Page 1

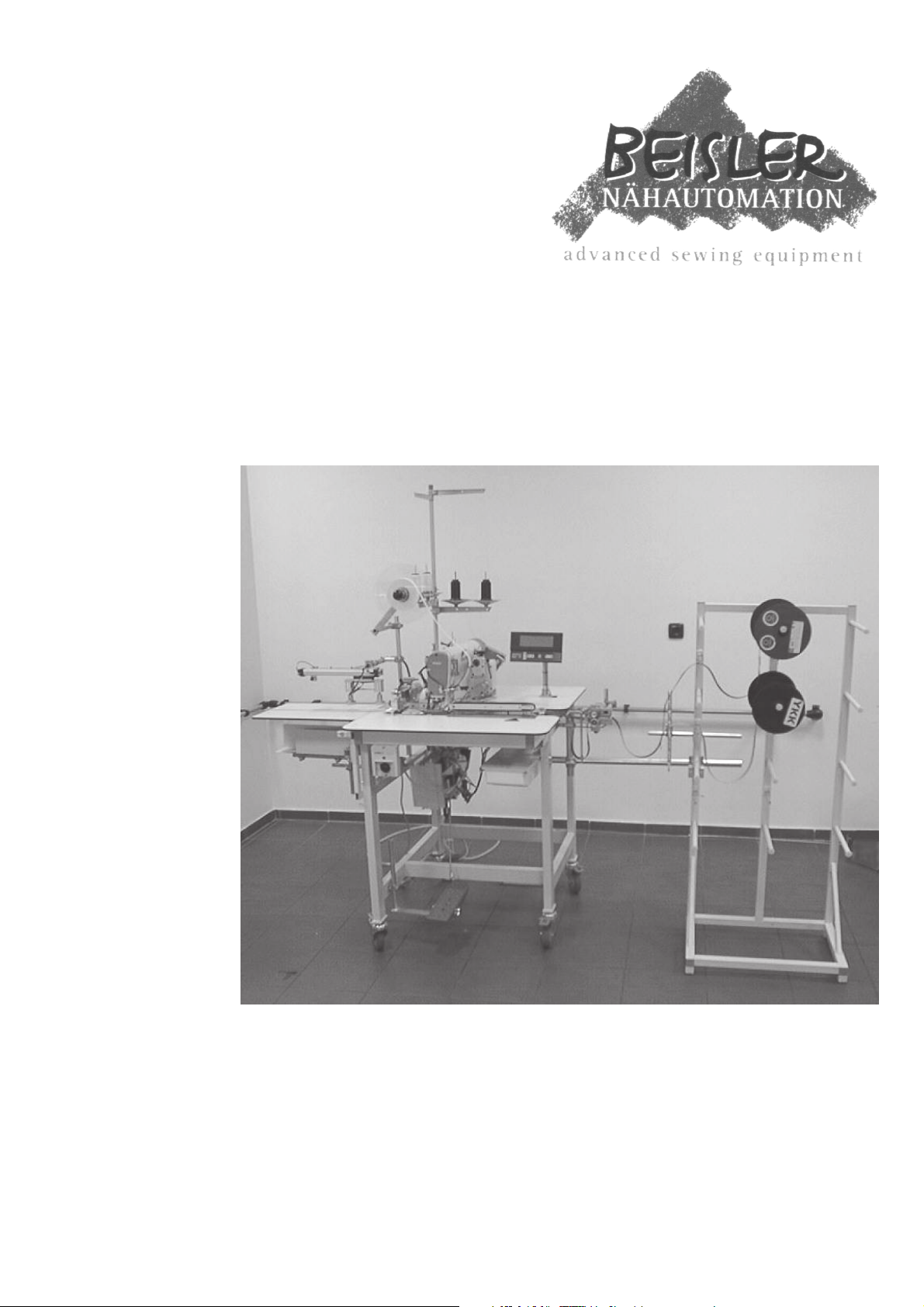

Fly Piece Unit

Series 1710/2

Operating Instructions

© 1999 Beisler GmbH, Hösbach

Version 2.0, 22.9.1999 – GB

Page 2

The Operating Instructions on hand contain the following parts:

Part 1: Operators Manual (Pages 1-xx)

this is addressed to the operator of the machine, that is the

person who works with and at the machine.

Part 2: Mechanics Manual (Pages 2-xx)

this is addressed to qualified technical staff and is used for the

putting into operation, set-up, troubleshooting and maintenance.

Please obey all rules and regulations concerning safety and accident

prevention contained in this manual.

The machine described in this manual is subject to a permanent technical

development. Technical changes without prior notice are reserved.

Page 3

Part 1 Operating instructions

Hint

These operating instructions contain all information required for the operation

of the machine. It adresses to the operator of the machine, that is the person

that works at and with the machine. Please obtain all rules and regulations.

Contents Page

Part 1 Operating instructions ........................................................................................1-1

1 Security advice and warning hints .................................................................... 1-3

1.1 Classification .........................................................................................................1-3

1.2 General security advice and warning hints .............................................................1-3

1.3 Introduction ............................................................................................................ 1-4

1.4 Target groups of the manual...................................................................................1-4

1.5 Authorized person ................................................................................................. 1-4

1.6 Contents of this manual .........................................................................................1-5

1.7 Range of validity .................................................................................................... 1-5

1.8 Copyright ...............................................................................................................1-5

1.9 Additional regulations ............................................................................................1-6

2 Preliminary remarks ...........................................................................................1-7

2.1 Limitation of liability ...............................................................................................1-7

2.2 Guarantee regulations ...........................................................................................1-7

2.3 Use as agreed ....................................................................................................... 1-8

2.4 Description of the machine .................................................................................... 1-8

2.5 Main parts of the machine .....................................................................................1-9

2.6 Technical data ....................................................................................................... 1-9

3 Switch on/off, Emergency-Stop, Restart ......................................................... 1-10

3.1 Switch on ............................................................................................................ 1-10

3.2 Switch off............................................................................................................. 1-10

3.3 Emergency-Stop using the main switch ............................................................... 1-10

3.4 Restart after Emergency-Stop ............................................................................. 1-11

3.5 Adjust compressed air pressure .......................................................................... 1-11

4 Operation of the sewing head ......................................................................... 1-11

5 Components of the machine ............................................................................1-12

5.1 Devices for the material supply ............................................................................ 1-12

5.2 Pull-off device ...................................................................................................... 1-13

5.3 Insertion area ....................................................................................................... 1-13

5.4 Operation device ..................................................................................................1-14

5.4.1 Components of the operation device .................................................................... 1-14

5.4.2 Explanation of the display .................................................................................... 1-14

5.5 Sewing head ........................................................................................................ 1-15

5.6 Cutting device ...................................................................................................... 1-15

5.7 Stacking device ................................................................................................... 1-16

1-1

Page 4

6 Operation of the Machine ................................................................................ 1-17

6.1 Production sequence ........................................................................................... 1-17

6.2 Alignment of the Fly Piece...................................................................................1-17

6.3 Program control ................................................................................................... 1-18

6.3.1 Available sewing programs .................................................................................. 1-18

6.3.2 Select a sewing program ..................................................................................... 1-18

6.4 Additional settings at the operation device ........................................................... 1-18

6.4.1 Select operation language ................................................................................... 1-19

6.4.2 Adjust display contrast ........................................................................................ 1-19

7 Cleaning and Maintenance .............................................................................. 1-20

7.1 Cleaning of the machine ...................................................................................... 1-20

7.2 Maintenance ........................................................................................................1-20

7.2.1 Check oil level in the sewing head ....................................................................... 1-20

7.2.2 Empty water separator ......................................................................................... 1-20

7.3 Troubleshooting hints ...........................................................................................1-20

1-2

Page 5

1 Security advice and warning hints

1.1 Classification

Three different types of hints are used in this manual, which are indicated with

different symbols and signalling words:

DANGER

This indicates a possibly dangerous situation or action, which may cause

injuries to persons or severe damage to the machine.

ATTENTION

This indicates a situation or action, which may cause damage to the machine.

Hint

This indicates hints for a better use and other helpful information or hints.

Please obey all rules and regulations.

1.2 General security advice and warning hints

Danger

Danger might arise for persons, things and environment by inappropriate

operation of this machine. Installation and maintenance duties may only be

carried out by authorized staff.

Danger

Danger of injuries in the range of the sewing head! Don’t grasp into the affected

area of the needle during the sewing process!

Danger

Before any operations at or with the machine (putting into operation, operation,

maintenance, repair, etc.) the person carrying out has to read and understand

this manual with each appendix completely.

Danger

Before carrying out maintenance or repair duties, the mains supply must be

cut off. Additionally pressure must be released from the pneumatical system.

Attention

The machine will be destroyed by a connection to a wrong mains voltage! See

the section ‘Technical data’ before connecting the power supply.

1-3

Page 6

1.3 Introduction

The manual on hand is divided into two main sections:

• the Operators Manual with all information required for the operation and

daily cleaning and maintenance routines of the machine;

• the Mechanics Manual with all further maintenance and repair duties and a

instruction for the programming of sewing programs.

1.4 Target groups of the manual

The two sections of the manual are adressed to:

Operators Manual to the operator of the machine which is the person

that works at and with the machine;

Mechanics Manual to qualified staff which is trained to estimate the

working duties and recognize possible danger at an

early time.

ATTENTION

All actions at and/or with the machine may only be executed by authorized

persons, who have read and understood the corresponding parts of this

manual.

Especially the following actions are subject to this regulation:

• operation including preparation, troubleshooting during production, cleaning, care

• Servicing (maintenance, inspection, repair)

• Transportation

ATTENTION

A specialist in accordance to IEC 364 and DIN EN 60204-1 is regarded as

qualified staff.

1.5 Authorized person

DANGER

There is danger to human beings, things and environment through inandequate

operation of this machine. Installation and maintenance duties may only be

carried out by authorized staff.

Persons are regarded as authorized, who are able to recognize possible

danger and judge the assigned duties from their technical education and

experience.

1-4

Operator of the machine

Persons are regarded as authorized, who were trained in the operation of this

machine and have read and understood the first part of this manual completely.

Staff for installation, preparation, programming and maintenance

Persons are regarded as authorized, who were trained in all aspects of the

machine and have read and understood the complete manual on hand.

Page 7

1.6 Contents of this manual

The Operating Instructions for the ‘Fly Piece Unit, Series 1710/2’ contains the

following parts:

1. Operators Manual

2. Mechanics Manual

3. Electrical wiring plans

4. Parts list

5. Operating Manual of the sewing head

Please check the documents delivered with the machine for completeness.

1.7 Range of validity

This operating manual is valid for machines manufactured by Beisler named

‘Fly Piece Unit, Series 1710/2’.

This operating manual is not valid for the sewing head applied in the machine.

Please refer to the operating manual of the sewing head delivered with the

machine, for which we don’t take any liability.

Further security advice (verbal and written) for this machine or the components

will not be repealed by this manual.

1.8 Copyright

© 1999 Beisler GmbH, Hösbach

Fly Piece Unit

The ‘Fly Piece Unit, Series 1710/2’ and this operating manual with all parts are

protected on copyright. Manufacture without license will be prosecuted by law.

All rights reserved on this operating manual, including reproduction in any

thinkable way, either by copying, printing, on any data recording media or in

translated form. Reproduction of this operating manual - even in extracts - only

with written approval by Beisler GmbH.

This operating manual contains a description of the product, but no promise of

certain qualities or results of use. The operating manual has been proved

before delivery. The Beisler GmbH takes the liability, that this operating manual if free of errors reducing its value for the estimated use. The editors don’t

take liability for consecuting damage arising through application of the operating manual. We are always thankful for hints and ideas.

The technical standard of the common delivery of product and operating

manual by the Beisler GmbH is decisive, if not other information is given.

Technical changes without prior notice are reserved, previous operating manuals loose validity.

The general conditions of sales and delivery of the Beisler GmbH are valid.

Do you have questions or problems with installation or putting into operation?

Don’t hesitate to call us.

Beisler GmbH

Frohnradstr. 10 - D-63768 Hösbach

Tel: (+49) 6021 / 50 19 0

Fax: (+49) 6021 / 50 19 10

1-5

Page 8

1.9 Additional regulations

This manual must be available at the machines location at any time.

The operator has to assure that only authorized persons work at and with the

machine.

The operator is obliged to check the machine for visible damage and faults at

least once per shift. Visible changes must be reported to the corresponding

official immediately after discovery.

The company using this machine has to assure that the machine is always

operated in faultless condition. Security installation may not be dismounted or

put out of function.

If security installation must be dismounted for preparation, repair or maintenance of the machine, they must be mounted immediately after the duties

have been terminated.

Unauthorized changes to the machine exclude liability of the manufacturer for

damages.

1-6

Page 9

2 Preliminary remarks

2.1 Limitation of liability

We guarantee the faultless functioning of our product in accordance with our

advertising, the product information edited by the Beisler GmbH and this

manual. Further product-features are not guaranteed. We take no liability for

the economy and faultless function if the product is used for a different purpose then that described in the chapter „Use as agreed“.

Compensation claims are generally impossible, except if intention or culpable

negligence by the Beisler GmbH is proved, or if assured product-features are

not provided. If this machine is used in environments, for which it is not suited

or which do not represent the technical standard, we are not responsible for

the consequences.

We don’t accept responsibility for damages at installations and systems in the

surroundings of this machine, which are caused by a fault of the product or an

error in this manual.

We are not responsible for the violation of patents and/or other rights of third

persons outside the Federal Republic of Germany.

We are not liable for damages, which result from improper operations according to this manual. We are not liable for missed profit and for consecuting

damages due to non-regardance of security advices and warning hints. We

don’t accept liability for damages which resulted from the use of tools and

accessoires which are not delivered and/or approved by the Beisler GmbH.

The products of the Beisler GmbH are designed for a long life. They represent

the standard of technique and science and were checked on all functions

individually before delivery. The electrical construction corresponds to the

current norms and regulations, particularly DIN 5713 / VDE 0113. Beisler

GmbH is doing product and market research for the further development and

permanent improvement of their products. In the case of faults and/or technical

trouble please contact the Beisler GmbH service staff. We assure that suitable

measures will be done immediately.

The Beisler GmbH guarantee regualtions are valid, which we will send to you

on demand.

2.2 Guarantee regulations

We guarantee the fault-free functioning of the ‘Fly Piece Unit, Series 1710/2’

according to this operating manual except the tools for a time range of six

months after delivery. If the machine is used in double- or triple-shift operation,

the term of guarantee is reduced to three or two months.

The term of guarantee starts with the date of delivery to the customer, independant from the time of putting into operation. Guarantee will be spoiled, if the

machine isn’t installed and operated according to this operating manual and

the regulations given by the Beisler GmbH staff. A cost-free repair is only

possible, if all regulations considering storage, transportation and putting into

operations have been obeyed.

Customers and third persons may only mesh with the machine after getting a

written approval by the Beisler GmbH. The Beisler GmbH takes no responsibility for injuries and damages arising from non-obeyance of this stipulation. All

warranty will be spoiled in this case.

The Beisler GmbH takes no responsibility for faults of the machine as consequence of defective or functional faulty equipment in the surrounding of the

machine or by the use of accessoires, which were not delivered by the Beisler

GmbH.

The general conditions of sale and delivery of the Beisler GmbH are valid.

1-7

Page 10

2.3 Use as agreed

The ‘Fly Piece Unit, Series 1710/2’ has been developed for the sewing of the

zipper onto the left-handed fly piece.

DANGER

This machine has been developed and build for a certain purpose. Adaptions

may influence security equipments negatively. We recommend to contact our

service staff in such a case.

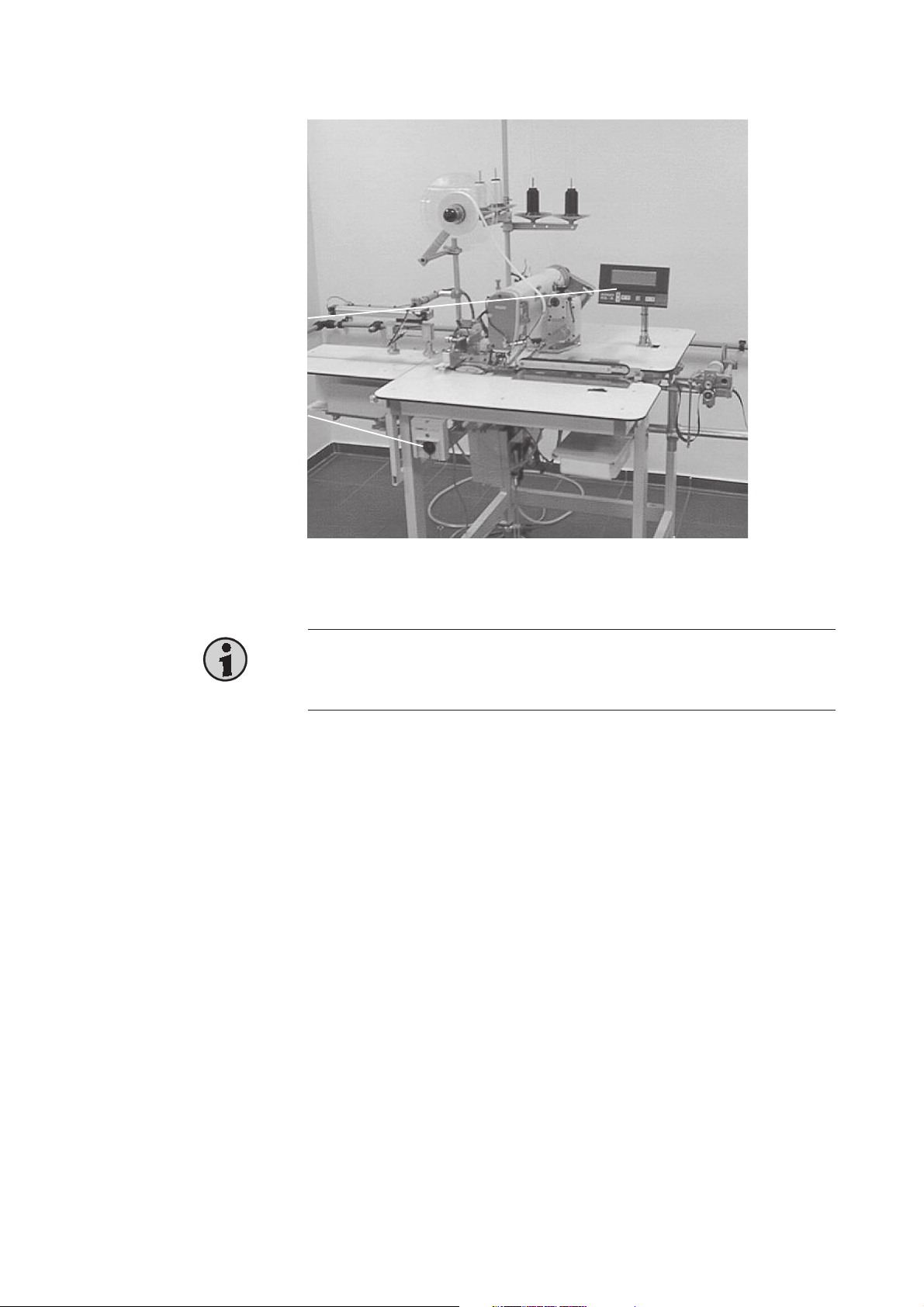

2.4 Description of the machine

The ‘Fly Piece Unit, Series 1710/2’ allows the rational sewing of the zipper

onto the left-handed fly piece. The machine is equipped with several guiding

facilities for the zipper and a sewing head.

All components of the machine are mounted on a base frame made of square

steel pipes and controlled by an innovative micro-processor system.

Machine operation is achieved with an operation device. Here you can open

several control programs, define new programs and check all machine components individually for maintenance and repair duties.

1-8

Page 11

2.5 Main parts of the machine

1

2

3

4

5

6

7

8

9

1 Spool rack

2 Supply roll back-up tape

3 Sewing head

4 Stacker stamp

5 Sliding table

6 Magacine

7 Main switch

8 Motor

9 Foot pedal

10 Operation device

11 Supply roll zipper

12 Zipper

13 Zipper supply device

14 Insertion area with transportation belt and start button

15 Compressed air supply unit

10

11

12

13

14

15

Further information on the components of the machine are contained in the

coming chapters.

2.6 Technical data

Dimensions (LxWxH) 00 x 00 x 00 mm

Table height 00 mm (adjustable)

Weight 00 kg

Electrical connection 220 V AC

Compressed air connection min. 5 bar

Power consumption 00 kW

Compr. air consumption est. 00 NL/part

1-9

Page 12

3 Switch on/off, Emergency-Stop, Restart

1

2

3.1 Switch on

Hint

The machine must be connected to the power and compressed air supply

before it can be switched on.

The main switch (2) is located at the machine front beneath the working table.

Turn the main switch (2) clockwise until it engages. The grip of the switch

points on the marking „1 – ON“. The display of the operation device (1) shows

the main screen.

3.2 Switch off

Turn the main switch (2) counter clockwise until it is released. The grip of the

switch points on the marking „0 – OFF“.

3.3 Emergency-Stop using the main switch

The main switch (2) is located at the machine front beneath the working table.

Turn the main switch counter clockwise, until it is released. All movements of

the machine will be stopped immediately, the machine will be free of electrical

power instantly.

1-10

Page 13

3.4 Restart after Emergency-Stop

ATTENTION

Before you restart the machine you should remove the reason for the

Emergency-Stop. Contact the responsible technician in any doubtful case.

The machine may only be restarted after the reason for the Emergency-Stop

has been removed.

Switch on the machine using the main switch. The current program number

will be imaged in the display of the operation device. The machine is ready to

use.

3.5 Adjust compressed air pressure

The machine needs an air pressure between 5 and 6 bar. This is adjusted at

the air supply unit:

1

2

3

4

5

1 Air connecting hose

2 Control to adjust the air pressure

3 Pressure gauge

4 Collector for condensing water

5 Release valve for condensed water

Check the air pressure at the pressure gauge (3). If the indicated value differs

from 6 bar, adjust the pressure by turning the black control (2).

4 Operation of the sewing head

The operation of the sewing head is explained in the separate manual of the

sewing head, which is part of the machine’s documentation.

Please obtain all rules and regulations.

1-11

Page 14

5 Components of the machine

The machine contains several components, which are arranged according to

their function:

1. Spool rack, supply roll rack of the back-up tape and supply roll rack for

zippers.

2. Zipper supply device for the tension-free insertion of the zipper into the

machine.

3. Insertion area with stop bar, transportation belt, cover plate and start

button.

4. Operation device with keys and display.

5. Sewing head with photo cell for the sewing of zipper, fly piece and back-up

tape.

6. Cutting device with photo cell for the cutting of the fly piece.

7. Stacking device with stacker stamps, sliding table and magacine.

5.1 Devices for the material supply

1

2

3

This machine is equipped with three devices for the supply of the required

materials:

• the spool rack (1), where the spools with the threads can be fixed;

• the roll rack for the back-up tape (2), located above the sewing head;

• the rack for the zipper rolls (3), where a great variety of different zippers can

be stored for production.

Please assure when inserting rolls onto the racks that the tapes or threads are

inserted into the corresponding guidings.

1-12

Page 15

5.2 Pull-off device

5

6

1

7

The pull-off device assures a tension-free insertion of the zipper into the

machine.

The zipper (7) comes through the front guiding (1) and then between driving roll

(2) and pressure roll (3). Then it comes around the pull switch (4) before it is

inserted under the cover through the rear guiding (5) and the insertion area (6).

If the zipper is pulled into the machine, the pull switch is pressed upward what

switches the motor on. The zipper will be inserted by the drive roll, until the

pull switch releases the contact.

5.3 Insertion area

In the insertion area, the zipper is located beneath a cover plate (1), on which

2

3

4

a stop (3) is mounted, where the fly piece can be aligned. After pressing the

start button (4), the transportation belt (2) will be lowered and pushes the fly

piece together with zipper and back-up tape under the sewing head.

1

2

3

4

1-13

Page 16

5.4 Operation device

5.4.1 Components of the operation device

The components of the operation device provide the following functions:

Display (1): all information required for the operation of the

machine are imaged here.

Cursor keys (2): use them to move the cursor and mark all

required commands and options.

Special key (4): press this key if several information is requi-

red for an adjustment.

Minus/Plus keys (3): use them to enable/disable functions, reduce/

increase numeric values and select programs.

1

2

3

4

5.4.2 Explanation of the display

After switching on with the main switch, the program will be displayed which

had been used previously. The machine is ready for sewing instantly:

PRO G .

001

TXT: HAU PTPRO GRAM M

Pcs.

A

0

Fn

1 Number of the current sewing program

2 Current step in the sewing program

3 Sewing speed

4 Photo cell mode

5 Automatic program execution

6 Stitch counting

STEP

03

14

A

STOP

D: 3000

A : 4 5

1-14

Page 17

5.5 Sewing head

1

2

3

4

1 Sewing head

2 Speed control transportation belt

3 Photo cell seam start/end

4 Sewing foot

With this machine you can sew zippers and back-up tape on large quantities

of left-handed fly pieces. The fly pieces are aligned at the stop bar beneath the

transportation belt. Then the start button must be pressed.

The transportation belt (driven by the sewing motor; speed adjustable at the

sewing head (2)) will be lowered what inserts fly piece, zipper and back-up

tape under the sewing foot.

The beginning of the fly piece is detected by the photo cell (3) which starts the

sewing. The same photo cell detects the end of the fly piece, which is the end

of the seam.

5.6 Cutting device

4

5

6

After the fly piece has been sewed at the sewing foot (1), it will be pushed

forward through the guiding (2). Another fly piece can be aligned and the

sewing can be started.

1

2

3

1-15

Page 18

When the next fly piece is pushed forward, the photo cell (3) detects the gap

between two fly pieces and triggers the command for the cutting (4) of zipper

and back-up tape. The sewed fly piece will be pulled onto the slide table (6) by

the stacker stamps (5).

5.7 Stacking device

1

2

3

After cutting zipper and back-up tape, the stacker stamps (1) will be lowered

and pull the fly piece onto the slide table (2). This will be opened and the fly

piece falls into the magacine (3).

The slide table is closed and the stacker stamps are driven into home position.

1-16

Page 19

6 Operation of the Machine

6.1 Production sequence

The ‘Fly Piece Unit, Series 1710/2’ works semi-automatic with high production

speed. The operator of the machine has to:

• select the desired sewing program;

• align the fly pieces correctly;

• start the sewing process by pressing the start button;

• supervise the fault-free functioning of the machine.

The following steps can be distinguished within the production sequence:

1. Align the fly piece at the stop bar beneath the transportation belt.

2. Press the start button to initiate the sewing process.#

3. The transportation belt will be lowered and pushes fly piece, zipper and

back-up tape under the sewing foot. When switching dark, the photo

cell gives the command for the start of the sewing.

4. When the fly piece left the range of the transportation belt, this will be

lifted and the next fly piece can be aligned.

5. After the fly piece has been sewed, zipper and back-up tape will be cut

and the fly piece is stacked in the magacine.

6.2 Alignment of the Fly Piece

1

2

3

Push the fly piece from the front below the transportation belt (1) until it

touches the rear stop (2). The left-handed end of the fly piece must be est. 1

cm away from the sewing foot.

When the fly piece is positioned correctly, press the start button (3) to start

the sewing process.

1-17

Page 20

6.3 Program control

Hint

This machine is controlled with programs, which are contained in the memory

of the machine and can be opened by the operator. The modification of

existing and the programming of new sewing programs should be reserved to

experienced and qualified personell. The possibilities are explained in the

second part of this manual.

6.3.1 Available sewing programs

In the daily production, the operator will only have to open one of the existing

sewing programs. The following programs are available as a factory setting:

Prog. Description

001 Main Program for sewing zipper and back-up tape

002 Manual Sewing;

after switching the photo cell dark you can sew with the programmed

sewing speed by pressing the foot pedal; the transportation belt

remains lifted, the sewing foot remains lowered, the photo cell is not

active and the sewing will be stopped when the foot pedal is

released

003 Additional Program – lift sewing foot

allows a safe threading up; the sewing foot is lifted and all program

functions will be disabled for safety reasons

The selected sewing program is imaged in the upper left corner of the display.

6.3.2 Select a sewing program

1. Use the arrow keys to move the cursor to the program number.

2. Press the Plus/Minus key repeatedly, until the desired program number is

displayed.

6.4 Additional settings at the operation device

The operator may not open the Setup pages of the machine control. This

should be preserved to especially educated and experienced technicians. You

have to enter the machine code to open the Setup pages.

Attention

Damage to the machine due to inadequate programming possible! The

machine code should be kept secret and accessible to persons only, who are

allowed to program and setup the machine.

Only two settings may be executed by the operator:

• select the operation language;

• adjust display contrast.

1-18

Page 21

6.4.1 Select operation language

Position the cursor on the program number and press the Minus key once.

This will be displayed:

PROG.

000

DEUTSCH

XXX

Use the arrow keys to move the cursor on the displayed operation language

(here: deutsch = german) and press the Plus key, until the desired operation

language is displayed.

Move the cursor back on „000“.

Hint

The descriptions in the sewing programs will always be displayed in the

language that had been used to enter them.

6.4.2 Adjust display contrast

Open page „Program 000“ (see 6.4.1) and position the cursor on the half-filled

circle symbol. Press the Plus or Minus key to adjust the contrast of the

display.

Position the cursor on „000“ and press the Plus key to select a sewing program.

D : 8000

1-19

Page 22

7 Cleaning and Maintenance

DANGER

Possible injuries due to improper execution of cleaning and maintenance

duties! The operator of the machine may only carry out the cleaning and

maintenance duties described in this section. Further measures are reserved

to the responsible service technician.

7.1 Cleaning of the machine

Hint

To achieve the value and daily functionality of this machine, it should always

kept clean and free of production waste.

Clean the machine components as described:

Operation device clean it using a dry, clean and lint-free cloth; heavy

dirt can be removed using a slightly saturated cloth.

Complete machine use a vacuum cleaner daily and if required to clean

the machine.

7.2 Maintenance

ATTENTION

Damage to the machine due to inadequate maintenance possible! The

execution of the maintenance duties should be reserved to experienced and

especially qualified staff. The required measures are described in the

mechanics manual in the second part of this documentation.

7.2.1 Check oil level in the sewing head

There is a window in the sewing head, where you can check the level of the oil

contained in the sewing head. Check the oil level daily and fill in required oil

immediately.

ATTENTION

Damage to the sewing head due to low oil! Check the oil level in the sewing

head daily and fill in missing oil immediately. Otherwise, the sewing head can

be damaged.

Information on the oil level check and filling in of missing oil is contained in the

operating instructions of the sewing head which is part of the machine documentation.

7.2.2 Empty water separator

1-20

The machine is equipped with a pressured air supply unit, where an automatic

water separator is mounted.

If there is water in the cup, it will be released automatically if the pressured air

supply is closed.

7.3 Troubleshooting hints

Whenever an error or fault appears or an error message is imaged in the

display, the responsible technician have to be contacted.

Page 23

Teil 2 Mechanics Manual

Hint

This part of the Operating Instructions contains all information required to put

the machine into operation and for the programming, troubleshooting and

maintenance. It addresses to qualified staff which is able to estimate the given

duties and discover possible danger at an early time. The Operators Manual

contained in part 1 is a part of this Mechanics Manual.

Contents Page

Teil 2 Mechanics Manual ..............................................................................................2-1

1 Delivery, Transportation, Packing......................................................................2-2

1.1 Range of delivery ................................................................................................... 2-2

1.2 Packing .................................................................................................................2-2

1.3 Transportation ........................................................................................................ 2-2

1.4 Storage ................................................................................................................. 2-2

2 Putting up – Connection – Setup .......................................................................2-3

2.1 Technical data ....................................................................................................... 2-3

2.2 Mechanical Installation .......................................................................................... 2-3

2.2.1 Unpacking and Putting up ..................................................................................... 2-3

2.2.2 Connect compressed air ........................................................................................2-4

2.3 Electrical Installation .............................................................................................2-4

2.4 Putting into Operation ............................................................................................2-5

3 Programming and Machine Setup ....................................................................2-6

3.1 General hints .........................................................................................................2-6

3.2 Select Setup pages ...............................................................................................2-6

3.3 Setup page -01 ......................................................................................................2-7

3.4 Setup page -02 ......................................................................................................2-7

3.4.1 Position actor, Turn direction, Needle position .......................................................2-7

3.4.2 Sewing speed (min. and max.) ............................................................................... 2-8

3.4.3 Foot pedal .............................................................................................................2-8

3.4.4 Cover Page ............................................................................................................2-9

3.4.5 Store error messages ............................................................................................ 2-9

3.4.6 Enable access code .............................................................................................. 2-9

3.5 Setup page -03 ......................................................................................................2-9

3.6 Setup page -10 .................................................................................................... 2-11

3.7 Program inputs and outputs................................................................................. 2-12

3.7.1 Setup page of inputs and outputs ........................................................................ 2-12

3.7.2 Settings for this machine ..................................................................................... 2-13

3.8 Meanings of the used symbols ............................................................................ 2-13

4 Use of the storage module ............................................................................... 2-15

4.1 Load data from the storage module...................................................................... 2-15

4.2 Write data on the storage module ........................................................................ 2-16

4.3 Write single programs on the storage module ......................................................2-16

4.4 Read a single sewing program into the machine control....................................... 2-17

5 Troubleshooting hints ....................................................................................... 2-18

5.1 Error – possible solution ...................................................................................... 2-18

5.2 Error messages in the display – possible solution ............................................... 2-18

5.3 Hints for several repair duties ............................................................................... 2-19

2-1

Page 24

1 Delivery, Transportation, Packing

1.1 Range of delivery

Hint

Check immediately after receiving the machine, whether all parts are delivered

completely and without any obvious damage. Later compensation claims

cannot be accepted.

If you detect damage to the transportation packing of the machine which may

indicate damage of the machine or parts of it, you should claim this immediately at the transporting company. This is the only way to keep all rights

against the transporting company.

1.2 Packing

The company Beisler tries to use recycleable packing materials only. Please

assure that these materials are treated in accordance to the local regulations.

1.3 Transportation

Generally it is possible to move the machine. Please follow these regulations:

1. Cut off the power and compressed air supply and make the pneumatic

system free of pressure.

2. Fix movable and loose parts.

3. Lift the machine frame evenly with a suitable transportation device; assure

that possible additional devices (e.g. stacker) are lifted with the machine.

Loosen the breaks at all transportation rolls, if the machine is equipped

with this option.

4. Move the machine carefully to the desired location.

ATTENTION

Attention during transports on sloping areas! The machine’s weight produces

high pulling power. Be sure to place the machine in environments, which are

suited for the machine.

1.4 Storage

If no other agreements are fixed for the storage of the machine, the following

requirements must be fulfilled:

1. In closed rooms only.

2. Temperature range -10 ... +45° C.

3. Humidity max. 80 %, not condensing.

2-2

ATTENTION

The machine can be damaged due to storage and/or transportation under

inacceptable conditions. Possible damage may be invisible from the outside.

Page 25

2 Putting up – Connection – Setup

ATTENTION

This machine may only be installed and put into operation by mechanically

and electrically qualified staff. This personell must read and understand the

complete Operating Instructions before.

2.1 Technical data

Dimensions 00 x 00 x 00 mm (LxWxH)

Table height 00 mm (adjustable)

Weight 00 kg

Electrical conn. 220 V AC

Power consumption 00 kW

Fuse 15 A

Compr. air conn. min. 5 bar

Req. compr. air quality free of oil

Compr. air consumptionest. 00 NL/part

2.2 Mechanical Installation

ATTENTION

Check prior to the installation, whether the desired location corresponds with

the environmental requirements for the machine. Please see section ‘Technical

Data’ for further information.

2.2.1 Unpacking and Putting up

1. Remove the packing material and possible transportation lockings.

2. Position the machine on a horizontal grounding.

3. Level the machine with the adjustable feet to a horizontal stand.

2-3

Page 26

2.2.2 Connect compressed air

1

2

3

4

1. Connect the compressed air hose (2) with a connector of you compressed

air system.

2. Open the compressed air supply.

3. Use the control grip (1) to adjust the machine’s compressed air pressure to

6 bar, readable at scale (3).

4. Water contained in the water separator (4) will be released automatically

when the machine is made free of pneumatical pressure.

2.3 Electrical Installation

Hint

All works at electrical components of this machine may only be carried out by

qualified staff in accordance to IEC 364 and DIN EN 60204-1.

DANGER

Hazardous electrical voltage inside the switchcase! Cut off the power supply to

avoid dangerous injuries. Please obey the safety regulations given at the

beginning of the Operating Instructions and the common rules for accident

prevention.

2-4

ATTENTION

The machine can be destroyed by a connection to a wrong electrical voltage!

Please check, whether the information given in section ‘Technical data’ meet

the local conditions before executing the electrical installation.

1. Use the power cord which is located at the rearside of the machine.

2. Plug it into a socket.

3. Lay the cable in a way that the danger of stumbling is avoided.

Page 27

DANGER

Danger to life in the case of unsufficient grounding! Ground the machine in

accordance to DIN EN 60204-1.

2.4 Putting into Operation

As a factory setting this machine has been adapted to the requirements of the

customer. The first putting into operation can be done easily:

1. Level the machine to a horizontal stand.

2. Execute electrical and pneumatical connection.

3. Switch the machine on with the main switch on the front side of the machine.

4. Check all safety installations on functionality.

DANGER

The machine may only be used for production after the safety installations had

been checked. If safety installation does not function, they must be repaired

first.

As a factory setting, several sewing programs are contained in the memory of

the machine. You can use one of these programs or program your own.

2-5

Page 28

3 Programming and Machine Setup

As a factory setting, three sewing programs are contained in the memory of

the machine, which can be selected and used by the operator. These programs are composed based on long-termed experience and should be sufficient for the normal use of the machine. The available sewing programs are

explained in part 1 ‘Operators Manual’ of the Operating Instructions.

The available programs can be modified and adapted to the individual requirements of the customer. You can also program new programs. All modified or

new programs can be copied to a memory module to backup the data.

3.1 General hints

When you want to set or modify certain functions, you will use the arrow keys

to position the cursor on the respective icon and press the Plus/Minus keys to

change the setting or value.

For several functions you can press the Special key to open the setup page

for the selected function.

The machine setup can be modified on the Setup pages:

Setup -01 Machine type

Setup -02 Position actor, turn direction, needle position, sewing speed,

storing error messages, enable access code

Setup -03 Sewing foot, photo cell

Setup -10 Inputs and Outputs

3.2 Select Setup pages

1. Position the cursor on the program number and press the Minus key. This

will be displayed:

PROG.

000

DEUTSCH

XXX

2. Position the cursor on the left-handed „x“ below the key icon.

3. Press the Minus key to display a zero.

4. Position the cursor on the middle „x“ and press the Minus key.

5. Position the cursor on the right-handed „x“ and press the Minus key.

6. Position the cursor on the program number 000 and press the Minus key.

Setup page -01 will be displayed.

: 3000

[ ]

2-6

Page 29

3.3 Setup page -01

SETUP

-01

Here you can set the machine type. For this machine, „Kettenstich“ (= chain

stitch) must be selected.

3.4 Setup page -02

SETUP

KETTENSTICH

-02

MARKE

P1

P2

TYPE

Six icons are displayed here, representing the machine functions. To select a

function, position the cursor on the corresponding icon and press the Special

key to open the setup page, or the Plus/Minus key to switch the function on or

off.

3.4.1 Position actor, Turn direction, Needle position

SETUP-02

---

280

0

80

Turn direction

After opening the page, the cursor is positioned on the icon of the turn direction. Press the Plus key to alter the turn direction (viewed on the belt disc).

III POS.

II POS.

0

I POS.

Define needle zero position

1. Position the cursor on the icon of the needle zero positon.

2. Turn the hand wheel with impetus in the set turn direction, until the angle

value below the turn direction icon changes.

2-7

Page 30

3. Continue turning the hand wheel, until the needle stands at the upper edge

of the stitch plate.

4. Press the Plus key to accept the value as zero position.

5. Press the Special key to leave the page or set the needle top and bottom

positions.

Set needle top and bottom positions

These positions are defined as a factory setting but it is possible to change

them:

1. Position the cursor on the label „II Pos.“.

2. Turn the hand wheel in turn direction, until the needle stands in the desired

top position.

3. Read the angle value below the icon of the turn direction (est. 280).

4. Press the Plus or Minus key to enter the displayed angle value into the box

beside the label „II Pos.“.

5. Position the cursor on the label „I Pos.“.

6. Press the Plus or Minus key to enter the angle value „80“ into the box

beside the label „I Pos.“.

7. Press the Special key to leave this page.

3.4.2 Sewing speed (min. and max.)

SETUP-02

Position the cursor on the listed values and press the Plus/Minus key to set

them as follows:

MAX.: 4200

MIN.: 400

ACC. 100 %

DEC. 80 %

Pull: 75

Press the Special key to leave this page.

3.4.3 Foot pedal

Hint

RESET

ON

MIN.: 400

MAX.: 4200

[ ]

5400

Pull: 75

67

100%

ACC.

80%

DEC.

2-8

The settings contained here are optimized as a factory setting and must not

be modified.

Page 31

3.4.4 Cover Page

Hint

This function is not required at this machine. The respective icon is disabled

(crossed out).

3.4.5 Store error messages

SETUP

-02

Position the cursor on the shown icon and press the Special key to open the

corresponding setup page.

Here, error messages are displayed together with the time of their appearance.

The service personell can use this to evaluate the status of the machine.

3.4.6 Enable access code

If the key icon is not crossed out, the machine code must be entered before

the Setup pages can be entered. If the machine code is disabled, the Setup

pages and all program data are accessible at any time.

ERROR PARTIAL TOTAL

--:-- 12:15

--:--

--:--

04:35

30:00%

38:20

27:15

40:00%

3.5 Setup page -03

SETUP

-03

S

Six icons are displayed here, but only two of them are enabled. To select the

setup page of a function, you have to position the cursor on the icon and press

the Special key.

D

2-9

Page 32

Hint

If the presser foot cannot be enabled, you will first have to switch off Output F1

on Setup page -10. More information is given further below.

SETUP-02

30V

(max)

15 V

[ms]

100

00

120

1. Position the cursor on the time for maximum power (lower line, left-handed

value) and press the Plus/Minus key, until 100 ms is set. This assures that

the presser foot is lifted safely after the end of the seam.

2. Position the cursor on the value of the holding voltage (upper row, middle

value) and press the Plus/Minus key until 15 V is set. This assures that

the magnetic valve for the foot lifting cannot be overloaded.

3. Position the cursor on the right side on the value of the start delay and

enter 120 ms. This time is needed that the presser foot is safely on the

fabrics before sewing starts.

4. Position the cursor on both presser foot icons and set them to „Presser

foot down“ (like shown in the drawing).

5. Press the Special key to leave this page.

6. Check whether the presser foot is programmed on „up“ on page „PROG

000“, too:

PROG.

: 4200

000

2-10

Page 33

3.6 Setup page -10

SETUP

-10

F1

M1

All inputs (F1 ... F12) and outputs (M1 ... M8) are displayed on this page. For

diabled inputs/outputs, the respective icon is crossed out.

At this machine, the output F1, F2 and F9 ... F12, and the inputs M4, M6 and

M7 must be disabled. Position the cursor on the icon of an input/output and

press the Plus/Minus key to alter the setting.

The outputs are valves and occupied as follows:

Valve description Output connector

F1 Y1 Lift sewing foot and puller pin 1

F3 Y3 Knife (Push valve) pin 5

F4 Y4 Knife (Push valve) pin 7

F5 Y5 Stacker stamp pin 9

F6 Y6 Stacker transport pin 11

F7 Y7 Slide table pin 13

F8 Y8 Transportation belt down pin 15

F2

F3

M3M2

F4

M4

F5

M5

F6

M6

M7

F8F7

M8

F9

F10

F11

F12

Hint

The output „Lift sewing foot and puller“ (Y1) cannot be programmed on Setup

page -10 and must be programmed on Setup page -03 (see there).

The inputs are occupied as follows:

Description Input connector

M1 ES1 Start button pin 2-4

M2 FZ3 Knife on and stacker start (photo cell) pin 6-4

M3 FZ3 Knife on and stacker start pin 8-10

M5 ES4 Initiator stacker transport in rear position

and slide table open

FZ2 Sewing stop;

pin 19 = -12 V, pin 20 = +12 V, switch output pin 18

2-11

Page 34

3.7 Program inputs and outputs

The inputs and outputs can be enabled/disabled on setup page -10. Enabled

inputs and outputs can be programmed.

To program an input or output, position the cursor on the respective icon and

press the Special key. The setup page will be opened.

Hint

The programming of inputs and outputs is not executed program-specific. The

setting is the same for all programs. Modifications effect all sewing programs.

3.7.1 Setup page of inputs and outputs

OUT F8

STEP STOP

PRG

STEP

A programming is shown for the example of output F6 (displayed in the upper

left corner of the display).

A function must be selected for each input/output, a start delay and duration

must be programmed. The selected function is displayed on the left side in

front of the background „I/O“. The icons will be explained further below.

The start delay is displayed to the right of the left-handed „hour glass“, the

active duration to the right of the right-handed hour glass. The avilable

functions are displayed above the hour glasses in a horizontal row.

Do the following to program an input or output:

1. Position the cursor on the icon of a function in the upper right part of the

display.

2. Press the horizontal arrow keys until the desired function icon is marked.

3. Press the Plus key to select the marked function icon. It will be displayed

in the area „I/O“.

4. Position the cursor on the time value to the right of the left-handed hour

glass icon if you want to program a start delay (in ms) for the selected

function.

5. Press the Plus/Minus key repeatedly, until the desired value is displayed.

6. Position the cursor on the time value to the right of the right-handed hour

glass, where you can program the active time (in ms) for the selected

funtion.

7. Press the Plus/Minus key repeatedly, until the desired time value is displayed.

8. Press the Special key to leave the setup page and store the changes.

9. Repeat this procedure for all inputs and outputs which you want to modify.

0

10

2-12

Page 35

3.7.2 Settings for this machine

The inputs and outputs at this machine should be programmed as follows:

Inputs

Start button

M1

STA

RT

Photo cell knife on

M2 Fn

Photo cell stacker stamp down and stacker start

M3 Fn

Stacker transport in rear position and slide table open

M5 Fn F7 ON

Ouputs

Sewing foot

Knife (push valve)

Knife (push valve)

F1

programmed on Setup page -03

F3

M

F4

M

F / F

F5 ON

F6 ON

0 400

90

F3 ON

F4 OFF

Stacker stamp

Stacker transport

Slide table

Transportation belt down

F5

F6

F7

F8

3.8 Meanings of the used symbols

Step type symbols

Pause - passing of a time

if the time symbol is programmed in a step, the program

sequence will be continued after the programmed time has

passed; outputs can be enabled in this step.

M

STEP

7 800

7 800

030

010

2-13

Page 36

A

Program-specific symbols

Continue with next step

it will be switched to the next step automatically after the

displayed step has been executed.

Manual sewing

if this icon is contained in a step, you can sew manually

pressing the foot pedal forward; switch to the next program

step by pressing the foot pedal backward.

Semi-automatic execution

if this icon is contained in a step, the step will be switched

on by pressing the foot pedal forward; after a programmed

time expired or a stitch counting, it will be switched to the

next step automatically.

Automatic execution

this step will be executed automatically.

Fn

STOP

STOP

Sewing foot up – down

Enabled outputs

one or several outputs are enabled in this step; position

the cursor on this icon and press the Special key, to

display the enabled outputs; crossed out icons represent

disabled outputs.

Stop

the program will be stopped after the execution of this

step; usually this icon is used in the last step of a sewing

program.

No stop

there will be no program stop but a continuation with the

next step.

indicates the position of the sewing foot at program start

and end.

2-14

Needle position after sewing stop

position the cursor on this icon and press the Plus key to

select, whether the needle shall stand in top or bottom

position after the stop.

Page 37

4 Use of the storage module

KK195

SETUP/PROG

SETUP

PRO G

DATA TRANSFER FRO M KK195 CHIP TO M O TOR

PRESS + TO CONTINU E PRESS TO CANCEL

All sewing programs and the setup data are stored on the storage module

delivered with the machine.

Hint

The delivered module is a backup copy of the machine data. It should be kept

at a safe place.

4.1 Load data from the storage module

1. Switch off the machine using the mains switch.

2. Plug the storage module KK 195 into the slot on the right side of the

operation device.

3. Switch on the machine using the mains switch.

4. The display shows you what you can load from the storage module:

5. Press the Plus key.

6. Confirm the inquiry, whether the data contained in the machine’s memory

shall be overwritten.

7. Use the arrow keys to mark one of the three options (SETUP/PROG =

setup-data and sewing programs will be loaded; SETUP = only setup-data

will be loaded; PROG = only sewing programs will be loaded).

8. Press the Plus key.

9. Now you have to confirm the loading of data into the machine control:

SETUP/PROG

SETUP

PRO G

KK195

CAU TION ! O LD KK195 DATA W ILL BE ERASED

PRESS + TO CONTINU E PRESS TO CANCEL

10.Press the Plus key to start the loading. The selected data will be loaded

into the machine control.

11. Then, setup page -02 will be displayed. Enter all data like described in

section 3.4.

12.Press the Special key. Program 001 will be displayed and the machine is

ready to use.

2-15

Page 38

4.2 Write data on the storage module

1. Switch off the machine using the mains switch.

2. Plug the storage module KK 195 (Part No. 24.831.08) into the slot on the

right side of the operation device.

3. Switch on the machine using the mains switch. This will be displayed:

SETUP/PROG

SETUP

PRO G

PRO D DATA

DATA TRANSFER FRO M KK195 CHIP TO M OTOR

PRESS + TO CONTINU E PRESS TO CANCEL

4. Press the key „Arrow to the right“ to turn the displayed arrow in the direction like shown in the picture.

5. Select one of four options using the vertical arrow keys: SETUP/PROG =

write setup data and sewing programs; SETUP = write setup data only;

PROG = write sewing programs only; PROG DATA = write program data

only.

6. Press the Plus key and this will be displayed:

KK195

SETUP/PROG

SETUP

PRO G

PRO D DATA

CAU TION ! O LD KK195 DATA W ILL BE ERASED

PRESS + TO CONTINU E PRESS TO CANCEL

7. Press the Plus key to overwrite data which are contained on the storage

module. Then, the selected data will be written.

8. Pull the storage module out of the operation device. The machine is ready

to use.

4.3 Write single programs on the storage module

Hint

For each single program, a separate storage module is required.

1. Select the program to be copied on the storage module.

2. Press the Special key and this will be displayed (example):

KK195

2-16

PRO G .

001

PRG

XXX

COUNTING

M ANUAL

AUTO

PRO G.

OPEN

SELF-TEACH

EDIT.

a/A /B

ALL

PRG

LÖSCHEN

W

R

Page 39

3. Position the cursor on the „W“ in the upper right corner of the display and

push the storage module into the slot at the operation device.

4. Press the Plus key to write the selected sewing program on the storage

module.

4.4 Read a single sewing program into the machine control

1. Select the program memory location, where the program shall be read to.

2. Press the Special key. The same will be displayed like shown in section

4.3.

3. Position the cursor on the letters „PRG“ and press the Plus key to delete

the data contained on the selected memory location.

4. An inquiry will be displayed, where you have to confirm the deletion by

pressing the Plus key. The deletion cannot be undone.

5. Plug the storage module into the slot at the operation device.

6. Position the cursor on the letter „R“.

7. Press the Plus key to read the program from the storage module into the

machine control.

8. Press the Special key to leave the page. The machine is ready to use.

Hint

You can use this procedure to copy a sewing program from one memory

location to another.

2-17

Page 40

5 Troubleshooting hints

5.1 Error – possible solution

The machine does not start and the control lamp on the operation

device MT800 is off – replace 10 A melting fuse; if the new fuse melts, too or

the machine does not start: replace control board KK66.

The devices will not be enabled – the motor functions but the devices like

thread cutter, foot lifting or needle cooling will not be enabled – replace 3 A

melting fuses, then cut off all devices electrically from the motor control;

switch on the machine and connect all devices one after another; after every

connection, switch on the machine and check melting fuses; in this way, the

defective device can be detected (possibly magnetic valve); if the electrical

elements of the devices are ok and the replacement of the fuses brought no

success: replace I/O-module, replace control board KK66.

The operation device MT800 is switched on, but the display is not clear

or without function – switch machine off and on; pull out the connecting

cable of the operation device MT800, check and remount it; possibly do the

same with the connecting cable between control board KK66 and I/O-module;

replace operation device MT800, replace I/O-module, replace control board

KK66.

5.2 Error messages in the display – possible solution

Fault in the control board (KG) – replace control board KK66.

External fault (KE) – switch machine off and on; check power supply; check

environment for disturbing devices (spark-generating devices, high-frequency

machines, a.s.o.).

Program defective (KP) – delete defective program and program it again; if

several programs are defective, all programs should be loaded from the

storage module; if the loaded programs are defective: replace control board

KK66.

Position actor defective (SG) – check the connecting cable of the position

actor; check the connecting cable between I/O-module and control board

KK66; replace position actor, replace I/O-module, replace control board KK66.

Driving belt loosened (CA) – make correct belt tension; check, whether the

motor is fixed properly on the base frame.

Motor overloaded (MS) – there can be many reasons: e.g. missing oil in the

sewing head, oil too cold, possibly sewing thread wrapped around the belt

disc, ...

Motor blocked (MB) – possible causes: machine blocked, needle blocked,

...

2-18

Page 41

5.3 Hints for several repair duties

Replacement of the I/O-module – the replacement of the I/O-module does

not require any adaption duties.

Replacement of the position actor – after replacement, the setting of the

needle zero position is required.

Replacement of control board KK66 – procedure: demount rear cover, pull

off four cable connectors to the control board, loosen both fixing screws, pull

off control board from the motor. Be aware to avoid damage to the electronical

components; put the control board into a bag protecting it from electro-statical

load and avoid any contact to metal things. After replacing the control board,

all setup data and the sewing programs must be loaded into the machine.

Replacement of the front box – this is the statical element of the connec-

tion control box and of the foot pedal; each transmission element of the pedal

is calibrated; since that, the front box should only be replaced as a whole.

Replacement of the motor – this is fixed with four screws in the motor

housing; the control board must be removed before it can be demounted.

Loading of new software – future developments can be loaded into the

control by replacing an EPROM; to replace the EPROM, remove rear cover,

replace EPROM (mounted on a frame in the upper left corner); when inserting

the new EPROM be sure to insert all pins and bend none.

2-19

Page 42

2-20

Loading...

Loading...