|

|

|

|

RS 485 Serial Communication Link. |

|

|

|

|

|

|

|

|

|

|

Frequency Resolution |

0.01 Hz. |

– |

|

|

|

|

|

|

|

|

|

Frequency Stability |

Analog +0.2%, |

– |

|

|

|

|

0–1 kHz pulse train +0.4%, |

|

|

|

|

|

0–10 kHz pulse train +0.1%, |

|

|

|

|

|

Keypad +0.1%, |

|

|

|

|

|

RS 485 Port +0.1%. |

|

|

|

|

|

|

|

|

|

|

V/Hz Ratio |

Programmable using FKNEE function |

54 |

|

|

|

|

(0.01 Hz resolution) |

|

|

|

|

|

400 VAC output models – 0.72 to 17.69. |

|

|

|

|

|

|

|

|

|

|

Acceleration/Deceleration |

Programmable – 0.1 to 600 seconds to maximum |

52 |

|

|

|

Ramps |

frequency (primary and alternate available). |

|

|

|

|

|

|

|

|

|

|

Minimum Frequency |

Programmable – 0.5 to 400 Hz (0.01 Hz increments). |

51 |

|

|

|

|

|

|

|

|

|

Maximum Frequency |

Programmable – 20 to 400 Hz (0.01 Hz increments). |

51 |

|

|

|

|

|

|

|

|

|

Torque Limit |

Four Quadrant Programmable – |

51, 56 |

|

|

|

|

5 to 200% torque (motoring mode); |

|

|

|

|

|

5 to 110% torque (regenerative mode); |

|

|

|

|

|

Individual program settings for FWD run, FWD regen, |

|

|

|

|

|

REV run, and REV regen. |

|

|

|

|

|

|

|

|

|

|

Torque Limit Deceleration |

Programmable – 0.1 to 30 Seconds. |

53 |

|

|

|

Rate |

|

|

|

|

|

|

|

|

|

|

|

Minimum Frequency in |

Programmable – 0.5 to 400 Hz. |

52 |

|

|

|

Torque Limit |

|

|

|

|

|

|

|

|

|

|

|

Torque Boost |

Programmable to suit requirements plus Autoboost. |

53, 54 |

|

|

|

|

|

|

|

|

|

Dynamic Braking |

30–200% of drive rating (10 sec. max.) standard. |

– |

|

|

|

|

Consult BERGES for model specific data. Additional |

|

|

|

|

|

capacity available by adding external DB kits. |

|

|

|

|

|

|

|

|

|

|

Adjustments |

Over 100 parameters can be monitored with over 80 |

– |

|

|

|

|

user adjustments. |

|

|

|

|

|

|

|

|

|

|

PWM Frequencies |

Two settings available. |

62 |

|

|

|

|

|

|

|

|

|

Agency Listing |

, UL® and CUL® Listed. |

– |

|

|

Protection |

Charge Indicator |

Indicates the presence of potentially lethal bus voltage. |

31 |

|

|

Features |

|

|

|

|

|

|

|

|

|

|

|

|

Ground Fault |

All models fully protected. |

– |

|

|

|

|

|

|

|

|

|

Output Short Circuit |

All models fully protected. |

– |

|

|

|

(Line-to-Line) |

|

|

|

|

|

|

|

|

|

|

|

Electronic Motor Overload |

Programmable Inverse Time Overload Trip. |

57, 58 |

|

|

|

|

|

|

|

|

|

Overvoltage Trip Level |

763 VDC. |

– |

|

|

|

(on DC bus) |

|

|

|

|

|

|

|

|

|

|

|

Undervoltage Trip Level |

395 VDC. |

– |

|

|

|

(on DC bus) |

|

|

|

|

|

|

|

|

|

30.10.97 |

Operating manual |

7 |

05_GB |

ACP 6000SLV — 0.75–55 |

|

BERGES |

Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126 |

|||

|

|

|

|

|

|

|

|

MODEL SERIES |

ACP 6000 |

SEE |

|

|

|

|

|

|

PAGE |

|

Protection |

|

Torque Limit |

4-Quadrant – Independently Programmable. |

51, 56 |

|

Features |

|

|

|

|

|

Program Lockout |

User definable security access code. |

64 |

||

|

|

||||

|

|

|

|

|

|

|

|

Line Start Lockout |

Prevents automatic start-up when line power is |

62 |

|

|

|

|

|

applied (defeatable by programming). |

|

|

|

|

|

|

|

|

|

Overtemperature |

Drive will shutdown if heat sink temperature exceeds |

– |

|

|

|

|

|

rating. |

|

|

|

|

|

|

|

|

|

|

DB Failure |

Drive will sense circuit failure and shutdown. |

– |

|

|

|

|

|

|

|

|

Error/Fault Messages |

19 fault codes, 6 warning displays. |

77 |

|

|

|

|

|

|

|

|

|

|

Fault Storage |

Last three (3) faults stored. Most recent displayed. |

48 |

|

|

|

|

|

|

|

|

Line Transient Limit |

2 kV Maximum (less than 40 microsecond duration). |

– |

|

|

|

|

|

|

|

|

|

External MOL Contact |

Compatible with NC fault contact. |

60 |

|

|

Operating |

Operating Controls |

1. Keypad: Forward, Reverse, Jog, Stop, Program, |

35 |

|

|

Features |

|

|

Shift, Enter, Local/Remote and Up/Down Arrows. |

|

|

|

|

|

2. Terminal strip: See typical connection diagrams |

32 |

|

|

|

|

(Page 72). |

|

|

|

|

|

3. RS 485 Serial Input/Output (SIO) Link. |

66 |

|

|

|

|

|

|

|

|

|

LED Indicators |

Forward, Reverse, Jog, Stop, Bus Charged and CPU |

37 |

|

|

|

|

active. |

|

|

|

|

|

|

|

|

|

|

Display |

2-lines of 16 characters, Super-Twist alphanumeric |

38, 63, 64 |

|

|

|

|

for all modes of operation. |

|

|

|

|

|

Programmable to display in English, French, Spanish |

|

|

|

|

|

or German. |

|

|

|

|

|

Any engineering units such as RPM, FPM, and GPM |

|

|

|

|

|

are supported. |

|

|

|

|

|

|

|

|

|

|

Auxiliary Relay |

Programmable as Fault Relay or to signal one of |

33, 59 |

|

|

|

|

eleven conditions. |

|

|

Programming |

Programming Levels |

Level 1 – Operator; |

45, 66 |

|

|

|

|

|

Level 2 – Engineer; |

|

|

|

|

|

Level 3 – Engineer with SIO. |

|

|

|

|

|

|

|

|

|

Parameter Block 00 |

Model #, software revision, rated current, heat sink |

– |

|

|

|

|

Drive Data |

temperature trip point, mfg. serial #, repair date code, |

|

|

|

|

|

and fault log. |

|

|

|

|

|

|

|

|

|

Parameter Block 10 |

Output frequency, voltage, motor current, motor load, |

– |

|

|

|

|

Status |

torque, drive temperature, elapsed time since power |

|

|

|

|

|

applied, and total hours of operation. |

|

|

|

|

|

|

|

|

|

Parameter Block 20 |

Definition of the LOCal/REMote keypad button in |

– |

|

|

|

|

Control |

reference to the keypad, terminal strip, and the SIO |

|

|

|

|

|

link. Also, various speed and torque references are |

|

|

|

|

|

contained within this block. |

|

|

|

|

|

|

|

|

|

Parameter Block 30 |

Various speed setpoints of the inverter. |

– |

|

|

|

|

Frequencies |

|

|

|

|

|

|

|

|

|

|

Parameter Block 40 |

Ramp time selections (the time from start to |

– |

|

|

|

|

Ramps |

maximum frequency FMAX or from FMAX to stop). |

|

|

|

|

|

|

|

|

|

Parameter Block 50 |

V/Hz curves, boost, minimum frequency at full |

– |

|

|

|

Voltage/Frequency |

voltage, and skip frequencies. |

|

|

|

|

|

Characteristics |

|

|

|

|

|

|

|

|

8 |

Operating manual |

30.10.97 |

ACP 6000SLV — 0.75–55 |

05_GB |

|

BERGES |

|

Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126 |

||||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MODEL SERIES |

|

|

|

|

|

|

|

ACP 6000 |

|

|

|

|

|

|

|

SEE |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PAGE |

|

||

|

Programming |

|

Parameter Block 60 |

|

Torque limit setpoints, slip compensation, overload |

– |

|

|

|||||||||||||||||||||

|

|

|

|

Torque Limit |

|

|

|

trip point, and auto-restart parameters. |

|

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

Parameter Block 70 |

|

METer output, open collector output, and fault relay |

– |

|

|

|||||||||||||||||||||

|

|

|

|

I/0 Definition |

|

|

|

|

|

|

|

definitions. |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

Parameter Block 80 |

|

|

Storage and Retrieval of standard or custom |

|

– |

|

|

|||||||||||||||||||

|

|

|

Program Options |

|

|

programs, complete reset to factory settings, auto- |

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

restart, line start-lockout, PWM selection, display of |

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

engineering units, alternate display languages, and |

|

|

|

|

|||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

customer access code storage. |

|

|

|

|

|

|

|

||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

Parameter Block 90 |

|

BAUD or communication rate, slave address, |

|

– |

|

|

||||||||||||||||||||

|

|

|

RS 485 Serial Link |

|

|

watchdog timer and retrieval of SIO generated fault |

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

Options |

|

|

|

|

|

|

|

|

codes. |

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

Parameter Block A0 |

|

Speed Ratio and various parameters relative to the |

– |

|

|

|||||||||||||||||||||

|

|

|

Option Parameters |

|

|

|

|

calibration of option cards (WPC). |

|

|

|

|

|

|

|

||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

Parameter Block B0 |

|

Option Board Identification and various parameters |

– |

|

|

|||||||||||||||||||||

|

|

|

Option Parameters |

|

|

relative to the calibration of option cards (WPC). |

|

|

|

|

|||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

Parameter Block C0 |

|

Used with program sequencer to control drive |

|

– |

|

|

||||||||||||||||||||

|

|

|

Event Control Bytes |

|

|

|

|

|

|

|

operation. |

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

Parameter Block E0 |

|

Used with program sequencer to control drive |

|

– |

|

|

||||||||||||||||||||

|

|

|

Event Count Bytes |

|

|

|

|

|

|

|

|

operation. |

|

|

|

|

|

|

|

|

|

|

|

||||||

|

Construction |

|

IP 00, IP 21, IP 54 |

|

|

|

|

|

IP 54 standard thru 37 kW. |

|

|

|

– |

|

|

||||||||||||||

|

Mounting |

|

IP 00 and IP 21 |

|

|

In separate enclosure free from dust, liquids and |

12 |

|

|

||||||||||||||||||||

|

Location |

|

|

|

|

|

|

|

|

|

|

|

|

|

corrosive fumes. |

|

|

|

|

|

|

|

|

|

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

IP 54 |

|

|

Indoor or Outdoor protected from direct sunlight. |

12, 33 |

|

|||||||||||||||||||

|

Ambient |

|

Operating Temperature |

|

|

|

|

|

IP 00 – 0 °C to 50 °C; |

|

|

|

|

|

– |

|

|

||||||||||||

|

Conditions |

|

|

|

|

|

|

|

|

|

|

|

IP 21/IP 54 – 0 °C to 40 °C. |

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

Storage Temperature |

|

|

|

|

|

|

-20 °C to +60 °C. |

|

|

|

|

|

– |

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

Humidity |

|

|

|

|

90% RH or less, noncondensing. |

|

|

|

– |

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Vibration |

|

|

|

|

|

|

|

0.6 G Maximum. |

|

|

|

|

|

– |

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

Elevation |

|

|

|

|

Below 1000 m without derating. |

|

|

|

– |

|

|

|||||||||||||

|

|

|

|

|

|

|

|

|

|

|

Table 1.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

DIMENSIONS/WEIGHT |

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

Type |

|

6000-7 |

6001-5 |

|

6002-2 |

|

6003-0 |

6004-0 |

|

6005-5 |

|

6007-5 |

|

6011-0 |

|

6015-0 |

|

6022-0 |

|

6030-0 |

|

6037-0 |

6045-0 |

|

6055-0 |

|

|

Dimensions (IP 00) |

mm |

|

|

221 ´ 301 ´ 135 |

|

|

229 ´ 441 ´ 203 |

|

|

356 ´ |

|

406 ´733 ´298 |

|

|||||||||||||||

|

(W ´ H ´ D) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

619 ´ 298 |

|

|

|

|

|

|

|||

|

Weight (IP 00) |

kg |

|

|

5,5 |

|

|

|

|

|

11,5 |

|

|

|

35,0 |

|

|

|

39,0 |

|

|

|

|||||||

|

Dimensions (IP 54) |

mm |

|

|

227 ´ 307 ´ 142 |

|

|

229 ´ 449 ´ 210 |

|

|

365 ´ |

|

|

417 ´ |

|

|

|

||||||||||||

|

(W ´ H ´ D) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

619 ´ 306 |

|

733 ´ 306 |

|

|

|||||

|

Weight (IP 54) |

kg |

|

|

6,0 |

|

|

|

|

|

12,5 |

|

|

|

44,0 |

|

|

|

51,0 |

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

30.10.97 |

Operating manual |

9 |

05_GB |

ACP 6000SLV — 0.75–55 |

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

1.5ACP Inverter Input/Output Ratings

AC RATINGS BY MODEL NUMBERS

|

|

Input ratings |

|

|

Maximum motor ratings |

|

||

|

|

|

|

|

|

|

|

|

|

|

Continuous |

|

Continuous |

1 min at 40 °C (2) |

|||

Inverter type |

KW |

KVA (5) |

A |

|

KVA |

A (1) |

KVA |

A |

6000-7 |

0.75 |

1.8 |

2.2 |

|

1.6 |

2.0 |

2.4 |

3.0 |

6001-5 |

1.5 |

3.4 |

4.3 |

|

2.9 |

3.7 |

4.4 |

5.6 |

6002-2 |

2.2 |

4.9 |

6.2 |

|

4.4 |

5.5 |

6.6 |

8.3 |

6003-0 |

3.0 |

5.5 |

7.0 |

|

4.9 |

7.0 |

7.4 |

10.5 |

6004-0 |

4.0 |

8.6 |

10.8 |

|

7.2 |

9.0 |

10.8 |

13.5 |

6005-5 |

5.5 |

12.8 |

16.0 |

|

10.4 |

13.0 |

15.5 |

19.5 |

6007-5 |

7.5 |

17.7 |

22.2 |

|

14.3 |

18.0 |

21.5 |

27.0 |

6011-0 |

11.0 |

24.7 |

31.0 |

|

19.1 |

24.0 |

28.7 |

36.0 |

6015-0 |

15.0 |

30.2 |

37.9 |

|

23.9 |

30.0 |

35.9 |

45.0 |

6022-0 |

22.0 |

45.3 |

56.8 |

|

35.9 |

45.0 |

53.8 |

67.5 |

6030-0 |

30.0 |

61.4 |

77.1 |

|

48.6 |

61.0 |

72.9 |

91.5 |

6037-0 |

37.0 |

75.5 |

94.7 |

|

59.8 |

75.0 |

89.6 |

112.5 |

6045-0 |

45.0 |

90.0 |

112.0 |

|

71.0 |

90.0 |

106.4 |

133.5 |

6055-0 |

55.0 |

111.0 |

134.0 |

|

88.0 |

110.0 |

131.5 |

165.0 |

|

|

|

Table 1.5 |

|

|

|

|

|

NOTES:

1)Value stored in parameter 03-IRAT. Wire size must be selected based upon 60/75 °C copper wire insulation rating.

2)For chassis models (IP 00), ratings are for 1 minute at +50 °C (40 °C external ambient when enclosed).

3)Control rated for 110% of motor rating (Continuous).

4)Motor thermal overload relay rating – 1.1 ´ continuous motor nameplate amps (necessary only in multimotor applications).

5)If the kVA rating of the power source exceeds ten times this value, the use of an isolation transformer or a line inductor is recommended.

1.6AC Inverter Fundamentals

The principal of operation of the ACP or any AC Inverter, is to provide both an adjustable voltage and an adjustable frequency to the AC motor. The ACP automatically maintains the required volts/hertz ratio, allowing the AC motor to run at its optimum efficiency and providing rated torque capability throughout the motor’s speed range.

The basic formula that relates the output frequency to motor speed is:

NS = |

60 × f |

|

|

P |

|

||

|

|

||

NS = Synchronous Speed (RPM) f = Frequency (Hertz) |

P = Number of pairs of poles. |

||

|

|

|

|

10 |

|

Operating manual |

30.10.97 |

|

ACP 6000SLV — 0.75–55 |

05_GB |

|

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

For Induction Motors:

Motor RPM = Synchronous Speed–Motor Slip (RPM).

The number of pairs of poles of a particular motor, and the amount of slip for a given load torque, are set by the motor’s design and manufacturer.

1.7Description of Operation

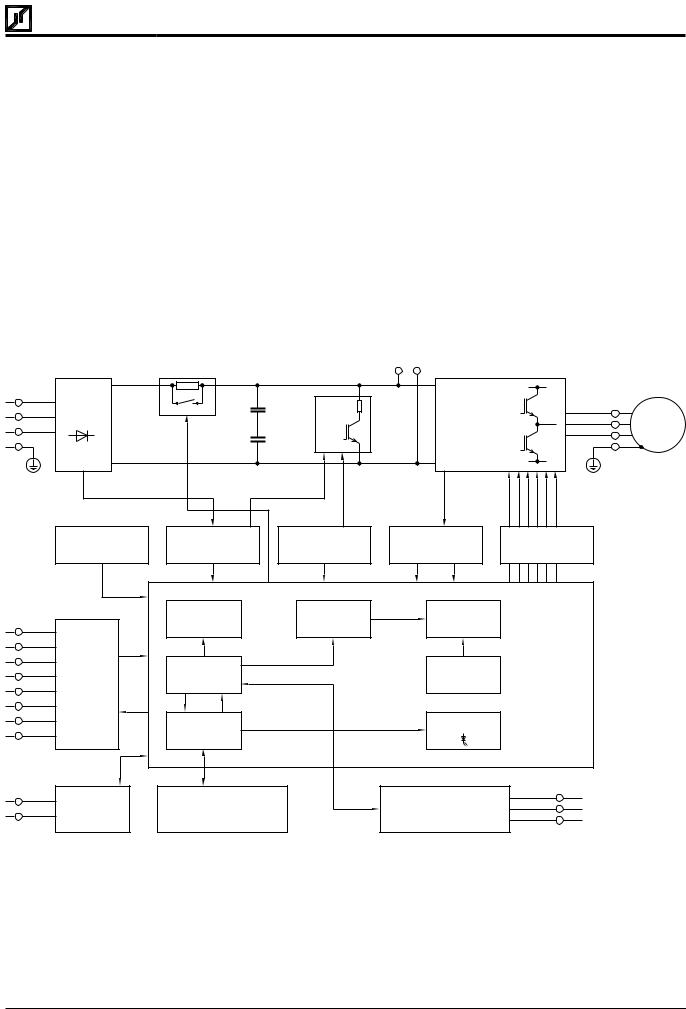

The primary functional blocks of the inverter are outlined in Figure 1.7.

The ultimate goal of any inverter is to accept fixed voltage and frequency from a power source and convert this power into variable voltage and frequency to control a three phase AC induction motor. The ACP 6000 does this and much more. It allows the user to interface into the very powerful electronics necessary to provide variable speed control of the motor, in a very friendly fashion.

Signals can be introduced to the terminal strip for full or partial control of the inverter. The powerful serial input output (SIO) link is available for total communication and programming. The keypad provides total control of programming and drive operation.

LINE INPUTS |

PRE-CHARGE |

DC BUS |

|

|

|

|

MOTOR |

|

RECTIFIER |

DC |

OUTPUTS |

|

|

||

|

BRAKE |

|

|

|

|

INVERTER BRIDGE |

|

|

|

|

M 3~

TEMPERATURE |

POWER SUPPLY |

VOLTAGE |

CURRENT |

DRIVER ELECTRONICS |

|

MEASUREMENT |

AND MONITOR |

MEASUREMENT |

MEASUREMENT |

||

|

|||||

|

RAMP |

CURRENT |

PWM- |

|

|

|

GENERATOR |

CONTROL |

GENERATOR |

|

|

|

CONTROL |

|

U/F- |

|

|

SIGNAL |

FUNCTIONS |

|

CHARACTERISTIC |

|

|

|

|

|

|

||

CONDITIONING |

|

|

|

|

|

|

CONTROL |

|

DIAGNOSIS |

|

|

|

|

|

|

||

|

AND PARAMETER |

|

|

|

|

|

BLOCK |

|

|

|

|

|

|

|

|

CPU |

|

SERIAL |

KEYPAD AND DISPLAY |

|

OPTION BOARD |

|

|

LINK (SIO) |

|

|

|||

|

|

|

|

Figure 1.7

30.10.97 |

Operating manual |

11 |

05_GB |

ACP 6000SLV — 0.75–55 |

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

2 Installation and enclosure dimensions

2.1General Rules for Installation

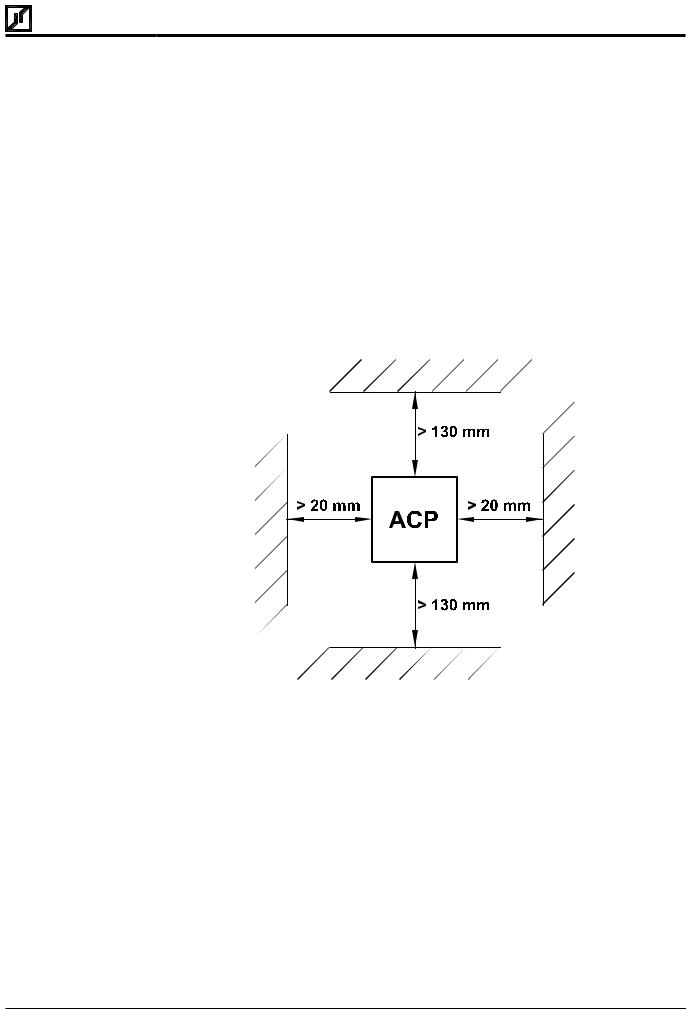

Improper installation of the inverter will greatly effect its life. Be sure to observe the following points when selecting a mounting location:

A.Mount the unit vertically and do not restrict the airflow to the heat sink fins on the back of the controller. The fan and fins allow cooling of internal components. Any air restriction could greatly reduce the life of the inverter, as well as resulting in nuisance overtemperature trips.

B.If the inverter has to be installed in a different position, external cooling is required for full capacity utilization.

C.The ACP inverter generates heat, and therefore there must be a sufficient amount of free space around the unit (see Figure 2.1). If the unit is accommodated in a housing together with a different unit, the prescribed minimum distances must be observed so that adequate ventilation can be ensured.

Figure 2.1

D.Do not install the inverter in a place subjected to high temperature, high humidity, or excessive vibration (consult Table 1.4 for temperature, humidity and maximum vibration limits).

E.Do not mount the ACP near heat generating equipment, or in direct sunlight.

F.BERGES inverters are generally designed so that they can be operated at ambient temperatures of 0 °C to +50 °C (IP 00) or 0 °C to 40 °C (IP 21/54) and at a relative humidity of up to 90%.

The occurrence of condensate must be avoided!

G.Please contact BERGES if the above values are exceeded. Therefore, when installing the unit, you must ensure that a heat buildup is prevented. In certain circumstances, the internal air circulation does not suffice when installing the unit in a control cabinet with a small volume.

12 |

Operating manual |

30.10.97 |

ACP 6000SLV — 0.75–55 |

05_GB |

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

H. The units should never be installed in the proximity of corrosive or flammable gases,

|

|

conductive dust or large magnetic and electric fields. |

|

I. |

Pay close attention during installation to ensuring that no objects (such as drilling swarf, |

|

|

wire or anything else) fall into the unit. Otherwise, a device fault cannot be excluded, even |

|

|

after longer periods of operation. |

ATTENTION! |

J. |

Do not use wire end ferrules for the control terminals. The terminals are designed |

so that the wires can be inserted in the terminals after twisting the individual wires.

K. Line starting

ACP is designed to provide controlled starting and stopping of AC motors by use of the keypad or external contacts connected to the control terminal strip. ACP may also be started by applying AC power to terminals L1, L2 and L3. The inverter has line-start-lock- out as a standard feature, to prevent automatic starting when line power is applied. This provision can be defeated by appropriate programming. The inverter may be started once every two minutes in this mode.

The safety of the operating personnel must be guaranteed in all operating states. Please refer to the safety instructions in chapter 1.0, page 2. The mains voltage must be switched off before opening or working on the device. Dangerous voltages are present as long as the charge indicator lamp is still lit.

30.10.97 |

Operating manual |

13 |

05_GB |

ACP 6000SLV — 0.75–55 |

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

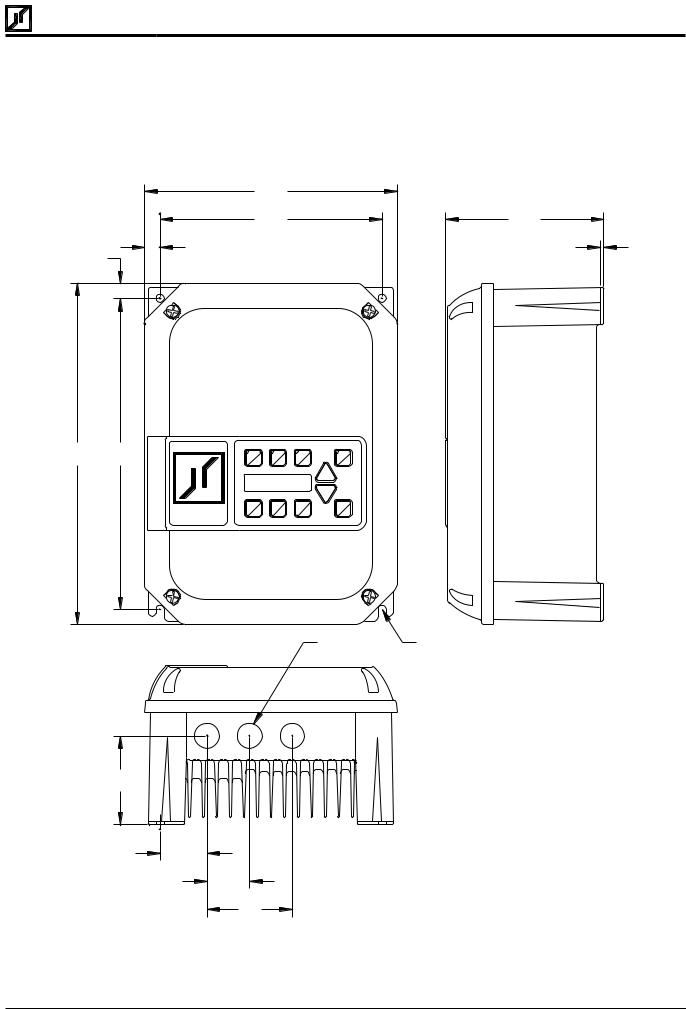

2.2Dimensional Data

The following pages show the dimensional data for the IP 00, IP 21 and IP 54 ACP inverters.

ACP 6000 – 0.75...4.0 kW (IP 21/IP 54)

227

200 |

142 |

14 |

3 |

14 |

|

307 280

BERGES

22 |

7 |

80

42

38

77

Figure 2.2.1

14 |

Operating manual |

30.10.97 |

ACP 6000SLV — 0.75–55 |

05_GB |

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

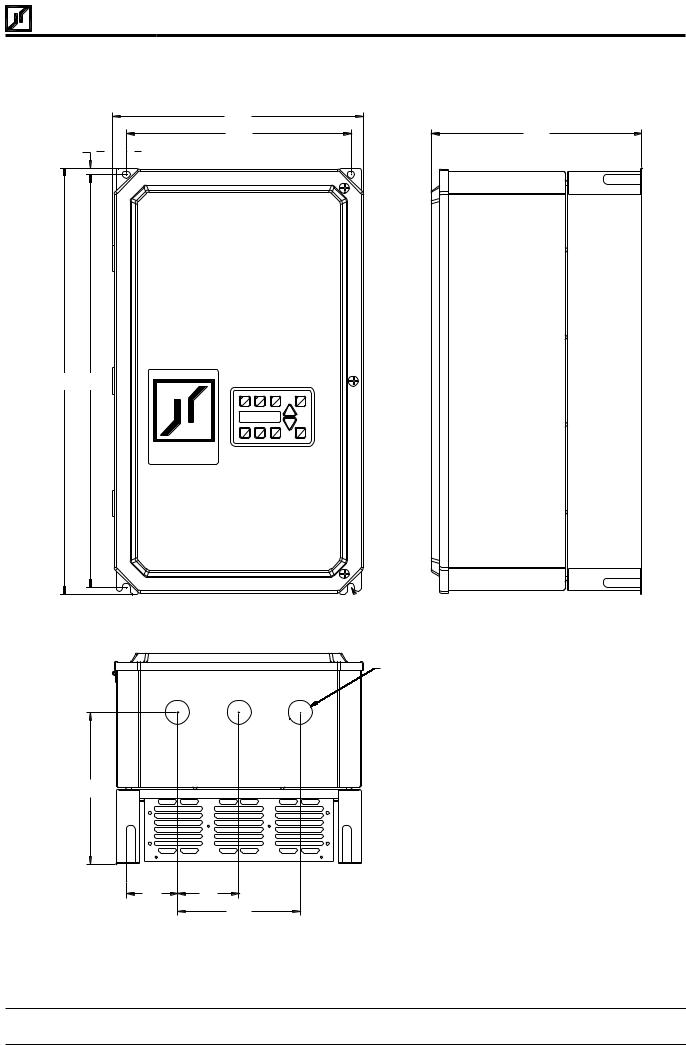

ACP 6000 – 0.75...4.0 kW (IP 00)

221

|

200 |

135 |

10 |

10 |

3 |

|

|

301 280

22 |

7 |

80

42

38

77

Figure 2.2.2

30.10.97 |

Operating manual |

15 |

05_GB |

ACP 6000SLV — 0.75–55 |

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

ACP 6000 – 5.5...15.0 kW (IP 21/IP 54)

229

200 |

210 |

15 |

14 |

|

449 419

BERGES

9

9

29

119

49 |

51 |

|

|

102 |

|

|

Figure 2.2.3 |

|

16 |

Operating manual |

30.10.97 |

ACP 6000SLV — 0.75–55 |

05_GB |

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

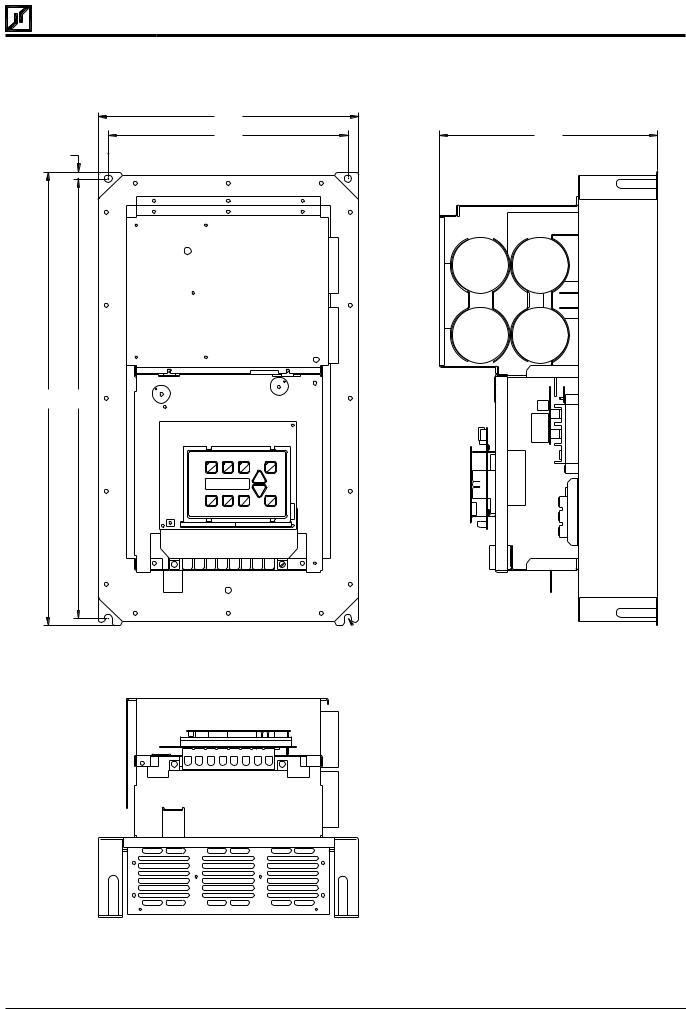

ACP 6000 – 5.5...15.0 kW (IP 00)

229

200 |

203 |

14

11

441 419

9

9

29

119

49

49  51

51

102

Figure 2.2.4

30.10.97 |

Operating manual |

17 |

05_GB |

ACP 6000SLV — 0.75–55 |

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

ACP 6000 – 22...30 kW (IP 21/IP 54)

365

327 |

306 |

9

21

21

619 600

BERGES

10

10

35

220

75 |

89 |

|

|

178 |

|

|

Figure 2.2.5 |

|

18 |

Operating manual |

30.10.97 |

ACP 6000SLV — 0.75–55 |

05_GB |

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

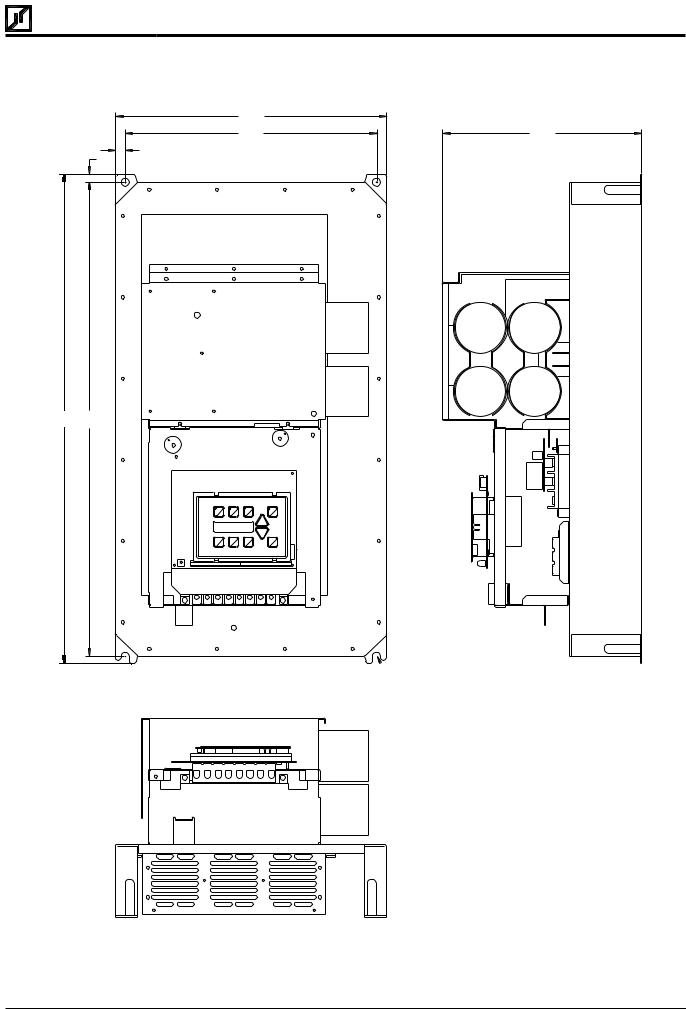

ACP 6000 – 22...30 kW (IP 00)

356

327 |

298 |

9  14

14

619 600

10

10

Figure 2.2.6

30.10.97 |

Operating manual |

19 |

05_GB |

ACP 6000SLV — 0.75–55 |

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

ACP 6000 – 37...55 kW (37 kW = IP 21 or IP 54; 45...55 kW = only IP 21)

417

378 |

306 |

21

12

733 711

BERGES

12

12

35

220

75 |

89 |

|

|

178 |

|

|

Figure 2.2.7 |

|

20 |

Operating manual |

30.10.97 |

ACP 6000SLV — 0.75–55 |

05_GB |

BERGES Berges electronic · D–51709 Marienheide-Rodt · Tel. 02264/17-0 · Fax 02264/17126

ACP 6000 – 37...55 kW (IP 00)

406

378 |

298 |

14

12

733 711

12

12

Figure 2.2.8

30.10.97 |

Operating manual |

21 |

05_GB |

ACP 6000SLV — 0.75–55 |

Loading...

Loading...