Beko CLEARPOINT S040 TWC Control, CLEARPOINT S050 TWC Control Instructions For Installation And Operation Manual

Instructions for installation and operation english

Instrucciones de montaje y de uso español

Instructions de montage et de service français

Manual de instalação e de instruções português

CLEARPOINT

®

S040 TWC Control

S050 TWC Control

Compressed air heater, adjustable

Calentador de aire comprimido, regulable

Réchauffeur d´air comprimé, réglable

Aquecedor de ar comprimido, ajustável

Dear customer,

Thank you for deciding in favour of the CLEARPOINT compressed air heater. Please read the present instructions carefully

before installing the heater and putting it into operation. The perfect functioning of the device can only be guaranteed if the

rules and conditions stated here are adhered to.

Estimado cliente,

muchas gracias por haber elegido el calentador de aire comprimido CLEARPOINT. Por favor, antes de montarlo y de ponerlo

en funcionamiento, lea atentamente estas instrucciones de instalación y de servicio y signa nuestras recomendaciones. El

perfecto funcionamiento del aparato sólo estará garantizado si observa estrictamente las normas y los consejos indicados.

Cher client,

Vous venez d’acquérir un réchauffeur d’air comprimé CLEARPOINT et nous vous en félicitons. Nous vous recommandons

de lire attentivement ces instructions avant le montage et la mise en service et de suivre nos conseils. Car, seul le respect

scrupuleux des prescriptions et consignes données, peut garantir le parfait fonctionnement de l’appareil.

Prezado cliente!

Agradecemos que tenha comprado o aquecedor de ar comprimido CLEARPOINT. Antes da montagem e tomada em funcionamento, queira ler com atenção estas instruções de instalação e serviçio e seguir es nossas indicações. Só observando de

modo meticuloso as normas e indicacoes pode ser garantido um funcionamento perfeito do aparelho.

08-036

CLEARPOINT S040 / S050 TWC Control

1

CLEARPOINT S040 / S050 TWC Control

2

CLEARPOINT S040 / S050 TWC Control

3

Please check whether or not these instructions

correspond to the CLEARPOINT compressed-air

heater (S040/S055 TWC type).

Application

Application is restricted to compressed air and inert gases

of uid group 2 in accordance with the 97/23/EC European

Guideline concerning pressure devices (Pressure Equipment

Directive). Abusive employment of the compressed-air heater

for the heating of other media or for purposes other than the

heating of compressed air or of inert gases of uid group 2 is

not allowed. The application in ex-areas is also not allowed.

The compressed-air heater is employed mainly where aerosols

and condensate, developing through cooling of the compressed

air, lead to disturbances:

• Malfunctions of measurement & control instruments

• Water blisters during spray painting

• Premature wear of tools as a result corrosion

• Freezing-up of valves and control elements during fast expan-

sion of compressed air

The compressed-air heater will only function when the indicated

operating voltage is applied.

Safety rules

• It is essential to observe the instructions for installation

and operation!

english

Danger!

High temperature at the housing!

Burns can result from the contact of unprotected parts of

the body with the hot housing (up to 176°F). Risk of re

through easily inammable objects, dusts and gases.

Caution!

Carry out installation works only when the system is pressureless, deactivated and cooled down!

Measures:

• Keep distance from the housing. Check the temperature

prior to touching it.

• Do not exceed the maximum compressed-air tempera-

ture (see identication plate)!

• Employ contact protection (recommended accesso-

ries).

• Use only suitable material for thermal insulation of the

device (392°F).

• Do not carry out repair works on the device on your

own! Defective devices must be returned to the manufacturer!

Danger !

Compressed air !

Risk of serious injuries or death through the contact with

quickly or suddenly emerging compressed air or through

bursting plant components.

Use pressure-resistant installation material!

Make sure that no persons or objects can be hit by condensate

or emerging compressed air.

Caution!

Carry out installation and maintenance works only when the

system is pressureless, deactivated and cooled down!

Measures:

• Do not exceed the maximum operating pressure (see

identication plate)

• Use pressure-resistant, metallic installation material

only!

Compressed-air supply and takeoff must be piped rmly.

As a result of the temperature development at the device, do

not employ plastic pipes. Make sure that persons or objects

cannot be hit by condensate which may be found inside the

device.

• Avoid chemically aggressive environments or cleaning

with aggressive agents, as these may affect the material

of the pressure vessel!

• Do not carry out repair works on the device on your

own! Defective devices must be returned to the manufacturer!

Danger!

Mains voltage!

There is the risk of an electric shock involving injury or

death when coming into contact with non-insulated components carrying mains voltage.

Caution!

Carry out installation works only when the system is pressureless, deactivated and cooled down! All types of electrical works

must be implemented by authorised and qualied personnel

only.

Measures:

• During electric installations, all regulations need to be

observed (VDE 0100)! In addition, national rules and

safety regulations regarding the dealing with electrical

devices must be adhered to!

• The connecting cable of the device must not come into

contact with the housing of the compressed-air heater!

• Do not use the compressed-air heater in ex-areas.

• Do not carry out repair works on the device on your

own! Defective devices must be returned to the manufacturer!

CLEARPOINT S040 / S050 TWC Control

4

english

General notes

• It is essential to observe the instructions for installation and

operation! Non-observance can lead to injury or damage to

the system! During electric installations, the national rules

and safety regulations in effect regarding the dealing with

electrical devices must also be adhered to!

• Do not exceed the permissible electrical voltage, operating

pressure and compressed air temperature (see Technical

Data)!

• Carry out installation works only when the system is pressureless, deactivated and cooled down! De-pressurise the

system and disconnect the device from the mains voltage!

If there is a leak in the compressed-air supply or discharge

line at the compressed-air heater, rst deactivate the compressed-air system. Only then may the leak be eliminated.

Leaks at the compressed-air heater itself require complete

replacement of the device!

• The compressed-air heater must not be repaired by oneself

but returned to the manufacturer.

• The compressed-air heater will only function when voltage is

applied.

• Installation and electrical connection must only carried out

by suitably qualied personal.

• The device is to be installed with the compressed air inlet

azt the top and the elctrical connection at the bottom (see

functional diagram).

• Only use temperature- and pressure-resistant components

(tubing, seals, sealant….)

• Check the device regularly to ensure correct functioning and

avoid damage!

- Check the device regularly for damage to the container

and the cable. Replace it, if required.

- For the point of installation, the following needs to be taken into account

- No strong vibrations via tubing or xing

- Good ventilation to prevent heat accumulation

- No direct contact to or insufcient distance from inammable materials

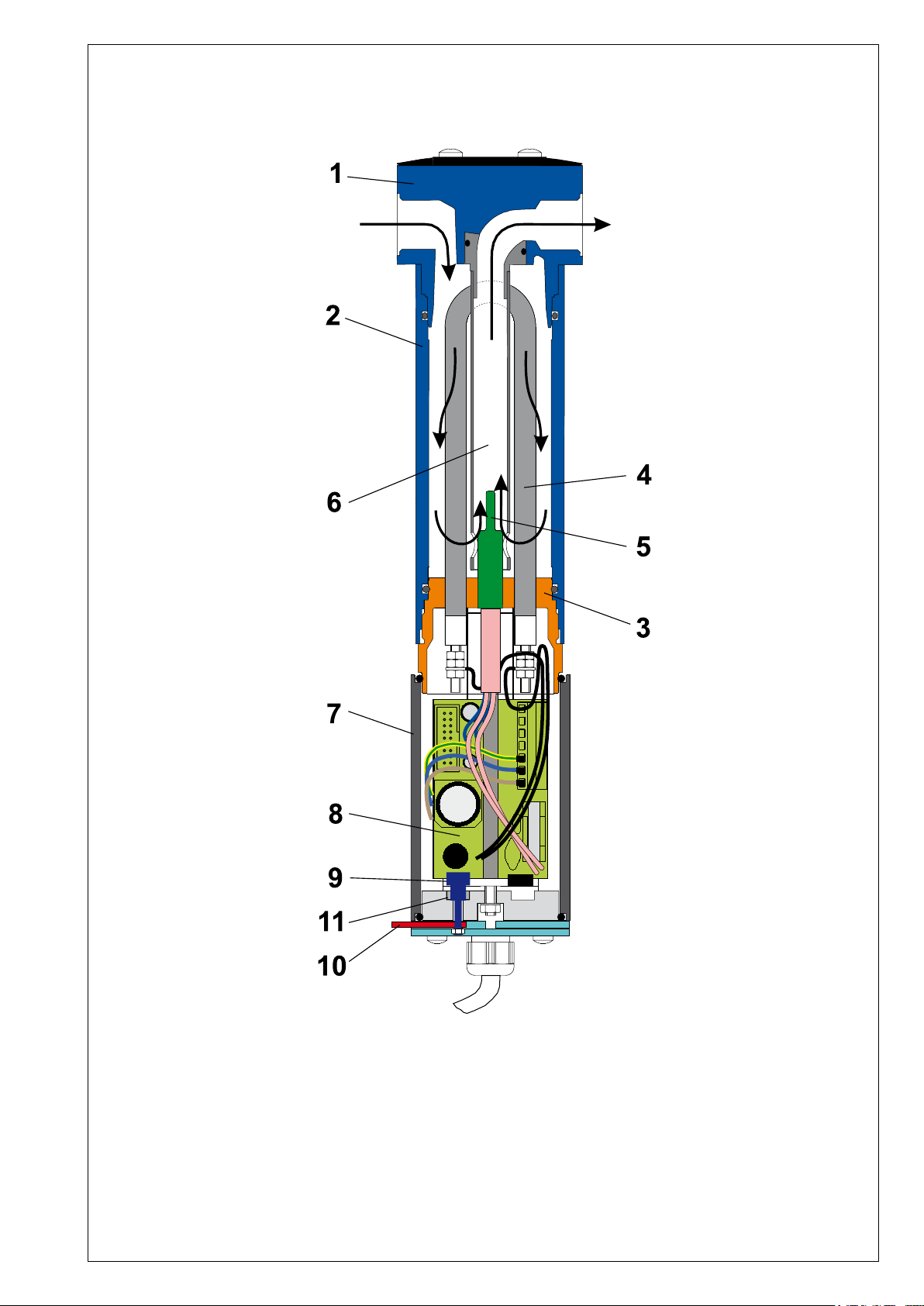

Function

The lter heater consists of a CLEARPOINT housing, in the

container (2) of which a compact screw-in part (3) with a heating element (4) is installed at the bottom. The screw-in part (3)

also contains a pressure-resistant shielded temperature sen-

sor (5). An internal sleeve (6) is xed centrally between head

(1) and screw-in part.

At the bottom part of the device is the electric housing (7), into

which the voltage supply (standard connecting cable with a

plug connector) and a printed circuit board (8) are integrated.

A potentiometer (9) is installed on the circuit board which can

be adjusted via a lever (10) protruding laterally at the bottom.

With this, the maximum temperature of the leaving compressed air is adjustable (adhesive labels with limit values, see

also "Technical data"). The electric housing is equipped with

an excess pressure protection (11), in case leaks between the

container (2) and the electric housing (7) should exist.

• Use only suitable material for thermal insulation of the de-

vice (392°F).

• Avoid chemically aggressive environments or cleaning with

aggressive agents!

• Protect device during operation against the external impact

of drip or splash water!

• A pre-heating phase of approx. 10 minutes prior to the actual

employment should be taken into account, as the heating-up

process is regulated by the electronic circuit and deliberately

undertaken slowly.

• Do not touch the device and pipes near the device during

operation! Although the device is equipped with an inter-

nal thermal overload protection, temperatures may rise to

176°F during standstill (no compressed-air withdrawal)! You

may need to protect the device against accidental contact (see recommended accessories). At short intervals

compressed-air withdrawal / standstill, the compressed-air

temperature may, for a short period of time, exceed 140°F.

• Pull out the connector plug during longer standstill periods

of the plant or de-energise the device. The socket for connecting the device plug should therefore be easily accessible. Ensure that the device’s connecting cable cannot

come into contact with the housing of the compressed

air heater!

The compressed-air entering at the lter head (1) is distributed and ows downwards in the container (2). Heating-up,

which is measured continuously with the temperature sensor

(5), is implemented via contact with the heating element (4).

Via the centrally installed internal sleeve (6), the heated compressed air ows towards the outlet at the lter head (1) and

then towards the compressed-air application.

The temperature sensor (5) and the electronic control which

are integrated into the printed circuit board (8) guarantee the

observance of the maximum surface temperature. Due to the

minor thermal mass of the heating element and to exact registration of the compressed-air temperature, fast adjustment of

the heating power within the performance curve of the device

is possible.

CLEARPOINT S040 / S050 TWC Control

5

english

CLEARPOINT S040 / S050 TWC Control

6

english

Installation

Contrary to conventional devices, CLEARPOINT compressed-

air heaters can also be operated with saturated compressed

air. However, the employment of a coalescence lter upstream

of the compressed-air heater, which removes aerosols from

the compressed air, is advisable. For practical reasons, the

compressed-air heater is installed directly upstream of the point

of application. The device is to be installed with the compressed

air inlet azt the top and the elctrical connection at the bottom

(see functional diagram).

Where the application requires a specic compressed air quality

and where a coalescence lter is to be installed in front of the

compressed air heater, the lter and lter heater can simply

be combined to a compact treatment system using connection

kit F2CK4.

1. Determine the point of installation,

- There must be no strong vibrations

- Good ventilation to avoid heat accumulation

- No direct contact with or insufcient distance from am-

mable materials

2. Depressurize the line.

3 Install device observing the direction of ow (see arrow on

black cap), combined with lters in a vertical position.

4 Use connection ttings with cylindrical thread according to

DIN-ISO 7/1228-1 / ANSI ASME B120.1-1983 and seal with

suitable sealant.

5. Install the socket for connecting the device plug in an

easily accessible position. The electrical connection of

compressed-air heaters of the type with a cable and without

a plug must be undertaken by authorised qualied personnel

only. The connecting cable must not come into contact

with the housing of the compressed-air heater or other

heated components of the plant!

Maintenance

Danger!

Compressed air!

Risk of serious injuries or death through the contact with

quickly or suddenly emerging compressed air or through

bursting plant components.

Danger

Mains voltage!

There is the risk of an electric shock involving injury or

death when coming into contact with non-insulated components carrying mains voltage.

Measures:

During electric installations, all regulations need to be

observed (VDE 0100)!

All types of electrical works must be implemented by au-

thorised and qualied personnel only.

Danger!

High temperature at the housing!

Burns can result from the contact of unprotected parts of

the body with the hot housing (up to 176°F). Risk of re

through easily inammable objects, dusts and gases.

Caution!

No maintenance works are required or permitted directly

at the compressed air heater. Defective devices need to

be returned to the manufacturer for repair.

Start-up procedure

1. Do not switch on the compressed air heater at this stage

(do not put the device plug into the socket)!

2. After correct installation, pressurize the device slowly until

a uniform pressure is established.

3. Check that the system is tight. In the case of leaks, shut

off the compressed air supply and remove the cause of the

leakage immediately! Repressurize the system.

4. Temperature pre-adjustment for an internal maximum tem-

perature (compressed-air outlet temperature):

- Lever stop on the right: approx. 86°F

- Lever stop on the left: approx. 140°F

5. The device type with a cable and without a plug must be con-

nected electrically by authorised qualied personnel only. As

regards devices with a plug, check whether or not a supply

voltage of 115 VAC is available at the plug connector. Then

plug in the device (safety plug).

6. A pre-heating phase of approx. 10 minutes prior to the actual

employment should be taken into account, as the heating-up

process is regulated by the electronic circuit and deliberately

undertaken slowly.

Maintenance works at the device are limited to regular inspections, the cycle of which the plant operator will determine:

a) Examination of the electric connecting cable

- no contact with the housing

- no damages in the coat of the cable

- proper connection to the mains supply

- deactivation during longer standstill periods or when the

factory is closed

b) Assessment point of installation (risk of re)

- sufcient ventilation, no thermal insulation at the device

- no contact to inammable materials and dusts and none

in the vicinity

- avoidance of splash water

c) Body of the device

- no mechanical damage on pressurised parts of the

housing

- correct seat of the electric housing (plastic bottom part)

- correct seat of the contact protection, as far as available

- richtiger Sitz von Berührungsschutz, soweit vorhanden

d)

Lever for the adjustment of the compressed-air temperature

- Check mobility / adjustability

- No mechanical damage

CLEARPOINT S040 / S050 TWC Control

7

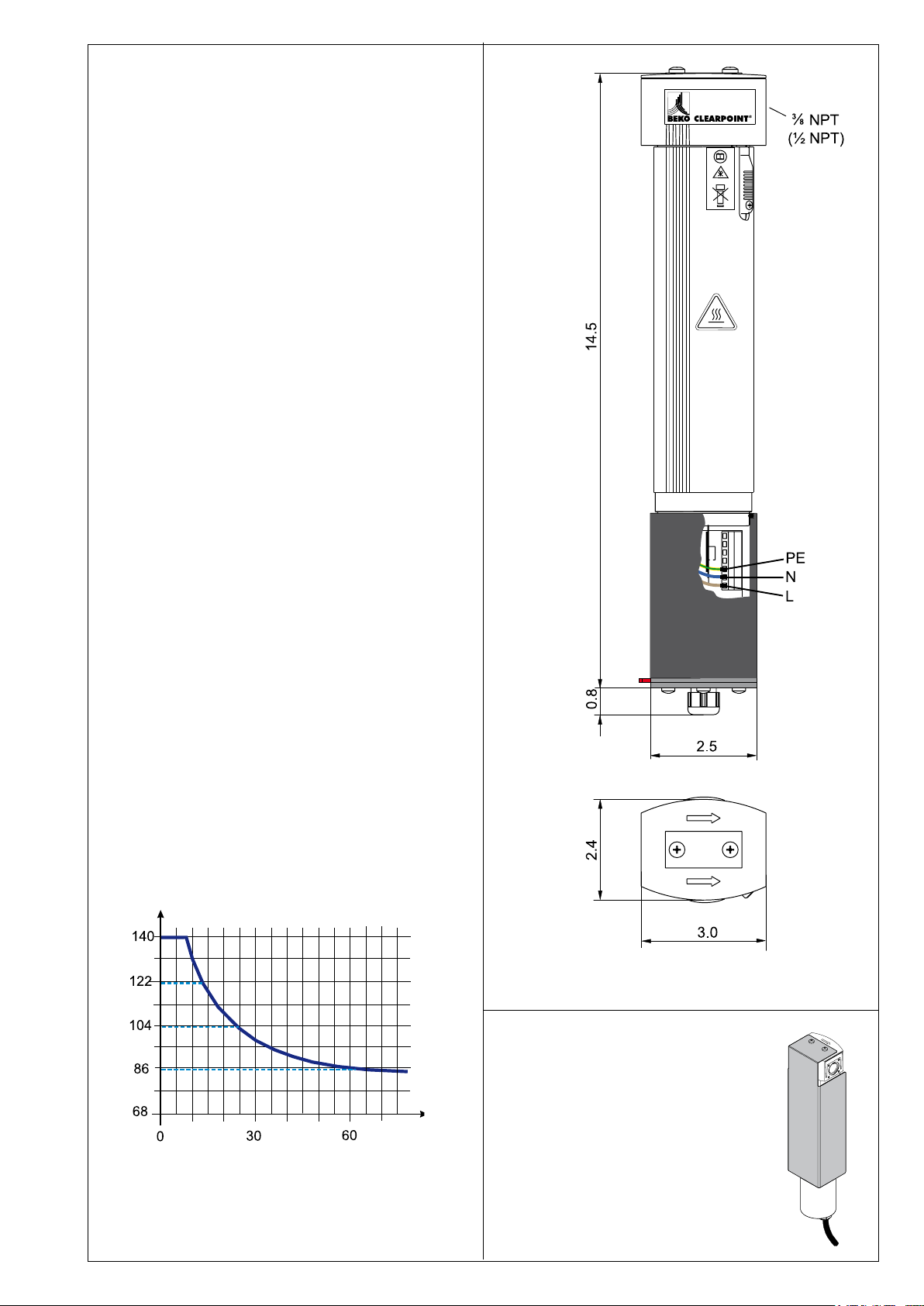

Technical data

Medium: Compressed air, inert gases

- free from aggressive substances

- dry to moisture-saturated

Housing material: Aluminium, anodized

Powder-coated outside

Bottom area POM

max. operating pressure PS: 232 psi

Pipe connection: 3/8 bei S040

½“ bei S050

Flow rate at 100 psi: max. 30 scfm at S040

max. 60 scfm at S050

Differential pressure: S040 at 30 scfm : < 2.0 psi

S050 at 60 scfm : < 3.0 psi

Inlet temperature: 35°F to 123°F

Ambient temperature: 35°F to 123°F

Setting range compressed-air outlet temperature:

86°F to 140°F

Internal safety cut-off temperature: 183°F

Max. outside temperature of housing: 176°F

Max. compressed-air outlet temperature: 140°F

Volume: 0.11 gallon

Voltage: 115 VAC / 50-60 Hz +/- 25%

Power *: 420 (750) W

Protection standard: IP 54

Weight: 5.3 lb

english

* at 68°F :

- making-current max 8 A

making-capacity max. 750 W

Increase in the temperature depending on the volume ow

- Compressed-air inlet temperature 68°F

- Adjustment range internal maximum temperature

(compressed-air outlet temperature) 86°F to 140°F

Temperature outlet (°F)

dimensions (inch)

Accessories

Touch protection :

to be installed on the lter head

Flow rate (scfm)

Order number.: XZ CPHZ 001

CLEARPOINT S040 / S050 TWC Control

8

CLEARPOINT S040 / S050 TWC Control

9

español

Por favor, compruebe que estas instrucciones

corresponden al calentador de aire comprimido

CLEARPOINT modelo S040/S050 TWC.

Uso

El uso del aparato se limita al aire comprimido y los gases

inertes del grupo de uidos 2 de acuerdo con la Directiva de

Equipos a Presión 97/23/CE. No es admisible el uso del calentador de aire comprimido para otros medios u otros nes que

no sean los de calentar aire comprimido o gases inertes del

grupo de uidos 2. Tampoco se permite el uso en zonas Ex.

El calentador de aire comprimido se utiliza preferentemente

allí donde los aerosoles y los condensados producidos por la

refrigeración del aire a presión provocan averías:

• fallos de funcionamiento de los instrumentos de medición y

regulación;

• burbujas de agua durante el pintado con espray;

• desgaste prematuro de las herramientas por la corrosión;

• congelación de las válvulas y de los elementos de regulación

por la rápida expansión del aire comprimido.

El calentador de aire comprimido sólo funcionará si se aplica

la tensión de servicio indicada.

Advertencias de seguridad:

• ¡Es imprescindible seguir las instrucciones de instalación

y de servicio!

• ¡No realice los trabajos de reparación del aparato por su

cuenta!

¡Los aparatos averiados deben enviarse al fabricante!

¡Peligro!

¡Alta temperatura en la carcasa!

Si alguna parte del cuerpo desprotegida entra en contacto

con la carcasa caliente (hasta +80ºC) pueden producirse

quemaduras. Peligro de incendio por objetos, polvos o

gases fácilmente inamables.

¡Atención!

¡Realizar los trabajos de instalación únicamente cuando el

sistema esté sin presión, sin tensión y frío!

Medidas:

• Mantener la distancia a la carcasa. Antes de tocarla,

comprobar la temperatura.

• ¡No superar la temperatura máxima del aire comprimido

(véase la placa de identicación)!

• Utilizar protección contra contactos (accesorio reco-

mendado).

• Aislar térmicamente el aparato sólo con materiales adecuados (200°C).

• ¡No realice los trabajos de reparación del aparato por su

cuenta!

¡Los aparatos averiados deben enviarse al fabricante!

¡Peligro!

¡Aire comprimido!

Existe peligro de sufrir lesiones graves o incluso la muerte

si se entra en contacto con aire comprimido que se escape

de forma rápida o repentina, o por la explosión de alguna

pieza del aparato.

¡Utilizar material de instalación resistente a la presión!

Asegúrese de que las personas o los objetos no puedan

recibir el impacto del condensado o del aire comprimido que

se escape.

¡Atención!

¡Realizar los trabajos de instalación únicamente cuando el

sistema esté sin presión, sin tensión y frío!

Medidas:

• ¡No superar la presión máxima de servicio (véase la placa

de identicación)!

• ¡Utilizar únicamente material de instalación metálico

resistente a la presión! Atornillar con rmeza la entrada y

la salida de aire comprimido. Debido a las temperaturas que

se desarrollan en el aparato, no usar tuberías de plástico.

Asegúrese de que las personas o los objetos no puedan

entrar en contacto con el condensado que pueda haber en

el interior del aparato.

• ¡Evitar entornos químicos agresivos y la limpieza con

detergentes agresivos, ya que éstos podrían atacar el

material de que está hecho el depósito de presión!

Peligro!

¡Tensión de la red!

Peligro de sufrir una descarga eléctrica con resultado de

lesiones o muerte por contacto con piezas no aisladas que

lleven tensión de red.

¡Atención!

¡Realizar los trabajos de instalación únicamente cuando el

sistema esté sin presión, sin tensión y frío! Todos los trabajos

eléctricos deben realizarse únicamente por personal técnico

cualicado.

Medidas:

• ¡Respetar todas las normas vigentes para instalaciones

eléctricas (VDE 0100)! ¡Cumplir también las disposicio-

nes y normas de seguridad nacionales para el manejo

de aparatos eléctricos!

• ¡El cable de conexión del aparato no debe entrar en

contacto con la carcasa del calentador de aire comprimido!

• No usar el calentador de aire comprimido en zonas con

peligro de explosión.

• ¡No realice los trabajos de reparación del aparato por su

cuenta!

¡Los aparatos averiados deben enviarse al fabricante!

Loading...

Loading...