Berges ACM D2, ACM S2 Operating Manual

Operat in g man ual

ACM

D2/S2

Table of contents

1. General information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.General safety instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2.Intended use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3.Transport, storage, installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.4.Electrical connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.5.Operating instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.6.Miscellaneous. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4. Technical data (input voltage 1 x 220...240V). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

5. Technical data (input voltage 3 x 380...460V). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

6. Technical data (input voltage 3 x 380...460V). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7. Power-derating in function of the switching frequency. . . . . . . . . . . . . . . . . . . . . . . . . . 10

8. Dimensional data ACM D2/S2 0.37 kW - 5.5 kW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

9. Dimensional data ACM D2 7.5 kW - 22.0 kW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

10. Dimensional data ACM D2 30.0 kW - 37.0 kW. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

11. Installation examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

11.1.Example 1: ACM D2/S2 0.37 kW - 2.2 kW (1 x 230V). . . . . . . . . . . . . . . . . . . . 14

11.2.Example 2: ACM D2/S2 0.75 kW - 37.0 kW (3 x 400V). . . . . . . . . . . . . . . . . . . 15

12. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

12.1.Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

12.2.Mains power connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

12.3.Motor connection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

12.4.Interference suppression measures / EMC (electromagnetic compatibility). . . . . 17

12.4.1.General information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

12.4.2.Installation notes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

12.5.Mains back-up fuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

12.6.Ventilation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

12.7.Control terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

12.8.Power terminals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

BERGES electronic

09.07.2001 Operating manual ACM D2/S2 1

13. Commissioning and settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

13.1. General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

13.2. Adaption to operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

14. Operating functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

14.1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

14.2. Control panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

14.3. Display. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

14.4. Help - function and language - select. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

14.5. Inverter status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

14.6. Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

14.7. Operating error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

14.8. Hardware error messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

15. Programming ACM D2/S2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

15.1. Program structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

15.2. Program level TAB1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

15.3. Program level TAB2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

15.4. Program level TAB3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

16. Braking chopper ACM D2/S2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

16.1. Braking chopper 0.37 kW - 1.1 kW (1 x 230V). . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

16.2. Braking chopper 0.75 kW - 37.0 kW (3 x 400V). . . . . . . . . . . . . . . . . . . . . . . . . . . 51

16.2.1. Minimum values for braking resistors (accessory) . . . . . . . . . . . . . . . . . . 51

16.2.2. Assembling the braking resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

17. Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

17.1. Programming key. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

17.2. Telecomander RC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

17.3. DVM - PLUS MP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

17.4. ACM - Synchronizer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

18. Faults and remedies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

19. Functions of ACM D2/S2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

20. Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Operatin g manual ACM D2/S2

Document: ACM/D2A-STD-E/A07

Edition: 09.07.2001

© 2001 BERGES electronic s.r.l. All rights reserved.

ArtNr: 38005000EN

BERGES electronic

2 Operating manual ACM D2/S2 09.07.2001

1.General information

Before you start with the installation and the starting up of the inverter, please read this manual carefully

and pay special attention to the notes and suggestions.

This manual must be made available to every user. Before working with the unit the user must become

familiar with it. This specially applies to the knowledge a nd observance of the following safety and

warning indications.

Used symbols:

Danger, warning

This symbol is used when the life or health of the user is in danger or a considerable damage to property

can occur.

Attention, essential measure

This symbol is shown on places of the manual, which are to be particularly consid ered for safe and

disturbance-free operation of the inverter.

2.Safety instructions

All instructions stated in this chapter are important for t he security of users and machines or systems

and should absolutely be considered.

2.1.General safety instructions

Inverters work with high voltages, which can cause death or serious injury by touching them. Depending

on the degree of protection of the inverter, in operation they may have live, uninsulated and possibly

also moving or rotating parts, as well as hot surfaces. In case of an inadmissible removal of the required

covers, an improper use and a wrong installation or operation, there is a danger of serious personal

injury and damage to property.

All operations serving transport, installation and commissioning as well as maintenance are to be

carried out by skilled technical personnel (observe IEC 364 or CENELEC HD 384 and national accident

prevention rules!). For the purposes of these basic safety instructions, "skilled technical personnel"

means persons who are familiar with the installation, mounting, commissioning and operation of the

product and have the qualifications needed for the performance of their functions.

2.2.Intended use

The application of the inverter described in this operating manual exclusively serves for the purpose

of continuously variable speed control of three-phase motors.

Inverters are components designed to be used in electrical installations or machinery.

Commissioning of the inverter (e.g. the starting of normal operation) is prohibited until the system has

been proved to conform to the provisions of the directive 89/392/EEC (Machinery Safety Directive -

MSD) and the 89/336/EEC (EMC directive).

The inverter meets the requirements of the low-voltage directive 73/231/EEC. They are subject to the

harmonized standards of the series EN 50178.

The operator of the system is solely liable for damage resulting from improper use of the inverter.

ATTENTION!

BERGES electronic

09.07.2001 Operating manual ACM D2/S2 3

2.3.Transport, storage, installation

The inverter must be protected against inadmissible mechanical loads. No components must be

bent and no insulating distances must be altered during transportation or handling. The inverters

are containing electrostatic sensitive components which are liable to damage through improper

use. Do not touch electronic components an d electrical contacts. Do not switch on inverters with

mechanical damaged electrical or electronic components, the accordance with the applied directi-

ves is no longer guaranteed in this case. With the installation of the inverter attention is to be paid

to the prescribed minimum distances as well as to a sufficient cooling. The climatic conditions shall

be in conformity with E N 50178.

2.4.Electrical connection

Before performing any installation work the system must be insulated from the mains supply and

protected accordingly.

After switching off the line voltage, wait for at least 5 minutes un til the DC-link capacitors are

discharged. Only then it is allowed to work on the device. In case of malfunctions, the discharge

time could be exceeded substantially.

Because of a possible leakage current > 3.5mA from the installed EMC-filter, the inverter is designed

only for permanent connection. For size and layout of the GND (earth) conduc tor also see EN

50178.

The inverters are designed to be installed in a switchgear cabinet and may only operate when

connected with earth-potential.

For a trouble-free operation of the inverter, the installation requirements and notes in this manual

are to be considered.

When using residual-current-operated circ uit-breakers pay attention to the compatibility with the

inverter. Depending on the type of the device the foll owing rules apply:

•Single-phase inverters: pulse-current sensitive (type A) or all-current sensitive (type B) residual-

current-operated circuit-breakers are admissible.

•Three-phase inverters: only all-current sensitive (type B) residual-current-operated circuit-brea-

kers are admissible.

Otherwise another protective measure such as separation from the environment by double or

reinforced insulation, disconnection from the mains or similar are to be used (EN 50178). The trigger

current of the residual-current-operated circuit-bre akers must be sufficiently dimensioned since

capacitive leakage currents (cable screens, filters) can e asily lead to false triggering.

2.5.Operating instructions

The inverter can be configured to restart automatically in case of an error. If necessary, the system

must be equipped with additional monitoring or protective features to avoid resulting dangers (see

accident prevention rules etc.).

The motor can be stopped by switching off the setpoint or deactivating the enable input. If required

for safety reasons, an inadvertent restart can be preven ted disconnecting the inverter from the

mains supply.

BERGES electronic

4 Operating manual ACM D2/S2 09.07.2001

2.6. Miscellaneous

We point out that we do not take the re sp onsibility for da ma ge and operation al disturbances resulting

from the neglect of this oper ating manual.

Technical changes may be carried out to improve the device and its functions.

Before you continue reading, please check whether technical amendments are attached

in the annex to this operating manual!

BERGES electronic

09.07.2001 Operating manual ACM D2/S2 5

3.Introduction

The present operating manual contains specifications, installation instructions and troubleshooting

procedures for ACM D2/S2 inverters.

The information in this manual must be known before installation of the inverter in order to

guarantee fault-free installation and thus maximum performance.

The information contained in this manual refers to the software versions

D2A-STD-020A

and

D2A-1300-021.

BERGES electronic

6 Operating manual ACM D2/S2 09.07.2001

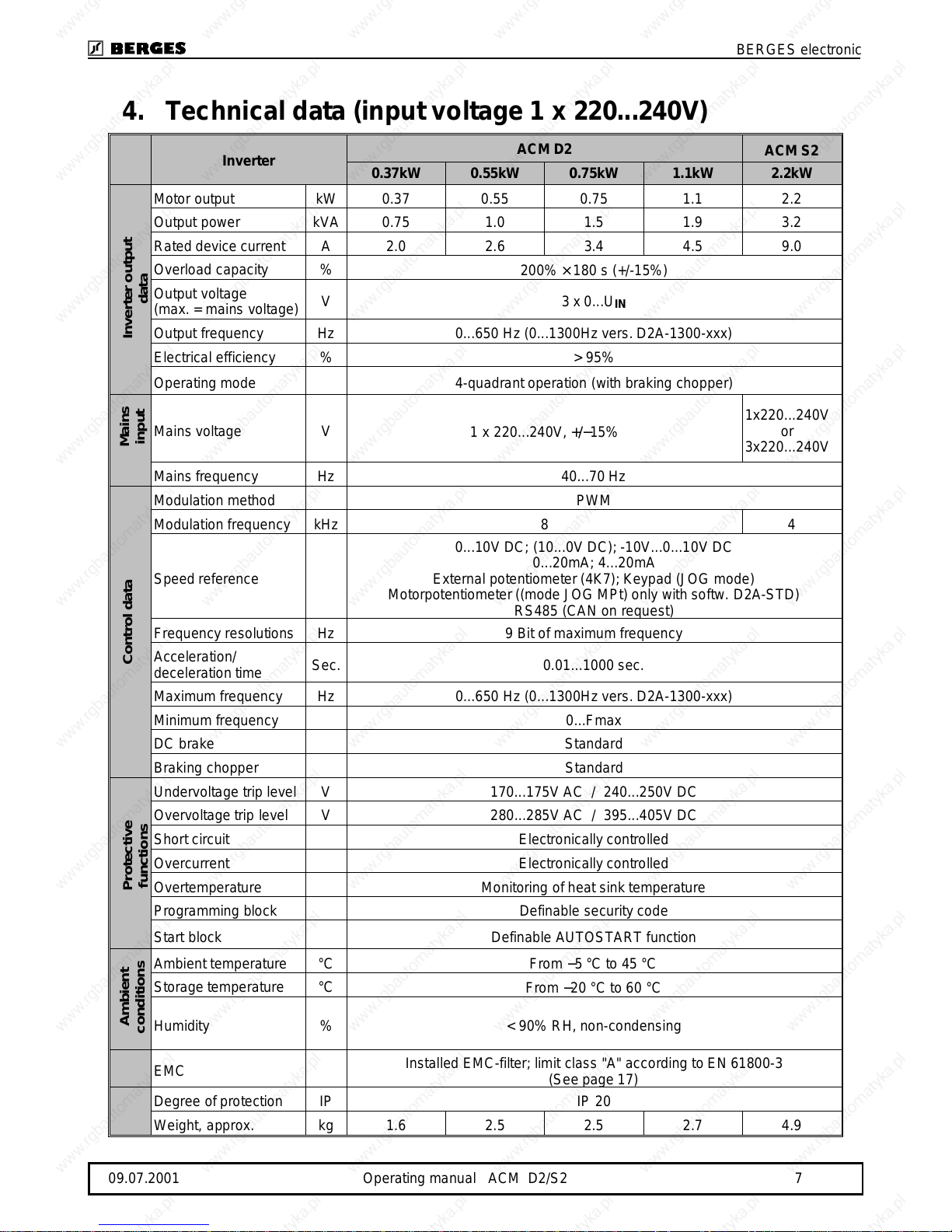

4. Technical data (input voltage 1 x 220...240V)

Inverter

ACM D2

ACM S2

0.37kW 0.55kW 0.75kW 1.1kW 2.2kW

Motor output kW 0.37 0.55 0.75 1.1 2.2

Output power kVA 0.75 1.0 1.5 1.9 3.2

Rated device current A 2.0 2.6 3.4 4.5 9.0

Overload capacity %

200% × 180 s (+/-15%)

Output voltage

(max. = main s voltage)

V3 x 0...U

IN

Output frequency Hz 0...650 Hz (0...13 00 Hz vers. D2 A-1 30 0-xxx)

Electrical efficiency % > 95%

Operating mode 4-quadrant operation (with braking chopper)

Mains voltage V

1 x 220...240V, +/−15%

1x220...240V

or

3x220...240V

Mains frequency Hz 40...70 Hz

Modula ti on method PWM

Modulation frequency kHz 8 4

Speed re fe re nce

0... 10V DC; (10.. . 0V DC); -1 0V...0...10V DC

0...20mA; 4...20mA

External potentiometer (4 K7); Ke ypad (J O G mode)

Motorpo te n t i om eter ((mode JOG MPt) only with softw. D2A-STD)

RS485 (CAN on request)

Frequency resolutions Hz 9 Bit of maximum frequency

Acceleration/

deceleration time

Sec. 0.01...1000 sec.

Maximum freque ncy Hz 0 ...65 0 Hz (0...13 00 Hz ve rs. D2A-1 30 0-xxx)

Minimum frequency 0...Fmax

DC brake Standard

Braking chopper Standard

Undervoltage trip level V 170...175V AC / 240...250V DC

Overvoltage trip level V 280...285V AC / 395...405V DC

Short circuit Electronically controlled

Overcurrent Electronically controlled

Overtempera ture Monitoring of heat sink tem pe rature

Programming block Definable security code

Start block

Definable AUTOSTART function

Ambient temperature °C

From −5 °C to 45 °C

Storage temperature °C

From −20 °C to 60 °C

Humidity % < 90% RH, non-condensing

EMC

Installed EMC-filter; limit class "A" according to EN 61800-3

(See page 17)

Degree of protection IP IP 20

Weight , approx. kg 1.6 2.5 2.5 2.7 4.9

Inverter output

data

Mains

input

Control dataProtective

functions

Ambient

conditions

BERGES electronic

09.07.2001 Operating manual ACM D2/S2 7

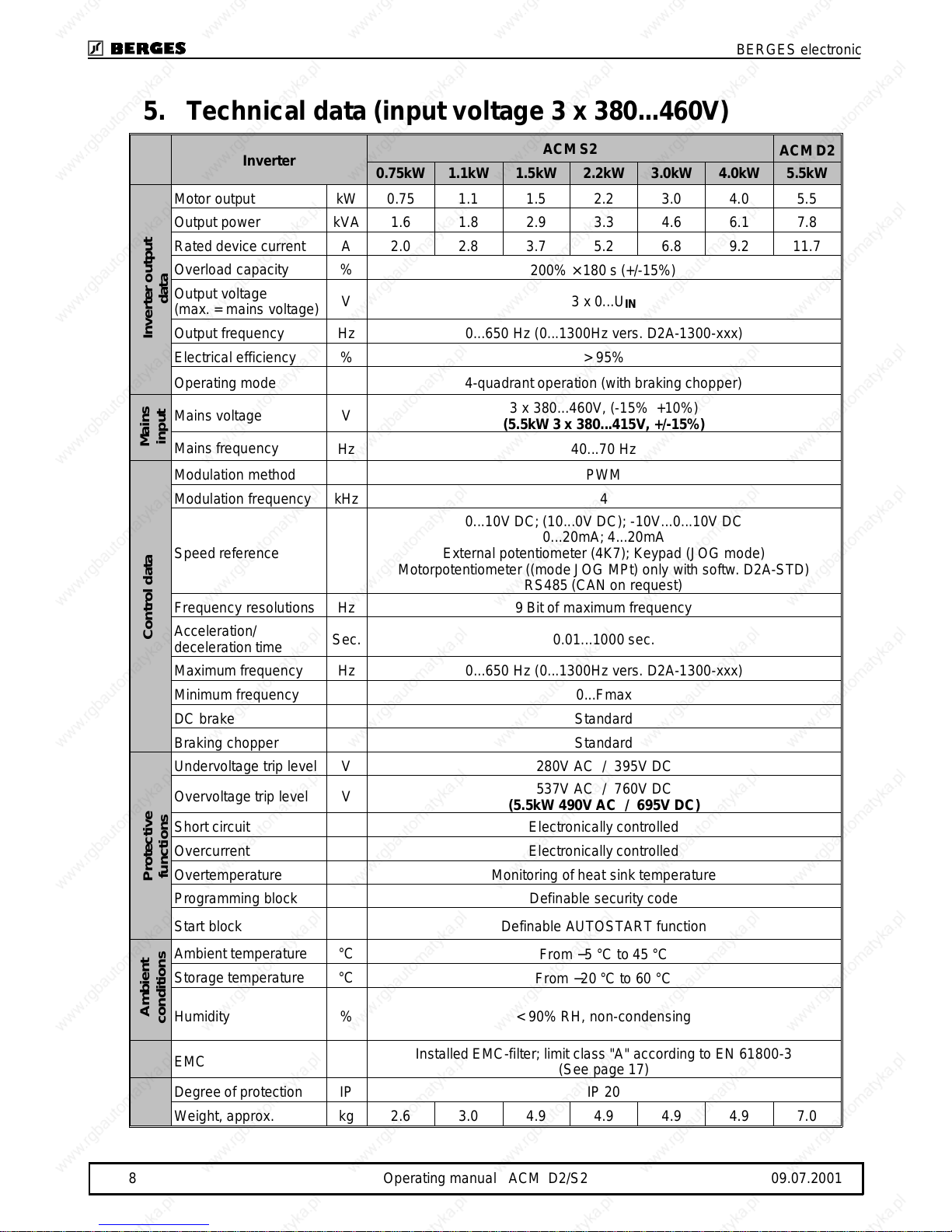

5. Technical data (input voltage 3 x 380...460V)

Inverter

ACM S2

ACM D2

0.75kW 1.1kW 1.5kW 2.2kW 3.0kW 4.0kW 5.5kW

Motor output kW 0.75 1.1 1.5 2.2 3.0 4.0 5.5

Output power kVA 1.6 1.8 2.9 3.3 4.6 6.1 7.8

Rated de vic e cu rre nt A 2.0 2.8 3.7 5.2 6.8 9.2 11.7

Overload capacity %

200% × 180 s (+/-15%)

Output voltag e

(max. = mains voltage)

V3 x 0...U

IN

Output frequency Hz 0...650 Hz (0...1300Hz vers. D2A-1300-xxx)

Electrical efficiency % > 95%

Operatin g mode 4-quadra nt ope ration (wi th brak i ng chopper)

Mains voltage V

3 x 380...460V, (-15% +10%)

(5.5kW 3 x 380...4 15V , +/-15%)

Mains freq uency

Hz 40...70 Hz

Modulation method PWM

Modulation frequency kHz 4

Speed reference

0...10V DC; (1 0. ..0V DC); -10V...0.. .10V DC

0...20mA; 4...20mA

External potentiometer (4K7); Keypad (JOG mode)

Motorpotentiometer ((mode JOG MPt) only with softw. D2A-STD)

RS485 (C A N on request)

Frequency resolutions Hz 9 Bit of maximum frequency

Acceleration/

deceleration time

Sec. 0.01...1000 sec.

Maximum frequency Hz 0...650 Hz (0...1300Hz v ers. D2A-1300-xxx)

Minimum frequency 0...Fmax

DC brake Standard

Braking chopper Standard

Undervoltage trip level V 280V AC / 395V DC

Overvoltage trip level V

537V AC / 760V DC

(5.5kW 490V AC / 695V DC)

Short circuit Electronically co ntrolled

Overcurrent Electronically controlled

Overtemperature Monitoring of heat sink temperature

Programming block Definable security code

Start block Definable AUTOSTART function

Ambient temperature °C

From −5 °C to 45 °C

Storage temperature °C

From −20 °C to 60 °C

Humidity % < 90% RH, n on-condensing

EMC

Installed EMC-filter; limit class "A" according to EN 61800-3

(See page 17 )

Degree of protection IP IP 20

Weight, ap prox. kg 2.6 3.0 4.9 4.9 4.9 4.9 7.0

Inverter output

data

Mains

input

Control dataProtective

functions

Ambient

conditions

BERGES electronic

8 Operating manual ACM D2/S2 09.07.2001

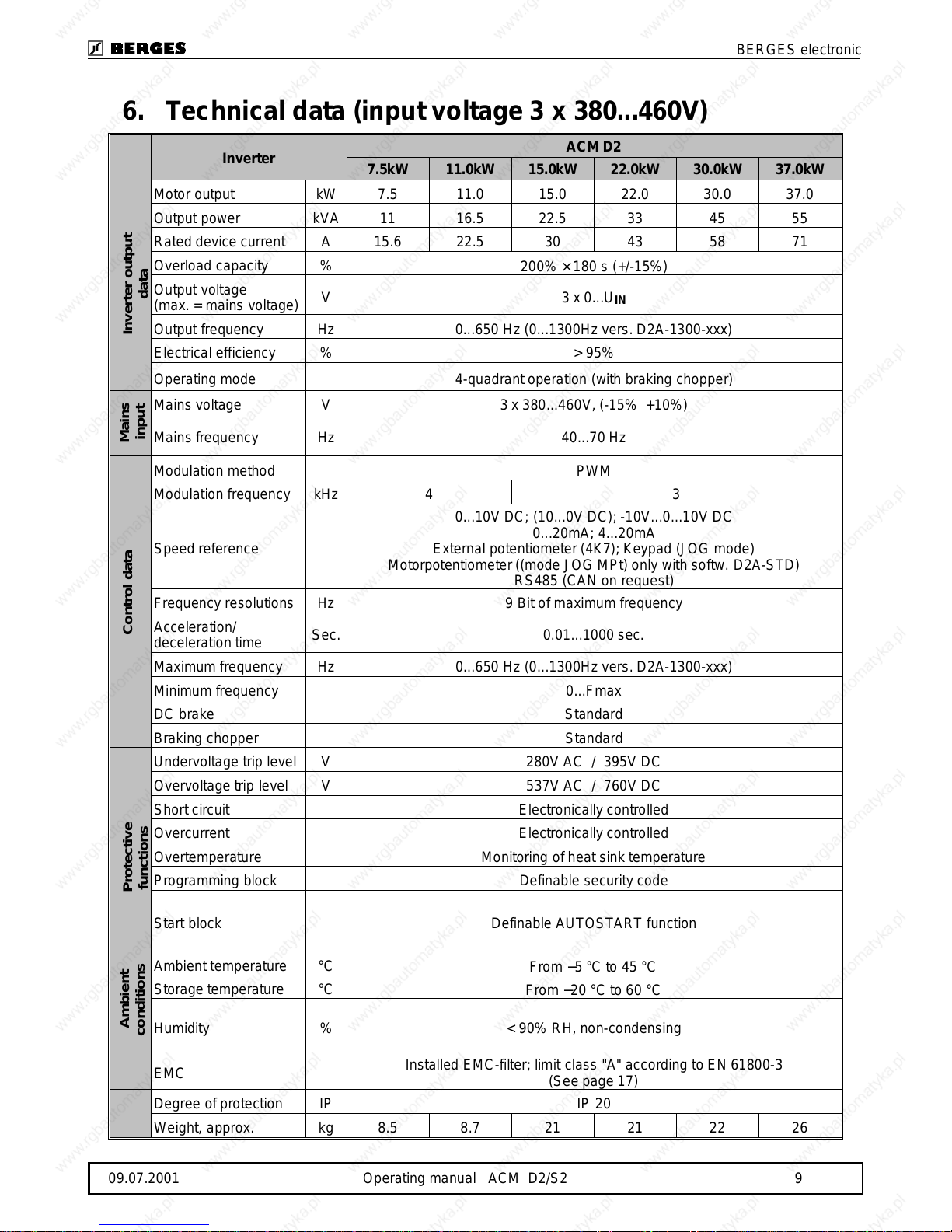

6. Technical data (input voltage 3 x 380...460V)

Inverter

ACM D2

7.5kW 11.0kW 15.0kW 22.0kW 30.0kW 37.0kW

Motor output kW 7.5 11.0 15.0 22.0 30.0 37.0

Output power kVA 11 16.5 22 .5 33 45 55

Rated device current A 15.6 22.5 30 43 58 71

Overload capacity %

200% × 180 s (+/-15%)

Output voltage

(max. = main s voltage)

V3 x 0...U

IN

Output frequency Hz 0...650 Hz (0...13 00 Hz vers. D2 A-1 30 0-xxx)

Electrical efficiency % > 95%

Operating mode 4-quadrant operation (with braking chopper)

Mains volta ge V 3 x 380...460V, (-15% +10%)

Mains frequency Hz 40...70 Hz

Modula ti on method PWM

Modulation frequency kHz 4 3

Speed re fe re nce

0... 10V DC; (10.. . 0V DC); -1 0V...0...10V DC

0...20mA; 4...20mA

External potentiometer (4 K7); Ke ypad (J O G mode)

Motorpo te n t i om eter ((mode JOG MPt) only with softw. D2A-STD)

RS485 (CAN on request)

Frequency resolutions Hz 9 Bit of maximum frequency

Acceleration/

deceleration time

Sec. 0.01...1000 sec.

Maximum freque ncy Hz 0 ...65 0 Hz (0...13 00 Hz ve rs. D2A-1 30 0-xxx)

Minimum frequency 0...Fmax

DC brake Standard

Braking chopper Standard

Undervoltage trip level V 280V AC / 395V DC

Overvoltage trip level V 537V AC / 760V DC

Short circuit Electronically controlled

Overcurrent Electronically controlled

Overtempera ture Monitoring of heat sink tem pe rature

Programming block Definable security code

Start block Definable AUTOSTART function

Ambient temperature °C

From −5 °C to 45 °C

Storage temperature °C

From −20 °C to 60 °C

Humidity % < 90% RH, non-condensing

EMC

Installed EMC-filter; limit class "A" according to EN 61800-3

(See page 17)

Degree of protection IP IP 20

Weight, approx. kg 8.5 8.7 21 21 22 26

Inverter output

data

Mains

input

Control dataProtective

functions

Ambient

conditions

BERGES electronic

09.07.2001 Operating manual ACM D2/S2 9

7.Power-derating in function of the switching

frequency

P

N

Nominal power

P

OUT

Output power

f

PWM

Switching frequency

Ambient conditions: T

amb

= 45°C

0,0

0,2

0,4

0,6

0,8

1,0

0481216

f

(kHz)

P

out

/ P

N

ACM D2/S2 0,37-2,2kW/230V

ACM S2 0,75-4,0kW/400V

ACM D2 5,5kW/400V

ACM D2 7,5kW/400V

ACM D2 11kW/400V

ACM D2 22-37kW/400V

ACM D2 15kW/400V

N

/ P

out

P

(kHz)

PWM

f

1230

1,2

1,0

0,8

0,6

0,4

0,2

0,0

6

BERGES electronic

10 Operating manual ACM D2/S2 09.07.2001

8.Dimensional data ACM D2/S2 0.37 kW - 5.5 kW

Additional mounting bracke t:

only for ACM D2 5.5kW

Dimensions (in mm)

ACM 1x230V ACM 3x400V

D2 S2 S2 D2

0,370,550,751,11,52,20,751,11,52,23,04,05,5

A

154153153153194194194194194194194194265

B

168168168168208208208208208208208208280

C

181181181181222222222222222222222222293

D

5353 53 585454 54 545454545458

E

108106106106109109109109109109109109116

F

-404045676767676767676790

G

- 146146151176176176176176176176176206

H

Ø6Ø6Ø6Ø6Ø6Ø6Ø6Ø6Ø6Ø6Ø6Ø6Ø6

I

180180180180174174174174174174174174180

J

190190190190179179179179179179179179200

K

1414 14 141414 14 141414141414

L

------------35

ACM D2 0.37 - 1.1kW

C B

A

F

G

L

E

D

H

H

ACM D2/S2 0.75 - 5.5kW

BERGES electronic

09.07.2001 Operating manual ACM D2/S2 11

9.Dimensional data ACM D2 7.5 kW - 22.0 kW

Dimensions (in mm)

ACM D2 (3x400V)

7.5 11.0 15.0 22.0

A

317 317 330 330

B

344 344 375 375

C

367 367 390 390

D

54.25 54.25 48 48

G

209 209 250 250

H

Ø7 Ø7 Ø6 Ø6

I

186 186 310 310

J

198 198 325 325

K

25 25 30 30

L

154.75 154.75 205 205

ACM D2 7.5 - 11.0kW ACM D2 15.0 - 22.0kW

BERGES electronic

12 Operating manual ACM D2/S2 09.07.2001

10. Dimensional data ACM D2 30.0 kW - 37.0 kW

Dimension s (in mm)

ACM D2 (3x400V)

30.0 37.0

A

442 442

B

343 408

C

422 422

D

242 242

E

35.5 67

F

65.5 98.5

G

Ø7 Ø7

H

255 255

ACM D2 30. 0 - 37.0kW

ACM D2 30.0 - 37.0kW

BERGES electronic

09.07.2001 Operating manual ACM D2/S2 13

11.Installation examples

11.1.Example 1: ACM D2/S2 0.37 kW - 2.2 kW (1 x 230V)

1)The GND terminals (10, 12 and 14) are floating and serve, among other things, as the

reference potential for shielded cables of the control inputs. This potential must be grounded

directly either at the control side (PLC or similar) or at the inverter (PE to one of the terminals

10, 12 or 14).

2)The option “Output chokes” is suitable for reducing the capacitive currents to ground and also

the interference originating from the inverter.

3)Option relay board “REL”, see functions OC1/OC2 page 48/49.

4)Option ACM - Synchronizer. (Only with Software D2A-STD).

5)Speed reference with motorpotentiometer possible only with Software D2A-STD.

The terminal assignment shown in this drawing refers to the setting “Active LOW”.

BERGES electronic

14 Operating manual ACM D2/S2 09.07.2001

11.2.Example 2: ACM D2/S2 0.75 kW - 37.0 kW (3 x 400V)

1)The GND terminals (10, 12 and 14) are floating and serve, among other things, as the

reference potential for shielded cables of the control inputs. This potential must be grounded

directly either at the control side (PLC or similar) or at the inverter (PE to one of the terminals

10, 12 or 14).

2)The option “Output chokes” is suitable for reducing the capacitive currents to ground and also

the interference origin atin g from the inverter.

3)Option relay board “REL”, see functions OC1/OC2 page 48/49.

4)Option ACM - Synchronizer. (Only with Software D2A-STD).

5)Speed reference with motorpotentiometer possible only with Software D2A-STD.

6)

Inputs non-insulated.

The terminal assignment shown in this drawing refers to the setting “Active LOW”.

BERGES electronic

09.07.2001 Operating manual ACM D2/S2 15

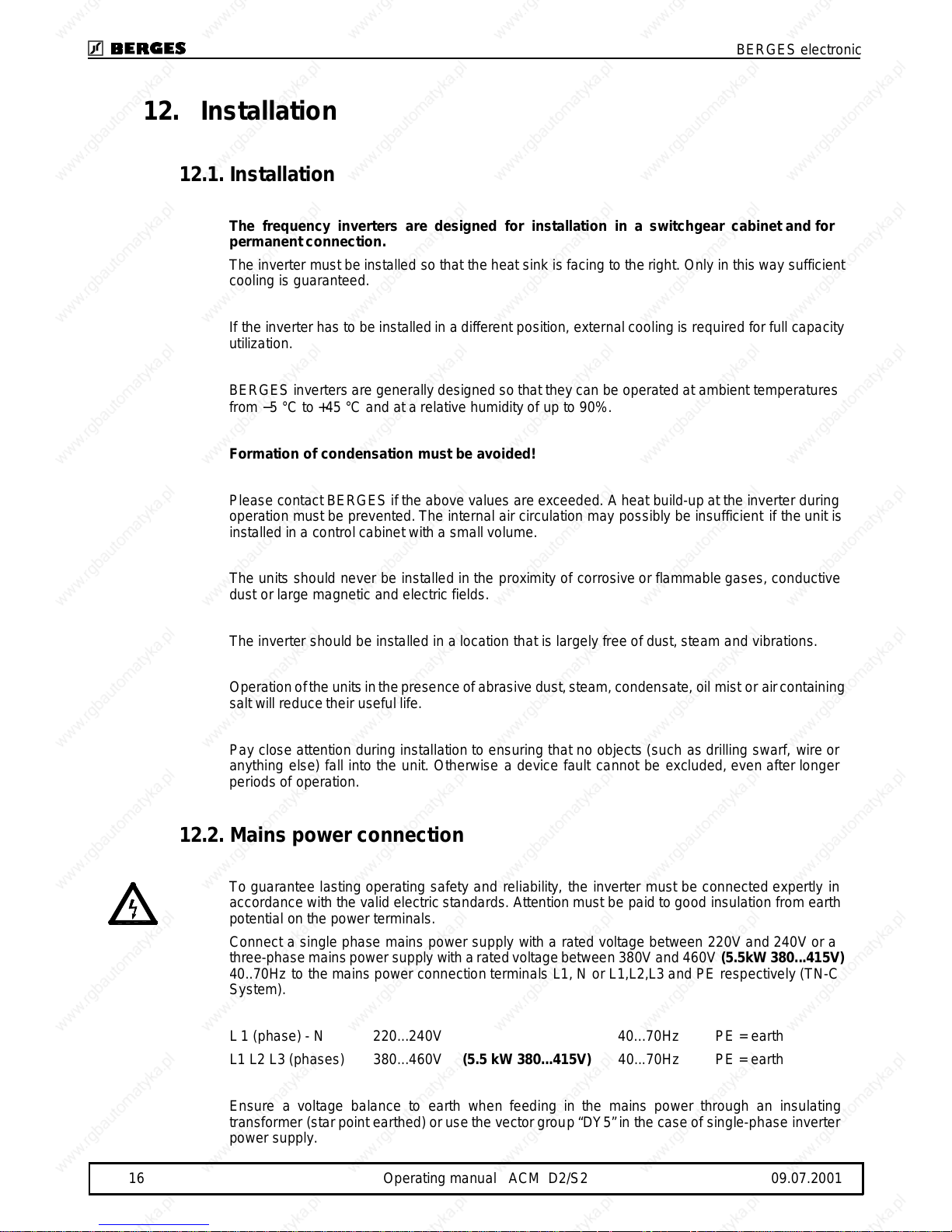

12.Installation

12.1.Installation

The frequency inverters are designed for installation in a switchgear cabinet and for

permanent connection.

The inverter must be installed so that the heat sink is facing to the right. Only in this way sufficient

cooling is guaranteed.

If the inverter has to be installed in a different position, external coolin g is required for full capacity

utilization.

BERGES inverters are generally designed so that they can be operated at ambient temperatures

from −5 °C to +45 °C and at a relative humidity of up to 90%.

Formation of condensation must be avoided!

Please contact BERGES if the above values are exceeded. A heat build-up at the inverter during

operation must be prevented. The internal air circulation may possibly be in sufficient if the unit is

installed in a control cabinet with a small volume.

The units should never be installed in the proximity of corrosive or flammable gases, conductive

dust or large magnetic and electric fields.

The inverter should be installed in a location that is largely free of dust, steam and vibrations.

Operation of the units in the presence of abrasive dust, steam, condensate, oil mist or air containing

salt will reduce their useful life.

Pay close attention during installation to ensuring that no objects (such as drilling swarf, wire or

anything else) fall into the unit. Otherwise a device fault cannot be excluded, even after longer

periods of operation.

12.2.Mains power connection

To guarantee lasting operating safety and reliability, the inverter must be connected expertly in

accordance with the valid electric standards. Attention must be paid to good insulation from earth

potential on the power terminals.

Connect a single phase mains power supply with a rated voltage between 220V and 240V or a

three-phase mains power supply with a rated voltage between 380V and 460V

(5.5kW 380...415V)

40..70Hz to the mains power connection terminals L1, N or L1,L2,L3 and PE respectively (TN-C

System).

L 1 (phase) - N 220...240V 40...70Hz PE = earth

L1 L2 L3 (phases) 380...460V

(5.5 kW 380...415V)

40...70Hz PE = earth

Ensure a voltage balance to earth when feeding in the mains power through an insulating

transformer (star point earthed) or use the vector group “DY5” in the case of single- phase inverter

power supply.

BERGES electronic

16 Operating manual ACM D2/S2 09.07.2001

12.3.Motor connection

Connect the motor cable to the

U, V, W

and PE terminals.

The inverter will be deactivated in the event of a short circuit at the terminals

U, V, W.

We recommend PTC evaluation using commercially available devices to achieve effective protection

of the motor.

If interrupting contacts (e.g. contactors or motor protection switches etc.) have to be installed between

the motor and inverter, the circuit must be configured so as to ensure that the

ENABLE

signal (terminals

10/11) is deactivated

before

separation of the inverter/motor connection. A relay switching time of

approx. 30 ms suffices.

Long motor cables (> 20m) in connection with high voltage peaks caused by the fast switching output

stages of the inverter may endanger the motor insulation. In such cases we recommend to use suitable

filter measures (e.g. motor chokes or dU/dt filters) to protect the motor.

12.4.Interference supp ression measures / EMC

(electromagnetic compatibility)

12.4.1.General information

Inverters are electronic devices which are used in industrial and commercial sys tems. In accordance

with the EMC-directives 89/336/EEC the inverters are not designed for independ en t operation. Thus

inverters should be used for further processing thro ugh competent machine/system manufacturers.

By this, the devices do not require a CE-marking. The proof of the conformity of the machine/system

with the required EMC-directives must be furnished by the manufacturer or operator of the system.

The inverters of the ACM series are equipped with an internal filter and designed to be used in class

"A" environments (first environment, restricted distribution) according to the product standard EN

61800-3.

The evaluation of the conformity took place in a practical structure having taken into account the

following installation notes.

Voltage peaks produced by other devices connected at the mains supply can possibly disturb or even

damage the inverter. Input ch ok es (option) can be used to protect the inverter against these voltage

peaks (caused e.g. by switching off of high loads from the mains).

12.4.2.Installation notes

During operation, electrical/electronic devices can influence or disturb each other via power supply or

other metallic connections.

The electromagnetic compatibility of the system is highly influenced by the manner of the installation.

Measures for the grounding, shielding and filtering are to be particularly considered. By paying attention

to the following installation notes it can be assumed that the EMC limit values for the system/machine

are kept.

•Inverters and optional components like input or output chokes must be in metal-to-metal contact

with the grounded mounting plate using the whole surface if possible. Use prefera bly galvanized

mounting plates. Painted mounting surfaces must be free from paint.

•Lay the mains, motor and control cables in large distance from each other.

•Use shielded motor cables connected to earth on both sides.

•Connect the motor cable shield with the PE terminal located in the terminal box of the motor. Use

possibly metallic cable glands.

•Optional output chokes must be mounted close to the inverter and connected with shielded cables.

Connect the cable shield to earth on both sides.

•Use shielded control cables connected to earth on both sides.

•Unshielded control cables must be twisted.

•Connect the cable shields either with the mounting plate using ground clamps and contacted over

as large an area or at an equipotential bar (see picture).

•Use a central earthing point for the whole machine/syste m (mounting plate). Connect this point to

earth using earth cables with a large cross section or fl at copper braids.

Remove any

paint or varnish!

Motor cable with

braided shield.

Large-area contacting

of the cable shield.

BERGES electronic

09.07.2001 Operating manual ACM D2/S2 17

•Do not extend the shields with single wires and do not interrupt them if possible.

•When constructing the switchgear cabinet or the system, separate the power section from the

control section. Eventually provide a shield between power and control section.

•Wire inductive switching elements (coils of contactors or relays) with RC-elements, free-wheeling

diodes or varistors.

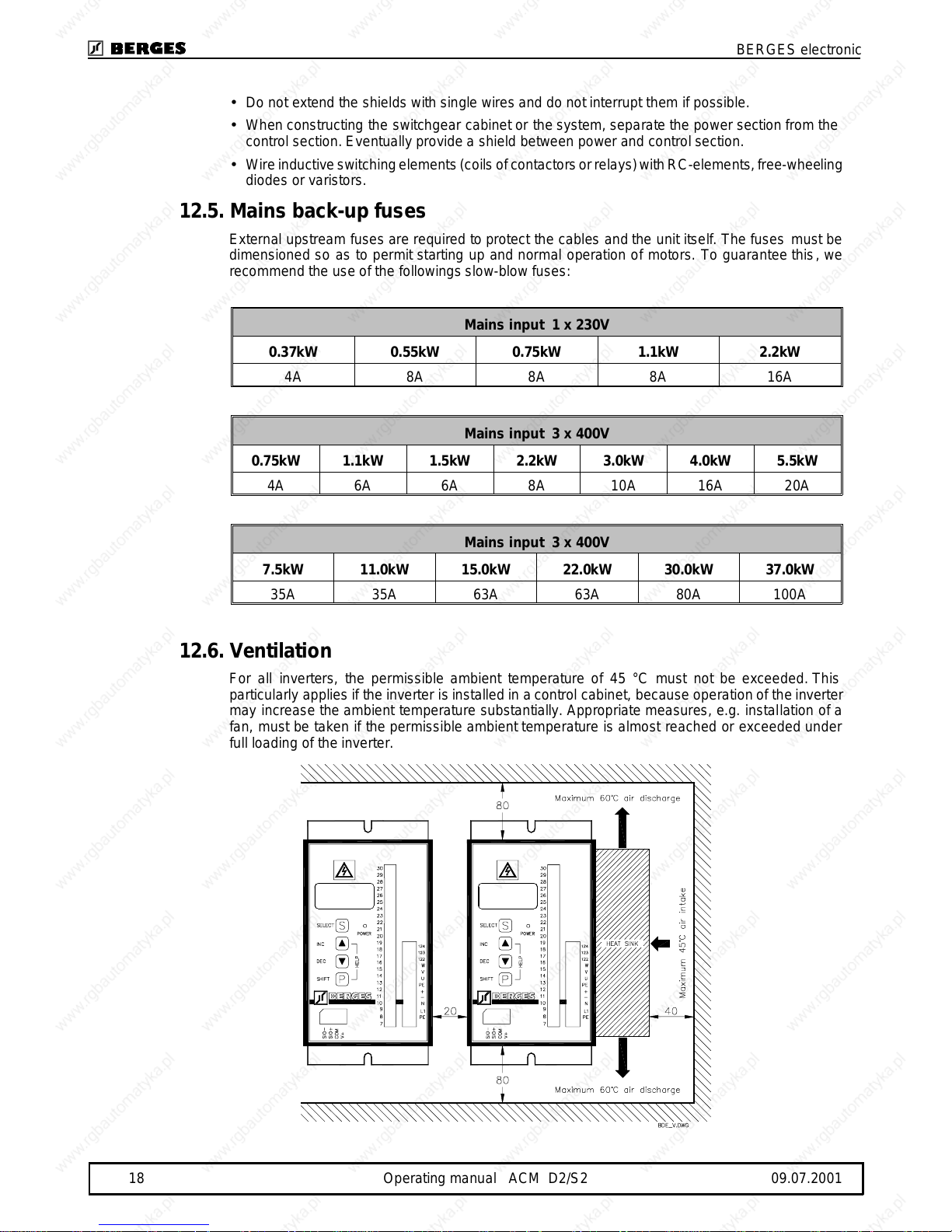

12.5.Mains back-up fuses

External upstream fuses are required to protect the cables and the unit i tself. The fuses must be

dimensioned so as to permit starting u p and normal operation of motors. To guarantee this, we

recommend the use of the followings slow-blow fuses:

Mains input 1 x 230V

0.37kW 0.55kW 0.75kW 1.1kW 2.2kW

4A 8A 8A 8A 16A

Mains input 3 x 400V

0.75kW 1.1kW 1.5kW 2.2kW 3.0kW 4.0kW 5.5kW

4A 6A 6A 8A 10A 16A 20A

Mains input 3 x 400V

7.5kW 11.0kW 15.0kW 22.0kW 30.0kW 37.0kW

35A 35A 63A 63A 80A 100A

12.6.Ventilation

For all inverters, the permissible ambient temperature of 45 °C must not be exceeded. This

particularly applies if the inverter is installed in a control cabinet, because operation of the inverter

may increase the ambient temperature substantially. Appropriate measures, e.g. installation of a

fan, must be taken if the permissible ambient temperature is almost reached or exceeded under

full loading of the inverter.

BERGES electronic

18 Operating manual ACM D2/S2 09.07.2001

Loading...

Loading...