Page 1

®

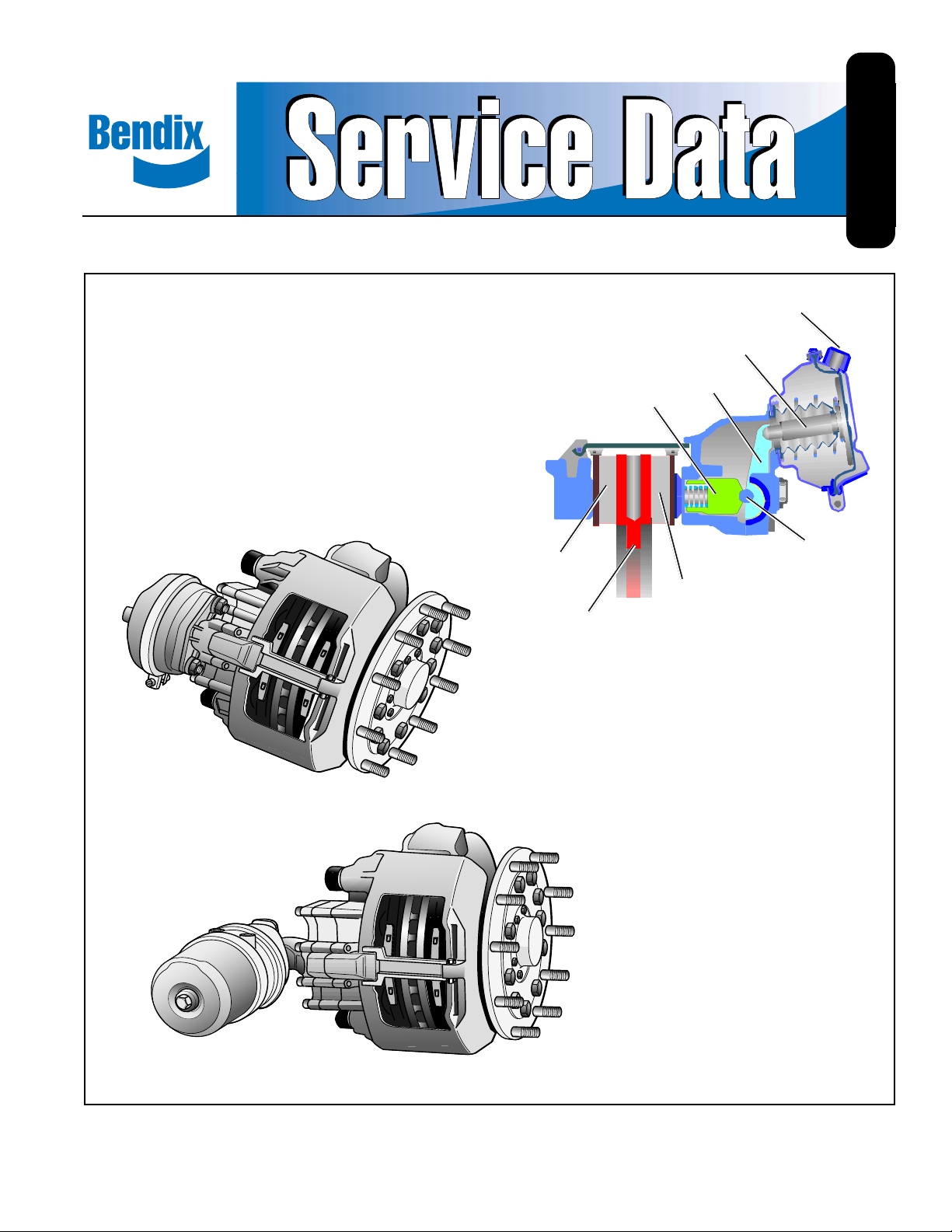

AIR DISC BRAKE (SB-6™ and SB-7™)

SD-23-7550

SUPPLY PORT

ACTUATOR ROD

AXIAL

OUTER BRAKE PAD

ROTOR

RETURN SPRINGS

LEVER

ACTUATING

BEAM

INNER BRAKE PAD

ECCENTRIC

BEARING

FIGURE 1 - BENDIX AIR DISC BRAKE

RADIAL

1

Page 2

2

Index

Page

1 Exploded view of brake

1.1 Axial Disc Brake Components 4

1.2 Axial Disc Brake Repair Kits 5

1.2.1 Axial Disc Brake Wear Indicator Kits 5

1.3 Radial Disc Brake Components 6

1.4 Radial Disc Brake Repair Kits 7

1.4.1 Radial Disc Brake Wear Indicator Kits 7

1.5 Brake Disc Rotor

2 General information

(for “ Axial- and Radial Disc Brake”)

2.1 Service Tools 9

2.2 Diagnostic Equipment 9

2.3 Lubrication 9

2.4 Torque requirements 9

3 Description and Function

3.1 Axial Disc Brake Sectioned View 10

3.2 Description of operation 11

3.2.1 Brake actuation 11

3.2.2 Brake release 11

3.2.3 Brake adjustment (automatic) 11

3.3 Radial Disc Brake Sectioned View 12

3.4 Description of operation 13

3.4.1 Brake actuation 13

3.4.2 Brake release 13

3.4.3 Brake adjustment (automatic) 13

4 Safety instructions for service work 13

(for “ Axial- and Radial Disc Brake”)

5 Brake Testing

(for “ Axial- and Radial Disc Brake”)

5.1 Troubleshooting procedure 14

5.2 Adjuster check 15

5.3 Wear limits of Brake Pads and Rotor 16

5.3.1 Brake wear check using Guide Pin (for Calipers with standard Guide Pins) 18

5.3.2 Brake wear check using Guide Pin (for Calipers with long Guide Pins) 19

5.3.3 Wear Indicators 20

5.4 Diagnostic-Equipment - Hand held device ZB9031 21

5.5 Diagnostic-Equipment - Vehicle mounted device ZB9033 21

6 Pad replacement

(for “ Axial- and Radial Disc Brake”)

6.1 Pad removal 22

6.1.1 Tappet Boot check 22

6.1.2 Caliper floatation check 23

6.2 Pad fitting 23

7 Tappet with Boot replacement

(for “ Axial- and Radial Disc Brake”)

7.1 Tappet with Boot removal 24

7.1.1 Adjuster thread inspection 25

7.2 Tappet with Boot fitting 25

8 Caliper Suspension Sealing 27

(for “ Axial- and Radial Disc Brake”)

8

Page 3

3

9 Guide Pin Bushing replacement 28

(for “Axial- and Radial Disc Brake”)

9.1 Brass Bushing replacement 28

9.2 Rubber Bushing replacement 28

10 Caliper replacement

(for “Axial- and Radial Disc Brake”)

10.1 Caliper removal 29

10.2 Caliper fitting 30

10.2.1 Caliper with Rubber Boot (10) 30

10.2.2 Caliper with Steel Cap (10a) 31

11 Carrier replacement 32

(for “Axial- and Radial Disc Brake”)

12 Actuation cylinder replacement

(for “Axial- and Radial Disc Brake”)

12.1 Brake Chamber removal 33

12.2 Brake Chamber fitting 33

12.3 Spring Brake removal 34

12.4 Spring Brake fitting 34

13 Additional Information

13.1 Service Video 35

13.2 Service Tool Kit 35

13.3 Diagnostic Equipment 35

Personal Notes

13.4 General Safety Guidelines 36

Page 4

4

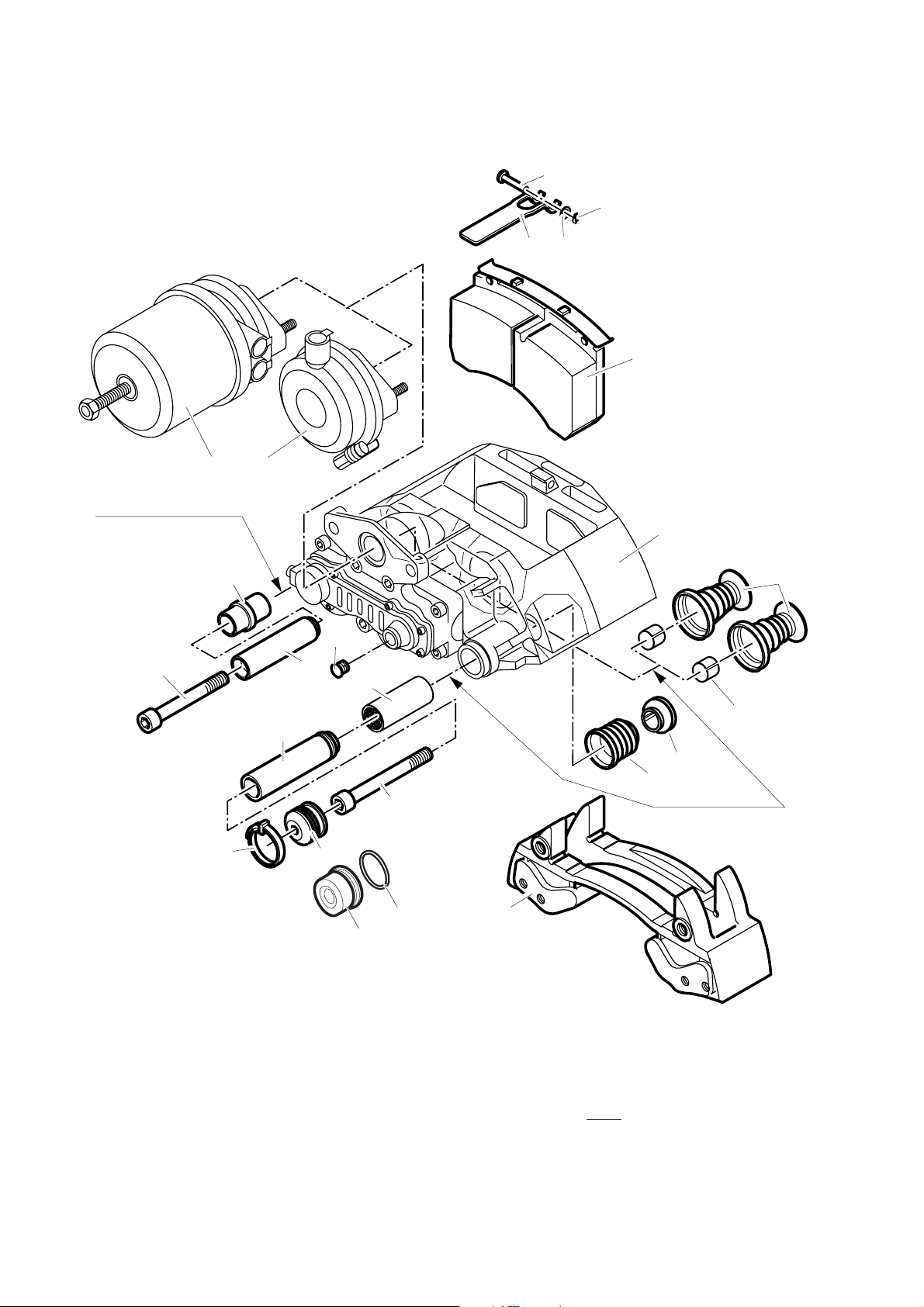

1 Exploded views

VF 00127/12-ÄiO1

26

44

11

39

6*

5

7

4

9

58

40

10

31

37

45

18/1

18/2

1

13

161

Assembly grease (white)

Assembly grease (coloured)

12

2

31a

10a

*

)

*

)

)

1 Caliper

2 Carrier

4 Sleeve

5 Sleeve

6 Rubber Bushing

7 Brass Bushing

9 Inner Boot

10 Outer Boot

10a Steel Cap

11 Pad Retainer

12 Pad

13 Tappet with Boot

18/1 Spring Brake

18/2 Brake Chamber

26 Spring Clip

31 Outer Boot Clip

31a O-Ring

37 Adjuster Cap

39 Caliper Bolt

40 Caliper Bolt

44 Pad Retainer Pin

45 Washer

58 Ring

161 Tappet Bushing

1.1 Axial Disc Brake Components

(for Wear Indicatators Kits see 1.2.1)

*

) possible variants by items 10a & 31a

Page 5

5

1.2 Axial Disc Brake Repair Kits

CAUTION

Use only Genuine Bendix® parts

The following Repair Kits are available

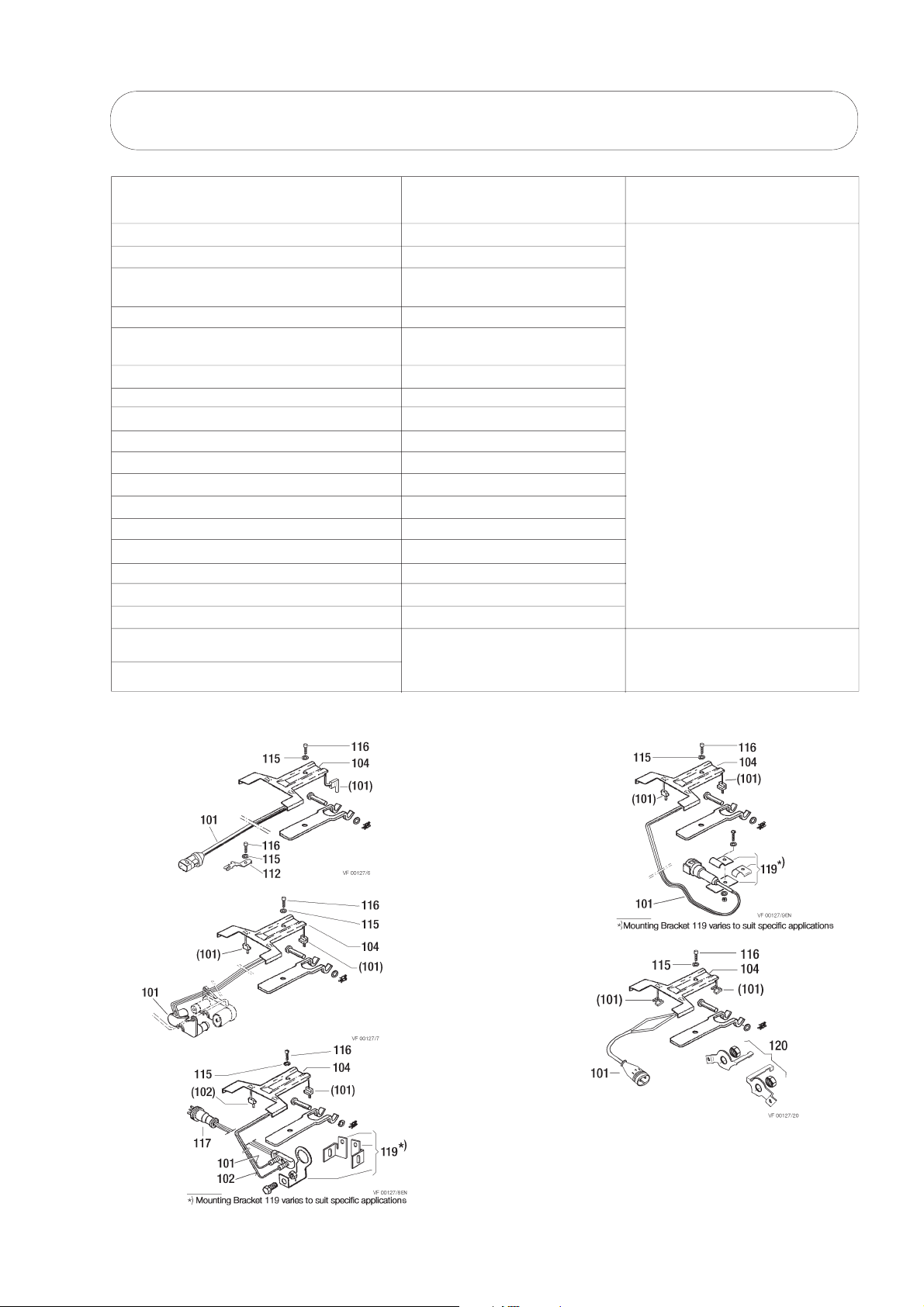

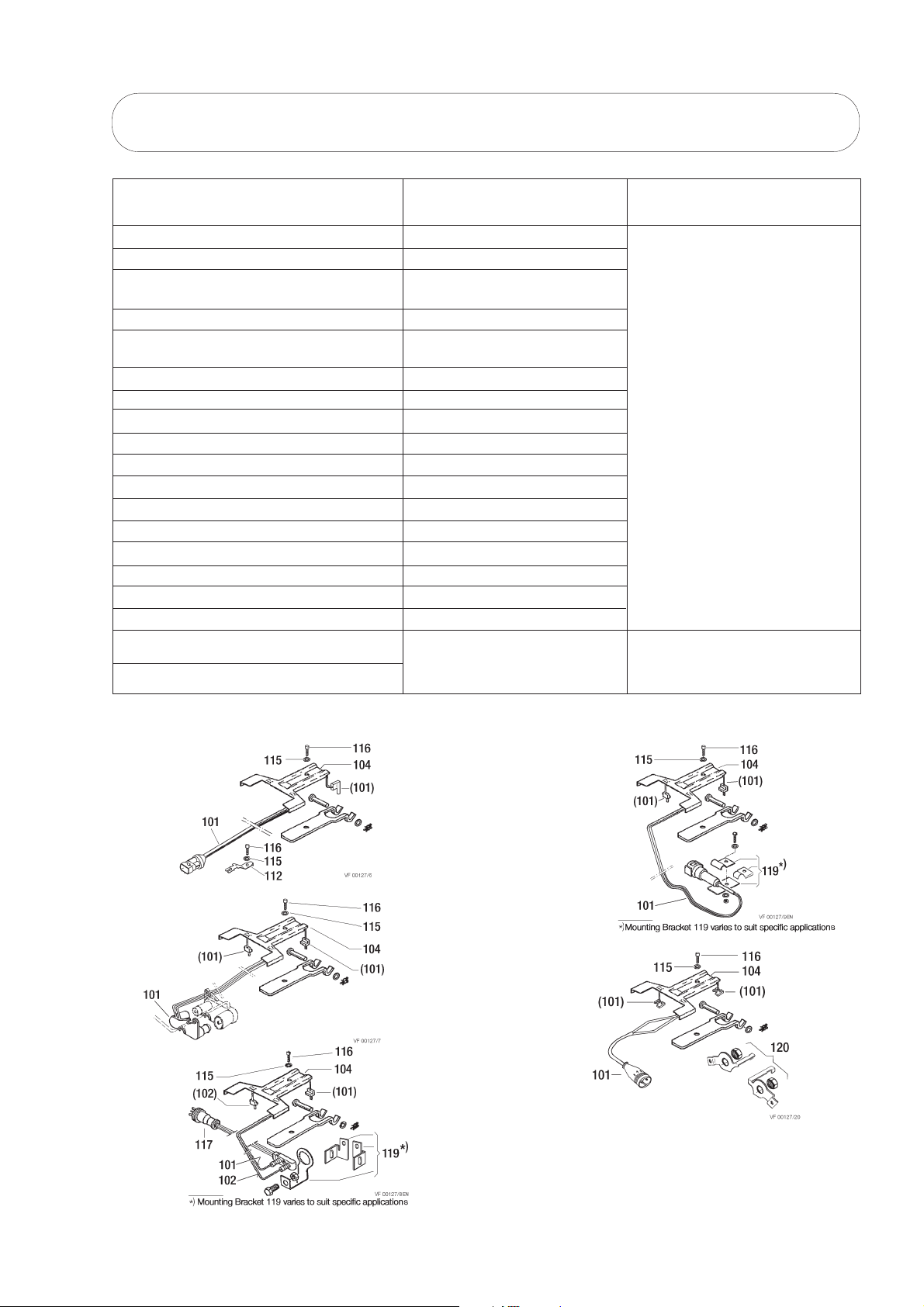

1.2.1 Axial Disc Brake Wear Indicator Kits

(Typical kits are shown below)

Type 1

Type 2

Type 4

Type 5

101 Sensor

102 Sensor

104 Cable Protection Plate

112 Clip

115 Spring Washer

116 Screw

117 Wear Indicator Cable

119 Bracket

120 Bracket

Type 3

Description Contents Association of Repair Kits to the Disc

Brakes and Repair Kit’s Order no.

Carrier Guide Kit 2, 4, 5, 31, 39, 40

Carrier Guide Kit (Steel Cap) 2, 4, 5, 10a, 31a, 39, 40

Wear Indicator Kit for variants see 1.2.1

(per axle) with or without 104

Guide Pins Kit 4-7, 9, 10, 31, 39, 40, 58

Guide Pins Kit (Steel Cap) 4, 5, 6, 7, 9, 10a, 31a, 39,

40, 58

Seal Kit for Guide Pins 9, 10, 31, 37, 58

Tappet and Boot Kit (2 pcs) 13, 161

Pad Set (per axle) 12, 26, 37, 44, 45 see www.Bendix.com for more

Adjuster Cap (4 pcs) 37 information

Pad Retainer Kit (per axle) 11, 26, 44, 45

Pad Retainer Kit (per axle) wear sensor 11, 26, 44, 45, 104, 115, 116

Kit for Floating Pin 4, 6, 39

http://www.Bendix.com

Outer Guide Seal Kit (10 pcs) 10, 31

Kit for Fixed Pin 5, 7, 9, 10a, 31a, 40, 58

Kit for Steel Cap 10a, 31a

Screw Kit for Steel Cap 10a, 31a, 39, 40

Screw Kit for Outer Boot 10, 31, 39, 40

Exchange Caliper r.h.

see Type plate

only in assembled condition

Exchange Caliper l.h.

on the Caliper

Page 6

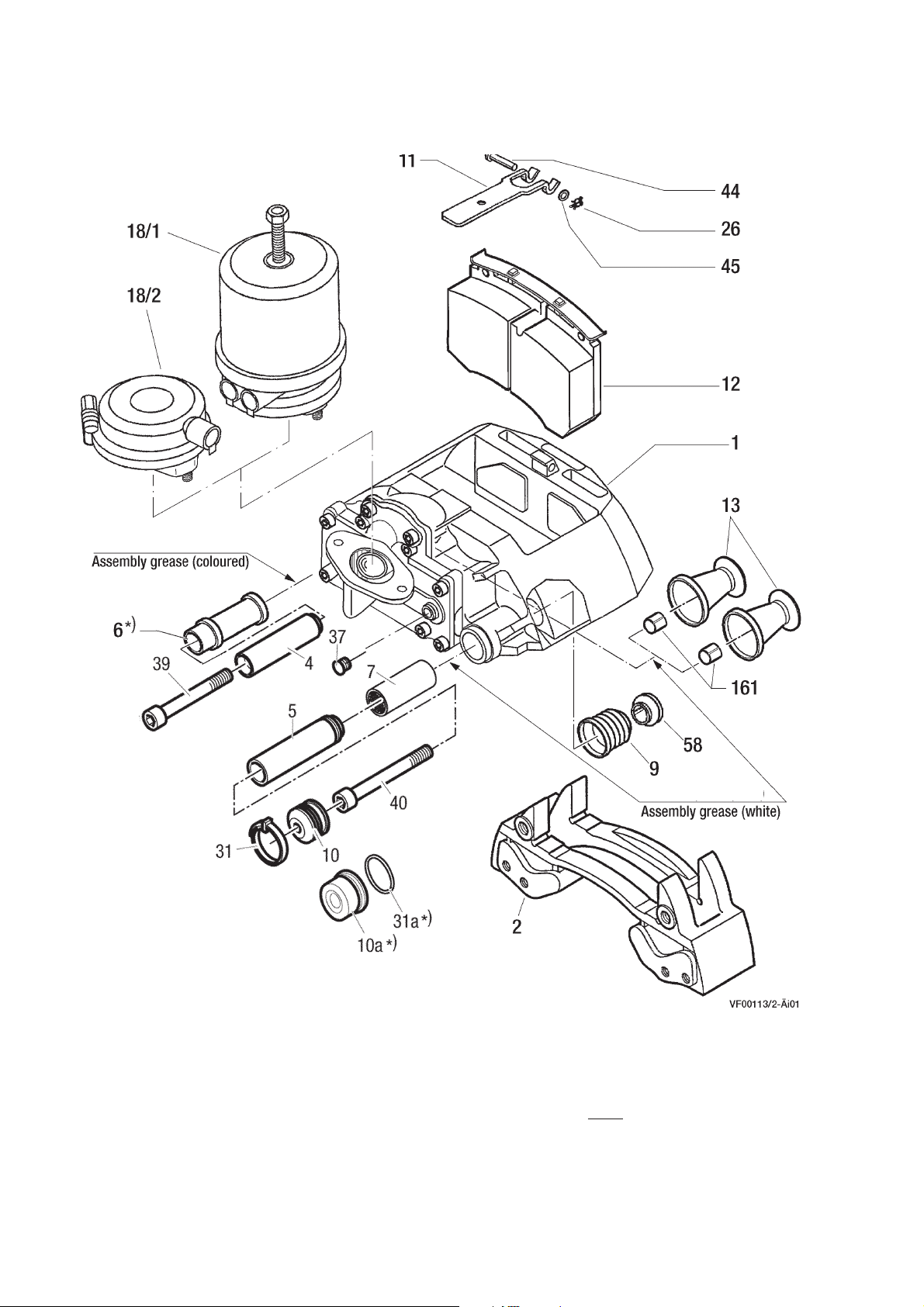

6

1 Caliper

2 Carrier

4 Sleeve

5 Sleeve

6 Rubber Bushing

7 Brass Bushing

9 Inner Boot

10 Outer Boot

10a Steel Cap

11 Pad Retainer

12 Pad

13 Tappet with Boot

18/1 Spring Brake

18/2 Brake Chamber

26 Spring Clip

31 Outer Boot Clip

31a O-Ring

37 Adjuster Cap

39 Caliper Bolt

40 Caliper Bolt

44 Pad Retainer Pin

45 Washer

58 Ring

161 Tappet Bushing

1.3 Radial Disc Brake Components

(for Wear Indicator Kits see 1.4.1)

*

) possible variants by items 10a & 31a

Page 7

7

1.4 Radial Disc Brake Repair Kits

CAUTION:

Use only Geniune Bendix parts

1.4.1 Radial Disc Brake Wear Indicator Kits

(Typical kits are shown below)

Type 1

Type 2

Type 4

Type 5

101 Sensor

102 Sensor

104 Cable Protection Plate

112 Clip

115 Spring Washer

116 Screw

117 Wear Indicator Cable

119 Bracket

120 Bracket

Type 3

Description Contents Association of Repair Kits to the Disc

Brakes and Repair Kit’s Order no.

Carrier Guide Kit 2, 4, 5, 31, 39, 40

Carrier Guide Kit (Steel Cap) 2, 4, 5, 10a, 31a, 39, 40

Wear Indicator Kit for variants see 1.2.1

(per axle) with or without 104

Guide Pins Kit 4-7, 9, 10, 31, 39, 40, 58

Guide Pins Kit (Steel Cap) 4, 5, 6, 7, 9, 10a, 31a, 39,

40, 58

Seal Kit for Guide Pins 9, 10, 31, 37, 58

Tappet and Boot Kit (2 pcs) 13, 161

Pad Set (per axle) 12, 26, 37, 44, 45 see www.Bendix.com for more

Adjuster Cap (4 pcs) 37 information

Pad Retainer Kit (per axle) 11, 26, 44, 45

Pad Retainer Kit (per axle) wear sensor 11, 26, 44, 45, 104, 115, 116

Kit for Rubber Sleeve 4, 6, 39

http://www.Bendix.com

Outer Guide Seal Kit (10 pcs) 10, 31

Repair Kit 5, 7, 9, 10a, 31a, 40, 58

Kit for Steel Cap 10a, 31a

Screw Kit for Steel Cap 10a, 31a, 39, 40

Screw Kit for Outer Boot 10, 31, 39, 40

Exchange Caliper r.h.

see Type plate

only in assembled condition

Exchange Caliper l.h.

on the Caliper

The following Repair Kits are available

Page 8

8

1.5 Brake Rotors

(for “Axial- and Radial Disc Brake”)

When replacing the Rotors, please also refer to the instructions provided by the Vehicle Manufacturer.

They should also referred to when spec'ing Bendix Rotors.

When replacing Rotors, please adhere to the recommended bolt tightening torques.

The use of non-approved Brake Rotors will reduce levels of safety and invalidate warranty.

Brake Rotors can be ordered through any authorized Bendix parts outlet.

More information can be found on the internet at www.Bendix.com

This information booklet is also available electronically when you visit www.Bendix.com.

Page 9

9

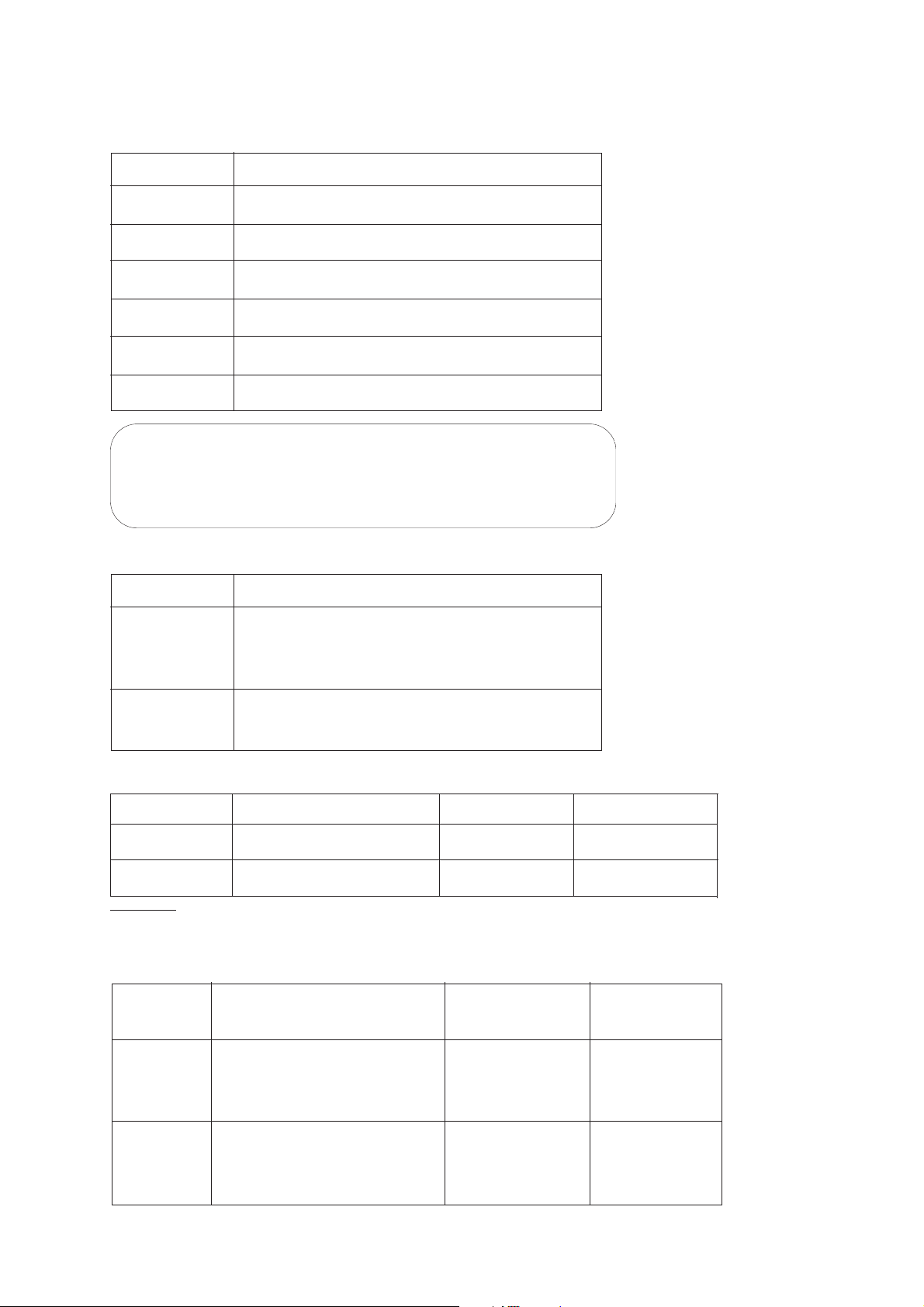

2 General Information

(for “Axial- and Radial Disc Brake”)

2.1 Service Tools

Part Number Description

ll 19252 Press-In Tool for Tappet and Boot (13)

ll 19253 Pull-In Tool for Inner Boot (9)

ll 19254 Pull-In/Out Tool for Brass Bushing (7)

II 32202 Wedged Fork for removal of Tappet and Boot (13)

II 36797 Grooving Tool for Brass Bushing (7)

Z001105 Press in Tool for Steel Cap (10a)

Item Number Torque spanner size

Ft. lbs. [Nm] in. (mm)

39 + 40 Caliper Bolts

M16x1.5 - 10.9 210±18 [285

±25

]

0.55 (14)

Actuator Mounting Nuts

M16x1.5 132+22 [180

+30

]

0.94 (24)

2.3 Lubrication

2.4 Torque requirements

2.2 Diagnostic Equipment

Part Number Description

ll 36695 ZB 9031 Hand held device for checking

Potentiometer function. ( Also Pad + Disc wear

when 13 pin chassis plug installed ).

ll 38691F ZB 9033 Chassis mounted device for measuring

Pad + Disc wear

Part Number Description Colour Application

ll 14525 Renolit HLT2 White

2)

Brass Bushing (7)

II 32793 Syntheso GL EP1 Green

2)

Rubber Bushing (6)

2)

Important Note: The correct Grease MUST be used for each Bushing!

Service tool kit ZB 9032 II 37951/004EX contains the

tools listed as well as this Service manual. The

service video is available separately

as Part No. KBP2060/1, in the UK, and elsewhere as

RA-SB0002 EN.

Page 10

10

1 Caliper

2 Carrier

4 Sleeve

5 Sleeve

6 Rubber Bushing

7 Brass Bushing

9 Inner Boot

10 Outer Boot

10a Steelcap

11 Pad Retainer

12 Pad

13 Tappet with Boot

16 Threaded Tube

17 Bridge

18/1 Spring Brake

18/2 Brake Chamber

19 Lever

20 Eccentric Bearing

22 Inner Seal Cap

23 Adjuster Unit

24 Turning Device

26 Spring Clip

27 Spring

28 Spring

30 Chain

31 Outer Boot Clip

31a O-Ring

32 Chain Wheel

33 Wear Sensor

37 Adjuster Cap

39 Caliper Bolt

40 Caliper Bolt

44 Pad Retainer Pin

45 Washer

46 Rotor

161 Tappet Bush

18/1

18/2

27

28

161

12 46 12 17 19

13 22 4 39 6

31

10

23

37

30

32

33

43

24

12

16

26

45

11

44

1

161 2

20

9

57

40

VF 00127/2-Äi01

31a*)

10a*)

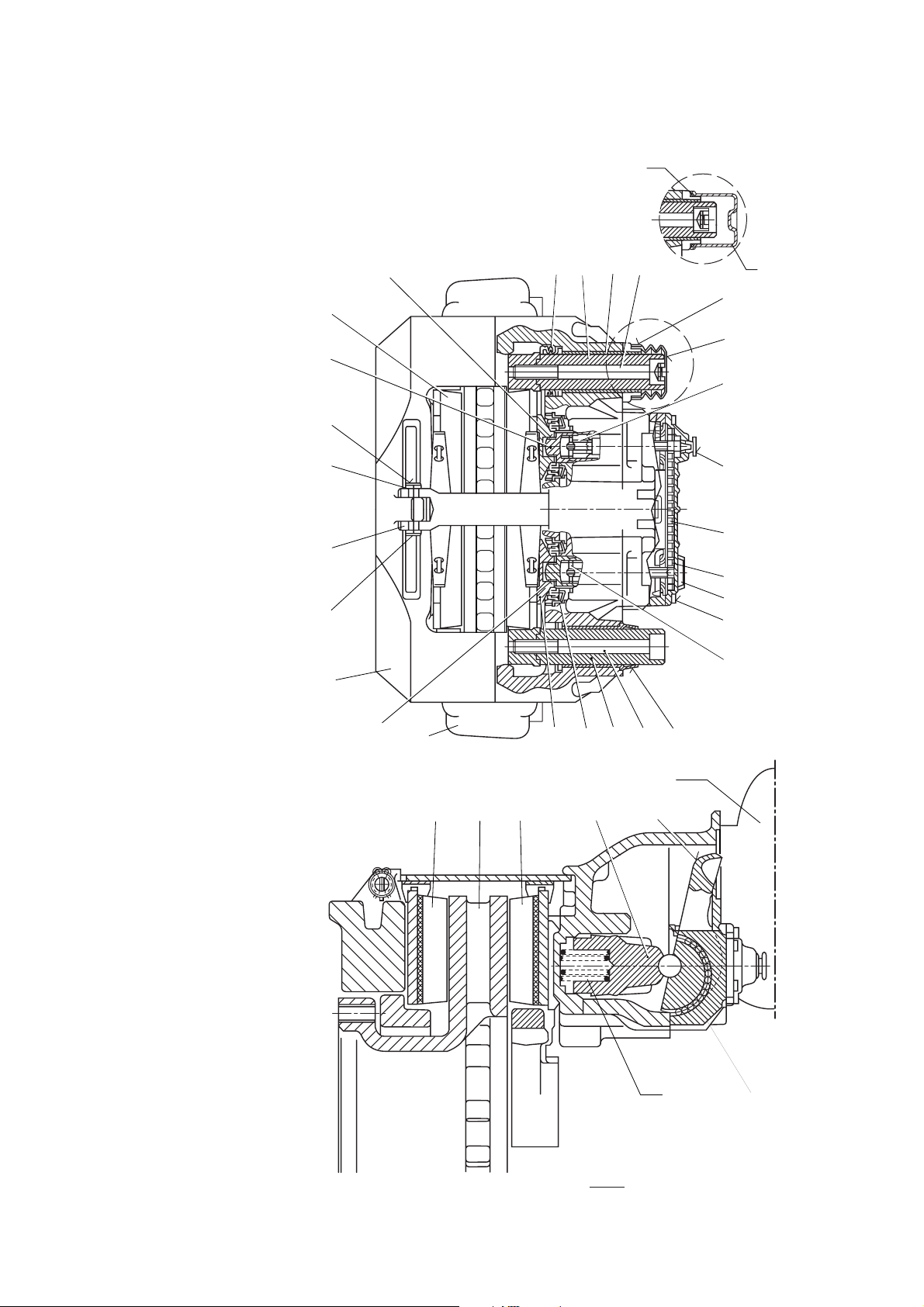

3 Description and function

3.1 Axial Disc Brake Sectioned View

*

) possible variants by items 10a & 31a

Page 11

11

3.2 Description of operation

(Floating Caliper principle)

3.2.1 Brake actuation

During actuation, the Push Rod of the Actuator (18/1

or 18/2) moves the Lever (19). The input forces are

transferred via the Eccentric Bearing (20) to the

Bridge (17). The force is then distributed by the

Bridge (17) and the two Threaded Tubes (16) to the

Tappets (13) and finally to the inboard Pad (12).

After overcoming the running clearance between the

Pads and the Rotor, the reaction forces are transmitted to the outboard Pad (12). The clamping forces on

the Pads (12) and the Rotor (46) generate the braking

force for the wheel.

3.2.2. Brake release

After releasing the air pressure, the two Return

Springs (27/28) push the Bridge (17) and Lever (19)

back to the start position; this ensures a running

clearance between Pads and Disc is maintained.

3.2.3 Brake adjustment (automatic)

To ensure a constant running clearance between

Disc and Pads, the brake is equipped with a low

wearing, automatic adjuster mechanism.

The Adjuster (23) operates with every cycle of actuation due to the mechanical connection with Lever

(19). As the Pads and Disc wear, the running clearance increases. The Adjuster (23) and Turning

Device (24) turn the Threaded Tubes (16) by an amount necessary to compensate for this wear. The total

running clearance (sum of clearance both sides of

Disc) should be between 0.03 and 0.04 in. (0.6 and

0.9 mm.; smaller clearances may lead to overheating

problems.

Page 12

12

3.3 Radial Disc Brake Sectioned View

1 Caliper

2 Carrier

4 Sleeve

5 Sleeve

6 Rubber Bushing

7 Brass Bushing

9 Inner Boot

10 Outer Boot

10a Steelcap

11 Pad Retainer

12 Pad

13 Tappet with Boot

16 Threaded Tube

17 Bridge

18/1 Spring Brake

18/2 Brake Chamber

19 Lever

20 Eccentric Bearing

22 Inner Seal Cap

23 Adjuster Unit

24 Turning Device

26 Spring Clip

27 Spring

28 Spring

30 Chain

31 Outer Boot Clip

31a O-Ring

32 Chain Wheel

33 Wear Sensor

37 Adjuster Cap

39 Caliper Bolt

40 Caliper Bolt

44 Pad Retainer Pin

45 Washer

46 Rotor

161 Tappet Bushing

*

) possible variants by items 10a & 31a

161

16

22

31a*)

10

31

7

9

5

40

10a*)

24

44

26

45

11

17

33

32

30

37

43

23

1

2

13 39 4 6

VF 00113/3-Äi01

12

27; 28 19 18/1; 18/2

20

46

VF 00113/4

Page 13

13

4 Safety Instructions for service work

(for “Axial- and Radial Disc Brake”)

Please refer to the relevant safety instructions for

repair work on commercial vehicles, especially for

jacking up and securing the vehicle.

Use only Genuine Bendix parts.

Please follow repair manual instructions and adhere

to the wear limits of the Pads and the Rotors - see

Section 5.3.

Use only recommended tools - see Section 2.1.

Tighten bolts and nuts to the recommended torque

values - see Section 2.4.

After re-fitting the wheel according to the Vehicle

Manufacturer’s recommendations, please ensure that

there is sufficient clearance between the Tire Valve

Stem, the Caliper and the wheel rim, to avoid damage to the Valve.

After service work:

Check the brake performance and the system behavior by actual road test.

3.4 Description of operation

(Floating Caliper principle)

3.4.1. Brake Actuation

During actuation, the Push Rod of the Actuator (18/1

or 18/2) moves the Lever (19). The input forces are

transferred via the Eccentric Bearing (20) to the

Bridge (17). The force is then distributed by the

Bridge (17) and the two Threaded Tubes (16) to the

Tappets (13) and finally to the inboard Pad (12).

After overcoming the running clearance between the

Pads and Rotor, the reaction forces are transmitted to

the outboard Pad (12). The clamping forces on the

Pads (12) and the Rotor (46) generate the braking

force for the wheel.

3.4.2. Brake release

After releasing the air pressure, the two Return

Springs (27/28) push the Bridge (17) and Lever (19)

back to the start position; this ensures a running

clearance between Pads and Rotor is maintained.

3.4.3 Brake adjustment (automatic)

To ensure a constant running clearance between

Rotor and Pads, the brake is equipped with a low

wearing, automatic adjuster mechanism. The

Adjuster (23) operates with every cycle of actuation

due to the mechanical connection with Lever (19). As

the Pads and Rotor wear, the running clearance

increases. The Adjuster (23) and Turning Device (24)

turn the Threaded Tubes (16) by an amount necessary to compensate for this wear. The total running

clearance (sum of clearance both sides of Rotor)

should be between 0.03 and 0.04 in. (0.6 and

0.9 mm.; smaller clearances may lead to overheating

WARNING!

Before starting repair work, block the

wheels to ensure that the vehicle cannot

roll away, before releasing the park brake.

See Page 36 for full Safety Guidelines.

problems.

Page 14

14

5 Brake Testing

(for Axial- and Radial Disc Brake)

5.1 Fault finding procedure

Lift vehicle,

turn wheel

by hand

Does wheel

turn smoothly?

Residual

pressure

within the

braking

cylinder?

NO YES

NO YES

NO YES

NO YES

NO YES

Check and if

necessary,

change or

service

preceding

braking device

END

NO YES

Running

clearance ok?

(see section 5.2)

Check adjuster

(see section 5.2)

END

Check and if

necessary,

maintain caliper

guide pins

(see section 9)

END

END

Adjuster ok?

END

Change caliper

(see section 10)

END

Tightness not

due to disc

brake

Caliper

guidance ok?

(see section 6.1.2)

Check and if

necessary,

maintain caliper

guide pins

(see section 9)

Brake pad wear

uneven?

(see note below)

Air Disc Brake

Running

clearance ok?

(see section 5.2)

Note: Difference between inboard and outboard pad less than 0.2in.(< 5mm), and diagonal wear ≤ 0.08in (2 mm)

NO Yes

END

FD00102EN-Äi01

Page 15

15

5.2 Adjuster check

The Adjuster should be turned counter-clockwise for

2 or 3 clicks (increasing running clearance).

M+P-KN-039

23

37

M+P-KN-043

By applying the brake 5 - 10 times (about 30psi, or

2 Bar) the Box End Wrench or Socket should turn

clockwise in small increments if the Adjuster is

functioning correctly (see notes below).

If Pads are not being changed, Cap (37) should be

replaced having lightly greased it with Renolit HLT2

(available as part number II14525).

NOTE:

As the number of applications increases, incremental

adjustment will decrease.

NOTE:

If the Box End Wrench or Socket does not turn, turns

only with the first application or turns forward and

backward with every application, the automatic

Adjuster has failed and the Caliper must be replaced.

CAUTION!

Make sure that the Box End Wrench or

Socket can turn freely while

completing the following procedures.

CAUTION!

Do not overload or damage the Adjuster

(23). Use only 8mm Box End Wrench

or 1/4Ó" drive Socket with a lever length

no greater than 4in. (100mm).

DO NOT use an Open Ended Wench

since this may damage the Adjuster shaft.

WARNING!

Before starting repair work, block the

wheels to ensure that the vehicle cannot

roll away, before releasing the park brake.

See Page 36 for full Safety Guidelines.

Remove wheel.

The caliper assemply should be pushed inboard on

its guide pins. Using a suitable tool, press the inboard pad (12) away from the Tappets and check

Tappet and inboard pad backplate - it should be between 0.02in. (0.5mm) & 0.04in. (1.0mm). If the running

clearance is too small or large, the adjuster may not be

functioning correctly and should be checked as follows.

Remove Cap (37).

M+P-KN-015

23

37

1

Page 16

16

5.3 Wear Limits of Pads and Rotors

Rotors

Measure thickness at the thinnest point. Avoid measuring near the edge of the disc as a burr may be present.

A = Rotor thickness (new condition) 1.77in. (45mm)

B = Rotor thickness (worn) 1.46in. (37 mm), Disc must

be replaced

C = Overall thickness of Pad (new) 1.18in. (30mm)

D = Backplate 0.35in. (9mm)

E = Minimum thickness of friction material 0.08in. (2mm)

F = Minimum allowed thickness in worn condition

for backplate and friction material 0.43in. (11mm)

(replacement of Pads necessary).

If wear dimension B ≤ 1.53in. (39 mm) Rotor should be

replaced together with Pads.

Wear dimension B = 1.46in. (37 mm) must not decrease. Minimum allowable thickness B=1.46in. (37 mm)

CAUTION!

Stay within the Rotor and Pad Wear Limits

Pads

The thickness of the Pads must be checked regularly

dependent on the usage of the vehicle.

The Pads should be checked to adhere to any applicable

legal requirements that may apply.

If no Wear Indicator has been connected, check for

wear at least every 3 months.

If friction material is less than 0.08in. (2mm) (see E), the

Pads must be replaced.

CAUTION!

These recommendations must be followed for proper brake performance.

M+P-KN-002

A

C

D

E

B

F

Page 17

17

max. 0.75 x a

max. 1.5 mm

VF 00127/3

A1 B

1

D1 C

1

a

CAUTION!

Follow these recommendations. Excessive

Pad or Disc wear will degrade optimum performance.

At each change of Pads check the Rotors for grooves

and cracks.

The diagram at the right shows possible conditions

of the surface.

A

1

= Small cracks spread over the surface

are allowed

B1 = Cracks less than 0.06in. (1.5mm) deep or wide,

running in a Radial direction, are allowed

C1 = Grooves (circumferencial) less than 0.06in. (1.5mm)

wide are allowed

D1= Cracks in the vanes are not allowed and the

Rotor MUST BE REPLACED.

a = Pad contact area

Note

In case of surface conditions A1,-C1, the Rotor can

remain in service until it has reached the minimum

thickness of 1.46in. (37 mm) is reached.

Knorr-Bremse Rotor are normally service-free and

refinishing, when changing Rotors, is not necessary.

However, refinishing could be useful, e.g. to increase

the load-bearing surface of the Pads, after severe

grooving on the entire friction surface has occurred.

To meet safety requirements, the minimum thickness

after refinishing is > 1.53in. (39 mm).

In addition, follow the recommendations provided by

the Vehicle Manufacturer.

Page 18

18

5.3.1 Brake Wear Check using Guide Pin (For all Axial and Radial Disc Brakes except those listed in

Section 5.3.2 - These Callipers do not have the rib in position B (see also Section 5.3.2)

M+P-KN-005

C

D

1

4

6

1

4

6

B

Pad conditions can be visually inspected without

removing the road wheel by noting the positon

of the Floating Pin (4) in the Caliper (1).

If dimension ‘C’ is less than 0.04in. (1mm), a more

accurate check of the Pads and Disc must be

B = without rib (see also Section 5.3.2)

C = pin protrusion - shown in new condition

D = minimal pin protrusion - Pads and Rotor must be

checked with road wheel removed

completed.

If necessary change the Pads - see Section 6

Page 19

19

5.3.2 Brake Wear Check using Guide Pin (Only for Axial Disc Brakes SB 7541, SB 7551 to SB 7629,

SB 7639 and Radial Disc Brakes SB 7102, SB 7112, SB 7103, SB 7113, SB 7104, SB 7114,

SB 7105, SB 7115, SB 7108, SB7118, SB 7109, SB 7119, SB 7120, SB 7130 - These Callipers do

have the rib in position B (see also Section 5.3.1)

Pad conditions can be visually inspected without

removing the road wheel by noting the positon

of the Floating Pin (4) in the Caliper (1).

If the head of the Floating Pin (4) is inside the

Rubber Bush (6) by a dimension D greater than

0.64in. (18mm), then a more accurate check of the

Pads and Rotor must be made.

If necessary, change the Pads - see Section 6.

B = with rib (see also Section 5.3.1)

C = new condition

D = 0.64in. (18mm) or more, Pads and Rotor must be

checked with road wheel removed

M+P-KN-006

1

4

6

C

D

1

4

6

B

Page 20

20

5.3.3 Wear Indicators

There are two types of Pad Wear Indicators available

to accommodate the differences in vehicle types and

manufacturers, including:

a) In - Pad Normally Closed Indicator - Circuit is

broken when Pad Wear reaches the limit.

b) In - Pad Normally Open Indicator - Circuit is

made when Pad Wear reaches the limit.

c) Wear Indicator using built in Potentiometer. This

is available either as an on/off version or

as a continuous signal version which can be

linked to the vehicle’s electronic monitoring

systems.

An optical or acoustic device may be linked to any of

the above.

Important

Please refer to the specifications provided by the

Vehicle Manufacturer

M+P-KN-007

M+P-KN-008

See Figure to the right.

Page 21

21

5.4 Bendix Diagnostic Equipment

The Bendix Diagnostic Unit ZB 9031 is a

hand held device suitable for vehicles that are fitted

with Bendix Air Disc Brakes using a continuous

signal type of Wear Potentiometer.

The wear condition of each brake can be measured

by connecting the device to a suitable 13 pin socket

(DIN 72570) where

fitted. This socket must have

been connected to each sensor by the vehicle

manufacturer.

The Diagnostic unit permits:

- Quick and simple wear check.

- A check of the potentiometer function.

A detailed instruction manual is included with

each unit.

5.5 Bendix Diagnostic Equipment

The Bendix Wear Check Module ZB 9033

is a chassis mounted device suitable for vehicles

that are fitted with Bendix Air Disc Brakes

using a continuous signal type of Wear

Potentiometer.

The module continuously monitors and displays the

wear at each brake.

For vehicles without an automatic brake control

system, particularly Trailer applications, the module

enables a quick and simple wear check.

The Wear Check Module permits:

- Up to six (6) Brakes to be checked together.

- LED monitoring of each Brake condition.

A detailed instruction manual is included with

each unit.

Page 22

22

Remove Cap (37).

Turn the Adjuster counter-clockwise until the Pads can

be removed. A clicking noise will be heard during

this procedure.

Push inboard Pad (12) toward Actuator.

Pull out both Pads (12).

M+P-KN-011

12

12

23

37

M+P-KN-012

13

6 Pad replacement

(for “Axial- and Radial Disc Brake”)

M+P-KN-010

26

45

11

44

WARNING!

Before starting repair work, block the

wheels to ensure that the vehicle cannot

roll away, before releasing the park brake.

See Page 36 for full Safety Guidelines.

6.1 Pad removal

Take the wheel off (refer to Vehicle Manufacturer’s

recommendations).

Remove Clip (26) and Washer (45), push down the

Pad Retainer (11) and remove Pin (44).

If the Pad Retainer (11) is corroded, it should be

replaced.

CAUTION!

Do not overload or damage the Adjuster

(23). Use only 8mm Box End Wrench

or 1/4” drive Socket with a lever length

no greater than 4in. (100mm).

DO NOT use an Open Ended Wrench

since this may damage the Adjuster shaft.

6.1.1 Tappet Boot Check

The Adjuster (23) should be screwed clockwise until

the boots are clearly visible.

The Boots should not show any damage.

Check the attachment of the Boots into the Caliper

housing.

Important

Any ingress of water or dirt past the Tappet Boot will

lead to corrosion and affect the function of the

Actuation Mechanism and Adjuster Unit.

If damaged, the Boot and Tappet must be replaced

(see Section 7).

Important

Before removing the Pads, it is strongly recommended

that the Adjuster mechanism should be checked for

correct operation. See Section (5.2)

Page 23

23

6.1.2 Caliper guidance check

Following Pad removal (Section 6.1)

Using hand pressure only (no tools), the Caliper (1)

must slide freely over the whole length of the Guide

Pin arrangement > 1.2in. (30mm).

During this operation the Sleeve (5) is sealed by the

Boot (9) and Cap (10) or Steel Cap (10a) and O-Ring

(31a). These must show no signs of damage. Check

that these are correctly seated.

The Caliper may have to be re-sealed by using a

suitable Kit (see page 5 or page 7).

Note:

Before placing the Pads into the Carrier, the Adjuster

(23) must be further de-adjusted by rotating it

counter clockwise.

Clean the Pad abutments.

Push Caliper (1) outboard and fit the outboard Pad

(12).

For fitting the inboard Pad (12), push Caliper (1) in the

opposite direction.

If fitted, replace Wear Indicators and fittings /

brackets, etc. See page 5 or 7.

957

10

64

1

M+P-KN-013-Äi01

31a*)

10a*)

M+P-KN-014

1

12

6.2 Pad installation

IMPORTANT!

Pads must be changed as an axle set

and NOT individually.

Use only Pads which are permitted by

the vehicle, axle, or brake manufacturer.

Failure to comply with this

policy may invalidate

the vehicle manufacturer’s warranty.

Rotate the Adjuster clockwise until the Pads come

into contact with the Rotor. Then turn back the

Adjuster 2 clicks.

CAUTION!

Do not overload or damage the Adjuster

(23). Use only 8mm Box End Wrench or

1/4" drive Socket with a lever length no

greater than 4 in. (100mm).

DO NOT use an Open Ended Wrench

since this may damage the Adjuster shaft.

*

) possible variants by items 10a & 31a

Page 24

24

IMPORTANT!

Pads require a break-in period. Heavy or

or prolonged braking should be

avoided during this break-in period.

7 Tappet with Boot replacement

(for “Axial- and Radial Disc Brake”)

7.1 Tappet with Boot removal

Note:

It may be easier to remove the Caliper from the axle

for replacement of the Tappets (see Section 10.1).

The Adjuster (23) must be screwed clockwise until

the Boots can be reached.

Exercise caution to avoid thread overrun if the Caliper

has been removed from the vehicle (see setion 7.1.1.).

To remove the Tappet Boot from the Caliper bore, a

Screwdriver should be used to deform the Boot location ring - see diagram.

M+P-KN-017

13

13

CAUTION!

Because it is not a replacement item, use

caution to avoid damage to the Inner Seal.

The hub should turn easily by hand after having

applied and released the brake.

The Cap (37) must then be replaced after it has been

lightly greased it with Renolit HLT2 (available as part

number II14525).

After setting the Pad Retainer (11) into the groove of

the Caliper (1), it must be pushed in to allow the

insertion of the Pad Retainer Pin (44).

Fit washer (45) and Spring Clip (26) to the Pad

Retainer Pin (44) (use only new parts).

Our recommendation is to fit the Washer (45) and

Spring Clip (26) pointing downwards (see diagram).

Wheel mounting (refer to Vehicle Manufacturer’s

recommentations).

M+P-KN-016

26

45

11

1

44

As with all brake pad replacements, new

Follow Industry recommendations to determine

the optimum break-in period for the vehicle.

Page 25

25

The Tappets (13) can be removed from the Threaded

Tubes by using Wedge Fork A. (Order No. II32202).

Remove the old Tappet Bush (116).

Check Inner Seal (arrow) and if damaged, replace the

Caliper.

7.1.1 Adjuster thread inspection

Place an new thickness Pad (12) into the outboard

gap to avoid overrunning of the Threaded Tubes.

IMPORTANT!

Threaded Tubes should not be extended

beyond thread engagement of the Bridge.

If thread engagement (synchronization) is

lost, the Caliper must be replaced.

For the inspection of the threads, the tubes must be

screwed out (max. 1.2in. [30mm]) by turning the Adjuster

(23) clockwise.

If Caliper is not installed on axle, put a spacer E

(length = 2.76in. [70mm]) into the Caliper (1) to avoid

overrunning of the Threaded Tubes (16) when adjusting

them out (see illustration opposite). During adjusting,

the threads can be checked for corrision damage.

In case of water ingress or corrosion, the Caliper

must be replaced.

7.2 Tappet with Boot installation

With Caliper fixed to axle:

Grease threads with RENOLIT HLT2 (Order No.

II14525).

Screw back Threaded Tubes (16), by turning the

Adjuster (23) counter-clockwise.

Place new Tappet Bushing (161) onto the head of the

Tube (16).

Sealing seat in the Caliper for Tappet with Boot (13)

must be clean and free of grease.

Place Tappet with Boot (13) onto the head of the

Tube.

Use Push-In Tool with the short strut (B)

(Order No II19252) for positioning and pressing-in the

Boot (13).

A

A

13

13

161

VF 00127/4

B

13

161

VF 00127/5

VF 00127/13

E

16

1

70 mm

16

12

46

M+P-KN-019

Page 26

26

M+P-KN-022

B

13

M+P-KN-023

B

13

M+P-KN-021

B

13

Using Tool B in reverse direction, the Tappet can be

pressed on.

With Caliper not installed on axle

Grease threads with RENOLIT HLT2 (Order No.

II14525).

Screw back Threaded Tubes (16), by turning the

Adjuster (23) counter-clockwise.

Sealing seat in the caliper for Tappet with Boot (13)

must be clean and free of grease.

Place new Tappet Bushing (161) onto the head of the

Tube (16).

Place Tappet with Boot (13) onto the head of the

Tube.

Use Push-In Tool with the long strut (B) (Order No

II19252) for positioning and pressing-in the Boot (13).

Using the Tool (B) in reverse direction, the Tappet can

be pressed on.

Page 27

27

8 Caliper Suspension sealing

(Replacement of inner Boot (9) )

(for the Axial and Radial Disc Brake)

Remove Caliper (see Section 10.1)

Remove Ring (58)

Pull out Sleeve (5)

Push out Boot (9) with screw driver.

Inspect and clean contact area of Boot (9)

Put new Boot (9) into the Cup (arrow) of the Tool C

(Order No II19253).

Position Sleeve with Boot (9) into the Caliper bore

and pull in.

Fit the Sleeve (5)

The Boot end must engage in the groove of the

Sleeve (5) (arrow). Lock with Ring (58) by pushing

on until it engages.

Important:

Before fitting the Caliper, the unsealed Sleeve with the

Rubber Bushing should be checked for its ability to

slide.

Fit Caliper (see Section 10.2).

M+P-KN-025

5

9

58

59

58

VF 00127/15

9

M+P-KN-026

9

C

Page 28

28

9 Guide Pin Bushing replacement

(for “Axial- and Radial Disc Brake”)

Remove Caliper (see Section 10.1)

Remove Sleeve (5) and inner Boot (9) (see Section 8).

9.1 Brass Bushing (7) replacement

Remove old Sleeve (5).

Pull out Bushing (7) with Tool (D) (Order No. II19254).

If Caliper has no groove (see arrow)

(Note: Groove is always located on the

inboard side)

Pull in new Brass Bush (7) with Tool (D).

If Caliper has a groove:

Pull in new Brass Bush (7) with Tool (D).

To prevent longitudinal displacement, use

Tool (F) (Order No II36797) to create

dents in bushing.

Check contact area of Brass Bushing (7) for burrs.

Remove burrs.

Grease Bushing with white Grease RENOLIT HLT2

(Order No II14525).

Insert new Sleeve (5).

Note:

The Guide Pins Kit contains new Sleeves (4) & (5)

and new Caliper Bolts (39) & (40) (see Section 1.2

and 1.4).

M+P-KN-030

6

4

7D

VF 00127/16

9.2 Rubber Bushing (6) replacement

Remove old Sleeve (4)

Pull Rubber Bushing (6) out of bore.

Check bore for corrosion, clean, if necessary coat bore

with Corrosion protection paint (e.g. Zinc spray).

Note:

Grease new Rubber Bushing (6) inside and outside with

green Grease SYNTHESO GL EP 1 (Order No

II32793).

7

D

VF 00127/17

Page 29

29

10 Caliper replacement

(for Axial- and Radial Disc Brake)

31

39

10

40

31a

10a

10

31

M+P-KN-024-Äi01

10.1 Caliper removal

Remove Pads (see Section 6.1)

Remove Actuator (see Section 12.1 and 12.3).

Remove Outer Boot Clip (31) and take off Outer Boot

(10)

Note:

In addition to Calipers with an Outer Boot (10) and

Outer Boot Clip (31), there are also versions available

with a Steel Cap (10a) and O-Ring (31a).

On models with Steel Caps (10a) and O-Rings (31a),

place tool (G) (Part Number Z001105) onto the Steel

Cap and tighten the threated pin by a hexagon

socket spanner. Then use hammer as shown.

Remove Caliper Bolts (39 and 40).

Deform new Rubber Bushing (6) and push from the

inner side of the Caliper into the bore.

Push Rubber Bushing (6) so that the outer positioning

ring locates in the groove (see arrows).

Note:

The Guide Pins Kit contains new Sleeves (4) & (5)

and new Caliper Bolts (39) & (40).

Assemble Sleeve (4)

Re-fit Caliper (see Section 10.2)

Important:

Torque Caliper Bolts to 210

+18

ft. lbs. (285

+25

Nm) and

check that the Caliper slides easily.

IMPORTANT!

mineral oil) for lubricating the Bushing or

Sleeve. Use only synthetic based green

Grease (Part Number II32793). Improper

Grease may cause the rubber Bushing to

swell and prevent proper floatation.

M+P–KN–031

6

Never use the white Grease (containing

Page 30

30

WARNING!

Hold the Caliper only on the exterior.

Never insert your fingers between

the Caliper and Carrier!

IMPORTANT!

permitted. Use only Genuine Bendix

service Exchange Calipers. Disassembly

of the Caliper will void any

Warranty Claim.

Remove Caliper from Carrier.

10.2 Caliper fitting

Check the Part No. on the label (arrow, Figure above

right) to ensure that you have selected the proper

replacement Caliper.

Note:

Service Exchange Calipers have a blue label.

The Service Exchange Caliper has a plastic cap or an

adhesive tape in the area of the Actuator attachment.

Remove the cap or tape after installing the Caliper

(see arrow).

Note:

The service exchange Caliper includes sealing and

guiding elements. The Pads are not included.

FD00114

10.2.1 Caliper with Rubber Boot (10)

Locate the Caliper to the Carrier.

Screw-in Caliper Bolts (39 and 40) and tighten to

210

+18

ft. lbs. (285

+25

Nm) (use only new parts).

Check that the Caliper slides easily.

Check the position of the Inner Boot (9) on the

Sleeve (5).

Check Adjuster function (see Section 5.2)

If necessary, use a new Rubber Boot (10).

Ensure grease-free seating of the Rubber Boot (10)

on the Caliper (1)

FD00116

31

39

10

40

31a

10a

FD00113

M+P-KN-027

5

9

58

WARNING!

Hold the Caliper only on the exterior.

Never insert your fingers between

the Caliper and Carrier!

Opening or dismantling the Caliper is not

Page 31

31

Tighten Rubber Boot Clip (31)

Fit the Pads (see Section 6.2)

Attach the Brake Chamber or Spring Brake (see

Section 12.2 or 12.4)

M+P-KN-042

39

31

3131

10.2.2 Caliper with Steelcap (10a)

It may be easier to remove the Caliper and the

Carrier from the axle to replace the Steel Cap.

IMPORTANT!

Replace the Rubber

Boot (10) by the Steel Cap (10a) when

replacing the Sleeve (5), the

O-Ring (31a) and the Screw (40)

at the same time. Replace only on the

recommendation of the Axle or Vehicle

manufacturer. On SB 6... (19.5“) only

permissible after manufacturing date

A0026. (see type plate).

Assembly at the Vehicle :

The fitting must be carried out with the Pads installed.

- Clean the area.

- Using the Grease supplied (II14525), lightly lubricate

the O-Ring and place it over the cast spigot (see

Sketch).

-Remove the Threated Pins from the assembly tool (G)

to avoid damaging the Steel Cap.

-Hold the new Steel Cap on the end of the Spigot.

By using a suitable press or special assembly tool

(Part Number Z001105) and a hammer, press the

Steel Cap fully on the spigot making sure not to

deform the Cap.

After removal, the Steel Cap and the O-Ring must

not be refitted.

IMPORTANT!

The Steel Cap (10a) and the O-Ring

are single use items - do not re-use.

FD00108

31a

10a

10

31

40

5

2mm

FD00106

X

X

V

Page 32

32

M+P-KN-036

2

11 Carrier replacement

(for Axial- and Radial Disc Brake)

Remove Caliper (see Section 10.1).

Remove Carrier (2) from axle.

Clean axle contact area.

Bolts are not supplied by Bendix. Attach the new

Carrier with new bolts from the truck manufacturer.

Attach the Caliper (see Section 10.2)

9

Clamping device

Direction

of pressure

FD00110EN

FD00112

9

5

Assemply on the Caliper and Carrier removed

from the axle:

IMPORTANT!

Special threaded Screw (40) and Steel

Cap (10a) as well as the O-Ring (31a)

must be renewed whenever Screw (40)

has been removed.

Put the Caliper on the Carrier.

Screw-in Caliper Bolts (39 and 40) and tighten to

210

+18

ft. lbs. (285

+25

Nm).

Check the position of the Inner Boot (9) on the

Sleeve (5).

Check that the Caliper slides easily.

In the exposed clamping (e.g. vice), press the Caliper

against the Carrier as far as possible. The Inner Boot

(9) must be in compressed condition to prevent

air being trapped inside of the Cap.

Assembly of the Steel Cap (10a) can now be

carried out as in Section “ Assembly at the Vehicle“.

Check Adjuster (Section 5.2).

IMPORTANT!

Replace the Rubber

Boot (10) by the Steel Cap (10a) when

replacing the Sleeve (5), the

O-Ring (31a) and the Screw (40)

at the same time. Replace only on the

recommendation of the Axle or Vehicle

manufacturer. On SB 6... (19.5“) only

permissible after manufacturing date

A0026. (see type plate).

Page 33

33

IMPORTANT!

Do not use Grease containing molyb-

denum disulphate. Use only Bendix

Actuators recommended

by the Vehicle Manufacturer.

12 Actuation cylinder replacement

(for “Axial- and Radial Disc Brake”)

Before fitting the new Brake Actuator, the sealing

surface of the Caliper (see arrow) must be cleaned, and

the Spherical Cup (19) in the Lever must be greased

with white Grease RENOLIT HLT2 (Order no II14525).

The surface area of the flange must be clean.

Attach Actuator with new Nuts

(self-locking EN ISO 7042) and torque tighten

to 133

+22

ft. lbs. (180

+30

Nm).

Connect the air hose and check for leakage.

Make sure that the hose is not twisted and that chafing

is not possible.

IMPORTANT!

Test any air hoses or fittings removed

during maintenance work, using a soap

18/2

VF 00127/10

19

M+P-KN-034-Äi01

12.1 Brake Chamber removal

Disconnect the air line from the Brake Chamber (18/2)

Unscrew the Brake Chamber Mounting Nuts (do not

re-use them).

Remove the Brake Chamber

12.2 Brake Chamber fitting

IMPORTANT:

New Brake Chambers (18/2) have drain plugs installed. Remove the bottom plug (see arrows). All other drain

holes should be plugged.

Road test vehicle before returning to service.

solution to check for leakage. A 1 inch

bubble in 1 minute is acceptable, otherwise

repair/replace components as necessary.

Page 34

34

12.3 Spring Brake removal

WARNING!

wheels to ensure that the vehicle cannot

roll away, before releasing the park brake.

Release the parking brake, move the Hand Control

Valve to the ‘run’ position.

Screw-out Release Bolt (arrow) with a maximum torque of 26 ft. lbs. (35Nm).

Release air from brake, move Hand Control Valve to

‘park’ position.

Mark the hoses to assist with re-connection, then

disconnect them from the Spring Brake Actuator (18/1).

Unscrew the Spring Brake Actuator Mounting Nuts (do

not re-use).

Remove the Spring Brake Actuator.

18/1

VF 00127/11

12.4 Spring Brake Installation

IMPORTANT!

New Spring Brake Actuators (18/1) have drain plugs

installed. Remove the bottom plug (see arrows).

All other drain holes should be plugged.

Before fitting the new Brake Actuator, the sealing

surfaces of the Caliper have to be cleaned, and the

Spherical Cup (19) in the Lever must be greased with

white Grease RENOLIT HLT2 (Order no II14525)

The surface area of the flange must be clean.

IMPORTANT!

Do not use grease containing

molybdenum disulphate.

Use only Bendix Actuators

recommended by the

Vehicle Manufacturer.

19

M+P-KN-034-Äi01

FD00115

IMPORTANT!

On Radial Disc Brakes the Drain Plugs in

the bottom of the Cylinder Flange must

be open.

Before starting repair work, block the

See Page 36 for full Safety Guidelines.

Page 35

35

Attach the Actuator with new Nuts

(self-locking EN ISO 7042) and torque tighten to

133

+22

ft.lbs. (180

+30

Nm).

Connect air hose, ensuring that hoses are correctly

connected.

Make sure that hoses are not twisted and that chafing is not possible.

IMPORTANT!

during maintenance work, using a soap solution to check for leakage. A 1 inch

Push park control valve in to release parking brake,

and check for leakage.

Screw in Spring Brake Release bolt to maximum

52 ft.lbs. (70 Nm).

13 Additional information

13.1 Service Video

A Video is available for additional

information.

Order number: RA-SB0002.EN Video (English)

RA-SB0002.FR Video (French)

RA-SB0002.PO Video (Portugese)

RA-SB0002.SP Video (Spanish)

13.2 Service Tool Kit ZB 9032

For service and repair work we recommend

our BendixTool Kit ZB 9032 II 37951/004EX,

which contains all the necessary special tools.

13.3 Diagnostic Equipment

For vehicles fitted with continuous

potentiometer type wear sensors,

Bendix Diagnostic Equipment may

be used to ensure quick and simple

measurement of wear at each caliper.

See sections 5.4 and 5.5.

Road test vehicle before returning to service. Test any air hoses or fittings reinstalled

bubble in 1 minute is acceptable, otherwise repair/replace components as necessary.

Page 36

13.4 General Safety Guidelines.

WARNING! Please READ and follow these

instructions to avoid personal injury or death:

When working on or around a vehicle, the

following general precautions should be

observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels. Always

wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When working in

the engine compartment, the engine should be shut

off and the ignition key should be removed. Where

circumstances require that the engine be in operation,

EXTREME CAUTION should be used to prevent

personal injury resulting from contact with moving,

rotating, leaking, heated or electrically charged

components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended procedures.

Use only the proper tools and observe all precautions

pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS™ air

dryer system or a dryer reservoir module, be sure to

drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the electrical

system in a manner that safely removes all electrical

power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all system

pressure has been depleted.

8. Use only genuine Bendix

components and kits. Replacement hardware, tubing,

hose, fittings, etc. must be of equivalent size, type

and strength as original equipment and be designed

specifically for such applications and systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do not

attempt repairs requiring machining or welding unless

specifically stated and approved by the vehicle and

component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored to

their proper operating condition.

11. For vehicles with Antilock Traction Control (ATC),

the ATC function must be disabled (ATC indicator

lamp should be ON) prior to performing any vehicle

maintenance where one or more wheels on a drive

axle are lifted off the ground and moving.

® replacement parts,

36

For more information

visit:

www.Bendix.com

BW2000 ©2002 Bendix Commercial Vehicle Systems LLC. All rights reserved. Printed in USA.

Loading...

Loading...