Page 1

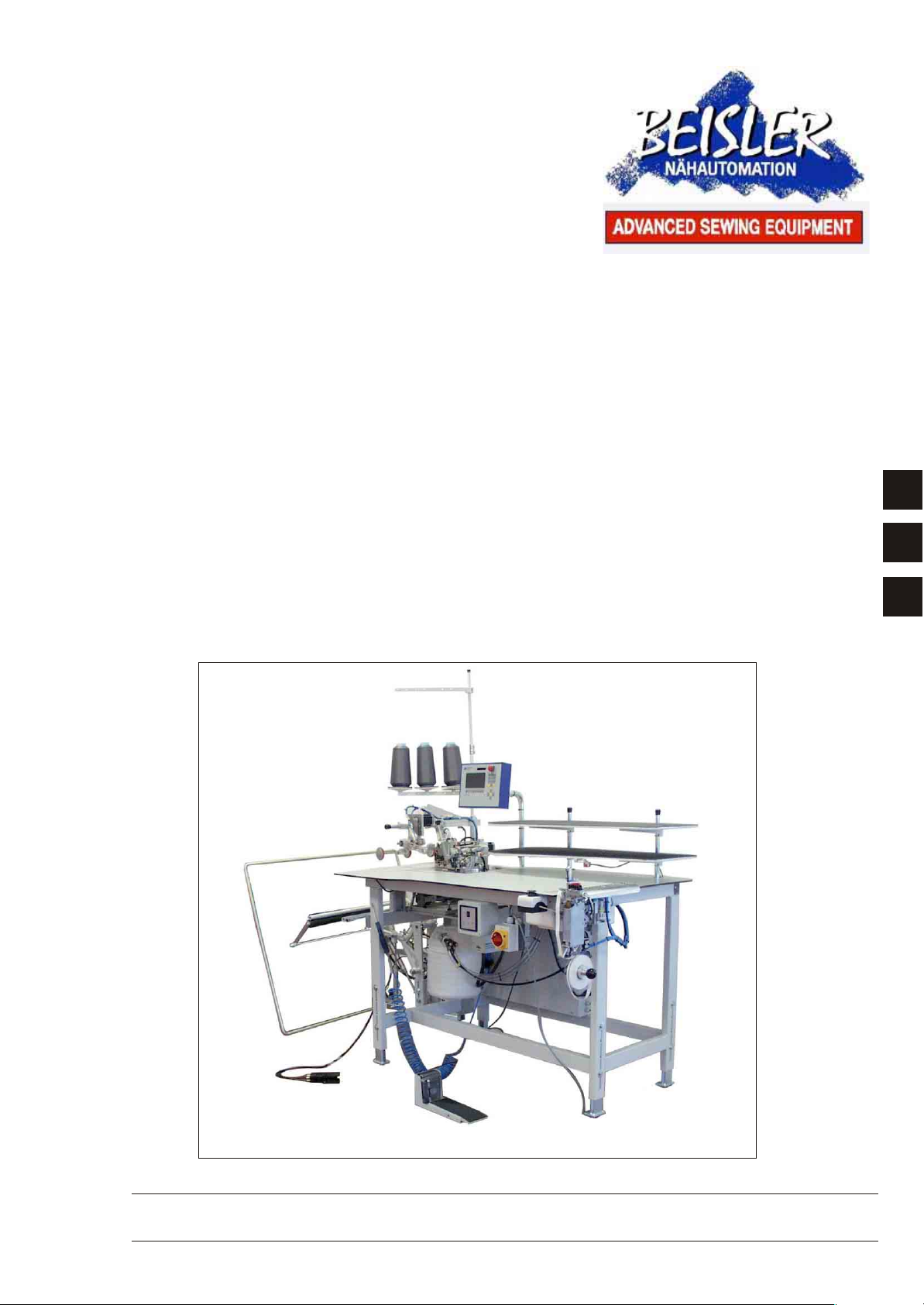

1265/5

Single-head se wing unit for serging and

overlocking for trou sers with knee li ning

Operating Instructions

Installations Instructions

Service Instructions

1

2

3

Telefon Ser vice +49 (0) 60 21/ 50 19 40 Telefax +49 (0) 60 21/ 54 00 61 E-mail: Vertrieb@beis ler-gmbh.de

Aus ga be / Edi ti on: 01/2007 Prin ted in Fe de ral Re pub lic of Ger ma ny Tei le-Nr.:/Part-No.:

Frohn rad stra ße 10, D-63768 Hös bach

Page 2

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruc ti o n m an ual contains im po r ta nt i nf or m at i on on ho w t o

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruc ti o n m an ual must always be av a i lab l e a t the

machine/sewing unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, i ncl u di n g e qu i pp i ng , troubleshooti ng du r i ng th e w or k

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair and/or

– Transport.

The user also has to assure that only authorized personnel work on

the machine.

The user is o bl i g ed to c he c k th e machine at leas t o nc e pe r shi f t for

apparent da ma ge s and to immediatl y r e po r t a ny ch anges (includin g

the performance i n se rv ic e), wh i c h im pa i r th e s a fe ty.

The user comp an y mu s t e ns u r e t ha t t he ma c hi n e i s only operated i n

perfect working order.

Never remove or disable any safety devices.

If safety dev i c e s ne ed to be removed for equipp i ng , r e pa i ri ng or

maintaining, the safety devices must be

remounted directly after completion of the maintenance and repair

work.

Unauthorized modification of the machine rules out liability of the

manufacture r fo r da ma ge res u l ti n g f r om th i s .

Observe all safety and danger recommendations on the machine/unit!

The yellow -and-black stri pe d s u rfa c es d es i g na te pe r ma ne nd da ng er

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

Page 3

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

2. Before putting into service also read the safety rules and

3. The machine must be used only for the purpose intended. Use of

4. When gauge parts are exchanged (e.g. needle, presser foot,

instruction book and operated by persons with appropriate

training.

instructions of the motor supplier.

the machine without the safety devices is not permitted. Observe

all the relevant safety regulations.

needle plate, feed dog and bobbin) when threading, when the

workplace is left, and during service work, the machine must be

disconnected from the mains by switching off the master switch or

disconnecting the mains plug.

5. Daily servicing work must be carried out only by appropriately

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance

unit.

Exceptions to this are only adjustments and functions checks

made by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time

as the entire sewing unit is found to comply with EC directives.

It is absolutely necessary to respect

the safety instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Page 4

Index Page:

Preface and generalsafetyinstru c tions

Part1: O perating instru c tions cl.1265/5

1. D escription ofproduct.......................................... 3

1.1 D escription ofproperuse ......................................... 3

1.2Briefdescription............................................... 3

1.3 Technicaldata ................................................ 4

2. O ptionalequipm ent(see annex) .................................... 5

3. Sw itc h ing on -Sw itc h ing off-Program stop ............................ 6

3.1Switching on ................................................. 6

3.2Switching off................................................. 6

3.3 Program stop ................................................ 7

3.4Restartafterprogram stop ........................................ 7

1

4. O peration ofthe sew ing m achinehead ............................... 8

4.1 G eneralnotes

......................................................... 8

4.2 Recom m ended threads .......................................... 9

4.3 Rem oving /Putting on the fabricsliding sheet............................. 10

5. O peration ofthe sew ing unit...................................... 11

5.1 Footswitch m achine sequence ...................................... 11

5.2 Feeding the trousers parts and starting the sew ing operation ................... 11

5.3Adjusting the edge guide ......................................... 13

5.4Adjusting the blow ing airforthe nozzles inthe tabletop ...................... 14

5.5Stackers ................................................... 15

5.5.1Standard stacker.............................................. 15

5.5.2 Throw -overstacker............................................ 16

5.5.3Alternating stacker ............................................ 17

5.6Fusing station (optional).......................................... 18

5.6.1Inserting adhesive tape .......................................... 18

5.6.2Switching the fusing station on and off ................................. 18

5.6.3Fusing ofknee lining and fronttrousers................................. 19

5.6.4Clening the stamp.............................................. 20

5.7 Feeding the trousersparts and starting the sew ing operation in conjunction w iththe fusing station 21

6. O peration ofthe control......................................... 23

6.1 O perator term inal.............................................. 23

6.2Userinterface ................................................ 24

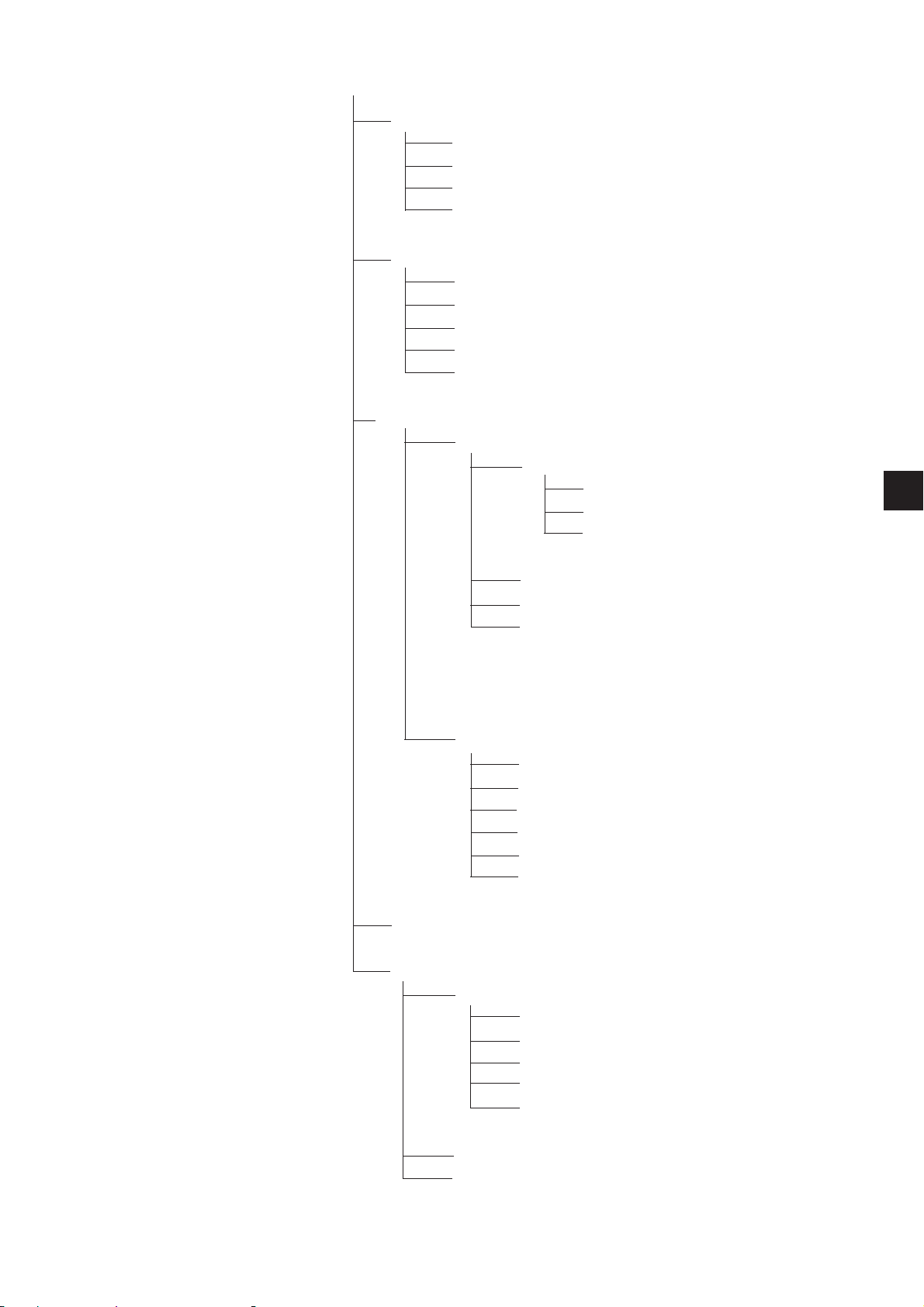

6.2.1 M enu stru c ture ofthe sew ing and setting program s......................... 24

6.3Mainscreen ................................................. 26

Page 5

Index Page:

6.4 Seam program s ............................................... 27

6.4.1Factory-setprogram s........................................... 27

6.4.2Selecting the seam program ....................................... 28

6.4.3 M anualsewing,contro lled viafootpedal ............................... 28

6.4.4 C hanging the program functions .................................... 29

6.4.4.1Quick adjustm entofthe m ain param eters viathe inputfields .................. 29

6.4.4.2 A ccess tothe w hole param eterlistofa seam function ...................... 30

6.4.4.3Switching a seam orm achine function on and off ......................... 30

6.4.4.4 S eam -specific param eters inthe access level1 .......................... 31

6.4.4.5 S eam -specific param eters inthe access level2 .......................... 40

6.5 Seam sequences .............................................. 43

6.6 Preseam s................................................... 45

6.7 Seam starting mode ............................................ 46

6.8Activating the sew ing m otor........................................ 46

6.9 Resetting the dailypiece counter .................................... 46

6.10 Input/O utputtest.............................................. 47

6.11 P rogram m ing m enus ............................................ 49

6.11.1 G eneralnotes ............................................... 49

6.11.2Allocatingafre e s torage location.................................... 49

6.11.3F1=INIT P aram eter ........................................... 49

6.11.4 F2 = M emoryCard............................................. 51

6.11.5F3=Diagnostics.............................................. 53

6.11.6 F5 = Additionalprogram s ........................................ 54

7. M aintenance ................................................ 56

7.1Cleaning and checking........................................... 56

7.2Oillubrication ................................................ 58

Page 6

1. D escription ofproduct

1.1 D escription ofproperuse

The 1265/5isasewing unitw hich can properlybeusedfor sew ing

lightto m edium -w eightm aterial.Such m aterialis,as a rule,m ade of

textilefibres.These m aterials are used inthe garm entindustry.

In generalonlydrymaterialm ustbe sewn on this m achine.The

materialm ustnotcontain any hard objects.

The seam is generally m ade w ithcorethread,polyesterfibre

orcotton threads.

The dim ensions forneedle and hook threads can be taken fro m the

tablein chapter 4.2.

Before using any other threads itis necessary toestimatethe

consequentialdangers and totake the respective safety m easures,if

required.

Thissewing unitm ustonlybeinstalled and operated in dry and

well-keptroom s.Ifthe sew ing unitisusedinotherroom s,w hich are

notdry and w ell-kept,further m easures to be agreed upon m ay

becom e necessary (see E N 60204-31 :1999).

W e,as m anufacturerofindustrialsewing m achines,assum e thatat

leastsem i-skilled operating personnelwillbe w orking on ourproducts

so thatallusualoperations and,w here applicable,theirrisks are

presum ed to be know n.

1

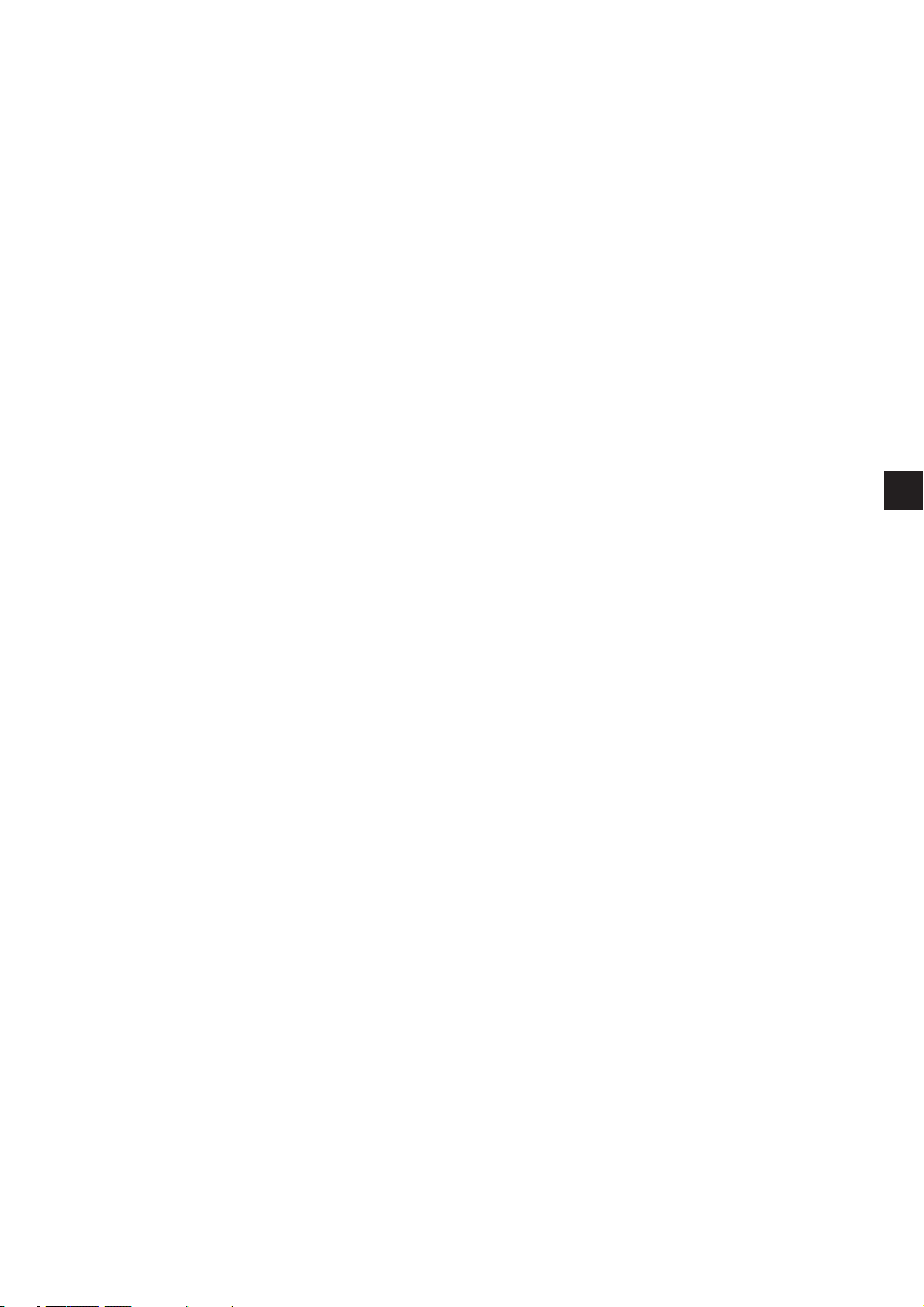

1.2Briefdescription

The B eisler 1265/5isasingle-head sew ing unitforserging oftrousers

partswith and w ithoutknee lining.The overlocking ofthe seatand fly

bow as w ellas ofthe trousers hem can be integrated.

Optionally you can w ork w ithorwithouta hotfusing station (lining on

top /lining below ).

Allsew ing unitcom ponents are m ounted on a stand w elded ofsquare

steeltubes and contro lled by a m icroprocessor system .

The sewing unitis operated viaacontrolpanel.H ere itis possibleto

callup various controlprogram s,to define new program s and to check

allinputs and outputsform aintenance and repairpurposes.

M achine head

–

Pegasus tw o-orthree-thread overlock m achine

EX T 5204-02 w ithtop feed

–

Separatestep m otorcontro l fortop feed and differentialfeed,for

setting the desire d lining fullness,also forstre tch fabrics

–

Microprocessorcontro l,freely program m able

–

Sewing drive E fka D C 1500

–

Autom aticfullness distribution atthe side seam and crotch seam ,

program m able

–

Height-adjustable edge guide fordifferentm aterialthicknesses

–

Autom atic contourguide,contro lled viastep m otor

–

Ejectorviastep m otor forprecise chain separating and positioning

the trousers before stacking

3

Page 7

1.3 Technicaldata

–

Step m otorcontro l w ith auxiliary feed for w ide and difficult

materials

–

Processing ofknee lining w ithoutfusing device forcut-to-size knee

lining

–

Optionalfusing unit

–

Lightbarrierforrecognizing the seam beginning and seam end for

autom aticsewing startand stop

–

Verticalcutterw ithsuction foroverlocking and serging in one

operation

–

C hain separating device w ithsuction,program m able

–

Adjustableblow ing nozzles inthe tabletop forsupporting the

materialfeed

–

Height-adjustablestand,infinitelyvariablefrom 850 m m to

1200 m m

–

Integrated stacking device

Machine head: Pegasus E XT 5204-02

Stitch type: 504/505

N um ber ofneedles: 1

N eedle system : B27

N eedlesize: N m 80 toNm110

Threads: see table chapter4.2

Speed: 7000 r/m inwithoutlining

6500 r/minwithlining

Speed upon

delivery: 6500 r/m in

Stitch length:m in. 1.0mm

max. 5.0mm

Seam w idth: 6 m m

Material:Lightto m edium -w eightm aterial

O perating pressure: 6 bar

Airconsum ption: 20 N L perw orking cycle

Rated voltage: 1 x 230 V 50/60 H z

Rated load: 0.9kVA

Dim ensions: 1500 x 900 x 1400 m m (L x W x H )

Working height: 850...1200 m m

(upper tabletop edge)

Weight: 120 kg

4

Page 8

2. O ptionalequipm ent

Noise value: LC = 81dB (A )

W orkstation-specificemission value according toDIN 45635-48-B-1

Stitch length: 3 m m

Seam length: 1160 m m

Speed: 7000 r/min

MaterialG 1 D IN 23328: 1 layer

M easuring pointaccording

toDIN 4895 part1 X = 600 m m Y = 350 m m Z = 600 m m

X-axis=atrightangles tothe feeding direction

Y-axis=mainfeeding dire c tion

Z-axis = height

See annex.

1

5

Page 9

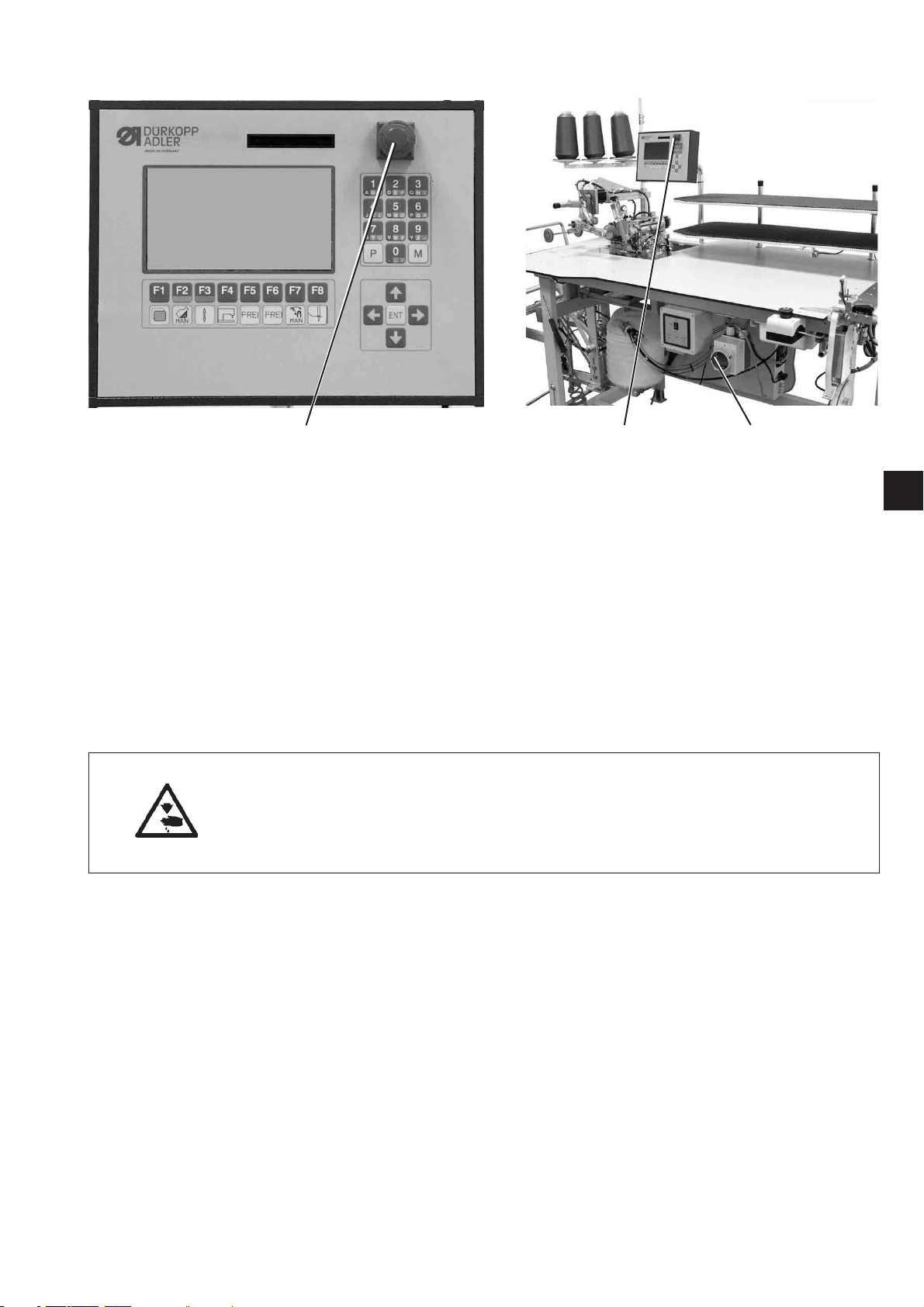

3. S w itching on -Sw itching off-Program stop

21

3.1Switching on

3.2Switching off

–

Switch on m ainswitch1(turn inclockw ise dire c tion).

The contro l loads the m achine program .

The startscreen appears inthe display ofthe controlpaneland

shows the follow ing m essage:

WAITING FOR RESET

–

Unlock the program stop key 2 atthe controlpanel.

–

Press program stop key 2 atthe controlpaneluntilitlocks.

–

Switch offm ainswitch1(turn counte r-c lockw ise).

6

Page 10

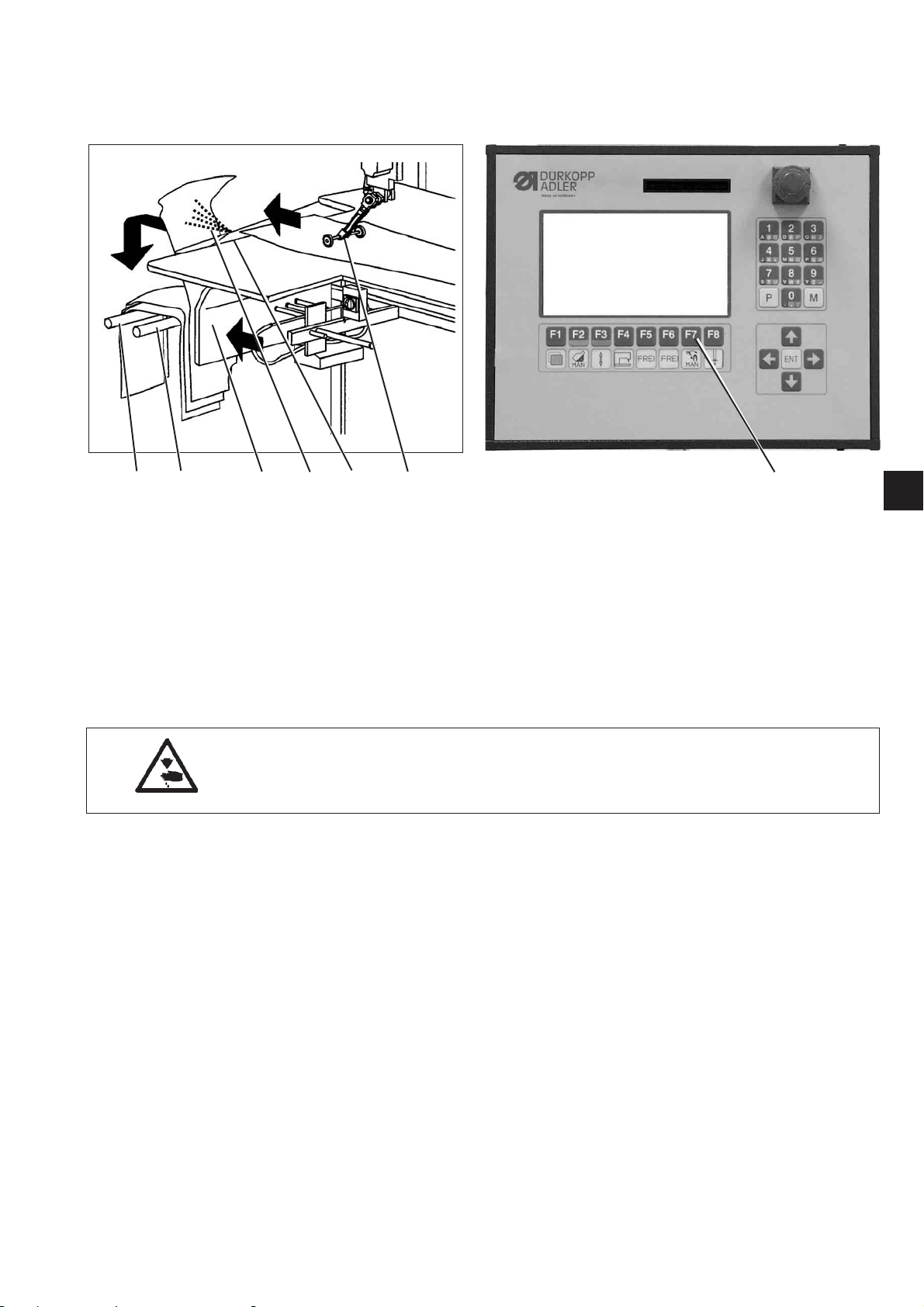

3.3 Program stop

2

3.4 R estartafterprogram stop

21

Foran im m ediatestop in case ofoperating errors,needle breakage

etc.the safety system ofthe 1265/5provides the follow ing m easures:

–

Press program stop sw itch2atthe controlpanel.

The running operations are stopped im m ediately.

–

Turn m ainswitch 1 counte r-c lockw ise.

The sewing unitdrops outim m ediately;

allm ovem entsofthe sew ing unitstop im m ediately.

Caution:R isk ofinjury!

Switch the m ainswitch off.

Clearthe faultonlywiththe sew ing unitswitched off.

Onlyrestartthe sew ing unitafterthe faulthas been cleared.

1

–

Switch on m ainswitch1(turn inclockw ise dire c tion).

–

Unlock the program stop sw itch.

The contro l loads the m achine program .

The m ain screen appears inthe display ofthe controlpanel.

The sewing unitis ready foroperation again.

7

Page 11

4. O peration ofthe sew ing m achine head

4.1 G eneralnotes

The operation ofthe sew ing m achine head (needleinsertion,threading

ofneedlethread and hook thread etc.)is described inthe separately

attached Pegasus operating instru c tions.

The instru c tion m anualisincluded inthe accessories ofthe sew ing

unit.

A tte n tion:R isk ofinjury!

Please read the operating instru c tions ofthe sew ing m achine head

carefully and observe allsafetyinstru c tions.

8

Page 12

4.2 R ecom m ended threads

N eedle system : B27

R ecom m ended

needlesize: N m 80 forvery thinmaterial

Nm 90 forthinmaterial

N m 100 form edium -w eightm aterial

High sew ing security and good sew ability are achieved w iththe

follow ing core threads:

–

Tw o-ply polyesterendless polyestercore-spun

(e .g.E picPoly-P oly,R asantx,Saba C ,...)

–

Tw o-ply polyesterendless cotton core-spun

(e .g.Frikka,K oban,R asant,...)

Ifthese threads are notavailable,the polyesterfibre orcotton threads

listed inthe table can also be sew n.

Often two-plycorethreads are offered by the thread m anufacturers

withthe sam e designation as three-ply polyesterfibre threads

(3cyl.-spun).This causes uncertaintywith regard totwisting and thread

thickness.

W hen in doubt,unravelthe thread and check w hetheritistwisted 2-or

3-ply.

The labelno.120 on the thread reelofa core thread corresponds e.g.

tothe thread size N m 80/2(seetablevalues in brackets).

In case ofm onofilam entthreads you can use needlethreads and hook

threads ofthe sam e thickness.The bestresults are achieved w ithsoft

and elasticthreads (software)ofthe thread thickness 130 D enier.

1

R ecom m ended thread thicknesses:

N eedlesize C o re th re a d C o re th re a d

Nm

N eedlethread H ook thread N eedlethread H ook thread

Polyester Polyester Polyester C otton

endless core-spun endless core-spun

LabelNo. LabelNo. LabelNo. LabelNo.

80

90 120 (N m 80/2) 120 (N m 80/2) 120 (N m 80/2) 120 (N m 80/2)

100 100 (N m 65/2) 100 (N m 65/2) 100 (N m 65/2) 100 (N m 65/2)

N eedlesize P olyester fibre thread C otton thread

N m (3cyl.-spun)

N eedlethread H ook thread N eedlethread H ook thread

80 N m 120/3 N m 120/3Ne

90 N m 80/3-120/3 N m 80/3-120/3Ne

60/3-80/3NeB60/3-80/3

B

50/3-70/3NeB50/3-70/3

B

100 N m 70/3-100/3 N m 70/3-100/3Ne

40/3-60/3NeB40/3-60/3

B

9

Page 13

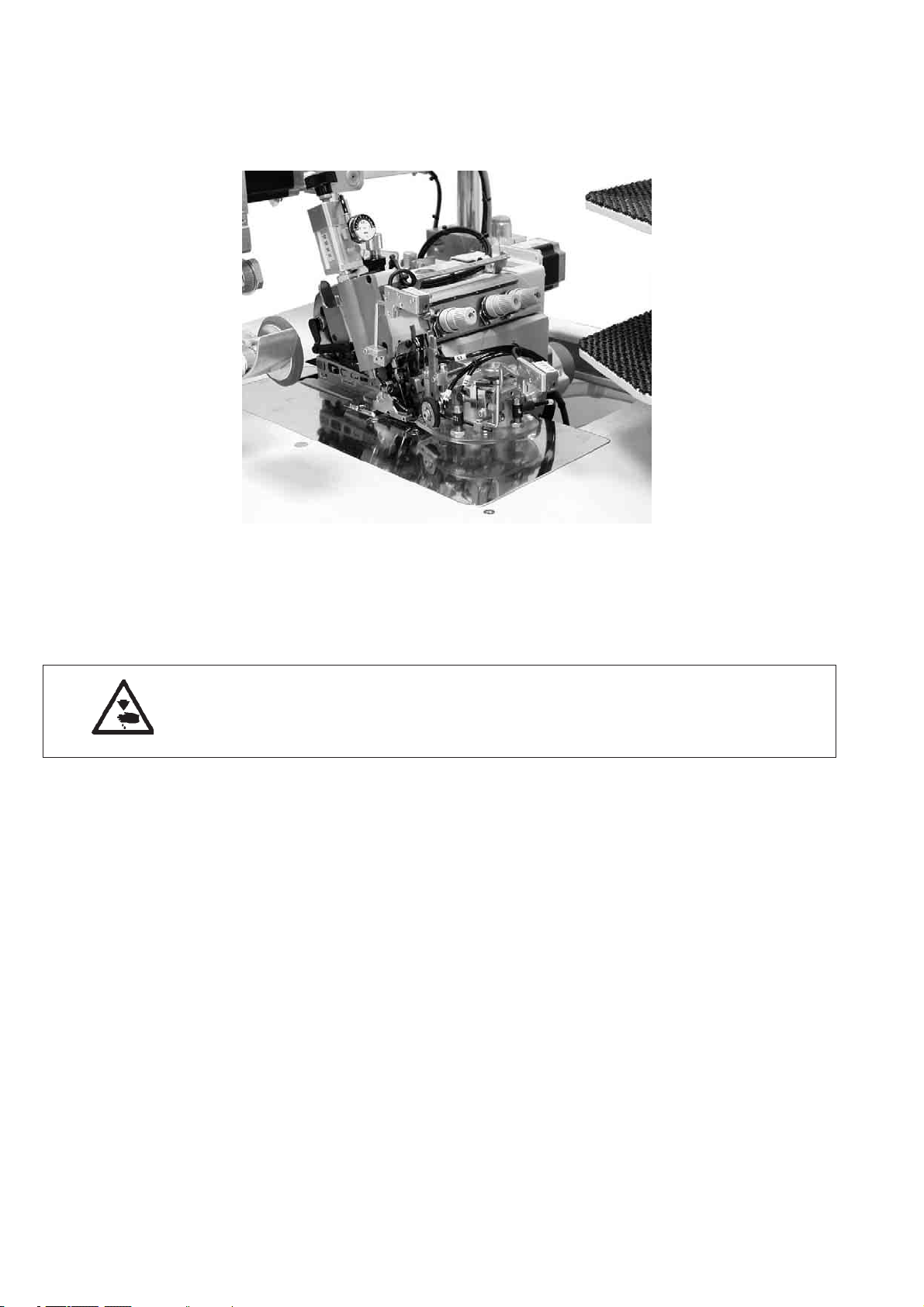

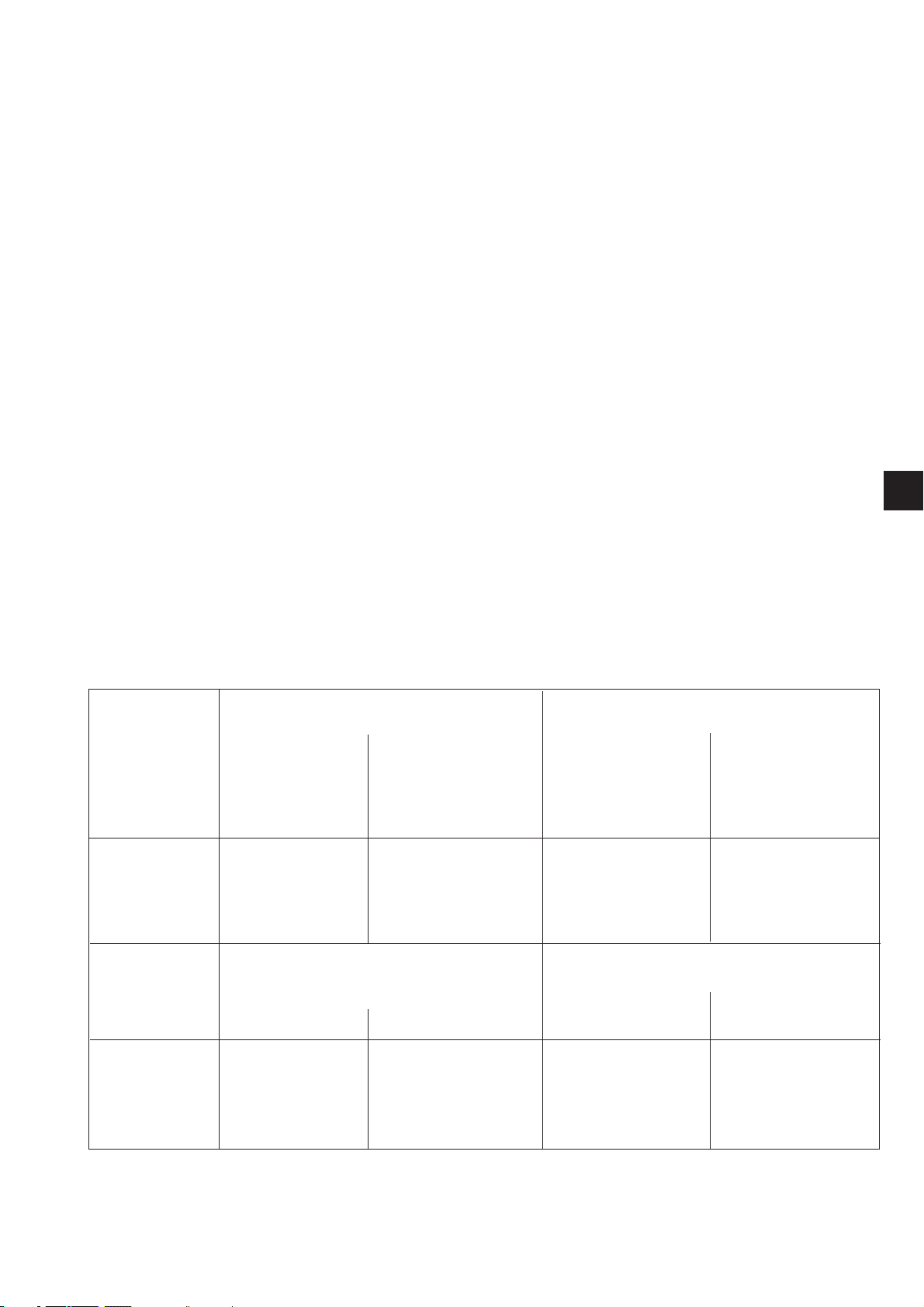

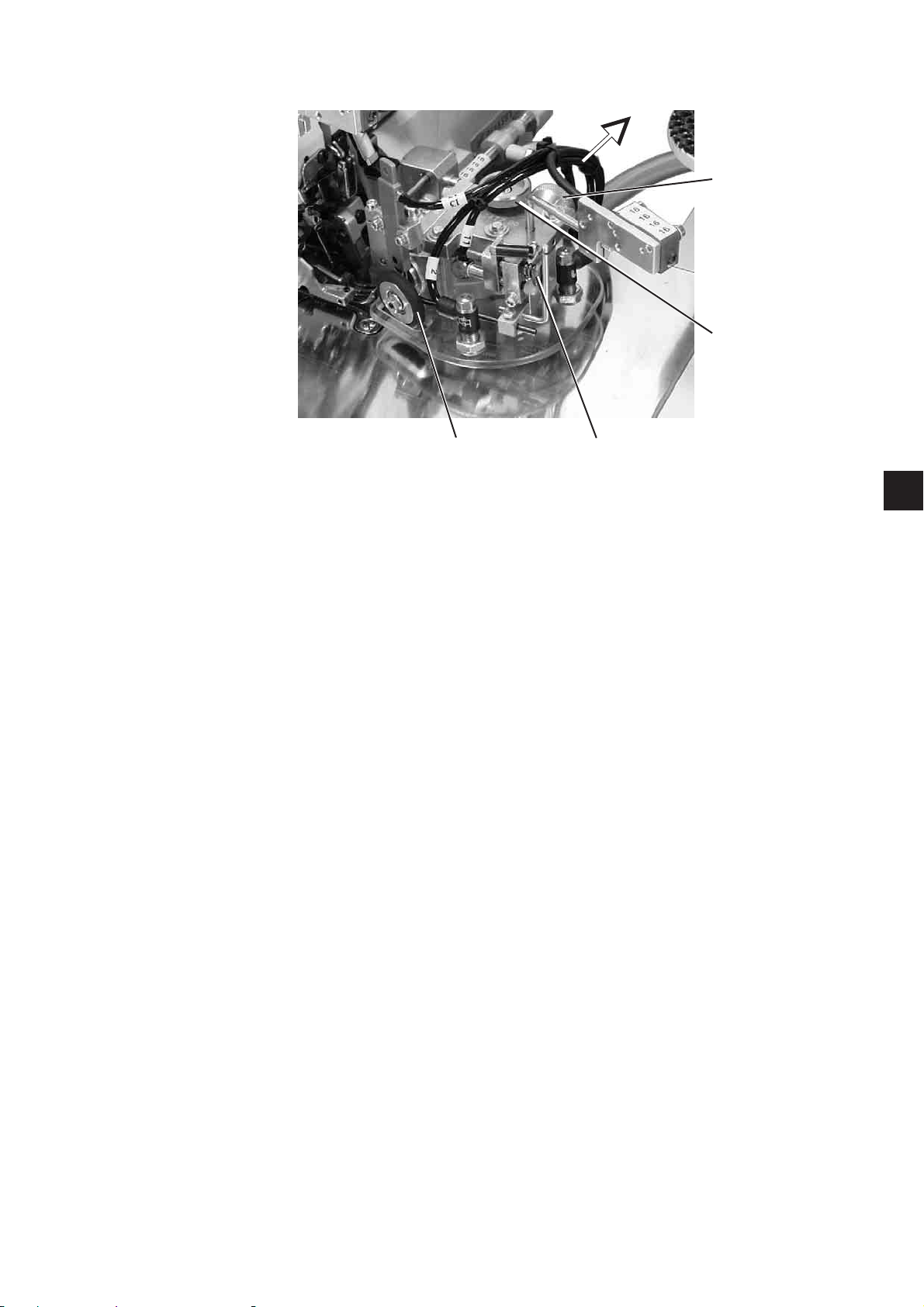

4.3Removing /Putting on the fabricsliding sheet

23

The fabricsliding sheet2 is heldinthe gap ofthe tabletop by the

m agnets1.

The edge guide3isfastened on the fabricsliding sheet.

Rem oving the fabricsliding sheet

–

Carefully rem ove the fabricsliding sheet2 fro m the m agnetsin

upw ard dire c tion.

–

Removethe fabricsliding sheet2 sidew ards.

The low ersection ofthe sew ing m achine head is accessible now .

P u tting on the fabricsliding sheet

–

Push the fabricsliding sheet2 intothe gap ofthe tabletop and

insertitin dow nw ard dire c tion.

23 1

10

Page 14

5. O peration ofthe sew ing unit

5.1 Footsw itch m achine sequence

Insomesewing program s the footsw itch serves forstarting various

functions.

The footsw itch is equipped w ithtw o contacts.

O ne contactislocated inthe reararea and isreleased by stepping

back.

The otherone islocated inthe frontarea and isreleased by

m echanicalload.

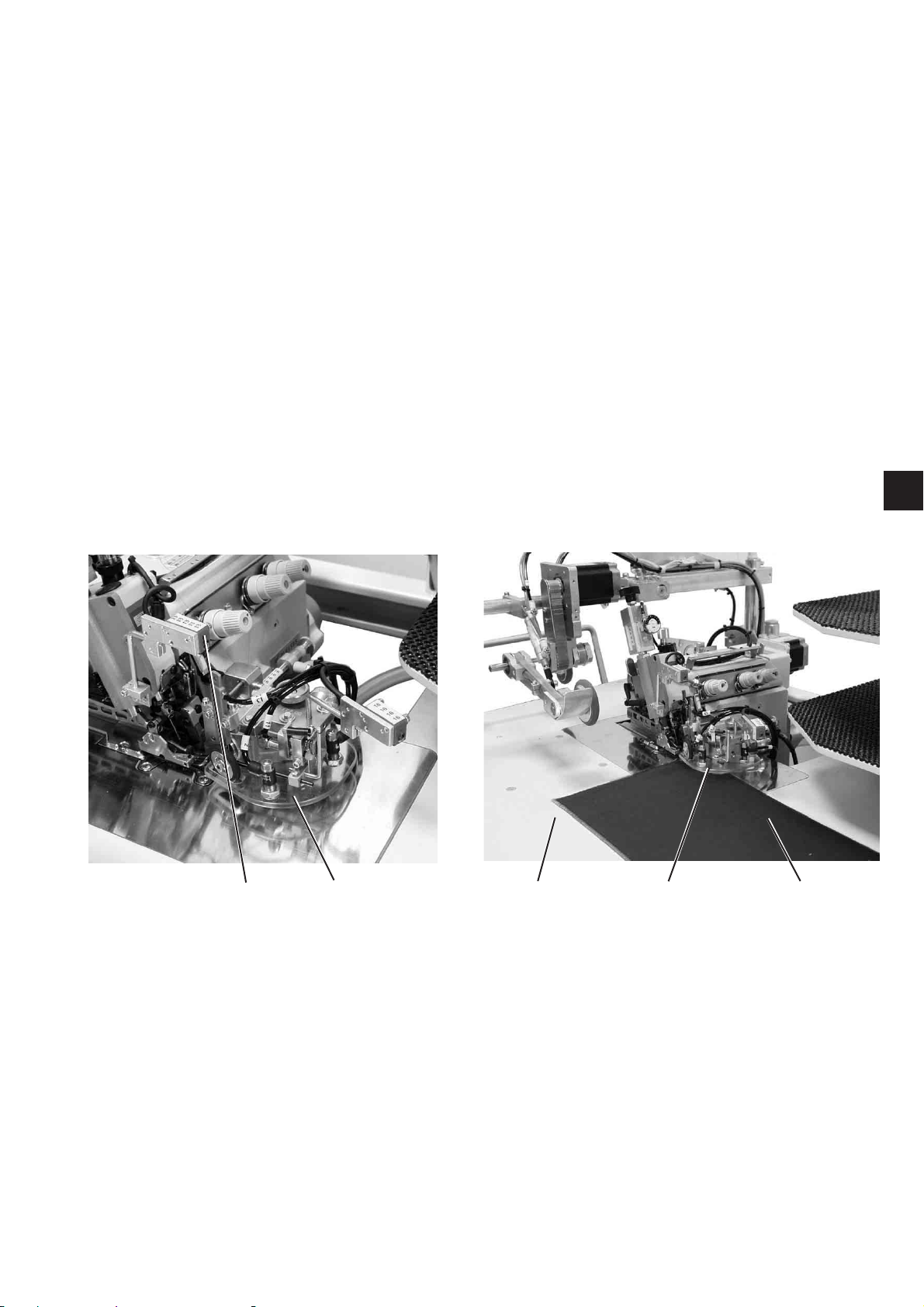

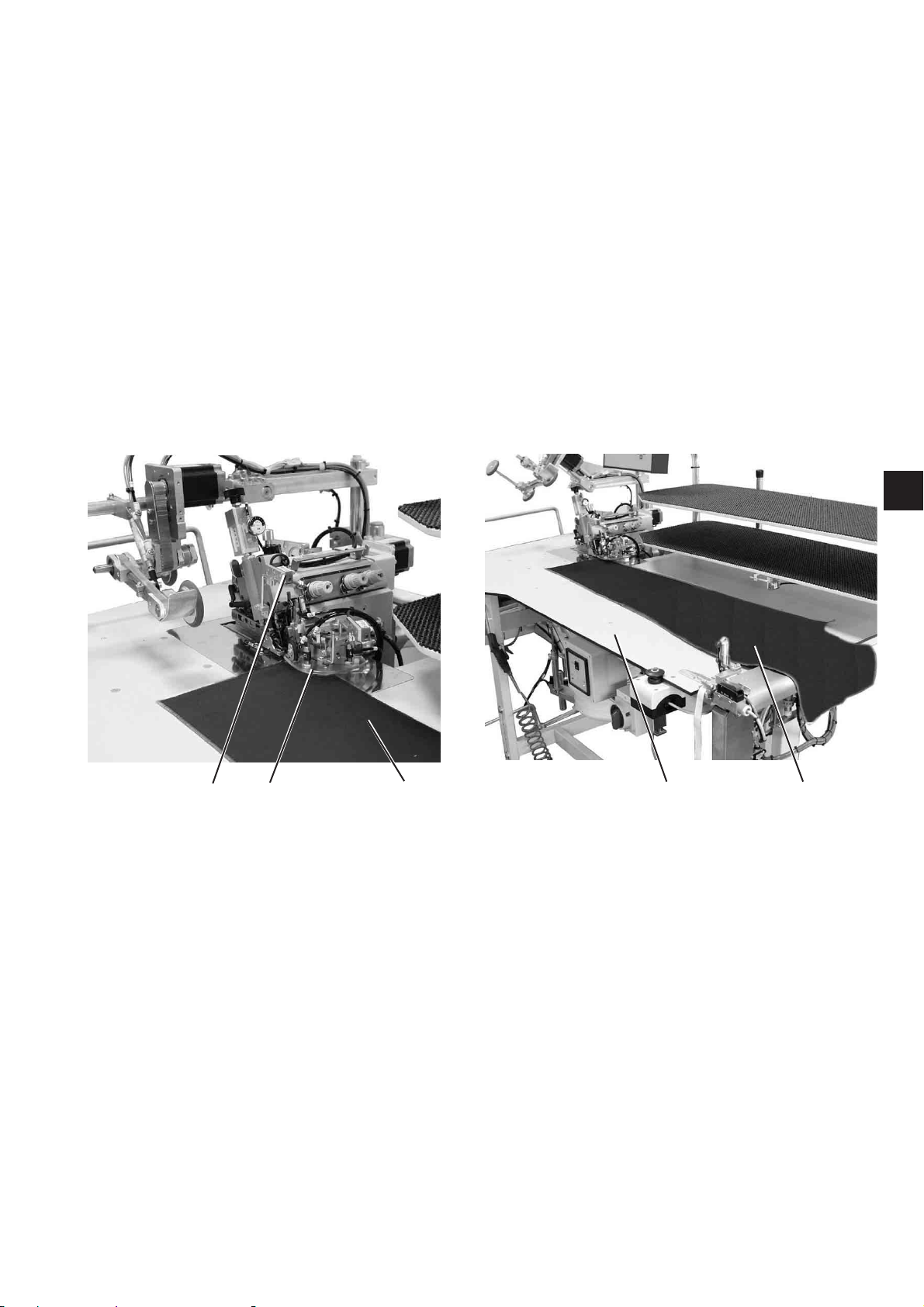

5.2 Feeding the trousers partsandstarting the sew ing operation

The overlock unit1265/5 w orks sem i-autom atically.

The operatorofthe sew ing unithas to proceed as follow s:

l callup the desired seam program

l feed the m aterialaccurately

l supervise the sew ing process

l re m o v e the finished partsfro m the stacker

1

42

Feeding the trousers partand starting the sew ing operation

1) Selectthe seam program atthe controlpanel(see chapter6.4.2).

2) Place the trousers part1 on the tabletop3fro m the rightand

position itprecisely underneaththe contourguide 2.

ATTENTION!

As soon as the trousers partis pushed underneaththe lightbarrier4,

the sew ing operation starts autom atically and the contourguide 2

low ers.

32 1

11

Page 15

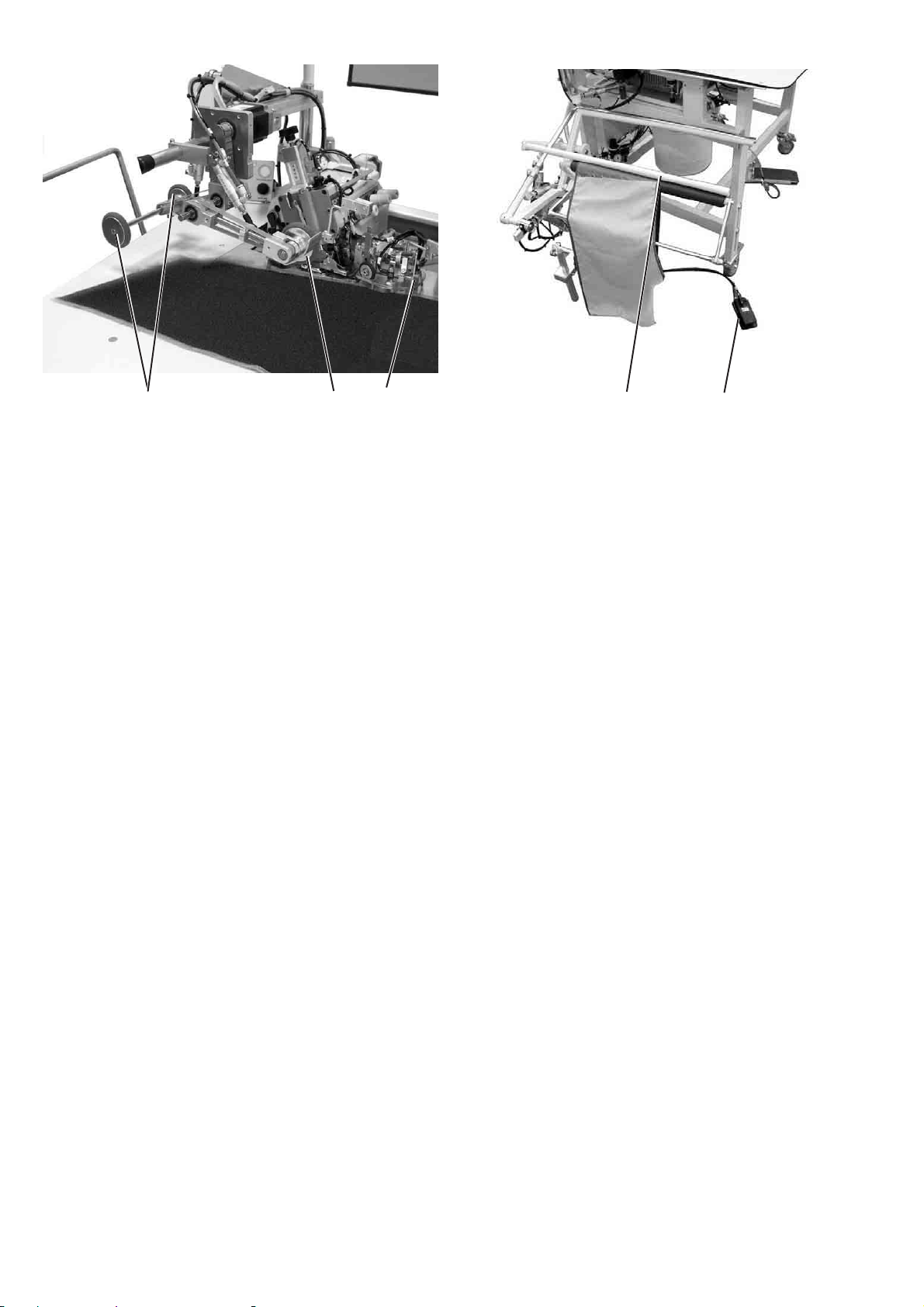

652

3) The trousers partis sew n.

4) The puller5 low ers,too,and supportsthe feeding ofthe trousers

part.

5) As soon as the m aterialhas passed the lightbarrier,the seam is

finished and the ejector6 low ers.

6) The contourguide 2 and the puller 5 m ove upw ards.

7) The ejector6 transportsthe m aterialoutofthe sew ing area.

8) The stacker clam p 8 m oves tothe front.

9) The ejector6 m oves upw ards again.

10) The trousers partisstacked.

11) A ctuatefootsw itch7forrem oving the w orkpieces.

Note

In ordertofacilitatethe m aterialfeed inthe area ofthe sew ing head

the tableblow ing and the ejector 6 can be engaged atthe seam

beginning.

(see chapter5.4)

87

12

Page 16

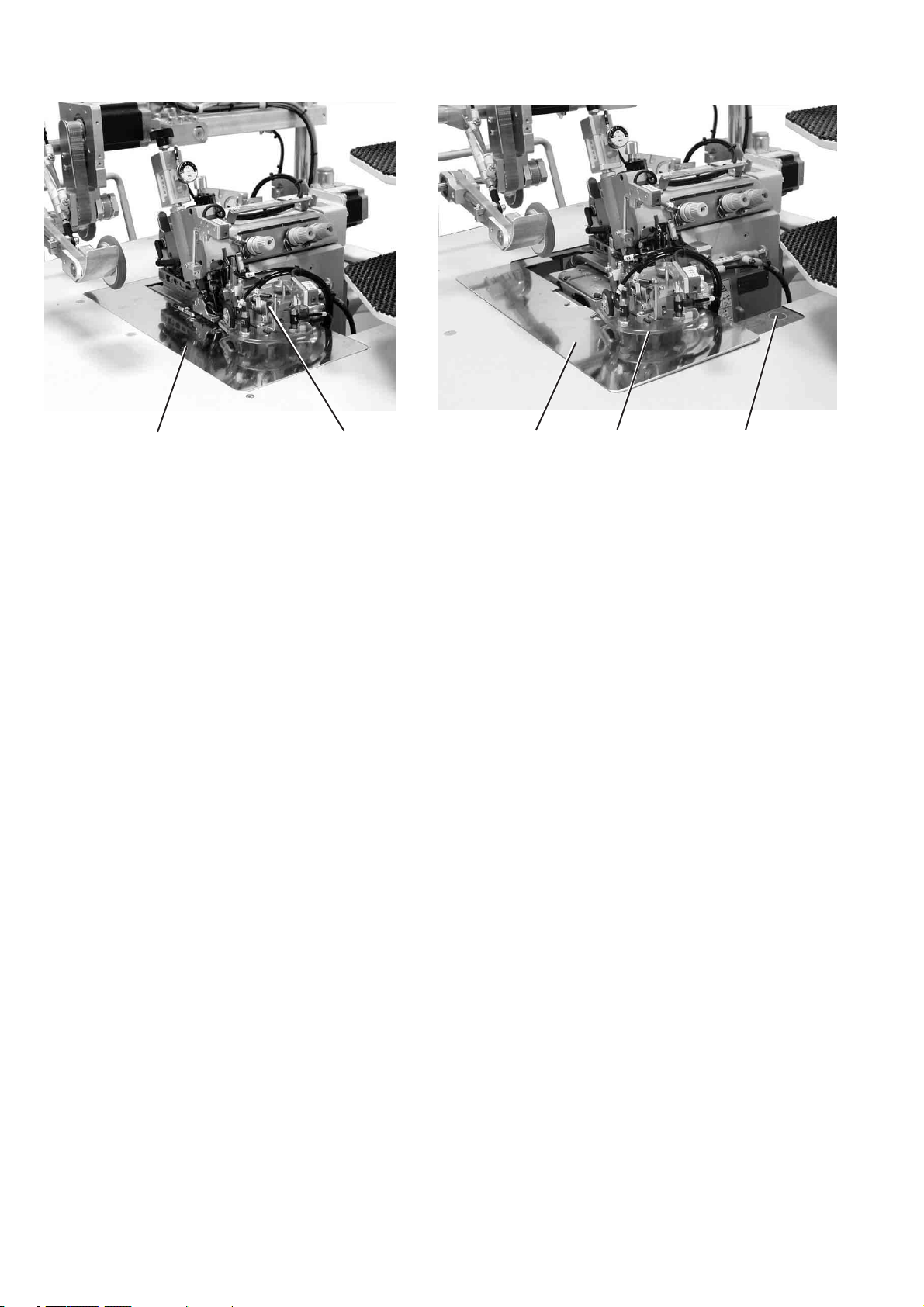

5.3Adjusting the edge guide

1

2

43

1

The height-adjustable edge guide ensures a precise positioning ofthe

trousers partinfrontofthe sewing head.The heightofthe edge guide

canbeadjusted depending on the thickness ofthe m aterialtobe

processed.

The draw roll4 guarantees a precise m aterialfeed underthe sew ing

foot.

Adjusting the heightofthe edge guide

–

Draw the dial1 inthe dire c tion ofarrow .

–

Setthe dial1 to one ofthe fourlock-in positions.

Position1=minim um height

Position4=maxim um height

Fine adjustm entofthe heightofthe edge guide

–

Turn the dial2 correspondingly.

S e tting the contactpressure ofthe roller 4

–

Turn the dial3 inclockw ise dire c tion.

The conta c t p re s s u re o f the rolleris reduced.

–

Turn the dial3 counte r-c lockw ise.

The conta c t p re s s u re o f the rollerisincreased.

13

Page 17

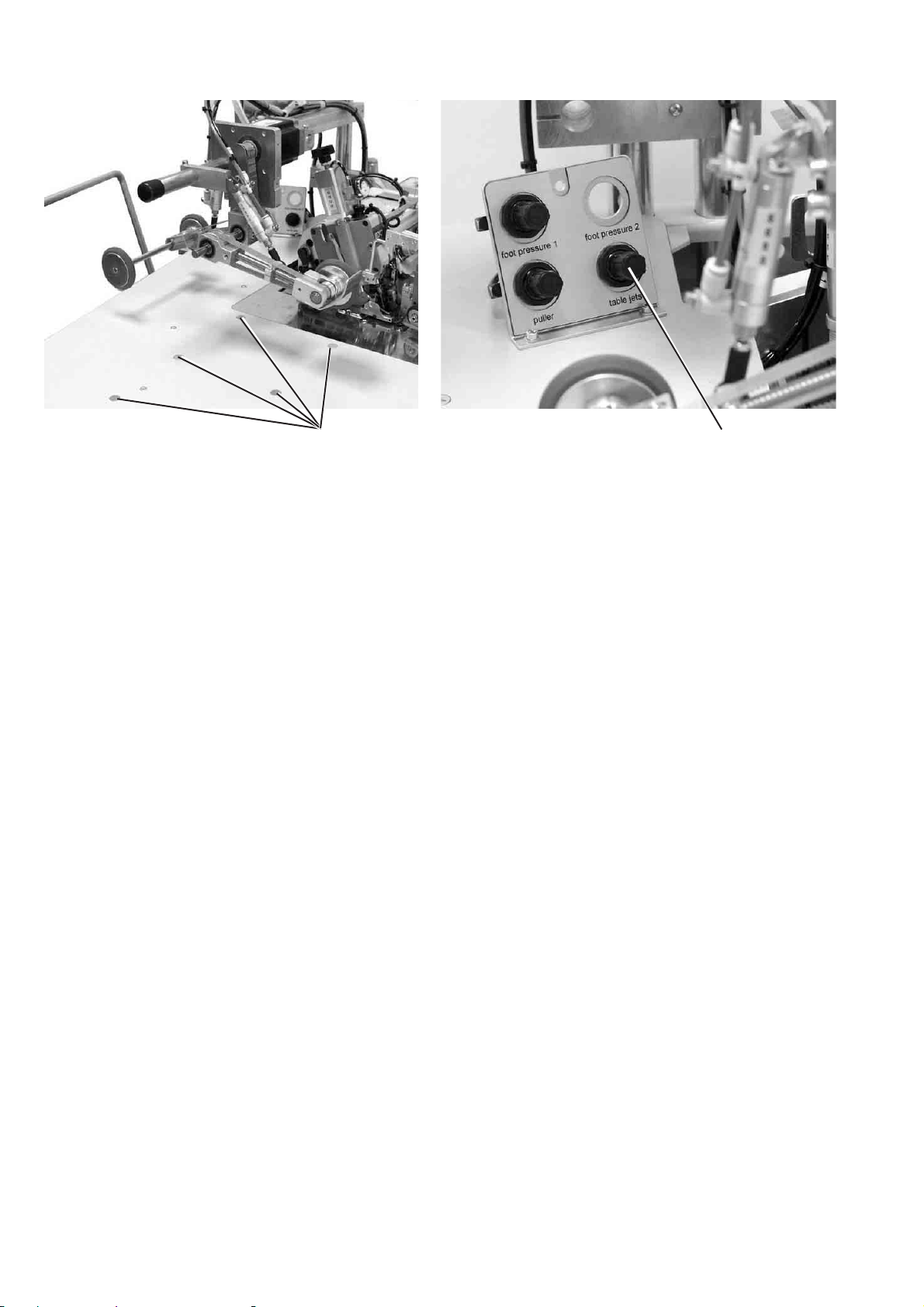

5.4Adjusting the blow ing airforthe nozzles inthe tabletop

1

The blastnozzles 1 inthe tabletop supportthe precise stacking ofthe

workpieces.

–

Setthe intensityofthe airblastw iththe dial2 atthe controlpanel.

Turn dialtothe right = increased intensityofairblast

Turn dialtothe left = reduced intensityofairblast

2

14

Page 18

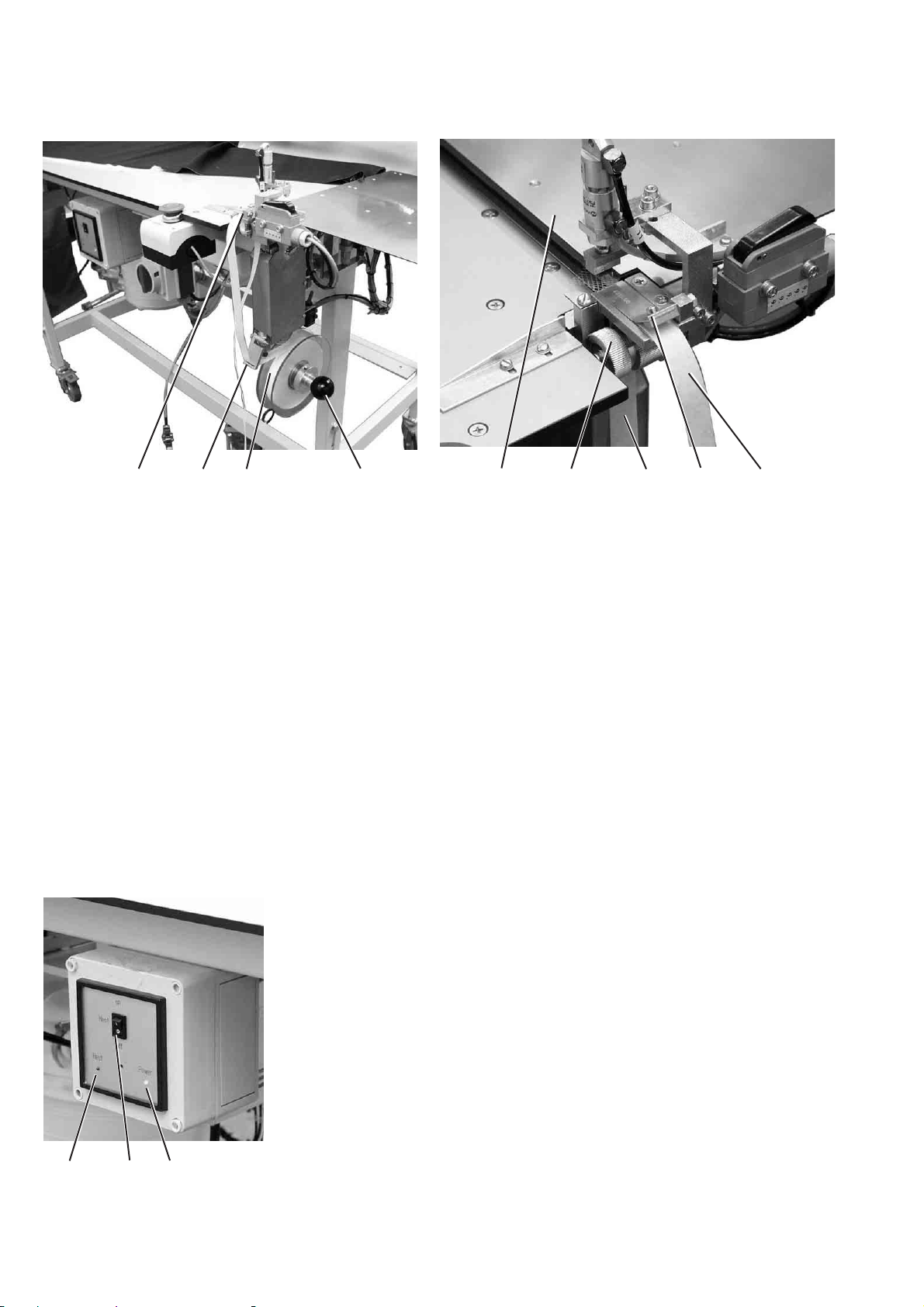

5.5Stackers

5.5.1Standard stacker

65 4 32 1

Onthe standard stackerthe finished w orkpieces are bundled.

As soon as the balance pointofthe trousers parthas been pushed

beyond the tabletop edge 2 by the ejector 1,the shield4ofthe stacker

extends and presses the trousers partagainstthe frontbundle bar 5.

The blow ing device1ofthe stacker blow s the trousers parton the

stackerover the tw o bundle bars 5 and 6.

The stacker isactivated by a controlpulse.The pneum aticfunctions

canbetaken fro m the pneum aticwiring diagram .

Caution:R isk ofinjury!

D o notreach intothe w orking area ofthe standard stacker during the

stacking operation.

M anualstacking

–

Press key F7 atthe controlpanel.

Astacking process is c a rried out.

F7

1

15

Page 19

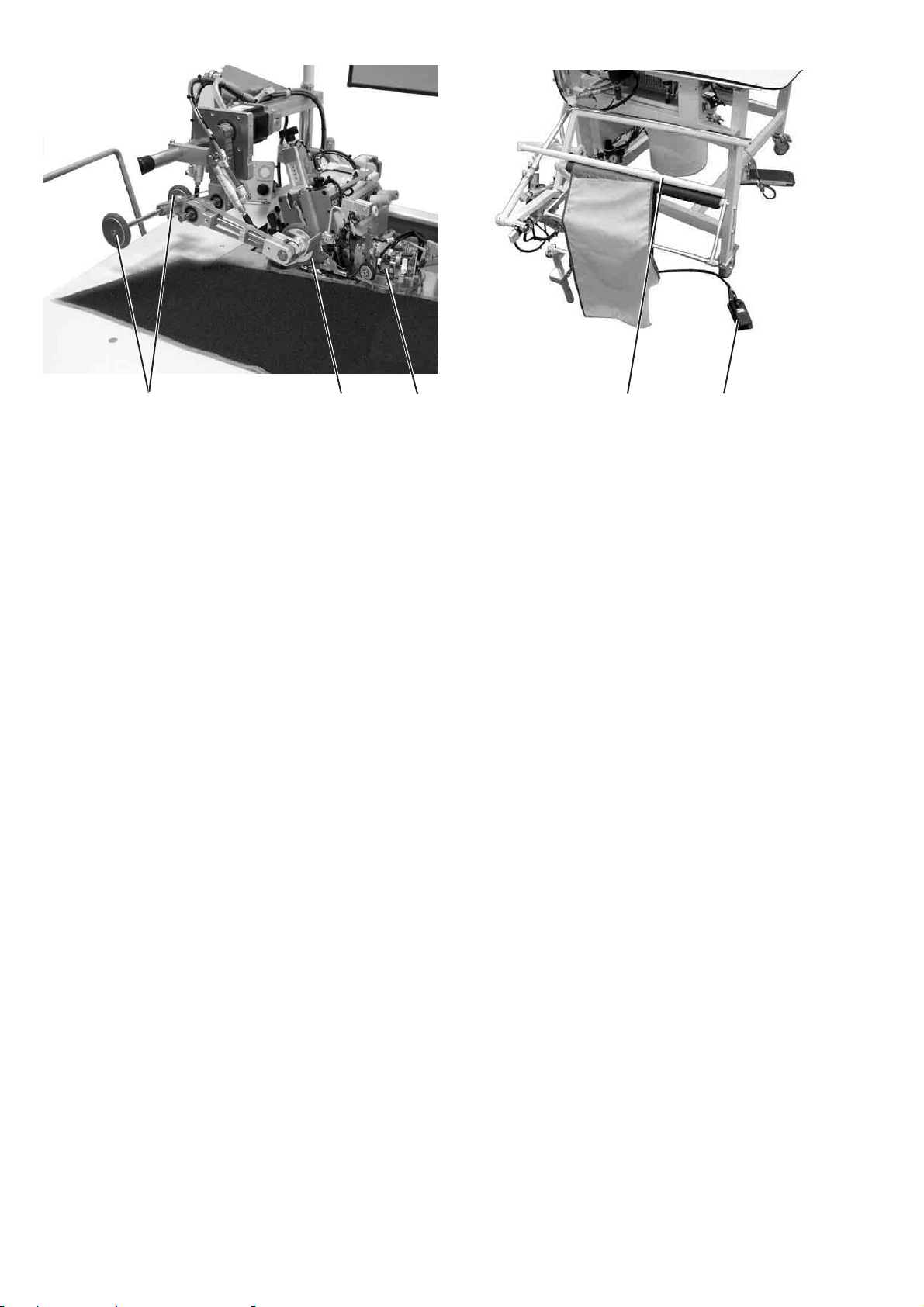

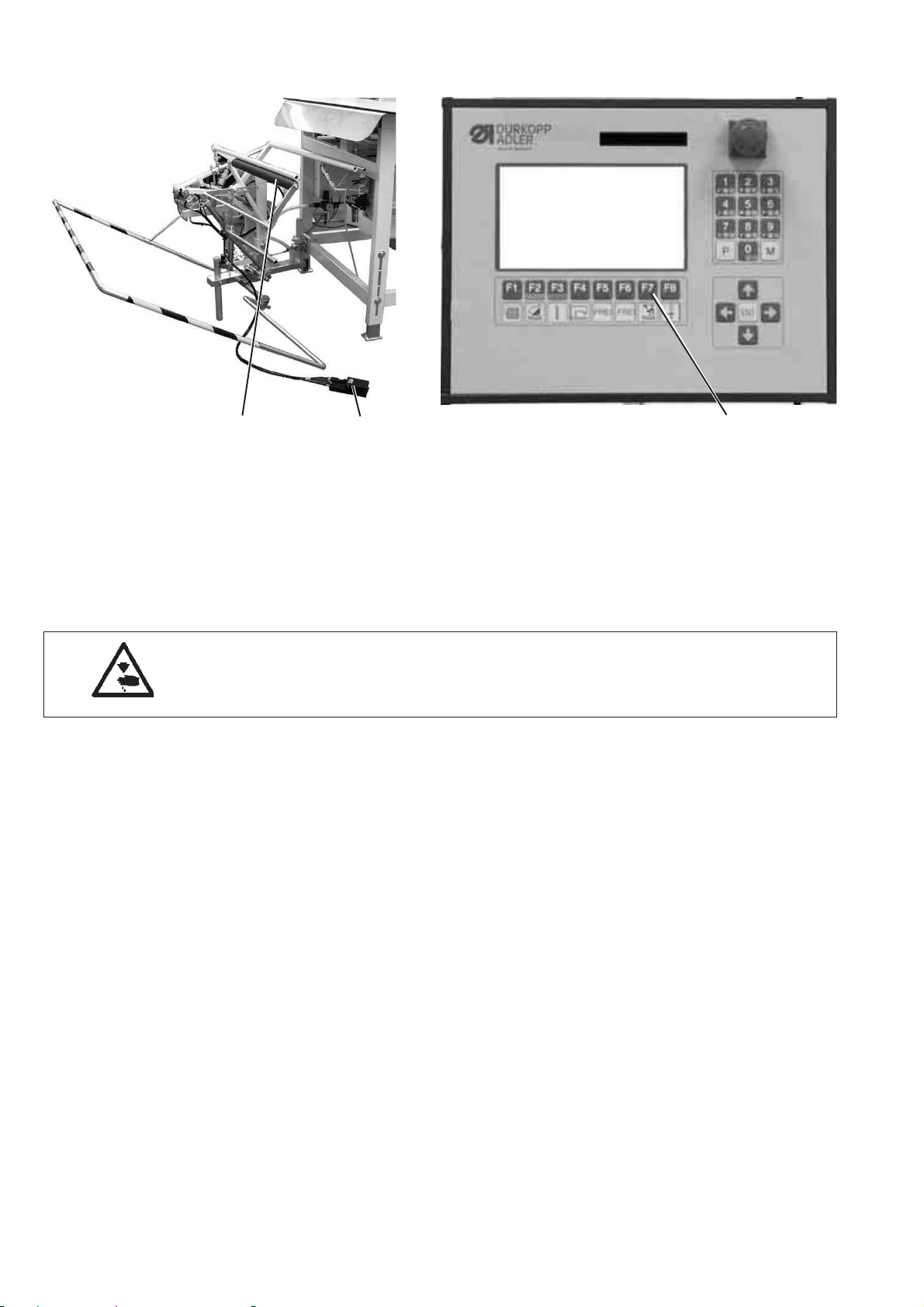

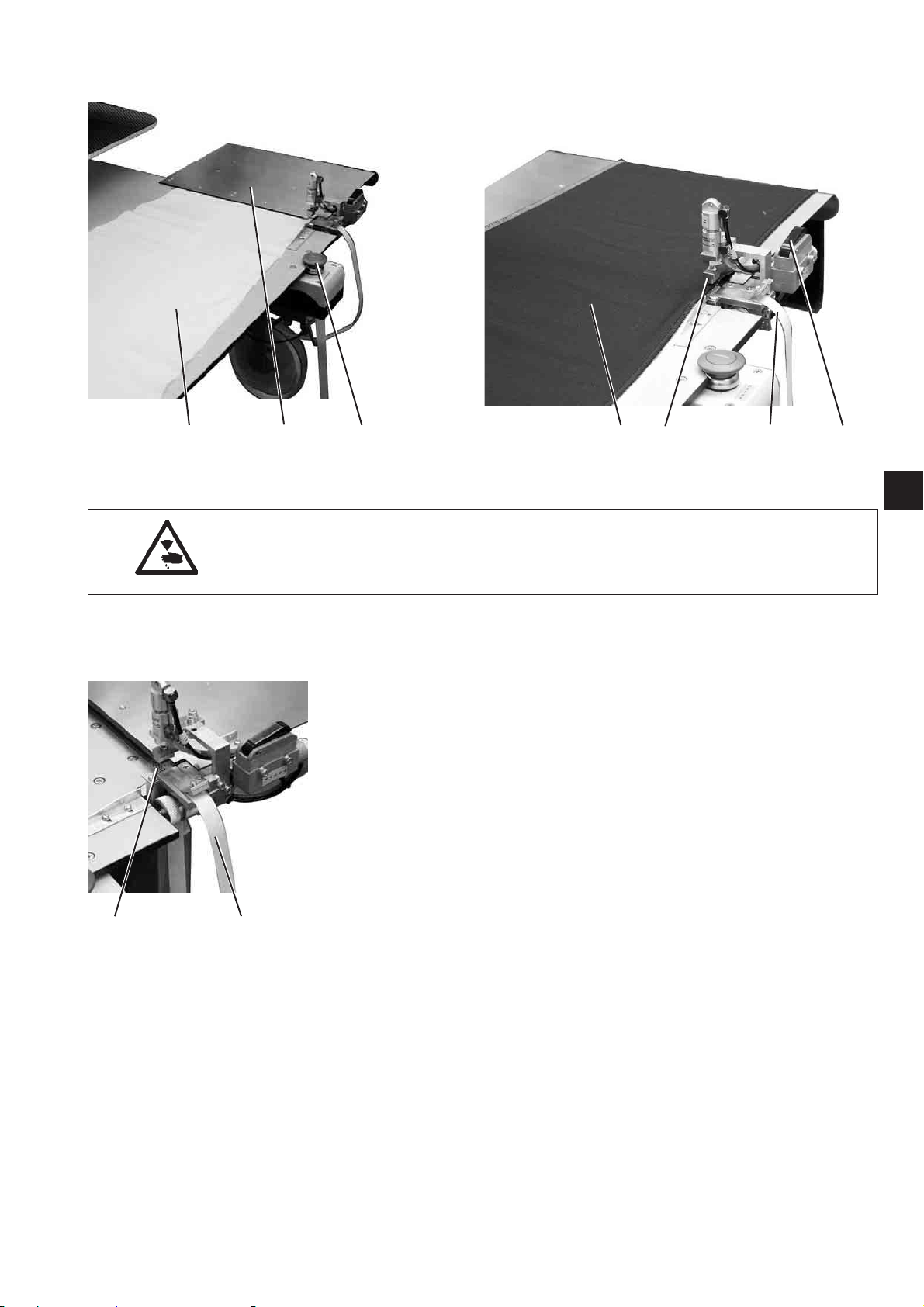

5.5.2 Throw -overstacker

21

The finished w orkpieces are stackedonthe throw -overstacker 2.

The stacked and clam ped w orkpieces can be rem oved by actuating the

footswitch 1.

The stacker isactivated by a controlpulse.The pneum aticfunctions

canbetaken fro m the pneum aticwiring diagram .

Caution:R isk ofinjury!

D o notreach intothe w orking area ofthe throw -overstacker during the

stacking operation.

M anualstacking

–

Press key F7 atthe controlpanel.

Astacking process is c a rried out.

Rem oving stacked parts

–

Actuatefootsw itch 1 and keep itactuated.

–

Removethe stacked parts.

F7

16

Page 20

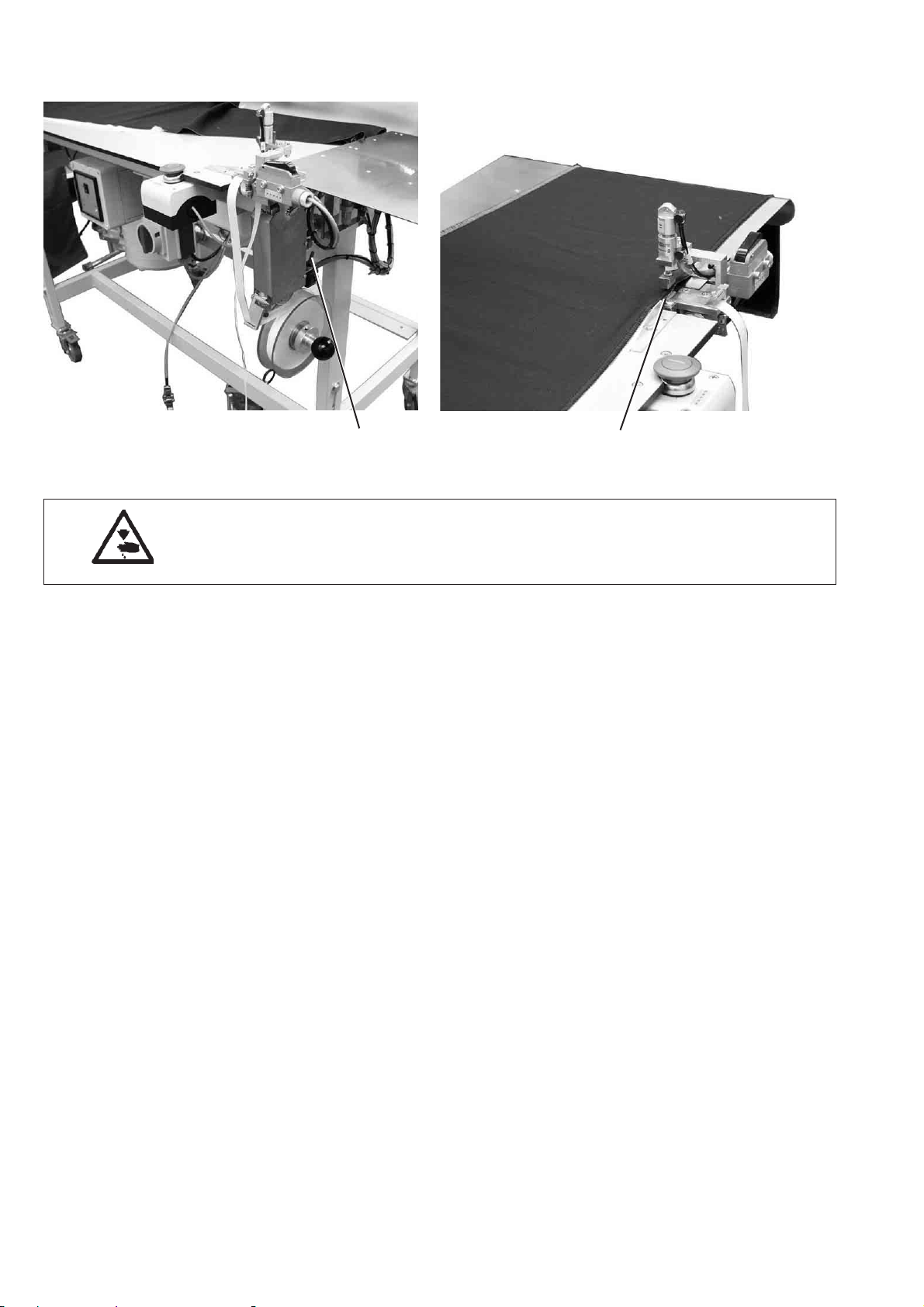

5.5.3Alternating stacker

6543 2 1

Onthe alternating stacker the rightand leftfinished w orkpieces are

stacked separately.

Forthis purpose the table7ofthe stackeris m oved from one side to

the otherafterevery sewing operation.

As soon as the balance pointofthe trousers parthas been pushed

beyond the tabletop edge 1 by the ejector 5,the shield2ofthe stacker

extends and presses the trousers partagainstthe frontbundle bar 3.

The ejector6 and the blow ing device atthe shield 2 position the

trousers partaccuratelyoverthe tw o bundle bars 3 and 4.

The stacker isactivated by a controlpulse.The pneum aticfunctions

canbetaken fro m the pneum aticwiring diagram .

Caution:R isk ofinjury!

D o notreach intothe w orking area ofthe alternating stacker during the

stacking operation.

M anualstacking

–

Press key F7 atthe controlpanel.

Astacking process is c a rried out.

7

1

F7

17

Page 21

5.6 Fusing station (optional)

5.6.1Inserting adhesive tape

432 1

–

Removethe rightsupporting disk by pulling the handle1strongly.

–

Inserta new rollofadhesive tape 2.

The fullrollm ustrotate counte r-c lockw ise w hen unw inding.

–

Push the rightsupporting disk w ith handle1onthe shaftagain until

itcatches.

–

Guide the adhesive tape through guide 3.

–

O pen flap 4 upw ards.

–

Separatethe adhesive tape2fro m th e c a rrierm aterial5.

–

Guide the adhesive tape 2 underthe flap 4 and draw itunderthe

clam p 7.

–

Guide th e c a rrierm aterial5 dow nw ards behind the transportroller6.

–

Close flap 4.

5.6.2Switching the fusing station on and off

–

The yellow signallamp1“Power”lightsupafterthe m ainswitch

has been switched on.

–

Press the toggleswitch2in position “O N ”.

76 542

18

Note

As long as the signallam p 3 “H eat”flashes,the low erstam p is being

heated up and has notyetreached the necessary tem perature.

Page 22

5.6.3 Fusing ofknee lining and fronttrousers

321

Caution:R isk ofburn!

D o nottouch the area around the fusing station.

The low erstam p is very hot.

Sew ing startofthe hem

To avoidadisplacem entofthe knee lining during the sew ing process a

glue dotfusing the lining atthe correctposition has tobesetwiththe

fusing station.

–

–

–

–

85

76 5 4

1

Position knee lining 3 underclam p 2.

Press clam p key 1.

The clamp2low ers and clam ps the knee lining.

The fusing tape5is pushed forw ard simultaneously and the

net-like fusing tape8is separated fro m the release paper.

Position trousers part7 and align itas per the lining.

Press the fusing key 4.

The upperstam p 6 m oves dow nw ards,the low erheated stam p

m oves upw ards so thattrousers partand lining are pressed w ith

the fusing tape lying in betw een.

Afterthe presetfusing timethe upperstam p 6 and the clamp2are

lifted autom atically and the low erstam p islow ered.

Lining and trousers partare fused now and can be positioned for

overlocking.

19

Page 23

5.6.4Cleaning the stam p

1

Caution:R isk ofburn!

Clean the stam p only w hen itiscold.

–

Actuatethe toggleswitch 1.

The low erstam p 2 m oves upw ards.

–

Clean the stam p.

–

Actuatethe toggleswitch 1 again.

The low erstam p 2 m oves dow nw ards.

2

20

Page 24

5.7 Feeding the trousers partsandstarting the sew ing operation in conjunction w ith

the fusing station

The overlock unit1265/5 w orks sem i-autom atically.

The operatorofthe sew ing unithas to proceed as follow s:

callup the seam program “Lining below ,sew ing startatthe

l

waistband”

l fuse upper fabric and knee lining atthe fusing station

l feed the w orkpiece accurately

l supervise the sew ing process

l re m o v e the finished partsfro m the stacker

l change the program and callup the seam program “Lining below,

sew ing startatthe hem ”

l feed the w orkpiece accurately

l supervise the sew ing process

l re m o v e the finished partsfro m the stacker

1

43 1 21

Feeding the trousers partand starting the sew ing process

1) Selectthe seam program atthe controlpanel(see chapter6.4.2).

2) Place the trousers part1 fro m the righton the tabletop 2 and

stra ightunderthe contourguide 3.

ATTENTION!

As soon as the trousers partis pushed underthe lightbarrier4,the

sew ing process starts autom atically and the contourguide3low ers.

21

Page 25

653

3) The trousers partis sew n.D uring the sew ing process the puller 5

low ers and supportsthe m aterialfeed.

4) As soon as the w orkpiece has passed the lightbarrier,the seam is

finished and bothejectors 6 low er.

5) The contourguide 3 m oves upw ards.

6) The ejector6 transportsthe m aterialoutofthe sew ing area.

7) The stacker clam p 8 m oves tothe front.

8) The ejector6 m oves upw ards again.

9) The trousers partisstacked.

10) A ctuatefootsw itch7forrem oving the w orkpieces.

Note

In ordertofacilitatethe m aterialfeed inthe area ofthe sew ing head

the tableblow ing and the ejector 6 can be engaged atthe seam

beginning.(see chapter5.4)

87

22

Page 26

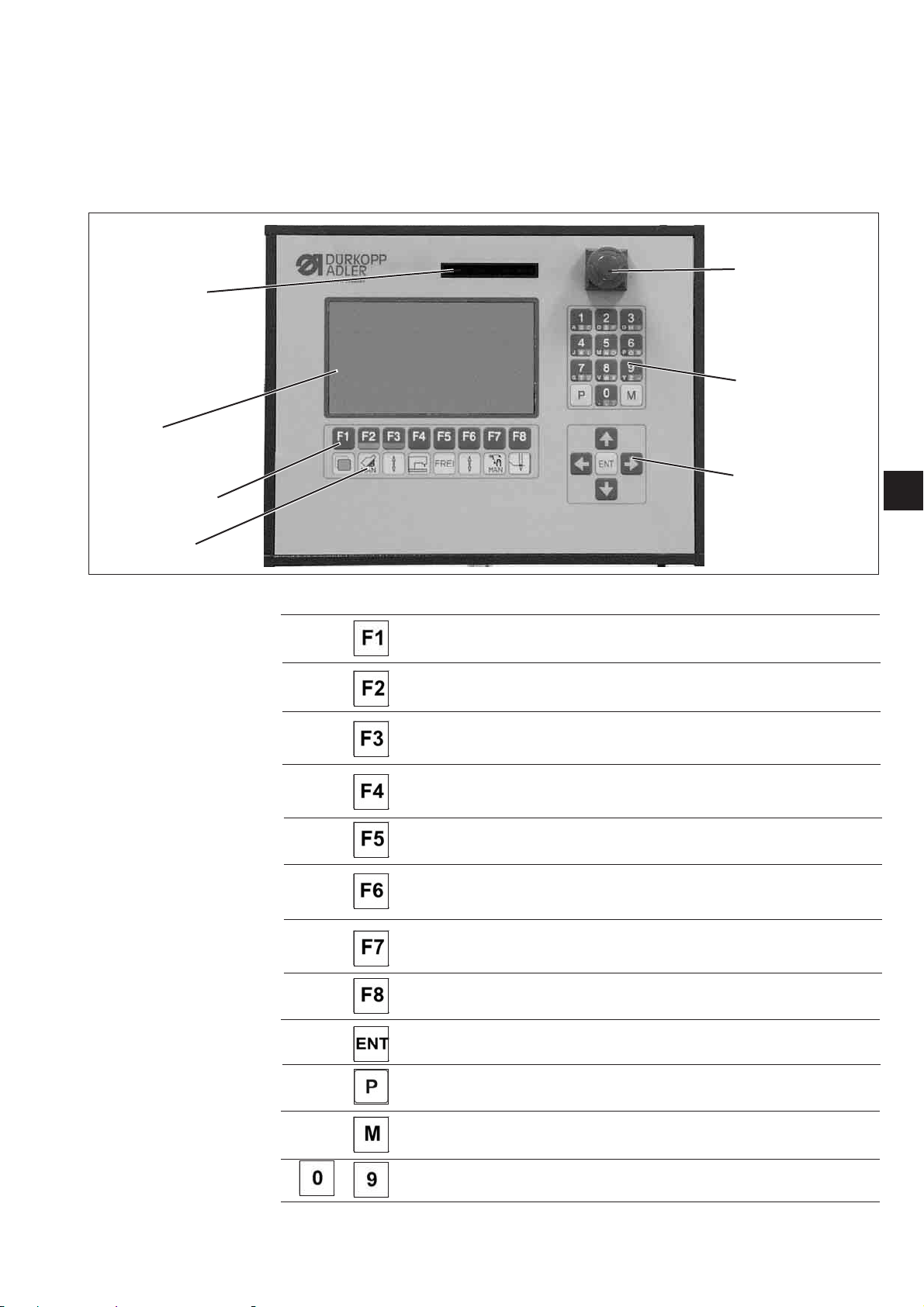

6. O peration ofthe contro l

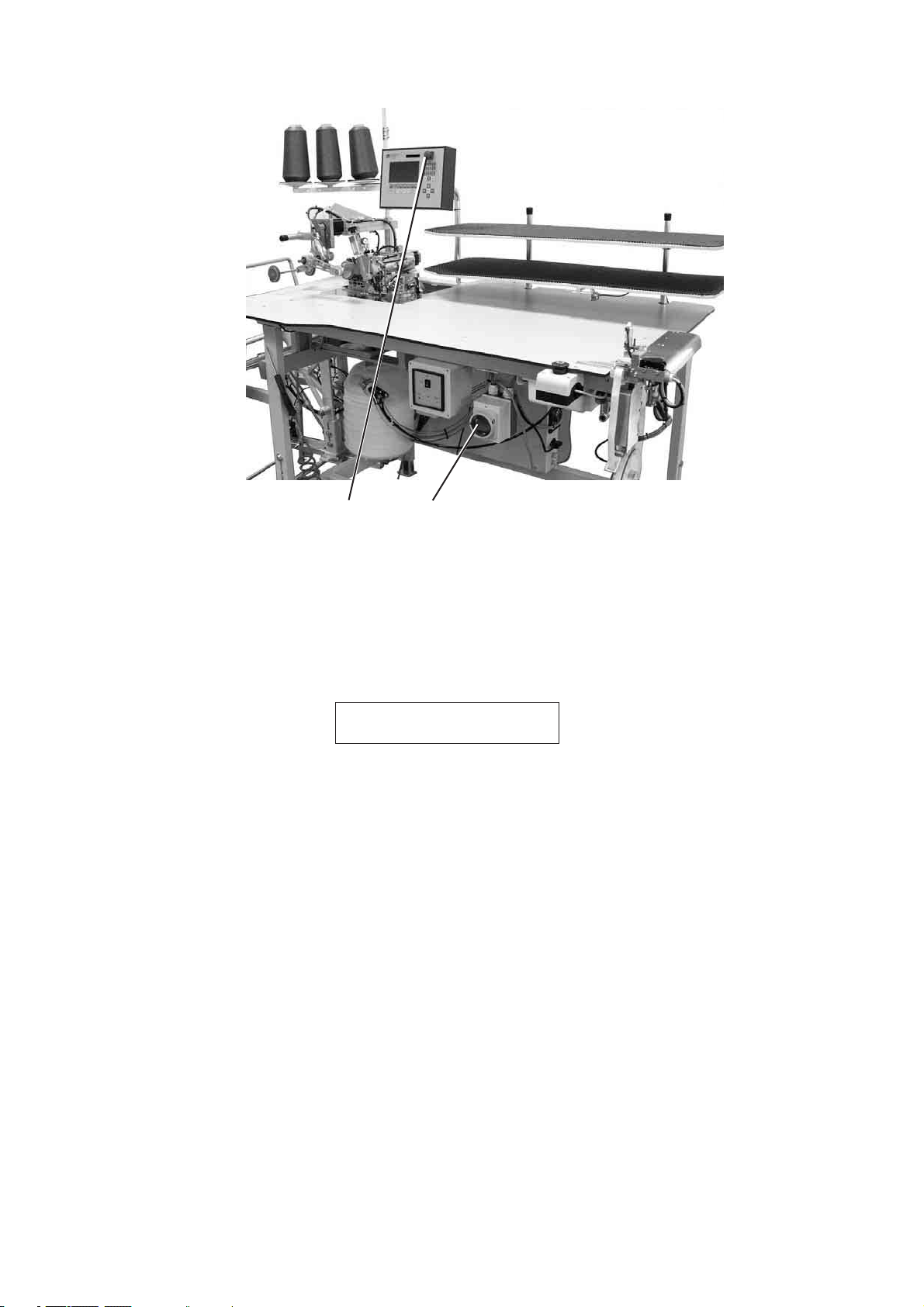

6.1Operatorterm inal

The operatorterm inalisthe display and inputm edium ofthe m achine

contro l.Inthe operator term inalthe m icroprocessorforthe contro l o f

the sew ing unitand the storage m edia (EPRO M )for securing the

program contro l a re installed.

Key

Slot Program stop

MemoryCard

Numericpad

Display

Function keys

Toolbar

A rro w k e y s

1

Key Function

Callup access level2 ofthe userm enu

Switch on m anualsewing

Selectseam param eters /m achine functions

Selectm achine param eters

fre e

Selectseam param eters /m achine functions

Activatestacking process

Switch on threading m ode

Enter key

Selectprogram m ing m ode

Callup m em ory (program s M 10 -20)

Directprogram selection/Inputofnum ericalvalues

23

Page 27

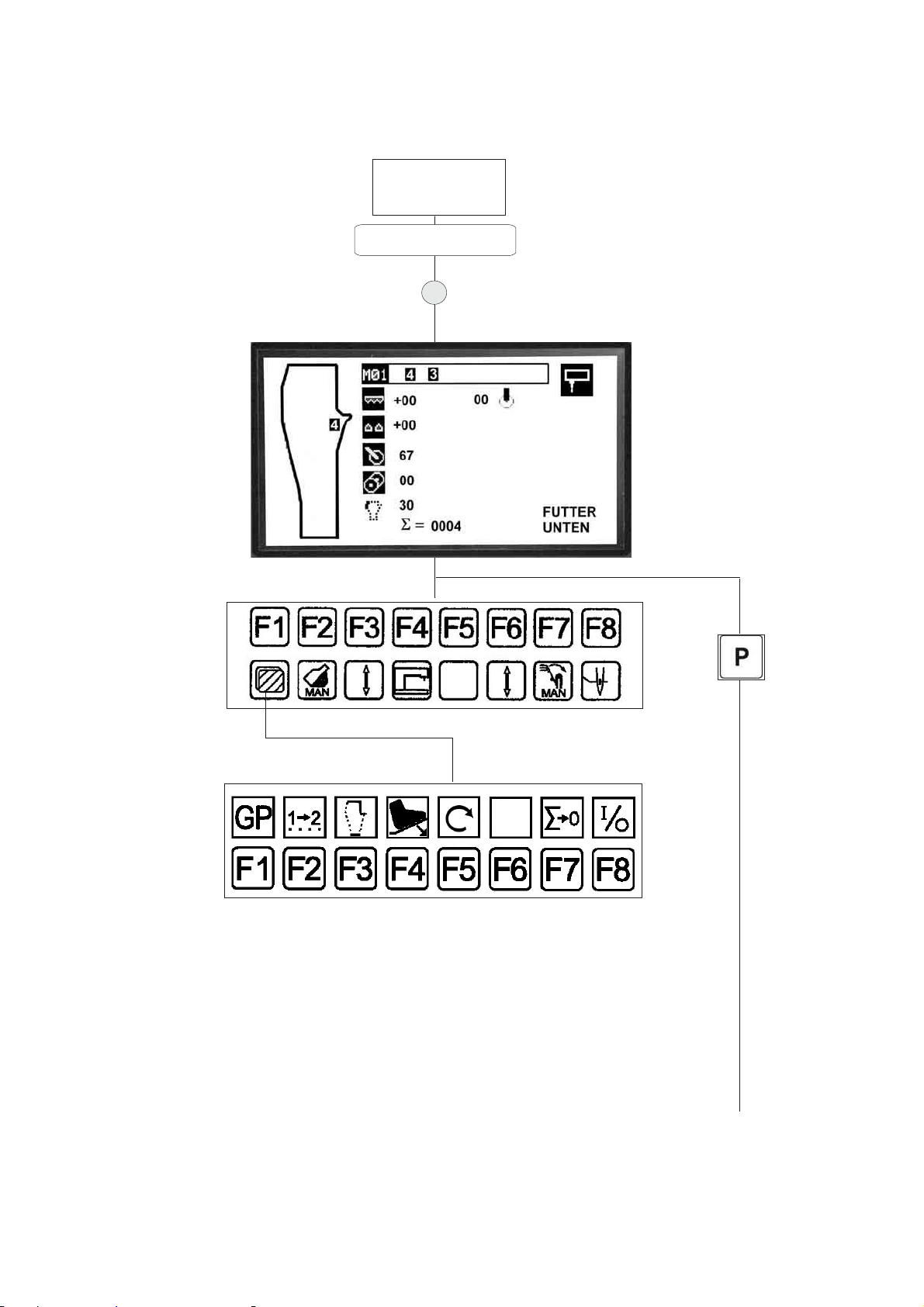

6.2 U serinterface

6.2.1Menustru c ture ofthe sew ing and setting program s

mainswitch

Switch on

Startscreen W aiting for reset

key program stop

Unlock

Main screen

A ccess level1

see page 23

A ccess level2

F1 = G lobalparam eters

F2 = Seam sequences

F3 = Param eters forpreseam s

F4 = M anualsewing start/A utom aticsewing start

F5 = M achine running atlow speed

F6 = fre e

F7 = D ailypiece counter

F8 = Inputs/O utputs m achine contro l

24

Program m ing m enus

see nextpage

Page 28

Program m ing m enus

F1 = INIT param eters

F1= EPROM globalparam eters

F2= EPROM seam param eters

F3 = C opy seam num ber

F4 = D elete seam

F2 = M em ory card

F1 = C urrentseam -> C ard

F2 = C ard -> C urrentseam

F3 = M achin e m e m o ry -> C a rd

F4 = C ard -> M achinememory

F5 = M em ory card form at

F3 = D iagnostics

F1 = Service test

F1 = M em ory test

F1= EEPROM 2K

F2= EEPROM 8K

F3 = R AM 8K

1

F4 = I/O m odulelong-term test

F5 =

F6 = Furthertests

F4 = Sewing head test

F1 = Sewing m otoractivation

F2 = Sewing m otorand puller

F3 = Ejector

F4 = Top feed

F5 = D ifferential

F6 = R eference value transm itter

F4 = Service code

F5 = Additionalprogram s

F2 = S ystem update

F1 = Eprom -> C ard

F2 = C ard -> E prom

F3=Text->Card

F4=Card->Texts

F 5 = R S 2 3 2 -> C a rd

F1 = R S 232 test

F2 = I/O adaptertest

F3 = com m unication test

F3 = Language selection

F4 = Piece counter

25

Page 29

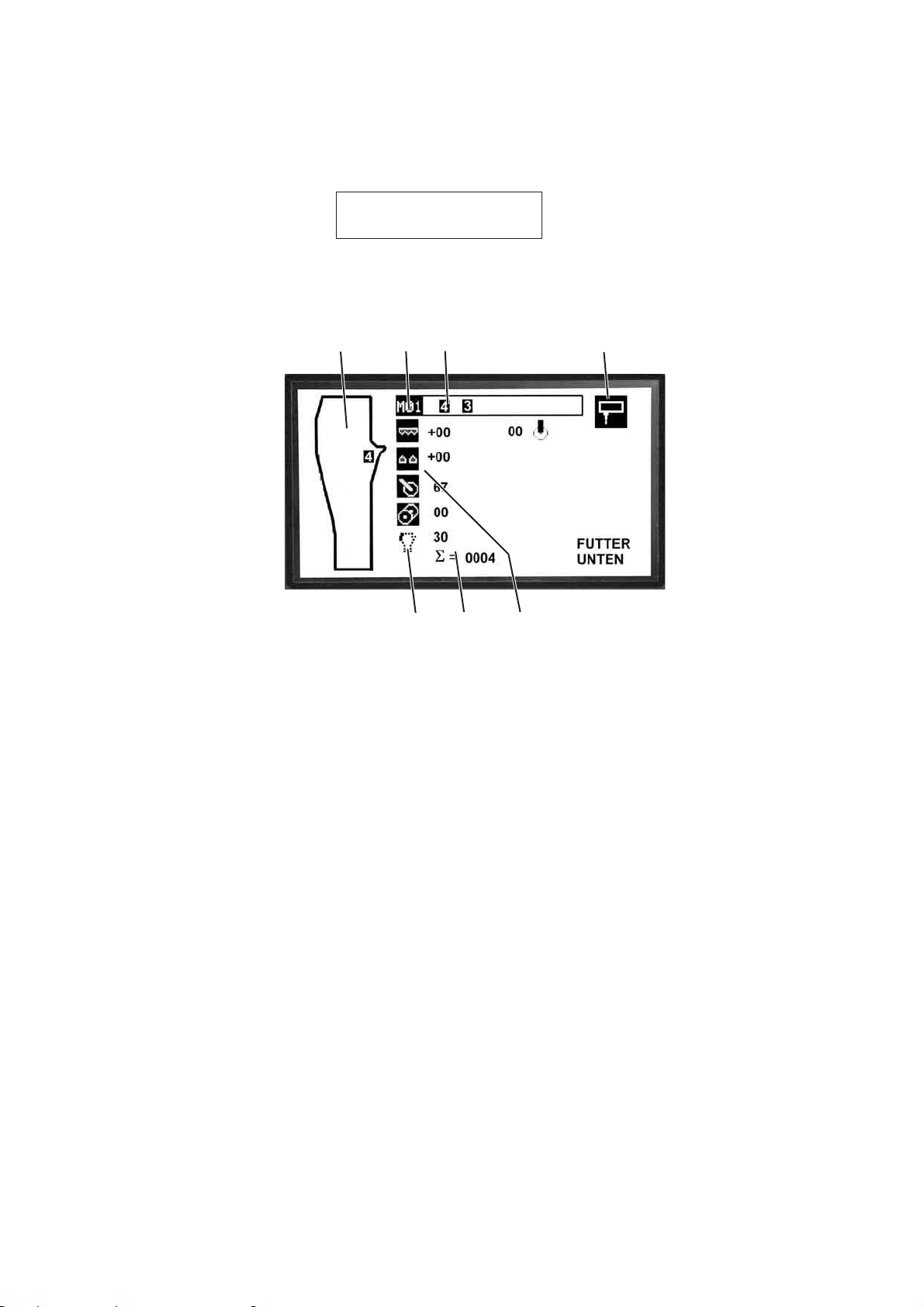

6.3Main screen

–

Switch on m ainswitch1(turn inclockw ise dire c tion).

The contro l loads the m achine program .

The startscreen appears inthe display ofthe controlpaneland

shows the follow ing m essage:

WAITING FOR RESET

–

Press the program stop key 2 atthe controlpaneland unlock

again.

The m ain screen appears w iththe follow ing display:

123 4

76 5

1 = S eam pattern ofthe currentseam inthe program

2= Designation ofthe program

A program can consistofseveralseam s

3 = S eam num berofthe program

4= Starting m ode ofthe sew ing unit(m anual/vialightbarrier)

5 = S ym bols ofseam functions (active)

6= Dailypiece counter

7 = S ym bolofa seam function (inactive)

Note:

Black-shadow ed sym bols,e.g.5 = active function

Sym bolswhich are notblack-shadow ed,e.g.7 = inactive function

26

Page 30

6.4 Seam program s

6.4.1 Factory-setprogram s

Inthe program controlm em ory up to 20 program s (M 01 -M 20)can be

program m ed.U p to8seamswiththe corresponding seam num bercan

be assigned to every program .

The seam s differby the controlparam eters assigned during the

program m ing process as w ellas by the contro l functions engaged.

The sewing unitisprovided w ithten program s preprogram m ed by the

m anufacturer.

Progr.No Seam N o. Sequence

M01 4 Hind trousers:crotch seam -sew ing startat

the w aistband

M02 5 Hind trousers:side seam -sew ing startat

the w aistband

M 03 6 /7 Fronttrousers:crotch and side seam

alternatelylining on top -sewing startatthe

waistband

M 04 5 /4 Fronttrousers:side and crotch seam

alternatelylining below -sewing startatthe

waistband

M 05 4 /5 Fronttrousers:crotch and side seam

alternatelylining below -sewing startatthe

waistband (Program forsew ing unitswith

fusing station and photocell15)

M 06 5 /4 Fronttrousers:side and crotch seam alternately

lining below -sewing startatthe hem

(P rogram forsew ing unitswithfusing station

and photocell15)

M 07 7 /5 Fronttrousers:side seam w ith pocketbag

lining on top and below alternately(with

m ovablestop)

M 08 4 /6 Fronttrousers:crotch seam ,lining below and

on top alternately

M09 1 Follow -up sew ing

M 10 134135 Program w ith preseam s

M11-20 fre e

1

Preseam s

Waistband seam s,fly seam s and hem seam s can be overlocked

separately.

The features ofthe preseam s are setinanownparameterlist.These

settings becom e onlyeffective if“preseam s”are activated inthe seam

program .

C rotch and side seam s

Crotch and side seam s can eitherbe overlocked inindividualseparate

sew ing operations or processed as com bined sewing operation w ith

seam alteration.

The preprogram m ed seam s are activated atthe controlpanelby rapid

access.

Identicalstitc h p a tte rn

Ifitis require d thatthe crotch seam and the side seam have an equal

stitch pattern,the knee lining has alwaystobefed inthe sam e position

(a lways below ).

The trousers partisfirstpositioned atthe w aistband and then atthe

hem (only possiblewithfusing station).

27

Page 31

6.4.2Selecting the program

1)Selecting the program via the num ericpad

The program s M 01 -M 09 are selected indirectaccess.

–

Enter the num berofthe desired program viathe num eric pad,e.g.

program M 04

–

Press key “4”.

The program s M 10 -M 20 are selected viathe m em ory.

–

Press key “M ”.

–

Selectthe num berofthe program ,e.g.15

–

Press key “1”and then key “5”.

2)Selectthe seam num berofa seam indirectaccess

(in case ofseam sequences)

1

2

–

Movethe cursorw iththe keys “ï“or“ð “tothe desired seam

num ber2.

6.4.3 M anualsew ing,contro lled viafootpedal

The function “m anualsewing”serves fortesting the sew ing head and

the sew ing equipm entas w ellas forim provem entoffaultysewing.

“M anualsewing"can be called up indirectaccess.

1)Sw itc h ing the function on

–

Press key “F2”.

–

C ontro l the sew ing speed by stepping on the pedal(ifavailable).

2)Sw itc h ing the function off

–

Press key “F2”once again.

The m ain screen appears inthe display.

The display show s the sym bolfor“m anualseam ”.

28

Page 32

6.4.4Altering the function ofthe seam program s

The param eters ofa program can be altered inthree steps:

1) Q uick adjustm entofthe m ain param eters viathe inputfields.

2) A ccess tothe entire p a ra m e terlist.

3) Sw itching a seam orm achine function on oroff.

6.4.4.1Quick adjustm entofthe m ain param eters viathe inputfields

1

The follow ing functions ofa seam program can be altered as tothe

values orsw itched on or offcom pletely:

Top feed

Increasing or reducing the value

Differentialfeed

Increasing or reducing the value

Puller

Param eter14,speed

Ejector

Param eter30,ejecting line

2

1

Pullerspeed,Param eter20

low speed atthe hip bow

Black-shadow ed sym bols,e.g.1 = function active.

Sym bolswhich are notblack-shadow ed,e.g.2 = function inactive.

Alte ring values

–

Press key “F3”or“F6”,untilthe inputfieldallocated tothe icon is

black-shadowed.

–

Increase orreduce the param eters dire c tlywiththe keys “ï“or“ð “.

–

Press key “P”.

The new value istaken over.

29

Page 33

6.4.4.2 A ccess tothe entire p a ra m e terlistofa seam function

–

Press key “F3”or“F6”,untilthe inputfieldallocated tothe icon is

black-shadowed.

–

Press key “EN T”.

The param eterlistbelonging tothe seam is opened.

–

Scrolltothe desired param eterw iththe keys “ñ “or“ò”.

–

Alterthe value w iththe keys “ï “or“ð “.

or

–

Enter the tw o-orthree-digitvalue viathe num eric pad.

–

Press key “P”.

The altered param etervalue istaken over.

6.4.4.3Switching a m achine function on oroff

–

Press key “F3”or“F6”,untilthe inputfieldallocated tothe icon is

black-shadowed.

–

Press key “EN T”.

The param eterlistbelonging tothe seam is opened.

–

Press key “F8”.

The function isactivated ordeactivated respectively.

–

Press key “P”.

The new value istaken over.

30

Page 34

6.4.4.4 S eam -specific param eters in access level1

Top and diffe re n tialfeed

In ordertoachieveacorrectfullness distribution the feeding features

ofthe differentialfeed and the top feed have to be adapted tothe knee

lining m aterial.

This adaptation is necessary ifthe lining is processed w ithfullness.

Top feed

Inthe program a correction ofthe fullness distribution can be m ade by

m eans ofthe top feed quick adjustm ent.

Forthis purpose itis possibletoalterthe position ofthe top feed-dog

as tothe m ainfeed-dog.

This adjustm entbecom es onlyeffective forthe seam line w hich has

been activated fora fullness distribution.

R ange ofvalues:-59 to+59

Diffe re n tialfeed

The position ofthe differentialfeed-dog as tothe m ainfeed-dog is

altered.

This adjustm entbecom es onlyeffective forthe seam line w hich has

been activated fora fullness distribution.

R ange ofvalues:-59 to+59

1

Subdivision ofthe seam in seam sections

Inthe sew ing area the trousers partis subdivided into seam sections.

l S eam A w iththe basicsetting S 1 -S4 w ith each 15,30,45 and

60 cm .

S5 isthe rem aining lengthofthe trousers w ith 255 cm

l S eam B w iththe basicsetting S 5 -S 2 w ith each 10,20,30 and

40 cm .

S1 isthe rem aining section fro m the photocell15 tothe knee lining

(norm ally2-7cm).

Thissection has tobedeterm ined by trialforevery w orkpiece.

l

The knee lining C reaches overfourofthe five sections.

Forevery ofthese seam sections the lengthofthe seam line can be

varied and the corresponding fullness (quantity) can be presetviathe

contro l.

31

Page 35

Alte ra tion offullness

–

Press key “F3”,untilthe cursorpointsonthe program .

–

Press key “EN T”.

The param eterlistbelonging tothe seam is opened.

1234

W hen opening the m enu the inputfield2ofthe param eter“basic

setting”isblack-shadow ed and can be altered.

The individualsections and the basicvalue 3 (quantity:orcm :resp.)

canbeselected w iththe keys “ñ“or“ò “. Ifthey are black-shadowed,

theycanbealtered w iththe keys “ï “or“ð “orthe num eric pad.

Ifthe sym bol4 isblack-shadow ed w iththe key “F8”,the five seam

sections (quantity: and cm :)are active.

Ifthe sym bol4 is deactivated w iththe key “F8”(notblack-shadow ed),

the value setinsymbol3isactive overthe w hole seam .

Seam sections

The seam sections 1 to 5 can be actived ordeactivated respectively.

Ifa seam section isactive (black-shadowed),the value altered inthe

main m enu

e.g. + 10 istaken overinthisactivated seam section only.

Exam ple:

Q uantity:50 + + 10 = quantity 60.

Ifa seam section isinactive (notblack-shadow ed),the value altered in

the m ain m enu

32

+10is nottaken overinthis seam section.

Onlythe value setin quantity:(e.g.50)isactive.

Page 36

Low speed

You can choose betw een “M ax.speed”and “R educed speed”.

IfatLO W SPEED:a black barhas been chosen in a seam section,the

sew ing speed is reduced inthissection.

Ifthe bar ishidden,M ax.speed isactive.

1234

1

Exam ple

The firstseam section1isinactive, the fourrem aining sections 2 are

active (sections 2 -5 are black-shadowed and m arked as active).

Functions

–

Activate ordeactive an individualsection by the function key “F3”“F7”underneath.

–

Function LO W SPEED fordifferentialfeed

or

function PRESSURE for top feed

-Activatethe respective section1to5atthe num ericpad

with key “F1”and the corresponding num ber.

Exam ple:Press “F1”+ “2”

–

Alterthe seam schem e w ith key “F2”(onlyincaseofdifferential

feed).

C hange betw een sewing startatthe hem and sew ing startatthe

waistband.

33

Page 37

Exam ples for subdivisions ofseam sections

1)S ide seam ,sew ing startatthe w aistband

Start

Sewing dire c tion

2) C rotch seam ,sew ing startatthe w aistband/fly

Sewing dire c tion

3) S ide seam ,sew ing startatthe hem .

Feeding position w hen using the optionalfusing station

Photocell15

Sewing dire c tion

34

Page 38

4) C rotch seam ,sew ing startatthe hem .

Feeding position w hen using the optionalfusing station

Photocell15

Start

Sewing dire c tion

Alte ra tion offullness

Forthe fullness the value ranges can be setas follow s (separatelyfor

differentialfeed and top feed):

1) Basicsetting offullness ifthe function

Top Feed isswitched on.

2) Fullness (quantity) foran individualsection tobesetseparately.

The individualsection has tobeactivated so thatthe setting

becom es effective.

3) The lengthofanindividualsection w here a fullness istobedistributed.

4) The function SEW AT LOW SPEED (differentialfeed only)

5) The function S LIGHTFOOT PRESSURE (top feed only)

1

35

Page 39

Puller speed

The photocellidentifies the deviation ofthe fabric contourfro m the

idealcontourand regulates the speed ofthe puller,ifrequired.

Ifthe trousers partsareshifted aside fro m the stop during the feed,

l

the speed istoo high.

Ifthe trousers partscurlupatthe stop,the speed istoo low .

l

The basic speed ofthe pullercanbealtered viathe inputfield.

Param eterPuller

14 PULLER SPEED

Main param eter/Basicsetting ofthe speed forthe m ain seam .

15 H IGHER PULLER SPEED

Increasing the speed steps w ithblocked photocell16,ifthe w orkpiece

curlsupatthe stop.

16 LOW ER PULLER SPEED

R educing the speed steps w ith unblocked photocell16,ifthe

workpiece isshifted aside fro m the stop.

17 SEAM SECTION UNTIL PULLER D O W N

The seam section untilthe pullerlow ers afterthe sew ing start.

18 SEAM SECTION W ITH PULLER D O W N

The lengthofthe seam section during w hich the pullerislow ered.

19 SEAM SECTIO N PULLER LIFTING

The lengthofthe seam section during w hich the pullerislifted to

re lease the fabric.

33UNTILAUXILIA RY R O LLER DO W N

The seam section afterthe sew ing startafterw hich the contourroller

low ers

Startatthe w aistband = photocell13

Startatthe hem = photocell15

34DURATION AUXILIA RY R O LLER D O W N

The lengthofthe seam section under the guidance ofthe low ered

contourroller.

36

Page 40

Ejector

The param eteralters the lengthofthe seam section overw hich the

ejectortransportsthe trousers parton the w orktablefro m the sew ing

head tothe stacker.

Body Textfett=

Param eterejector

25 SEAM SECTION UNTIL RO LLER D O W N

The seam section afterthe sew ing startuntilthe ejectorlow ers;

only require d forheavy-w eightm aterial

26 SEAM SECTION W ITH R O LLER D O W N

The lengthofthe seam section overw hich the ejectorislow ered atthe

sew ing start.

27UNTIL RO LLER STO P/KETTUP

The seam section overw hich the ejectortransportstostop the m aterial

and to separatethe chain.

28DURATIO N O F R O LLER STO P/KETTU P

The timethe ejectorstops forseparating the chain.

30 EJECTOR TRANSPO RT LENG TH

Main param eter/Basicsetting ofthe ejectortransportlength untilthe

workpiece is delivered tothe stacker.

31UNTILSTACKER START

The tim e untilthe stacker startsafterthe ejectorhas lifted.

(F ixthe w orkpiece untilthe stackerhas taken itoversafely)

32STACKER MODE

Setting ofthe differentstacking operations (stacker types)

00 = Function sw itched off

01 = S w itch function on

02 = fre e

03 = alternating stacker

10 C LO S ING THE FEED

Function ofthe feeding unit(pullerand ejector)

00 = the feeding unitalwaysrem ains initslow erposition

01 -99 = the feeding unitlow ers afterthe seam section w hich has

been sethere

1

Note -Pneum aticstop

The sewing unitcan optionally be equipped w ith a pneum aticstop.

Withthis equipm enta pocketbag can be placed betw een trousers part

and lining and overlocked.The seam section up tothe pocketend is

sewn m anually; the rem aining seam section issewnfully autom atically.

The seam course sew n m anuallyis determ ined by param eter10 ofthe

seam function C LO S ING THE FEED.

Atthe end ofthis seam section the feeding unitlow ers,the pneum atic

stop m oves tothe sew ing footand the seam contro l istaken overby

the contourguide.

37

Page 41

Low puller speed at the hip bow

The param eteralters the basicvalue ofthe pullerspeed w hen sew ing

offthe hip bow .

The pullerspeed can be adapted tothe shape ofthe hip bow .

(in conjunction w ith photocell15).

Param eterLow puller speed atthe hip bow

20 LOW SPEED AT HIPBOW

Main param eter/Basicsetting ofthe pullerspeed forthe hip bow .

21 LOW SPEED UP TO HIPBOW

The seam section sew n w iththe pullerspeed ofthe m ain seam until

the speed is reduced atthe hip bow .(R eference point= photocell15)

22DURATIO N OF LOW SPEED AT HIPBOW

The seam section sew n atlow speed inthe hip bow .

35UP TO FLY BLO W ING

The lengthofthe seam section afterunblocked photocell13,untilthe

flyisblow n.

36DURATION OF FLY BLOW ING

Duration ofthe blow ing operation.

11 UNTIL BLADE SW IVELS O UT

Transportlengthfro m the photocell13or15untilthe blade sw ivels out.

44 S W IVELLING TH E PU LLER

Thisfunction is only require d forthe crotch seam .

01 = Function on

00 = Function off

45 PULLER A FTER H IPBOW

The section the puller rem ains low ered afterDURATION OF LOW

SPEED AT HIP B O W (param eter22).

Pullerspeed as setin param eter14.

Flyroller

37UNTIL FLY R O LLER D O W N

R equire d forpreseam 3 fora betterguidance ofthe fly bow .

38

38DURATION OFFLY ROLLER DOWN

The timeforw hich the flyrollerislowered.

Page 42

Selection ofm achin e p a ra m e te rs

The sewing behaviourofthe sew ing unitis determ ined by the settings.

01 SEW ING AT LOW SPEED

R educed sewing speed during the sew ing start(softstart).

02 SEW ING AT HIGH SPEED

Mainsewing speed.

03 SEW ING START AT LOW SPEED

Section ofdecelerated sew ing start(softstart).

05 SEAM SECTION UNTILCONTOURGUIDE DOW N

S eam section sewn fro m the sew ing startuntilthe contourguide is

low ered.

06UNTILTABLE BLOW ING ON

S eam section sewn fro m the sew ing startuntilthe blow ing nozzles of

the w orktable are provided w ith com pressed air.

1

07DURATION OF TABLE BLOW ING

The section overw hichaworkpiece is additionallytransported by

com pressed air.

09REDUCED SPEED

R educed speed ofthe sew ing head sw itched on w iththe function

SEW ING AT LO W SPEED fordifficult seam sectio n s (S 1 - S 5 ).

Reference point= lightbarrierF13 or F15).

39

Page 43

6.4.4.5 S eam -specific param eters inthe access level2

Globalparam eters

Globalparam eters are values contro lling the basicfunctions ofthe

sew ing unit.

Note

Ifglobalparam eters are altered,the alteration w illinfluence allseam

program s stored.

Alte ra tion ofglobalparam eters

The globalparam eters ofthe sew ing unitare optimally setand

coordinated by the m anufacturer.

Byinappropriatealteration ofthe values the w orking quality can be

affected;atw orstm achine com ponents can be dam aged.

–

Press key “F1”.

You gettothe userlevel2.

–

Press key “F1”.

The param eterlistis opened.

–

Scrolltothe desired param eterw iththe keys “ñ “or“ò”.

–

Press key “EN T”.

–

Alterthe value w iththe keys “ï “or“ð “.

or

–

Enter the tw o-orthree-digitvalue atthe num eric pad.

–

Press key “EN T”.

The altered param etervalue istaken over.

–

Press key “P”.

You quitthe m enu and return tothe access level2.

–

Press key “P”.

You return tothe access level1.

01 FZ B EG INNING OF DOW N TIME

Tim e delay betw een feeding operation (lightbarrierrecognizes

“b locked”)and sew ing start

02FZBLOCKED -> FOOT DOW N

The tim e untilthe sew ing footislow ered and the sew ing operation

starts

(s e tting depends on the m aterial).

03THREAD LIFTING SEAM BEG INNING

N um ber ofstitches w ithreleased needlethread before itistensioned

again.

04DURATION OF KETTUP AT THE BEGINNING

Lengthofthe kettup function atthe seam beginning incm.

Incaseofthree-thread heads a longersuction process is necessary.

Switch offto save energy.

05 SEAM SECTION TO BE RESTITCHED

S eam section w here follow -up stitches are sewn ifthe w orkpiece is

m anually rem oved fro m the sew ing equipm entw hilesewing (e.g.in

order to separatethe chain).

40

Page 44

06DURATION OF KETTUP AT THE SEAM END

Duration ofthe kettup function atthe seam end.

Switch offto save energy.

07THREAD LIFTING AT THE SEAM END

The num berofstitches untilthe needlethread isreleased atthe seam

end.

08FZBLOCKING TIMEATTHE END

Tim e delay for feeding a new w orkpiece (blocking timeafterlight

b a rrierunblocked).

09PHOTOCELL 15ON/OFF

Switching status ofphotocellF15 onlyavailablewith optionalfusing

station.

01 = Function on

00 = Function off

Ifno lightbarrieris m ounted,an errorm essage appears.

10 STACKER -> EJECTOR DOW N

The timethe ejectorislowered and fixes the w orkpiece untilitistaken

overby the stacker.

1

11 CONTOUR SCANNING TIME

R esponse timefor altering the pullerspeed (photocell16)

12THREAD M ONITOR SENSITIVITY

Setting ofthe thread m onitor

00 = Function off

01 = H igh sensitivity

99 = Low sensitivity

(the setting depends on the sew ing thread used)

13 EFKA POSITION UP

N eedle position dow n atthe sew ing start,needle position up w hen

threading.

41

Page 45

14 S TITC H LEN G TH

Synchronisation ofthe low ering position ofthe pullerand the stitch

lengthofthe sew ing unit.

ATTEN TION !

Astitch lengthalteration has an effecton allseam sections.

–

Setthe stitch lengthatthe handw heel2 ofthe m achine head

(e .g.step 6 corresponds toastitch length ofapprox.3.2mm)

–

Markthe desire d low ering position M ofpuller1onthe w orkpiece.

–

Setting ofparam eter14 as tothe low ering position ofthe puller

(range oftolerance 2 cm )

Ifthe puller low ers too early(PosA)=the setvalue istoo high

Ifthe puller low ers too late(Pos.B)=the setvalue istoo low

15 TO P FEED M AX PO S:

Maximum fullness.

Securityvalue.

The value m ustnot be altered.

16 D IFFERENTIAL M AX POS:

Maximum fullness.

Securityvalue.

The value m ustnot be altered.

20 M AX SPEED

Safeguard ofthe m aximum sewing speed

42

29 C-HEAD OFF/ON MODE

Refers tothe fusing station.

00 = Fusing station off

01 = Fusing station on

37CLAMP CLOSED

Timestam p fusing station

Page 46

6.5 Seam sequences

In a program individualseam s can be deactivated orthe seam

sequence can be altered respectively.

A deactivated seam is notdeleted,butcan be called up and activated

again atany time.

Thisfunction becom es onlyeffective inthe currentprogram .

Determ ining the seam sequence

–

Selectprogram .

Exam ple:M 01

–

Press key “F1”.

You gettothe userlevel2.

–

Press key “F2”.

1

1

–

Enter the num berofthe firstseam viathe num eric pad.

–

Place the cursoron the nextposition w iththe key “ð “.

–

Enter the num berofthe second seam .

Adding a seam betw een tw o positions

–

Place the cursoron the seam num ber infrontofw hich a new seam

isto be added w iththe keys “ï“or“ð “.

Forexam ple on seam num ber4

–

Press key “EN T”.

Afree position1is added betw een the seam num bers already

available.

1

–

Enter the num berofthe new seam .

–

Press key “P”.

The seam sequence istaken over.

43

Page 47

Deleting a seam from a seam sequence

–

Selectprogram .

Exam ple:M 01

–

Press key “F1”.

You gettothe userlevel2.

–

Press key “F2”.

1

–

Place the cursoron the seam num bertobedeleted fro m the seam

sequence w iththe keys “ï“or“ð “.

–

Press key “0”.

The seam is deleted.

–

Press key “P”.

The seam sequence istaken over.

44

Page 48

6.6 Preseam s

Withthe sew ing unit1265/5also the preseam s (w aistband seam 1,

crotch seam 2 and hem seam 3)can be sew n.

Calling up the param eterlistfor preseam s

–

Press key “F1”.

You gettothe userlevel2.

–

Press key “F3”.

1. PRESEAM SPEED

Sewing speed

PRESEAM TOP FEED

Basicsetting offullness

PRESEAM DIFFERENTIAL

Basicsetting offullness

PRESEAM W ITH RO LLER

Lengthin cm untilthe auxiliary rollerlow ers,m ax.99 cm

2. PRESEAM SPEED

Sewing speed

PRESEAM TOP FEED

Basicsetting offullness

PRESEAM DIFFERENTIAL

Basicsetting offullness

PRESEAM W ITH RO LLER

Lengthin cm untilthe auxiliary rollerlow ers,m ax.99 cm

3. PRESEAM SPEED

Sewing speed

PRESEAM TOP FEED

Basicsetting offullness

PRESEAM DIFFERENTIAL

Basicsetting offullness

LINKED W ITH SEAM NUM BER

The third preseam can be linked w ithamain seam

in orderto access the seam param eters ofsam e.

1

Note

The linked m ain seam m ustnotbe used anyw here else inthe program .

45

Page 49

6.7 Seam starting m ode

Tw o starting m odes ofthe sew ing sequence are available:

Startby photocell(autom atic sequence)

Startby footpedal

Alte ring the starting m ode

–

Press key “F1”.

You gettothe userlevel2.

–

Press key “F4”.

Pedalstartforseam off

Pedalstartforseam on

6.8Activating the sew ing m otor

Fortesting the m achine head the sew ing m otorcanbeactivated.

–

Press key “F1”.

You gettothe userlevel2.

–

Press key “F5”and keep itpressed.

The sewing m otorruns as long as the key “F5”is pressed.

6.9 R esetting the dailypiece counter

–

Press key “F1”.

You gettothe userlevel2.

–

Press key “F7”.

The dailypiece counteris resetto“0".

46

Page 50

6.10 Input-O utputtest

Viathe input-output-testititpossibletoselectthe inputs and outputsof

the sew ing unitcontro l fortrouble shooting and forchecking individual

machine steps.

The outputs(Out)are called up and tested separately. T h e

corresponding inputs(Inp)are indicated w iththe active output.

Activated inputs /outputs are m arked by highlighted identification

num bers.

Inputtest

The inputsaretested dire c tly.

Exam ple:Photocell13

–

Pushapiece ofpaper1 betw een photocell13 and supportsheet.

InputN o.13 isblack-shadow ed.

O utputtest

–

Press key “F1”.

You gettothe userlevel2.

–

Press key “F8”.

–

Selectthe colum n ofnum bers w iththe keys “ñ “or“ò”.

–

Selectthe identification num berw iththe keys “ï“or“ð “.

–

Press key “EN T”.

The identification num berisblack-shadowed and the outputis

activated.

–

Press key “EN T” once again.

The outputis deactivated.

Inputelem ents

Signal InputNo.

1

1

S02 02 GND bridge on photocell15,ifw ithout

hem recognition “FZ 15”

S04 04 Push-button lining clam p

S05 05 Push-button fusing start

S09 09 Thread m onitor

S13 13 Photocellprogram start

S15 15 Photocellhem recognition

S16 16 Photocellcontourcontro l

47

Page 51

O utputelem ents

Valve O utputN o.

Y01 01 Sewing foot lifting

Y02 02 C ontourguide blow ing on

Y03 03 C ontourguide up/dow n

Y04 04 Flyblow ing on

Y05 05 Puller dow n/up

Y06 06 Ejector dow n/up

Y07 07 Swivelling the puller on

Y08 08 Feeding unit up/dow n

Y09 09 Swivelling the blade on

Y10 10 Tension lifting on

Y11 11 Auxiliary roller dow n/up

Y12 12 Sewing foot:high pressure on

Y13 13 Flyroller(optional) dow n/up

Y14 14 Fusing stam p dow n/up

Y15 15 Lining clam p dow n/up

Y16 16 M ovable guide backw ards/forw ards

Y26 26 M ove stacker (optional)on

Y27 27 Stacker start im pulse

Y30 30 Tableblow ing on

Y31 31 Kettup suction on

Y32 32 Dirt s u c tion on

48

Page 52

6.11 Program m ing m enus

6.11.1 G eneralnotes

The program m ing m enus allow the generation ofprogram s and the

corresponding seam s.

Inprincipalitis possibleto generate a com plete new program .A n

easierw ay is:

l to copy a program provided by the m anufacturertoafre e s torage

location inthe m em ory and to adaptittothe conditions ofyour

production.

l to copy an already m odified program toafre e s torage location inthe

memoryandtofurtheradaptit.

In orderto generate a new program the follow ing steps are required:

1) Allocateafre e s torage location

2) Add seam s orcopy existing seam s

to a program

3) C onfigurate seam s (adaptthem tothe production)

Scrolling dow n the program m ing levels

W hen the program m ing m enus are called up,the m enu dealtw ithlast

isalwaysindicated.

The num berpreceding the functions show s w hich program m ing level

has been called up.

In ordertocallupacertainfunction you have to scrolldow n the

program m ing m enus and service m enus.

Calling up a program m ing m enu

–

Scrolling dow n a program m ing m enu

–

Press key “ï“.

6.11.2Allocating a fre e s torage location

The storage locations M 01 - M 10 have been provided w ith program s by

the m anufacturer.The storage locations M 11 -M 20 are free.

–

Press key “M ”.

–

Enter the two-digitnum berviathe num eric pad.

1

Press key “P”.

6.11.3F1=INIT P aram eter

Functions inthe m enu InitParam eter:

l F1 = EPROM globalparam eter

l

F2= EPROM seam param eter

l

F3 = copy seam num ber

l

F4 = delete seam

49

Page 53

F3 = C opying the seam num ber(program num ber)

ATTENTION!

The currentprogram is o v e rw ritten.

–

Press key “P”.

The program m ing leveliscalled up.

–

Press key “F1”.

The function INIT PARAM ETER iscalled up.

–

Press key “F3”.

The function COPYING O F SEAM NUM BER iscalled up.

–

Enter the num berofthe program tobecopied viathe num eric pad.

–

Press key “EN T”.

C onfirm the copying.

The display indicates*OK PLEASE W AIT!*. T h isisahintthatthe

copying is bein g c a rried out.

Finallythe display ofthe program show s the program num berw ith

the seam s.

F4 = D eleting a seam program

A program consists ofseveralseam s.

The contentsofthese seam s,the seam param eters,can be deleted

com pletely.

The currentprogram cannotbe deleted.

–

Press key “P”.

The program m ing leveliscalled up.

–

Press key “F1”.

The function INIT PARAM ETER iscalled up.

–

Press key “F4”.

The function DELETE SEAM iscalled up.

–

Enter the num berofthe seam tobedeleted w ith one ofthe keys

“1 ” to“9”.

–

Press key “P”.

Startthe deleting procedure.

The display indicates a checkback

“ARE YOU SURE ?*

–

Press key “EN T”.

The new setting isstored and you return tothe selection m enu.

The display indicates*OK PLEASE W AIT!*. T h isisahintthatthe

deleting procedure is bein g c a rried out.

50

Page 54

6.11.4 F2 = M em ory card

F1 = C urrentseam -> C ard

l

F2 = C ard -> C urrentseam

l

F3 = M achin e m e m o ry -> C a rd

l

F4 = C ard -> M achinememory

l

F5 = M em ory card form at

l

F1 = C urrentseam -> C ard (storing the dataonthememorycard)

The m em ory function optionallyallow s the securing ofonly one

selected program orthe securing ofallprogram s.

–

Push th e m e m o ry c a rd intothe slotofthe operating term inal.

–

Press key “P”

.The program m ing m enus are called up.

–

Press key “F2”

.The functionMEMORY CARD iscalled up.

Securing a selected program

–

Press key “F1”.

The function C urrentseam -> C ard iscalled up.

oder

Securing allprogram s

–

Press key “F3”.

The function M ACHINE MEMORY ->Cardiscalled up.

–

Press key “EN T”.

The checkback is confirm ed.

1

The display indicates*OK PLEASE W AIT!*. T h isisahintthatthe

datatransferis bein g c a rried out.

51

Page 55

F2 = C ard -> C urrentseam (data transferfrom the m em ory card to the control)

Data secured on the m em ory card can optionallybetransfe rre d tothe

contro l a s individualprogram oras com plete data poolofallprogram s.

Note

Ifthe com plete data poolofallprogram s istransfe rre d tothe contro l,

alldata are overw ritten,even seam s w hich had been altered inthe

m eantime.

Therefore alterations ofseam s shouldalwaysbe im m ediatelystored

as individualdataprotection on thememorycard.

–

Push th e m e m o ry c a rd intothe slotofthe operating term inal.

–

Press key “P”.

The program m ing m enus are called up.

–

Press key “F2”.

The functionMEMORYCARD iscalled up.

Transfer the selected program to the control

–

Press key “F2”.

Transferthe selected program indicated on the display.

The function CARD -> CURRENT SEAM iscalled up.

or

Transfer allprogram s to the control

–

Press key “F4”.

Transferthe com plete data poolofallprogram s.

The function CARD -> M ACHINE MEMORY iscalled up.

–

Press key “EN T”.

The checkback is confirm ed.

F5 = M em ory C ard Form at

The display indicates*OK PLEASE W AIT!*Thisisahintthatthe

datatransferis bein g c a rried out.

Ifadditionalm em ory cards (optionallyavailable) are used fordata

back-up,the storage m edium has tobeform atted before being used

forthe firs t time.

–

Push th e m e m o ry c a rd intothe slotofthe operating term inal.

–

Press key “P”.

The program m ing m enus are called up.

–

Press key “F2”.

The functionMEMORYCARD iscalled up.

–

Press key “F5”.

The function M EMORY CARD FORMAT iscalled up.

The display indicates the checkback *A R E Y O U S U R E ?*

–

Press key “EN T”.

The checkback is confirm ed.

The display indicates*OK PLEASE W AIT!*. T h isisahintthatthe

form atting is bein g c a rried out.

52

Page 56

6.11.5F3=Diagnostics

The m enu D IAG NO STICS includes service functions fortesting sew ing

units,aggregates as w ellas the initiators foractivating the aggregates.

F1 = Service test

F1 = M em ory test

F1= EEPROM 2K

F2= EEPROM 8K

F3 = R AM 8K

F4 = I/O M odulelong-term test

F5 = I/O Analog output

F6 = Furthertests

F1 = R S 232 Test

F2 = I/O Adaptertest

F3 = C om m unication test

F4 = Sewing head test

F1 = Activating the sew ing m otor

F2 = Sewing m otorand puller

F3 = Ejector

F4 = Top feed

F5 = D ifferential

F6 = R eference value transm itter

1

–

–

–

Note

These service functions should only b e c a rried outunder the guidance

ofthe Beislerservice departm entorin cooperation w ith experienced

service personnel.

A tte n tion:R isk ofbreakage!

During the testsindividualm achine aggregates orm achine sequences

are started.Ifcom ponents have been disassem bled com pletelyor

partiallyorifthey are notoperational,m achine com ponents m ay be

dam aged.

Makeatestonly w hen the m achine is ready foroperation.

F1 = Service test/F1 = M em ory test

ATTEN TION !

Alldatainthememories are deleted.

Press key “P”.

The program m ing leveliscalled up.

Press key “F3”.

The function D IAG NOSTICS iscalled up.

Callup the testfunctions.

F1= EEPROM 2K

F2= EEPROM 8K

F3 = R AM 8K

53

Page 57

F1 = Service test/F4 = I/O MODULE LONG-TERM TEST

A tte n tion:R isk ofinjury!

Alloutputs are autom aticallyswitched one afterthe other.

F4 = Sew ing head test/F1 = A C TIVATING THE SEW ING M OTOR

The currentspeed iscomparedwiththe idealspeed ofthe sew ing

motor.

–

Enter the speed atthe num eric pad.

–

Press key “EN T”.

The m otorstarts,the currentspeed is m easured and indicated.

–

The m easured speed can be com pared w iththe testspeed.

–

Press key “P”.

The testisfinished.

F4 = Sew ing head test/F2 = S E W ING M OTOR AND PULLER

Testofthe step m otors.

F4 = Sew ing head test/F3 = E JE C TO R

Test ofthe ejecting section.

F4 = Sew ing head test/F4 = Top feed

Test ofthe top feed function

F4 = Sew ing head test/F5 = D iffe re n tial

Test ofthe differentialfeed function

F4 = Sew ing head test/F6 = R eference value transm itte r

Test ofthe reference value transm itter

6.11.6 F5 = A dditionalprogram s

54

F2 = System update

A system update can be carried out.

–

Press key “P”.

The program m ing m enus are called up.

–

Press key “F5”.

The function ADDITIO NAL PRO G RAM S iscalled up.

–

Press key “F2”.

The function “system update”iscalled up.

–

Selectthe requested function.

F1 = Eprom -> C ard

F2 = C ard -> E prom

F3=Text->Card

F4=Card->Texts

F 5 = R S 2 3 2 -> C a rd

Page 58

F4 = Piece counter

F3 = Language selection

The language ofthe m enu navigation and ofthe hintsindicated inthe

displaycanbealtered.

–

Press key “P”.

The program m ing m enus are called up.

–

Press key “F5”.

The function ADDITIO NAL PRO G RAM S iscalled up.

–

Press key “F3”.

The function LANGUAGE SELECTION iscalled up.

–

Selectthe requested language.

The totalquantityofworkpieces sewn w iththe sewing unitis registered

by m eans ofa counting function.This counting function cannotbe

re s e t to zero.

–

Press key “P”.

The program m ing m enus are called up.

–

Press key “F5”.

The function ADDITIO NAL PRO G RAM S iscalled up.

–

Press key “F4”.

The function P IECE CO UNTER iscalled up.

–

R ead the m eter.

1

55

Page 59

7. M aintenance

7.1Cleaning and checking

Caution:R isk ofinjury !

Switch the m ainswitch off.

The m aintenance ofthe sew ing unitm ustonly b e c a rried outw iththe

machine sw itched off.

Maintenance w ork has to be done afterthe intervalsindicated inthe

tables atthe latest(see colum n “O perating hours”).

The processing offluffymaterialm ay require shorterm aintenance

intervals.

Aclean sew ing unitprotectsfro m d isturbances.

1

Maintenance w ork E xplanation O perating

to be done hours

M achine head

-R em ove sew ing dustand thread

re m a inders.

(e .g.w ith com pressed airpistol)

Suction device

Clean the entire area 1 ofthe thread guides

underthe fabricsliding sheet

Em pty container2 ofthe suction device

-Turnthe bottom partofthe containerto

the left

and rem ove it

-Emptythe container

-Screwthe bottom parton againin

clockw ise dire c tion

2

8

8

56

Page 60

6543

Maintenance w ork E xplanation O perating

to be done hours

Pneum aticsystem

- Check the w ater levelinthe

pressure regulator3

The w aterlevelm ustnotrise up tothe filter

insert4.

- Letthe w aterrun outofthe w aterseparator

underpressure afterpressing the drain

plug 5.

40

1

-Clean the filterinsert4

R

-Makeleak testofthe system

The filterinsert4 separates dirtand condensed

water.

- S eparatethe sew ing unitfro m the

com pressed air net.

-Pushindrainplug 5.

The pneum atic system ofthe

sew ing unithas tobepressureless.

-Screwthe w aterseparator6 off

- R em ove filterinsert4.

Washthe dirtyfiltertray and the filterinsert

with benzine (no solvent!)

and blow them clean.

- R eassem blethe w ater separator

and connectthe m aintenance unit.

500

500

57

Page 61

7.2Oillubrication

1

Caution:R isk ofinjury !

Oilm ay cause skin eruption.

Avoidalongercontactw iththe skin.

W ash yourselfthoroughlyaftera contact.

ATTEN TION !

The handling and disposalofm ineraloilsis subjecttolegal

regulations.

Deliverused oiltoanauthorized collecting station.

Protectyourenvironm ent.

Be carefulnottospillany oil.

Oilthe head ofthe sew ing unitexclusivelywithlubricating oilDA-10 or

an equivalentoilw iththe follow ing specification:

–

Viscosity at40° C : 10 m m ²/s

–

Ignition point: 150° C

D A -10 can be boughtatthe sales pointsofDÜRKOPP ADLER AG

underthe follow ing parts num bers:

C ontainer250 m l: 9047 000011

C ontainer1 litre: 9047 000012

C ontainer2 litres: 9047 000013

C ontainer5 litres: 9047 000014

Maintenance w ork E xplanation O perating

to be done hours

Lubrication

C heck the oillevelatthe sew ing m achine

head regularly(inspection glass 1).

8

58

Please take furtherdetailsfro m the enclosed

operating instru c tions ofthe sew ing m achine

head.

Page 62

In dex Page:

Part 2: As sem bly in stru c tions cl. 1265/5

1. Sco pe of de li very............................................... 3

2. G e ne ra l no tes ................................................. 3

3. In stal ling th e se wing unit.......................................... 4

3.1 Trans port pro tec tions ............................................. 4

3.2Set ting the wor king height.......................................... 5

3.3 M oun ting the thre ad reel hol der....................................... 6

3.4Alig ning the con tro l pa nel........................................... 6

3.5 M oun ting and alig ning the sta cker ..................................... 7

3.5.1 M oun ting the throw -over sta cker .................................... 7

3.5.2 M oun ting the al ter na ting sta cker .................................... 8

3.6 M oun ting the tray ............................................... 10

4. Elec tri cal con nec ti on ............................................ 11

4.1 C he cking the no mi nal vol ta ge ........................................ 11

4.2Ma king the mains con nec ti on ........................................ 11

5. Pneu ma tic con nec ti on ........................................... 12

6. Put ting into ope ra ti on............................................ 13

6.1Se wing test................................................... 13

2

1

Page 63

11

2

1

3

4

10

5

9

8

7

6

Page 64

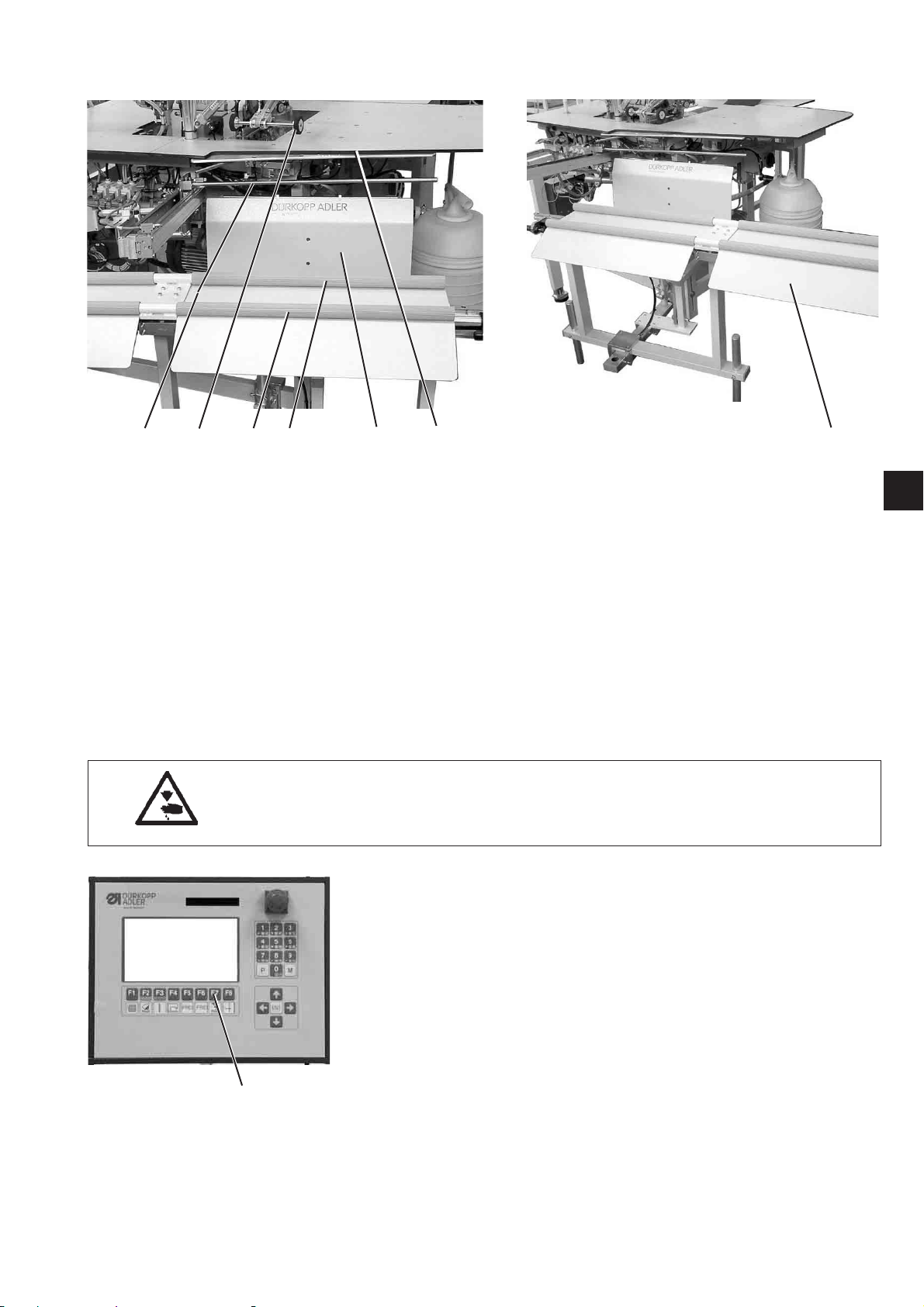

1. S co pe of de li very

The scope of delivery is dependent on your order.

The sew ing unit consists of:

–

1Sewing machine head (a s per order)

–

2 Thread reel holder

–

3 C ontro l with contro l panel

–

4Material tra y

–

5clam p for knee lining (optional)

–

6Fusing station for knee lining (optional)

–

7 Foot sw itch

–

8Stand and table top

–

9Suction device with suction container

–

10 Stacker (a s per order)

–

11 E jector

–

C om pressed air maintenance unit with com pressed air

pistol

2. G e ne ra l

2

ATTEN TION !

The sew ing unit must only be installed by tra ined specialist staff.

Any work on the electrical equipm ent of the sew ing unit must

only be c a rried out by electricians or correspondingly instru c ted

persons.

The mains plug must be pulled out.

The enclosed operating instru c tions of the drive motor m anufacturer

have to be observed.

3

Page 65

3. In stal ling the se wing unit

3.1Trans port pro tec tions

1

Before installing the sew ing unit all transport protections have to be

rem oved.

Transport protections at th e sew ing unit

–

Remove the protective foils 1.

–

Remove the security tapes fro m the thread reel holder, the

machine table etc.

–

Remove the machine head fastenings 2 (2 x)

Transport protections at th e th ro w -o v e r stacker

4

3

2

–

Remove the security tape 4 fro m the stacker.

–

Remove the security tape 3 and put the foot pedal dow n.

4

Page 66