Page 1

Bendix® R-12P™ Pilot Relay Valve

SD-03-1063

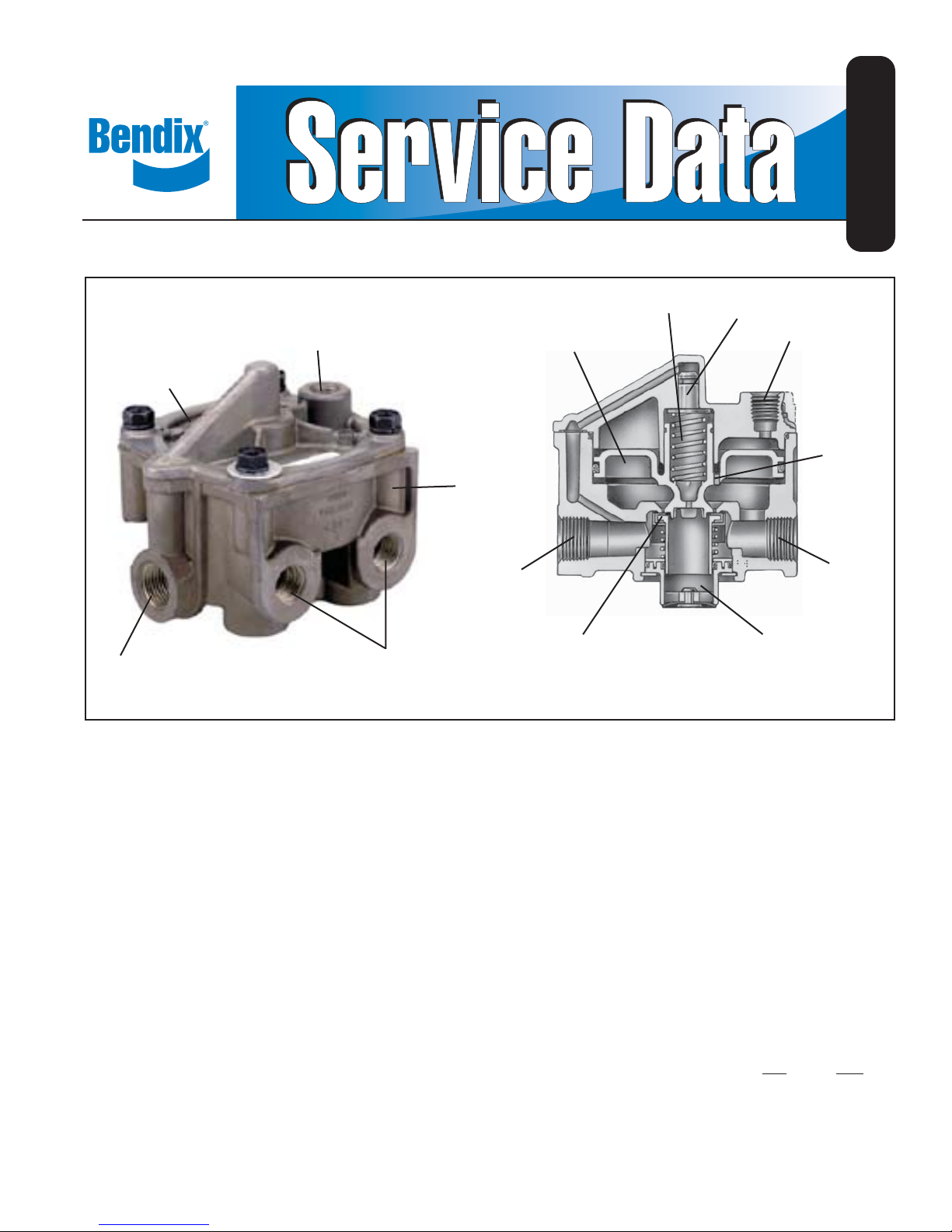

1/4” CONTROL

COVER

1/2” SUPPLY (2)

FIGURE 1 - CUTAWAY AND EXTERNAL VIEW

3/8” DELIVERY (4)

BODY

1/2”

SUPPLY

RELAY

PISTON

INLET/EXHAUST

VALVE

RESERVE

SPRING

LOAD

PISTON

1/4” CONTROL

EQUALIZING

ORIFICE

3/8”

DELIVERY

EXHAUST

DESCRIPTION

The R-12P™ pilot relay valve is designed to speed up

control signal application and release on long non-towing

trailers, towing trailers, dollies, and long wheelbase tractors.

It does this without adversely affecting the control signal.

The R-12P™ valve replaces the current R-8P™ valve.

Unlike a standard relay valve used as a “booster,” which

typically has a 2-4 psi differential between control and

delivery , the R-12P™ valve has zero differential. It “speeds”

up control line signal application and release in a train

of vehicles, and it delivers the same air pressure that it

receives. This provides a uniform brake signal to all trailer

and dolly brakes, even during light applications.

The unique R-12P™ valve feature is that it uses a supply

air pressure load to quicken the valve’s response time. By

balancing the pressure signal to all trailer and dolly brakes,

the R-12P™ valve aids in achieving overall vehicle brake

pressure balance, timing balance, and stability.

It also substantially improves brake lining wear balance

on combination vehicles by making even the most distant

brake contribute its share of braking effort.

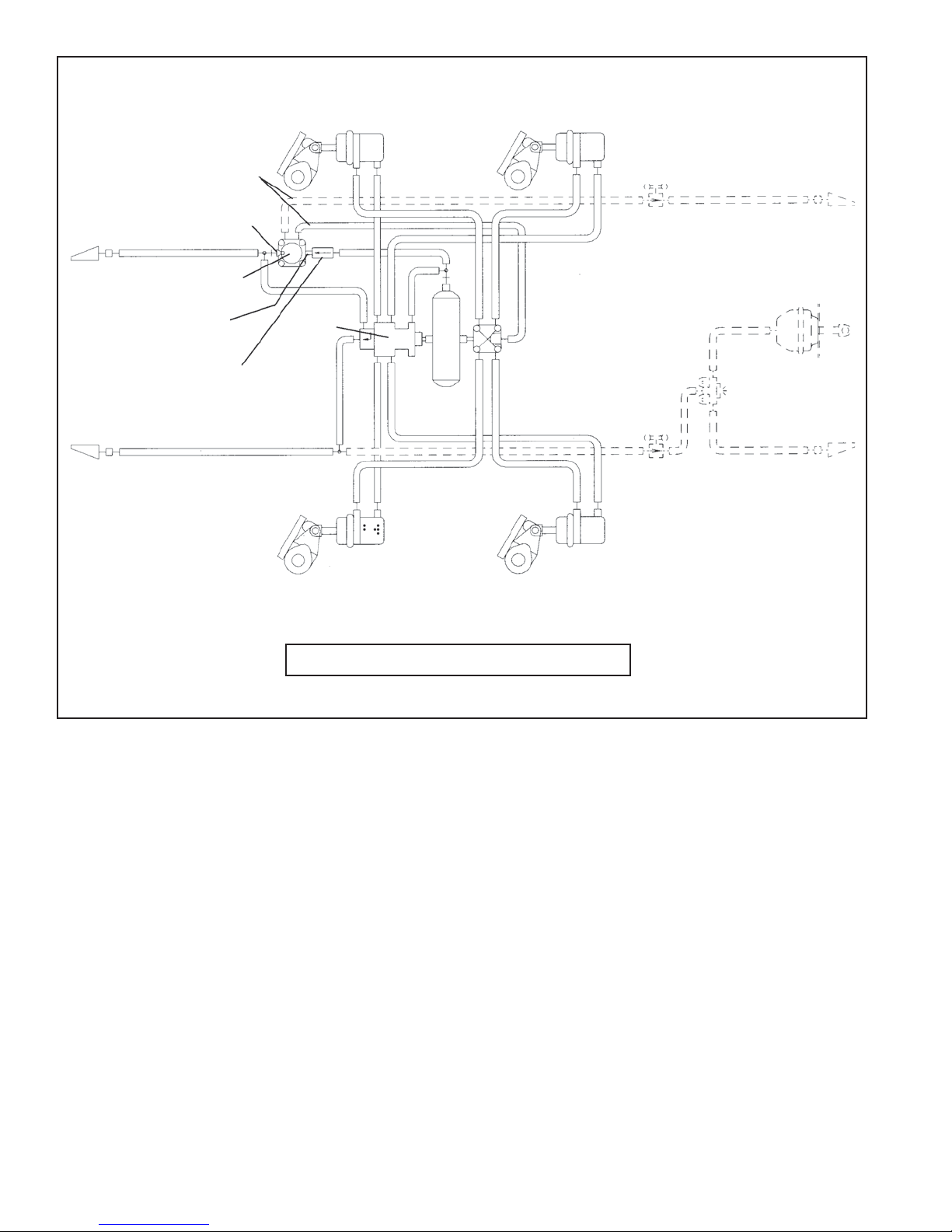

Figure 2 shows the R-12P™ valve in a trailer air brake

schematic. Note that additional air lines for a towing trailer

are shown as dashed lines.

The R-12P™ valve uses the R-12™ valve family lower body

and standard Bendix mounting brackets. It can also be

reservoir-mounted.

The body and cover are die-cast aluminum, and the valve’s

weight is approximately 2.3 lbs. Porting is as follows:

Qty. Size

Supply (SUP) 2 1/2”

Delivery (DEL) 4 3/8”

Control (CON) 1 1/4”

Exhaust (EXH) 1 --

1

Page 2

TRAILER BRAKE SYSTEM WITH R-12P™ PILOT RELAY VALVE

VENTED

DELIVERY

CONTROL

CUT-OUT

COCK

CONTROL

SUPPLY

™

R-12P

VALVE

SUPPLY

SINGLE

CHECK VALVE

SPRING

BRAKE

VALVE

RESERVOIR

SLACK ADJUSTER

-- -- -- -- -- ADDITIONAL PLUMBING FOR TOWING TRAILER

SERVICE RELAY

VALVE

BRAKE CHAMBER

QUICK

RELEASE

VALVE

VENTED

CUT-OUT

COCK

FIGURE 2 - TYPICAL R-12P™ PILOT RELAY VALVE SYSTEM SCHEMATIC

OPERATION

CHARGING

When the air brake system is charging, the relay pis ton’s

exhaust seat is against the inlet/exhaust valve due to

the force of the reserve spring. Reservoir air enters the

R-12P™ valve supply port and becomes active upon the

inlet/exhaust valve. At the same time, reservoir air passes

through the R-12P™ valve body channel to the load piston.

Supply air builds simultaneously and equally underneath the

inlet/exhaust valve and above the load piston. While supply

pressure continues to hold the inlet/exhaust valve against

2

its seat, it also moves the load piston into contact with the

relay piston. However, even though force is increasing on

the relay piston, it does not move the inlet/exhaust valve.

The effective area of the inlet/exhaust valve is larger than

the effec tive area of the load piston. Therefore, load piston

force cannot overcome inlet/exhaust valve force. So supply

air builds to governor cut-out and the inlet/exhaust valve

remains closed. This is the position of the R-12P™ valve

in normal run mode, as shown in Figure 3.

Page 3

LOAD PISTON

RELAY PISTON

SUPPLY PORT

INLET/EXHAUST

VALVE

FIGURE 3 - CHARGING

CONTROL

PORT

DELIVERY

PORT

Note that these events occur quickly , due to the “preload”

on the relay piston. This preload, provided by supply air

pressure acting on the load piston, is a feature unique to

the R-12P

™

valve.

BALANCE

Air pressure being delivered by the open inlet valve is

also effective underneath the R-12P™ valve relay piston.

When air pressure beneath the piston approaches control

pressure on top of the piston, the piston and inlet valve lift

together and close the inlet valve. The exhaust remains

closed, and the valve achieves “force balance.” That is,

the piston and inlet/exhaust valve are in their neutral

state. This is the position commonly known as “balanced”

when referring to conventional relay valves. However,

conventional relay valves cannot achieve true air pressure

balance because of their inherent differentials. The R-12P™

valve achieves this balance because of its equalizing

orifi ce. The orifi ce allows control pressure and delivery

pressure to be “common” and equalize. In this position,

shown in Figure 5, sustained service brake applications

can be held, with no “residual” differential.

LOAD PISTON

RELAY PISTON

SUPPLY PORT

INLET/EXHAUST

VALVE

FIGURE 4 - NORMAL (RAPID) APPLICATION

CONTROL

PORT

NORMAL (RAPID) APPLICATION

Figure 4 shows an R-12P™ valve receiving a “normal”

service brake application. “Normal” means the control

signal is applied rapidly enough to build up pressure on

the relay piston and “open” the inlet valve, causing the

R-12P™ valve to react like a relay valve. The relay piston

opens the inlet, allowing supply air to fl ow out the delivery

port to the next valve in the system.

EQUALIZING

ORIFICE

PROVIDES AIR

PRESSURE

BALANCE

SUPPLY PORT

INLET/EXHAUST

VALVE

FIGURE 5 - BALANCE

LOAD PISTON

RELAY

PISTON

CONTROL PORT

DELIVERY

PORT

3

Page 4

RELAY PISTON

LOAD PISTON

CONTROL PORT

LOAD PISTON

RELAY PISTON

CONTROL PORT

SUPPLY PORT

INLET/EXHAUST

VALVE

FIGURE 6 - RAPID EXHAUST FIGURE 7 - EQUALIZING (SLOW) APPLICATION

DELIVERY PORT

EXHAUST

SUPPLY PORT

INLET/EXHAUST

VALVE

DELIVERY PORT

RAPID EXHAUST

Figure 6 shows a rapid service brake release. Air above

the relay piston travels back out the control port to be

exhausted. With the lack of air pressure above the

piston, air pressure below lifts the piston, closing the inlet

and opening the exhaust. Delivery air then exhausts to

atmosphere.

EQUALIZING (SLOW) APPLICATION

When a control signal enters the R-12P™ valve, it acts

on the relay piston. However, Figure 7 shows the control

signal passing through the valve without causing piston

movement. The air is passing through the relay piston’s

equalizing orifi ce, directly through the valve and out the

delivery port to the next valve in the air system. This

situation occurs if air pressure build-up is slow and the

pressure above the relay piston is not strong enough to

open the valve. (Air pressure above the piston must be at

least 3 psi greater than air pressure below the piston to

cause movement.)

For example, if a vehicle is traveling over a long downhill

grade, the driver may want to limit speed and maintain

vehicle control through proper gearing, engine speed and

a light service brake application.

LOAD PISTON

RELAY PISTON

CONTROL PORT

In the equalizing application, even though the inlet valve

does not open, the control signal is not decreased because

the equalizing orifi ce allows it to pass directly through the

R-12P™ valve. Note that this condition exists during very

slow service brake applications.

4

SUPPLY PORT

INLET/EXHAUST

VALVE

FIGURE 8 - EQUALIZING (SLOW) EXHAUST

DELIVERY PORT

Page 5

If, during the light brake application, the driver modulates

the treadle slowly , and not enough to open the R-12P™ inlet

valve, the desired control pressure will still pass on to the

next valve, maintaining zero differential.

EQUALIZING (SLOW) EXHAUST (SEE FIGURE 8)

RELAY PISTON

LOAD PISTON

RESERVE SPRING

SEALS EXHAUST

As described earlier, the result of any service brake

application with an R-12P™ valve is air pressure balance

above and below the relay piston. If the brake valve is

modulated slowly upon release so that pressure beneath

the piston is not great enough to open the exhaust, delivery

air will pass through the equalizing orifi ce and out the

control port to be exhausted.

REDUCTION OF SUPPLY PRESSURE

Figure 9 shows the R-12P™ valve with no supply pressure.

With no supply air, the reserve spring is strong enough to

hold the relay piston on the exhaust seat, but it is not strong

enough to overcome the force of the inlet/exhaust valve

spring. So both inlet and exhaust valves are closed.

Service Brake Applications with Reduced Supply

Pressure

Rapid Application - Use of Supply Line Single Check

Valve

If a rapid service brake application is made, control air moves

the relay piston and opens the inlet valve; but there is no

supply air to deliver. Control air then travels into the supply

port. The single check valve in the R-12P™ valve supply

port (shown in Figure 2) prevents this air from escaping to

atmosphere through the open or damaged supply source.

Control air also passes through the equalizing orifi ce and

out the delivery port, assuring no reduction or loss of control

signal to subsequent vehicles.

Equalizing (Slow) Application

If an equalizing (slow) service brake application is made

with reduced supply air pressure, control air passes

through the equalizing orifi ce and out the delivery port to

subsequent vehicles in the train.

Control air cannot escape to atmosphere because the

reserve spring keeps the exhaust closed.

CONTROL

PORT

SUPPLY PORT

INLET/EXHAUST

VALVE

FIGURE 9 - REDUCTION OF SUPPLY PRESSURE

DELIVERY PORT

WARNING! PLEASE READ AND FOLLOW

THESE INSTRUCTIONS TO A VOID PERSONAL

INJURY OR DEATH:

When working on or around a vehicle, the following

general precautions should be observed at all times.

1. Park the vehicle on a level surface, apply the

parking brakes, and always block the wheels.

Always wear safety glasses.

2. Stop the engine and remove ignition key when

working under or around the vehicle. When

working in the engine compartment, the engine

should be shut off and the ignition key should be

removed. Where circumstances require that the

engine be in operation, EXTREME CAUTION should

be used to prevent personal injury resulting from

contact with moving, rotating, leaking, heated or

electrically charged components.

3. Do not attempt to install, remove, disassemble

or assemble a component until you have read

and thoroughly understand the recommended

procedures. Use only the proper tools and observe

all precautions pertaining to use of those tools.

4. If the work is being performed on the vehicle’s

air brake system, or any auxiliary pressurized air

systems, make certain to drain the air pressure

from all reservoirs before beginning ANY work

on the vehicle. If the vehicle is equipped with an

AD-IS® air dryer system or a dryer reservoir module,

be sure to drain the purge reservoir.

5

Page 6

5. Following the vehicle manufacturer’s recommended

procedures, deactivate the electrical system in a

manner that safely removes all electrical power

from the vehicle.

6. Never exceed manufacturer’s recommended

pressures.

7. Never connect or disconnect a hose or line

containing pressure; it may whip. Never remove

a component or plug unless you are certain all

system pressure has been depleted.

®

8. Use only genuine Bendix

replacement parts,

components and kits. Replacement hardware,

tubing, hose, fi ttings, etc. must be of equivalent

size, type and strength as original equipment and

be designed specifi cally for such applications and

systems.

9. Components with stripped threads or damaged

parts should be replaced rather than repaired. Do

not attempt repairs requiring machining or welding

unless specifi cally stated and approved by the

vehicle and component manufacturer.

10. Prior to returning the vehicle to service, make

certain all components and systems are restored

to their proper operating condition.

11. For vehicles with Antilock Traction Control (ATC),

the ATC function must be disabled (ATC indicator

lamp should be ON) prior to performing any vehicle

maintenance where one or more wheels on a drive

axle are lifted off the ground and moving.

SERVICE CHECKS

1. Remove any accumulated contaminants. Visually

inspect the valve’s exterior for excessive corrosion

or physical damage. Repair/replace the valve as

necessary.

2. Inspect all air lines connected to the valve for signs

of wear or physical damage. Repair/replace as

necessary.

3. Test air line fi ttings for excessive leakage and tighten

or replace as necessary.

OPERATIONAL AND LEAKAGE TESTS

1. Block the vehicle’s wheels and fully charge the air

system.

2. Apply and release the service brakes several times

and check for prompt response of the brakes at all

appropriate wheels.

3. With the air system fully charged, apply a soap solution

to the R-12P™ valve exhaust port. Leakage of a 1”

bubble in 5 seconds is permissible.

4. Make and hold a full brake application and again apply

a soap solution to the R-12P™ valve exhaust. Leakage

of a 1” bubble in 3 seconds is permissible.

5. With the brakes still applied, apply a soap solution

around the valve where the cover meets the body. No

leakage at this point is permitted.

PREVENTIVE MAINTENANCE

Important: Review the Bendix Warranty Policy before

performing any intrusive maintenance procedures. A

warranty may be voided if intrusive maintenance is

performed during the warranty period.

No two vehicles operate under identical conditions, as a

result, maintenance intervals may vary. Experience is a

valuable guide in determining the best maintenance interval

for air brake system components. At a minimum, the valve

should be inspected every 6 months or 1500 operating

hours, whichever comes fi rst, for proper operation. Should

the valve not meet the elements of the operational tests

noted in this document, further investigation and service

of the valve may be required.

If the valve does not function as described; or if leakage is

excessive, repair the valve or replace it at any authorized

parts outlet.

NOTE: If a supply line single check valve is present (see

Figure 2), check it for leakage. Disconnect the inlet

side of the single check valve and coat the open

end with a soap solution. Make and hold a full

brake application. Leakage of a one inch bubble in

fi ve seconds is permissible. If the valve’s leakage

is excessive, replace it with a 1/2” single check

valve.

REMOVAL

1. Drain all system air pressure.

2. Identify and mark or label all air lines and their

connections to the R-12P™ valve and the single check

valve, if present. Then disconnect the air lines.

3. Remove the R-12P™ valve from the vehicle.

6

Page 7

FASTENER

COVER

LOAD

PISTON

3

RELAY PISTON

4

1

2

RESERVE

SPRING

BODY

12

11

10

9

8

7

6

5

FIGURE 10 - EXPLODED VIEW

INSTALLATION

1. Use the mounting bracket provided, or, if securing the

valve to a reservoir, use a Schedule 80 (heavy wall)

short couple pipe nipple.

2. Reconnect all air lines to the valve using the

identifi cation made during removal. Be sure to use pipe

thread sealant.

3. T est all air fi ttings for excessive leakage and tighten as

needed. Also, perform OPERA TIONAL AND LEAKAGE

TESTS before placing the vehicle back into service.

DISASSEMBLY

The following procedure is for reference only. Always

have the appropriate maintenance kit on hand, and use

its instructions in lieu of those presented here. Refer to

Figure 10 throughout.

™

CAUTION: The R-12P

a bench vise during disassembly. However,

overclamping will cause damage to the valve

and result in leakage and/or malfunction. If a

vise is used, position the valve so the jaws

bear on the supply ports on opposing sides

of the valve’s body.

valve may be lightly clamped in

1. Remove the four fasteners that secure the cover to the

body. Then slowly remove the cover.

2. Remove and discard the small o-ring(1) that seals the

internal channel and the large o-ring(2) between the

cover and the body.

3. Remove the load piston from the cover. Note: If

necessary, use approximately 20 psi of shop air,

directed into the load piston’s air passage in the cover ,

to dislodge it. CAUTION: The piston will leave the cover

with some force.

4. Remove and discard the load piston’s o-ring(3).

5. Remove the reserve spring and the relay piston from the

body . Remove and discard the relay piston’s o-rings(4)

and (5).

6. While holding exhaust cover(7), remove and discard

the snap ring(6) that secures the cover to the body.

7. Remove and discard exhaust cover(7) and its o-rings(8)

and (9).

8. Remove and discard valve spring(10), valve retainer(11),

and inlet/exhaust valve(12) from the body.

7

Page 8

CLEANING & INSPECTION

1. Using mineral spirits or an equivalent solvent, clean and

thoroughly dry all metal parts. Do not damage bores

with metal tools.

2. Wash all non-metallic components in a soap and water

solution. Dry thoroughly.

3. Inspect interior and exterior of all metal parts for severe

corrosion, pitting, and cracks. Superfi cial corrosion

and/or pitting on the exterior of the body and cover

is acceptable. Replace the entire valve if the body or

cover interior show signs of corrosion or pitting.

4. After washing, inspect relay piston for cracks, wear,

or distortion. Replace the valve if these conditions are

found.

5. Make certain the air channel running from the cover

through the top surface of the body to the supply port

is clear and free of obstruction.

6. Inspect the pipe threads in the body. Make certain they

are clean and free of thread sealant.

7. Inspect all air line fi ttings for corrosion. Replace as

necessary. Remove all old thread sealant before

reuse.

ASSEMBLY

1. Before assembly , lubricate all o-rings, seals, and pistons

as well as body and cover bores, using the lubricant

provided in the maintenance kit. Use all of the lubricant,

and spread it evenly on all rubbing surfaces.

2. Install valve retainer(11) on inlet/exhaust valve(12) so

that the fl ange of the retainer surrounds the rubber

portion of the valve.

3. Install inlet/exhaust valve(12) in the body.

4. Install valve spring(10) over the inlet/exhaust valve in

the body.

5. Install large and small diameter o-rings(8) and (9) in

exhaust cover(7).

6. Place the exhaust cover on the inlet/exhaust valve

spring. Then depress the cover against the spring’s

force into the body. Secure the cover with snap

ring(6).

7. Install o-rings(4) and (5) onto the relay piston. Then

place the reserve spring in the piston and install the

piston into the body.

8. Install the load piston’s o-ring(3) onto the load piston.

Then install the load piston into the cover, small end

fi rst.

9. Install small o-ring(1) that seals the internal channel

and large o-ring(2) onto the cover.

10. Place the cover on the body and secure with its four

fasteners. Torque to 120 - 150 in. lbs.

11. Perform OPERATIONAL AND LEAKAGE TESTS before

returning the vehicle to service.

8

BW1711 © 2007 Bendix Commercial Vehicle Systems LLC. All rights reserved. 7/2007 Printed in U.S.A.

Loading...

Loading...