Page 1

vb Balancer Series Portable Instruments

Datasheet

Bently Nevada Machinery Condition Monitoring

Description

Unbalanced rotating machinery can cause high levels of

vibration which can degrade bearing life and cause major

mechanical complications. Reduce the possibility of outages

and downtime with our vbBalancer and vbBalancer+

portable instruments. Used on-site, they detect unbalanced

machinery and help you diagnose and immediately fix issues

before they become serious, expensiveproblems.

After you input a few basic parameters describing a machine,

use vbBalancer to identify current unbalance levels and

determine ifthe machine is operating within ISO 1940

standards.

If a machine needs balancing, use vbBalancer to identify the

mass and position of permanent balance weights.

To verify that balancing is working, the vbBalancer Series

record basic vibration spectra. Use vbBalancer to view

spectra before and after balancing to validate broad-band

improvement.

132M3167 Rev. A

The two-channel vbBalancer instrument has two

accelerometer inputs for simultaneous recordings. The fourchannel vbBalancer+ instrument uses vibration readings

from four accelerometer inputs to calculate the optimum

balance weights to apply to two correction planes,

minimizing total machine vibration. This enables you, for

example, to monitor both horizontal and vertical axes on a

two-bearing machine, giving you confidence that the

balance you applied to one axis has not worsened vibration

on the other.

The vbBalancer Series provides recordings with up to 800 lines

of resolution and up to 5 kHz Fmax. The vbBalancer Series has

plenty of storage capacity and features all-day battery life.

We back these instruments with a five year warranty.

Page 2

vb Balancer Series Portable Instruments

Datasheet 132M3167 Rev. A

The vbBalancer Series offers:

l Two or four-channel simultaneous

recordings

l Dual-plane balancing

l Laser speed sensor for machine speed

and vibration phase angle detection

l Keyphasor tach mode (vbBalancer+

only)

l 800 line vibration spectra with Fmax up to

5 kHz

l 1 GB memory

l ≥ 95 dB dynamic range

l Both instruments support IEPE

Accelerometer sensors, and the

vbBalancer+ additionally supports

velocity and displacement sensors

l The vbBalancer+ additionally supports

these balancing-related analysis

features: coast-down and run-up, bump

test, orbit plot

l Sensor cable self-test feature

l USB host port for data transfer to external

USB drive

l Upgradable Proflash system and free

firmware updates for five years

2/10

Page 3

vb Balancer Series Portable Instruments

Datasheet 132M3167 Rev. A

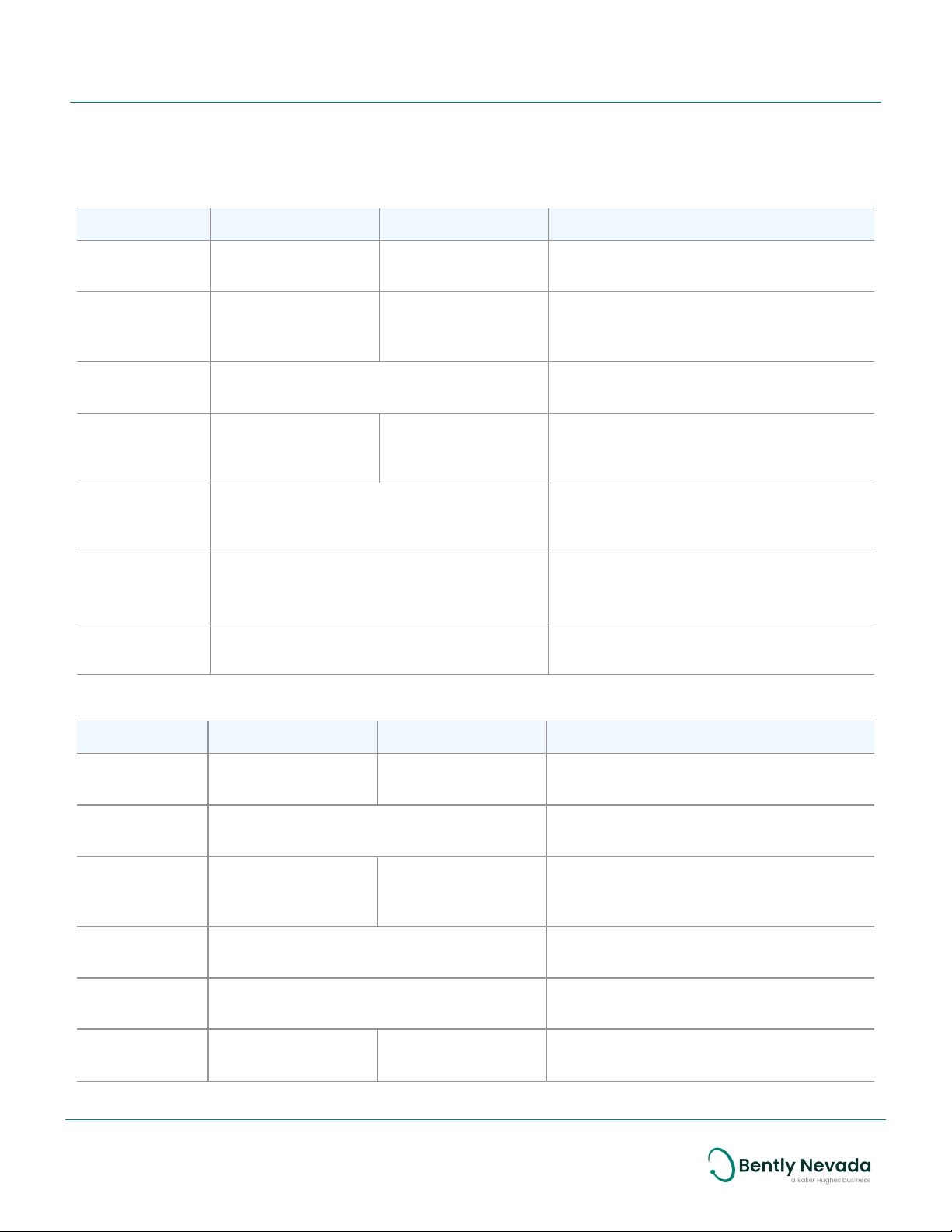

Specifications

Sensors

Parameter vbBalancer vbBalancer+ Notes

Channels

(simultaneous)

Compatible

sensor types

AC coupled

range

Connectors 2 x BNC (CH1/CH2) 1 x BNC (CH1)

Analog to

digital

conversion

Sensor

excitation

current

Sensor

detection

Two Four Simultaneous sampling

Accelerometer Accelerometer,

velocity and

displacement

16 V peak-peak Allows for ± 8 V sensor output swing (±

1 x LEMO (CH2, CH3,

CH4)

24-Bit ADC

0 mA or 2.2 mA (configurable),

24 V maximum

Warns if short circuit or not connected

Tachometer

80 g)

Safety feature: break-free inline

connector

2.2 mA required for IEPE/ICP®-type

accelerometer

Parameter vbBalancer vbBalancer+ Notes

Sensor Laser sensor with

reflective tape

Laser sensor

range

Other sensor

types

supported

Power supply

to sensor

TTL pulse rating 3.5 V (4 mA) min, 28 V (5 mA) max,

Keyphasor*

thresholds

Contact, TTL, pulse Contact, TTL, pulse,

N/A 7.7 ± 0.5 V 13.2 ± 0.8

10 cm to 2 m nominal Dependent on size of reflective tape

off-state 0.8 V

Laser sensor with

reflective tape

Keyphasor

5 V, 50 mA

V 18.5 ± 1 V

Sensor triggers on beam reflection

Optically isolated output

Nominally 8 V, 13 V, 18 V

3/10

Page 4

vb Balancer Series Portable Instruments

Datasheet 132M3167 Rev. A

Speed range 10 RPM to 300 000 RPM (0.2 Hz to 5 kHz) Pulse width at least 0.1 ms

Accuracy +/- 0.1%

Parameter Indication

Parameter vbBalancer vbBalancer+ Notes

Dynamic

signal range

Harmonic

distortion

Units g or m/s2 or adB

Magnitude &

cursors

Base accuracy ± 1% (approximately 0.1dB) % of reading

High frequency

attenuation

AC coupling

attenuation

Attenuation

due to

Integration

Overall value: RMS, waveform true pk-pk,

Less than -70 dB typical Other distortions and noise are lower

in/s or mm/s or vdB

dual cursors, harmonics

≤ 0.1 dB 100 Hz to 5 kHz Attenuation tolerances are in addition to

≤ 0.1 dB 10 Hz to <100 Hz

≤ 0.1 dB 10 Hz to <100 Hz

≤ 1.5 dB 1 Hz to <10 Hz

> 95 dB Typical at 400 line resolution

0-peak, peak-peak or RMS

Auto-scale by 1000x when required. US &

mil or mm or µm

≤ 3 dB 1 Hz to <10Hz

SI options for adB & vdB

Digital readouts on chart

base accuracy

Values apply to single integration

(acceleration to velocity). Double the

values for double integration

(acceleration to displacement).

Spectrum Display

Parameter vbBalancer vbBalancer+ Notes

Fmax ranges 25, 50, 100, 125, 150, 200, 300, 400, 500, 600,

800,1000, 1200, 1600, 2000, 2500, 3000, 4000,

5000 Hz

Fmin possible

range

Resolution 800lines

Frequency

scale

Amplitude

scale

Window, Hanning, 50%, 4 x Linear

Acceleration, velocity or displacement Linear or log scales, auto or manual

0 to Fmax Instrument zeroes all spectral lines below

Hz, CPM, Orders Linear scale with zooming

4/10

Or equivalent CPM values or ordersbased from 1X to 999X

Fmin

scaling

Page 5

vb Balancer Series Portable Instruments

Datasheet 132M3167 Rev. A

overlap,

averaging

Waveform Display

Parameter vbBalancer vbBalancer+ Notes

Number of

samples

Time scale 160ms to 32 seconds Or orders based from 1 to 999 revs

2048

Data Logging

Parameter vbBalancer vbBalancer+ Notes

Data storage 1 GB

Data storage

structure

Max. folder size 10 000measurement locations

Folders/ machines No limits are applied, 50 character

names

Balancing

Parameter vbBalancer vbBalancer+ Notes

Planes and

Sensors

Speed range 30 to 60 000 RPM

Measurement

type

Two planes

Two sensors

Acceleration, velocity, displacement

Two planes

Four sensors

Weight modes

Remove trial

weights

Manual data

entry

Storage Against machines in data structure No limits applied

Channel

selection

Single or dual

channel

Angle 0° to 360°

Fixed position

Circumference arc

User choice Removed weight automatic

Yes Allows re-entry of previous balance jobs

Up to four channels

simultaneous

Examples: weights on fan blades, linear

distance around circumference

recalculation

Display and Communication

Parameter vbBalancer vbBalancer+ Notes

5/10

Page 6

vb Balancer Series Portable Instruments

Datasheet 132M3167 Rev. A

Display Graphic Grayscale LCD White LEDback light

Resolution and

size

Supported

languages

Communication

with PC

USB host port USB 2.0, supplying 5 V, 250 mA Save folders to USB flash drive

480x 320 (HVGA), 5.5” (140 mm) Readable in direct sunlight

EN, ZH,FR, DE, JA, PT, RU, ES

USB and ethernet PROFLASH to upgrade instrument

firmware

Battery and Charger

Parameter vbBalancer vbBalancer+ Notes

Battery type Custom Lithium Ion pack

7.4 V, 4500mAh

Operating time 10 hours Back light on (60 second time-out)

Charger type Internal charging, automatic control External power pack 12 V DC, 3 A output

Charge rate 3 A nominal Three hours for complete charge

Mechanical

Parameter vbBalancer vbBalancer+ Notes

Size 9.9” W x 5.8” L x 2.4” H (252 x 148x60) mm

Weight 2.7 lb (1.2 kg) Includes battery and strap

Environmental Limits

Parameter vbBalancer vbBalancer+ Notes

Operating

temperature

Storage

temperature

and humidity

Ruggedness 4’ (1.2 m) drop onto concrete, IP65 Procedure: 26 drops following MIL-STD-

14 °F to 122 °F (-10 to 50) °C

-4 °F to 140 °F (-20 to 60) °C

95% relative humidity

If storage exceeds one month: up to 95 F

(35 C), 85% RH

810F-516.5-IV

6/10

Page 7

vb Balancer Series Portable Instruments

Datasheet 132M3167 Rev. A

Compliance and Certifications

FCC

This device complies with part 15 of the

FCC Rules. Operation is subject to the

following two conditions:

l This device may not cause harmful

interference.

l This device must accept any

interference received, including

interference that may cause

undesired operation.

EMC

EN 61326-1: 2012

EN 61326-2-3: 2012

EMC Directive 2014/30/EU

Electrical Safety

EN 62133: 2002

LV Directive 2014/35/EU

RoHS

RoHS Directive 2011/65/EU

Hazardous Area Approvals

For the detailed listing of country and

product specific approvals, refer to the

Approvals Quick Reference_Guide

(108M1756) available from

BNTechSupport.com.

CSA CSA Class I,

Division 2 (Groups

A, B, C, D)

7/10

Page 8

vb Balancer Series Portable Instruments

Datasheet 132M3167 Rev. A

Ordering Information

For the detailed listing of country and

product specific approvals, refer to the

Approvals Quick Reference_Guide

(108M1756) available from

BNTechSupport.com.

You can order all accessories included in the

Basic Kit, Balancing Kit, and Zone 2 Laser Tach

kit separately.

VBBALANCER-AA

VBBALANCERPLUS-AA

A: Agency Approval

01

Basic Kit

We offer the vb Balancer Series Portable

Instruments instrument in a basic kit with the

option to purchase System 1 or Ascent software

and license separately.

listed have limited regional availability due to

certification requirements.

Part

Number

108M4049-01USB flash drive

CSA / NRTL / C (Class 1, Division 2)

* Kit items with multiple part numbers

Description Qty

vbBalancer is a

two-channel

vbBalancer+ is a

four-channel

portable data

collector

contains vbX

Manager and

installation guide

together with

reference guides

and brochures for

vbSeries and other

products.

1

1

ACCL0547

or

200350

*

138M7748 Transducer cable,

113M5585

MAGF0104

???

CBTB0278 TripleBNC adapter 1 for

CABU0213 USB data transfer

110M8172 LEMO-BNC TTL

PLUS0230 Category A power

PLSA0241 Category D power

PLAU0228 Category M power

PLHK0245 Category G power

PLEU0229 Category C power

CBVB0032 vbx instrument

109M2384- Neck strap with 1

Straight

accelerometer

4 ft straight

Accelerometer

magnetic base

cable

Tach/Keyphasor

cable

plug

USA / Canada

plug

South Africa / India

plug

Australia / New

Zealand / China

plug

Hong Kong / UK

plug

Europe

carry bag

2 for

vbBalancer

4 for

vbBalancer+

2 for

vbBalancer

4 for

vbBalancer+

2 for

vbBalancer

4 for

vbBalancer+

vbBalancer+

1

1

1

1

1

1

1

1

8/10

Page 9

vb Balancer Series Portable Instruments

Datasheet 132M3167 Rev. A

02 Sensor Keeper

108M4044 AC power adapter 1

DCCA0041 DC car adapter 1

108M3536

108M4048

SCOUT100_Series

and vbSeries

Quick_Start_

Guide

vbBalancer &

vbBalancer+

Instrument

Reference_Guide

1

1

Accessory Kits

Balancing Kit - 108M4050-04

Part

Number

113M5529-01 Reflective tape, one roll, 60cm1

LASA0315 Laser Tach Kit Zone 2 rated 1

Description Qty

108M4066 Circlips - 20Mm Stainless 1

108M4067 Arp115 O-ring 2

108M4069 Laser Tach Zone 2 rated 1

Miscellaneous Parts

Part

Number

MAGM0064

VBMR0222 Stainless safety rings (one pair)

100M5828 vbSeries hard case

DTC70262 vbSeries dust cover

BATT0575 Replacement battery pack, Li-Ion

Accelerometer magnetic base

Maleconnection

7.4 V 5 Ah

Description

CBL50216 Laser cable, five meters 1

MAGA0063 Laser magnetic stand 1

CB5G0024 Sensor cable, five meters,

green

CB5R0025 Sensor cable, five meters,

red

CBBL0026 Carrying case for the kit 1

Zone 2 Laser Tach Kit - LASA0315

Part

Number

108M4064 Laser Tacho Holder 1

Description Qty

2

2

9/10

Page 10

vb Balancer Series Portable Instruments

Datasheet 132M3167 Rev. A

Copyright 2020 Baker Hughes Company. All rights reserved.

Bently Nevada, Orbit Logo, Keyphasor and vbSeries are registered trademarks of Bently Nevada, a Baker Hughes

Business, in the United States and other countries. The Baker Hughes logo is a trademark of Baker Hughes Company.

All other product and company names are trademarks of their respective holders. Use of the trademarks does not

imply any affiliation with or endorsement by the respective holders.

Baker Hughes provides this information on an “as is” basis for general information purposes. Baker Hughes does not

make any representation as to the accuracy or completeness of the information and makes no warranties of any

kind, specific, implied or oral, to the fullest extent permissible by law, including those of merchantability and fitness

for a particular purpose or use. Baker Hughes hereby disclaims any and all liability for any direct, indirect,

consequential or special damages, claims for lost profits, or third party claims arising from the use of the

information, whether a claim is asserted in contract, tort, or otherwise. Baker Hughes reserves the right to make

changes in specifications and features shown herein, or discontinue the product described at any time without

notice or obligation. Contact your Baker Hughes representative for the most current information.

The information contained in this document is the property of BakerHughes and its affiliates; and is subject to

change without prior notice. It is being supplied as a service to our customers and may not be altered or its content

repackaged without the express written consent of Baker Hughes. This product or associated products may be

covered by one or more patents. See Bently.com/legal.

1631 Bently Parkway South, Minden, Nevada USA 89423

Phone: 1.775.782.3611 or 1.800.227.5514 (US only)

Bently.com

10/10

Loading...

Loading...