Page 1

®

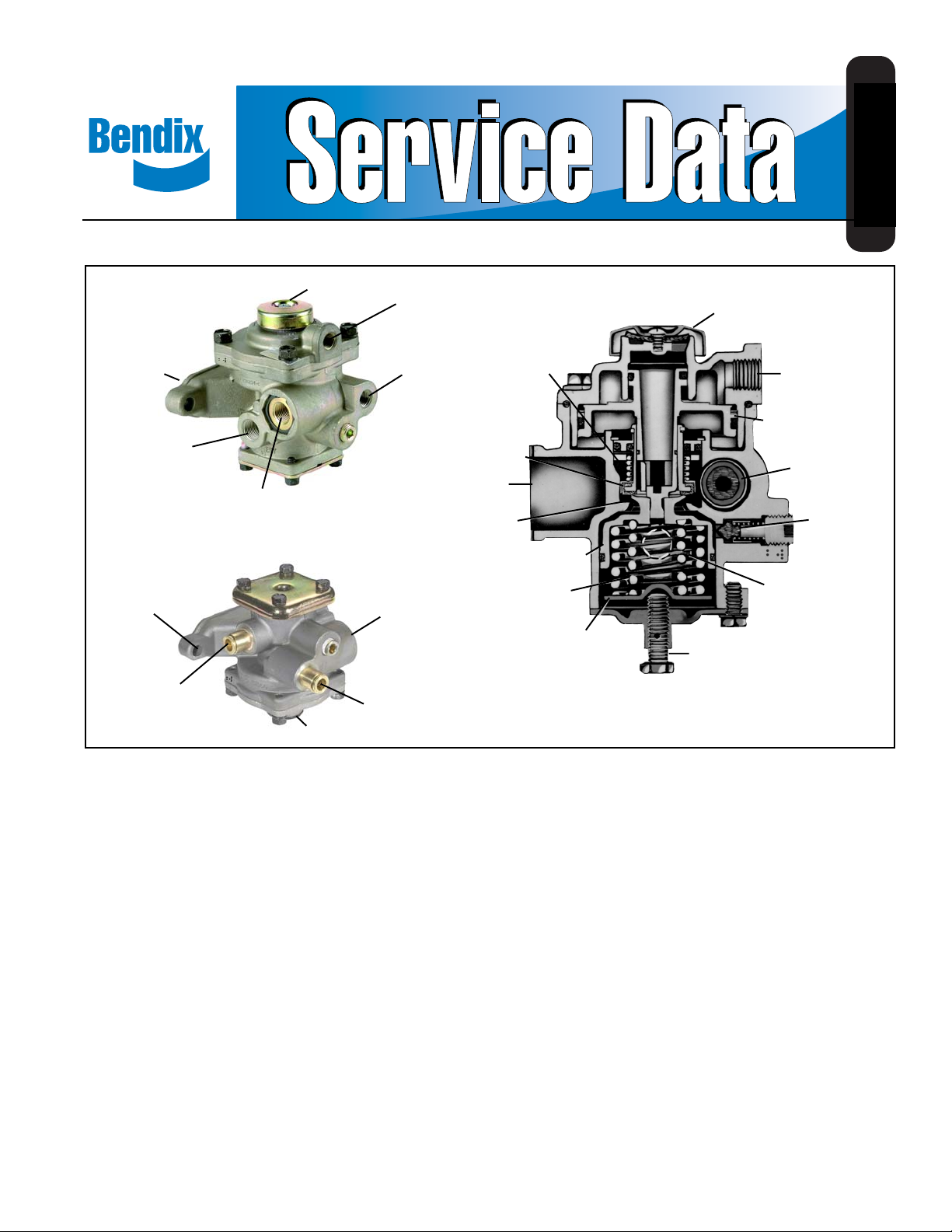

Bendix® R-7™ Modulating Valve

SD-03-4504

MOUNTING

HOLE (2)

DELIVERY (2)

MOUNTING

HOLE (2)

BALANCE

BALANCE

PORT

EXHAUST

EXHAUST

CONTROL

PORT

SUPPLY

PORT

SUPPLY

CONTROL

INLET

EXHAUST

VALVE

MOUNTING

SURFACE

INLET

VALVE

SEAT

INNER SPRING

INLET

VALVE

SPRING

BALANCE

PISTON

OUTER SPRING

EXHAUST

CONTROL

PORT

CONTROL

PISTON

DOUBLE CHECK

VALVE (SUPPLY

PORT & BALANCE

PORT)

SINGLE

CHECK

VALVE

DELIVERY

PORT (2)

ADJUSTING SCREW

FIGURE 1 - EXTERIOR & INVERTED VIEW

DESCRIPTION

The R-7™ modulating valve is used in conjunction with a

dual air brake system and spring brake actuators, and

performs four functions:

1. Limits hold-off pressure to the spring brake actuators

(adjustable).

2. Provides for quick release of air pressure from the spring

cavity of the spring brake actuator allowing a fast

application of the spring brake actuators.

3. Modulates spring brake actuator application should a

failure occur in the service brake system.

4. Prevents compounding of service and spring forces.

The valve has one 1/4" control, one 3/8" supply, one 1/4"

balance, two 3/8" delivery NPTF ports, and an exhaust port

protected by an exhaust diaphragm. The valve incorporates

two 13/32" holes for mounting.

FIGURE 2 - SECTIONAL VIEW

Note for model year 2001 and later International Trucks only:

There is an inverted R-7™ valve, which appears inverted from

the other pictures in this document. A standard R-7™ valve

and an inverted R-7™ valve are not interchangeable. See

Figure 1 for a picture of an inverted R-7™ valve.

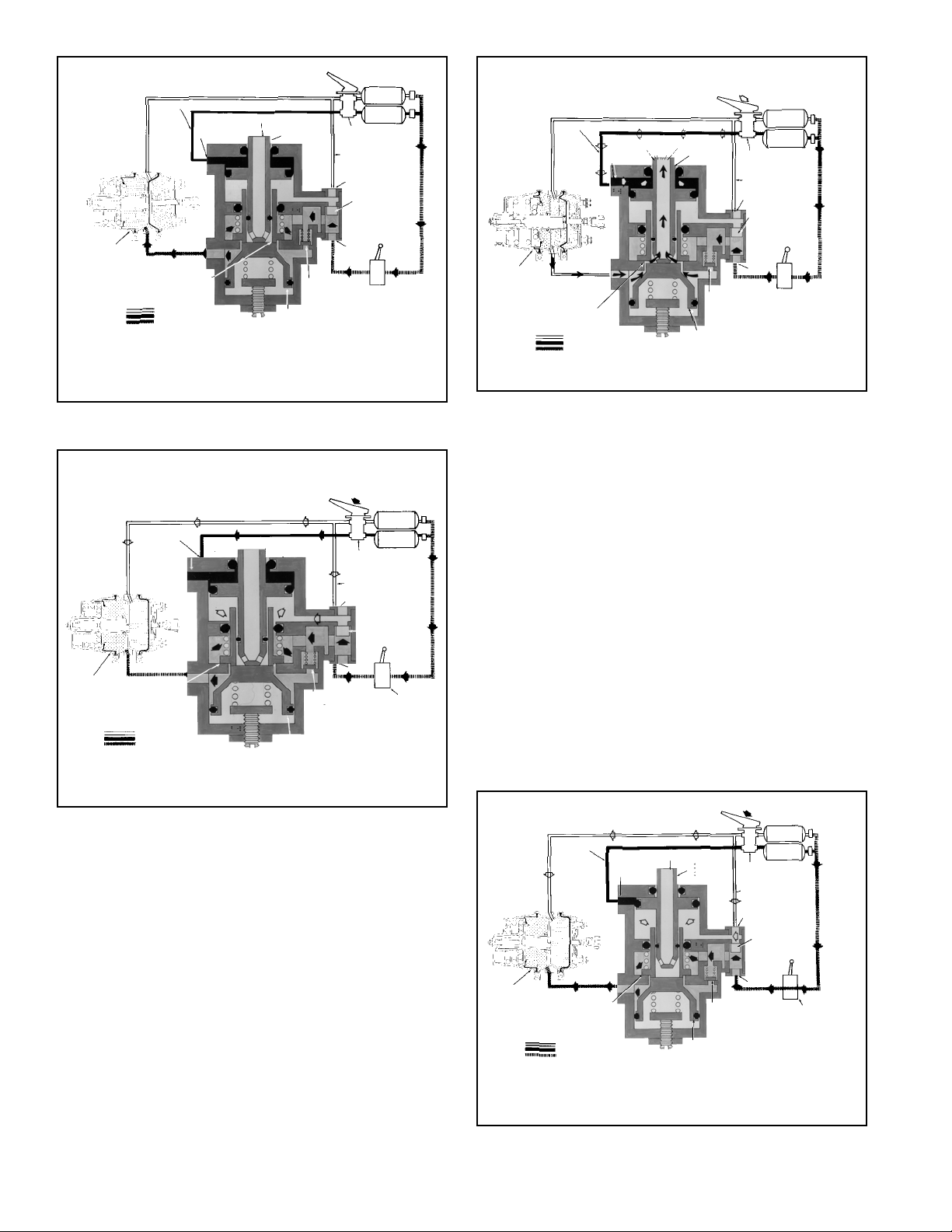

OPERATION - CHARGING SPRING BRAKE

ACTUATORS (FIGURE 3)

Air pressure used to control the spring brake actuators enters

the valve through the supply port, passing through one side

of the double check valve, through the open inlet valve, over

the balance piston, and out the delivery ports to the spring

brake actuators. When air pressure in the spring brake

actuator cavity has released the spring brake actuators and

when air pressure on top of the balance piston is sufficient

to overcome the force of the balance piston spring, the

balance piston moves allowing the inlet valve spring to close

the inlet valve, shutting off further air pressure from the

reservoir supplying the modulating valve.

1

Page 2

SPRING

BRAKE

ACTUATOR

PRIMARY SECONDARY PARK -

SECONDARY SERVICE CIRCUIT

CONTROL

PORT

INLET/EXHAUST

VALVE

EXHAUST

PORT

CONTROL

PISTON

BALANCE PISTON

DUAL BRAKE

VALVE

PRIMARY

SERVICE

CIRCUIT

BALANCE

PORT

DOUBLE

CHECK VALVE

SUPPLY

PORT

SINGLE

CHECK

VALVE

+ SPRING BRAKE HOLD-OFF PRESSURE

- SERVICE AIR PRESSURE

o ATMOSPHERE PRESSURE

#1 RES.

#2 RES.

PARK

CONTROL

VALVE

SPRING

BRAKE

ACTUATOR

PRIMARY SECONDARY PARK -

SECONDARY SERVICE CIRCUIT

CONTROL

PORT

INLET/EXHAUST

VALVE

EXHAUST

PORT

#1 RES.

CONTROL

PISTON

SINGLE

CHECK

VALVE

BALANCE PISTON

+ SPRING BRAKE HOLD-OFF PRESSURE

- SERVICE AIR PRESSURE

o ATMOSPHERE PRESSURE

#2 RES.

DUAL BRAKE

VALVE

PRIMARY SERVICE

CIRCUIT

BALANCE

PORT

DOUBLE

CHECK

VALVE

SUPPLY

PORT

PARK

CONTROL

VALVE

FIGURE 3 - CHARGING

DUAL BRAKE

VALVE

PRIMARY SERVICE

CIRCUIT

BALANCE

PORT

DOUBLE

CHECK VALVE

SUPPLY

PORT

#1 RES.

#2 RES.

CONTROL

PARK

VALVE

SPRING

BRAKE

ACTUATOR

PRIMARY SECONDARY PARK -

SECONDARY

SERVICE

CIRCUIT

INLET/EXHAUST

VALVE

CONTROL

PORT

EXHAUST

PORT

CONTROL

PISTON

SINGLE

CHECK

VALVE

BALANCE PISTON

+ SPRING BRAKE HOLD-OFF PRESSURE

- SERVICE AIR PRESSURE

o ATMOSPHERE PRESSURE

FIGURE 4 - NORMAL SERVICE APPLICA TION

NOTE: The force of the spring below the balance piston is

adjustable by an external screw on the modulating

valve. This adjustment is normally made so that

the inlet valve will close at a slightly greater pressure

than the hold-off pressure of the spring brake

actuator, but below maximum system pressure.

OPERATION - NORMAL SERVICE APPLICATION

(FIGURE 4)

When a service application is made by actuating the dual

brake valve, air from the primary circuit is delivered to the

lower side of the control piston through the balance port,

and air from the secondary circuit is delivered to the top of

the control piston through the control port. Because air

pressure from the primary and secondary circuits are not

equal, there will be a slight movement of the control piston.

FIGURE 5 - SERVICE APPLICA TION LOSS OF PRIMARY

CIRCUIT

OPERA TION - SERVICE APPLICA TION WITH LOSS OF

AIR IN PRIMARY CIRCUIT (FIGURE 5)

A service application made with a loss of air in the primary

circuit would result in reduced air pressure delivered to the

lower area of the control piston. Air pressure from the

secondary circuit on top of the control piston would force

the piston down, opening the exhaust valve and allowing air

pressure in the spring cavity of the spring brake actuator to

release and the spring brake actuator to apply the brakes.

The pressure differential between the primary and secondary

circuits regulates the amount of air pressure released from

the spring cavity of the spring brake actuator. This result s

in a total brake application on the rear axle which is

proportionate to the braking on the other axles.

SECONDARY

SPRING

BRAKE

ACTUATOR

PRIMARY SECONDARY PARK -

SERVICE

CIRCUIT

INLET/EXHAUST

VALVE

CONTROL

PORT

EXHAUST

PORT

CONTROL

PISTON

SINGLE

CHECK

VALVE

BALANCE PISTON

+ SPRING BRAKE HOLD-OFF PRESSURE

- SERVICE AIR PRESSURE

o ATMOSPHERE PRESSURE

FIGURE 6 - SERVICE APPLICA TION LOSS OF SECONDARY

CIRCUIT

#1 RES.

#2 RES.

DUAL BRAKE

VALVE

PRIMARY SERVICE

CIRCUIT

BALANCE PORT

DOUBLE

CHECK VALVE

SUPPLY

PORT

PARK

CONTROL

VALVE

2

Page 3

OPERA TION - SERVICE APPLICA TION WITH LOSS OF

AIR IN SECONDARY CIRCUIT (FIGURE 6)

A service application made with a loss of air in the secondary

circuit would result in less or no air delivered to the top of

the control piston; however, the piston would not move and

braking on the rear axle(s) is assured because the primary

circuit supplies rear axle service brakes. The spring brake

actuators will not be actuated.

OPERA TION - P ARKING (FIGURE 7)

When the handle of the parking control valve is placed in the

“park” (exhaust) position, the modulating valve’s supply air

pressure and the air pressure in the spring brake actuator

cavities is exhausted. The single check valve speeds the

exhaust of air from the actuator cavities by allowing the air

on top of the balance piston to exhaust by the double check

valve through the supply port to atmosphere. When air

pressure drops sufficiently, the balance piston opens the

inlet valve thus opening the larger passage in the modulating

valve insuring rapid exhaust of the balance of air pressure in

the spring cavity of the spring brake actuator.

SECONDARY

SERVICE

CIRCUIT

SPRING

BRAKE

ACTUATOR

INLET/EXHAUST

VALVE

PRIMARY SECONDARY PARK -

FIGURE 7 - PARKING

CONTROL

PORT

EXHAUST

PORT

CONTROL

PISTON

SINGLE

CHECK

VALVE

BALANCE PISTON

+ SPRING BRAKE HOLD-OFF PRESSURE

- SERVICE AIR PRESSURE

o ATMOSPHERE PRESSURE

#1 RES.

#2 RES.

DUAL BRAKE

VALVE

PRIMARY SERVICE

CIRCUIT

BALANCE

PORT

DOUBLE

CHECK VALVE

SUPPLY

PORT

PARK

CONTROL

VALVE

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A warranty

may be voided if intrusive maintenance is performed during

the warranty period.

No two vehicles operate under identical conditions, as a

result, maintenance intervals may vary. Experience is a

valuable guide in determining the best maintenance interval

for air brake system components. At a minimum, the R-7

valve should be inspected every 6 months or 1500 operating

hours, whichever comes first, for proper operation. Should

the R-7™ valve not meet the elements of the operational

tests noted in this document, further investigation and service

of the valve may be required.

SERVICE TESTS

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO AVOID

PERSONAL INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation,

EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble or

assemble a component until you have read and

thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s air

brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure from

all reservoirs before beginning ANY work on the

vehicle. If the vehicle is equipped with an AD-IS

air dryer system or a dryer reservoir module, be

sure to drain the purge reservoir.

5. Following the vehicle manufacturer’s

recommended procedures, deactivate the

electrical system in a manner that safely removes

all electrical power from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove a

component or plug unless you are certain all

system pressure has been depleted.

8. Use only genuine Bendix® replacement parts,

components and kits. Replacement hardware,

tubing, hose, fittings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifically for such applications and

systems.

™

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifically stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

at all times.

™

3

Page 4

OPERATING TEST

Block vehicle and hold by means other than vehicle brakes.

Charge air brake system to governor cut-out pressure.

1. Place parking control valve in “park” position. Observe

that spring brake actuators apply promptly. Remove

one line from delivery port of valve and install test gauge

known to be accurate. Place parking control valve in

“release” position. Observe that spring brake actuators

release fully .

2. With parking control valve in “release” position, note

gauge pressure reading. (Check vehicle manual for

correct spring brake actuator hold-off pressure.) If

pressure reading is incorrect, modulating valve should

be adjusted. (See section “Adjustment of Modulating

V alve - Spring Brake Actuator Hold-Off Pressure”.)

3. Place parking control valve in “park” position - gauge

reading should drop to zero promptly . A lag (more than

1 second) in drop of pressure would indicate faulty

operation of the single check valve (within the modulating

valve).

4. With the parking control valve in the “park” position fully

apply foot brake valve several times and note a pressure

reading increase on the gauge each time the brake is

applied. If pressure reading does not occur, the

modulating valve requires servicing or replacing.

5. Place parking control valve in “release” position.

Determine the reservoir which supplies balance port and

drain completely .

Apply foot brake valve several times and note that pressure

reading on gauge decreases each time foot brake valve is

applied. After foot brake valve has been applied several times,

pressure on gauge will drop to the point where release of the

spring brake actuators will no longer occur.

LEAKAGE TEST

Place the park control valve in the “release” position; using

a soap solution, coat exhaust and vent hole (in proximity of

adjusting screw). Slight bubble leakage permitted.

If the valve does not function as described, or if leakage is

excessive, it is recommended that it be repaired or replaced

with a genuine Bendix service replacement valve.

ADJUSTMENT OF MODULATING VALVE - SPRING

BRAKE ACTUATOR HOLD-OFF PRESSURE

Block vehicle by means other than vehicle brakes. If it has

been ascertained that hold-off pressure for the spring brake

actuators is incorrect (see section “Operating Test”),

adjustment should be made as follows:

1. Build system pressure to governor cut-out

(approximately 120 psi). It is important that system

leakage for a single vehicle not exceed a 2 psi drop in

one (1) minute with brakes released. Correct system

leakage before proceeding with adjustment.

2. Place parking control valve in “park” position and install

an accurate test gauge in a delivery port of the

modulating valve. Place parking control valve in “release”

position and observe pressure reading on the test gauge.

Refer to vehicle manual for recommended pressure.

Adjust as necessary.

TO RAISE HOLD-OFF PRESSURE

Loosen lock nut. Turn adjusting screw clockwise and observe

reading on gauge. T o raise hold-of f pressure, turn adjusting

screw clockwise - to lower hold-off pressure, turn adjusting

screw counterclockwise until pressure is below that desired

and then turn screw clockwise to desired pressure. Tighten

locknut securely after completing adjustment.

DISASSEMBLY

1. Remove exhaust cover screw, exhaust cover and

exhaust diaphragm.

2. Remove four (4) cap screws and lockwashers and cover.

Remove o-ring from cover.

3. Remove control piston and remove three (3) o-rings from

control piston.

4. Remove large retaining ring from body and remove inlet/

exhaust valve assembly .

5. Remove ring from inlet/exhaust valve assembly. Remove

o-ring retainer, remove o-ring from o-ring retainer.

Remove washer and spring. Remove valve retainer and

valve from valve body.

6. Remove four (4) cap screws from other cover. (Do not

disturb center cap screw unless spring brake hold off

pressure is to be adjusted). See Section “Adjustment

of Modulating V alve”.

7. Remove cover and inner and outer springs.

8. Remove balance piston. Remove o-ring from balance

piston.

9. Remove retaining ring from supply port and remove

supply adapter and double check valve assembly.

Remove o-ring from supply adapter. Remove double

check valve from shuttle guide. (NOTE: T o ease removal

of supply adapter, a pipe nipple can be screwed in

adapter.)

10. Remove allen head plug from single check valve service

port. Remove single check valve assembly . (If single

check valve is difficult to remove, it can be dislodged

inside bore of body of valve).

4

Page 5

ASSEMBLY

Before assembly, lightly lubricate all o-rings, bores and

mating surfaces with silicone lubricant BW-650-M (Bendix

Pc. No. 291 126).

1. Install single check valve assembly and allen head plug.

Tighten securely .

2. Install o-ring on supply adapter, install shuttle guide over

supply adapter and install double check valve in guide.

3. Install adapter and double check valve assembly in

supply port. Install retaining ring, making certain the

retaining ring is engaged in groove.

4. Install o-ring on balance piston and install balance piston

in bore of body .

5. Install inner and outer springs and spring seat (note

that cone shaped protrusion on spring seat faces

springs).

6. Install cover with four (4) cap screws, torque to

approximately 45 in. lbs. (Do not disturb center cap

screw unless spring brake hold-off pressure is to be

adjusted. See section “Adjustment of Modulating

V alve”).

7. Install valve on valve body. Install valve ret ainer, spring,

and washer. Install o-ring on o-ring retainer. Install

o-ring retainer , compress ret ainer and install retaining

ring, making certain retaining ring is engaged in groove

of valve body .

8. Install inlet/exhaust valve assembly in body. Install

retaining ring making certain the retaining ring is engaged

in groove in bore of body .

9. Install three (3) o-rings on control piston. Install control

piston in body . (Larger diameter stem should point up).

10.Install o-ring on cover. Install cover with four (4) cap

screws and lockwashers. T orque to approximately 100

in. lbs.

1 1. Install exhaust diaphragm and exhaust cover.

TESTING REBUILT R-7™ MODULATING VALVE

Perform operating and leakage tests as outlined in “Service

Tests” section.

5

Page 6

6

BW1445 © 2004 Bendix Commercial Vehicle Systems LLC. All rights reserved. 3/2004 Printed in U.S.A.

Loading...

Loading...