Page 1

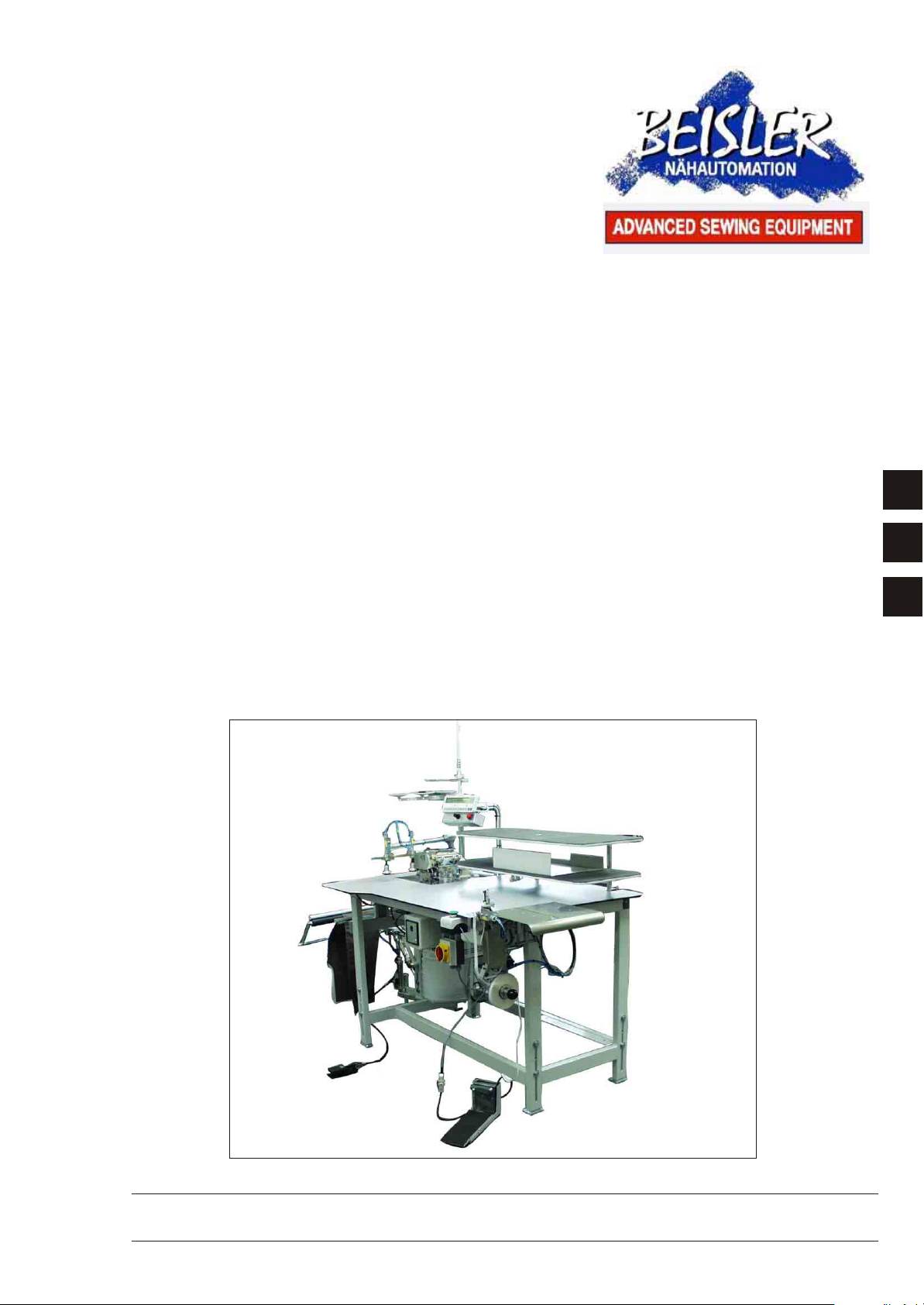

1225/5

Single-head se wing unit for serging and

overlocking for trou sers with knee li ning

Operating Instructions

Installation Instructions

Servic Instructions

1

2

3

Telefon Ser vice +49 (0) 60 21/ 50 19 40 Telefax +49 (0) 60 21/ 54 00 61 E-mail: Vertrieb@beisler-gmbh.de

Aus ga be /Edi ti on:06/2005Prin ted inFe de ral Re pub lic ofGer ma nyTei le-Nr.:/Part-No.:DOC000052

Frohn rad stra ße 10, D-63768 Hös bach

Page 2

Page 3

Foreword

This instruction manual is intended to help the user to become familiar

with the machine and take advantage of its application possibilities in

accordance with the recommendations.

The instruc ti o n m an ual contains im po r ta nt i nf ormation on how to

operate the machine securely, properly and economically. Observation

of the instructions eliminates danger, reduces costs for repair and

down-times, and increases the reliability and life of the machine.

The instruction manual is intended to complement existing national

accident prevention and environment protection regulations.

The instruc ti o n m an ual must always be av a il ab l e a t the

machine/sewing unit.

The instruction manual must be read and applied by any person that is

authorized to work on the machine/sewing unit. This means:

– Operation, i ncl u di n g e qu i pp i ng , troubleshooti ng du r ing the work

cycle, removing of fabric waste,

– Service (maintenance, inspection, repair and/or

– Transport.

The user also has to assure that only authorized personnel work on

the machine.

The user is o bl i g ed to c he c k th e machine at leas t o nc e pe r shi f t for

apparent da ma ge s and to immediatl y r e po r t a ny ch an ges (including

the performance i n se rv ic e), wh i c h im pa i r th e s a fe ty.

The user comp an y mu s t e ns u r e t ha t t he ma c hi n e i s only operated i n

perfect working order.

Never remove or disable any safety devices.

If safety dev i c e s ne ed to be removed for equipp i ng , r e pa i ri ng or

maintaining, the safety devices must be

remounted directly after completion of the maintenance and repair

work.

Unauthorized modification of the machine rules out liability of the

manufacture r fo r da ma ge res u l ti n g f r om th i s .

Observe all safety and danger recommendations on the machine/unit!

The yellow -and-black stri pe d s u rfa c es d es ignate permanend da ng er

areas, eg danger of squashing, cutting, shearing or collision.

Besides the recommendations in this instruction manual also observe

the general safety and accident prevention regulations!

Page 4

General safety instructions

The non-observance of the following safety instructions can cause

bodily injuries or damages to the machine.

1. The machine must only be commissioned in full knowledge of the

2. Before putting into service also read the safety rules and

3. The machine must be used only for the purpose intended. Use of

4. When gauge parts are exchanged (e.g. needle, presser foot,

instruction book and operated by persons with appropriate

training.

instructions of the motor supplier.

the machine without the safety devices is not permitted. Observe

all the relevant safety regulations.

needle plate, feed dog and bobbin) when threading, when the

workplace is left, and during service work, the machine must be

disconnected from the mains by switching off the master switch or

disconnecting the mains plug.

5. Daily servicing work must be carried out only by appropriately

trained persons.

6. Repairs, conversion and special maintenance work must only be

carried out by technicians or persons with appropriate training.

7. For service or repair work on pneumatic systems, disconnect the

machine from the compressed air supply system (max. 7-10 bar).

Before disconnecting, reduce the pressure of the maintenance

unit.

Exceptions to this are only adjustments and functions checks

made by appropriately trained technicians.

8. Work on the electrical equipment must be carried out only by

electricians or appropriately trained persons.

9. Work on parts and systems under electric current is not permitted,

except as specified in regulations DIN VDE 0105.

10. Conversion or changes to the machine must be authorized by us

and made only in adherence to all safety regulations.

11. For repairs, only replacement parts approved by us must be used.

12. Commissioning of the sewing head is prohibited until such time

as the entire sewing unit is found to comply with EC directives.

It is absolutely necessary to respect

the safety instructions marked by these signs.

Danger of bodily injuries !

Please note also the general safety instructions.

Page 5

Index Page:

Preface and general safety instructions

Teil 1: Operating instructions cl. 1225/5

1. Description of product

1.1 Description of proper use ......................................... 3

1.2 Brief description ............................................... 3

1.3 Technical data ................................................ 4

2. Optional equipment ............................................ 5

3. Switching on - Switching off - Program stop

3.1 Switching on ................................................. 5

3.2 Switching off ................................................. 5

3.3 Program stop ................................................ 6

3.4 Restart after program stop ........................................ 6

1

4. Operation of the sewing machine head

4.1 General notes ................................................ 7

4.2 Recommended threads .......................................... 8

4.3 Removing / Putting on the fabric sliding sheet............................. 9

4.4 Setting the differential feed ........................................ 10

5. Operation of the sewing unit

5.1 Fusing station ................................................ 11

5.1.1 Inserting adhesive tape .......................................... 11

5.1.2 Switching the fusing station on and off ................................. 11

5.1.3 Fusing of knee lining and front trousers................................. 12

5.1.4 Cleaning the stamp ............................................. 13

5.2 Foot switch machine sequence ...................................... 14

5.3 Feeding the trousers parts and starting the sewing process .................... 14

5.4 Adjusting the edge guide ......................................... 16

5.5 Adjusting the blowing air for the nozzles in the table top ...................... 17

5.6 Stacker .................................................... 18

6. Operation of the control

6.1 Operator terminal .............................................. 19

6.2 User interface ................................................ 20

6.2.1 Menu structure of the sewing and setting programs ......................... 20

6.3 Seam programs ............................................... 22

6.4 Adjusting the control ............................................ 24

6.4.1 Altering seam-specific parameters.................................... 24

6.4.2 Altering global parameters ........................................ 27

6.4.3 Input - Output test.............................................. 28

Page 6

Index Page:

6.4.4 Creation of seam programs ........................................ 29

6.4.5 Altering seam programs ( Changing / Completing the sequence) ................. 30

6.4.6 Deleting a seam program ......................................... 30

7. Error messages .............................................. 31

8. USB stick

8.1 General notes ................................................ 32

8.2 Formatting the USB stick ......................................... 32

8.3 Plugging the USB stick in the control .................................. 32

8.4 USB functions ................................................ 33

8.4.1 Storing data on the USB stick....................................... 35

8.4.2 Loading data from the USB stick ..................................... 35

8.4.3 Data comparison .............................................. 36

8.4.4 Deleting data from the USB stick..................................... 36

8.4.5 Loading software version from the USB stick ............................. 37

8.5 Removing the USB stick .......................................... 38

9. Maintenance

9.1 Cleaning and checking ........................................... 39

9.2 Oil lubrication ................................................ 41

Page 7

1. Description of product

1.1 Description of proper use

The 1225/5 is a sewing unit which can properly be used for sewing

light to medium-weight material. Such material is, as a rule, made of

textile fibres. These materials are used in the garment industry.

In general only dry material should be sewn on this machine. The

material must not contain any hard objects.

The seam is generally made with core thread, polyester fibre

or cotton threads.

The dimensions for needle and hook threads can be taken from the

table in chapter 4.2.

Before using any other threads it is necessary to estimate the

consequential dangers and to take the respective safety measures, if

required.

This sewing unit must only be installed and operated in dry and

well-kept rooms. If the sewing unit is used in other rooms, which are

not dry and well-kept, further measures to be agreed upon may

become necessary (see EN 60204-31 : 1999).

We, as a manufacturer of industrial sewing machines, assume that at

least semi-skilled operating personnel will be working on our products

so that all usual operations and, where applicable, their risks are

presumed to be known.

1

1.2 Brief description

The Beisler 1225/5 is a single-head sewing unit for serging of trousers

parts with and without knee lining. The overlocking of the seat and fly

bow as well as of the trousers hem can be integrated.

For a displacement-free processing the lining is fused with the upper

fabric at a hot fusing station.

All sewing unit components are mounted on a stand welded of square

steel tubes and controlled by a microprocessor system.

The sewing unit is operated via a control panel. Here it is possible to

call up various control programs, to define new programs and to check

all inlets and outlets for maintenance and repair purposes.

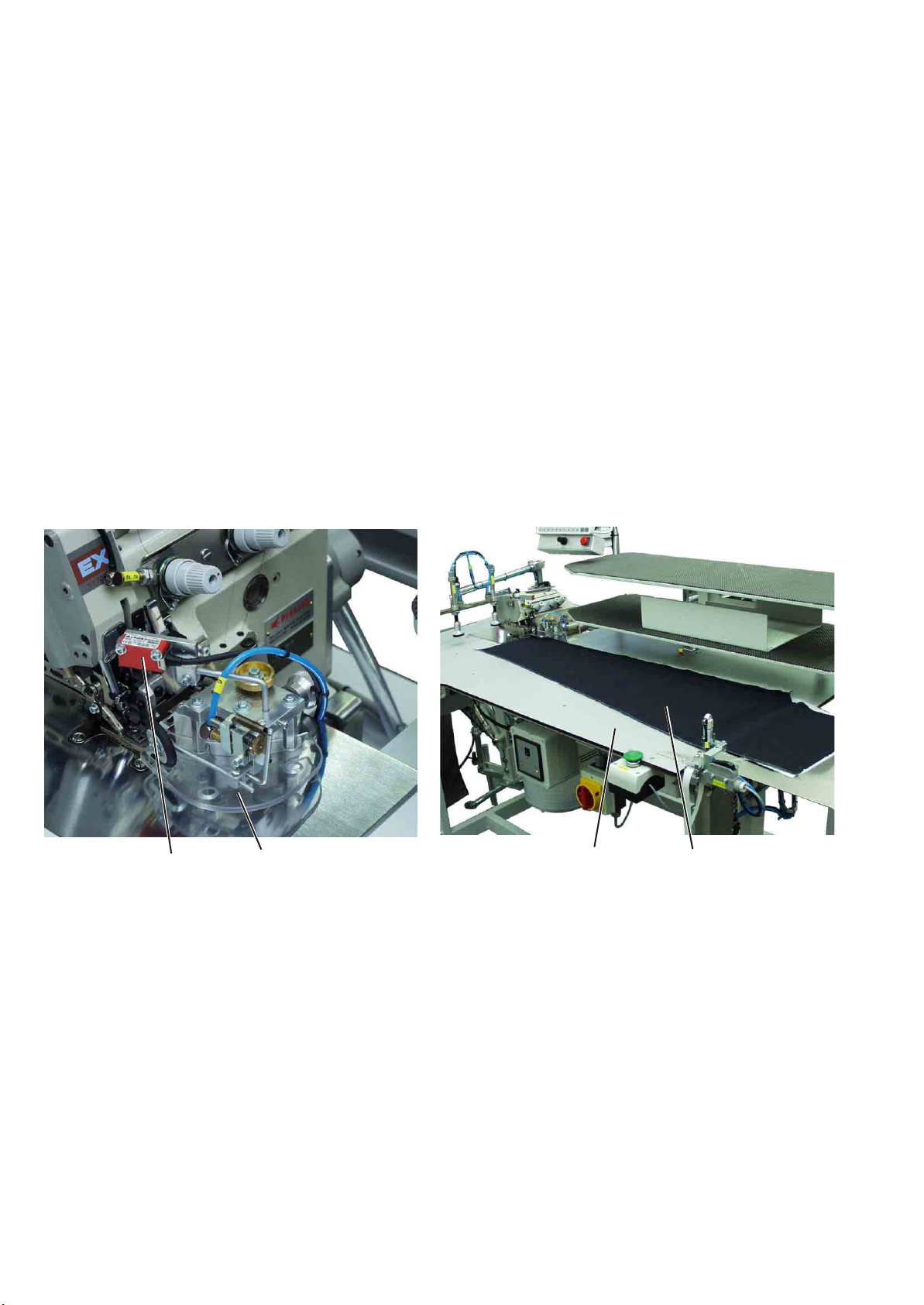

Machine head

–

Pegasus two- or three-thread overlock machine

S52-134B

–

Direct drive Efka Type DC 1500 /AB 221

–

Microprocessor control, freely programmable

–

Light barrier for recognizing the seam beginning and seam end for

the automatic sewing start and stop

–

Height-adjustable edge guide for different material thicknesses

–

External control panel Efka V850 with:

- Menu navigation

- Freely programmable parameters for “machine

parameters”, “Global parameters”, “Program sequences”

- Input and output tests

- 20 program storage locations

- up to 7 seam programs per program storage location

3

Page 8

1.3 Technical data:

–

Vertical cutter with suction for overlocking and serging in one

operation

–

Chain separator with suction, programmable

–

Adjustable blowing nozzles in the table top for supporting the

material feed

–

Height-adjustable stand, infinitely variable from 850 mm to

1200 mm

–

Integrated stacking device

Machine head: Pegasus S52-134B

Stitch type: 504/ 505

Number of needles: 1

Needle system: B27

Needle size: Nm 80 to Nm110

Threads: see table chapter 4.2

Speed: 8500 r/ min

Speed upon

delivery: 7500 r/ min

Stitch length: min. 1.0 mm

max. 5.0 mm

Seam width

Standard S52 head: 6 mm

Optional S52 head: 4 mm/ 5 mm

Material: Light to medium-weight material

Operating pressure: 6 bar

Air consumption: 20 NL per working cycle

Rated voltage: 1 x 230 V 50/60 Hz

Rated load: 0.9 kVA

Dimensions: 1500 x 900 x 1400 mm (L x W x H)

Working height: 850...1200 mm

(upper table top edge)

Weight: 120 kg

Noise level: LC = 81dB (A)

Workstation-specific emission value according to DIN 45635-48-B-1

Stitch length: 3 mm

Seam length: 1160 mm

Speed: 7000 r/min

Material: G1 DIN 23328 1 layer

Measuring point according to

DIN 4895 Part 1 X = 600 mm Y = 350 mm Z = 600 mm

x - axis = at right angles to the feeding direction

y - axis = main feeding direction

z - axis = height

4

Page 9

2. Optional equipment

See annex

3. Switching on - Switching off - Program stop

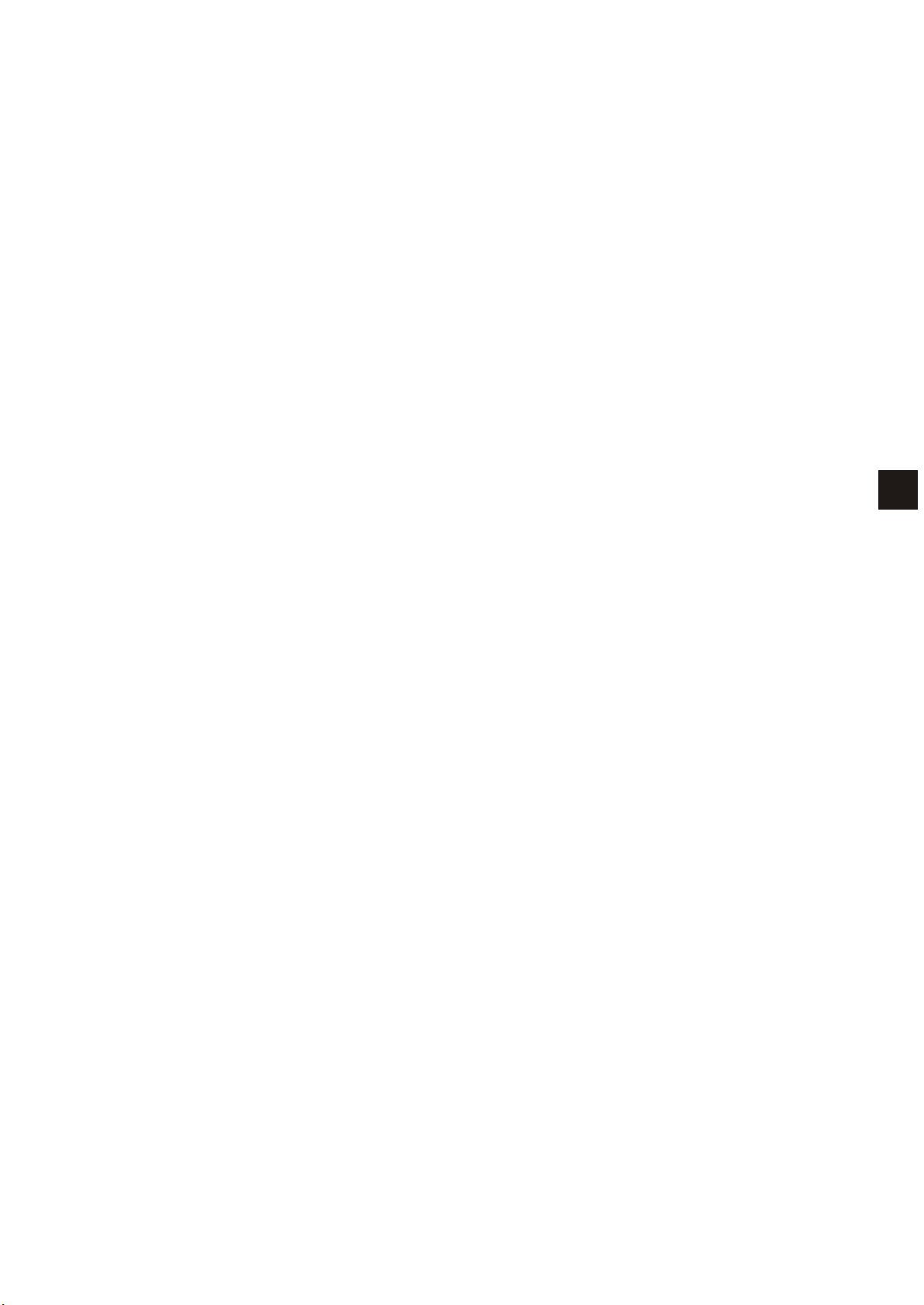

1

3.1 Switching on

3.2 Switching off

1

–

Switch on main switch 1 (turn in clockwise direction).

The control loads the machine program.

The basic display appears in the display of the control panel.

–

Switch off main switch 1 (turn counter-clockwise).

5

Page 10

3.3 Program stop

For an immediate stop in case of operating errors, needle breakage

etc. the safety system of the 1225/5 provides the following measures:

–

–

3.4 Restart after program stop

Caution: Risk of injury!

Switch the main switch off.

Clear the fault only with the sewing unit switched off.

Only restart the sewing unit after the fault has been cleared.

–

–

2

Press program stop switch 2 at the control panel.

The running operations are stopped immediately.

Turn main switch 1 counter-clockwise.

The sewing unit drops out immediately;

all movements of the sewing unit stop immediately.

Switch on main switch 1 (turn in clockwise direction).

Unlock the program stop switch.

The control loads the machine program.

The basic display appears in the display of the control panel.

The sewing unit is ready for operation again.

2 1

6

Page 11

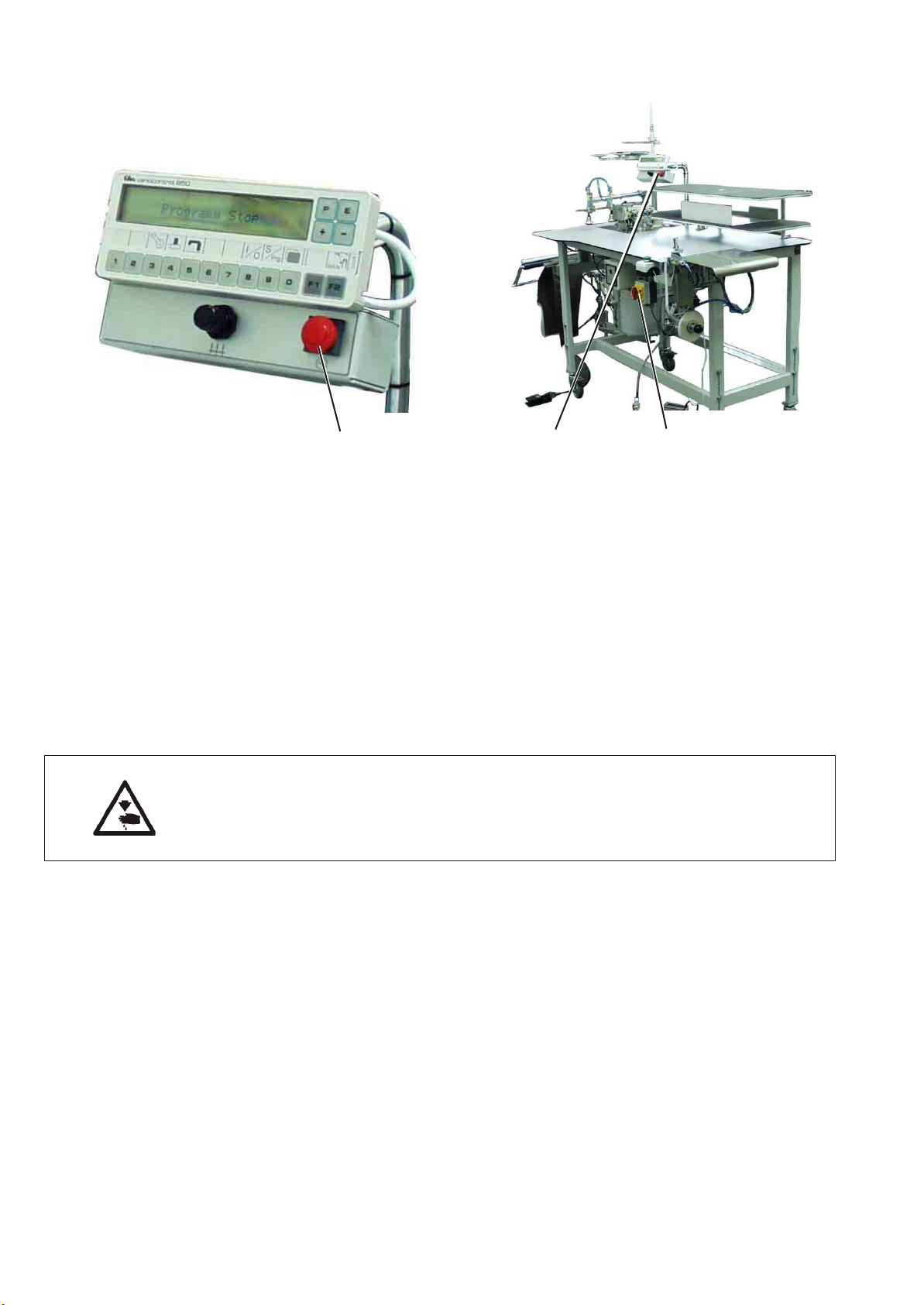

4. Operation of the sewing machine head

4.1 General notes

1

The operation of the sewing machine head (needle insertion, threading

of needle thread and hook thread etc.) is described in the attached

separate Pegasus operating instructions.

The instruction manual is included in the accessories of the sewing

unit.

Attention: Risk of injury!

Please read the operating instructions of the sewing machine head

carefully and observe all notes on safety.

7

Page 12

4.2 Recommended threads

Needle system: B27

Recommended

needle size: Nm 80 for very thin material

Nm 90 for thin material

Nm 100 for medium-weight material

High sewing security and good sewability are achieved with the

following core threads:

–

Two-ply polyester endless polyester core-spun

(e.g. Epic Poly-Poly, Rasant x, Saba C, ...)

–

Two-ply polyester endless cotton core-spun

(e.g. Frikka, Koban, Rasant, ...)

If these threads are not available, the polyester fibre or cotton threads

listed in the table can also be sewn.

Often two-ply core threads are offered by the thread manufacturers

with the same designation as three-ply polyester fibre threads

(3cyl.-spun).This causes uncertainty with regard to twisting and thread

thickness.

When in doubt, unravel the thread and check whether it is twisted 2- or

3-ply.

The label no. 120 on the thread reel of a core thread corresponds e.g.

to the thread size Nm 80/2 (see table values in brackets).

In case of monofilament threads you can use needle threads and hook

threads of the same thickness. The best results are achieved with soft

and elastic threads (software) of the thread thickness 130 Denier.

Recommended thread thicknesses:

Needle size Core thread Core thread

Nm

Needle thread Hook thread Needle thread Hook thread

Polyester Polyester Polyester Cotton

endless core-spun endless core-spun

Label No. Label No. Label No. Label No.

80

90 120 (Nm 80/2) 120 (Nm 80/2) 120 (Nm 80/2) 120 (Nm 80/2)

100 100 (Nm 65/2) 100 (Nm 65/2) 100 (Nm 65/2) 100 (Nm 65/2)

Needle size Polyester fibre thread Cotton thread

Nm (3cyl.-spun)

Needle thread Hook thread Needle thread Hook thread

80 Nm 120/3 Nm 120/3 Ne

60/3-80/3 NeB 60/3-80/3

B

90 Nm 80/3-120/3 Nm 80/3-120/3 NeB 50/3-70/3 NeB 50/3-70/3

100 Nm 70/3-100/3 Nm 70/3-100/3 NeB 40/3-60/3 NeB 40/3-60/3

8

Page 13

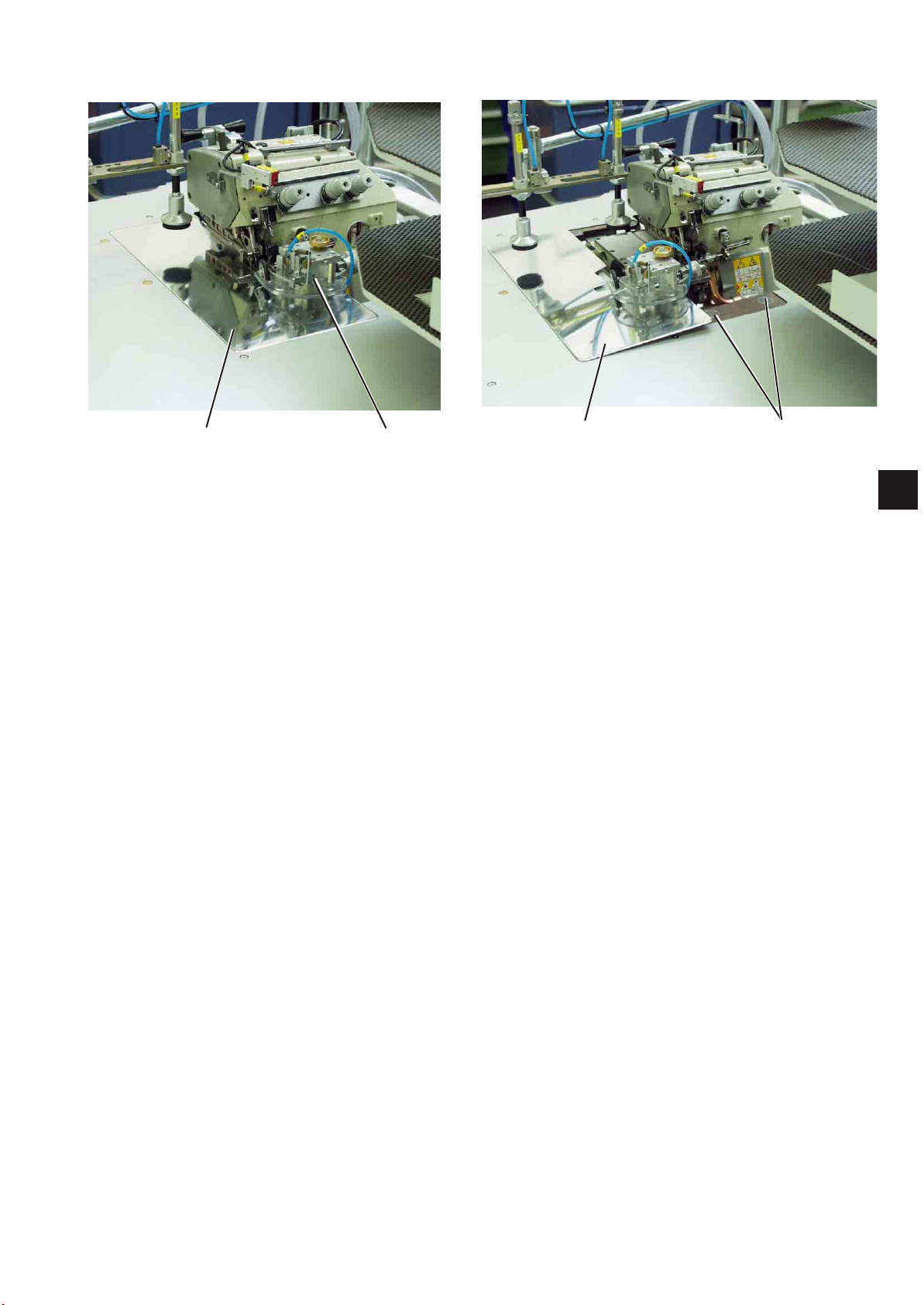

4.3 Removing / Putting on the fabric sliding sheet

2 3

The fabric sliding sheet 2 is held in the gap of the table top by the

magnets 1.

The edge guide 3 is fastened on the fabric sliding sheet.

Removing the fabric sliding sheet

–

Carefully remove the edge guide 3 from the magnets in upward

direction.

–

Swivel the fabric sliding sheet aside.

The lower section of the sewing machine head is accessible now.

Putting on the fabric sliding sheet

–

Push the fabric sliding sheet into the gap of the table top and insert

in downward direction.

2 1

1

9

Page 14

4.4 Setting the differential feed

2 1

By the differentials the behaviour of the feed-dogs can be altered.

Permanent differential

The left lever 2 (seen from behind) influences the permanent

differential, which is active during the whole sewing process.

The setting range is between -10 and + 6.

The higher the setting (positive numbers),the more the material is

gathered. The lower the setting (negative numbers), the more the

material is stretched.

Additional differential

The right lever 1 influences the additional differential, which is

programmable in the control and provides additional width in certain

seam sections only.

The setting range is between 0 and + 16.

The higher the positive number, the more additional lining is gathered

at the programmed positions.

10

Page 15

5. Operation of the sewing unit

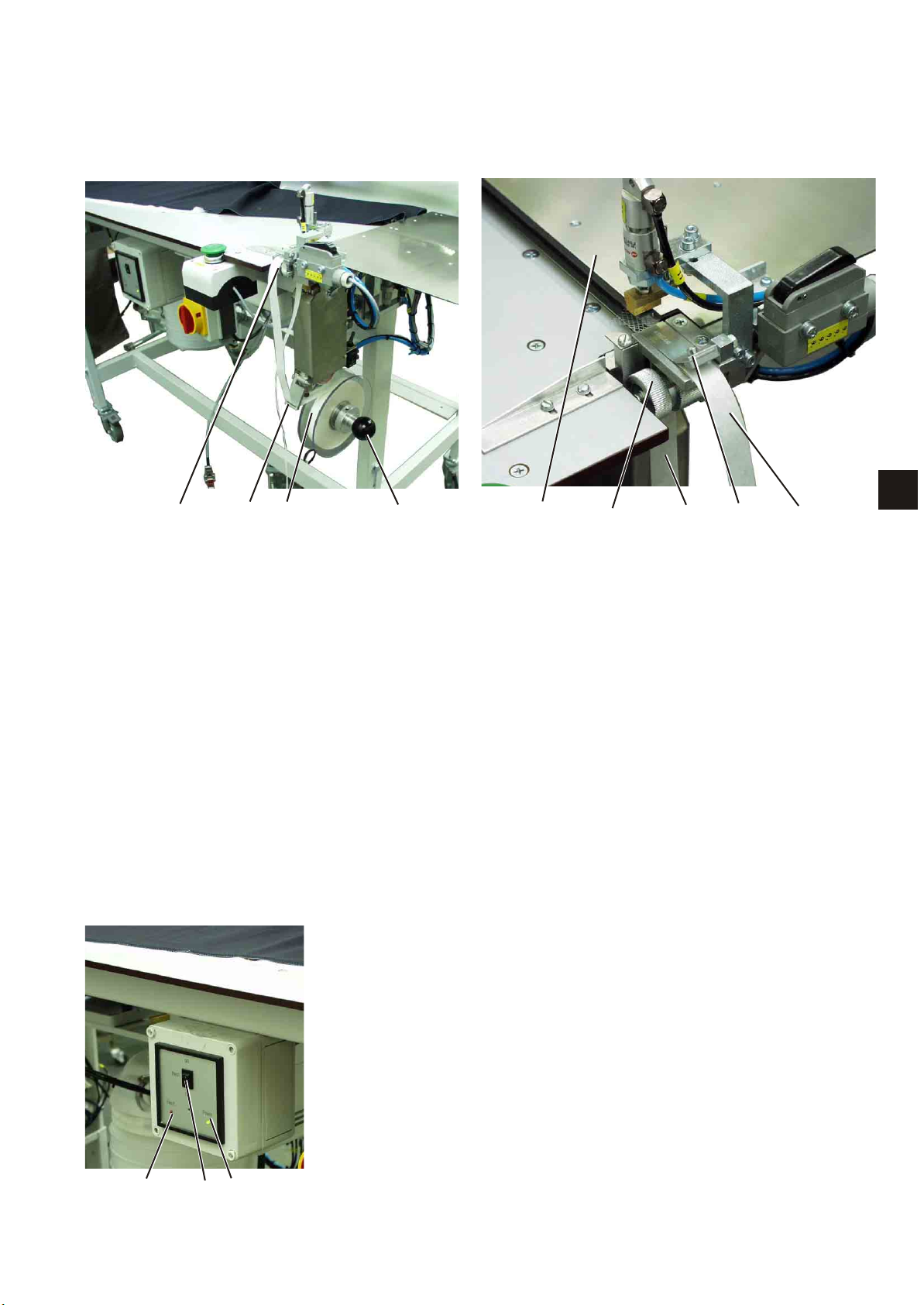

5.1 Fusing station

5.1.1 Inserting adhesive tape

1

4 3 2 1

–

Remove the right supporting disk by pulling the handle 1 strongly.

–

Insert a new roll of adhesive tape 2.

The full roll must rotate counter-clockwise when unwinding.

–

Push the right supporting disk with handle 1 on the shaft again until

it catches.

–

Guide adhesive tape through guide 3.

–

Open flap 4 upwards.

–

Separate adhesive tape 2 from the carrier material 5.

–

Guide adhesive tape 2 under the flap 4 and draw it under the

clamp 7.

–

Guide the carrier material 5 downwards behind the transport

roller 6.

–

Close flap 4.

5.1.2 Switching the fusing station on and off

–

The yellow signal lamp 1 “Power” lights up after the main switch

has been switched on.

–

Press toggle switch 2 in position “ON”.

7 6 5 4 2

3 2 1

Note

As long as the signal lamp 3 “Heat” flashes, the lower stamp is being

heated up and has not yet reached the necessary temperature.

11

Page 16

5.1.3 Fusing of knee lining and front trousers

3 2 1

8 5

7 6 5 4

Caution: Risk of burn!

Do not touch the area around the fusing station.

The lower stamp is very hot.

To avoid a displacement of the knee lining during the sewing process a

bonding point has to be set with the fusing station fusing the lining at

the correct position.

–

Position knee lining 3 under clamp 2.

–

Press clamp key 1.

The clamp 2 lowers and clamps the knee lining.

The fusing tape 5 is pushed forward simultaneously and the

net-like fusing tape 8 is separated from the release paper.

–

Position trousers part 7 and align as per the lining.

–

Press fusing key 4.

The upper stamp 6 moves downwards, the lower heated stamp

moves upwards so that trousers part and lining are pressed with

the fusing tape lying in between.

After the preset fusing time the upper stamp 6 and clamp 2 are

lifted automatically and the lower stamp is lowered.

Lining and trousers part are fused now and can be fed for

overlocking.

12

Page 17

5.1.4 Cleaning the stamp

1

Caution: Risk of burn!

Clean the stamp only when it is cold.

–

Throw toggle switch 1.

The lower stamp 2 moves upwards.

–

Clean the stamp.

–

Actuate toggle switch 1 again.

The lower stamp 2 moves downwards.

2

1

13

Page 18

5.2 Foot switch machine sequence

In some of the seam programs the foot switch serves for releasing

various functions.

The foot switch is equipped with two contacts.

One of them is located at the rear and is released by stepping back.

The other one is located at the front and is released by pressure of the

heel.

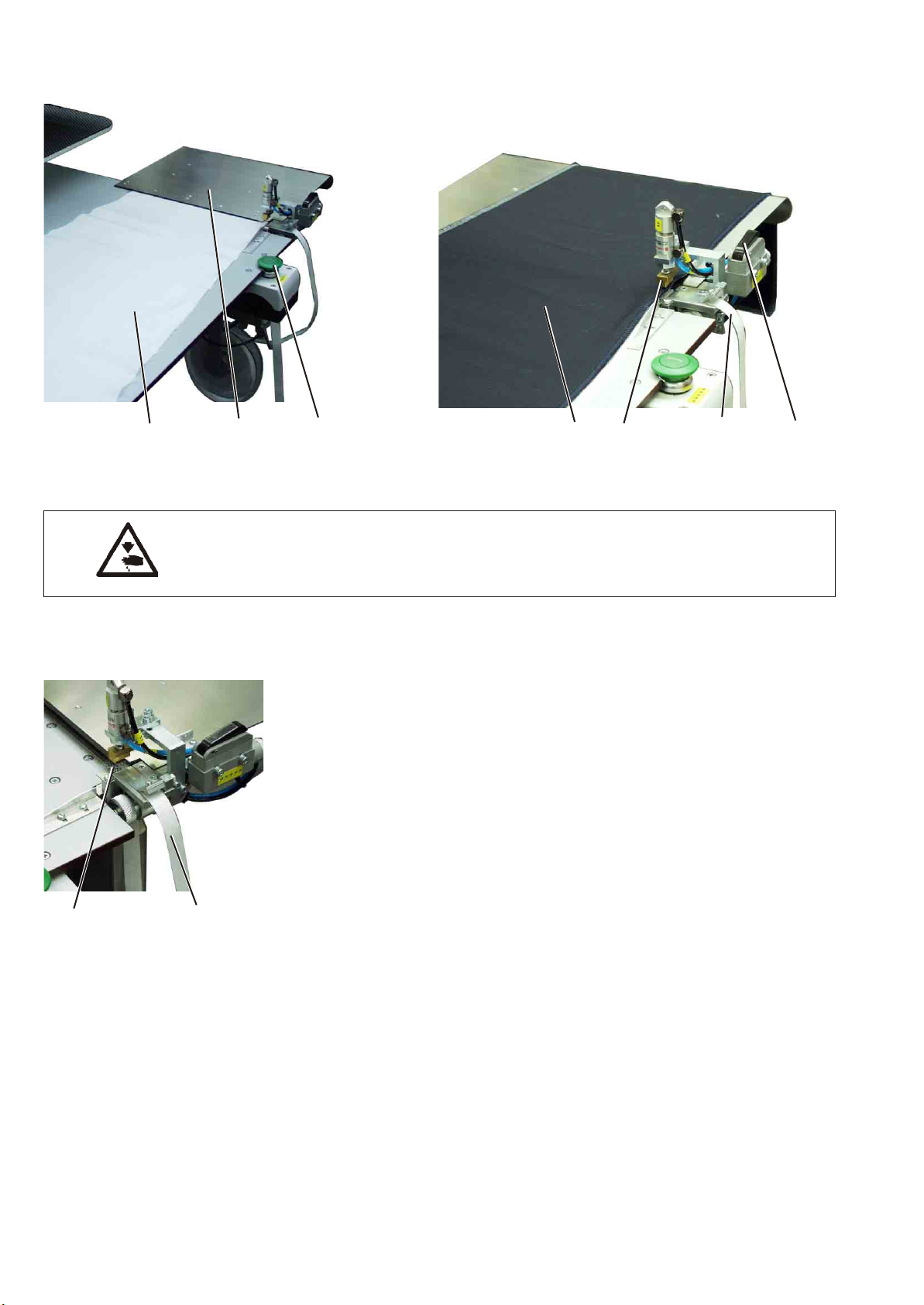

5.3 Feeding the trousers parts and starting the sewing process

The overlock unit 1225/5 works semi-automatically.

The operator of the sewing unit has to do the following:

® call up the desired seam program;

® fuse upper fabric and knee lining at the fusing station;

® feed the workpiece precisely;

® supervise the sewing process of the sewing unit;

® take the finished parts out of the stacker.

14

4 3

2 1

Feeding the trousers part and starting the sewing process

1) Select the seam program at the control panel (see chapter 6.3).

2) Place the trousers part 1 from the right on the table top 2 and

straight underneath the contour guide 3.

ATTENTION!

As soon as the trousers part has been pushed under the light barrier 4,

the sewing process starts automatically and the contour guide 3

lowers.

Page 19

6 5

8 7

3) The trousers part is sewn.

4) As soon as the workpiece has left the light barrier,the seam is

finished and both stamps 6 lower.

5) The contour guide moves upwards.

6) The swivelling device 5 transports the material out of the sewing

area.

7) The stacker clamp 8 moves to the front.

8) The stamps 6 move upwards again.

9) The trousers part is stacked.

10) Actuate foot switch 7 for removing the workpieces.

Note

In order to facilitate the material feed in the area of the sewing head

the table blowing can be engaged. (see chapter 5.5)

1

15

Page 20

5.4 Adjusting the edge guide

4 3 2 1

The height-adjustable edge guide ensures a precise positioning of the

trousers part in front of the sewing head. The height of the edge guide

can be adjusted depending on the thickness of the material to be

processed.

The draw roll 3 guarantees a precise material feed under the sewing

foot.

Adjusting the height of the edge guide

–

Draw the dial 1 in the direction of arrow.

–

Set the dial 1 to one of the four lock-in positions.

Position 1 = minimum height

Position 4 = maximum height

Fine adjustment of the height of the edge guide

–

Turn the dial 2 correspondingly.

Setting the contact pressure of the roller 4

–

Turn the dial 3 in clockwise direction

the contact pressure of the roller is increased

–

Turn the dial 3 counter-clockwise

the contact pressure of the roller is reduced

16

Page 21

5.5 Adjusting the blowing air for the nozzles in the table top

1

2

1

The blast nozzles 1 in the table top support the precise stacking of the

workpieces.

–

Set the intensity of the air blast with the dial 2 at the control panel.

Turn dial to the right = increased intensity of air blast

Turn dial to the left = reduced intensity of air blast

17

Page 22

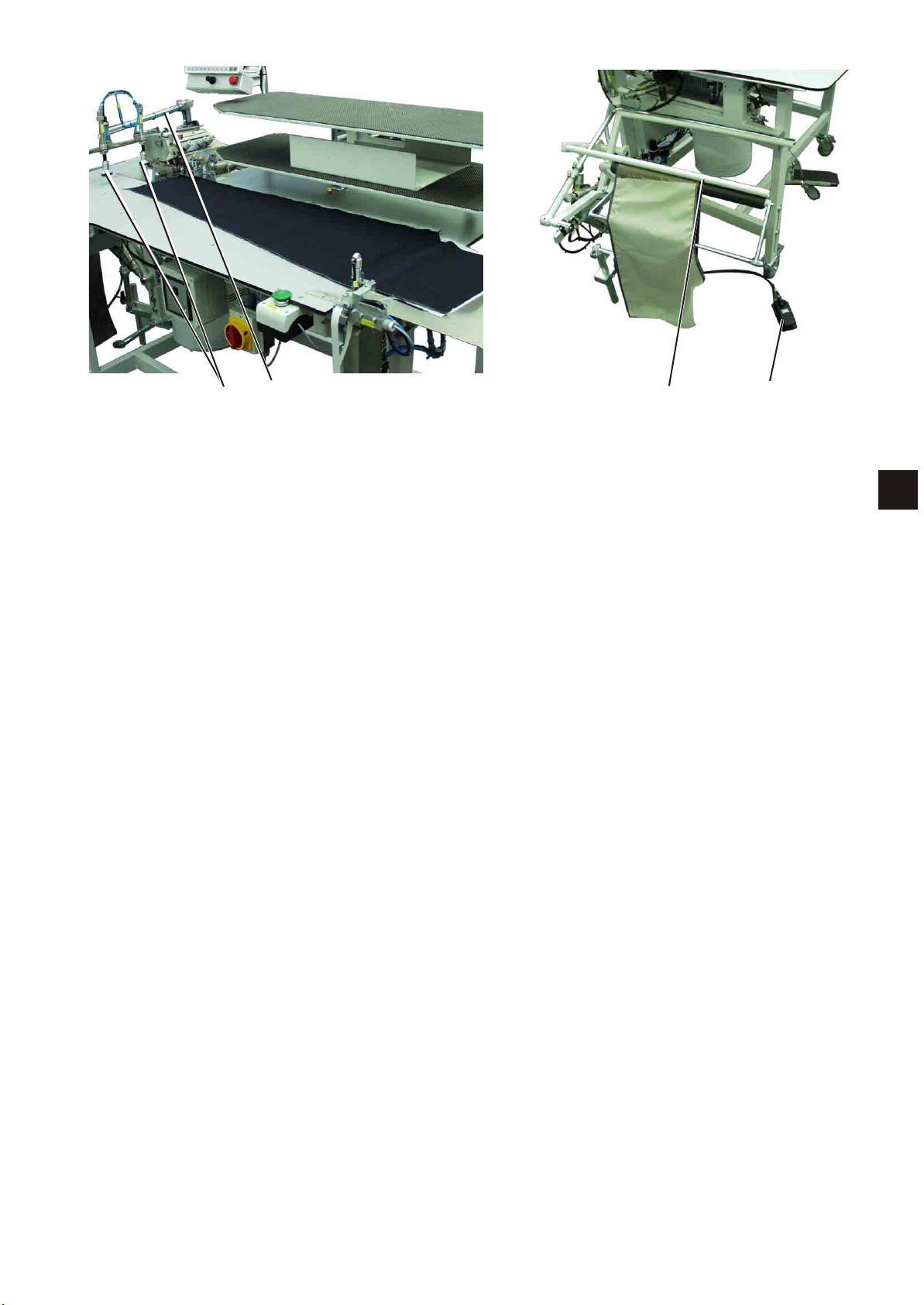

5.6 Stacker

2 1

The finished workpieces are stacked on the throw-over stacker 2.

The stacked and clamped workpieces can be removed by actuating the

foot switch 1.

The stacker is accessed by a control pulse. The pneumatic functions

can be taken from the pneumatic wiring diagram.

Caution: Risk of injury!

Do not reach into the working area of the throw-over stacker during the

stacking operation.

Manual stacking

–

Press key 3 at the control panel.

A stacking process is carried out.

Removing stacked parts

–

Actuate foot switch 1 and keep it actuated.

–

Remove the stacked parts.

3

18

Page 23

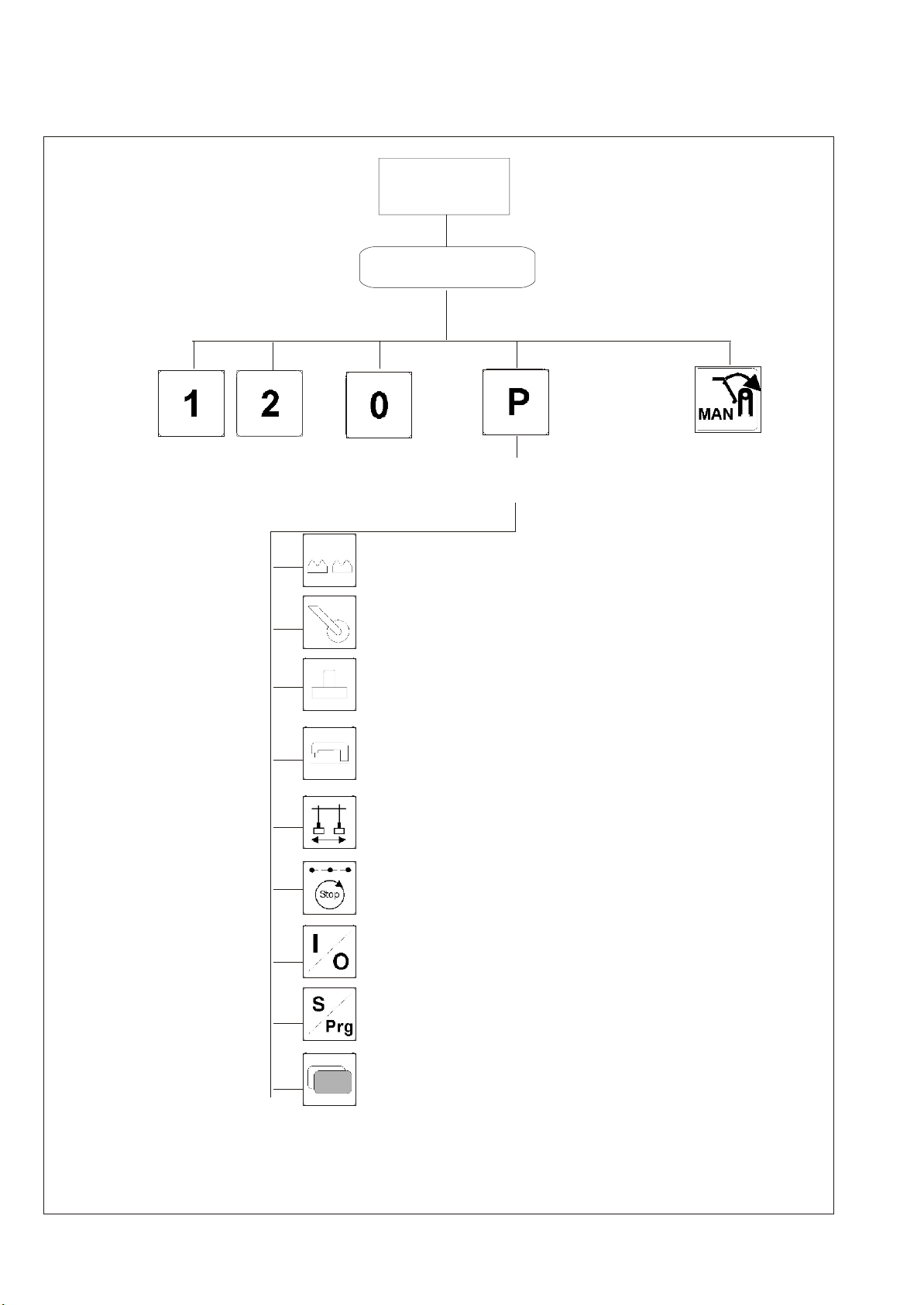

6. Operation of the control

6.1 Operator terminal

For the input and output of data an operator terminal with an LCD

display and function keys is used.

Display Enter keys

Function keys

Keys 1 - 0 Program-

stop

Key Function

— Seam program 1 to program 20

Manual stacking

Menu selection/ Data storage

Function bottom feed

Set function auxiliary roller

Set function holding stamp

Set machine parameters

Function swivelling device

Key sewing stop in the seam

1

Input/ output test

Sequence programming (S)

Program creation (Prg)

Set global parameters

Enter key

Select parameters / scroll

Alter parameter values

19

Page 24

6.2 User interface

6.2.1 Menu structure of the sewing and setting programs

Switch on

main switch

Main screen

to

Call up sewing programs Menu selection Key F2

Manual

stacking

Key 2 Adjust bottom feed

Key 3 Adjust auxiliary roller

Key 4 Adjust holding stamp

Key 5 Set machine parameters

Key 6 Adjust swivelling device

Key 7 Sewing stop in the seam

Key 8 Input-Output test

20

Key 9 Program creation / Sequence creation

Key 0 Set global parameters

Page 25

Calling up sewing programs

–

Switch the main switch on.

The control initializes.

The seam program previously used is loaded.

–

Press one of the keys “1, 2, 3, 4, 5, 6, 7, 8, 9, 0”.

The selected seam program is loaded.

Calling up the parameter menu

–

Switch the main switch on.

The control initializes.

The previously used program appears in the display.

–

Press key “P”.

The selection menu is called up.

–

Press one of the keys “1, 2, 3, 4, 5, 6, 7, 8, 9, 0”.

The display changes over to the corresponding function.

Manual stacking

When the seam program is selected:

–

Press key “F2”.

The stacker makes a stacking movement.

1

21

Page 26

6.3 Seam programs

Designation of the individual seams:

1 = hem

2 = waistband

3 = fly seam or seat seam

4 = crotch seam

5 = side seam

6 = crotch seam from the hem

7 = side seam from the hem

A seam program in the display of the control panel

22

Program No. Seam No.

Page 27

The sewing unit 1225/5 is delivered with 8 standard seam programs:

Program Description

001 Crotch seam (4) from the waistband

002 Side seam (5) from the waistband

003 Crotch seam (6) from the hem

004 Side seam (7) from the hem

005 Side seam (8) with prefabricated pocket from

the waistband

Manual start

006 Side seam (9) with prefabricated pocket from

the hem

Automatic start up to the pocket

Finish seam manually

007 Crotch seam (4) and side seam (5) alternately

008 Crotch seam (6) and side seam (7) alternately

1

23

Page 28

6.4 Adjusting the control

The parameter values are altered in the individual parameter menus.

–

Press key “P”.

–

Select the menu item.

–

Select the parameter to be altered with the keys “F1” or “F2”.

–

Press key “E”.

–

Alter the parameter value with the keys “Plus” or “Minus”.

–

Press key “P”.

The new parameter value is stored.

–

Press key “P”.

You return to the selection menu.

–

Press key “P”.

You return to the sewing program.

6.4.1 Altering seam-specific parameters

Adjusting the bottom feed

Via this parameter the bottom feed is adjusted.

Parameter 07: Length of line 1

Setting range: 0 …00

Parameter 09: Length of line 2

Setting range: 0 …00

Parameter 11: Length of line 3

Setting range: 0 …00

Parameter 73: Fullness of line 1

Setting range: ON/ OFF

Parameter 74: Fullness of line 2

Setting range: ON/ OFF

Parameter 75: Fullness of line 2

Setting range: ON/ OFF

Adjusting the auxiliary roller

Via this parameter the auxiliary roller is adjusted.

Parameter 13: Number of stitches when the auxiliary roller lowers.

Setting range: 0 …400 stitches

Parameter 14: Number of stitches how long the auxiliary roller

remains lowered.

Setting range: 0 …300 stitches

24

Page 29

Adjusting the holding stamp

Via this parameter the holding stamp is adjusted.

Parameter 15: Time when the stamp lowers.

Setting range: 0 …20

Parameter 16: Time how long the warp separator remains switched

on.

Setting range: 0 …100

Parameter 17: Switch the stacker on or off

Setting range: 0 / 1

Parameter 47: Time of stacker movement

Setting range: 0 …2000

Parameter 57: Time how long the holding stamp is down

Setting range: 0 …2000

Altering the machine parameters

Parameter 30: Set the main speed

Setting range: 0 …8500

1

Parameter 31: Switch manual sewing on or off

Setting range: 0 / 1

Parameter 32: Number of stitches how long the table blowing

remains switched on

Setting range: 0 …400 stitches

Parameter 34: Number of stitches until the contour guide

lowers

Input: 0 …400 stitches

Parameter 44: Number of stitches until the contour guide

lowers

Input: 0 …200

Parameter 60: Softstart speed

Setting range:

500 ...5000

Parameter 61: Switch the softstart on or off

Setting range: 0 / 1

Parameter 76: Switch the start via light barrier on or off

Setting range: 0 / 1

Parameter 77: Switch the autostart on or off

Setting range: 0 / 1

Parameter 78: Number of stitches when the autostart starts

Setting range: 0 ...400 stitches

Parameter 98: Switch the lining clamp on or off

Setting range: 0 / 1

25

Page 30

Altering the swivelling device

Via this parameter the swivelling device is adjusted.

Parameter 62: Number of stitches when the blade extends.

Setting range: 0 …00

Parameter 63: Number of stitches how long the blade

remains retracted.

Setting range: 0 …00

Parameter 64: Switch the swivelling of the stacker on or off

Setting range: 0 / 1

Parameter 69:

Input: 0 / 1

Altering the seam lines

Via this parameter the parameters for the individual seam lines are set.

Parameter 81: Length of seam line 1

Setting range: 0 …00

Parameter 82: Switch the speed reduction in seam line 1 on or off

Setting range: 0 / 1

Parameter 83: Reduce the speed in seam line 1

Setting range: 0 …7000

Parameter 84: Switch the stop within the seam on or off

Setting range: 0 / 1

Parameter 85: Switch the sewing foot lift within the seam on or off

Setting range: 0 / 1

Parameter 86: Seam line 2

Parameter 90: Values see seam line 1

Parameter 91: Seam line 3

Parameter 95: Values see seam line 1

26

Page 31

6.4.2 Altering the global parameters

Parameter 45: Number of stitches until the table blowing is switched

on

Input: 0 …200

Parameter 46: Duration of the stacker impulse

Input: 0 ..2000

Parameter 47: Time of stacker movement

Input: 0 …

Parameter 48: Speed limitation

Input: max. 8500

Parameter 49: Speed at warp separation

Input: 0 …5000

Parameter 50: Number of stitches until the thread tension

Input: 0....50

Parameter 56: Seam programming on/ off

Input: 0 and 1

is opened (seam end)

On = Determine the seam sequences in the current

program

Off = Create the next free program with seams

1

Parameter 57: Time how long the holding stamp is down

Input: 0 …2000

Parameter 58: Display of the software version

Parameter 59: Number of stitches how long the seam chain is

sucked (seam beginning)

Input: 0 ...150

Parameter 65: Thread tension lift at the beginning

Input: 0 …

Parameter 66: Fusing time

Input: 0 …

Parameter 67: Time of the swivelling movement to the stacker

Input: 0 …

Parameter 68: Time when the swivelling device swivels back

Input: 0 …

Parameter 80: Reset the daily piece counter

27

Page 32

6.4.3 Input - Output test

Via the input - output test the different input and output elements can

be checked.

Input test

–

Press key “P”.

–

Press key “8”.

–

Actuate the corresponding input.

Example:

Cover the light barrier.

–

Press key “Program stop”.

The program is quitted.

Input elements

Switch Designation

01 Light barrier 01

03 Light barrier 03 sewing start of hem

05 Switch “Program stop”

08 Lining clamp

09 Fusing stamp

Output test

–

Press key “P”.

–

Press key “8”.

–

Press key “Plus”.

–

Select the output element to be tested with the keys “Plus” or

“Minus”.

–

Switch the output on or off with the key “F2”.

–

Press key “Program stop”.

The program is quitted.

Output elements

Switch Designation

Y01 Sewing foot up / down

Y02 Thread tension lift open / closed

Y03 Contour guide up / down

Y04 Stacker impulse on

Y05 Holding stamp up / down

Y06 Auxiliary roller up / down

Y07 Swivelling device on / off

Y08 Swivelling the blade on / off

Y09 Tape feed on / off

Y10 Differential on / off

Y11 Fusing stamp up / down

Y12 Warp separator / off

Y13 Table blowing on /off

Y14 Dirt suction on / off

28

Page 33

6.4.4 Creation of seam programs

Note

Before a new seam program can be created or an existing one can be

deleted, the global parameter “56” has to be set to the value “0”.

This avoids that the existing programs are changed inadvertently.

–

Press key “P”.

–

Press key “0” (global parameters).

–

Change over to parameter 56 with key “F1”.

–

Press key “E”.

The parameter 56 is selected.

–

Set the parameter value to “0" with key “Minus.

–

Press key “P”.

The new parameter value is stored.

–

Press key “P”.

You return to the selection menu.

Creating a seam program

–

Press key “P”.

–

Press key “9” (Prg = programs).

–

Press key “F1” twice.

–

Select a seam with one of the keys “1” to “9”.

–

Press key “E”.

The selected seam is taken over.

–

Select a further seam with one of the keys “1” to “9”.

1

or

–

Press key “P”.

The new setting is stored and you return to the selection menu.

Note

After the creation of a new seam program the parameter “56" has to be

reset to the value “1” for safety reasons.

29

Page 34

6.4.5 Deleting a seam program

–

Press key “P”.

–

Press key “9”.

–

Press key “F2”.

The display indicates:

DELETE?

–

Press key “F2” anew.

The program is deleted.

–

Press key “P”.

You return to the selection menu.

6.4.6 Altering seam programs (Changing / Completing the sequence)

Note

Before a seam program can be altered,the parameter “56” has to be

set to the value “1".

This avoids that the existing programs are deleted inadvertently. (see

chapter 6.4.3, paragraph 1)

–

Select the program to be altered.

–

Press key “P”.

–

Press key “9” (S = sequence).

–

Select a free location with the keys “Plus” or “Minus”.

–

Select a seam number with the keys “1” to “9”.

You can select further seam numbers or quit the menu.

–

Select another free location with the keys “Plus” or “Minus”.

Or

–

Press key “P”.

The seam program is stored and you return to the selection menu.

30

Page 35

7. Error messages

In case of an error in the control system or in the machine program

corresponding error messages are indicated in the display.

Display Meaning

Error 1 One of the parameters “18” or “19” is switched on

(value = 1)

Error 2 Both parameters “18” and “19” are switched on

(value = 1)

Error 3 In the current program the last

existing seam was to be deleted.

Errors of free programming

Info U1 FP custom code wrong, e.g. describing a parameter

which does not exist.

Info U2 Wrong system function

Info U3 Wrong in / out number

Info U4 Too many user variables

Info U5 Too many system variables

Info U6 Not enough storage location for the user program

Info U7 Wrong or undefined key in the Vario

Info U8 Unknown device address

Info U9 Fatal exception error

1

Errors and informations bootload

Info B1 Switch on control in the boot mode and press key “F2”

Info B2 Programming of segment number

Info B3 Flash programming failed

Info B4 Flash programming okay

31

Page 36

8. USB stick

8.1 General notes

1

The USB stick 1 serves for storing and transferring of the sewing unit

software.

By means of the USB stick program and parameter data can also be

transferred to other sewing units.

Commercially available USB 1 sticks can be used, too.

8.2 Formatting the USB stick

Before using a new USB stick this has to be formatted correspondingly.

The file format is the “FAT 16” system.

–

Format the USB stick with the FAT 16 system via a PC.

8.3 Plugging the USB stick in the control

–

Switch the main switch off.

–

Plug the USB stick 1 in the lower slot of the Efka control.

–

Press key “P” and keep it pressed.

–

Switch the main switch on.

The message appears for a moment.

USB. DEV. DETECT:

–

Keep key “P” pressed until the following message appears in the

display:

SERVICE - CODE

32

–

Enter CODE 3112.

–

Press key “E”.

Page 37

8.4 USB functions

The following functions can be carried out with a USB stick:

1) Storing and loading of global parameters

File extension = *. PAR

Parameter Function

F-510 Securing from the control on the USB stick

F-511 Loading from the USB stick in the control

F-512 Comparing USB stick and control data

F-513 Deleting data from the USB stick

2) Storing and loading of programs and seam parameters

File extension = *.PAY

Parameter Function

F-514 Securing from the control on the USB stick

F-515 Loading from the USB stick in the control

F-516 Comparing USB stick and control data

F-517 Deleting data from the USB stick

1

3) Loading a new software version

File extension = *.PRG

Parameter Function

F-523 Load a new software version from the USB

stick in the

control

By means of the FAT 16 file system the control allocates file names

with max. 8 characters.

Max. 8 characters 1 2 3 4 5 6 7 8

Software version 1 2 2 0 _ 5 D _ 1 A .PRG

Machine type

Language

Equipment

1 = Parameter file

2 = Program file

Version

33

Page 38

If different program or parameter files are stored, the control allocates

a new name each.

Example:

Storing of different parameter data

1st file 0100DATA.PAR

2nd file 0101DATA.PAR

etc.

The files can individually be renamed by the file manager or explorer

on a PC.

Note

On principle, the Efka control can read data from the main level of the

USB stick only. Data from subdirectories cannot be processed.

34

Page 39

8.4.1 Storing data on the USB stick

–

Enter parameter.

Example: 510

–

Press key “E”

The cursor flashes.

–

Press key “F2”.

The file name chosen by the control appears.

Example

0100DATA.PAR

–

Press key “E”.

The data are written on the USB stick.

Note

The file name is allocated automatically.

1

8.4.2 Loading data from the USB stick

–

–

–

–

–

–

Enter parameter.

Example: 511

Press key “E”

The cursor flashes.

Press key “F2”.

The name of the first file stored on the stick appears.

Example

0100DATA.PAR

Select the desired file with the keys “+” or “-”.

Press key “E”.

The message appears.

READ DATA YES = E

Press key “E” within 2 seconds.

The data are read from the USB stick.

35

Page 40

8.4.3 Data comparison

–

Enter parameter.

Example: 512

–

Press key “E”.

The file name chosen by the control appears.

Example

0100DATA.PAR

–

Press key “E”.

The message appears.

READ DATA YES = E

–

Press key “E” within 2 seconds.

The data of the USB stick and the control are compared.

The message appears.

READ DATA

Possible displays

8.4.4 Deleting data from the USB stick

–

–

–

–

DATA OK The data on the stick are identical

with the data of the control

DATA DIFFERENT The data of the stick and the control are

not identical.

Enter parameter.

Example: 513

Press key “E”.

The cursor flashes.

Press key “F2”.

The name of the first file appears on the stick.

Example

0100DATA.PAR

Select the desired file with the keys “+” or “-”.

Example

36

0105DATA.PAR

–

Press key “E” within 2 seconds.

The data from the USB stick are deleted.

The message appear.s

READY

Page 41

8.4.5 Loading software version from the USB stick

–

Enter parameter 523.

–

Press key “E”.

The cursor flashes.

–

Press key “F2”.

The name of the first file stored on the stick appears.

Example

20_5D_1A.PRG

–

Select the desired parameter file with the keys “+” or “-”.

–

Press key “E”.

The message appears.

READ DATA YES = E

–

Press key “E” within 2 seconds.

The data are read from the USB stick.

–

Press key “P” and wait approx. 3 seconds until “Save Data” fades

out.

–

Press key “E” twice.

The cursor flashes.

–

Press key “F2”.

The name of the first file stored on the stick appears.

Example

20_5D_2A.PRG

–

Select the desired program file with the keys “+” or “-”.

–

Press key “E”.

The message appears.

1

READ DATA YES = E

–

Press key “E” within 2 seconds.

The data are read from the USB stick.

–

Switch the main switch off and on again.

The new software version is loaded now.

37

Page 42

8.5 Removing the USB stick

1

–

Switch the main switch off.

–

Pull the USB stick 1 out of the slot of the Efka control.

38

Page 43

9. Maintenance

9.1 Cleaning and checking

Caution: Risk of injury !

Switch the main switch off.

The maintenance of the sewing unit must only be carried out with the

machine switched off.

Maintenance work has to be done after the intervals indicated in the

tables at the latest (see column “Operating hours”).

The processing of fluffy material may require shorter maintenance

intervals.

A clean sewing unit protects from disturbances.

1

1

2

Maintenance work Explanation Operating

to be done hours

Machine head

- Remove sewing dust and

thread remainders.

(e.g. with compressed air pistol)

Suction device Empty container 2 of the suction device

Clean the entire area 1 of the thread guides

under the fabric sliding sheet

- Turn the bottom part of the container to the

left and remove it

- Empty the container

- Screw the bottom part on again in

clockwise direction

8

8

39

Page 44

6 5 4 3

Maintenance work Explanation Operating

to be done hours

Pneumatic system

- Check the water level in the

pressure regulator 3

The water level must not rise up to the filter

insert 4.

- Let the water run out of the water separator

under pressure after pressing the drain

plug 5.

40

- Clean the filter insert 4

R

- Make leak test of the system

The filter insert 4 separates dirt and

condensed water.

- Separate the sewing unit from the

compressed air net.

- Push in drain plug 5.

The pneumatic system of the

sewing unit has to be pressureless.

- Screw the water separator 6 off

- Remove filter insert 4.

Wash the dirty filter tray and the filter insert

with benzine (no solvent!)

and blow them clean.

- Reassemble the water separator

and connect the maintenance unit.

500

500

40

Page 45

9.2 Oil lubrication

2 1

1

Caution: Risk of injury !

Oil may cause skin eruption.

Avoid a longer contact with the skin.

Wash yourself thoroughly after a contact.

ATTENTION !

The handling and disposal of mineral oils is subject to legal

regulations.

Deliver used oil to an authorized collecting station.

Conserve your environment.

Be careful not to spill any oil.

Oil the head of the sewing unit exclusively with lubricating oil DA-10 or

an equivalent oil with the following specification:

–

Viscosity at 40° C: 10 mm²/s

–

Ignition point: 150° C

DA-10 can be bought at the sales points of DÜRKOPP ADLER AG

under the following parts numbers:

Container 250 ml: 9047 000011

Container 1 litre: 9047 000012

Container 2 litres: 9047 000013

Container 5 litres: 9047 000014

Maintenance work Explanation Operating

to be done hours

Lubrication

Check the oil level at the sewing machine head

regularly (inspection glass 1 and 2).

8

Please take further details from the enclosed

operating instructions of the sewing machine

head.

41

Page 46

Note:

42

Page 47

In dex Page:

Part 2: Assembly in structions cl. 1225/5

1. Sco pe of de li very ............................................... 3

2. Ge ne ral no tes ................................................. 3

3. In stal ling the se wing unit

3.1 Trans port pro tec tions ............................................. 4

3.2 Setting the wor king height .......................................... 5

3.3 Mounting the thread reel hol der....................................... 6

3.4 Aligning the con trol panel........................................... 6

3.5 Con necting the foot pe dal........................................... 7

3.6 Mounting and alig ning the stacker ..................................... 7

3.7 Alig ning the ma te ri al trays .......................................... 8

3.8 Aligning the con trol panel........................................... 8

4. Elec tri cal con nec ti on

4.1 Che cking the no mi nal vol ta ge........................................ 9

4.2 Ma king the mains con nec ti on ........................................ 9

5. Pneu ma tic con nec ti on ........................................... 10

6. Put ting into ope ra ti on

6.1 Se wing test ................................................... 11

2

Page 48

11

2

3

1

4

10

5

9

8

6

7

Page 49

1. Sco pe of de li very

The scope of delivery depends on your order.

The sewing units consists of:

–

1 Sewing machine head (as per order)

–

2 Thread reel holder

–

3 Control with control panel

–

4 Material tray

–

5 Clamp for knee lining

–

6 Fusing station for knee lining (optional)

–

7 Foot switch

–

8 Stand and table top

–

9 Suction device with suction container

–

10 Stacker

–

11 Swivelling device

–

Compressed air maintenance unit with compressed air

pistol

2. Ge ne ral no tes

2

ATTENTION !

The sewing unit must only be installed by trained specialist staff.

Any work on the electrical equipment of the sewing unit must

only be carried out by electricians or correspondingly instructed

persons.

The mains plug must be pulled out.

The enclosed operating instructions of the drive motor manufacturer

have to be observed.

3

Page 50

3. In stal ling the se wing unit

3.1 Trans port pro tec tions

1

Before the installation of the sewing unit all transport protections have

to be removed.

Transport protections of the sewing unit

–

Remove the protective foils 1.

–

Remove the security tapes at the thread reel holder, machine table

etc.

Transport protections of the stacker

–

Remove the security tape 3 from the stacker.

–

Remove the security tape 2 and put the foot pedal down.

3 2

4

Page 51

3.2 Setting the working height

2

1

The working height is adjustable between 850 and 1200 mm

(measured up to the top edge of the table top).

–

Loosen screws 1 and 2 on all four spars.

–

Set the desired working height with the help of suitable auxiliary

means.

In order to avoid jamming lift the table top equally on both sides.

–

Retighten screws 1 and 2 on all four spars.

2

5

Page 52

3.3 Mounting the thre ad reel hol der

2 1 3 2

–

Insert thread reel holder 1 in retainer 2.

–

Tighten the thread reel holder with the two screws 3.

3.4 Aligning the con trol panel

3 2 1

The control panel 1 has been lowered for transportation.

–

Loosen screws 3.

–

Pull tube 2 holding the control panel right to the top.

–

Retighten screws 3.

6

Page 53

3.5 Connecting the foot pe dal

2

–

Position the foot pedal 1 within easy reach.

–

Make plug connection 2.

3.6 Mounting and aligning the stacker

2 1

2

5 4 3 2 1 7 6

–

Approach the stacker with the holder 4 to the sewing unit.

–

Screw the holder 4 on the sewing unit with two screws 5.

–

Align the stacker in such a way that the smoother 6 is in parallel

position to the edge of the table top 7.

–

Tighten screws 5.

–

Screw earth wire 2 on the stacker.

–

Attach the compressed air lines 1 and 3 to the distributor.

7

Page 54

3.7 Alig ning the ma te ri al trays

3 2 1 4

The material trays 2 and 3 have been lowered for transportation.

–

–

–

Loosen screws 4 at the spars 1.

Draw the material trays to the corresponding working height.

Tighten screws 4.

8

Page 55

4. Elec tri cal con nec ti on

ATTENTION !

Any work on the electrical equipment of the sewing unit must only be

carried out by electricians or correspondingly instructed persons.

The mains plug must be pulled out.

4.1 Che cking the no mi nal vol ta ge

ATTENTION !

The nominal voltage indicated on the type plate of the sewing machine

control and the mains voltage must correspond.

Nominal voltage = 190 - 240 V, 50/60 Hz

4.2 Ma king the mains con nec ti on

–

Connect the mains plug.

2

9

Page 56

5. Pneu ma tic con nec ti on

For the operation of the pneumatic components the sewing unit has to

be provided with anhydrous compressed air.

ATTENTION!

For a trouble-free function of the pneumatic control processes the

compressed air net has to be rated as follows:

Even in the moment of maximum air consumption the minimum

operating pressure must not drop below 6 bar.

In case of a too high air pressure decrease:

–

–

Increase the compressor output.

Increase the diameter of the compressed air supply line.

3 2 1

Connecting the compressed air maintenance unit

–

Connect the connecting hose 3 to the compressed air net.

Setting the operating pressure

–

The operating pressure amounts to 6 bar.

It can be read off at the manometer 1.

–

For setting the operating pressure pull up and turn the rotary

handle 2.

- Turn in clockwise direction = increase the pressure

- Turn counter-clockwise = reduce the pressure

ATTENTION !

No oil-bearing compressed air must be fed from the compressed air

net.

Behind the filter cleaned compressed air is withdrawn as blowing air

for cleaning machine parts and for blowing workpieces out.

Oil particles contained in the blowing air lead to malfunction and stains

on the workpieces.

10

Page 57

6. Put ting into ope ra ti on

6.1 Se wing test

After completion of the installation work a sewing test should be made.

–

Plug in the mains plug.

Caution: Risk of injury!

Switch the main switch off.

Thread in needle and hook thread only with the sewing unit switched

off.

–

Thread in needle and hook thread

(see operating instructions of the sewing machine head).

–

Switch the main switch on.

The control is initialized.

–

Select the sewing program.

–

For feeding and operating see part 1:

Operating instructions 1225/5

2

11

Page 58

Page 59

Index Page:

Part 3: Service instructions class 1225/5

1. General notes ................................................ 3

2. Brief instructions for the sewing head

2.1 Adjusting the needle bar height ...................................... 4

2.2 Adjusting the hook .............................................. 5

2.2.1 Distance between left hook and needle.................................. 5

2.2.2 Distance between right hook and needle................................. 7

2.3 Adjusting the needle protection ...................................... 9

2.3.1 Hind needle protection............................................ 9

2.3.2 Front needle protection ........................................... 10

2.4 Adjusting the feed-dog............................................ 11

2.4.1 Feed-dog position .............................................. 11

2.4.2 Feed-dog height ............................................... 12

2.5 Presser foot .................................................. 13

2.5.1 Presser foot lift head EX5204 ....................................... 13

2.5.2 Presser foot lift head S52 .......................................... 14

2.5.3 Presser foot .................................................. 15

2.6 Upper and lower knife ............................................ 16

2.6.1 Changing and adjusting the upper knife ................................. 16

2.6.2 Changing and adjusting the lower knife ................................. 17

2.7 Thread regulation of overlock hook .................................... 18

3

3. Adjusting the sewing unit

3.1 Adjusting the light barrier .......................................... 19

3.2 Setting the seam width ........................................... 20

3.3 Adjusting the swivelling device....................................... 21

3.4 Direct sewing drive ............................................. 22

3.4.1 Setting the reference............................................. 22

4. Oil lubrication

4.1 Oil change and oil filter change ...................................... 23

5. Maintenance ................................................. 24

Page 60

Page 61

1. General notes

The service instructions on hand describe the adjustment of the

single-head overlock unit 1225/5.

The manual consists of:

Brief instructions for the sewing head

·

Service instructions for the sewing unit

·

ATTENTION !

The brief instructions are a summary of the detailed operating

instructions of the sewing head. In any case these operating

instructions have to be carefully read and all regulations have to be

observed. The Beisler company does not guarantee the accuracy of

the following specifications.

ATTENTION !

The operations described in the service instructions must only be

executed by qualified staff or correspondingly instructed persons

respectively!

Caution: Risk of injury !

In case of repair, alteration or maintenance work switch the main

switch off.

Carry out adjusting operations and functional tests of the running

machine only under observation of all safety measures and with utmost

caution.

The instruction manual on hand describes the adjustment of the

sewing unit in an appropriate sequence.

Please observe in this connection that various setting positions are

interdependent.

Therefore it is absolutely necessary to do the adjustment following the

described order.

For all setting operations of parts involved in the stitch formation a new

needle without damage has to be inserted.

3

3

Page 62

2. Brief instructions for the sewing head

2.1 Adjusting the height of the needle bar

1

2

3

Caution: Risk of injury!

Switch the main switch off.

Check and adjust the height of the needle bar only with the sewing unit

switched off.

Standard checking

In the top dead centre of the needle bar the distance between the

needlepoint 4 and the throat plate should amount to 9.7 - 9.9 mm.

–

Move the needle bar in its top dead centre.

–

Check whether the distance between needlepoint4 and throat

plate 5 amounts to 9.7 - 9.9 mm.

4

Correction

–

Unscrew screws 1 and remove cover 2.

–

Move the needle bar in its top dead centre.

–

Swivel the sewing foot out.

5

–

Loosen screw 3 until the needle bar can just be pushed.

–

Shift the needle bar in such a way that the distance between

needlepoint 4 and throat plate amounts to 9.7 - 9.9 mm.

–

Tighten screw 3.

–

Screw cover 2 on again.

4

Page 63

2.2 Adjusting the hook

2.2.1 Distance between left hook and needle

5

2,3 - 2,5 mm

1

2

3

4

Caution: Risk of injury!

Switch the main switch off.

Check and adjust hook only with the sewing unit switched off.

5

Cross-line adjustment

Standard checking

In the left reverse point of hook 5 the distance between the middle of

the needle and the hook tip should amount to 2.3 - 2.5 mm.

–

Move the left hook in its left reverse point by handwheel.

–

Check whether the distance between the middle of the needle and

the hook tip amounts to 2.3 - 2.5 mm.

Correction

–

Unscrew the throat plate, the front feed-dog as well as the front

and hind needle protection.

–

Move the hook in its left reverse point by handwheel.

–

Loosen screw 1 and take care that the hook abuts on stop 2.

–

Tighten screw 1 again.

–

Loosen screw 4 until the hook support 3 can just be turned.

–

Turn the hook support in such a way that that distance between the

middle of the needle and the hook tip amounts to 2.3 - 2.5 mm.

Note

Do not yet tighten screw 4.

3

5

Page 64

2,3 - 2,5 mm

0 - 0,05 mm

3

6

7

4

Adjustment in sewing direction

Standard checking

The distance between hook tip 6 and needle 7 should amount to

0.0 - 0.05 mm.

–

Turn handwheel in direction of rotation until the hook tip is exactly

at the level of the middle of the needle.

–

Shift the hook support 3 in such a way that the distance between

hook support and needle amounts to 0.0 - 0.05 mm.

–

Check the cross-line adjustment once again and readjust, if

necessary.

–

Tighten screw 4.

6

Page 65

2.2.2 Distance between right hook and needle

1

4

8

7

5

6

3

2

Caution: Risk of injury!

Switch the main switch off.

Check and adjust the hook only with the sewing unit switched off.

9

10

4,3 - 4,5 mm

Cross-line adjustment

Standard checking

When the right hook is in its top reverse point, the distance between

hook tip 9 and the middle of the needle should amount to 4.3 - 4.5 mm.

–

Screw off thread guides 1 and 3 as well as cover 2.

–

Move the hook in its top dead centre by handwheel.

–

Loosen screw 4 until the hook can just be pushed.

–

Shift the hook in such a way that the hook shank (1) is flush with

the right side of the hook holder.

–

Loosen screw 6 a little.

–

Turn lever 5 in such a way that there is a distance of 4.3 - 4.5 mm

between hook tip and the middle of the needle.

Take care that the bar 8 in the bearing 7 does not move too heavy.

–

Tighten screw 6.

Note

Do not yet tighten screw 4.

3

7

Page 66

4

Adjustment in sewing direction

Standard checking

When the right hook crosses the left hook, the distance “A” should

amount to 0.5 mm and the distance “B” to 0.2 mm.

Correction

–

Turn handwheel in direction of rotation until the right hook crosses

the left hook.

–

Turn and shift the right hook in such a way that the distance “A”

amounts to 0.5 mm and the distance “B” to 0.2 mm.

–

Tighten screw 4 in this position.

–

Check all adjustments once again and readjust, if necessary.

–

Remount thread guides 1 and 3 as well as cover 2.

–

Adjust thread guides according to chapter “thread regulation of the

overlock hooks”.

Note

The right overlock hook is dependent on the needle size.

Use hook No. 28 for needles Nm 60 - 80 and hook No. 22 for needles

Nm 80 - 100.

8

Page 67

2.3 Adjusting the needle protection

2.3.1 Hind needle protection

1

3

2

3

4

4

Caution: Risk of injury!

Switch the main switch off.

Check and adjust the needle protection only with the sewing unit

switched off.

3

Standard checking

When the tip of the left hook 3 is at the level of the middle of the

needle, the needle protection 1 should abut on the needle. There

should be a distance of 0.0 - 0.05 mm between hook tip and needle.

–

Turn handwheel in direction of rotation until the hook tip points in

the needle direction.

–

Check the distance between hook tip and needle.

Correction of the mobile version

–

Turn handwheel in direction of rotation until the hook tip points in

the needle direction.

–

Loosen screw 2.

–

Shift the needle protection 1 in such a way that it abuts on the

needle and there is a distance of 0.0 - 0.05 mm between hook tip

and the middle of the needle.

–

Tighten screw 1.

Correction of the stationary version

–

Turn handwheel in direction of rotation until the hook tip points in

the needle direction.

–

Loosen screws 4.

–

Shift the needle protection 3 in such a way that it abuts on the

3

needle and there is a distance of 0.0 - 0.05 mm between hook tip

and the middle of the needle.

–

Tighten screws 4.

9

Page 68

2.3.2 Front needle protection

1

1

4

Caution: Risk of injury!

Switch the main switch off.

Check and adjust the needle protection only with the sewing unit

switched off.

Standard checking

In the lower dead centre of the needle the distance between needle

protection 1 and needle should amount to 0.03 - 0.05 mm.

–

–

Correction

–

–

–

–

2

Turn handwheel in direction of rotation until the needle is in its

lower dead centre.

Check the position of the front needle protection.

Turn handwheel in direction of rotation until the needle is in its

lower dead centre.

Loosen screw 2.

Shift the needle protection 1 in such a way that there is a distance

of 0.03 - 0.05 mm between needle protection and needle.

Tighten screw 2.

10

Page 69

2.4 Adjusting the feed-dog

2.4.1 Feed-dog position

2 1

1

2

Caution: Risk of injury!

Switch the main switch off.

Check and adjust the feed-dog position only with the sewing unit

switched off.

Standard checking

In their highest position the feed-dogs should be horizontal.

–

Turn handwheel in direction of rotation until the feed-dogs are in

their highest position.

–

Check the position of the feed-dogs.

Correction

–

Turn handwheel in direction of rotation until the feed-dogs are in

their highest position.

–

Loosen screw 1.

–

Turn screw 2.

Feed-dogs are horizontal

Feed-dogs are inclined backwards

3

–

Tighten screw 1.

Feed-dogs are inclined forwards

11

Page 70

2.4.2 Feed-dog height

6

3

323

4

5

1

Caution: Risk of injury!

Switch the main switch off.

Check and adjust the feed-dog height only with the sewing unit

switched off.

Standard checking

When the feed-dogs are in their highest position, the teeth of the main

feed-dog 4 should be 0.8 mm above the top edge of the throat plate,

the teeth of the differential feed-dog 5 0.9 to 1.0 mm and the teeth of

the auxiliary feed-dog 6 0.6 to 0.7 mm.

–

Turn the handwheel in direction of rotation until the feed-dogs are

in their highest position.

–

Check the position of the feed-dogs to the throat plate.

Correction

–

Unscrew throat plate.

–

Loosen screws 1, 2 and 3 a little.

–

Put throat plate on again.

–

Set the height of the feed-dogs.

–

Remove the throat plate.

–

Tighten screws 1, 2 and 3.

–

Put throat plate on again and tighten.

12

Page 71

2.5 Presser foot

2.5.1 Presser foot lift head EX5204

7 6 5 4 3 2 1

Caution: Risk of injury!

Switch the main switch off.

Check and adjust the presser foot lift only with the sewing unit

switched off.

3

Standard

When the piston rod 7 is extended, the lever 6 should abut on screw 5

and the clearance under the sewing feet should amount to 4 mm.

8

Correction

–

Loosen counternut 4 and screw the screw 5 down completely.

–

Swivel the sewing foot in.

–

Turn handwheel in direction of rotation until the teeth of the

feed-dog are underneath the top edge of the throat plate.

–

7

Loosen screw 2 and press ring 1 backwards as far as it will go.

–

Tighten screw 2 in this position.

Take care that ring 1 and lever 3 have no axial backlash.

–

Press lever 6 down until there is a distance of approx. 4 mm

between sewing foot and throat plate.

–

Let screw 5 abut on lever 6 in this position and fix it by a locknut.

Note

If lever 6 does not abut on screw 5 when the piston rod 7 of the

cylinder is extended, please proceed as follows:

–

Loosen nut 8.

–

Shift cylinder 1 correspondingly.

–

Tighten nut 8.

13

Page 72

2.5.2 Presser foot lift head S52

2

3

4

9

10

1

11

7

6

8

5

Caution: Risk of injury!

Switch the main switch off.

Check and adjust the presser foot lift only with the sewing unit

switched off.

Standard

When the piston rod 1 is extended, the lever 4 should abut on screw 6

and the clearance under the sewing feet should amount to 5 mm.

Furthermore there should be a distance of 0.3 mm between stop 11

and screw 10 in this position.

Correction

–

Loosen counternut 5 and screw the screw 6 down completely.

–

Swivel the sewing foot in.

–

Turn handwheel in direction of rotation until the teeth of the

1

feed-dog are underneath the top edge of the throat plate.

–

Loosen screw 2 and press ring 3 backwards as far as it will go.

–

Tighten screw 2 in this position.

Take care that ring 3 and lever 4 have no axial backlash.

–

Press lever 7 down until there is a distance of approx. 5 mm

between sewing foot and throat plate.

–

Let screw 6 abut on lever 4 in this position and fix it by a locknut.

Note

If lever 4 does not abut on screw 6 when the piston rod 1 of the

cylinder is extended, please proceed as follows:

–

Loosen nut 8.

–

Shift cylinder 1 correspondingly.

–

Tighten nut 8.

–

Loosen screw 9.

–

Turn screw 10 in such a way that there is a distance of approx. 0.3

mm between screw 10 and stop 11.

Take care that lever 7 is pressed down as far as it will go.

–

Tighten screw 9.

14

Page 73

2.5.3 Presser foot

1

3

Caution: Risk of injury!

Switch the main switch off.

Check and adjust the presser foot only with the sewing unit switched

off.

Standard checking

When the feed-dogs are in their lowest position, the sole of the presser

foot should be 0.1 to 0.2 mm up at the front.

Furthermore, the needle hole of the sewing foot and that of the throat

plate should be in line.

–

Move the feed-dogs in low position.

–

Check the presser foot position.

2

3

Correction

–

Loosen screws 2 and 3.

–

Shift the presser foot in such a way that the needle hole of the

presser foot and that of the throat plate are in line.

–

Tighten screws 2 and 3.

Take care that the sole of the presser foot is above the throat plate

in parallel position.

–

Turn screw 1 in such a way that the sole of the presser foot is 0.1

to 0.2 mm up at the front.

15

Page 74

2.6 Upper and lower knife

2.6.1 Exchanging and adjusting the upper knife

Head EX 5205-22/233-6KS Head S52 134B

3 2 1

Caution: Risk of injury!

Switch the main switch off.

Exchange and adjust the upper knife only with the sewing unit

switched off.

1

2

3

4

6

5

7

Standard

In the lowest position of the upper knife the front edge of the blade

should be 0.5 to 1.0 mm underneath the top edge of the throat plate.

Correction

–

Turn the handwheel until the needles are in their top reverse point

and swivel the sewing foot out.

–

Screw off screw 1.

–

Remove the knife holder 2 with the knife.

–

Loosen screw 3 and remove the knife.

–

Insert a new,sharp knife and tighten with screw 3.

–

Insert knife holder 2 and tighten slightly with screw 1.

–

Turn the handwheel until the knife is in its lowest position.

–

Shift the knife in such a way that it slightly abuts on the lower knife

and the front edge of the blade is approx. 0.5 to 1.0 mm

underneath the top edge of the throat plate.

Head S52 134B only

–

Let the stops 4 and 5 abut on the knife in this position and tighten

screws 1 and 3.

–

Turn the handwheel until the knife is in its highest position.

–

Loosen screw 6.

–

Shift the lower knife to the left and let it spring against the upper

knife.

–

Tighten screw 6.

16

Page 75

2.6.2 Changing and adjusting the lower knife

Head EX 5205-22/233-6KS Head S52 134B

4

3

4 3 2 1

1

2

Caution: Risk of injury!

Switch the main switch off.

Exchange and adjust the lower knife only with the sewing unit switched

off.

Standard

The blade of the lower knife has to be flush with the top edge of the

throat plate.

Correction

–

Remove the fabric sliding sheet.

–

Swivel the sewing foot out.

–

Loosen screw 4.

–

Draw the holder of the lower knife 3 to the left as far as it will go

and tighten screw 4 slightly.

–

Loosen screw 2 and remove the old knife.

–

Insert a new, sharp knife in guide 1 in such a way that the blade is

flush with the top edge of the throat plate.

–

Tighten screw 2.

–

Turn the handwheel until the upper knife is in its highest position.

–

Loosen screw 4 and let the holder of the lower knife 3 spring

against the upper knife.

–

Tighten screw 4.

3

17

Page 76

2.7 Thread regulation of overlock hook

1

10

2

3

4

5

9

Caution: Risk of injury!

Switch the main switch off.

Check and adjust the thread regulation only with the sewing unit

switched off.

Standard

The position of the individual thread guides or thread pullers is

dependent on the material, the sewing thread and the stitch type.

Therefore the following setting values have to be regarded as standard

values only.

Correction

–

Turn the handwheel until the right hook is in its top reverse point.

–

Loosen screw 10 and shift the thread puller 9 in such a way that

there is a distance of approx. 32 mm between the middle of the

screw and the middle of the eyelet.

–

Tighten screw 10.

Take care that the thread puller 9 is in vertical position.

–

Loosen screws 6 and 8 a little.

–

Position the thread pullers 3 and 7 as shown in the illustration.

–

Tighten screws 6 and 8.

–

Loosen screw 4 a little.

–

Position the thread guide 5 as shown in the illustration.

–

Tighten screw 4.

–

Loosen screw 2 a little.

–

Shift the thread guide 1 in such a way that the screw 2 is in the

centre of the longitudinal hole.

–

Tighten screw 2.

Note

If the seam requires more or less thread, shift the thread pullers 3 and

7 in the direction “+” or “-” respectively.

8

6

7

18

Page 77

3. Adjusting the sewing unit

3.1 Adjusting the light barrier

2 1

6 5

5 4 3

Caution: Risk of injury!