BENDIX SD-02-1302 User Manual

Bendix Brake Chambers

SD-02-1302

Different size brake chambers are identified by numbers

which specify the effective area of the diaphragm. A type

30 brake chamber has 30 square inches effective area.

Since one side of a brake chamber diaphragm is exposed

to the applying air pressure and the other side to atmospheric

pressure, the chamber has a pressure and a non-pressure

side. The non-pressure plate is usually vented to atmosphere

with four holes, however, on those inst allations where the

chamber must be weather-proof, venting is accomplished

through a drilled passage in the mounting bolts and the rod

opening in the non-pressure plate is sealed by either a

boot or an o-ring seal.

The standard diaphragm material is a compound of natural

rubber with a fabric interior of nylon. Neoprene-nylon

diaphragms are optionally available.

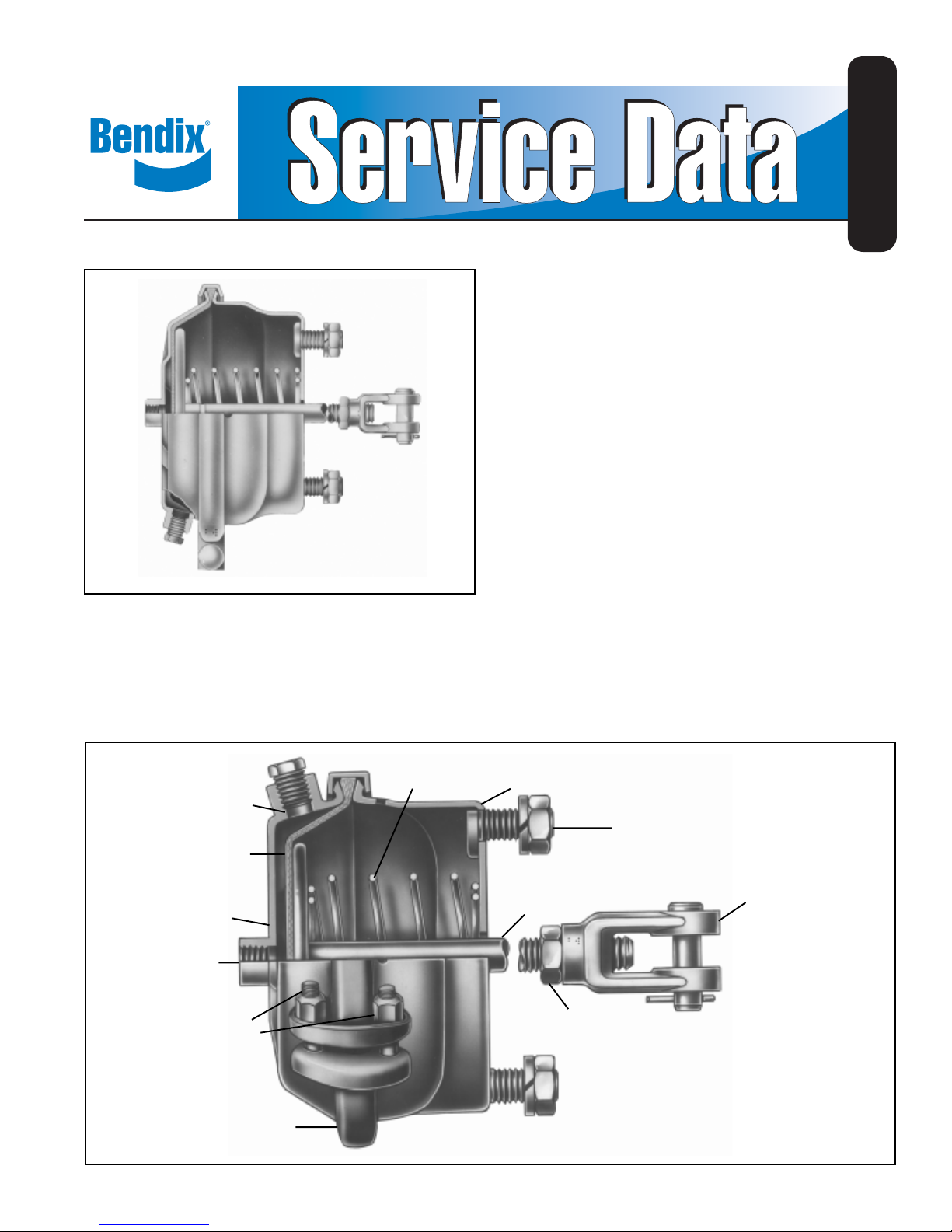

DESCRIPTION

The brake chamber is a diaphragm type actuator which

converts the energy of air pressure into mechanical force.

The diaphragm is held between the pressure plate and nonpressure plate by either a one piece clamp ring or a two

piece clamp ring (Figs. 1 and 2).

SPRING

INLET PORT

DIAPHRAGM

PRESSURE PLATE

INLET PORT

CLAMP RING

NUTS & BOLTS

Smaller chambers such as type 3 and type 6 have one 1/4

in. NPT inlet port in the center of the pressure plate. Larger

size chambers may have a center port and a side located

port or either one. Current production Type 20 chambers

and larger, generally have 3/8 in. NPT ports to facilitate

compliance with FMVSS 121.

NON

PRESSURE

PLATE

MOUNTING

BOLTS

PUSH ROD

ASSY.

LOCK NUT

YOKE

CLAMP RING

1

OPERATION

Controlled air pressure enters the brake chamber through

the inlet port and acts upon the diaphragm moving the push

plate and rod assembly forward.

When the brake chamber is used to actuate cam type brake

foundation assemblies, the yoke (which is threaded on the

push rod) is connected to a slack adjuster, which in turn is

connected to the brake cam shaft. This forward motion of

the push rod rotates the slack adjuster , cam shaft and cam

applying the vehicle brakes.

The greater air pressure admitted to the brake chamber, the

greater the force applied by the push rod and conversely,

the less pressure applied to the brake chamber the less

force applied by the push rod. Push rod force is determined

by multiplying the delivered air pressure by the effective

diaphragm area. For example, if 60 psi is admitted to a type

30 brake chamber, the lineal force on the end of the push

rod is approximately 1800 lbs.

CLAMP RING TYPE BRAKE CHAMBER DA T A

(Dimensions in Inches)

Max. Max. Stroke

Stroke at Which

Effective * With Brakes

Area Outside Max. Brakes Should Be

Type (Sq. In.) Diameter Stroke Adjusted Readjusted

6 6 4-1/2 1-5/8 Should 1-1/4

9 9 5-1/4 1-3/4 be as 1-3/8

12 12 5-1 1/16 1-3/4 short as 1-3/8

16 16 6-3/8 2-1/4 possible 1-3/4

20 20 6-25/32 2-1/4 without 1-3/4

24 24 7-7/32 2-1/4 brakes 1-3/4

30 30 8-3/32 2-1/2 dragging 2

36 36 * * 2-1/4

*Dimensions listed do not include capscrew head

projections for rotochambers and bolt projections for

clamp type brake chambers.

FIGURE 3

When air pressure is released from the brake chamber, the

push rod return spring in combination with the brake shoe

return spring returns the diaphragm, push plate and rod

assembly, slack adjuster and brake cam to their released

positions releasing the brakes.

PREVENTIVE MAINTENANCE

A. Every Month, 8,000 Miles or 300 Operating Hours,

depending on type of operation

1. Check push rod travel and adjust travel at the slack

adjuster if needed. Push rod travel should be as short

as possible without brakes dragging. Excessive push

rod travel reduces braking efficiency, shortens

diaphragm life, gives slow braking response and

wastes air.

2. Check push rod to slack adjuster alignment from

release to full stroke position to be sure push rod

moves out and returns properly without binding at

the non-pressure plate hole or with other structures.

Also check the angle formed by the slack adjuster

arm and push rod. It should be greater than 900 when

the chamber is in the released position and approach

900 at maximum re-adjustment stroke.

3. Check tightness of mounting nuts. Check cotter pins

to make sure they are in place.

4. Check all hoses and lines. They should be secure

and in good condition.

B. Every Year or after each 100,000 Miles or 3600 Operating

Hours, depending on type of operation

1. Disassemble and clean all parts.

2. Install new diaphragm or any other parts if they are

worn or deteriorated. When the diaphragm, spring,

or both are replaced, they should be replaced in the

corresponding chamber on the same axle.

OPERATING AND LEAKAGE TESTS

A. OPERATING TEST

1. Apply brakes and observe the push rods move out

promptly and without binding.

2. Release brakes and observe that the push rods return

to the released position promptly and without binding.

3. Check push rod travel. Push rod travel should be as

short as possible without brakes dragging. Adjust

travel of push rod at slack adjuster if necessary .

B. LEAKAGE TEST

1. Make and hold a full brake application.

2. Using soap solution, coat clamping ring(s). If leakage

is detected, tighten clamping ring only enough to

stop leakage. DO NOT OVERTIGHTEN as this can

distort sealing surface or clamping ring. Coat area

around push rod hole (loosen boot if necessary). No

leakage is permitted. If leakage is detected, the

diaphragm must be replaced.

REMOVING AND INSTALLING

A. REMOVING

1. Block vehicle wheels.

2. Release air pressure in all reservoirs.

3. Disconnect line to chamber .

4. Remove the yoke pin.

5. Remove the brake chamber .

2

Loading...

Loading...