Page 1

Technical Bulletin

Bulletin No: TCH-013-018 Effective Date: 8/24/2009 Cancels: N/A Page: 1 of 3

Subject: Bendix

When installing valve components on a vehicle, including service replacement parts, the installer needs to carefully

follow the installation guidelines. Not following these guidelines can lead to damage of the valve and reduced

vehicle braking. Bendix Commercial Vehicle Systems LLC has identifi ed that some Bendix® AT- 3™ solenoid

valve bodies have become damaged and may result in leakage. Bendix recommends that the crimp area

of the AT-3™ valve be inspected and replace the valve if this area has been found to have become loose.

See Figure 1.

The Bendix® AT- 3™ solenoid valve is a specialized air brake valve which may be used for several functions,

depending on the specifi c vehicle needs. Most typically, the AT-3™ solenoid valve is used in the Bendix

automatic traction control and Bendix® ESP® stability systems. See Figure 2 for typical applications of the Bendix

AT-3™ solenoid valve. One or two of these valves may be installed on a vehicle.

Valve Body

Supply Port

®

AT-3™ Valve Leakage

Crimp Area

Mounting Holes

Delivery

Por t

Solenoid Body

Clamp From

Both Sides of

Mounting Hole

Flange

Permitted

Clamp

Location

Never Clamp

Using Solenoid

Body

Permitted

Clamp

Location

Electrical

Connector

Service /

Exhaust

Por t

®

ATC

FIGURE 1 - THE BENDIX® AT-3™ SOLENOID VALVE

To identify if the AT-3™ solenoid valve on your vehicle is damaged, perform the following inspection. Follow all

standard industry safety precautions, including, but not limited to, those included in this document.

1. Park the vehicle on a level surface and block the wheels and/or hold the vehicle by means other than the air

brakes.

2. Drain the air pressure from all vehicle reservoirs.

™

3. Locate the AT-3

4. With the valve mounted on the vehicle, grasp the solenoid body with your hand and attempt to rock it, checking

for looseness of the crimp area. If the solenoid body moves, or rocks, then the valve is damaged and should

be replaced. Replacement valves are available through any Bendix authorized parts distribution center. If a

replacement valve is needed, be sure to follow the installation guidelines included with the valve to prevent

damage to the replacement valve.

solenoid valve(s) on the vehicle. See Figure 2.

Continued ...

Page 2

Bulletin No: TCH-013-018 Effective Date: 8/24/2009 Cancels: N/A Page: 2 of 3

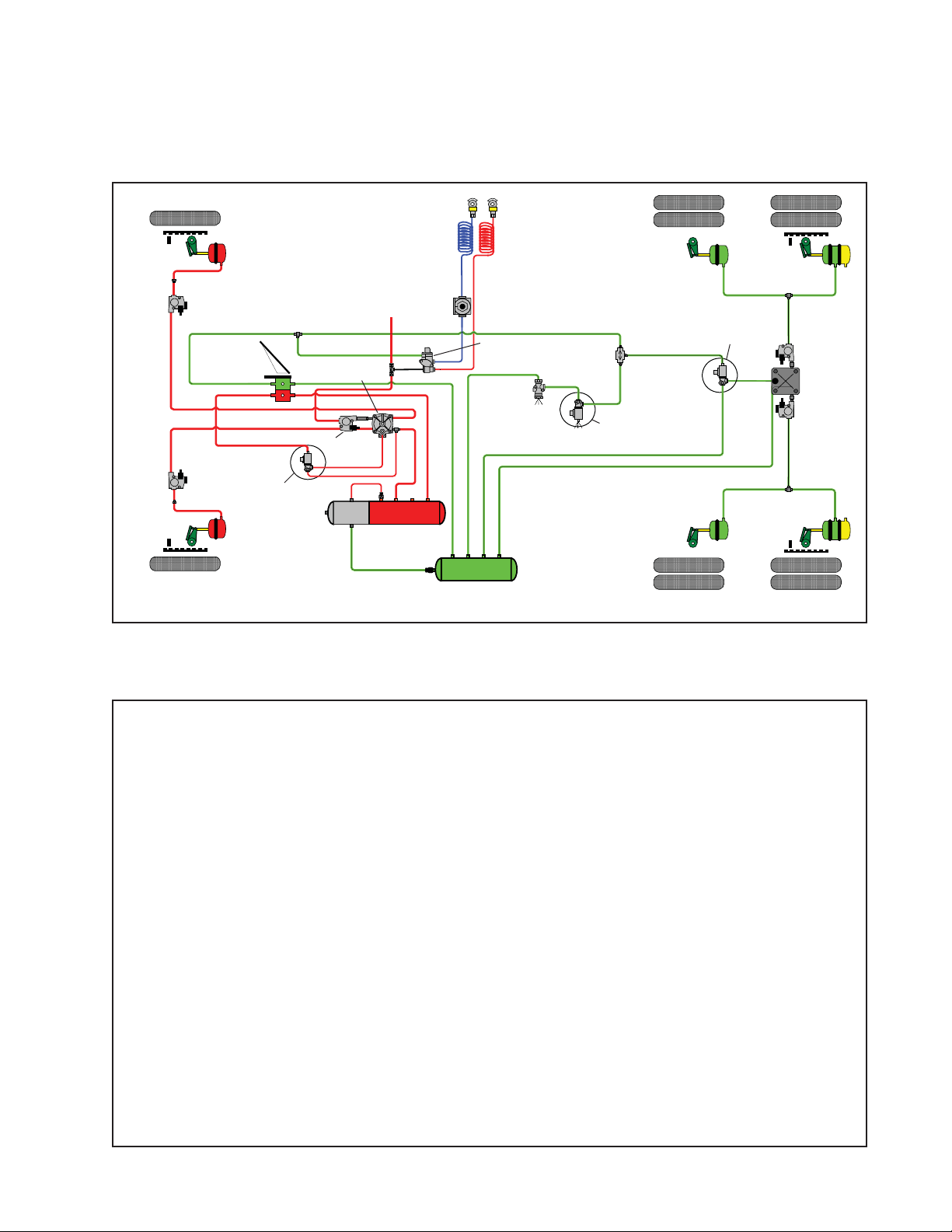

Supply

Secondary

Primary

Subject: Bendix

ABS

Modulator

Foot Brake

Trailer Modulator Valve

ABS

Modulator

®

AT-3™ Valve Leakage

From Trailer

Control Valve

Piloted

SER

DEL

SUP

Relay Valve

Supply

Secondary

Valve

AT-3

Solenoid

Valve - Steer

Axle (ESP)

™

Quick

Release

Valve

Tractor

Protection

Primary

PRIMARY

Valve

Pressure

Reducing

Valve

Double

Check

Valve

SUP

DEL

EXH

AT-3™ Solenoid Valve

(HSA-Hill Start Aid)

™

Solenoid

AT-3

Valve - Drive Axle

(ATC / ESP)

SER

DEL

SUP

ABS

Modulator

Relay

Valve

ABS

Modulator

FIGURE 2 - EXAMPLE APPLICATIONS OF BENDIX® AT- 3™ SOLENOID VALVE; 6X4 TRACTOR WITH

TRACTION CONTROL, ELECTRONIC STABILITY AND HILL START AID

WARNING! Please READ and follow these instructions to

avoid personal injury or death:

When working on or around a vehicle, the following general

precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the parking

brakes, and always block the wheels. Always wear safety

glasses.

2. Stop the engine and remove ignition key when working

under or around the vehicle. When working in the engine

compartment, the engine should be shut off and the ignition

key should be removed. Where circumstances require that

the engine be in operation, EXTREME CAUTION should be

used to prevent personal injury resulting from contact with

moving, rotating, leaking, heated or electrically charged

components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and thoroughly

understand the recommended procedures. Use only the

proper tools and observe all precautions pertaining to use

of those tools.

4. If the work is being performed on the vehicle’s air brake

system, or any auxiliary pressurized air systems, make

certain to drain the air pressure from all reservoirs before

beginning ANY work on the vehicle. If the vehicle is

equipped with an AD-IS® air dryer system or a dryer

reservoir module, be sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s recommended

procedures, deactivate the electrical system in a manner

that safely removes all electrical power from the vehicle.

6. Never exceed manufacturer’s recommended pressures.

7. Never connect or disconnect a hose or line containing

pressure; it may whip. Never remove a component or

plug unless you are certain all system pressure has been

depleted.

8. Use only genuine Bendix

®

replacement parts, components

and kits. Replacement hardware, tubing, hose, fi ttings,

etc. must be of equivalent size, type and strength as

original equipment and be designed specifi cally for such

applications and systems.

9. Components with stripped threads or damaged parts

should be replaced rather than repaired. Do not attempt

repairs requiring machining or welding unless specifi cally

stated and approved by the vehicle and component

manufacturer.

10. Prior to returning the vehicle to service, make certain all

components and systems are restored to their proper

operating condition.

11. For vehicles with Automatic Traction Control (A TC), the A TC

function must be disabled (ATC indicator lamp should be

ON) prior to performing any vehicle maintenance where

one or more wheels on a drive axle are lifted off the ground

and moving.

Page 3

Bulletin No: TCH-013-018 Effective Date: 8/24/2009 Cancels: N/A Page: 3 of 3

M

(

Subject: Bendix

®

AT-3™ Valve Leakage

The following is for reference only and should not

be used in lieu of the instructions provided with the

service replacement valve.

ASSEMBLY

Note: All torques specified in this document are

assembly torques and can be expected to fall off slightly

after assembly. Do not re-torque after initial assembly

torques fall. For assembly, use hand tools or torque

limited drivers only . Do not use impact driver to install

any fi ttings. Use a professional grade thread sealant

on all air hose connections to this valve.

INSTALLATION

Bendix approves two methods of installation:

(a) either install the valve onto the vehicle with OEM

approved mounting bolts, and then attach the

fi ttings, or,

(b) bench installation of the fi ttings, using only the

clamp location shown in Figure 1, before installing

the valve on the vehicle.

1. Clean and inspect all air lines and electrical

harnesses for damage and replace as necessary.

Select one of the two fi tting installation methods, either

install the valve onto the vehicle fi rst, or clamp, as shown

in Figure 1, using a bench vise for steps 2 and 3.

2. With thread sealant applied, connect the (1/4-18

NPT) supply and delivery air lines to the valve to

an initial torque of 15 ± 3 ft. lbs. The fi ttings may be

oriented clockwise, no more than one (1) additional

turn to its fi nal position.

3. For vehicles where the service / exhaust port is

used, apply thread sealant to the hose connector

and tighten to 18 ft. lbs. (25 N•m).

Where the fi ttings were installed using a bench vise,

now install the valve onto the vehicle.

4. In cases where the service / exhaust port is open to

the atmosphere, remember to install the valve with

this port oriented downwards (within 30 degrees of

vertical). Where used, re-install the snorkel tube

retained during disassembly . Be sure to check that

the snorkel tube has a constant downward slope.

Consider installing a snorkel tube for open service

ports in locations where road spray could enter the

valve.

5. Reconnect the wire harness to the solenoid using

the identifi cation made during the REMOVAL step.

Be sure to check that the harness has suffi cient tie-

wraps, etc. to prevent any damage during vehicle

operation.

6. Test valve as outlined in Operational and Leakage

Tests.

OPERATIONAL AND LEAKAGE TESTS

1. Chock the wheels, fully charge the air brake system

and apply the brakes.

2. Coat the valve with a soap solution; leakage of a

one-inch bubble in 3 seconds is permitted. Where

the service / exhaust port is open to the atmosphere,

do not spray the soap solution directly into this port,

or snorkel tube, where installed.

OPERATION TEST

Since this valve is used for different functions depending

on the vehicle, consult the vehicle Operator’s Manual

for further information. For vehicles where this valve is

being used for A TC functions, you may also refer to the

Antilock Traction Controller’s Service Data sheet (visit

www.bendix.com) for operational test(s) for traction

functionality. In addition, for certain vehicle air brake

systems, a PC with the Bendix® ACom™ Diagnostics

software (BW2329) may be used to test the valve.

BENDIX TECHNICAL ASSISTANCE TEA

BENDIX TECHNICAL ASSISTANCE TEAM

For direct telephone technical support, call the Bendix Tech Team at: 1-800-AIR-BRAKE

For direct telephone technical support, call the Bendix Tech Team at: 1-800-AIR-BRAKE

1-800-247-2725), option 2 Monday through Friday, 8:00 A.M. to 6:00 P.M. EST, and follow

(1-800-247-2725), option 2 Monday through Friday, 8:00 A.M. to 6:00 P.M. EST, and follow

the instructions in the recorded message, or you may e-mail: techteam@bendix.com.

the instructions in the recorded message, or you may e-mail: techteam@bendix.com.

©2009 Bendix Commercial Vehicle Systems LLC 8/09. All Rights Reserved. Printed in U.S.A.

Loading...

Loading...