Beretta A400 Xplor User Manual

IT Italiano

EN English

FR Français

ES Español

DE Deutsch

RU Pусский

SV Svenska

GR Ελληνικά

2

ALWAYS KEEP THIS MANUAL WITH YOUR FIREARM. INCLUDE IT WITH THE FIREARM WHEN IT CHANGES OWNERSHIP.

WARNING: FIREARMS CAN BE DANGEROUS AND CAN POTENTIALLY CAUSE SERIOUS INJURY, DAMAGE TO PROPERTY OR DEATH, IF HANDLED IMPROPERLY. THE FOLLOWING SAFETY RULES ARE AN IMPORTANT REMINDER THAT FIREARM SAFETY IS YOUR RESPONSIBILITY.

WARNING: Always ensure that the safety is fully engaged until ready to fire.

NOTICE: The Manufacturer and/or its Local Official Distributors assume no liability for product malfunction or for physical injury or property damage resulting in whole or in part from criminal or negligent use of the product, improper or careless handling, unauthorised modifications, use of defective, improper, handloaded, reloaded or remanufactured ammunition, customer misuse or neglect of the product, or other factors beyond manufacturer's direct and immediate control.

In addition to the Basic Safety Rules, there are other Safety Rules pertaining to the loading, unloading, disassembly, assembly and use of this firearm, located throughout this manual.

WARNING: READ THE ENTIRE MANUAL CAREFULLY BEFORE USING THIS FIREARM. MAKE SURE THAT ANY PERSON USING OR HAVING ACCESS TO THIS FIREARM READS AND UNDERSTANDS THIS ENTIRE MANUAL PRIOR TO USE OR ACCESS.

NOTICE: As the interchangeable barrel of this shotgun has a serial number different from that stamped on the receiver, it may be necessary, when referring to the gun, to specify also the serial number of the barrel/s.

WE RECOMMEND THE USE OF ORIGINAL BERETTA SPARE PARTS AND ACCESSORIES. THE USE OF OTHER MANUFACTURER'S SPARE PARTS AND ACCESSORIES COULD CAUSE MALFUNCTIONS AND/ OR BREAKAGES THAT WILL NOT BE COVERED BY THE BERETTA WARRANTY.

!

!

!

EN

!

!

3

BASIC SAFETY RULES

CAUTION: READ THIS MANUAL CAREFULLY BEFORE USING THE SHOTGUN.

CAUTION: FIREARMS CAN BE DANGEROUS AND CAN POTENTIALLY CAUSE SERIOUS INJURY, DAMAGE TO PROPERTY OR DEATH, IF HANDLED IMPROPERLY. THE FOLLOWING SAFETY RULES ARE AN IMPORTANT REMINDER THAT FIREARM SAFETY IS YOUR RESPONSIBILITY.

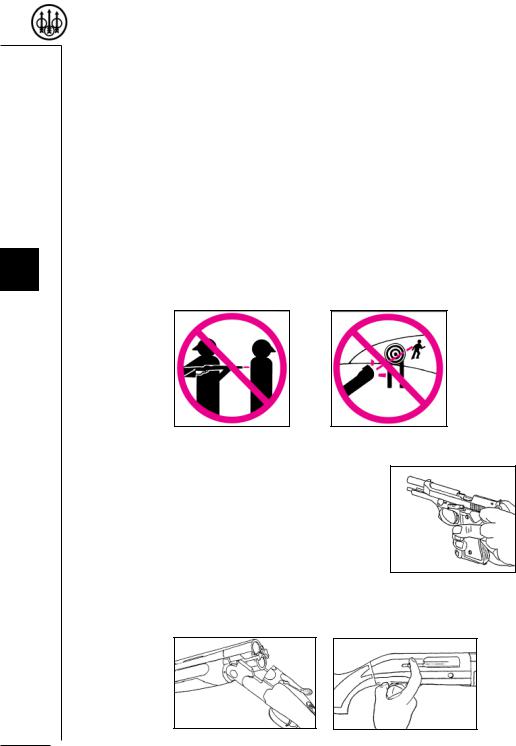

1.NEVER POINT A FIREARM AT SOMETHING THAT IS NOT SAFE TO SHOOT.

Never let the muzzle of a firearm point at any part of your body or at another

person. This is especially important when loading or unloading the firearm. When you are shooting at a target, know what is behind it. Some bullets EN can travel over a mile. If you miss your target or if the bullet penetrates the target, it is your responsibility to ensure that the shot does not cause

unintended injury or damage.

2.ALWAYS TREAT A FIREARM AS IF IT WERE LOADED.

Never assume that a firearm is unloaded. The only certain way to ensure there are no cartridges in a firearm is to open the chamber and visually and physically examine the inside to see if a round is present. Removing or unloading the magazine will not guarantee that a firearm is unloaded or cannot fire. Shotguns and rifles can be checked by cycling or removing all rounds and

by then opening and inspecting the chamber so that a visual inspection of the chamber for any remaining rounds can be made.

4

3.STORE YOUR FIREARM SO THAT CHILDREN CANNOT GAIN ACCESS TO IT.

It is your responsibility to ensure that children under the age of 18 or other unauthorised persons do not gain access to your firearm. To reduce the risk of accidents involving children, unload your firearm, lock it and store the ammunition in a separate locked location. Please note that devices intended to prevent accidents - for example, cable locks, chamber plugs, etc., - may not prevent use or misuse of your firearm by a determined person. Firearm storage in a steel gun safe may be more appropriate to reduce the likelihood of intentional misuse of a firearm by a child or unauthorised person.

EN

4.NEVER SHOOT AT WATER OR AT A HARD SURFACE.

Shooting at the surface of water or at a rock or other hard surface increases the chance of ricochets or fragmentation of the bullet or shot, which can result in the projectile striking an unintended or peripheral target.

5.KNOW THE SAFETY FEATURES OF THE FIREARM YOU ARE USING, BUT REMEMBER: SAFETY DEVICES ARE NOT A SUBSTITUTE FOR SAFE HANDLING PROCEDURES.

Never rely solely on a safety device to prevent an accident. It is imperative that you know and use the safety features of the particular firearm you are handling, but accidents can best be prevented by following the safe handling procedures described in these safety rules and elsewhere in the product manual. To further familiarise yourself with the proper use of this or other firearms, take a Firearms Safety Course taught by an expert in firearms use and safety procedures.

6.PROPERLY MAINTAIN YOUR FIREARM.

Store and carry your firearm so that dirt or lint does not accumulate in the working parts. Clean and oil your firearm, following the instructions provided in this manual, after each use to prevent corrosion, damage to the barrel or accumulation of impurities which can prevent use of the firearm in an emergency. Always check the bore and chamber(s) prior to loading to ensure that they are clean and free from obstructions. Firing with an obstruction

5

EN

in the barrel or chamber can rupture the barrel and injure you or others nearby. In the event you hear an unusual noise when shooting, stop firing immediately, engage the manual safety and unload the firearm. Make sure the chamber and barrel are free from any obstruction, like a bullet blocked inside the barrel due to defective or improper ammunition.

7.USE PROPER AMMUNITION.

Only use factory-loaded, new ammunition manufactured to industry specifications: CIP (Europe and elsewhere), SAAMI® (U.S.A.). Be certain that each round you use is in the proper calibre or gauge and type for the particular firearm. The calibre or gauge of the firearm is clearly marked on the barrels of shotguns and on the slide or barrel of pistols. The use of reloaded or remanufactured ammunition can increase the likelihood of

excessive cartridge pressures, case-head ruptures or other defects in the ammunition that can cause damage to your firearm and injury to yourself or others nearby.

8.ALWAYS WEAR PROTECTIVE GLASSES AND EARPLUGS WHEN SHOOTING.

The chance that gas, gunpowder or metal fragments will blow back and injure a shooter who is firing a gun is rare, but the injury that can be sustained in such circumstances can be severe, including the possible loss of eyesight. A shooter must always wear impact resistant shooting glasses when firing any firearm. Noise-reducing earplugs or headphones will reduce the risk of damage to hearing caused by prolonged shooting activity.

9.NEVER CLIMB A TREE, FENCE OR OBSTRUCTION WITH A LOADED FIREARM.

Open and empty the chamber(s) of your firearm and engage the manual safety before climbing or descending a tree or before climbing a fence or jumping over a ditch or other obstruction. Never pull or push a loaded firearm toward yourself or another person. Always unload a firearm, visually and physically check to see that the magazine, loading mechanism and chamber are unloaded, and action is open before handing it to another person.

Never take a firearm from another person unless it is unloaded, visually and physically checked to confirm it is unloaded, and the action is open.

6

10.AVOID ALCOHOLIC BEVERAGES OR JUDGEMENT/REFLEX IMPAIRING MEDICATION WHEN SHOOTING.

Do not drink and shoot. If you take medication that can impair motor reactions or judgement, do not handle a firearm while you are under the influence of the medication.

11.NEVER TRANSPORT A LOADED FIREARM.

Unload a firearm before putting it in a vehicle (chamber empty, magazine empty). Hunters and target shooters should load their firearm only at their destination, and only when they are ready to shoot. If you carry a firearm for self-protection, leaving the chamber unloaded can reduce the chance of an unintentional discharge.

12.LEAD WARNING.

Discharging firearms in poorly ventilated areas, cleaning firearms, or handling ammunition may result in exposure to lead and other substances known to cause birth defects, reproductive harm, and other serious physical injury. Have adequate ventilation at all times. Wash hands thoroughly after exposure.

CAUTION: It is YOUR responsibility to know and abide by Federal, State and Local laws governing the sale, transportation and use of firearms in your area.

WARNING: This firearm has the capability of taking your life or the life of someone else! Always be extremely careful with your firearm. An accident is almost always the result of not following basic firearm safety rules.

Especially for U.S. consumers:

For information about Firearm Safety Courses in your area, please visit the National Rifle Association’s web site at www.nra.org.

EN

!

!

7

|

|

|

NOMENCLATURE |

|

|

|

|

A |

Receiver |

|

|

|

A1 |

Trigger |

|

|

|

A2 |

Safety button |

|

|

|

A3 |

Trigger guard |

|

|

|

A4 |

Trigger guard retaining pin |

|

|

|

A5 |

Breech bolt release button |

|

|

|

A6 |

Carrier |

|

|

|

A7 |

Carrier stop push button |

|

|

|

A8 |

Loading gate |

|

|

|

A9 |

Ejection port/cartridge chamber |

|

|

|

A10 |

Cut-off |

|

|

|

B |

Breech bolt assembly |

EN |

|

|

||

|

B1 |

Cocking handle |

||

|

|

|

B2 |

Two lugs locking head |

|

|

|

B3 |

Operating rods with sleeve |

|

|

|

C |

Barrel |

|

|

|

C1 |

Barrel breech |

|

|

|

C2 |

Indexing lugs |

|

|

|

C3 |

Locking shoulders |

|

|

|

C4 |

Gas cylinder |

|

|

|

C5 |

Piston with elastic seal |

|

|

|

C6 |

Exhaust valve assembly |

|

|

|

C7 |

Optimachoke® HP choke tube |

|

|

|

C8 |

Choke tube spanner |

|

|

|

C9 |

Front sight |

|

|

|

C10 |

Top rib |

|

|

|

C11 |

Muzzle |

|

|

|

D |

Stock |

|

|

|

D1 |

Recoil pad |

|

|

|

D2 |

Kick Off device |

|

|

|

E |

Fore-end |

|

|

|

E1 |

Fore-end flange with exhaust port |

|

|

|

F |

Magazine tube |

|

|

|

G |

Front swivel |

|

|

|

H |

Fore-end cap |

|

|

|

|

|

|

|

|

|

|

8

CONTENTS

BASIC SAFETY RULES |

4 |

NOMENCLATURE |

8 |

DESCRIPTION |

10 |

DATA AND TECHNICAL CHARACTERISTICS |

15 |

OBSTRUCTION / CHOKE TUBES CONDITION CHECK |

16 |

ASSEMBLY OF PACKAGED FIREARM |

16 |

LOAD CHECK |

19 |

AMMUNITION |

20 |

HOW TO LOAD THE FIREARM |

21 |

HOW TO USE THE CUT-OFF DEVICE |

23 |

HOW TO UNLOAD THE SHOTGUN |

24 |

DISASSEMBLY |

25 |

BERETTA OPTIMACHOKE® HP CHOKE TUBES |

26 |

ROUTINE MAINTENANCE |

29 |

SPECIAL MAINTENANCE |

31 |

REASSEMBLY |

31 |

STOCK DROP AND CAST MODIFICATION |

33 |

STORAGE |

35 |

EN

9

DESCRIPTION

In 1960, one of the world's first semi-automatic gas operated field shotgun was created: the Beretta mod. 60. Since then, building on the experience and skills acquired in designing and constructing this reliable operating system, Beretta is pleased to present its new A400 Xplor series.

Developed from the versatile Beretta gas operated, self-cleaning system, the advanced design of the new A400 Xplor uses an exclusive exhaust valve that allows the shotgun to “fire” a broad range of ammunition. In combination with the rotating head of the breech bolt, the new system further reduces the already low recoil felt, directing the recoil force directly in line with the shoulder of the shooter. This minimises recoil of the firearm on firing and lends additional stability to the rifle in firing subsequent rounds.

In the new semi-automatic A400 Xplor, Beretta has thought of every detail in the design phase, with the utmost attention to comfort, design and maintenance EN requirements. The new parts design, the minimal number of components, the new materials and new anti-recoil devices make the A400 Xplor the new

standard for future generations of semi-automatic shotgun.

DESIGNED FOR PERFORMANCE AND COMFORT

Every detail, from the greatest to the very smallest, has been the object of careful study and assessment in order to attain two key objectives: visual appeal and superior performance. The ellipse motif and the Beretta logo, interpreted artistically on the back of the fore-end, is uniformly yet discreetly discernible on the main parts, giving the shotgun a futuristic, state of the art design.

The receiver: The ergonomically rounded back of the light alloy receiver fits smoothly into the stock, enabling rapid and instinctive target acquisition. Constructed using a special aluminium alloy, the A400 Xplor has undergone a colored anodic oxidation process that protects the firearm from rusting and scratching.

The cocking handle has been resized to minimise effort in the manual breech bolt opening phase.

The trigger guard, in heavy duty polymer, has an innovative new texture. Its new semi-square shape makes finger positioning easier. The rounded shape and absence of sharp corners have been designed for more rapid, more secure trigger grip. The use of a technopolymer ensures that the colour will remain in the parts traditionally subject to rubbing while at the same time enhancing sensitivity of touch in cold climates. The opening of the trigger guard is bigger so the trigger is accessible even to a gloved hand.

The cut-off and breech bolt release button have been resized, with contours designed for fast, safe and reliable operation, with maximum noise reduction during firing.

10

The trigger mecchanism has been redesigned. The new stainless steel carrier withstands rust and wear and offers more sturdiness in the execution of its vital function.

The safety button, also newly designed, now offers a wider surface for easier operation. For accidental engaging or disengaging, the safety is protected and topped by a protruding edge that also enhances its appearance.

The trigger is chrome-plated for ultimate rust protection. Its silver colour sets it apart from the other parts of the shotgun.

The fore-end has long, slender contours that add to the harmony of the A400 Xplor’s overall design. Combined with the design of the gas flange, the front section of the firearm is absolutely unique. The new checkering, created using sophisticated laser technology, wraps around and provides a more secure grip

even in bad weather conditions, while the surface remains pleasant to the touch. EN The artistic interpretation of the Beretta logo can be seen at the back. The length

of the fore-end has been revisited to make hand positioning easier, thereby improving the handling and swinging of the shotgun. The cap has a new polymer structure that makes it very lightweight, weather and rust-resistant.

The stock has also been totally reconceived to provide superior comfort and a secure grip to ensure the highest performance during firing. Made of fine walnut carefully selected for its colour characteristics, design and resistant finish, its grip contour is designed to optimally accommodate the hand of the user with a top ambidextrous finger rest, a characteristic only found in the finest hunting guns. The underside of the grip is flush with the stock, creating an unparalleled effect of continuity and harmony. The grip is optimised thanks to the doublesided “diamond-cut” laser checkering, chosen for its appearance and for its exclusive slip-proof qualities.

To ensure reduced recoil felt, the ultra-light recoil pad offers an ideal support surface made of technopolymer foam, for enhanced recoil absorption.

REDUCED NUMBER OF COMPONENTS

The Beretta semi-automatic A400 Xplor is characterised by a particularly small number of assemblies. The shotgun is composed of five main assembly groups which can be field stripped by the user, for quick and easy disassembly. A firearm that can be easily taken apart is also easier to clean. Easy cleaning encourages to perform more careful maintenance on the firearm ensuring long-term reliability.

11

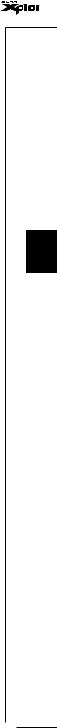

ROTATING BOLT HEAD LOCK

The Beretta semi-automatic A400 Xplor has a breech bolt with a rotating head with two lugs that operate the lock of the barrel breech. The long breech has two indexing lugs and a large support surface that make it possible to eliminate the movement of the barrel when firing, thereby increasing precision. The breech bolt body is connected with the two operating rods and therefore is guided and activated symmetrically, with components sliding more smoothly as a result, for easier disassembly and reassembly of the breech bolt unit.

GAS-OPERATED SYSTEM WITH EXHAUST VALVE

|

The exclusive |

gas-operated |

system, |

patented |

by |

Beretta, |

with |

||||

|

a self-cleaning cylinder |

and piston, has a self-cleaning |

exhaust |

||||||||

EN |

valve, |

so |

that |

excess |

pressure caused by |

the |

most |

powerful |

|||

cartridges can be decreased automatically: as a result, the shotgun |

|||||||||||

|

without |

any |

adjustment |

or |

intervention |

can shoot |

cartridges |

from |

|||

|

70 mm (2 3/4 in) /24 g (7/8 oz), to 76 mm (3 in) /57 g (2 oz). The “UNICO” |

||||||||||

|

version can fire from 70 mm (2 3/4 in) /24 g (7/8 oz) cartridges to the powerful |

||||||||||

|

Supermagnum 89 mm (3 1/2 in) /64 g (2 1/4 oz) loads. |

|

|

|

|

||||||

Beretta recommends: To immediately obtain superior firearm performance and optimum cartridges versatility from your A400 Xplor, fire some medium power cartridges first (32g/1 1/8 oz).

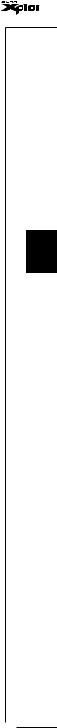

The semi-automatic gas-operated A400 Xplor has also been optimised to ensure lower gas dispersal. As a result, the system has a self-cleaning feature that further minimises maintenance and significantly reduces the stress to which the operating parts are subjected to at higher charges, thereby ensuring the greatest possible service life of the firearm.

The new piston has been designed to constantly clean out gunpowder residue in the cylinder, increasing the efficiency of the firearm and reducing the need for maintenance. The elastic piston seal has a rough finish to optimise cleaning.

!SHOTGUN ASSEMBLY WARNING: In order to prevent damage to the elastic piston seal, first insert the piston into the chamber cylinder and then insert the magazine tube cap shaft through the piston hole.

The valve unit is connected to the barrel, making assembly and disassembly of the barrel itself easier.

SUPER RESISTANT RECEIVER

Completely and precisely machined from a solid block of special light alloy aluminium, it has moveable parts in steel, polymers, high quality light alloys, assembled with particular care, checked and polished to ensure exceptional operation. All metal parts are protected by special finishes against wear, and tear and rusting. The length of the receiver is shorter in the semi-automatic versions of the A400 Xplor series, to minimise bulkiness of the firearm and obtain easy

12

handling in the narrow spaces, even when using long barrels. The safety button can be reversed for left-handed shooters.

OPTIMA-BORE® HP BARREL/OPTIMACHOKE® HP

TUBES

In alloy steel, made with the exclusive cold hammering process to ensure perfect concentricity, the barrel of the new Beretta semi-automatic A400 Xplor is exceptionally robust and lightweight at the same time. Designed for use with steel shot cartridges, it has a new Optima-Bore® HP (High Performance) internal profile with a lengthened forcing cone for enhanced pattern distribution and reduced felt recoil. The bore is chrome plated to ensure the longest life and resistance to rust, wear and tear and to increase the shot velocity, while it is deep blued on the exterior.

The new Beretta Optimachoke® HP (High Performance) internal choke tubes are

designed to reduce shot deformation and to enhance shot pattern distribution EN and concentration. Made in high performance nickel plated steel, the Beretta

Optimachoke® HP choke tubes ensure the highest protection against rust and resistance to use of steel shot.

The attention that Beretta pays systematically to reduce the recoil reached new heights with the A400 Xplor.

The A400 Xplor is the only semi-automatic shotgun in the world to be equipped (depending on the specific model or by request) with three anti-recoil devices. The combination of the three devices results in an unprecedented shooting experience.

KICK OFF DEVICE RECOIL ABSORPTION

The Beretta Kick Off system (supplied with the Kick Off version of the A400 Xplor) has been created to further attenuate the recoil sensation of the firearm on firing. Thanks to the Kick Off device, the recoil force gradually disperses through two hydraulic (oil) dampers inserted on the inside of the stock with evident comfort for the shooter. At the same time, vibrations and movement reporting of the barrel are significantly reduced on shooting. Longevity, reliability and handling of the firearm are guaranteed.

PATENTED KICK OFF3 DEVICE FOR RECOIL

ABSORPTION

KICK OFF3 is the very latest innovation in the effective and noticeable reduction of recoil, developed by the Kick Off design team at Beretta. The KICK OFF3 is located inside the stock bolt tube and works during the final backward travel phase of the breech bolt during the operating cycle, for impact attenuation and shock reduction.

13

Loading...

Loading...