Page 1

®

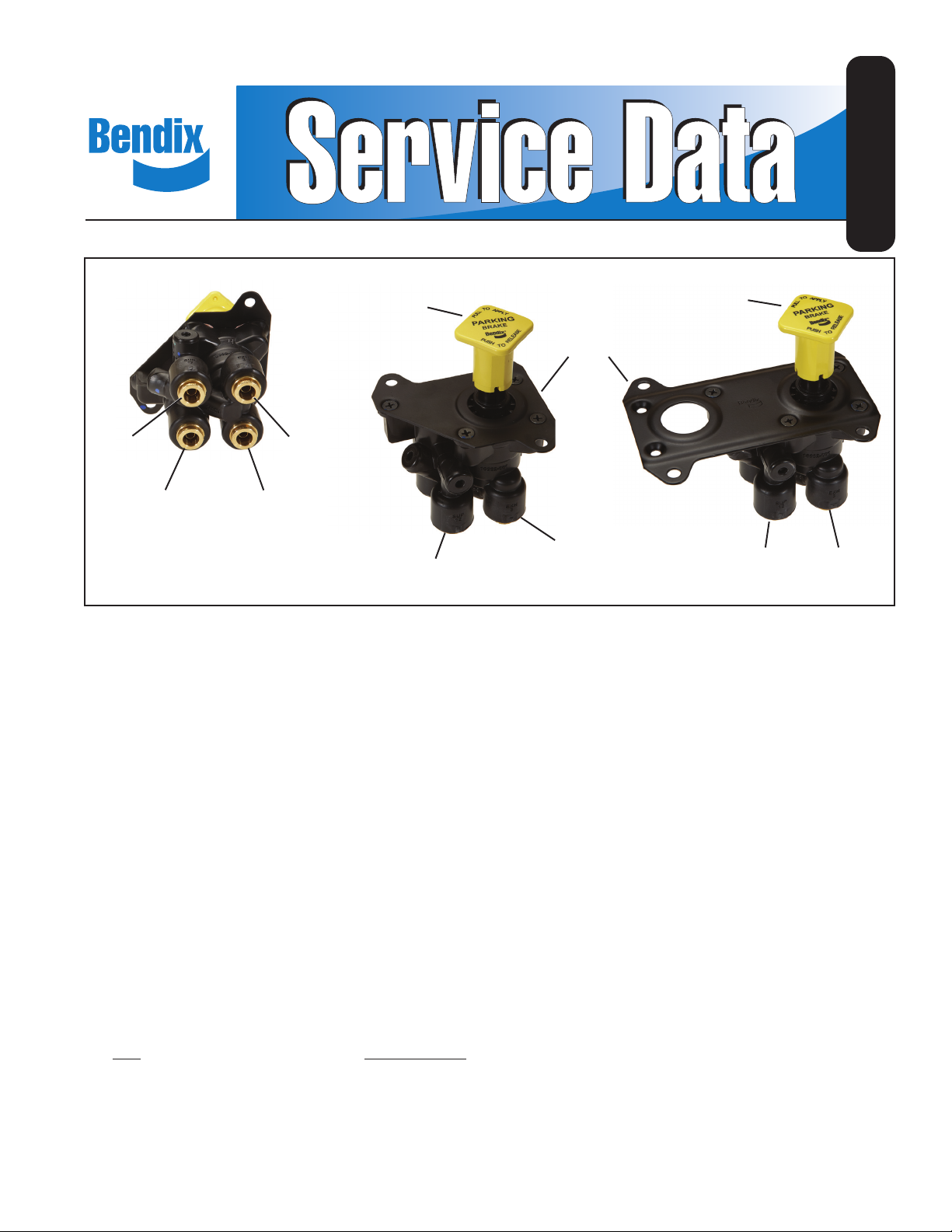

Bendix® PP-DC® Park Control Valve

SD-03-3619

BUTTON

SUPPLY

12

SUPPLY

11

FIGURE 1 - BENDIX® PP-DC® PARK CONTROL VALVE

EXHAUST

3

DELIVERY

21

SUPPLY

12

DESCRIPTION

The Bendix® PP-DC® park control valve is a push-pull,

manually operable on/off valve. It is dash board-mounted

and provides in-cab control of truck or bus parking brakes.

The valve is pressure sensitive—it automatically

moves from the applied to the exhaust position when

total system pressure drops below 20 to 40 psi. (Note

that this is a Bendix

mandated requirement. Refer to Bendix Technical

Bulletin TCH-003-051). Also, manually pulling the

button will apply the parking brakes.

The PP-DC valve body is made of non-metallic, noncorrosive material, and the cover is available in several

variations (see Figure 1). The valve is designed to accept

pipe thread fi ttings or push-to-connect fi ttings that use SAE

J844 non-metallic air brake tubing.

Ports:

Port Embossed I.D.

Primary Reservoir Supply SUP 11

Secondary Reservoir Supply SUP 12

Delivery DEL 21

Exhaust EXH 3

®

product specification and not a

BUTTON

COVER

EXHAUST

3

SUPPLY

12

EXHAUST

3

OPERATION

GENERAL

The PP-DC valve receives its supply of air from the primary

service reservoir or the secondary service reservoir,

whichever is at the higher pressure. When the button

is pushed in, the valve delivers air to the spring brake

chambers (usually through a spring brake valve such as

the Bendix

valve). The air releases the spring brakes for normal vehicle

operation.

To apply the parking brakes, the button is pulled out, which

exhausts the PP-DC valve delivery and releases air from

the spring brake chambers.

When total system pressure drops below 20 to 40 psi,

the valve will automatically “pop out,” which removes the

hold-off air in the chambers and applies the spring brakes.

PARKING BRAKES RELEASED

To release the parking brakes, the push-pull button is

pushed in. The PP-DC valve plunger moves, closing the

exhaust port with the exhaust seal and allowing the plunger

o-ring to move past the guide spool. Supply air then travels

out the delivery port to release the brakes.

®

SR-7® valve and a relay, or quick release,

1

Page 2

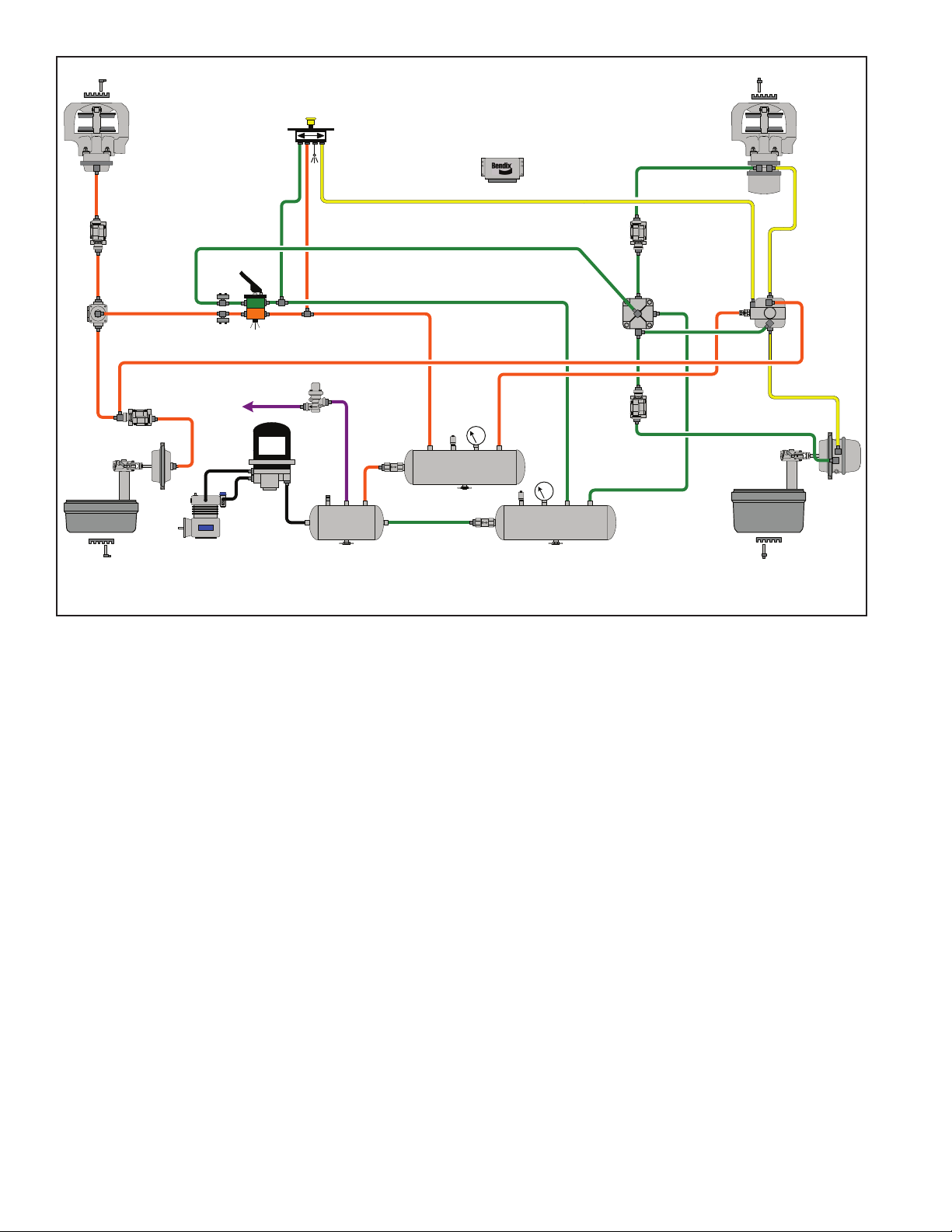

Bendix®

ADB-22X

Disc Brake

Antilock

Modulator

(4 places)

Quick Release

Valve

™

Brake Valve

To Accessories

Air Dryer

®

Bendix

PP-DC®

Park Control

Valve

®

Bendix

PR-3™/ PR-4™

Valve

Bendix

EC-60

Controller

Front

Axle Reservoir

®

™

Electronic

Disc Brake

Service

Relay

Valve

ADB-22X

™

®

Bendix

®

SR-7

Spring Brake

Modulating

Valve

Supply

Reservoir

Air Compressor

Air disc & drum brake actuation combined on a single axle are shown for pictorial purposes only.

FIGURE 2 - TYPICAL 4 X 2 TRUCK SCHEMATIC WITH BENDIX

Note that Figure 3 shows the primary service reservoir

supplying the Bendix

®

PP-DC® valve. The double check

valve diaphragm has sealed the secondary reservoir supply

port and allows air to pass from the primary reservoir into

the PP-DC valve.

If primary service reservoir pressure drops below secondary

service reservoir pressure, the double check valve reacts

as shown in Figure 4. It seals the primary service reservoir

supply port and supplies the Bendix PP-DC park control

valve with air from the secondary service reservoir. The

push-pull button remains in and the spring brakes remain

released.

PARKING BRAKES APPLIED

Figure 5 shows the PP-DC valve in the parking-brakesapplied position. This will occur when the driver manually

pulls out the push-pull button, or when the total system

pressure drops to below 20 to 40 psi.

As shown in Figure 6, when the button “pops” out, the

exhaust seal moves to open the exhaust port to the

atmosphere, allowing delivery line pressure to exhaust.

The plunger o-ring moves to seal off supply pressure.

Spring brake hold-off air is exhausted through the spring

brake relay valve.

Rear

Axle Reservoir

®

PP-DC® PARK CONTROL VALVE

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A

warranty may be voided if intrusive maintenance is

performed during the warranty period.

No two vehicles operate under identical conditions; as

a result, maintenance intervals may vary. Experience is

a valuable guide in determining the best maintenance

interval for air brake system components. At a minimum, the

PP-DC valve should be inspected every six (6) months or

1500 operating hours, whichever comes fi rst, for proper

operation. Should the PP-DC valve not meet the elements

of the Operational Tests noted in this document, further

investigation and service of the valve may be required.

SERVICE CHECKS

1. Remove any accumulated contaminants. Visually

inspect the valve’s exterior for excessive wear or

physical damage. Repair/replace as nec essary.

2. Inspect all air lines connected to the valve for signs of

wear or physical damage. Repair/replace as necessary.

3. Test air line fi ttings for excessive leakage. Repair or

replace as necessary.

2

Page 3

PRIMARY

SUPPLY

SECONDARY

SUPPLY

EXHAUST DELIVERY

PRIMARY

SUPPLY

SECONDARY

SUPPLY

EXHAUST DELIVERY

FIGURE 3 - PARK BRAKE RELEASED (Primary Reservoir

Supply)

FIGURE 5 - PARK BRAKE APPLIED

PRIMARY

SUPPLY

FIGURE 4 - PARK BRAKE RELEASED (Secondary Reservoir

Supply)

SECONDARY

SUPPLY

EXHAUST

DELIVERY

PRIMARY

SUPPLY

FIGURE 6 - PARK BRAKE EXHAUST

SECONDARY

SUPPLY

EXHAUST DELIVERY

3

Page 4

LEAKAGE AND OPERATIONAL TESTS

To perform the tests that follow, connect two separate

120 psi air sources to the Bendix® PP-DC® valve supply

ports. Tee an accurate test gauge into the supply lines,

and provide for a means to control supply line pressure.

Connect a small volume with a gauge to the delivery port.

LEAKAGE TEST

1. Supply the valve with 120 psi from the primary reservoir

supply port. With the button out, coat the exhaust port

and the plunger stem with a soap solution. Leakage

should not exceed a 1” bubble in fi ve (5) seconds. There

should be no leakage from the secondary reservoir

supply port.

2. With the button out, supply the valve with 120 psi from

the secondary reservoir supply port. There should be

no leakage from the primary reservoir supply port.

3. With the button in, coat the exhaust port and the plunger

stem with a soap solution. Leakage at both areas should

not exceed a 1” bubble in three (3) seconds.

OPERATIONAL TEST

1. With the button out, supply either supply port with

120 psi of air. Then push the button in. Air pres sure

should rise in the delivery volume equivalent to supply

pressure.

2. Pull the button out. Delivery pressure should exhaust

to 0 psi.

3. Build each supply source to 120 psi. Decrease supply

pressure at the secondary service reservoir supply port

at a rate of 10 psi per second. Primary supply pressure

and delivery pressure should not drop below 100 psi.

Repeat the test for decreasing primary service reservoir

pressure.

4. Build each supply source to 120 psi. Then decrease

both supply pressures to below 20–40 psi. The button

should automatically “pop” out when pressure drops

within that range.

If the PP-DC park control valve fails to function as

described, or if leakage is excessive, repair the valve or

replace it at the nearest authorized Bendix

®

parts outlet.

REMOVAL

1. Identify and mark or label all air lines and their

connections on the valve.

2. Remove the PP-DC valve from the vehicle and save

the mounting hardware.

INSTALLATION

1. Install the Bendix PP-DC valve in its location on the

dashboard. Using the mounting hardware saved in

“REMOVAL,” secure the valve to the vehicle.

2. Reconnect all air lines to the valve using the

identifi cation made in “REMOVAL.”

3. Perform “LEAKAGE AND OPERATIONAL TESTS”

before placing the vehicle back in service.

DISASSEMBLY

The disassembly and assembly procedures that follow

are for reference only. Always have the appropriate

maintenance kit on hand and use its instructions in lieu

of those presented here. Refer to Figure 7 throughout the

procedure.

1. Turn the button counterclockwise to remove it from the

plunger stem.

2. Remove the four screws that secure the cover to the

body, and remove the cover.

3. Pull the plunger stem to remove the plunger and the

guide spool from the body.

4. Remove plunger spring(6) and discard.

5. If necessary, use a screwdriver to carefully remove the

check valve seat from the body. Be sure not to damage

the check valve seat or the body.

6. Remove and discard check valve seat o-rings(7)

and (8).

7. Turn the body upside down and gently tap it on a fl at

surface to remove check valve(9). Discard the check

valve.

8. Remove the guide spool from the plunger. Remove and

discard o-ring(1) from the guide spool.

9. Remove and discard o-rings(2), (3) and (5) from the

plunger. Also remove and discard exhaust seal(4).

CLEANING & INSPECTION

1. Wash all metal parts in mineral spirits and thoroughly

dry.

2. Inspect all re-usable parts for excessive wear or

damage. Inspect the body for gouges or deep scuffi ng.

Replace key numbers 1-9 (and any parts not determined

usable) with genuine Bendix

®

replacements.

ASSEMBLY

Before assembly, lubricate all o-rings, o-ring grooves,

rubbing surfaces and bores with Bendix silicone lubricant

(Bendix piece number 291126) or equivalent.

1. Place check valve(9) into its seat in the body with its

fl at surface facing upward. If necessary, reach into the

body to make sure the valve is seated evenly in the

bore.

2. Install o-rings(7) and (8) on the check valve seat and

install the check valve seat into the body. Make sure

the seat is fully seated—its surface should be even with

the body’s surface.

3. Install plunger spring(6) into the body. Make sure it

stands upright and is seated properly in the body bore.

(It should surround the protrusion or “lip” at the bottom

of the body bore.)

4. Install o-rings(2), (3), (5) and exhaust seal(4) onto the

plunger. Then install the plunger into the body. Line up

the plunger’s index tabs with the spaces in the body

bore for ease of installation.

4

Page 5

BUTTON

COVER

1

GUIDE

SPOOL

SCREW

2

3

PLUNGER

STEM

CHECK VALVE SEAT

PLUNGER

INDEX TABS

4

5

6

BODY

7

8

9

FIGURE 7 - EXPLODED VIEW

5

Page 6

5. Install o-ring(1) onto the guide spool. Then install the

guide spool over the plunger and into the body. Press

the guide spool into place fi rmly.

6. Place the cover onto the body and secure with its four

screws. Torque to 35 in. lbs.

7. Thread the button clockwise onto the plunger stem.

It should take approximately three (3) full button

revolutions to install it on the plunger. The protrusions

on the side of the plunger should line up with the button

grooves. Push on the button a number of times to make

sure the plunger moves freely throughout its range of

motion.

NOTE: BEFORE PLACING THE VEHICLE BACK

INTO SERVICE, PERFORM THE “LEAKAGE AND

OPERATIONAL TESTS” IN THIS DOCUMENT.

6

SD-03-3619_US_006 © 2013 Bendix Commercial Vehicle Systems LLC, a member of the Knorr-Bremse Group. All Rights Reserved.

Loading...

Loading...