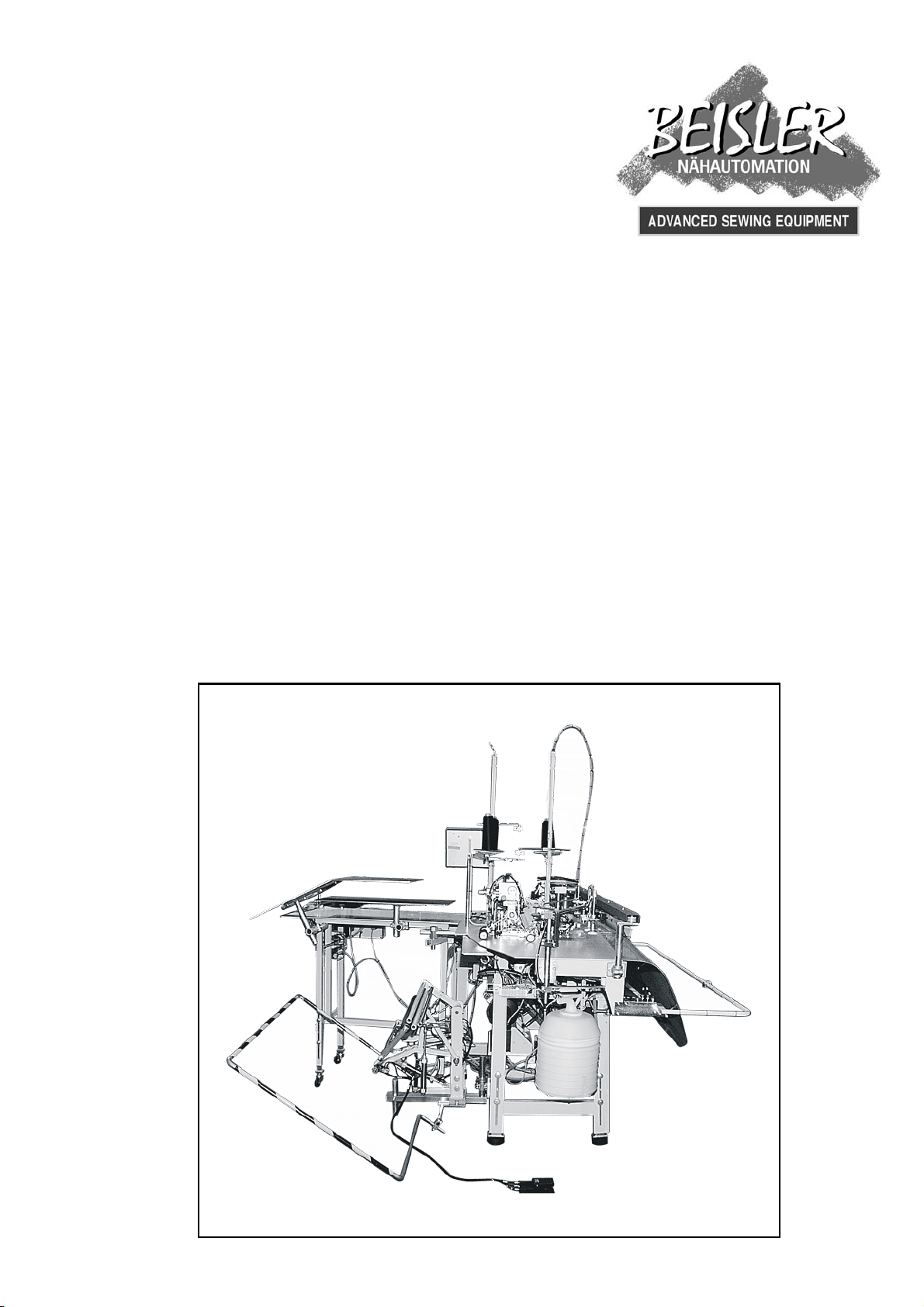

Page 1

Working Instructions Automatic Multi-Head Serging Machine Beisler GmbH

V

Working Instructions

Working Instructions

Automatic Multi-Head Serging Machine 1360-1365/4

Valid: 06-2002 A

A-1

ersion 1.1 13.01.2003

Page 2

Working Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Contents of the working instructions

The working instructions are divided into four sections:

A. General notes

Safety instructions for the operating and service personnel and for the

operator of the machine.

B. Operating instructions

Instructions for the personnel operating and handling the machine.

C. Service instructions

Instructions for the personnel in charge of the initial start-up, setting up

and service of the machine.

D. Programming instructions

Instructions for the service personnel in charge of preparing and setting

up the machine.

Scope of the working instructions

These working instructions describe the AUTOMATIC MULTI-HEAD

SERGING MACHINE 1365-4 of Beisler GmbH and apply only to those

machine parts and components that are standard equipment of the AUTOMATIC MULTI-HEAD SERGING MACHINE 1365-4.

They do not apply to accessories or machine parts (e.g. sewing head)

from third parties that the machine is equipped or retrofitted with. For

those components, the working instructions of the respective manufacturer or supplier apply.

A-2

Page 3

Working Instructions Automatic Multi-Head Serging Machine Beisler GmbH

Section A

General notes

A-3

Page 4

Working Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Contents

A.1 Safety instructions ............................................................................... A-5

A.1.1 Exclusion of liability ..................................................................... A-5

A.1.2 Copyright ..................................................................................... A-5

A.1.3 Important information for the operator ........................................ A-6

A.1.4 Warranty ...................................................................................... A-6

A.1.5 Important information for the operating personnel ..................... A-7

A.1.6 Important information for the service personnel ......................... A-7

A.2 Explanation of symbols ....................................................................... A-8

A.2.1 Symbols used in the working instructions .................................. A-8

A.2.2 Symbols used on the machine ................................................... A-8

A.3 Use of the device ................................................................................... A-9

A.3.1 Correct use .................................................................................. A-9

A.3.2 Incorrect use ............................................................................... A-9

A.4 Safety requirements ........................................................................... A-10

A.4.1 Standards and directives .......................................................... A-10

A-4

Page 5

Working Instructions Automatic Multi-Head Serging Machine Beisler GmbH

Safety instructions

A.1

A.1.1 Exclusion of liability

Beisler GmbH warrants the faultlessness of the product as set forth by

their advertisement, product information and these working instructions.

Other product characteristics are not warranted.

Beisler GmbH is not responsible for the profitability or for the correct

function of the automatic multi-head serging machine 1365-4 if it is

used for other purposes than those defined in section Correct use.

Beisler GmbH is not responsible for damage that arises from the use of

non-defined and non-approved spare parts or accessories.

A.1.2 Copyright

© 2002 Beisler GmbH, Hösbach

Automatic multi-head serging machine

The automatic multi-head serging machine 1365-4 and all related parts

are protected by copyright. Any reproduction of the machine will be prosecuted.

Working instructions

These working instructions are protected by copyright. No part of the

working instructions, including figures and tables, may be reproduced

or translated in any form or by any means, electronic or mechanical, without the express written permisson of Beisler GmbH.

Beisler GmbH

Frohnradstr. 10

63768 Hösbach

Deutschland

Phone: ++ 49 / 6021 / 50 19 0

Fax: ++ 49 / 6021 / 50 19 10

eMail: vertrieb@beisler-gmbh.de

A-5

Page 6

A.1

A.1.3 Important information for the operator!

This machine has been manufactured in keeping with the latest technological developments and is operationally safe. However, it may present

potential hazards, particularly if it is operated by inadequately trained

personnel or if it is not used correctly:

For personnel operating and handling the machine, the operator

Use the operating instructions to familiarize the operating person-

Use the service instructions to familiarize the service personnel

For any modifications of the machine that have not been approved

The contents of the working instructions are subject to change wit-

Concerning translations into foreign languages, the German versi-

Should you encounter problems that are not mentioned in these

Keep these working instructions close to the machine so that

Working Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Safety instructions

must prepare written instructions in a reasonable form and in the

language of the operating personnel based on these working instructions (Germany: Accident Prevention Regulations UVV VGB 1 §

7.2).

nel with the functions, operation, and care of the machine and

check to see if the operating personnel fully understands these instructions.

with the setting up and maintenance of the machine.

by Beisler GmbH in writing, the operator is fully responsible.

hout further notice.

on of these working instructions is binding.

working instructions, please contact your supplier immediately for

your own safety. Please do not hesitate to contact Beisler if you

have any suggestions that help to improve this product.

safety instructions and information on operation, setting-up,

and maintenance are always accessible.

Warranty

Beisler GmbH warrants the safety, operatability, and repair without charge of the automatic multi-head serging machine 1365-4 for a period of 6

months under the condition that:

the machine is used exclusively for the intended purpose and ser-

viced in accordance with the information in these working instructions,

modifications of the machine are carried out only with prior written

approval of Beisler GmbH,

only original spare parts or accessories approved by Beisler GmbH

are used. For a complete list of all approved spare parts, please

contact Beisler GmbH.

If the machine is used for more than 10 hours per day (shift operation),

the warranty period is reduced to 3 months.

The warranty period starts with the delivery of the machine to the operator.

A-6

Page 7

Working Instructions Automatic Multi-Head Serging Machine Beisler GmbH

Safety instructions

A.1

A.1.5 Important information for the operating personnel!

Please note that any work to the automatic multi-head serging machine

1365-4 must be carried out only by trained operating personnel:

Operating personnel means persons:

that have been given initial instructions for sewing automats and that

have been trained for the operation and handling of the automatic

multi-head serging machine 1365-4 on the basis of these operating

instructions,

that have been informed about potential risks arising from their work

with the machine,

that are capable of assessing their work with the machine due to occupational experience and instruction of the safety regulations and

of recognizing potential hazards during work,

Cleaning of the machine or of machine parts must be performed only

by personnel that has been informed about potential hazards arising

during the cleaning work.

Prior to the initial operation of the automatic multi-head serging ma-

chine 1365-4, read the operating instructions carefully so that you

can make full use of the advantages of the machine and to prevent

damage.

A.1.6 Important information for the service personnel!

Please note that service work to the automatic multi-head serging machine 1365-4 must be carried out only by authorized and adequately

trained expert personnel:

Expert personnel means persons:

that have aquired their expertise by a special training in machine

technology or electrical engineering or by a special advanced training or a comparable qualification,

that have acquired the knowledge required to perform all works for

setting up and servicing the automatic multi-head serging machine

1365-4 from a training by Beisler GmbH,

that are capable of assessing their work with the machine due to occupational experience and instruction of the safety regulations and

of recognizing potential hazards during work.

Prior to carrying out any service work to the automatic multi-head

serging machine 1365-4, read the entire working instructions carefully so that you can make full use of the advantages of the machine

and to prevent damage.

A-7

Page 8

A.2

A.2.1 Symbols used in the working instructions

is used if non-observance may cause serious or even lethal injuries.

is used if non-observance may cause medium to minor injuries or damage.

Working Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Explanation of symbols

WARNING!

CAUTION!

NOTE!

is used for hints and useful information.

A.2.2 Symbols used on the machine

WARNING: DANGER!

Caution! Observe working instructions.

WARNING: HIGH VOLTAGE!

Caution! Prior to opening, pull out power plug.

A-8

Page 9

Working Instructions Automatic Multi-Head Serging Machine Beisler GmbH

Use of the machine

A.3

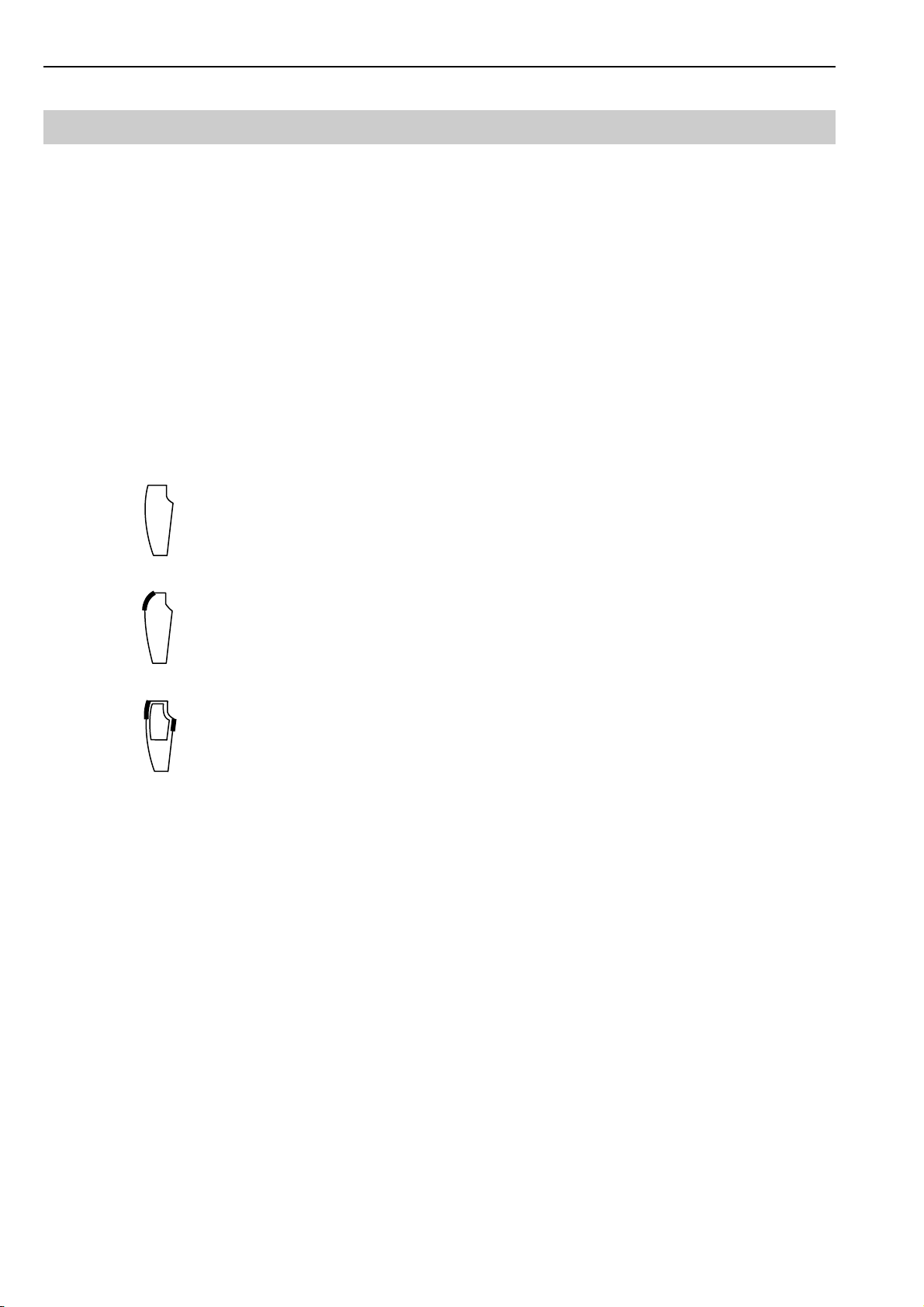

A.3.1 Correct use

The AUTOMATIC MULTI-HEAD SERGING MACHINE 1365-4 is a

sewing machine for the automatic serging of inseams and side seams of trousers panels with or with knee lining.

The machine can be used for processing all conventional materials

for outerwear.

The machine has been designed for permanent operation in indu-

stry.

The AUTOMATIC MULTI-HEAD SERGING MACHINE 1365-4 has

been tested for electromagnetic compatibility and is suited for installation in industrial operating rooms.

A.3.2 Incorrect use

The AUTOMATIC MULTI-HEAD SERGING MACHINE 1365-4 must

not be operated in rooms that do not comply with the location requirements.

The AUTOMATIC MULTI-HEAD SERGING MACHINE 1365-4 must

not be operated in the vicinity if devices or systems that produce

strong magnetic fields as otherwise the correct function of the program control may be impaired.

A-9

Page 10

A.4

A.4.1 Standards and directives

DIN EN, Part 1:1991-11, Part 2:1995-06

DIN EN 60601, Part 1:1994-05

DIN EN 50178 (VDE 0160): 1998-04

DIN EN 50082 (VDE 0839) Part 2:1997-11

DIN EN 60204 (DIN VDE 0113): 1993-06

Working Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Safety requirements

Safety of machines

Safety regulations for electrically operated measuring and control installations, general requirements.

Equipment of power systems with electronic devices

Electromagnetic compatibility, basic specification, immunity to interference.

Part 1: Domestic, business and commerce, small enterprises.

Part 2: Industry.

Electrical equipment of industrial machines

A-10

Page 11

Operating Instructions Automatic Multi-Head Serging Machine 1365-4 Beisler GmbH

Section B

Operating Instructions

B-1

Page 12

Operating Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Contents

B.1 Description of the machine .................................................................. B-3

B.1.1 Functional units ........................................................................... B-3

B.2 Functions of the machine ..................................................................... B-4

B.2.1 Operating principle and machine cycle ...................................... B-4

B.2.2 Securing the sewing pieces ........................................................ B-5

B.2.3 Guiding of the sewing pieces ...................................................... B-6

B.2.4 Serging the seam ........................................................................ B-9

B.2.5 Width distribution for knee lining ............................................... B-10

B.2.6 Transport ................................................................................... B-11

B.2.7 Stacking ..................................................................................... B-13

B.2.8 Switches .................................................................................... B-14

B.2.9 Operating panel......................................................................... B-16

B.2.10 Sewing programs ...................................................................... B-17

B.3 Operation .............................................................................................. B-19

B.3.1 Preparing the machine .............................................................. B-19

B.3.2 Selecting a sewing program ..................................................... B-20

B.3.3 Passing thread through needles ............................................... B-21

B.3.4 Modifying sewing program functions ........................................ B-21

B.3.5 Resetting the day counter to zero ............................................. B-24

B.3.6 Moving the cross transport manually ........................................ B-24

B.3.7 Resuming the sewing process at the B machine ..................... B-25

B.3.8 Securing the sewing pieces ...................................................... B-26

B.3.9 Sewing process ......................................................................... B-27

B.3.10 Stopping a sewing program ...................................................... B-30

B.3.11 Moving the machine to zero position ........................................ B-30

B.3.12 Shutting the machine down ...................................................... B-30

B.3.13 Cleaning the machine ............................................................... B-30

B-2

Page 13

Operating Instructions Automatic Multi-Head Serging Machine 1365-4 Beisler GmbH

Description of the machine

B.1

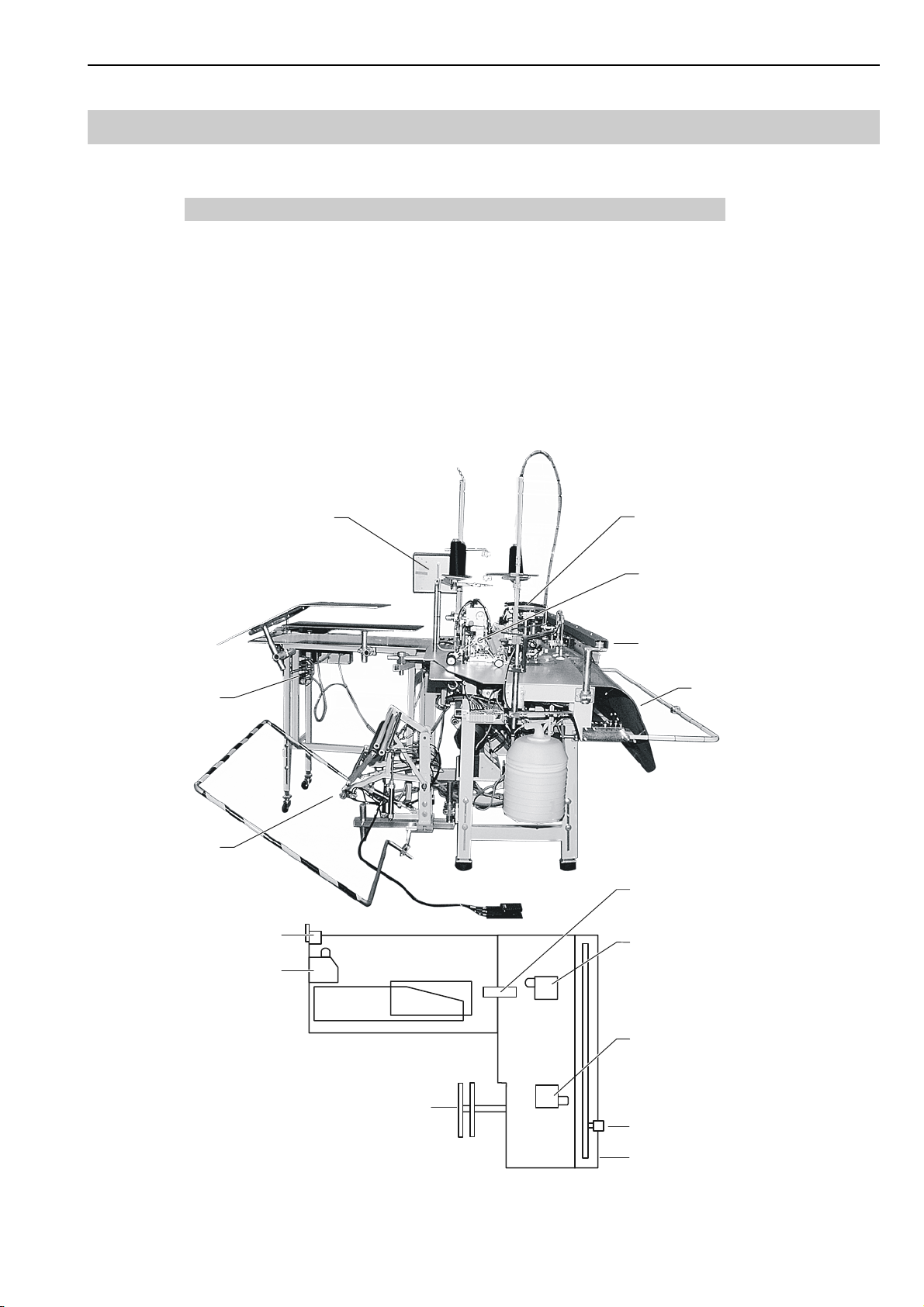

B.1.1 Functional units

The AUTOMATIC MULTI-HEAD SERGING MACHINE 1365-4 consists of six

functional units:

1

Operating panel

2

A machine

3

B machine

4

Cross transport with sliding panel

6

Stacker

7

Bonding station

Optionally, the automatic serging machine may be equippped with a third sewing

head (8 C machine) for serging the short seams (waistband seam, hem seam,

and fly seam).

5

C

B-3

A

B

Fig. 1

Page 14

B.1

B.2.1 Operating principle and machine cycle

Operating principle:

The automatic multi-head serging machine 1365-4 allows the automated

serging of inseams and side seams of trouser panels, with or without knee

lining. The machine can be equipped with up to three sewing heads.

C machine (optional) for serging the waistband, hem, and fly seam,

A machine for serging the inseam or side seam. If the machine has only

B machine for serging the seam opposite the trouser panel worked with

The operating principles of the A machine and of the B machine are identical:

During the sewing process, the contour guide controls the routing of the

seam along the fabric contour. The sewing unit sews and serges the fabric contour automatically and incorporates the fullness for the knee lining,

if required.

Operating Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Functions of the machine

two sewing heads, the A machine can be used for serging the waistband, hem, and fly seam in a separate machine cycle.

the A machine.

Machine cycle, Fig. 2:

The trousers panels are prepared on the two shel-

ves 3:

At the bonding station 5, the front trousers

panel and the knee lining are secured to each

other with a bonding mesh.

Now, the short seams can be serged at the C

machine 4 or at the A machine 6.

Then, the sewing pieces are lined up at the

contour guide of the A machine 6, and the

fully automatic sewing process starts.

The cross transport picks up the sewing pie-

ces at the transport unit of the A machine and

transports them to the B machine 2 where

the second, opposite seam is serged.

The transport unit of the B machine transports

the sewing piece from the working plate to the

stacker 1 where they are stacked on top of each other.

As soon as the sewing process starts at the A machine, the next trou-

sers panels can be secured at the bonding station.

B

A

C

Fig. 2

B-4

Page 15

Operating Instructions Automatic Multi-Head Serging Machine 1365-4 Beisler GmbH

Functions of the machine

B.1

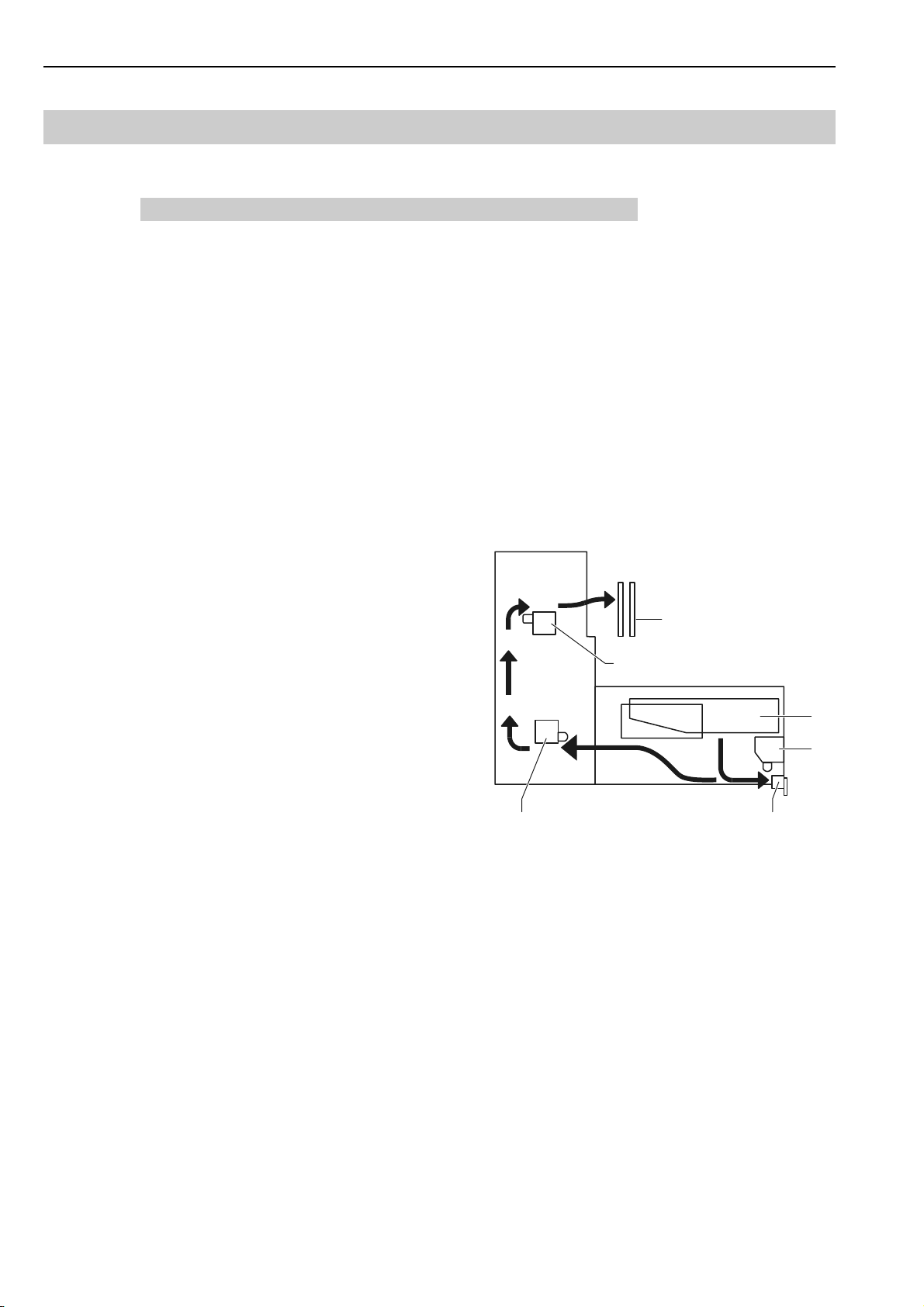

B.2.2 Securing the sewing pieces

Bonding station, Fig. 3:

To prevent the trousers panel and the knee lining from being shifted during the sewing process, they are secured to each other by hot pressing at a lateral location.

At the bonding station 1, a

bonding mesh strip 3 is placed between knee lining and

trousers panel and heated by

the lower stamp 4 of the

press unit. Then, the upper

stamp 3 and the lower

stamp 4 press the sewing

pieces together so that they

are secured to each other.

Fig. 3

B-5

Page 16

B.2

B.2.3 Guiding of the sewing pieces

The guiding of the sewing pieces along the stop of the A and B machines

is controlled by the combined action of contour guide and puller. When sewing with excessive arc contours, the support is activated for rotating the

sewing pieces.

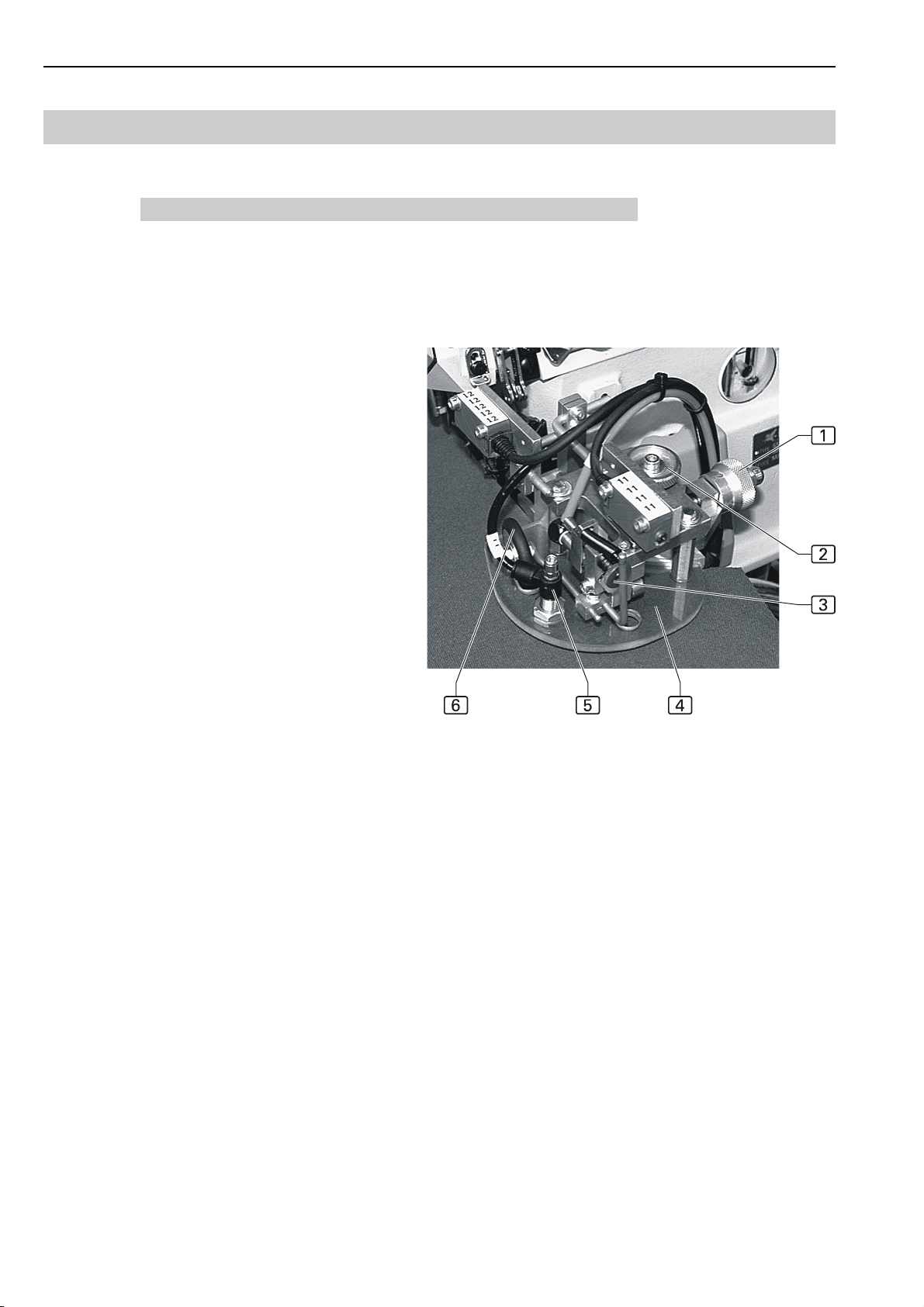

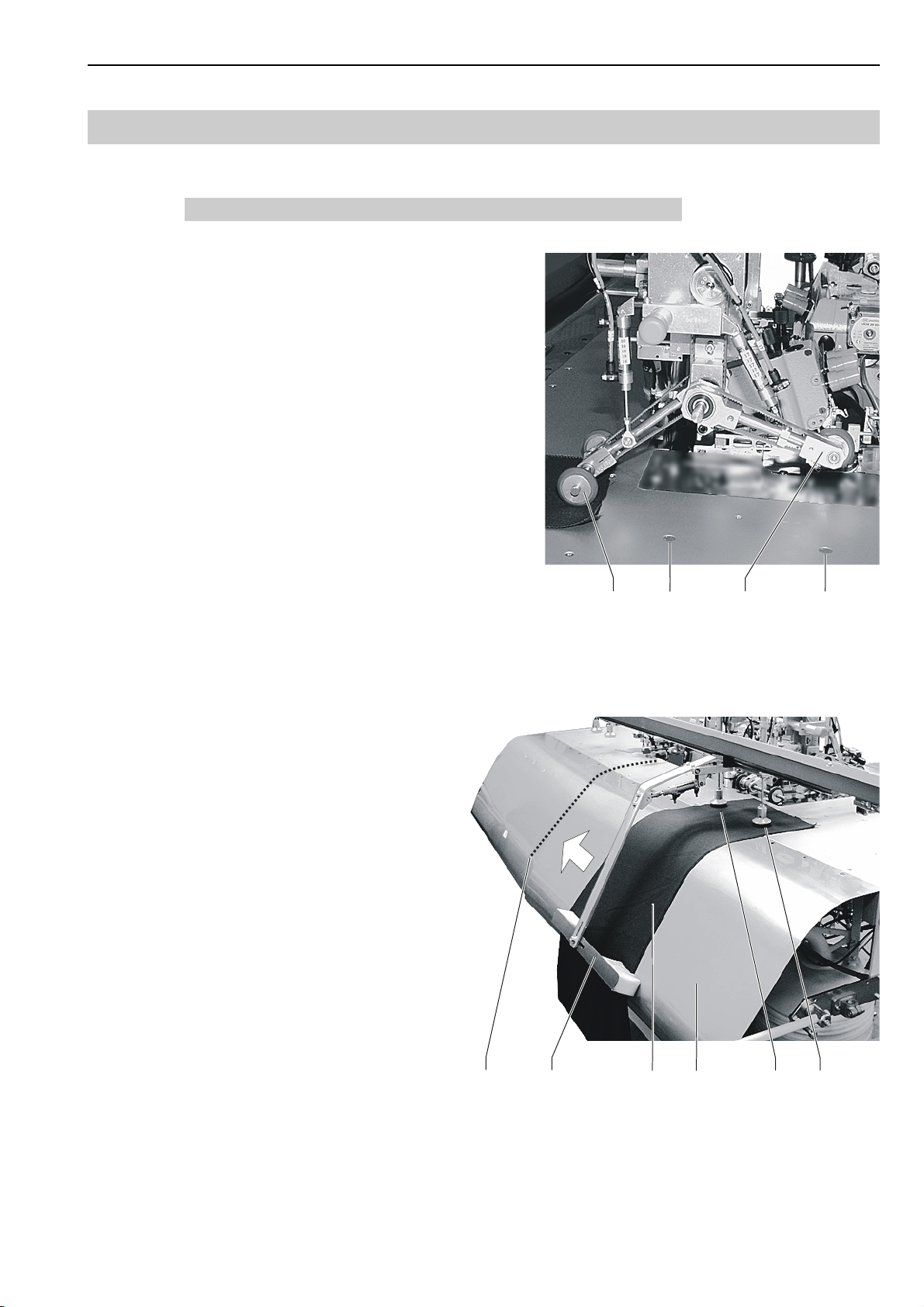

Contour guide, Fig. 4:

Operating Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Functions of the machine

During the transport of trousers panel

and knee lining to the sewing unit, the

contour guide controls the shape of

the fabric contour and ensures the exact routing of the seam along the sewing unit stop.

At the contour guide, the following

settings are made for the thickness of

the fabric:

Height quick adjustment 1 of the

contour guide:

Use this control for the rough adjustment of the thickness.

The distance between the contour

guide sliding plate

working plate can be changed in

four stages of 0.8 mm each in

both directions. Stage 1: smallest

distance (0.8 mm), Stage 4: largest distance (3.2 mm)

Height fine adjustment 2 of the

contour guide:

The adjustment made with the height quick adjustment can be fineadjusted. The following should be observed as a rule:

A single fabric layer should pass easily below the sliding plate

while a double layer must not pass through the gap.

The pressure that the contour roller 6 applies to the sewing pie-

ces is set with the adjustment screw 3.

The setting of the compressed-air nozzle 5 that blows the sewing pieces against the stop should not be changed to adjust the contour control.

4

and the

4

Fig. 4

B-6

Page 17

Operating Instructions Automatic Multi-Head Serging Machine 1365-4 Beisler GmbH

Functions of the machine

B.2

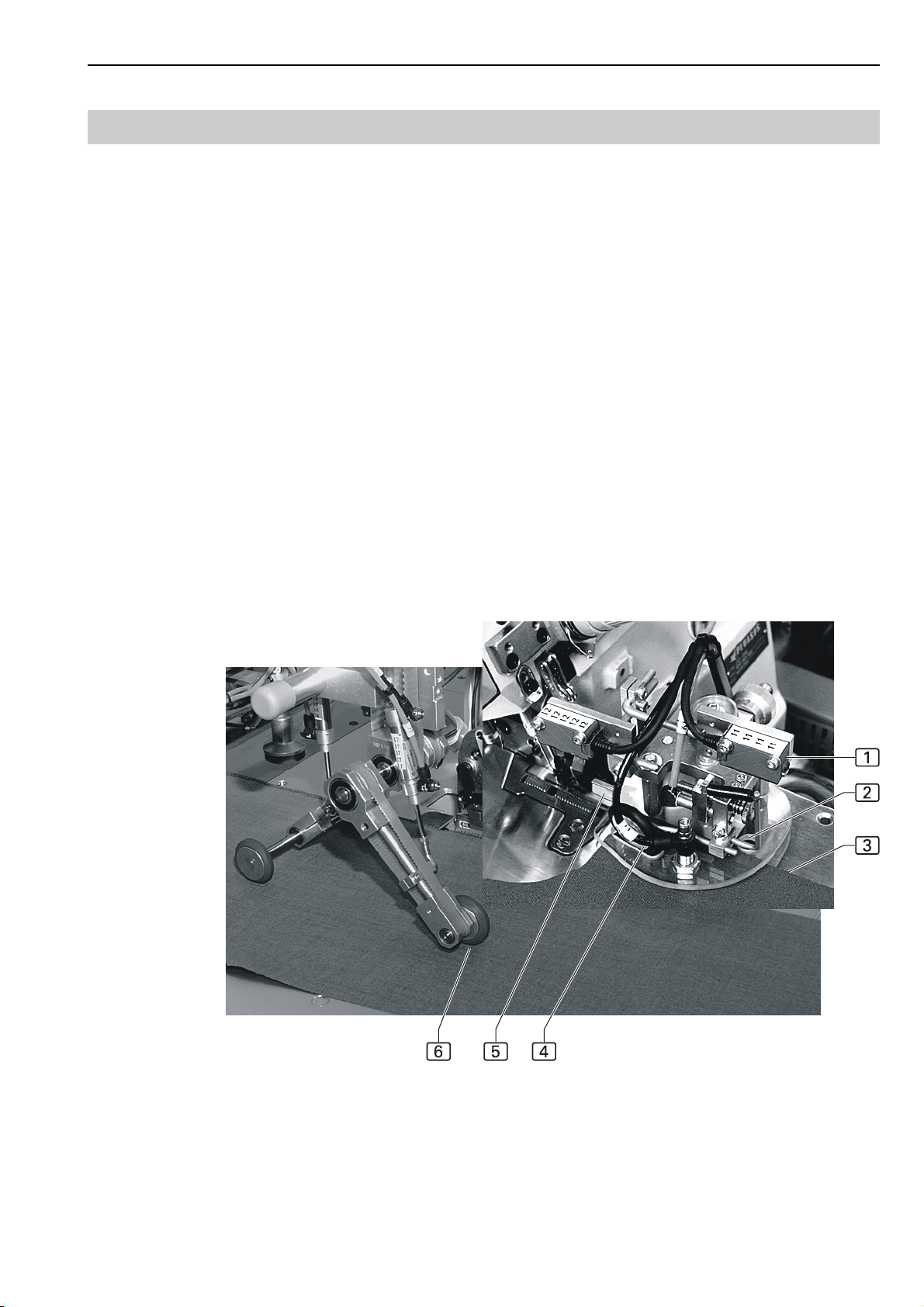

Control, Fig. 5:

The control of the sewing pieces along the sewing stop 5 is affected

by:

the puller speed 6,

the pressure that the contour roller 4 applies to the sewing pie-

ces.

The photocell 1 uses the reflective film 2 to determine the deviation of the fabric contour 3 from the ideal routing and readjusts the speed

of the puller 6 as required.

If the sewing pieces are shifted sideways away from the stop, the

puller speed is too high,

if the sewing pieces warp at the stop, the puller speed is too low..

The frequency for adapting the puller speed is set with the program control

In addition, the contour roller 4 pushes the sewing material toward the

stop 5 as a result of its orientation. The lateral thrust depends on the

pressure that the contour roller applies to the sewing pieces:

If the sewing pieces are shifted sideways away from the stop, the

pressure is too high,

if the sewing pieces warp at the stop, the pressure is too low.

The required contour roller pressure is determined in sewing tests in

combination with the puller speed.

B-7

Fig. 5

Page 18

B.2

Support, Fig. 6:

Operating Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Functions of the machine

In the sewing range of the waist curve, the position of the support

is changed at the B machine to rotate the trousers panel for the sewing

process. If the trousers panel inseam is effected at the B machine, the

puller also swings out at the pivot

2

to ensure that the trousers

panels are positioned correctly at

the stacker.

1

Fig. 6

B-8

Page 19

Operating Instructions Automatic Multi-Head Serging Machine 1365-4 Beisler GmbH

Functions of the machine

B.2

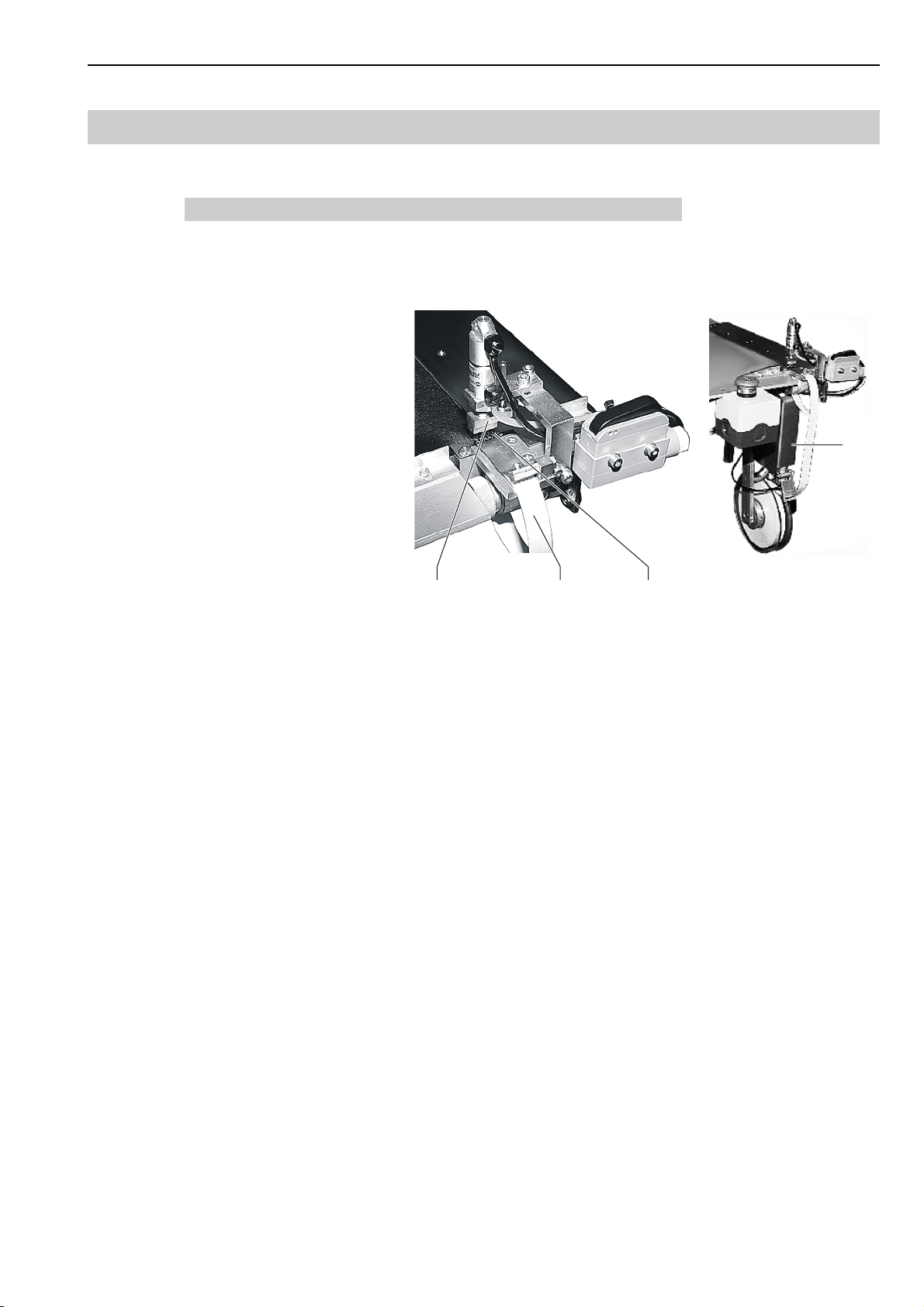

B.2.4 Serging the seam

Sewing heads, Fig. 7:

Each sewing head performs the sewing, thread

cutting, and serging functions. The sewing units

of the A and B machine also incorporate the

fullness for the knee lining, as required.

The start of the sewing process is triggered by

the photocell 1 when the sewing pieces

at the stop 3 of the sewing unit are moved toward its sensor range. As soon as the photocell recognizes the sewing pieces (photocell

darkens), the sewing process at the A machine starts:

the trousers panel is sewn,

the knife 4 serges the seam,

the thread rests are aspired into the waste

container.

This sewing process is repeated at the B machine for the opposite seam.

2

NOTE - Reflective surfaces of the photocells!

The reflective surfaces of the photocells at the A and B machines must not

be damaged or dirty as otherwise the sewing unit control may be impaired.

NOTE - Cancelling the sewing process!

When the program stop switch at the operating panel is depressed, all

machine movements and the sewing process are stopped immediately. The

switch is locked after it has been depressed and must be unlocked for a

reset (machine restart).

Abb. 7

B-9

Page 20

B.2

S3

S4

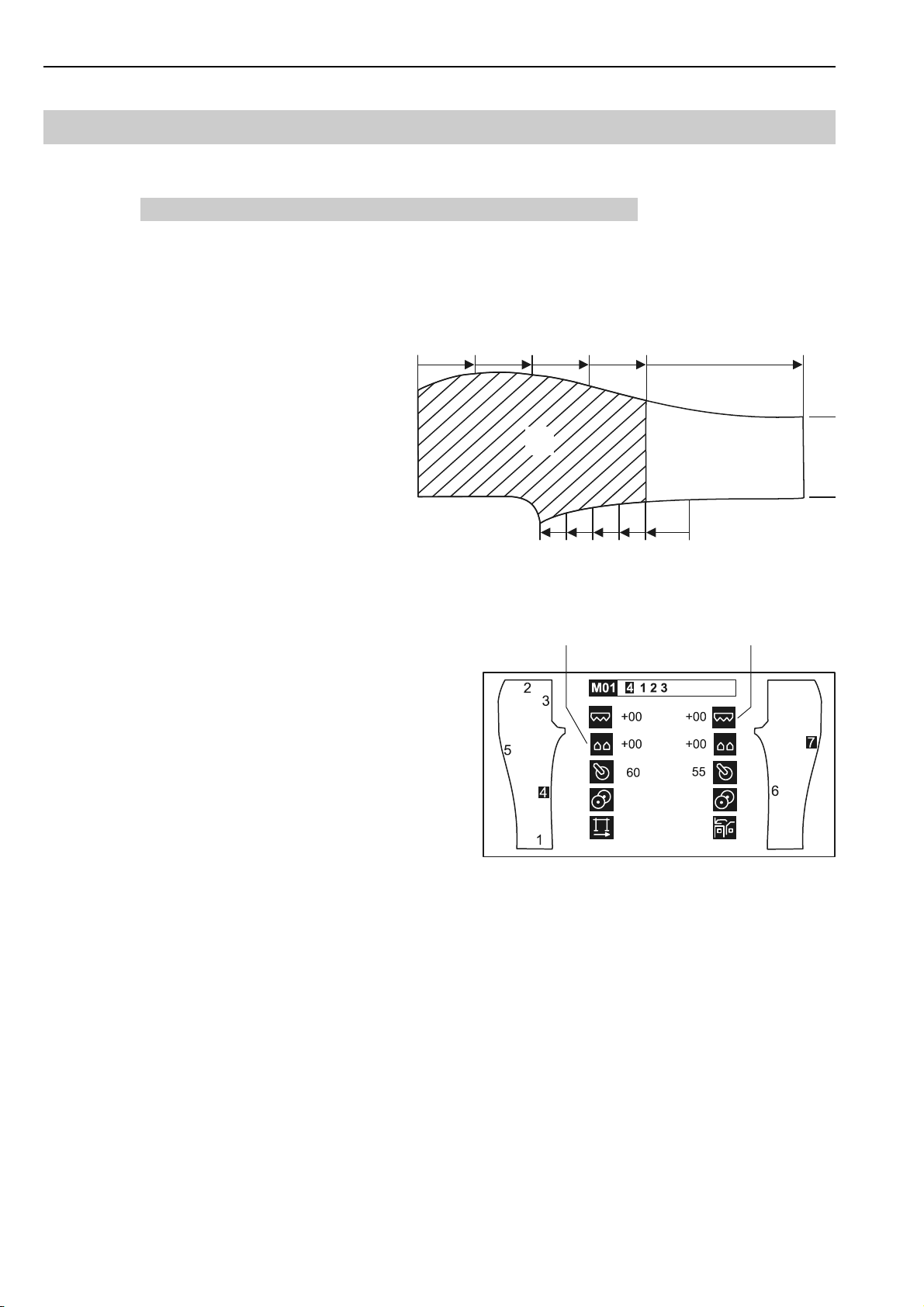

B.2.5 Width distribution for knee lining

To ensure the correct width distribution, the transport characteristics of differential transport and top transport must be matched to fit the material of

the knee lining. This is required when waved lining is sewn.

Presetting, Fig. 8:

Functions of the machine

In the sewing range of side seam A

and inseam B, the trousers panel

splits into five sections with the knee

lining C extending over four of these sections. For each section, the

length can be varied and the pertaining fullness (quantity) can be preset

with the program control (see Section D, Programming Instructions).

S1

Operating Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

S2

C

S5

A

B

Quick adjustment, Fig. 9:

The operating panel allows direct access for

the quick adjustment of the fullness by modifying top transport 2 and differential transport 1. Select the corresponding function and

modify it in a range between -19 and +19.

S5 S4 S3 S2 S1

Fig. 8

Fig. 9

B-10

Page 21

Operating Instructions Automatic Multi-Head Serging Machine 1365-4 Beisler GmbH

Functions of the machine

B.2

B.2.6 Transport

Transport unit of A machine, Fig. 10:

The transport unit of the A machine consists of

puller 2 and roller 3.

The puller transports the sewing pieces du-

ring the sewing process.

The roller moves the sewing pieces to the

cross transport and also supports the trans-

port function of the puller. This function can

be enabled for heavy fabrics.

To improve the gliding characteristics of the trousers panels, the working plate has six compressed-air nozzles 1 near the A machine. The air

blows from below against the trousers panels; the

resulting air cushion reduces friction during the

transport.

Cross transport, Fig. 11:

The cross transport, consisting of double stamp

1

and accessory stamp 4, picks up the sewing pieces 3 at the A machine and transports

them across the sliding panel 2 to the B machine. If the sewing process at the B machine is not completed, the cross

transport stops at a wait position 5 in front of the B machine.

Fig. 10

B-11

Fig. 11

Page 22

B.2

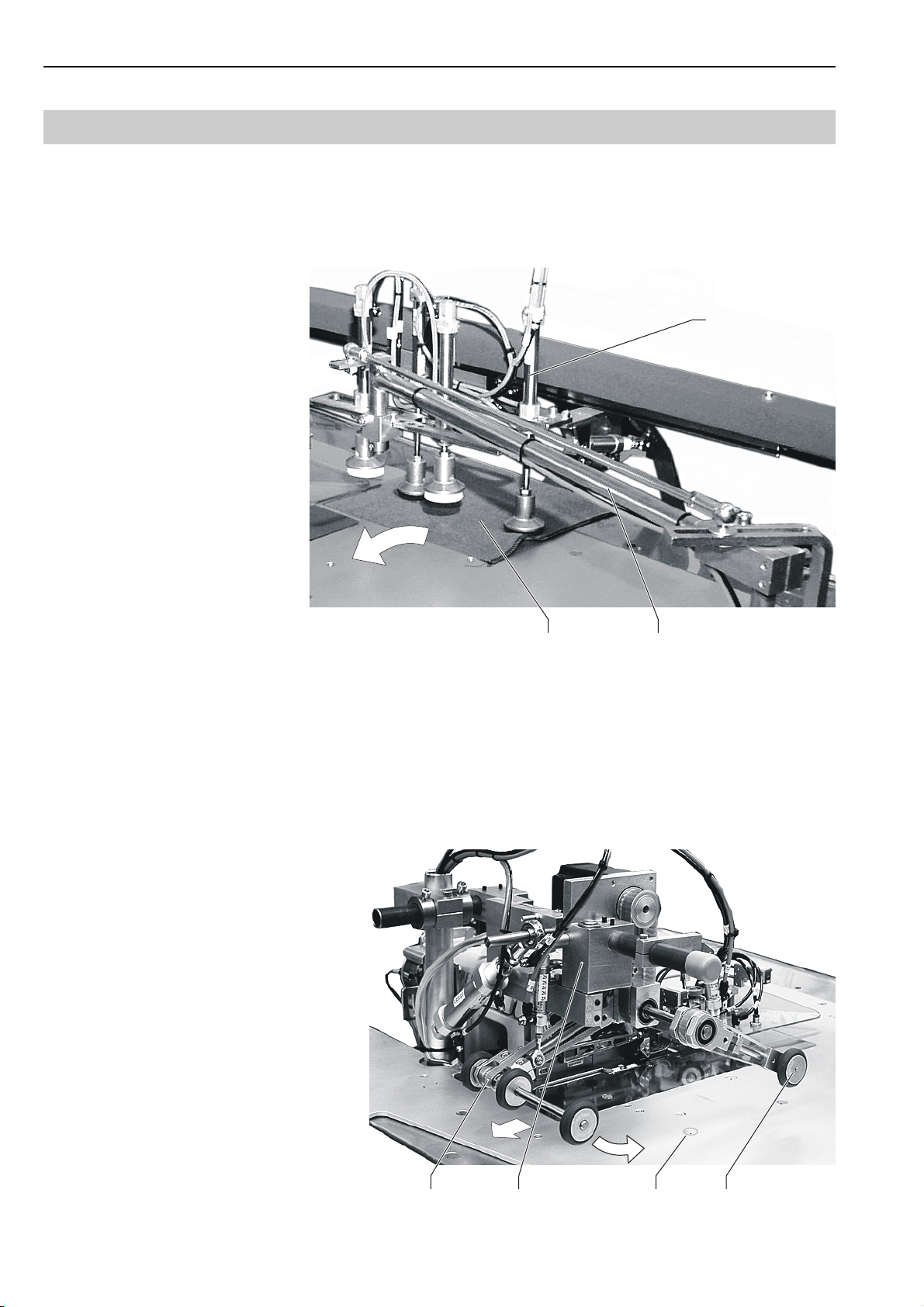

Swing arm, Fig. 12:

Operating Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Functions of the machine

The swing arm 1 receives the sewing pieces 1 from the cross transport 2 and lines them up at the contour guide of the B machine.

Transport unit of the B machine, Fig. 13:

The transport unit of the B machine comprises the puller 1 and a

roller 4.

The puller transports the sewing pieces during the sewing process,

the roller moves the sewing pieces from the worktable to the stak-

ker. To ensure that the trousers panels are stacked flush at the

stacker, the roller swings out at the pivot 3 when inseams are

sewn.

The working plate has compressed-air nozzles 2 near the B machine. Just like at the A machine, the transport process is

supported by a compressed

air cushion.

Fig. 12

Fig. 13

B-12

Page 23

Operating Instructions Automatic Multi-Head Serging Machine 1365-4 Beisler GmbH

Functions of the machine

B.2

B.2.7 Stacking

Stacker, Fig. 14:

As soon as the chain is severed, the automatic stacker is activated and

deposits the sewing piece over the bundle rod.

To remove the sewing pieces, the footswitch is depressed so that the

stacker bundle clamp opens.

Fig. 14

B-13

Page 24

B.2

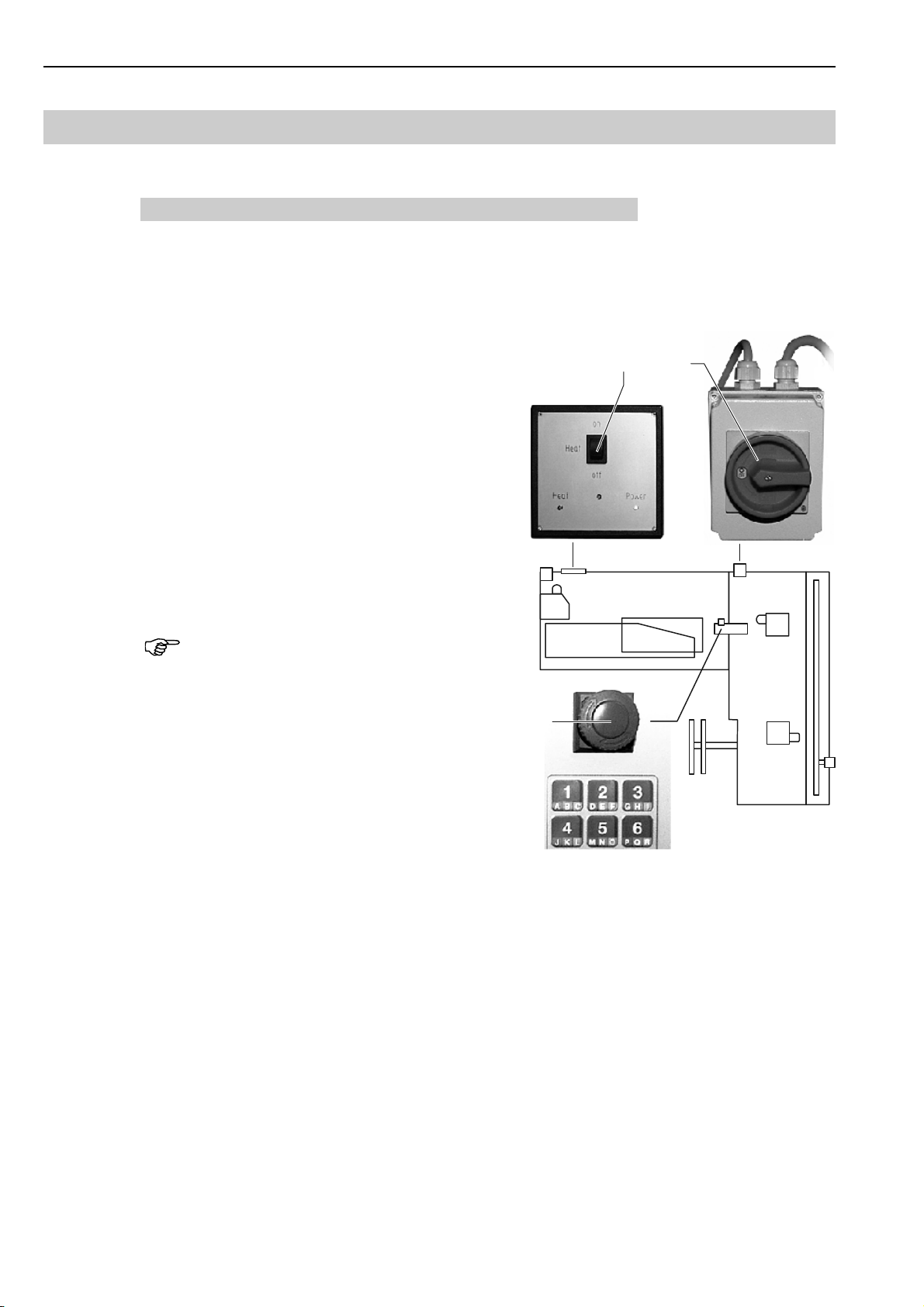

B.2.8 Switches

Power switch / Emergency stop switch, Fig. 15:

Program stop switch

Operating Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Functions of the machine

Main switch / Emergency stop switch

The main switch 2 is used to switch the power supply of the machine on or off. In case of extended production intermissions, the machine must be switched off with the main switch so that all functional units

are disabled. The main switch is located at the machine frame below the A machine and is also used

as an emergency stop switch.

On/off switch for the bonding station heating module

The heating module 1 of the bonding station has

a thermostat with a separate on/off switch that is installed below the bonding station.

When the program stop switch 3 is pressed, all

machine movements and the sewing process are interrupted immediately.

The switch is locked after it has been pressed. When

rotated clockwise, the switch is unlocked and returns

to its original position. The control performs a reset.

NOTE - Program stop switch!

C

A

When the program stop switch is actuated, it merely cancels the machine cycle while the program control and

the machine drive continue to be supplied with electric

voltage. To interrupt the power supply, switch the machine off using the main switch.

B

Fig. 15

B-14

Page 25

Operating Instructions Automatic Multi-Head Serging Machine 1365-4 Beisler GmbH

Functions of the machine

B.2

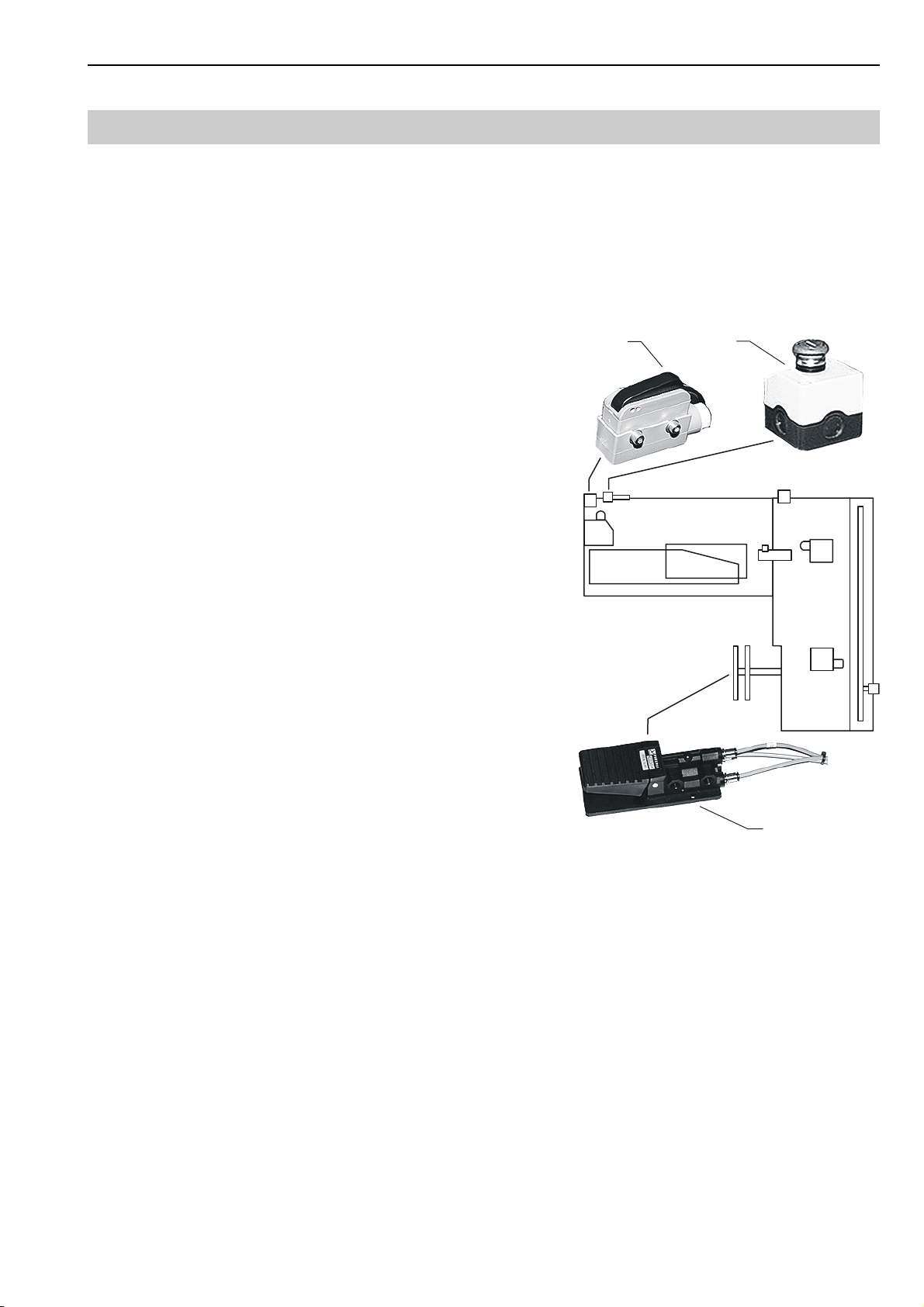

Function switches, Fig. 16:

Clamp switch 2 for opening/closing the bonding clamp

During normal operation, the bonding clamp is open. The knee lining

is pushed below the bonding clamp to be secured to the trousers panel. When the clamp switch is pressed, the bonding clamp closes, and

the knee lining is secured for the bonding process.

Bonding switch 1 for activating the bonding stamps

The trousers panel is placed onto the knee lining.

When the bonding switch is pressed, the upper and

lower stamps of the bonding unit are pressed

against each other and the bonding mesh between

the stamps bonds the sewing pieces together.

Footswitch for stacker

When this footswitch is pressed, the stacker bundle

clamp opens so that the sewing pieces can be removed. When the footswitch is released, the bundle

clamp closes again.

3

C

A

B

Fig. 16

B-15

Page 26

B.2

B.2.9 Operating panel

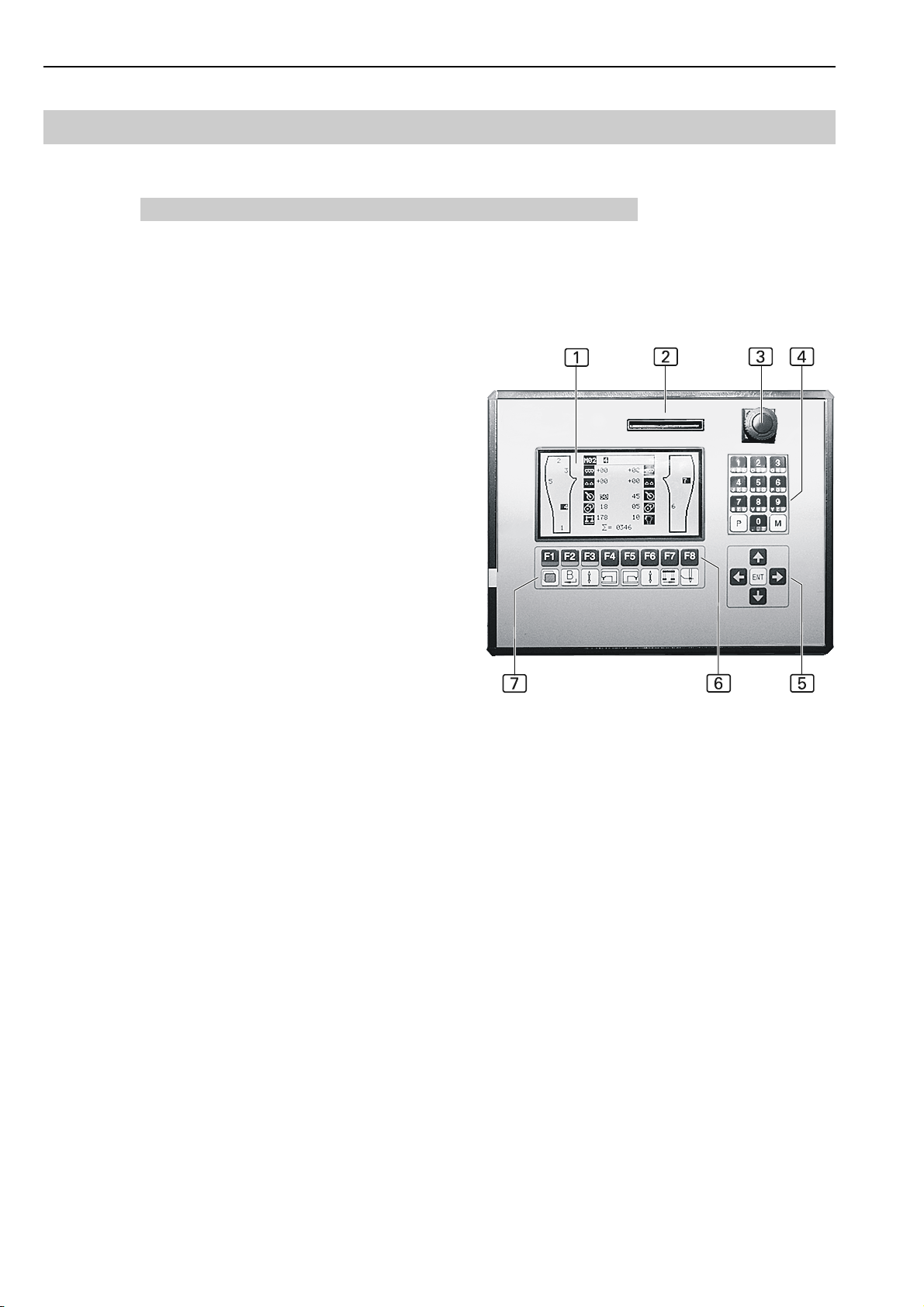

Fig. 17: The operating panel is the display and data input medium of the

machine control. It contains the microprocessor that controls the machine and the storage media (EPROM) for backups of the program control.

Operating Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Functions of the machine

Display

Slot 2 for memory card

Program stop switch

Numeric keypad

1

The display shows information about the machine control and the sewing program parameters. If a function for a sewing program is

enabled or disabled, the symbol for that

function and the pertaining parameter value

are displayed or disappear.

The memory card is the storage medium for

backups of any machine control data. Sewing

programs can be copied to the memory card

and retrieved back into the machine control,

if required.

3

This switch is used for cancelling the machine

cycle.

4

Use the numeric keypad to enter all modifiable numeric values. The sewing programs

M01-M09 are activated by entering the corresponding numbers. To activate the sewing programs M10-M20, press the M key, then enter the

corresponding numbers. Use the P key to select submenus, to confirm data input or to exit the programming mode.

Fig. 17

Arrow keys

Each pressing of the UP or DOWN arrow key will move the cursor one

line up or down in the selected menu.

Use the LEFT or RIGHT arrow key to mark the desired parameter in

the selected menu or to scroll through the selected menu if the parameter list consists of several pages.

Function keys

Use the function keys to select the program control menus.

Symbol bar

The symbol bar indicates the menus that can be selected directly from

the start level by using the function keys.

All other menus for setting machine or program functions can be selected from the various program levels. The display of the operating

panel shows the pertaining menu symbols.

5

6

7

B-16

Page 27

Operating Instructions Automatic Multi-Head Serging Machine 1365-4 Beisler GmbH

Functions of the machine

B.2

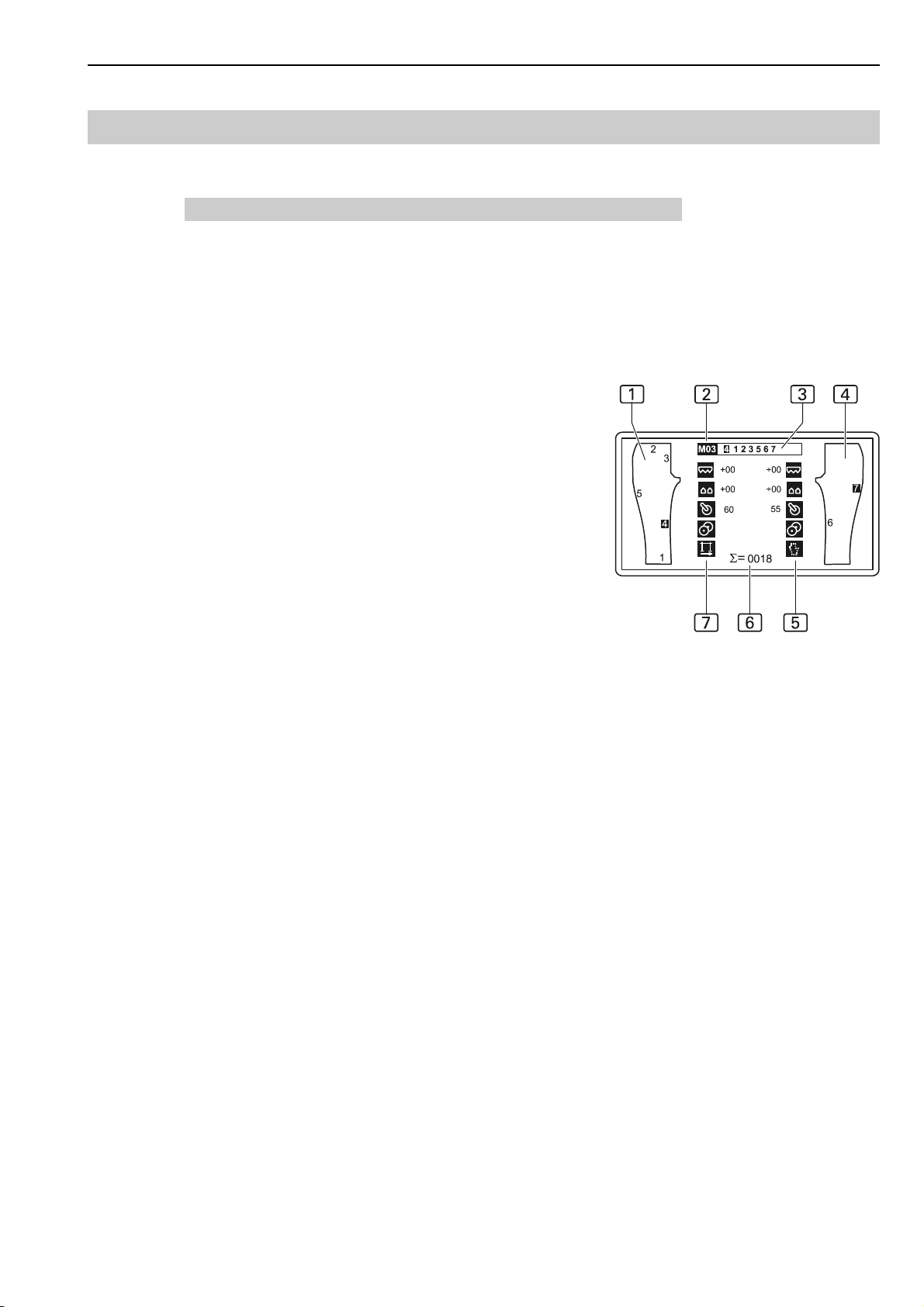

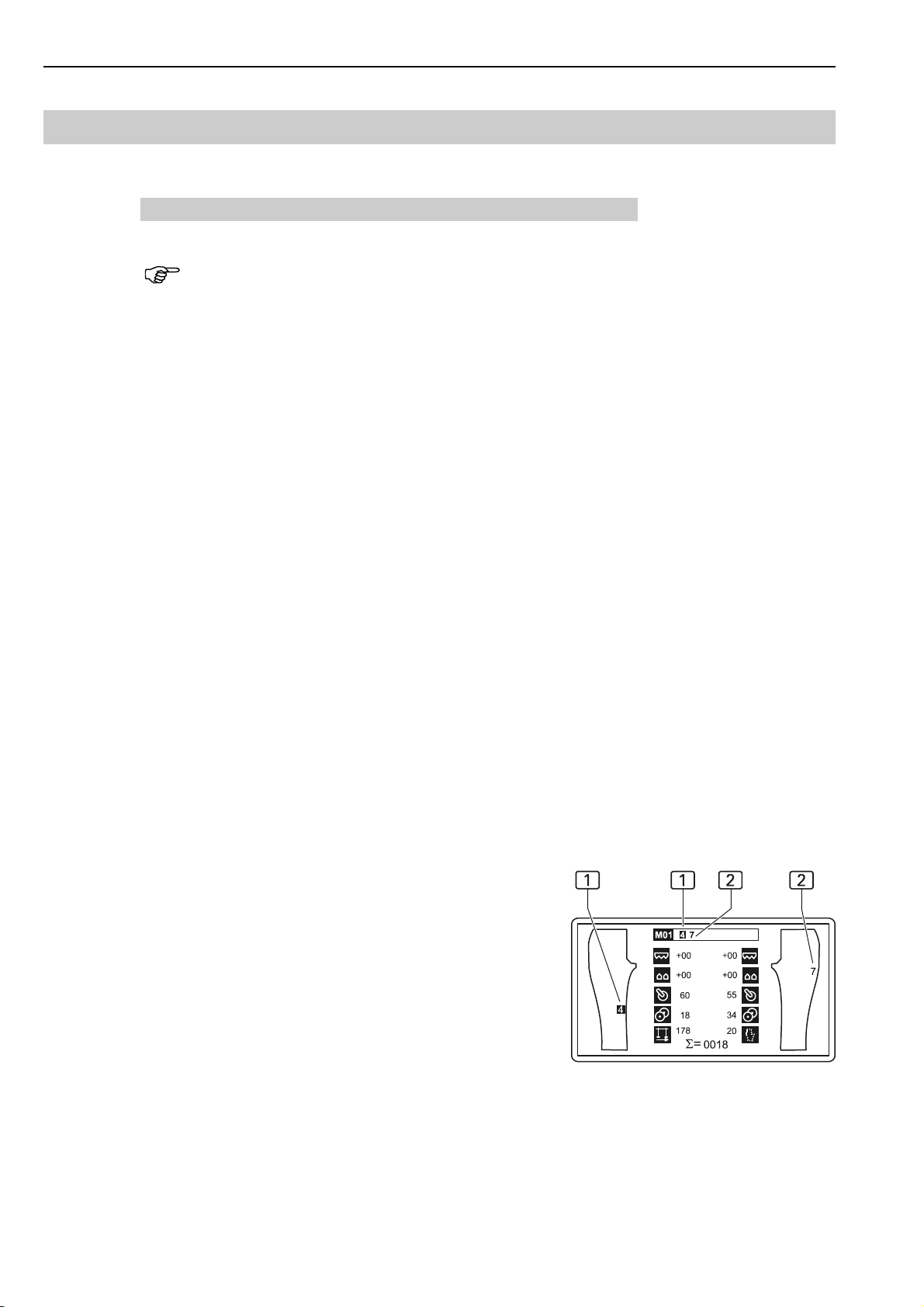

B.2.10 Sewing programs

The program control memory can store up to 20 sewing programs (M 01-

M 20). Up to 7 seams with corresponding seam numbers 3 can be as-

signed to each sewing program 2. The seams differ by their control pa-

rameters that are assigned to them by their sewing program and by the

control functions that are enabled.

Fig. 18: The display shows the structure of the selected sewing program:

1

4

2

3

5

6

7

The structure is explained with the example of sewing program

M 03 (trousers front panel with knee lining) that can effect the

short seams as well as inseams and side seams in alternati-

on.

The A machine can effect the short seams 1, 2, and 3 manually:

The inseams and the side seams are serged automatically:

The B machine effects the corresponding opposite seams:

Seams of the A machine

Seams of the B machine

Description of the sewing program

(a sewing program may consist of several seams)

Seam number of the sewing program

Symbols of the activated sewing functions of the

B machine

Day counter for completed seams

Symbols of the activated sewing functions of the

A machine

1 hem seam

2 waistband seam

3 fly seam

4 inseam

5 side seam

6 inseam

7 side seam

Fig. 18

If the A machine effects inseam 4 of the right front trousers panel, the

B machine serges the opposite side seam 7; if the A machine effects side

seam 5 of the left front trousers panel, the B machine serges the opposi-

te inseam 6.

The enabled control functions are displayed as symbols 7 and 5 for the

A and B machines. If the control function of a sewing program is disabled,

the pertaining symbol appears as a pictogram on a bright background. The

control parameters of the functions can be modified by entering values.

B-17

Page 28

B.2

A sewing program can be combined with one seam or with several seams.

If a sewing program with several seams is selected, the seams are effected

from left to right in the sequence of their seam numbers. The sequence of

the seam numbers can be changed.

Factory settings

The program control has three factory-installed sewing programs.

M 0 - M 03 for standard fabric materials.

M 09 sewing program for manual finishing.

M 07 - M 08: These memory locations are unassigned.

M 10 - M 20: Use these memory locations for modified or freely pro-

The symbols for the sewing programs indicate the sections of the seam

for which fullness has been programmed.

Operating Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Functions of the machine

grammable sewing programs.

M 01 normal rear panel

M 02 rear panel with excessive waist curve

M 03 front panel with knee lining

B-18

Page 29

Operating Instructions Automatic Multi-Head Serging Machine 1365-4 Beisler GmbH

Operation

B.3

B.3.1 Preparing the machine

Prior to a production start, check the supply connections, connect the ma-

chine to the compressed air system and to the power supply system, and

prepare the sewing head.

1. Connect the machine to the power supply system.

WARNING - Electric shock!

Contact with current-carrying components may cause a lethal electric shock. Check plug and cable before connecting

machine to power supply system.

Do not use damaged plugs, sockets or cables to con-

nect the machine to the power supply system!

The machine is operated with a supply voltage of 230 V

± 10 % at 50/60 Hz. The power supply cable must have

a minimal cross section of 1,5 mm.

Before connecting the machine to the power supply sy-

stem, check to see if the ratings of the power supply

system in the operating room correspond with the ratings on the nameplate at the rear of the machine.

If the ratings for voltage (V) and maximum current (A)

do not match, the machine must not be connected.

Insert the grounding plug into a properly grounded and

fused power socket.

Make sure that the power supply cable is not subjected

to tensile or pressure forces.

2. Switch the machine on by moving the main switch to position I. After

the machine has been switched on, its control program is powered up.

The display shows the most recently selected sewing program.

3. Switch the heating module on. Wait until the red indicator goes out to

indicate that the lower stamp has reached its operating

temperature.

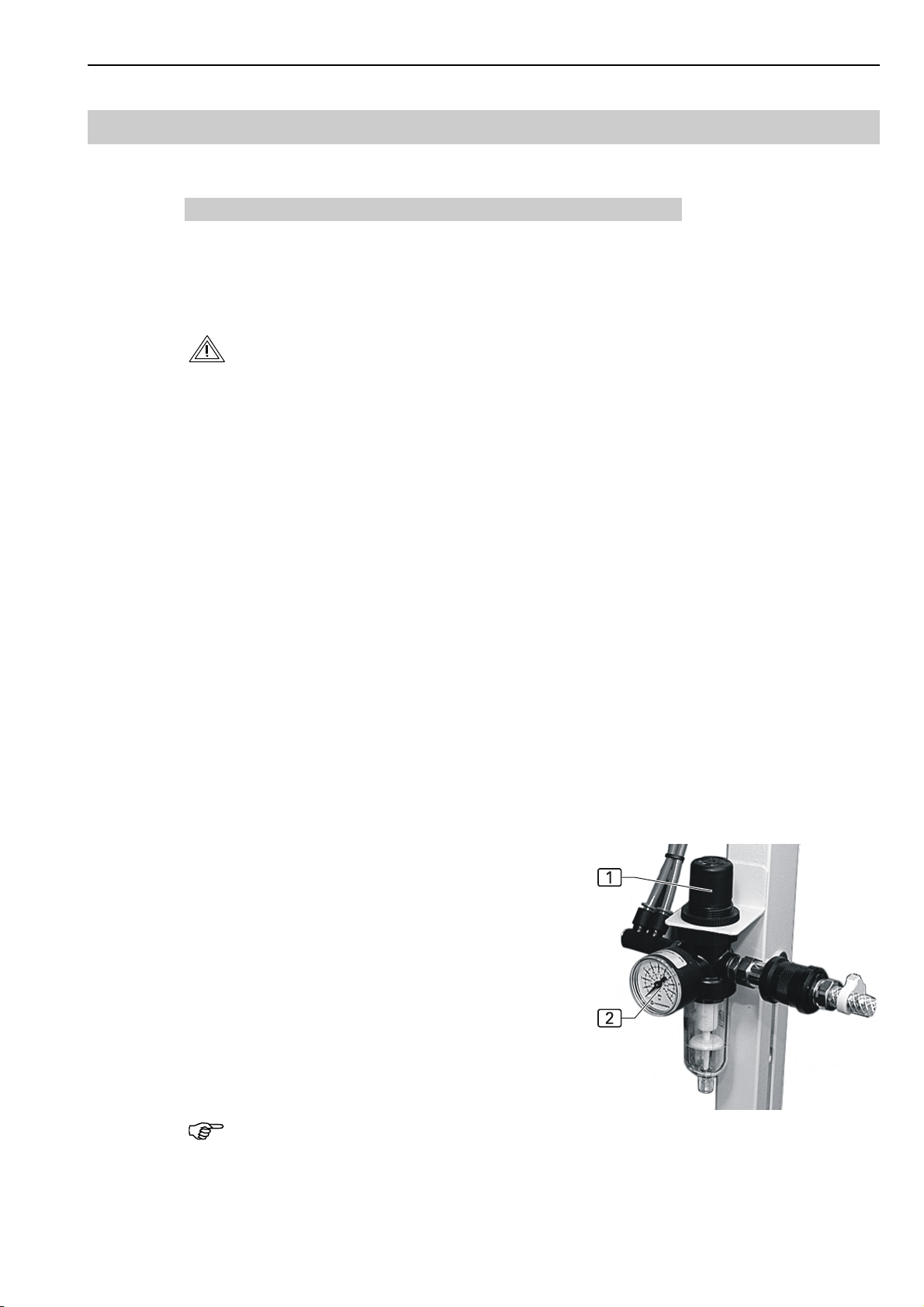

4. Fig. 19: Connect the machine to the compressed air

supply system by installing the compressed air hose

connector to the outlet of the compressed air supply system in the operating room. A pressure reducer 1 reduces the compressed air to the operating pressure of

6 bar. Check the manometer 2 to see if the correct

operating pressure has been set. The pressure reducer is located at the machine frame below the B machine.

5. Insert needle, pass top thread through needle and in-

stall bottom thread spool to sewing head (see operating instructions of sewing head manufacturer or supplier).

NOTE - Passing thread through needle!

On both machines, the program control supports the passing

of the thread through the needle.

Fig. 19

B-19

Page 30

B.3

B.3.2 Selecting a sewing program

1. Select the sewing program at the operating panel.

Operating Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Operation

NOTE - Operating functions!

The following pages describe only the major functions of the

operating functions that are required for the immediate production run.

For a detailed description of the program control and for

details about program control settings and programming of

sewing programs, please refer to Section D, Programming

Instructions, of these working instructions.

The sewing programs M01-M09 can be selected in direct access:

Enter the number of the sewing program at the numeric keypad , e.g.

5.

The sewing programs M10-M20 are selected from the memory:

Select the memory function:

Press the ) key

Select the number of the sewing program, e.g. 15:

Press the 1and 5 keys

2. Activate the seam number of a selected seam in direct access.

Move the cursor to the seam number:

Press the &or / key

Fig. 20: Display of the seam number:

1

Active seam number

2

Passive seam number

B-20

Fig. 20

Page 31

Operating Instructions Automatic Multi-Head Serging Machine 1365-4 Beisler GmbH

Operation

B.3

B.3.3 Passing thread through needles

This function allows the easy passing of thread through the needles on both

sewing heads. The photocells are switched off so that the sewing units are

disabled. The pressure foot is lowered, the transport units are raised.

1. Prepare the sewing unit for the passing of the thread:

Press the hkey

+

2. Pass the thread through needle and hook.

3. Enable the sewing unit:

Press the hkey

B.3.4 Modifying sewing program functions

For A machines and B machines, the value range of the following functions

of a sewing program can either be modified or completely enabled or disabled as executable machine function:

v Top transport In addition to basic setting

w Differential transport In addition to basic setting

# Puller Parameter 14, speed

x Roller Parameter 30, transport distance

Ä Cross transport Parameter 39, transport distance

Fig. 21: Enabled functions 1 are displayed as inverted sym-

bols. A disabled function 3 appears as a pictogram on a bright

background. The parameter value assigned to a function is displayed in the corresponding input field 2 to the right or to the

left of the function symbol.

The parameters assigned to the functions are either the additional increase or the reduction of basic values or the direct

modification of the main parameters of a seam.

Sewing speed Basic value, speed

B-21

Fig. 21

Page 32

B.3

Changing values

1. Select the function at the A machine or B machine:

2. Increase or reduce the value using the arrow keys:

3. Confirm input:

Operating Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Operation

Press the c or f key

s s

until the symbol assigned to the input field appears on a black background.

Press the & or / key

Press the (key

v Top transport

Within a sewing program, the width distribution can be corrected by quick

adjustment of the top transport both at the A machine and at the B machine.

To achieve this, the position of the top transport unit to the main transport

unit can be changed within a value range of -19 to +19. This setting affects

only that section of the seam for which fullness has been enabled.

w Differential transport

The position of the differential transport unit to the main transport unit of

the sewing unit can also be changed by quick adjustment within a value

range of -19 to +19. This setting affects only that section of the seam for

which fullness has been enabled.

# Puller speed

The photocell determines the deviation of the fabric contour from the ideal

routing and readjusts the puller speed, as required.

If the sewing pieces are shifted sideways away from the stop, the pul-

ler speed is too high,

if the sewing pieces warp at the stop, the puller speed is too low.

The frequency for adapting the puller speed is set with the program con-

trol.

The basic speed of the puller can be changed by using the input field.

x Roller

The parameter changes the length of the distance along which the roller

transports the sewing piece from the A machine to the point where the cross

transport picks it up or at the B machine from the worktable to the stacker.

B-22

Page 33

Operating Instructions Automatic Multi-Head Serging Machine 1365-4 Beisler GmbH

Operation

B.3

Ä Cross transport

This value is used for setting the actual transport distance from the A machine to the B machine or the distance along which the cross transport

moves the sewing piece from the wait position in front of the B machine

to the point where the swing arm picks it up.

Sewing speed at waist curve

The parameter changes the basic value of the puller speed when the waist

curve is sewn. Depending on the waist curvature, a puller speed that has

been adapted accordingly can be set.

Enabling or disabling functions

For specific sewing patterns or as the result of a specific material behavior, all six functions can be enabled or disabled individually or in combinations.

1. Select the function at the A machine or B machine:

Press the cor fkey

s s

until the symbol assigned to the input field appears on a black background.

2. Move to the basic parameter menu of the selected function:

Press the %key

3. Enable or disable the function:

Press the hkey

4. Confirm input:

Press the (key

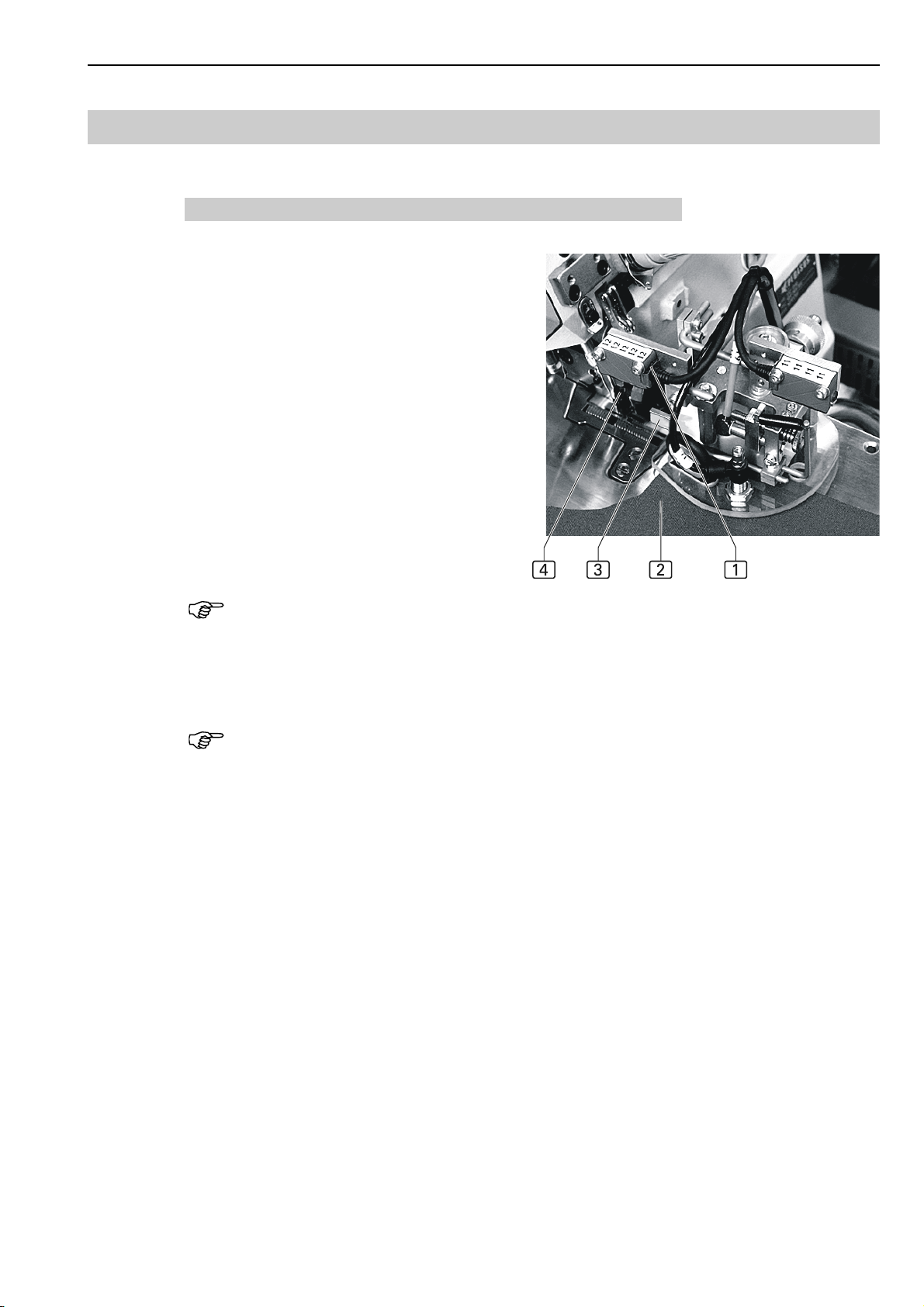

Fig. 22: At the B machine 1 where the inseam 2 is effec-

ted, press the F8 key 4 to enable the puller 3 function.

When this program function is selected, the parameter list

assigned to this specific sewing function 5 is opened.

For details about the programming of sewing programs, please

refer to Section D, Programming Instructions, of these working

instructions.

B-23

Fig. 22

Page 34

B.3

B.3.5 Resetting the day counter to zero

This function is used to reset the day counter to zero before a new production

cycle or after a completed cycle.

1. Move to access level 2:

Operating Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Operation

Press the akey

j

The display shows the symbols of the selectable functions on this le-

vel.

BD"yz!FH

abcdefgh

2. Select the function for resetting the day counter:

F

Keep the gkey depressed for approx 3 seconds

The day counter is reset to zero.

3. Confirm reset and return to access level 1:

Press the ( key.

Display: S = 0000

B.3.6 Moving the cross transport manually

Use this function for the manual transport of a sewing piece from the A

machine to the B machine. When the key is pressed, the two cross transport

stamps are lowered, and the transport moves to the pick-up position at the

B machine; from there, the remaining part of the machine cycle is triggered automatically and continued.

1. Position the sewing piece below the two stamps.

2. Start the cross transport manually:

Press the g key

n

The cross transport moves to the wait position in front of the B machi-

ne.

3. The automatic machine cycle continues.

B-24

Page 35

Operating Instructions Automatic Multi-Head Serging Machine 1365-4 Beisler GmbH

Operation

B.3

B.3.7 Resuming the sewing process at the B machine

After the sewing process at the B machine has been interrupted, it can be

resumed by lining up the sewing piece at the contour guide photocell. This

manual interference in the machine cycle may be necessary e.g. if a failure

occurs in the cross transport.

1. Stop the sewing process of the B machine:

Press the bkey

[

2. Resume the sewing process of the B machine:

The automatic sewing process is resumed when the sewing piece is lined

up manually at the photocell of the B machine.

B-25

Page 36

B.3

B.3.8 Securing the sewing pieces

The trousers panels are prepared at the upper shelf, the knee lining is prepared at the lower shelf.

Bonding the trousers panels:

1. Make sure that the bonding sta-

1. Fig. 23: Line up knee lining

2. Press clamp switch 3; the

3. Place trousers panel onto lining

4. If the sewing pieces are aligned

5. The bonding clamp opens.

6. The trousers panels are now securely attached to each other and can

Operating Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Operation

tion heating module has reached

its operating temperature; the red

indicator 6 must be off.

1

below the bonding clamp 2.

clamp lowers and secures the

knee lining. Simultaneously, a fixed section of the bonding mesh

5

is advanced and removed

from the backing tape at the separator.

and align properly. To change the

position of the knee lining, press

the clamp switch to open the

bonding clamp.

properly on top of each other,

press the bonding switch 4.

The upper stamp is lowered,

presses knee lining, bonding

mesh, and trousers panel against the heated lower stamp and is then

raised.

be lined up for the serging process at the A machine.

Fig. 23

B-26

Page 37

Operating Instructions Automatic Multi-Head Serging Machine 1365-4 Beisler GmbH

Operation

B.3

B.3.9 Sewing process

Starting the automatic machine cycle:

1. Select the seam at the operating panel.

Example: If a right front trousers panel is to

be sewn, the A machine effects the inseam

and the B machine effects the side seam,

if the left front trousers panel is sewn first,

the A machine effects the side seam and the

B machine effects the inseam.

2. Fig. 24: In any case, always align the waistband

side of the trousers panels at the A machine.

Slide trousers panels to just before the stop

below the sliding panel 4 of the contour guide

and smoothen.

3. Then, slide the trousers panels into the sensor

range 2 of the photocell 1. When the fabric

interrupts the light beam at the reflective surface,

the automatic machine cycle is started automatically. The seam is sewn and serged at the A

machine.

3

NOTE - Starting the sewing process!

To ensure the correct routing of the seam, the trousers panels must be released as soon as the transport unit of the sewing head has seized the sewing pieces.

NOTE - Resetting the insertion process!

Before the response delay period of the photocell has elapsed,

the insertion process can be cancelled by moving the trousers panels out of the sensor range of the photocell.

After the sewing process has started, the machine cycle can

only be cancelled by pressing the program stop switch or by

pressing the function key F1.

Fig. 24

B-27

Page 38

B.3

4. Fig. 25: The two stamps

Operation

2

of the cross transport

receive the sewing pieces

3

from the roller 1 of

the A machines transport

unit.

Operating Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

5. Fig. 26: The sewing pieces 3 are

then moved over the sliding panel

to the B machine. If the B machine is

still busy, the cross transport

stops in a wait position in front of the

B machine.

1

2

6. Fig. 27: The swing arm 2 moves the trousers

panels 1 to the contour guide of the B machine.

B-28

Page 39

Operating Instructions Automatic Multi-Head Serging Machine 1365-4 Beisler GmbH

Operation

B.3

7. Fig. 28: The swing arm 2 lines

the sewing pieces 3 up at the

stop 4 in the sensor range of

the photocell 1; this starts the

sewing process at the B machine. The seam is sewn and serged automatically.

8. Fig. 29: The trousers panels 1 are then

moved across the worktable to the stacker unit

2

where they are stacked on top of each

other.

8. Fig. 30: Due to its overlapping

mode layout, the automatic serging machine is very efficient:

Up to four trousers panels can be

integrated in one machine cycle.

Sewing pieces 1 on the

shelf.

At the B machine, a trousers

panel 5 is sewn.

The trousers panel 4 is at

the wait position at the B

machine.

Panel 3 is received by the

cross transport.

Panel 2 is lined up at the

B machine.

B-29

Page 40

B.3

B.3.10 Stopping a sewing program

You can use the program stop switch of the operating panel to stop the

machine cycle.

1. Fig. 30: Press the program stop switch 1.

2. To restart the machine after a program stop, all functions must be re-

Operating Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Operation

All machine movements and the sewing process are stopped immediately. The switch is locked after it has been pressed.

set and the machine cycle must be reset to zero position. This is done

by unlocking the program stop switch.

Rotate the switch clockwise until it is locked and returns to its original

position.

The control program performs a restart.

B.3.11 Moving the machine to zero position

Prior to a production start, after machine tests or after sewing program

modifications, the machine must be reset to its zero position before a machine cycle can be started:

1. Press the program stop switch.

2. Unlock the program stop switch.

B.3.12 Shutting the machine down

For extended work intermissions, the machine must be shut down completely.

1. Switch off power supply by moving the main switch to the 0 position.

2. Disconnect the machine from the compressed air supply.

B.3.13 Cleaning the machine

The machine must be cleaned after large production series or at least once

a day, whichever occurs first.

CAUTION - Danger of injuries!

If the machine is put in motion accidentally, persons in its

direct vicinity may be caught by moving parts which may

cause injuries.

Prior to any cleaning work, disconnect the machine from the

power supply!

Turn the machine off using the main switch.

Remove the power plug from the socket and protect it

from accidental reconnection.

Fig. 30

1. Remove fabric residues.

2. Blow off dust and thread residues from sewing head, working plate, main

clamp, and linear rail using compressed air.

3. Empty waste container: Unscrew container 2 from head 1 by rotating container clockwise.

4. Screw container counterclockwise onto container head.

Fig. 31

B-30

Page 41

Service Instructions Automatic Multi-Head Serging Machine1365-4 Beisler GmbH

Section C

Service Instructions

C-1

Page 42

Service Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Contents

C.1 Delivery of the machine ........................................................................... 3

C.1.1 Packaging ....................................................................................... 3

C.1.2 Standard equipment ........................................................................ 3

C.2 Location requirements ............................................................................. 4

C.2.1 Floor quality..................................................................................... 4

C.2.2 Interior climate................................................................................. 4

C.2.3 Floor space requirements ............................................................... 4

C.2.4 Supply connections ......................................................................... 5

C.3 Start-up....................................................................................................... 6

C.3.1 Aligning the machine table .............................................................. 6

C.3.2 Compressed-air connections .......................................................... 6

C.3.4 Power supply ................................................................................... 7

C.3.5 Safety check .................................................................................... 8

C.4 Operation and shut-down ........................................................................ 9

C.4.1 Working with the machine ............................................................... 9

C.4.2 Shutting the machine down ............................................................ 9

C.5 Maintenance ............................................................................................ 10

C.5.1 Inspection ......................................................................................10

C.5.2 Cleaning ........................................................................................ 10

C.5.3 Service .......................................................................................... 11

C.5.4 Removing/installing the operating panel....................................... 12

C.5.5 Transport unit toothed belts .......................................................... 13

C.5.6 Replacing the roller toothed belt ................................................... 14

C.5.7 Adjusting the transport rollers .......................................................14

C.5.8 Adjusting the contour guide .......................................................... 15

C.5.9 Positioning the contour guide photocells ...................................... 16

C.5.10 Adjusting the photocell light sensitivity ......................................... 16

C.5.11 Adjusting the chain cutter knife and stop ...................................... 17

C.5.12 Replacing the cross transport toothed belt ................................... 18

C.5.13 Adjusting the cross transport photocells ....................................... 19

C.5.14 Adjusting the cross transport and swing arm stamps................... 20

C.5.15 Setting the pressures .................................................................... 21

C.5.16 Inserting the bonding strip at the bonding station ........................ 21

C.5.17 Adjusting the stacker control cams ............................................... 22

C.5.18 Adjusting the thread monitors ....................................................... 23

C.5.19 Stepper motor PCB with transmission .......................................... 24

C.5.20 Inputs and outputs of the main PCB .............................................25

C.5.21 Adjusting the stepper motor PCB ................................................. 26

C.6 Troubleshooting ...................................................................................... 27

C.7 Technical data ......................................................................................... 29

C-2

Page 43

Service Instructions Automatic Multi-Head Serging Machine1365-4 Beisler GmbH

Delivery of the machine

C.1

C.1.1 Packaging

The machine is delivered in a solid packaging box on a pallet. All pakkaging materials can be separated and reused.

Pallet made of pine wood

Packaging box made of plywood / transport carton

Polyethylene film (PE))

NOTE - Shipping braces!

During shipping, moving machine parts are protected with shipping braces (cable ties). The positions of all parts fitted with shipping braces are

marked with red labels.

After the machine has been installed and aligned, the shipping braces

must be removed.

NOTE - Damages in transit!

If any damage presumably caused by incorrect transport is found when

the machine is unpacked, please contact your supplier immediately.

C.1.2 Standard equipment

The machine is delivered in an operative condition. The standard equipment includes:

Automatic multi-head serging machine

The machine is equipped with several customer-specific acces-

sories. For checking the exact layout, the information on the delivery note is authoritative.

Service kit with machine oil.

Operating panel and program control:

Preinstalled (ready-for-use) operating panel.

Memory card with factory-programmed standard sewing pro-

grams.

Technical documents:

Operating instructions.

Service instructions.

Programming instructions.

C-3

Page 44

C.2

C.2.1 Floor quality

The floor of the room where the machine is to be installed must have a

sufficient surface strength. The location of the machine must be free of

vibrations.

If several machines are to be installed in one room, the static load bearing capacity of the ceiling must be considered.

Weight:

Machine with accessories approx 200 kg

C.2.2 Interior climate

Climatic requirements for the operating room:

The machine must only be stored or operated in closed operating

rooms.

Room temperature +10° C to +45° C

Relative humidity 80 % max.

Service Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Location requirements

C.2.3 Floor space requirements

For operation during production and for service works, the machine

must be freely accessible from all sides. On all sides, there must be a

minimum clearance of 1 m.

Dimensions:

L x W x H 2300 x 2200 x 1700 mm

NOTE - Electromagnetic interference!

The machine must not be installed in the immediate vicinity of devices or electrical components (e.g. transformers)

generating a strong magnetic field as otherwise the correct function of the program control may be impaired.

C-4

Page 45

Service Instructions Automatic Multi-Head Serging Machine1365-4 Beisler GmbH

Location requirements

C.2

C.2.4 Supply connections

The machine requires on-site power supply cables with a minimal

cross-section of 1.5 mm and a connection to a compressed-air supply

system.

Power connection:

The power supply of the machine requires a properly grounded power

connection with:

Grounding plug 230 V ± 10 %, 50/60 Hz

Fusing 16 A

NOTE - Peak voltages!

The correct function of the machine requires that the power system supplies a constant current. Peak voltages

may particularly impair the stability of the program control.

Compressed-air supply:

The on-site compressed-air supply system must meet the following requirements:

Operating pressure 6 bar

Compressed-air quality oil-free

Compressed-air consumption 40 NL/AT

C-5

Page 46

C.3

C.3.1 Aligning the machine table

After the machine has been installed at the desired location, the machine table must be aligned:

Set machine table to required height.

Level machine table horizontally on all sides.

Setting the table height:

1. Fig. 1: Lift machine: Connect lifting device at lift points (arrows) be-

2. Loosen locating screws 2 on all table legs.

3. Pull table legs 4 out to the desired length and retighten locating

4. Tighten the height adjustment locating screws 2.

5. Lower machine onto floor.

6. Level worktable horizontally in all directions.

7. Tighten the height adjustment locating screws 2.

Service Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Start-up

low the crossmembers. If the machine is equipped with the optional

transport rollers, release brakes before lifting

screws.

NOTE - Shipping braces!

Before the machine is connected to the power supply system and operated, all shipping braces must be removed.

Cut off cable ties.

Remove labels.

Remove protective film from operating panel.

C.3.2 Compressed-air connections

Fig. 2: The compressed-air connection is preinstal-

led on the machine. It comprises the following components:

Pressure reducer 2 with manometer 4 and

water separator 4,

Pressure hose with push-in plug 3.

The pressure reducer ist installed to the machine

frame below the B machine.

Connecting the machine to the compressed-air

supply system:

1. Connect pressure hose plug to on-site terminal

unit.

2. Open on-site compressed-air supply.

3. Set pressure reducer to a machine operating

pressure of 6 bar by rotating pressure reducer

knob 1 and read value on manometer 4:

To increase pressure, rotate in the clockwise direction.

To reduce pressure, rotate in the counterclockwise direction.

Fig. 1

Fig. 2

C-6

Page 47

Service Instructions Automatic Multi-Head Serging Machine1365-4 Beisler GmbH

Start-up

C.3

C.3.4 Power supply

The machine is connected to a power supply system of 230 V ± 10 % at

50/60 Hz.

WARNING - Electric shock!

Contact with current-carrying components may cause a lethal electric shock. Check plug and cable before connecting machine to power supply system.

Do not use damaged plugs, sockets or cables to con-

nect the machine to the power supply system!

Before connecting the machine to the power supply sy-

stem, check to see if the ratings of the power supply

system in the operating room correspond with the ratings on the nameplate at the rear of the machine.

If the ratings for voltage (V) and maximum current (A)

do not match, the machine must not be connected.

Insert the grounding plug into a properly grounded and

fused power socket.

Make sure that the power supply cable is not subjected

to tensile or pressure forces.

Route the power supply cable in a way that ensures

free access to and around the machine.

NOTE - Works to the electrical system!

Works to the electrical system of the machine must only

be carried out by qualified and authorized expert personnel. Tampering with the machine without authorization will

make the warranty void.

C-7

Page 48

C.3

C.3.5 Safety check

Before the machine is released for operation, all safety devices must be

checked for their correct operation.

Perform safety check:

1. Check to see if the protective strap around cross transport and stak-

3. The main switch also serves as an emergency off switch. To check

4. Check the function of the program stop switch by starting a machine

5. Unlock the program stop key. The program control initiates a reset,

Service Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Start-up

CAUTION - Danger of injuries!

The safety devices protect the operating and service personnel while are working on or with the machine.

If the safety devices are fully or partially inoperative, the

machine must not be started up.

ker has been shifted down to the secured position.

the function of this switch, turn the machine on, start a machine cycle and turn the machine off during the sewing process using the

main switch. All operational movements of the cross transport and of

the assist transport as well as the sewing process must stop, and

the program control must switch off.

cycle and pressing the switch. The machine operation must be interrupted.

the cross transport must move to its basic position, and the stacker

mechanisms must be in its basic position.

C-8

Page 49

Service Instructions Automatic Multi-Head Serging Machine1365-4 Beisler GmbH

Operation and shut-down

C.4

C.4.1 Working with the machine

Factory settings

The program control of the machine has been programmed with 12

standard sewing programs at the factory:

Sewing programs M 01 to M 03 for the automated serging of rear

trousers panels and front trousers panels with or without knee lining

made of standard materials.

The sewing programs M 10 to M 20 are freely programmable.

These sewing programs are so powerful that they can be used for serging nearly all common trousers shapes.

They are furthermore perfectly suited for training operating personnel

and can be used as a template for programming customer-specific sewing programs.

For details about the programming of sewing programs, please refer to

Section D, Programming Instructions.

C.4.2 Shutting the machine down

If the machine is to be shut down, it must be disconnected from all energy supply sources.

Disconnecting the machine from the power supply system:

1. Turn the machine off by moving the main switch to position "0".

2. Remove the power plug from the socket and protect it against acci-

dental reconnection.

Disconnecting the machine from the compressed-air supply system:

1. Shut off the on-site compressed-air supply system.

2. Remove the compressed-air hose plug from the terminal unit.

NOTE - Dust-proof protection!

If the machine is to be shut down for an extended period

of time, it should be covered with a plastic tarpaulin.

C-9

Page 50

C.5

Service Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Maintenance

Warning - Electric shock!

Contact with current-carrying components may cause a lethal electric shock

If the machine is put in motion accidentally, persons in its

direct vicinity may be caught by moving parts which may

cause injuries.

Prior to any service, cleaning or maintenance works, disconnect the machine from the power supply system!

Turn the machine off using the main switch.

Remove power plug from socket and protect it against

accidental reconnection.

If the power supply is not required for repair or set-up

work, the machine must be disconnected from the power supply system.

C.5.1 Inspection

The machine must be inspected annually. The inspection comprises

particularly the following items:

safety devices of the machine,

operativeness of the program control,

correct function of inputs and outputs.

C.5.2 Cleaning

The machine must be cleaned after large production series or at least

once a day, whichever occurs first.

Cleaning the machine surfaces:

1. Disconnect machine from power supply system.

2. Remove fabric residues.

3. Blow off dust and thread residues thoroughly from the sewing head,

from the working plate, from the clamp, and from the linear rail using

compressed air.

4. Wipe machine components dry using a dry, clean cloth.

NOTE - Plastic surfaces!

Some parts of the machine surfaces are made of plastic

materials. Solvents can dissolve plastics and make them

unusable.

Do not clean the machine surfaces (particularly the operating panel) with cleaning agents that contain solvent.

C-10

Page 51

Service Instructions Automatic Multi-Head Serging Machine1365-4 Beisler GmbH

Maintenance

C.5

C.5.3 Service

The following service works must be carried out in the specified intervals.

Checking the sewing head oil level (daily):

1. The oil level is checked at the sewing head sight glass.

The level must be between the marks for the upper and

lower limits. If the level drops below the mark for the minimal level, refill oil.

2. For details on the recommended oil type and refilling

procedure, please refer to the operating instructions of

the sewing heads that are attached to this machine.

Fig. 3: Emptying the water separator (weekly):

1. Have a suitable container available.

2. Drain water at pressure reducer water separator.

Press button 1 at pressure reducer collector and keep

it depressed until all the water has been drained.

Fig. 3

C-11

Page 52

C.5

Service Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Maintenance

NOTE - Repairs!

Any repairs to the machine must only be carried out by an

authorized Technical Service or by personnel that has

been instructed about the setting up and maintenance of

the machine on the occasion of a training by the supplier

or manufacturer of the machine.

NOTE - Liability!

Use only original spare parts for installing or replacing

machine components.

The manufacturer and supplier will not assume liability for

spare parts from third-party suppliers.

C.5.4 Removing/installing the operating panel

1. Disconnect machine from power supply.

2. Remove two locating screws and disconnect interface connector.

3. Remove retaining screws from operating panel bracket.

4. Remove operating panel, install new panel and secure using screws.

5. Connect interface connector to RS 232 interface and secure using

two locating screws.

C-12

Page 53

Service Instructions Automatic Multi-Head Serging Machine1365-4 Beisler GmbH

Maintenance

C.5

C.5.5 Transport unit toothed belts

The transport unit at the A and B machines consists of three components that are each driven by a toothed belt:

Stepper motor,

puller (fabric transport),

roller (assist transport)

Replacing the stepper motor toothed belt:

1. Lower the transport unit manually onto the working plate as described in Section D, Programming Instructions.

2. Switch the machine off.

3. Fig. 4: Slacken the toothed belt 1 by removing the locating screw

3

of the stepper motor mounting plate.

4. Lift the toothed belt out of the stepper motor drive roller 2 and above the transport roller 6; for this, the pneumatic cylinder rod

must be removed from the lower suspension 5.

5. To install, route the toothed belt over the fabric transport linkage; position it on the shaft drive roller, then position it on the stepper motor

drive roller.

6. To pretension the toothed belt, push the plate with the stepper motor

down and tighten the locating screw 3. If the pretensioning is correct, it must be possible to depress the center of the belt approx 5

mm until counterpressure is felt.

7. Install the pneumatic cylinder rod to the mounting block and secure

it using the screws.

4

Replacing the fabric transport toothed belt:

1. Lower the transport unit manually onto the working plate as described in Section D, Programming Instructions.

2. Switch the machine off.

3. Fig. 4: Slacken the toothed belt

8

by removing the Allen screw

7

at the bearing and sliding the

spacer shaft with the transport rollers 6 up.

4. Remove the toothed belt from the

drive roller and from the idle roller.

5. To install, place the toothed belt

into the idle rollers and drive roller. Pretension the belt by sliding

the spacer shaft with the transport

roller down and tightening the Allen screw 7. If the pretensioning

is correct, it must be possible to

depress the center of the belt approx 10 mm until counterpressure

is felt.

C-13

Fig. 4

Page 54

C.5

C.5.6 Replacing the roller toothed belt

1. Lower the transport unit manually onto the wor-

2. Switch the machine off.

3. Fig. 5: Slacken the toothed belt 3 by removing

4. Remove the toothed belt from the drive roller and

5. To install, place the toothed belt into the idle rol-

Service Instructions Automatic Multi-Head Serging Machine 1365-4Beisler GmbH

Maintenance

king plate as described in Section D, Programming Instructions.

the Allen screw 1 at the bearing and sliding the

spacer shaft with the transport rollers 2 up.

from the idle roller.

lers and drive roller. Pretension the belt by sliding

the spacer shaft with the transport rollers down

and tightening the Allen screw 1. If the pretensioning is correct, it must be possible to depress

the center of the belt approx 10 mm until counterpressure is felt.

NOTE - Transport roller orientation!

After the toothed belt has been replaced,

the distance between the transport rollers and the working

plate must be checked.

C.5.7 Adjusting the transport rollers

Fig. 6: The transport rollers of the puller and of the

roller should contact the working plate in the lowered

position (i.e. distance A must be zero in the lowered

position).

The pressure that the transport rollers apply to the

working plate is controlled individually for each machine by a pressure reducer (see page C.15)

Setting the distance between transport rollers

and working plate:

1. Lower the transport unit manually onto the working plate as described in Section D, Programming Instructions.

2. Switch the machine off.

3. To avoid contact between the working plate and

the transport rollers, adjust the position of the

pneumatic cylinder clamp 2 to the corresponding spacer shaft 3:

Loosen the clamp locating screw 1 and shift

the clamp on the spacer shaft. Slide clamp up

to reduce the distance, slide clamp down to

increase the distance.

Fig. 5

Fig. 6

C-14

Page 55

Service Instructions Automatic Multi-Head Serging Machine1365-4 Beisler GmbH

Maintenance

C.5

C.5.8 Adjusting the contour guide

The following adjustments are made for the contour guide:

Height quick adjustment:

Fig. 7: Use the handwheel 2 of the four-stage quick adjustment for

the rough adjustment of the material thickness. With each additional

stage, the distance between the sliding plate and the working plate

increases by a fixed value of 0.8 mm. The selected stage is indicated at

the hand-wheel.

Stage 1 0.8 mm

Stage 2 1.6 mm

Stage 3 2.4 mm

Stage 4 3.2 mm

Height fine adjustment:

The adjustment made with the height quick adjustment 1 can be fineadjusted using the height fine adjustment 2. The following should be

observed as a rule: The sliding plate 4 should lower as fas as possible, the fabric must pass easily below the sliding plate.

1. Slide the sewing material below the sliding plate.

2. Push the sliding plate manually

down all the way to the stop.

3. To lower the sliding plate even further, rotate the handwheel

counterclockwise.

4. Pull fabric below sliding plate to

check whether the sewing material

can pass easily.

1

Contour roller pressure:

The pressure that the contour roller

6

applies is crucial for the conti-

nuous guiding of the sewing pieces

along the sewing unit stop. The required pressure is determined by trial and

error.

1. Line up sewing piece and start machine cycle. If the sewing pieces

are shifted sideways away from the