Page 1

L8542067

02/2013 rev 9

UNIONE NAZIONALE COSTRUTTORI

AUTOMATISMI PER CANCELLI, PORTE

SERRANDE ED AFFINI

DA.24V / CP.EVA

Page 2

2

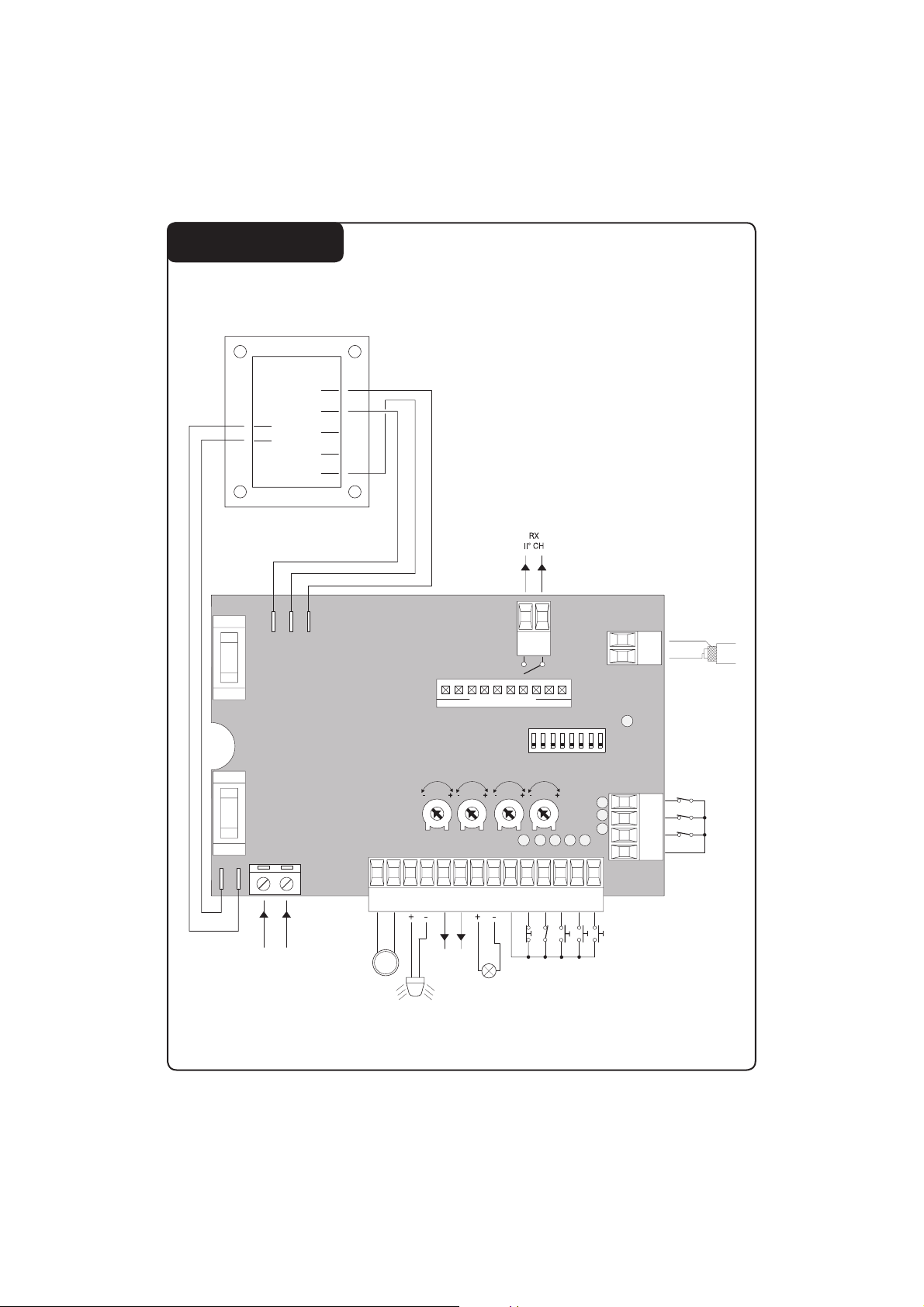

DA.24V

M

RA DIO

230Vac

50/60Hz

N L

S1

L1

VA UX VM OT

0

N1

COM

P.P.

OPEN

PHOT

SWC

SWO-R

SWC-R

STOP

CLOSE

SHIELD

ANT

ANT

24Vac

500mA max

111098765 1312 14 15 16 174

21201918

2524

2829

SLWCL SLWOP AMP TCA

F2

F1

T1A

230V:T1.6A

120V:T3.5A

1 8

26

23

23N

L

0

18

LAMP

24Vac

BAR

LIGHT

24Vdc

STP

POWER

PH OP CH PP

SWC-R

SWO-R

SWC

(+) (-)

Page 3

3

CP.EVA

M

RA DIO

230Vac

50/60Hz

S1

VA UX VM OT

0

COM

P.P.

OPEN

PHOT

SWC

SWO-R

SWC-R

STOP

CLOSE

SHIELD

ANT

ANT

24Vac

500mA max

111098765 1312 14 15 16 174

21201918

2524

2829

SLWCL SLWOP AMP TCA

F1

T1A

1 8

26

23

23

0

18

LAMP

24Vac

BAR

LIGHT

24Vdc

STP

POWER

PH OP CH PP

SWC-R

SWO-R

SWC

(+) (-)

N

L

F2:1,6AT (230V)

F2:3,5AT (115V)

Page 4

8

EC declaration of confirmity

Declaration pursuant to Directives 2004/108/EC(EMC); 2006/95/EC(LVD)

Manufacturer: Automatismi Benincà SpA.

Address:

Via Capitello, 45 - 36066 Sandrigo (VI) - Italy

Declares that the product:

Command central for 1 24Vdc motor, for road barriers: DA.24V - CP.EVA

is compliant with the conditions of the following EC Directives:

• DIRECTIVE 2004/108/EC OF THE EUROPEAN PARLIAMENT AND COUNCIL of December 15 2004

regarding the approximation of the legislations of the member States relative to electromagnetic compatibility and

that repeals directive 89/336/CEE, according to the following concurred norms:

EN 61000-6-2:2005, EN 61000-6-3:2007.

• DIRECTIVE 2006/95/EC OF THE EUROPEAN PARLIAMENT AND THE COUNCIL of December 12

2006 concerning the approximation of the legislations of the member States relative to electrical material destined

to be used within certain voltage limits, according to the following concurred regulations:

EN 60335-1:2002 + A1:2004 + A11:2004 + A12:2006 + A2:2006 + A13:2008; EN 60335-2-103:2003.

if applicable :

• DIRECTIVE 1999/5/EC OF THE EUROPEAN PARLIAMENT AND THE COUNCIL of March 9 1999

regarding radio devices and terminal and telecommunications devices and the reciprocal recognisances of their

conformity, according to the following concurred regulations: ETSI EN 301 489-3 V1.4.1 (2002) + ETSI EN 301

489-1 V1.4.1 (2002) + ETSI EN 300 220-3 V1.1.1 (2000) + EN 60950-1 (2001)

Benincà Luigi, Legal manager.

Sandrigo, 02/11/2010.

WARNINGS

This manual has been especially written to be use by

qualified fitters.

None of the information provide in this manual can be

considered as being of interest for the end users.

Preserve this manual for future needs.

The technician has to furnish all the information related to

the step by step function, the manual and the emergency

function of the operator, and to deliver the manual to the

final user.

;

Foresee on the supply net an onnipolar switch or

selector with distance of the contacts equal or

superior to 3 mms.

Verify that of the electrical system there is an awry differential interrupter and overcurrent protection.

Some typologies of installation require the connection of

the shutter to be link at a conductive mass of the ground

according to the regulations in force.

The electrical installation and the operating logic must

comply with the regulations in force.

The leads fed with different voltages must be physically

separate, or they must be suitably insulated with additional

insulation of at least 1 mm.

The leads must be secured with an additional fixture near

the terminals.

During installation, maintenance and repair, interrupt

the power supply before opening the lid to access the

electrical parts

Check all the connections again before switching on the

power.

The unused N.C. inputs must be bridged.

The descriptions and the present illustrations in this manual

are not binding. Leaving the essential characteristics of the

product unchanged, the manufacturer reserves himself

the right to bring any change of technical, constructive

or commercial character without undertaking himself to

update the present publication.

Page 5

9

DA.24V/CP.EVA Control Unit

INPUT/OUTPUT FUNCTIONS

N° of terminals Function Description

1-2 Power supply Input, 230Vac 50/60Hz (1-Neutral/2-Phase)

4-5 Motor 24Vdc Connection to motor, 24Vdc

6-7 Flasher Flasher connection, 24Vac 40W max.

8-9 24 Vac

Output, accessories power supply - 24Vac/0.5A max.

IMPORTANT: If the battery charger board CB.24V is installed,

the output (without mains power connected) has a 24Vdc polarised voltage. Make sure the devices are correctly connected

(i.e. 8:+24Vdc - 9:-24Vdc).

10-11 Road barrier lights

Connection of barrier beam lights, 24Vdc (10+/11+) -200mA

max (equal to approx. 6 lights).

12 COM Common to all control inputs.

13 STOP Input, STOP push-button (N.C. contact)

14 PHOT

Input, safety devices connection, N.C. contact

(ex. Photocells)

15 OPEN Input, OPEN push-button (N.O. contact)

16 CLOSE Input, CLOSE push-button (N.O. contact)

17 Step-by-Step Input, step-by-step push-button (N.O. contact)

18 COM Common, limit switches.

19 SWC

Input, CLOSURE limit switch (N.C. contact).

When this contact is opened, power supply to the motor is cutoff at the end of the road barrier closing operation.

TECHNICAL DATA

Contol unit supply

24 Vdc

Power supply

230 Vac 50/60 Hz

Output supply

1 motor 24Vdc

Power maximum motor

120 W

Output supply accessories

24Vdc 500mA max.

Protection level

IP54

Operating temp.

-20°C / +50°C

Radio receiver

Removable connector for radio receiver

Page 6

10

20 SWO-R

Input, braking limit switch in the opening phase (N.C. contact).

When this contact is opened, braking starts during the barrier

opening phase.

21 SWC-R

Input, braking limit switch in the closing phase (N.C. contact).

When this contact is opened, braking starts during the barrier

closing phase.

24-25 Antenna

Connection of the antenna radio receiver removable board

(24-signal/25-screen).

28-29 Radio 2nd Ch Output, N.O. contact of the second radio channel.

VAUX-0-VMOT Secondary Connection of the transformer secondary winding

L1-N1 Primary Connection of the transformer primary winding

J3 Radio receiver Removable connector for radio receiver.

TRIMMER FUNCTIONS

SLOWCL The motor speed during braking in the closing phase is adjusted by this trimmer.

Braking starts with the triggering of the SWC-R limit switch and ends when the SWC limit

switch is activated.

SLOWOP The motor speed during braking in the opening phase is adjusted by this trimmer.

Braking starts with the triggering of the SWO-R limit switch and ends when the time preset

with Dip-Switch N°8 has elapsed.

AMP The obstacle detection amperometric sensor sensitivity is adjusted by this trimmer.

The sensor is activated in both opening and closing phases.

It is not activated during braking in the opening phase.

Should an obstacle be detected:

In the opening phase, the road barrier movement is stopped.

In the closing phase, the barrier is stopped and then re-opened completely.

TCA

This trimmer allows the adjustment of the automatic closure time if activated by Dip-Switch No. 1.

The adjustment ranges between 1s minimum and 90s maximum

DIP-SWITCH FUNCTIONS

DIP 1 “TCA” The automatic closure is enabled or disabled

Off: disabled automatic closure

On: enabled automatic closure

DIP 2 “PRELAM.” Forewarning flashing light is enabled or disabled

Off: disabled forewarning flashing light

On: enabled forewarning flashing light. The flashing light is activated 3s before the

starting of the motor.

DIP 3 “SCL” (DIP 1 must be ON) This enables or disables the rapid closure function after the

photocell activation.

Off: Disabled function. After the activation of the photocell, the automatic closure

time remains unchanged.

On: Enabled rapid closure function. After activation of the photocell, the automatic

closure time is reduced by 1 second.

DIP 4 “P.P. Mod” The operating mode of the “P.P. (Step-by-Step) Push button” and of the transmitter

are selected.

Off: Operation: OPEN > STOP > CLOSE > STOP >

On: Operation : OPEN > CLOSE > OPEN >

Page 7

11

DIP 5 “LIGHT” The operating mode of the road barrier lights connected to terminals 10/11 is

selected.

Off: Slow flashing with open or closed road barrier.

Fast flashing during operation.

On: Fixed light on, with up or moving road barrier. Light off with barrier down,

controlled by the triggering to the SWC-R limit switch.

DIP 6 “COND.” The multi-flat function is enabled or disabled.

Off: disabled multi-flat function.

On: enabled multi-flat function. The P.P. (Step-by-step) impulse or the impulse

of the transmitter have no effect in the opening phase and during TCA phase (if

activated).

DIP 7 “AMPCL” The amperometric sensor is enabled or disabled during braking in the closing

phase.

Off: Enabled amperometric sensor during braking in the closing phase

On: Disabled amperometric sensor during braking in the closing phase..

DIP 8 “Trall-OP” The amperometric sensor is activated or deactivated during braking in the opening

phase.

Off: 2 sec braking with inactivated amperometric sensor.

On: 2 sec braking with activated amperometric sensor. If the amperometric

sensor is activated during the 2s braking, the road barrier stops immediately its

movement.

If required, the system can be controlled in SERVICE MAN mode by switching all Dip Switched to ON

TO ADJUST THE ROAD BARRIER SPEED

WARNING! This adjustment affects the safety level of the automatic system.

Check that the force applied to the road barrier beam complies with regulations in force.

Any change in speed requires a new calibration of the amperometric sensor.

A Faston (VMOT) connector is provided on the power supply transformer. This allows for the adjustment of

the road barrier motor speed at three different levels (18-23-26).

By positioning the Faston (VMOT) to 18 a lesser speed is provided, by moving the Faston to 26 a higher

speed is provided.

Should the VE.AM mobile stand or the VE.RAST rack be present, reduce the beam speed.

DIAGNOSTICS OF LEDS

The control unit is provided with a series of self-diagnostic LEDs which permit to check all functions:

POWER LED It flashes to indicate the presence of mains power supply

STOP LED It switches off when the STOP button is activated

PHOT LED It switches off when the photocells are not aligned or in the presence of obstacles

OPN LED It switches on when the OPEN button is activated

CLS LED It switches on when the CLOSE button is activated

PP LED It switches on when the PP button is activated

SWC LED It switches off when the SWC closing limit switch is activated

SWO-R LED It switches off when the SWO-R opening braking limit switch is activated

SWC-R LED It switches off when the SWC-R closing braking limit switch is activated

WASTE DISPOSAL

If the product must be dismantled, it must be disposed according to regulations in force regarding the

differentiated waste disposal and the recycling of components (metals, plastics, electric cables, etc..). For

this operation it is advisable to call your installer or a specialised company.

Page 8

AUTOMATISMI BENINCÀ SpA - Via Capitello, 45 - 36066 Sandrigo (VI) - Tel. 0444 751030 r.a. - Fax 0444 759728

Loading...

Loading...