Page 1

Contents: Page:

Part 4: Programming Instructions for Class 739

Programme version:

Contents: Page:

1. Programming of 739-23......................................... 3

1.1 Introduction ................................................ 3

Operating elements of the key bar (control panel)........................ 4

1.3 Operating mode ............................................. 5

1.3.1 Structure of sewing programme and setting and test programmes ................ 5

1.3.2 Starting of sewing machine programme ................................ 6

1.4 Setting programmes(F3) ........................................ 7

1.4.1 List of setting programmes........................................ 7

1.4.2 Measuring of transponder reading position .............................. 8

1.4.3 Measuring of “needle position” ..................................... 8

1.4.4 Edge cutter zero position......................................... 9

1.4.5 Piece counter ............................................... 10

1.4.6 Error memory ............................................... 10

1.5 Default parameter settings (F4).................................... 11

1.6 Multitest (F2) ............................................... 11

1.6.1 Display of machine class and software version ........................... 12

1.6.2 Display of input change ......................................... 12

1.6.3 Switching of outputs ........................................... 13

1.6.4 Testing of sewing motor ......................................... 14

1.6.5 Testing of step motors .......................................... 15

1.6.6 Testing of transponder reading unit .................................. 16

1.6.7 Testing of key bar ............................................. 17

1.6.8 Testing of control RAM .......................................... 17

1.6.9 Testing of control FLASH......................................... 18

1.6.10 Adjustment of bobbin thread monitor.................................. 18

1.7 Global parameters (F1) ......................................... 19

1.7.1 Piece counter ............................................... 19

1.7.2 Sewing motor speed ........................................... 20

1.7.3 Stitch length ................................................ 20

1.7.4 Setting of material clamp infeed time ................................. 21

1.7.5 Setting of initial bartack ......................................... 21

1.7.6 Setting of final bartack .......................................... 22

1.7.7 Setting of initial stitch condensation .................................. 23

1.7.8 Setting of end stitch condensation ................................... 24

Page 2

Contents: Page:

1.7.9 Switching on/off of thread monitor ................................... 25

1.7.10 Setting of reduced sewing motor speed ................................ 25

1.7.11 Setting of edge cutter speed....................................... 26

1.7.12 Setting of suction delay.......................................... 26

1.8 Special functions for the repair of a thread breakage...................... 27

1.9 Tread breakage in seam (needle thread) .............................. 27

1.10 Dispays and error messages ..................................... 28

1.10.1 Error messages .............................................. 28

1.11 Loading of programme in control system ............................. 29

Appendix .................................................. 30

A.1 Inputs and Outputs ............................................ 30

2. Dacs739 software ............................................ 31

2.1 Introduction................................................. 31

2.2 System requirements ........................................... 31

2.3 Installation of Dacs739 .......................................... 32

2.4 Starting of Dacs739 ........................................... 32

2.5 Help options ................................................ 33

2.6 Dacs739 tutorial .............................................. 34

2.6.1 Generation of a seam contour...................................... 34

Page 3

1. Programming of 739

1.1 Introduction

This programming manual includes instructions for the safe and

economical handling of the new “DAC” (Dürkopp Adler Control) control

system.

Programming convenience

The following functions must be programmed by the user.

–

Display/delete piece counter

–

Sewing motor speed

–

Stitch length

–

Initial bartack

–

Final bartack

–

Initial stitch condensation

–

End stitch condensation

–

Switch thread monitor on/off

Setting and test programmes

The DAC includes the comprehensive functions of the

MULTITEST testing and monitoring software.

The system is controlled by a microcomputer, which also monitors the

sewing process and indicates incorrect operation and errors.

Errors and test results are displayed on a 8-digit LED display with 7

segments. During normal operation, the display shows data regarding

the operation of the unit and the sewing process.

If an error occurs in the operation or the sewing process, the current

function is terminated.

In certain cases the main switch must be switched off in order to

eliminate an error for safety reasons.

Certain error messages are designated for service personnel only.

Special programmes simplify the mechanical configuration and

make it possible to quickly check input and output components without

the need for additional measuring devices.

4-3

Page 4

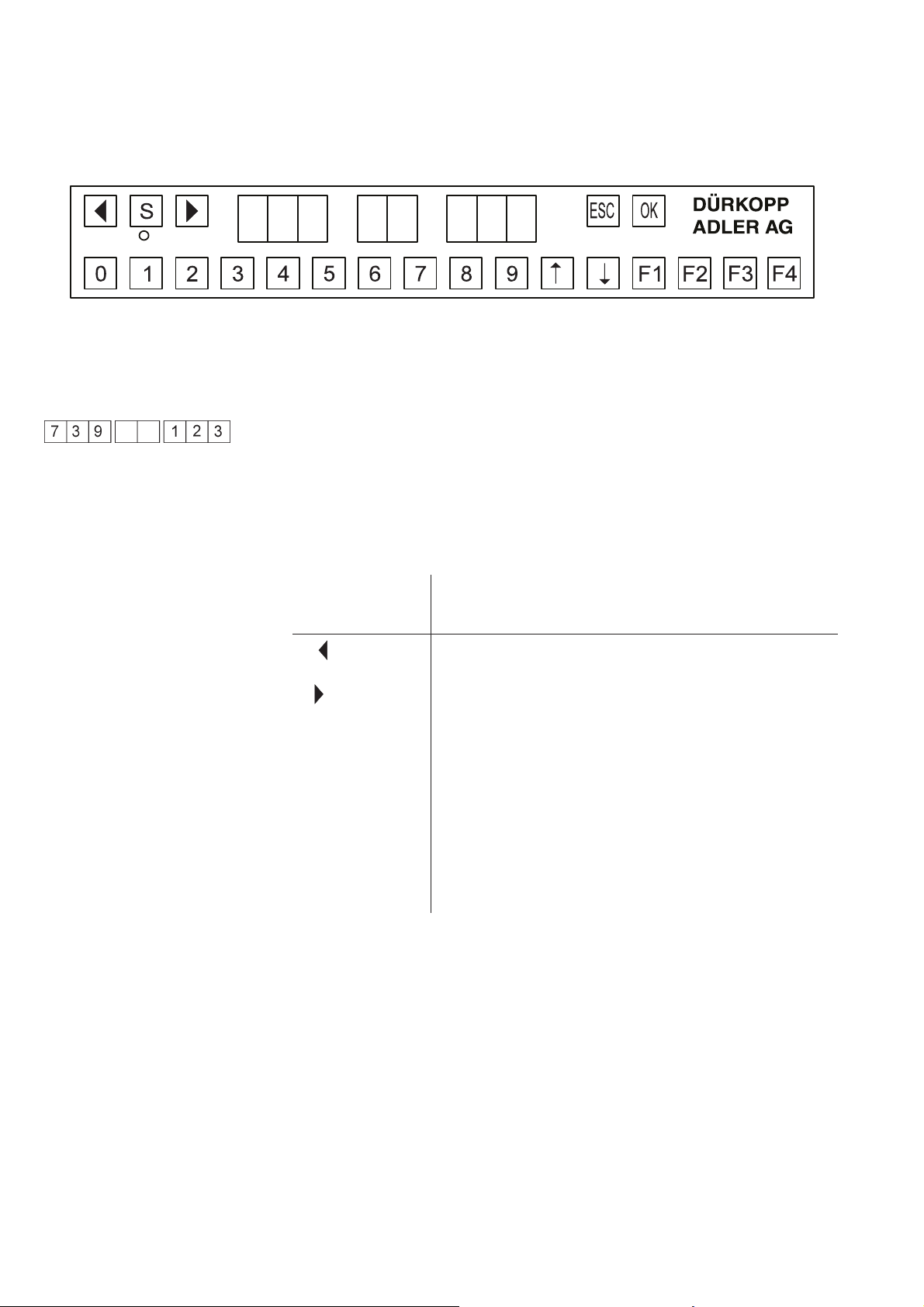

1.2. Operating elements of the key bar (control panel)

For the input and output of data, the machine is equipped with a key

bar

including an 8-digit display, which is divided into 3 distinct blocks.

Display

During the standard programme run, the display is structured as

follows:

left 3 digits: sewing machine class

centre 2 digits: no display

right 3 digits: piece counter

If a test programme is activated, the display shows various other

parameters.

Key/

key groups Function

Key for the selection of a function

S Start key for the infeed of a template

Key for the selection of a function

ESC Cancellation of sewing process/sewing machine is

reset to initial position

OK Confirmation of an entry

0 to 9 Entry of numerical values

á Modification of settings in indicated direction

â Modification of settings in indicated direction

F1, F2,

F3, F4

Function keys

4-4

Page 5

1.3 Operating mode

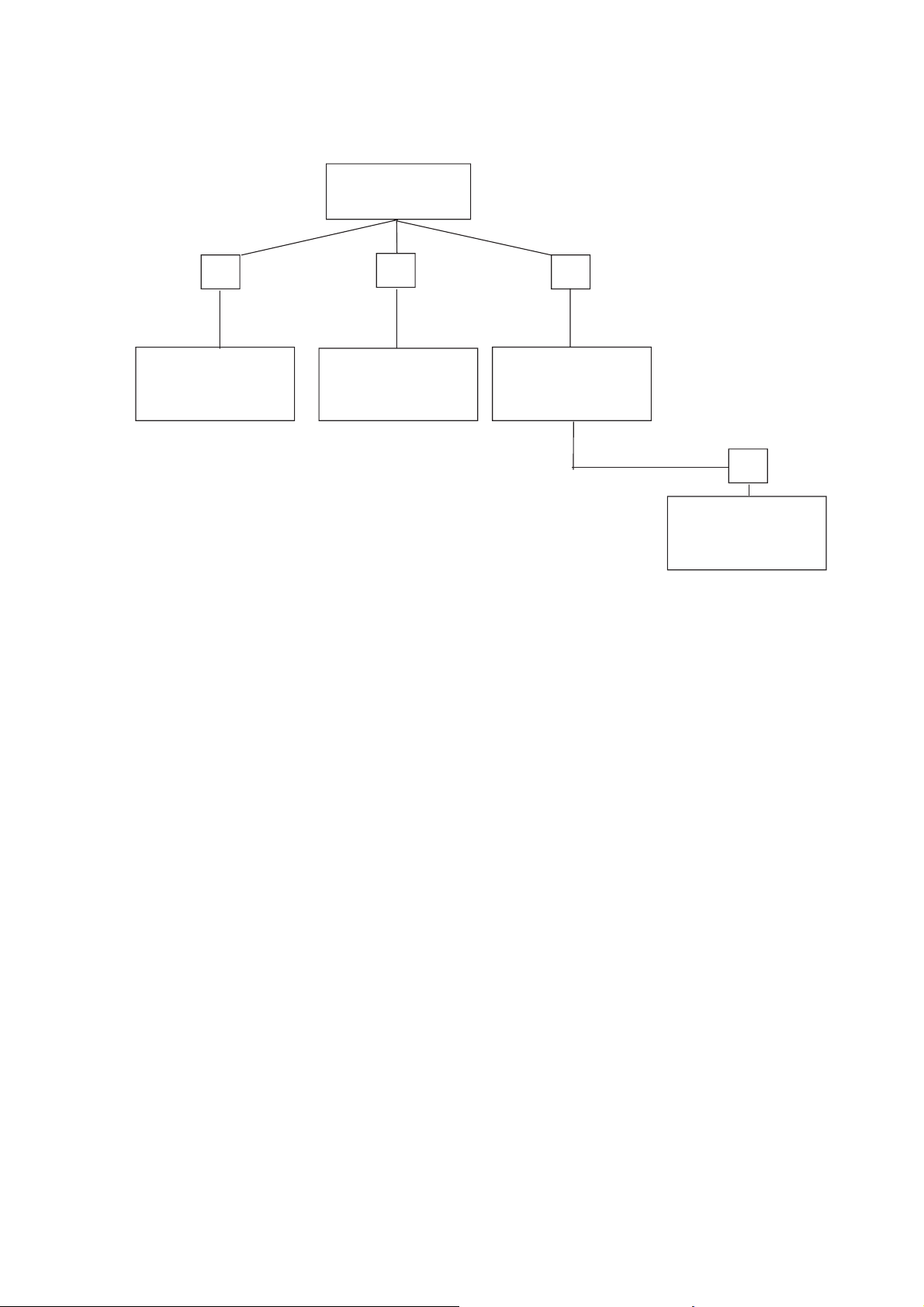

1.3.1 Structure of sewing programme and setting and test programmes

Switch on

main switch

F1 F2 F3

Global Multitest Setting programmes

parameters (2XX) (3XX)

(1XX)

F4

Parameter

default settings

Calling of global parameters

–

Prior to the start of a new sewing process, press “F1” key.

Calling of setting and test programmes

–

Switch on main switch.

The control system is initialised.

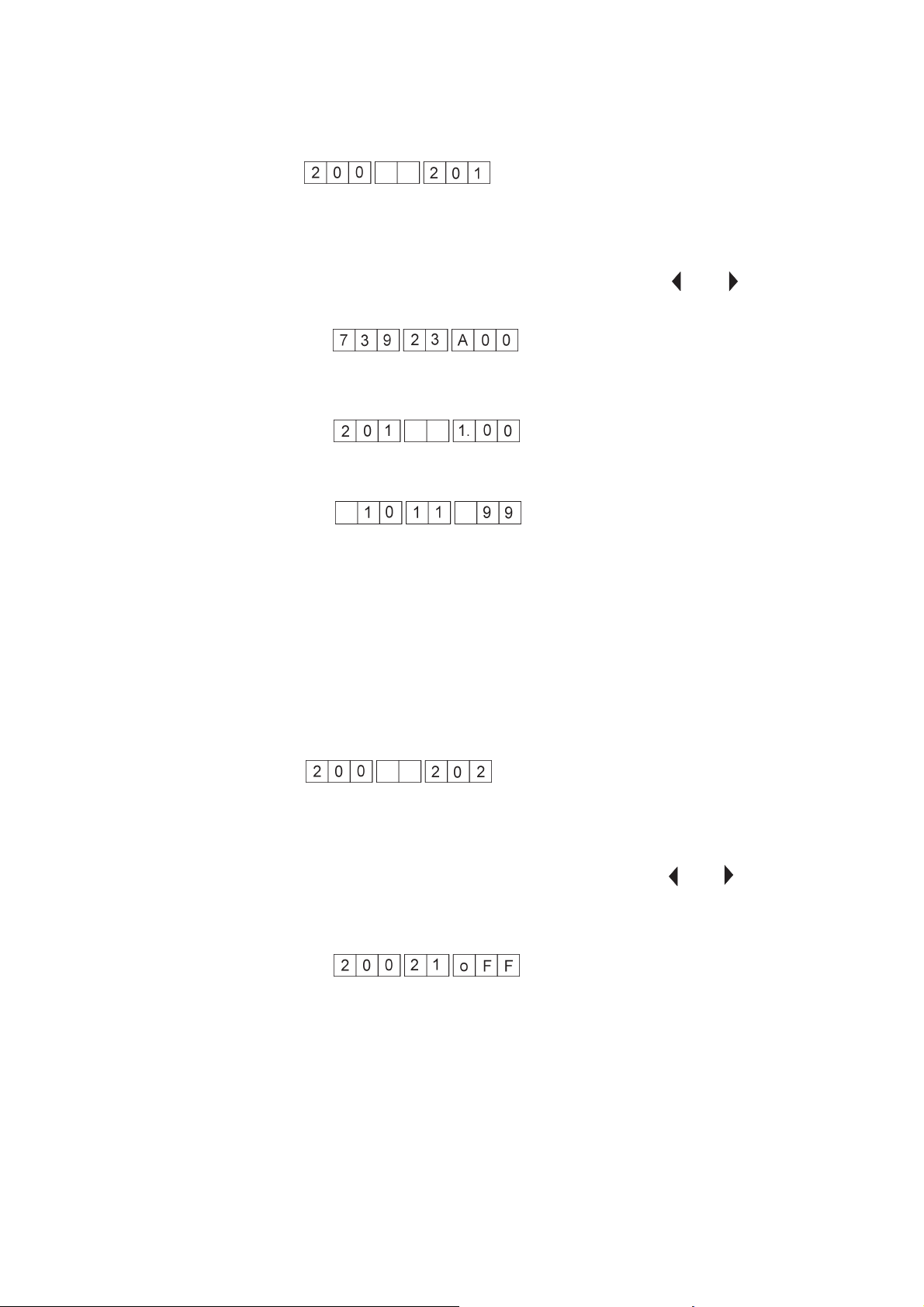

During display of “739 23 A00", press one of the following keys:

–

Press “F2” key.

The display changes to the test programmes group.

–

Press “F3” key.

The display changes to the setting programmes group.

–

Press “9” key.

The machine runs slower.

For checking and testing purposes.

–

Press “8” key.

If a material clamp is inserted, it is sewed again.

Cancel function by switching off the sewing machine.

4-5

Page 6

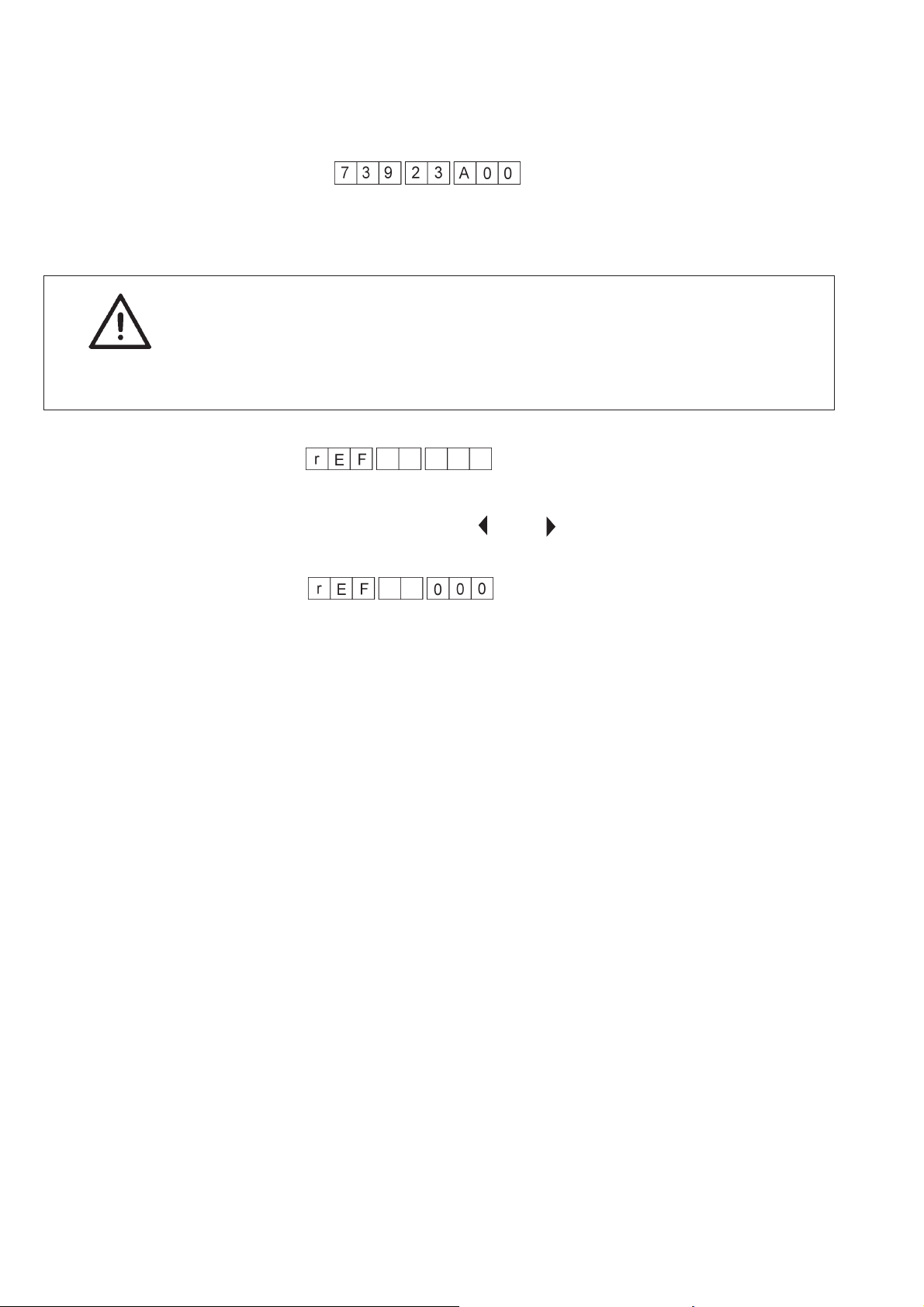

1.3.2 Starting of sewing machine programme

–

Switch on the main switch.

The control system is initialised.

The start message is displayed.

To operate the sewing machine, the sewing axes must first be

positioned in the reference position.

CAUTION!

The reference run must be carried out by the operator.

CAUTION Risk of breakage!

Do not insert a material clamp during the reference run.

The following display indicates that a reference run is necessary:

To manually remove a material clamp that is inserted in the machine,

press the arrow keys “ ” and “ ”.

–

Press the “OK” key.

The reference run is carried out.

After successful referencing, the display changes to:

After 0.5 seconds, the machine programme changes to operating

mode.

4-6

Page 7

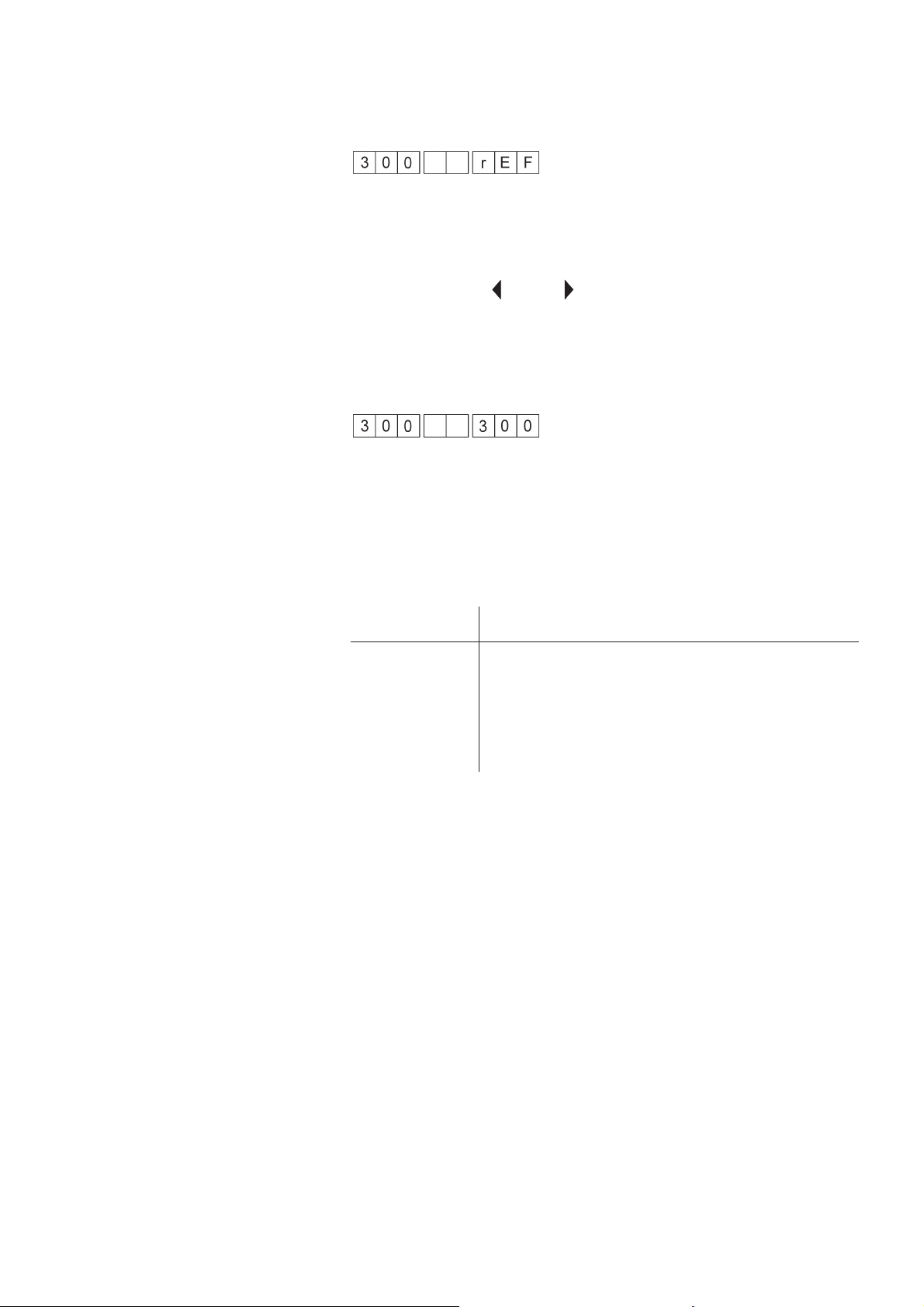

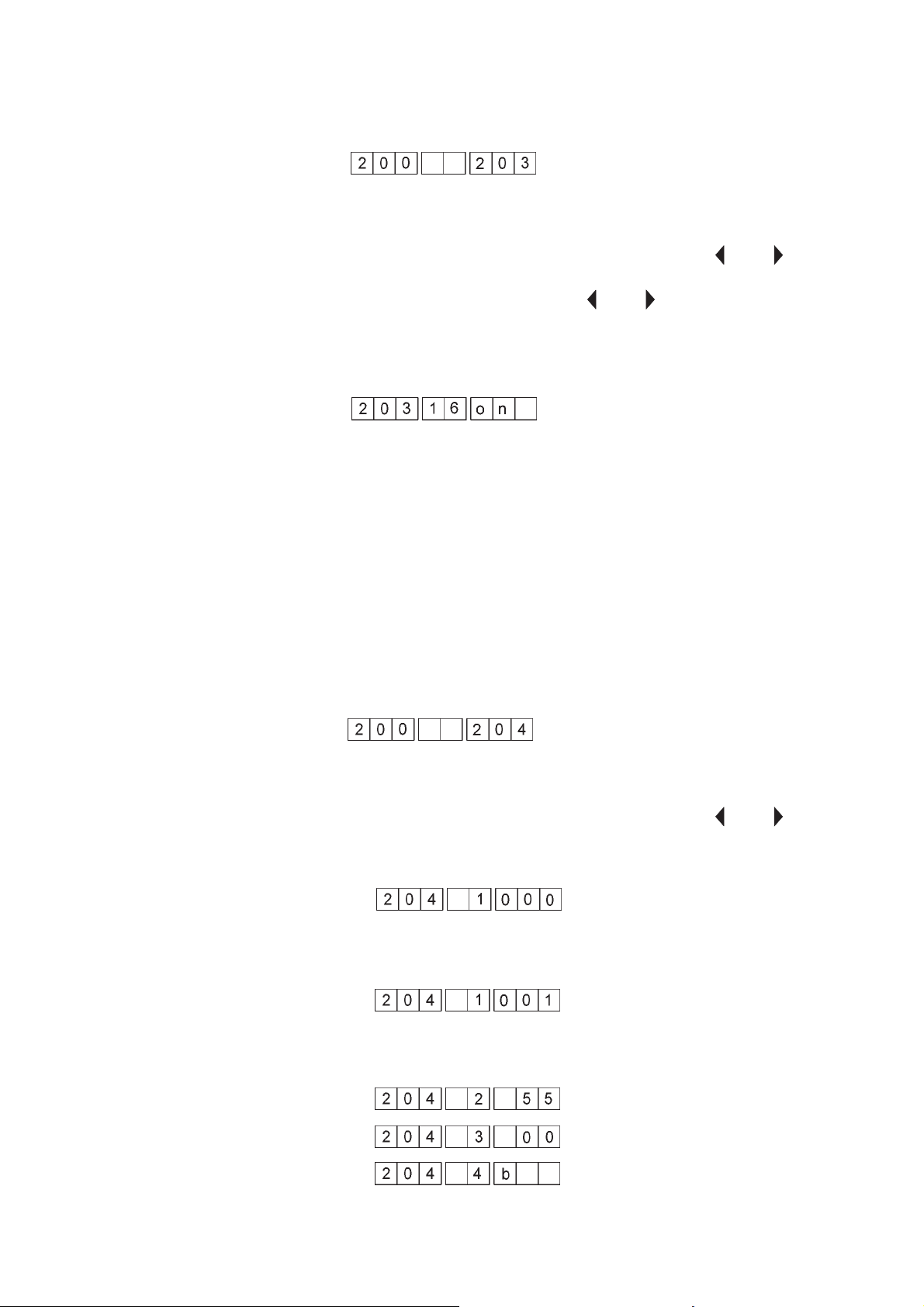

1.4 Setting programmes (F3)

Press the F3 function key to call the setting programmes. The display

reads as follows:

Prior to executing the setting programmes, the sewing axes must be

referenced.

–

Press the “OK” key.

The reference run is carried out.

–

Use the keys “ ” and “ ” to select the required setting

programme.

–

Press the “OK” key.

The setting programme is started.

The first digits show the activated menu function, while the last three

digits indicate the selected function.

1.4.1 List of setting programmes

Number Name

301 Measuring of transponder reading position

302 Measuring of needle position

303 Measuring of edge cutter zero position

304 Display of DA counter

305 Display of error memory

4-7

Page 8

1.4.2 Measuring of transponder reading position

This setting programme is used to adjust the reading position of the

transponder in the material clamp.

Operating steps

–

Insert the setting template into the X-guide of the sewing machine.

–

Select the setting programme by means of the “ ” or “ ” key.

–

Press the “OK” key.

The setting programme is started.

The X and Y axes are moved to the current transponder reading

position.

–

To select a direction, press the corresponding key.

“1" key: X position

”2" key: Y position

Example: Change of X direction

–

Press key “á”or“â”.

The position for the reading of the transponder is moved in the

selected direction.

The last three digits of the display indicate the distance from the

original position in steps of 0.5 mm.

–

Press the “OK” key.

The new position is saved.

–

Press the “ESC” key.

The system returns to the programme for basic settings (300).

1.4.3 Measuring of needle position

This setting programme allows for the adjustment of the needle

position in relation to the material clamp.

–

Insert the setting template into the X-guide of the sewing machine.

–

Select the setting programme by means of the “ ” or “ ” key.

–

Press the “OK” key.

The setting programme is started.

The X and Y axes are moved to the current needle position.

–

To select a direction, press the corresponding key.

“1" key: X position

”2" key: Y-position

Example: Change of Y position

4-8

Page 9

1.4.4 Edge cutter zero position

–

Press “3”.

Press “á”or“â”.

The needle position is moved in the selected direction and relative

to the material clamp in steps of 1/10 mm.

The last three digits of the display indicate the distance from the

original position.

or

–

Press “4”.

Press “á”or“â”.

The needle position is moved in the selected direction and relative

to the material clamp in steps of 5/10 mm.

The last three digits of the display indicate the distance from the

original position.

–

Press the “OK” key.

The new position is saved and the system returns to the

programme for basic settings (300).

or

–

Click the “ESC” key.

The system returns to the programme for basic settings (300)

without saving the new position.

This function is used to define the zero position of the edge cutter.

–

Select the setting programme by means of the “ ” or “ ” key.

–

Press the “OK” key.

The edge cutter is moved to its initial position.

–

Press the “á”or“â” key.

The zero position is moved into the selected direction.

The last three digits of the display show the distance from the initial

position.

Adjust the zero position in such a way that the edge cutter is

pointing straight ahead.

–

Press the “OK” key.

The new position is saved.

–

Press the “ESC” key.

The system returns to the setting programme for basic settings

(300).

4-9

Page 10

1.4.5 Piece counter

1.4.6 Error memory

This function displays the total number of pieces processed by the

sewing machine.

–

Select the setting programme by means of the “ ” or “ ” key.

–

Press the “OK” key.

A following prompt is displayed:

–

Enter code number “???” by means of the numerical keys.

The total counter value of the sewing machine is displayed.

Counter in the above example: 1,234,500 sewing cycles.

–

To reset the counter and the error memory, press the “F4” key.

Note

This menu is designed for DA technicians only.

This function is used to display the error memory data of the sewing

machine.

–

Select the setting programme by means of the “ ” or “ ” key.

–

Press the “OK” key.

The display reads as follows:

Symbols:

“nn” Error memory number (1 - 32)

“GG” Error group

“NNN” Error number

–

To browse through the error memory, press “á”or“â” key.

or

–

Press the “ESC” key.

The system returns to the programme for basic settings (300).

4-10

Page 11

1.5 Default parameter settings (F4)

To reset the unit to the default parameters, press the “F4” key (default

parameters). The display reads as follows:

The following functions are completed:

–

Internal memory is initialised.

–

Error memory is deleted.

–

Default values are loaded.

1.6 Multitest (F2)

If the “F2” key is pressed immediately after the main switch is witched

on, the machine changes to test mode.

The following test programmes are available:

No. Name

201 Display of the software version

202 Testing of control inputs

203 Testing of control outputs

204 Testing of sewing motor

205 Testing of positioning by means of the step mo-

206 Testing of CAN BUS

207 Testing of transponder reading unit

208 Testing of key bar

209 Testing of control RAM

210 Testing of control FLASH

211 Setting of hook thread monitor (if installed)

tors

Operating steps

–

Switch on main switch.

The control system is initialised.

–

Press the F2 function key while “739 23 00" is displayed.

After a display test, the display changes to the group of setting

programmes.

4-11

Page 12

1.6.1 Display of machine class and software version

No entries can be made in this test programme.

It is exclusively designed to query the machine class and the current

software version.

Operating steps

–

Switch to test mode (see chapter 1.6)

–

Select the test programme by means of the “ ” or “ ” key.

–

Press the “OK” key.

The machine class is displayed.

–

Press the “OK” key.

The software version is displayed.

–

Press the “OK” key.

The date of the software is displayed.

1.6.2 Display of input change

Press “OK” key.

The system returns to the basic multitest programme.

This test programme monitors the entire input picture for changes. If a

change occurs, the input number and the switching status are

displayed.

Operating steps

–

Switch to test mode (see chapter 1.6)

–

Select the test programme by means of the “ ” or “ ” key.

–

Press the “OK” key.

–

Enter input manually.

The display reads e.g.:

4-12

–

Input No. 21 changed to “Off” status.

For inputs, see appendix A.1

Page 13

1.6.3 Switching of outputs

In this test programme, you have the option to individually switch the

outputs. The change of a switch is indicated in the display.

Operating steps

–

Switch to test mode (see chapter 1.6)

–

Select the test programme by means of the “ ” or “ ” key.

–

Press the “OK” key.

–

Select the output with the “ ” or “ ” key.

–

Change the switching status by means of the “á”or“â” key

(ON-OFF).

Example: Testing of output 16

Output 16 is switched to “ON” status.

The output status is not altered upon change to another output number.

Therefore, you have the option to set up any possible combination.

After exiting the test mode, all outputs are reset to “OFF”.

1.6.4 Testing of sewing motor

For outputs, see appendix A.1

This option allows for the testing of the sewing motor.

Operating steps

–

Switch to test mode (see chapter 1.6)

–

Select the test programme by means of the “ ” or “ ” key.

–

Press the “OK” key.

The sewing motor is called from the serial interface and initialised.

After successful initialisation,

is displayed. If an error occurs during initialisation, the respective

error code is displayed.

–

Press the “OK” key.

The display shows three digits of the 9-digit sewing motor software

version.

4-13

Page 14

–

Press the “OK” key.

The display shows three digits of the 9-digit sewing motor software

date code.

–

Press the “OK” key.

The status of the communication with the sewing motor is

displayed.

–

Press the “OK” key.

The error status of the sewing motor is displayed.

–

Press the “OK” key.

The error status message is acknowledged.

–

is displayed. The sewing motor can now be tested at a set speed.

–

Press key “á”or“â” to select the speed

(200 to 4000 r.p.m. in steps of 200 r.p.m.).

–

Press the “OK” key.

The sewing motor is started at the pre-selected speed.

The speed is displayed to the right of the display (3 digits) in 100

r.p.m.

–

Press the “ESC” key.

The sewing motor is stopped and reset to the basic multitest

programme.

4-14

Page 15

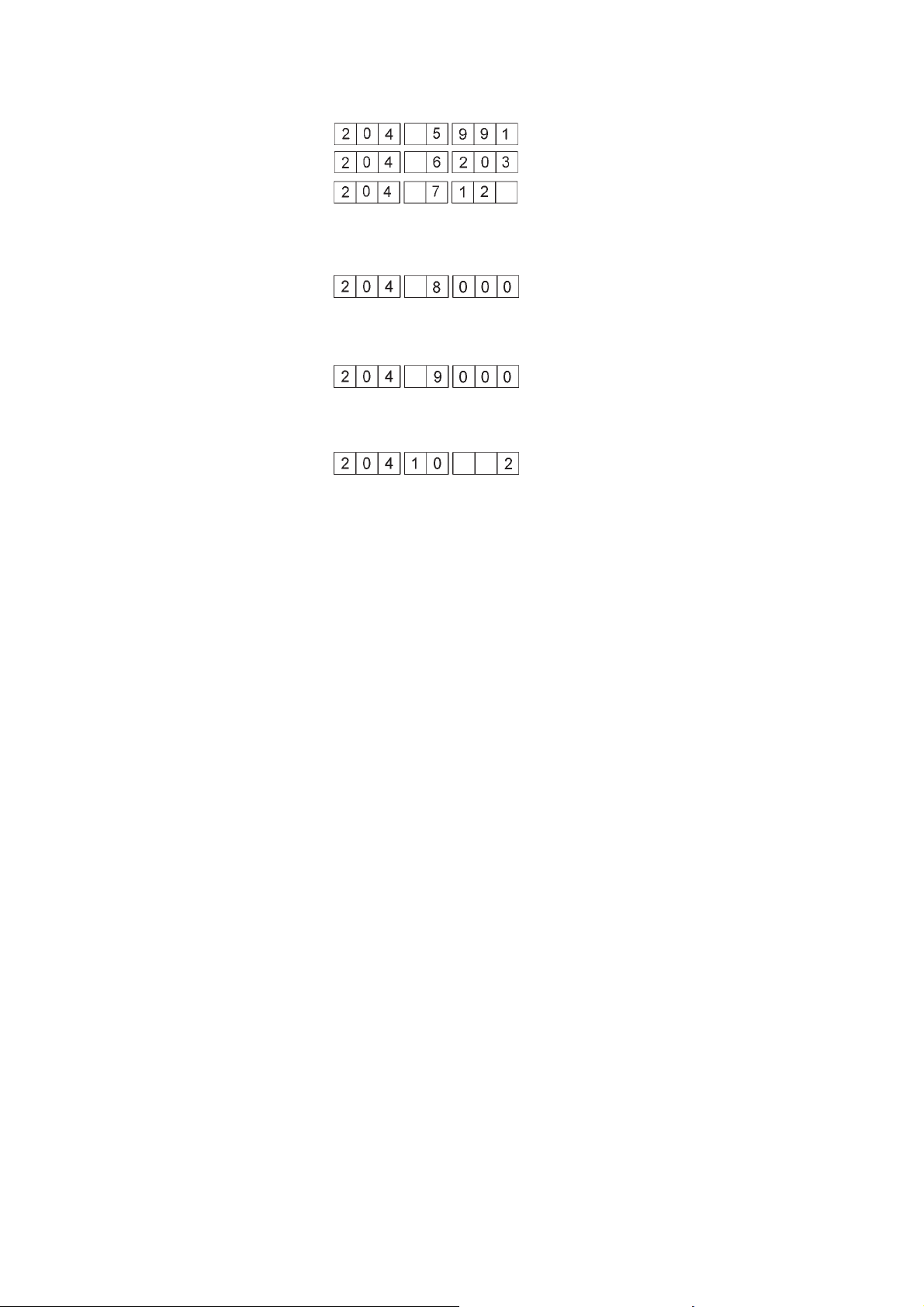

1.6.5 Testing of step motors

This option allows for the testing of the step motors.

CAUTION!

To complete the test programme, the axes must be referenced.

Operating steps

–

Insert the setting template into the X-guide of the sewing machine.

–

Switch to test mode (see chapter 1.6).

–

Select the test programme by means of the “ ” or “ ” key.

–

Press the “OK” key.

The following data is displayed:

–

Press the “OK” key.

The reference run is started.

After completion of the reference run, the three step motor axes

complete 50 test cycles each.

The control checks whether the reference position has been reached

without step losses. If no step loss has occurred, the display reads as

follows:

If step losses have occurred, the display reads as follows:

The figure before “Err” indicates the axis/axes where a step loss

occurred.

Display Axis

1 X axis

2 Y axis

3 X and Y axes

4 Z axis

5 X and Z axes

6 Y and Z axes

7 X and Y and Z axes

–

Press “OK” key.

The system returns to the basic multitest programme.

4-15

Page 16

1.6.6 Testing of transponder reading unit

This programme allows for the testing of the transponder reading unit.

Operating steps

–

Switch to test mode (see chapter 1.6).

–

Select the test programme by means of the “ ” or “ ” key.

–

Press the “OK” key.

The transponder reading unit is initialised.

Upon correct initialising the display changes to:

If initialising could not be carried out, the following error code is

displayed:

–

Press the “OK” key.

The 9-digit software version number of the transponder reading

unit is displayed in three steps. Continue by pressing the “OK” key.

The display switches to:

The control system waits for 20 seconds for a transponder to be read.

–

Insert setting template into the sewing machine and move it across

the aerial within these 20 seconds.

The transponder is read, and the display reads as follows:

If errors occur during the reading of the transponder, the display reads

as follows:

4-16

Page 17

1.6.7 Testing of key bar

1.6.8 Testing of control RAM

With this test programme, the individual keys of the operating panel

can be tested.

Operating steps

–

Switch to test mode (see chapter 1.6).

–

Select the test programme by means of the “ ” or “ ” key.

–

Press the “OK” key.

The test programme is started.

–

Press the individual keys.

Example: “F1" function key

–

Press the “ESC” key.

The system returns to the basic multitest programme.

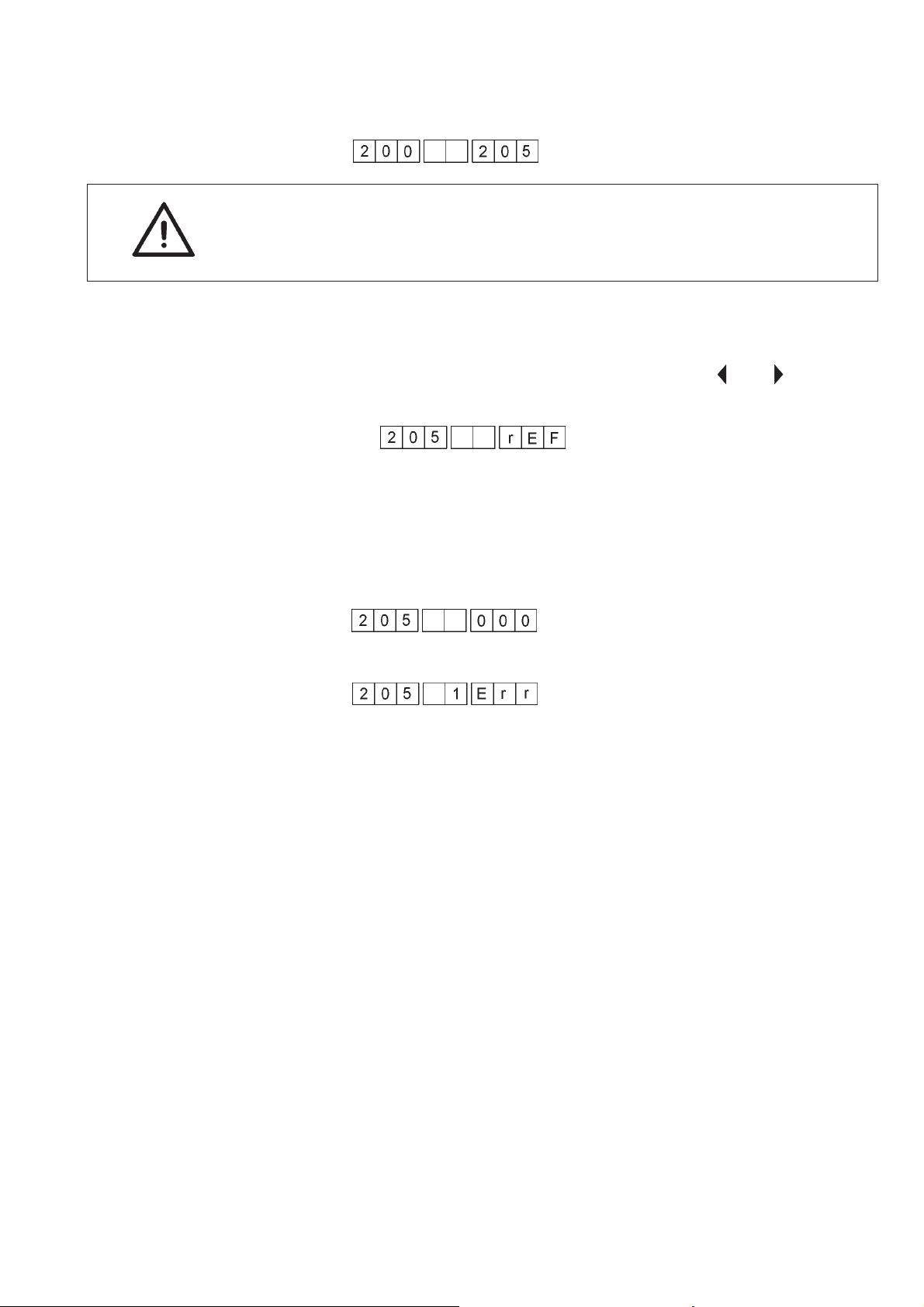

This option allows for the testing of the RAM.

Operating steps

–

Switch to test mode (see chapter 1.6).

–

Select the test programme by means of the “ ” or “ ” key.

–

Press the “OK” key.

The test programme is started.

The display reads as follows:

Display if OK:

Display if error occurred:

–

Press the “OK” key.

The NV-RAM capacity of the control system is displayed.

DAC2b

DAC2c

4-17

Page 18

1.6.9 Testing of control FLASH

This option allows for the testing of the flash memory.

Operating steps

–

Switch to test mode (see chapter 1.6).

–

Select the test programme by means of the “ ” or “ ” key.

–

Press the “OK” key.

The test programme is started.

The display reads as follows:

Display if OK:

Display if error occurred:

1.6.10 Setting of the bobbin thread monitor (optional)

With this test programme, the sensitivity of the remaining thread

monitor (RTM) can be adjusted.

Operating steps

–

Switch to test mode (see chapter 1.6)

–

Select the test programme by means of the “ ” or “ ” key.

–

Press the “OK” key.

The test programme is started.

The display reads as follows:

The remaining thread monitor is initially set to its lowest sensitivity.

When the light barrier is activated, a counter displayed in the last three

digits of the display, is started.

4-18

–

Press the “ESC” key.

The system returns to the basic multitest programme.

Page 19

1.7 Global parameters (F1)

These parameters can be modified before or during every sewing

process.

The new values apply however only after the next start of the entire

process.

–

Press the “F1” key.

The machine switches to ”global parameter" mode.

–

Select the desired submode by means of the “ ” or “ ” key.

Note

Press the “F4” key to reset all “global parameters” to the respective

default values.

List of setting menus

No. Setting

101 Piece counter

102 Setting of sewing motor speed

103 Setting of stitch length

104 Setting of template infeed

105 Setting of initial bartack

106 Setting of final bartack

107 Setting of initial stitch condensation

108 Setting of end stitch condensation

109 Switching on/off of thread monitor

110 Setting of reduced sewing speed

111 Setting of edge cutter speed

112 Setting of suction delay

1.7.1 Piece counter

The piece counter parameter can be reset to “0" by the operator.

Simultaneously, the counter in the main display (daily counter) is reset.

Operating steps

–

Select menu with the “ ” or “ ” key.

–

Press the “OK” key.

–

Press the “F4” key.

The counter is reset to “0".

4-19

Page 20

1.7.2 Sewing motor speed

1.7.3 Stitch length

With this parameter, the sewing motor speed can be adjusted to suit

individual requirements.

Operating steps

–

Select menu with the “ ” or “ ” key.

–

Press the “OK” key.

–

Press key “á”or“â” to select the speed

(200 to 4000 r.p.m in steps of 200 r.p.m.).

–

Press the “OK” key.

The set speed is applied.

Note

The speed settings in the individual transponders are ignored.

If the speed is set to “0", the machine sews according to the speed

settings of the transponders.

With this parameter, the stitch length can be adjusted.

Operating steps

–

Select menu with the “ ” or “ ” key.

–

Press the “OK” key.

–

Set the desired stitch length with the “á”or”â” key

(2.0 to 3.0 mm, step width 0.1 mm).

–

Press the “OK” key.

The set stitch length is transferred to the control system.

Note

The stitch length settings in the individual transponders are ignored.

If the stitch length is set to “0", the machine sews according to the

stitch length settings of the transponders.

4-20

Page 21

1.7.4 Setting of material clamp infeed time

With this parameter, the time during which the X axis is running to feed

a new template into the machine is set.

Operating steps

–

Select menu with the “ ” or “ ” key.

–

Press the “OK” key.

–

Set the desired time with the “á”or“â” key

(0 to 60 seconds).

Example: 30 seconds

–

Press the “OK” key.

The set time is transferred to the control system.

1.7.5 Setting of initial bartack

With this parameter, the initial bartack for the contour to be sewed can

be defined.

The first digit of the display indicates the type of initial bartack, while

the second digit indicates the number of stitches in the tack.

Tack type: 1 = Single tack

2 = Double tack

Number of stitches 0 to 20 stitches

Example: Tack type = 1, number of stitches = 6

Note

If the tack type is set to “0", the machine sews according to the tack

settings of the transponders.

Operating steps

–

Select menu with the “ ” or “ ” key.

–

Press the “OK” key.

–

Set the desired tack type with the “1" or ”2" key.

–

Set the desired number of stitches in the tack with the “á”or“â”

key.

–

Press the “OK” key.

The set values are transferred to the control system.

or

–

Press the “ESC” key.

The changes are cancelled.

4-21

Page 22

1.7.6 Setting of final bartack

With this parameter, the final bartack for the contour to be sewed can

be defined.

The first digit of the display indicates the type of final bartack, while the

second digit indicates the number of stitches in the tack.

Tack type: 1 = Single tack

2 = Double tack

Number of stitches 0 to 20 stitches

Example: Tack type = 1, number of stitches = 6

Note

If the tack type is set to “0", the machine sews according to the tack

settings of the transponders.

Operating steps

–

Select menu with the “ ” or “ ” key.

–

Press the “OK” key.

–

Set the desired tack type with the “1" or ”2" key.

–

Set the desired number of stitches in the tack with the “á”or“â”

key.

–

Press the “OK” key.

The set values are transferred to the control system.

or

–

Press the “ESC” key.

The changes are cancelled.

4-22

Page 23

1.7.7 Setting of initial stitch condensation

With this parameter, the initial stitch condensation for the contour to be

sewed can be defined.

The first digit of the display indicates the number of stitches, while the

last digits in the display indicate the stitch length for the stitch

condensation.

Number of stitches 0 to 20 stitches

Stitch length 0.5 mm to 2.3 mm in 8 steps

Example: Number of stitches = 5, stitch length = 0.5 mm

Note

If the stitch length is set to “0", the machine sews according to the

stitch condensation settings of the transponders.

Operating steps

–

Select menu with the “ ” or “ ” key.

–

Press the “OK” key.

–

Set the desired number of stitches with the “á”or“â” key.

–

Set the desired stitch length with keys “1" to ”8".

–

Press the “OK” key.

The set values are transferred to the control system.

or

–

Press the “ESC” key.

The changes are cancelled.

4-23

Page 24

1.7.8 Setting of end stitch condensation

With this parameter, the end stitch condensation for the contour to be

sewed can be defined.

The first digit of the display indicates the number of stitches, while the

last digits in the display indicate the stitch length for the stitch

condensation.

Number of stitches 0 to 20 stitches

Stitch length 0.5 mm to 2.3 mm, in 8 steps

Example: Number of stitches = 5, stitch length = 0.5 mm

Note

If the stitch number is set to “0", the machine sews according to the

stitch condensation settings of the transponders.

Operating steps

–

Select menu with the “ ” or “ ” key.

–

Press the “OK” key.

–

Set the desired number of stitches with the “á”or“â” key.

–

Set the desired stitch length with keys “1" to ”8".

–

Press the “OK” key.

The set values are transferred to the control system.

or

–

Press the “ESC” key.

The changes are cancelled.

4-24

Page 25

1.7.9 Switching on/off of thread monitor

With this parameter, the thread monitor can be switched on or off

respectively.

Operating steps

–

Select menu with the “ ” or “ ” key.

–

Press the “OK” key.

The selected setting are displayed.

–

Select the desired setting with the “0" or ”1" key.

0 = Thread monitor switched off

1 = Thread monitor switched on.

–

Press the “OK” key.

The set values are transferred to the control system.

or

–

Press the “ESC” key.

The changes are cancelled.

1.7.10 Setting of reduced sewing motor speed

With this parameter, you have the option to adjust the reduced sewing

motor speed.

If the parameter is set to “0", the reduced speed saved in the

transponder is applied.

The speed can be adjusted in steps of 200 r.p.m.

Operating steps

–

Select menu with the “ ” or “ ” key.

–

Press the “OK” key.

The selected settings are displayed.

–

Set the desired reduced speed with the “á”or”â” key.

–

Press the “OK” key.

The set value is saved.

or

–

Press the “ESC” key.

The changes are cancelled.

4-25

Page 26

1.7.11 Setting of edge cutter speed

With this parameter, you have the option to set the speed of the edge

cutter.

If the parameter is set to “0", the edge cutter speed saved in the

transponder is applied.

The speed can be adjusted in steps of 200 r.p.m.

Operating steps

–

Select menu with the “ ” or “ ” key.

–

Press the “OK” key.

The selected settings are displayed.

–

Set the desired speed with the “á”or“â” key.

–

Press the “OK” key.

The set value is saved.

or

–

Press the “ESC” key.

The changes are cancelled.

1.7.12 Setting of suction delay

With this parameter, you have the option to adjust the delay until the

suction unit is switched on.

If the parameter is set to “0", the switching delay saved in the

transponder is applied.

The switching delay is set in % values of the material clamp seam

length.

Operating steps

–

Select menu with the “ ” or “ ” key.

–

Press the “OK” key.

The selected setting are displayed.

–

Set the desired switch-on delay with the “á”or“â” key.

–

Press the “OK” key.

The set value is saved.

or

Press the “ESC” key.

The changes are cancelled.

4-26

Page 27

1.8 Special functions for the repair of a thread breakage

After a thread breakage has occurred, the sewing machine must be

switched off, re-threaded and then switched on again.

To insert the needle thread and the bobbin thread under the thread

cutter hook after threading, proceed as follows:

–

Press the “1" key.

The display reads as follows:

The thread cutter is activated for one second. Within this time, both

threads can be placed under the hook.

After one second, the basic display appears.

1.9 Thread breakage in seam (needle thread)

If a thread breakage occurs in the seam, the sewing process is

interrupted and an error / warning message is displayed.

Note

The “Err” display is blinking.

(Error group 0, error number 1 = needle thread broken)

4-27

Page 28

1.10 Displays and error messages

If an error or a warning occurs, a respective message is displayed at

the key bar.

The various errors are displayed in the form of 5-digit codes. The “Err”

display is blinking to clearly indicate that an error occurred.

1.10.1 Error messages

Group Number Description

0 Thread breakage

1 Thread monitor error

5 Step motor error

1 Needle thread

2 Bobbin thread

1 Bobbin thread is used up.

Re-wind bobbin

2 Needle thread is broken

Re-thread needle thread

1 Z axis referencing error.

The Z motor did not reach its reference point

within 20 seconds.

2 Y axis referencing error.

The Y motor did not reach its reference point

within 20 seconds.

3 YZ referencing error.

The Y motor and/or the Z motor did not reach

its/their reference point within 20 seconds.

4 X axis referencing error.

The X motor did not reach its reference

position (gauge pin) within 20 seconds upon

setting of a position (301, 302) or upon testing

of the step motor axes (2059).

8 XY axes system positioning error.

The XY system did not reach its target position

within 5 seconds upon positioning.

16 Z axis positioning error.

The Z axis did not reach its target position

within 5 seconds upon positioning.

24 Positioning error.

The XYZ system did not reach its target

position within 5 seconds upon positioning.

50 Step motor high-level error.

Step motor high-levels indicate a hardware

error.

4-28

Page 29

Group Number Description

6 Sewing motor error

1 Poor connection

2 Communication interrupted

3 Illegal command

4 Command buffer full

5 Protocol error

6 Timeout

7 Sending register 422

8 NAK

9 Drive not ready

10 UART not ready

11 Hardware error

50 Sewing motor timeout upon thread cutting

process

7 Internal errors

1 Contour data memory full.

The contour requires more than 1600 stitches.

2 Error upon cycle calculation.

Incorrect direction of rotation in the cycle, or

calculation overflow.

3 Error, NV-RAM data lost.

Default values are activated, reference

positions must be set again.

Call menus 301, 302 and 303.

4 Power fail input is activated.

Insufficient supply voltage to the sewing

machine.

10 Transponder errors

0 Zero-point gauge pin recognised, but

transponders could not be read.

1 Communication timeout Transponder reading

unit.

Communication with the transponder module is

disrupted. The module does not respond.

4 Transponder content is damaged. Incorrect

transponder checksum.

8 Communication error with the transponder

reading unit.

Transfer is disrupted. Incorrect transfer

checksum.

1.11 Loading of the programme to the control system

The DAK 2A/B control system is equipped with a flash memory. It is

thus possible to transfer the software data via a boot box or a PC to the

control system.

4-29

Page 30

Appendix

A.1 Inputs and Outputs

Input Description

S1 Reference switch Z axis

S4 Reference switch Y axis

S5 Reference switch X axis

S8 Needle thread monitor

Output Description

Y1 Blower (edge cutter on)

Y2 Release thread tension

Y3 Thread cutter on

Y4 Vacuum suction on

Y5 Thread clamp on (thread scissors)

Y6 Release thread clamp (thread scissors)

4-30

Page 31

2. Dacs739 software

2.1 Introduction

The Dacs739 software is a user-friendly tool to create your own sewing

templates for the 739-23 sewing machine.

A two-dimensional graphics editor allows for the design or modification

of seam contours by mouse-click or by numerical entries.

The software package includes a comprehensive help function.

Additional functions:

The programme carries out plausibility checks of all entries.

•

Calculation of the ideal material clamp contour after completion of

•

the seam contour by the programme.

Calculation of the fullness contour

•

The material clamp contour can be printed out on a scale of 1:1.

•

The seam contour, material clamp contour and fullness contour can

•

be written to a transponder by means of a read/write device.

All data of the material clamps can be archived, reread and

•

modified.

2.2 System requirements

Dacs739 requires the following hardware and software components:

PC with 486 or Pentium processor

•

MS Windows 95, 98 or NT version 3.5.1 or later

•

Minimum 16 MB RAM

•

CD-ROM drive or 3.5 “ floppy disk drive

•

10 MB free memory on hard disk

•

Free serial port

•

VGA graphic card, min. 600 x 800 pixels, 256 colours

•

Mouse

•

Windows-compatible printer including driver

•

4-31

Page 32

2.3 Installation of Dacs739

–

Terminate all programmes in Windows and deactivate all virus scan

programmes.

–

Place the Dacs739 CD into your CD-ROM drive

or

insert disk no. 1 into your 3.5" floppy drive.

–

Follow the instructions of your platform:

For Windows NT 3.5.1, select the “Run” command from the “File”

menu of the programme manager.

For Windows 95, 98 or Windows NT 4.0, select the “Run” command

from the start menu.

–

Enter d:\setup.exe (whereby d: is your CD-ROM drive)

or

enter a:\setup.exe and click “OK”.

–

The “Welcome” screen is displayed. Follow the instructions on the

screen.

–

Click “Next”.

Confirm the default values for target drive and folder displayed

under “Target folder”.

Click “Browse” or enter a different folder and/or drive.

2.4 Starting of Dacs739

–

Click “Next”.

Confirm the programme folder displayed under “Programme

folder”,

or

enter a different folder.

–

Click “Next” to start the installation.

–

When asked to do so, insert the next disk into the floppy disk drive.

–

Follow the instructions for your platform:

Open the programme group “Dacs739" in the programme manager

of Windows NT 3.5.1 and double-click the ”Dacs739" programme

icon.

In Windows 95, 98 or Windows NT 4.0, click the start menu and

select “Programmes > Dacs739> Dacs739".

4-32

Page 33

2.5 If you need help ...

Dacs739 includes a comprehensive online help facility. It can be called

at any time by pressing “F1”.

Contents of help facility

The help topics are divided into five categories. Each category is

represented by a button in the help contents window.

The following table provides an overview of the information available in

the individual categories.

Button Topics

Introduction Reference to further help

Operation List of the

programme functions

Useful hints

Dialogs

Menues Description of the menu commands

Context-related help

Use the context-related help to call up the relevant help texts

for a specific Dacs739 option.

If the “Context help” button is selected from the toolbar, the mouse

pointer changes to an arrow with a question mark. Click anywhere in

the Dacs739 window, e.g. a button in the toolbar.

The help topic corresponding to the clicked object is displayed.

4-33

Page 34

2.6 Dacs739 tutorial

2.6.1 Creation of a seam contour

“Standard" toolbar

This practical tutorial allows you to familiarize yourself with the

Dacs739 software within a very short time. It covers all the basic steps

that must be carried out for the creation and archiving of your own

individual contours.

The tutorial includes additional information on any given topic and

indicates, where the respective chapter can be found in the online help

facility of Dacs739.

Dacs739 support multi-tasking so that several documents can be

processed simultaneously.

–

Start the Dacs739 software

(see chapter 2.4).

The programme window is opened.

–

Select “File > New”.

The document window is divided into two parts.

To the left, a tree diagram is displayed, showing the sections of the

seam contour. To the right, a CAD design window for the seam contour

to be drawn is displayed.

Below the menu bar, the “standard” toolbar is displayed, while the

“drawing” toolbar is located to the right. At the bottom of the screen,

the “status bar” is displayed.

Menu bar “Drawing” toolbar

Tree diagram

Entry field for the

seam contour

Zero point P0

Origin of the

system of coordinates

Status bar

The zero point P0 is the origin of the coordinates system. It is always

located in the bottom left corner of the CAD window. The coordinates

run from this point, increasing upwards and to the right.

4-34

Page 35

Additional information

For more information, click the object you would like to know more

about in the diagram.

Import of background pictures

Depending on the application, (waistband extension or flap), a

background picture can be imported.

This background picture is very helpful for the entry of the seam

contour.

–

Open “File > HPGL import”.

–

Select a file:

flap_pattern.plt for the entry of a flap pattern

bottom seam start/end

or

waist-band_pattern.plt for the entry of a waistband extension.

4-35

Page 36

Entry of the seam contour

The following exercise introduces you to the entry of a seam contour

for a curved flap.

The seam contour is entered as a line, i.e. the starting point of a

segment corresponds to the end point of the preceding segment.

When a segment is deleted, its starting point becomes the starting

point of the following segment.

When a segment is inserted, the next existing segment is divided into

two segments of straight lines.

The segment type (straight, arc of circle) can be modified at a later

stage.

–

Select “Tools > Settings".

–

Activate the “Direction” option in the dialog.

–

Activate the “Grid” option.

–

Enter 5.0 mm for “Width” and “Height” respectively.

4-36

Page 37

Drawing of first seam segment

–

In the toolbar, select the

“Drawing” icon for lines.

–

Drag the mouse pointer to the first coordinate for the starting point

of the flap (X = 50/ Y = 50).

The coordinates are displayed in the status bar.

–

Click the left mouse button.

The starting coordinate is entered.

–

Drag the mouse pointer vertically upwards to pointX=50/Y=85.

–

Click the left mouse button.

The ending coordinate is entered.

Seam segment properties

–

Click the bottom line (last drawn line) in the tree structure.

Last drawn line

–

Click the right mouse button (or double-click the left mouse button)

and activate the “Properties” menu.

If necessary, correct the coordinates in the “Line” menu.

X /Y values for starting point

X /Y values for end point

4-37

Page 38

–

Click the “Style” menu.

–

Select the listbox for the type of line and select “Continuous line”.

Note

Use a continuous line for seam segments to be sewed and a “Dotted

line” for seam segments that are not to be sewed.

–

Click the “Sewing options” menu.

–

Activate the “Segment is sewed” option in the dialog.

Note

In the “Sewing options” dialog, a reduced sewing speed or a reduced

stitch length can be assigned to selected seam segments (see also

“Seam properties”, page 44).

The “Length adjustment” option is currently not activated.

–

Press the “Enter” key.

The settings are saved.

4-38

Page 39

Drawing of second seam segment (curve)

–

Select the

icon for curve in the “Drawing” toolbar.

–

Drag the mouse pointer to the end point of the preceding line (X =

50/ Y = 85).

–

Click the left mouse button.

The starting coordinate is entered.

–

Drag the mouse pointer to the upper right point

X=60/Y=95.

–

Click the left mouse button.

The ending coordinate is entered.

–

Drag the mouse to the left to point X = 58/ Y = 95. The radius of the

circle is generated.

–

Click the left mouse button.

The ending coordinate is entered.

The arc is defined by the three points P1, P2 and P3.

The radius of the arc can be modified by means of points M and

P3.

Note

To delete the last drawn segment, press the “Del” key.

4-39

Page 40

Click

Arc

Seam segment properties

–

In the tree structure, click the arc.

–

Click the right mouse button (or double-click the left mouse button)

and activate the “Properties” menu.

If necessary, correct the coordinates in the “Arc” menu.

–

Check the settings for “Style” and “Sewing options”.

4-40

Page 41

Drawing of next seam segment

–

Drag the mouse pointer to the end point of the arc

(X = 60/ Y = 95).

–

Click the left mouse button.

The starting coordinate is entered.

–

Drag the mouse pointer to the upper right point

X = 95/ Y = 102.

–

Click the left mouse button.

The ending coordinate is entered.

–

Drag the mouse to the left to the point X = 78/ Y = 95. The radius of

the circle is generated.

–

Click the left mouse button.

The ending coordinate is entered.

–

Click the right mouse button (or double-click the left mouse button)

and activate the “Properties” menu.

If necessary, correct the coordinates in the “Arc” menu.

–

Check the settings for “Style” and “Sewing options”.

Seam segment for the curve at the centre

–

Enter the coordinates for the curve at the centre of the flap as

described above.

Starting point = X = 95/Y=102

End point = X = 105/Y=102

Radius = X = 100/Y=104

–

Check the arc properties in the “Properties” dialog.

4-41

Page 42

Arcs 4 and 5

–

Enter the coordinates for the next two arcs of the flap.

Arc 4

Starting point X = 105/Y=102

End point X = 140/Y=95

Radius X = 125/Y=95

Arc 5

Starting point X = 140/Y=95

End point X = 150/Y=85

Radius X = 150/ Y = 87.5

Arc 4

Arc 5

4-42

Page 43

Drawing of last seam segment

–

Select the

icon for line in the “Drawing” toolbar.

–

Enter the coordinates for the last line of the flap.

Line 6

Starting point X = 150/Y=85

End point X = 150/Y=50

The drawing of the flap is completed. All seam segments are

individually displayed in the tree structure. Every individual seam

segment can be modified at any later stage.

Line 6

4-43

Page 44

Seam properties

–

In the tree structure, click “Seam”.

–

Click the right mouse button.

The “Seam properties” dialog is displayed.

–

Enter the desired values for the seam.

The following values are available:

Stitch length: 1.0 to 4.0 mm.

Suction delay: 0% to 93 %, in steps

Speed: 200 to 4000 r.p.m.

Reduced speed: 200 to 4000 r.p.m.

Limited speed: 200 to 4000 r.p.m.

–

Click “Seam start”.

–

Activate a “Stitch condensation” with a stitch length of

0.5 mm and 6 stitches.

The following options are available:

Standard = no tack / no stitch condensation

•

Tack/double tack 1 to 15 stitches

•

Stitch condensation 0.5 to 2.25 mm, 1 to 15 stitches

•

–

Click “Seam end”.

–

Activate a “Stitch condensation” with a stitch length of

0.5 mm and 6 stitches.

4-44

Page 45

Generation of mirrored seam segments or flaps

For symmetrical seam courses, you have the option to mirror individual

seam segments to a centred line. The second half of a symmetrical

seam curve can thus be generated with ease.

If a diagonal flap has been entered, the entire flap can be mirrored.

Calculation of seam template

The seam template is calculated automatically by the system. You

have however the option to subsequently modify the template.

–

Select “Objects > Calculate seam template” from the menu bar.

The template is calculated and displayed in the CAD window.

The tree structure is extended by the individual segments of the

template.

Note

All template segments can be individually modified in the properties

dialog.

4-45

Page 46

Calculation of fullness contour

The fullness contour is also calculated automatically by the system.

You have the option to subsequently modify the template.

Select “Objects > Calculate fullness template” from the menu bar.

The template is calculated and displayed in the CAD window.

The individual segments of the pattern are added to the tree structure.

File properties

For every document, you have the option to save additional

information. This simplifies the file management.

–

Select “File > File properties”.

–

Enter your details in the available fields.

Saving of seam contour

–

Select “File>Save as”.

The “DACS739\Documents” folder is opened automatically.

–

Enter a name for your seam contour in the “File name” field.

(Example: Seam contour 1)

–

Click the “Save” button.

4-46

Page 47

Data transfer to the transponder

Seam contours, material clamp contours and fullness contours can be

transferred individually to the transponder in the “Material clamp zero

point” gauge. The “Material clamp zero point” gauge is included in the

delivery.

You have thus the option to transfer individual contours to the stitching

plate, where they can be controlled and processed.

–

Connect the transponder to your PC

see operating instructions of the transponder).

–

Place the “Material clamp zero point” gauge with the respective

transponder onto the transponder device.

–

Select “File > Transponder”.

–

According to your needs, select:

Transfer seam data, or

Transfer template data, or

Transfer fullness data.

The selected data is transferred to the transponder in the gauge.

4-47

Page 48

Sample flaps and waistband extensions

In the “Documents” inventory of Dacs software, various sample files for

flaps and waistband extensions are saved.

These samples can be modified.

Caution!

Prior to modification, save the sample files under a different name.

Congratulations!

You have reached the end of this tutorial. Please remember that more

information on all topics is available from the online help.

The further procedure for the creation of material clamps is described

in

“Part 5: Instructions for material clamp manufacture class 739-23".

4-48

Loading...

Loading...