Page 1

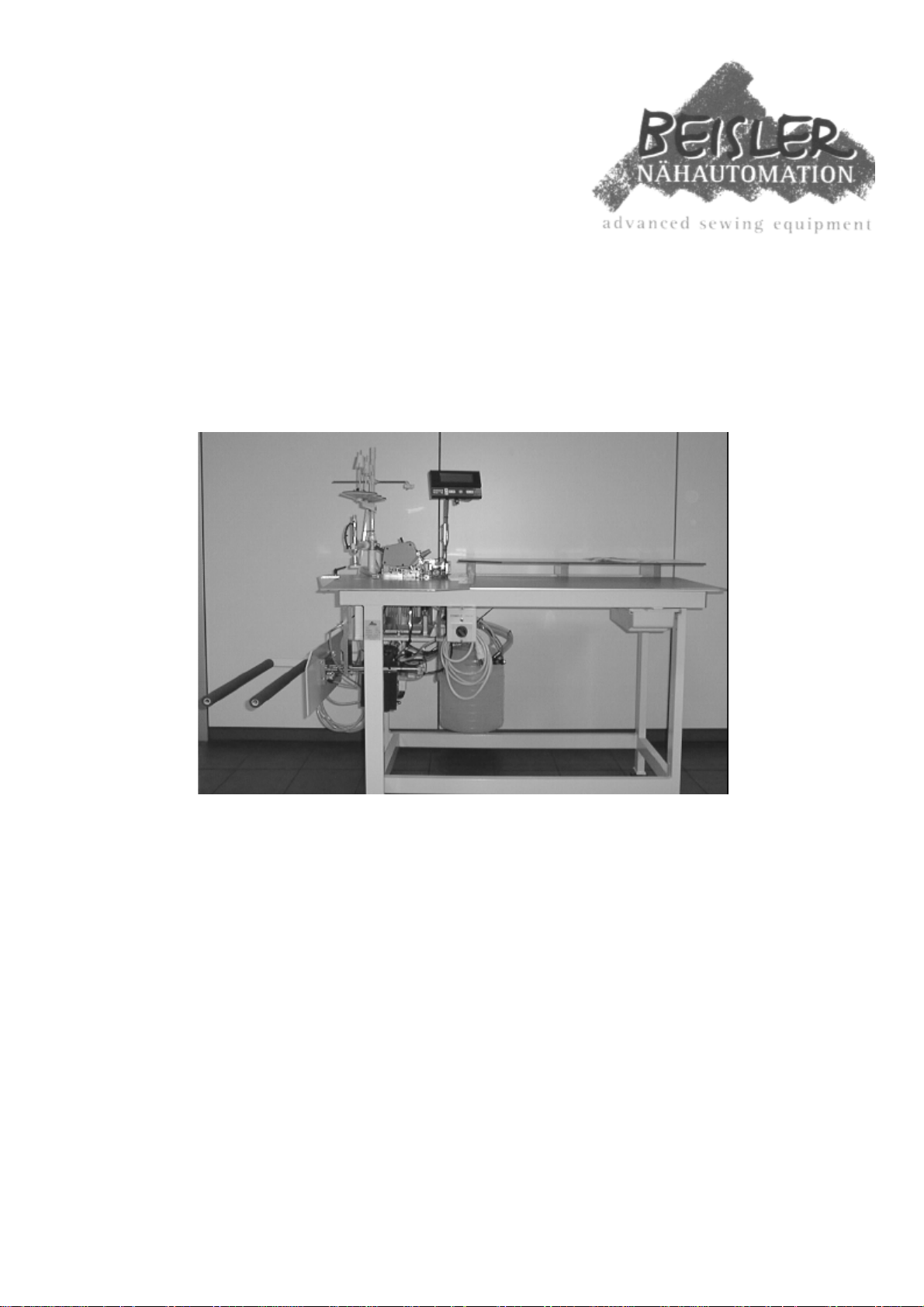

Automatic Single Head

Serging Unit, series 1220/4

Operating instructions

Version 3.0, dated 06-28-1999 – GB

© 1997-99 Beisler GmbH, Hösbach

Frohnradstr. 10 y D-63768 Hösbach y Phone-No. Service: +49-6021-501940 y Fax: +49-6021-540061

Page 2

Betriebanleitung Kurznaht-Automat 2111

© Beisler GmbH, Hösbach

Page 3

Contents

1 Security advice and warning hints 1-1

1.1 Classification 1-1

1.2 Range of validity 1-2

1.3 Authorized person 1-2

1.4 General security advice and warning hints 1-3

1.5 Copyright 1-4

2 Preliminary remarks 2-1

2.1 Introduction 2-1

2.2 Limitation of liability 2-2

2.3 Guarantee regulations 2-3

2.4 Use as agreed 2-4

2.5 Description of the machine 2-4

2.6 Major parts of the machine 2-5

3 Security 3-1

3.1 Available security systems 3-1

3.1.1 Main switch 3-2

3.1.2 Overload protection switch 3-2

3.2 Security measures of the operator 3-3

4 Delivery, transportation, storage 4-1

4.1 Delivery 4-1

4.2 Transportation 4-1

4.3 Storage 4-2

5 Installation 5-1

5.1 Technical data 5-1

5.2 Mechanical installation 5-2

5.2.1 Unpack and put up 5-2

5.2.2 Connection of air supply 5-2

5.2.3 Electrical installation 5-3

5.3 First putting into operation 5-4

6 Operation of the machine 6-1

6.1 Controls and indicators 6-1

6.1.1 Operating device 6-2

6.1.2 Reset key 6-3

6.1.3 Main switch 6-3

6.2 Operation 6-3

6.2.1 Machine sequence 6-3

6.2.2 Program operation 6-4

6.2.3 Select a program 6-5

Page 0-1

Page 4

Operating manual Automatic single head serging unit 1220/4

6.3 Create own programs 6-5

6.3.1 Enter machine code 6-6

6.3.2 Set language 6-6

6.3.3 Adjust setup data 6-6

6.3.4 Use of the storage module 6-13

6.4 Height adjustment of the contour guiding 6-17

6.5 Short operating instructions for the

sewing head 6-18

6.5.1 Adjust height of needle pole 6-18

6.5.2 Distance of the left grab to the needle 6-20

6.5.3 Distance of the right grab to the needle 6-22

6.5.4 Rear needle protection 6-24

6.5.5 Front needle protection 6-26

6.5.6 Position of the transporter 6-28

6.5.7 Transporter height 6-29

6.5.8 Stroke of the presser foot 6-30

6.5.9 Presser foot 6-32

6.5.10 Upper knife 6-34

6.5.11 Bottom knife 6-35

6.5.12 Thread regulation for ‘Überwendlich’ grab 6-36

6.5.13 Oil filter changing 6-37

6.5.14 Oil changing 6-38

7 Cleaning and maintenance 7-1

7.1 Maintenance of the machine 7-1

7.1.1 Water separator at air connector 7-2

7.1.2 Oil level in the sewing head 7-2

7.1.3 Check the drive belt 7-3

7.2 Required cleanings 7-3

Page 0-2 © Beisler GmbH, Hösbach

Page 5

Chapter 1: Security advice and warning hints

1 Security advice and warning

hints

1.1 Classification

Three different types of hints are used in this manual, which are

indicated with different symbols and signalling words:

DANGER

This indicates a possibly dangerous situation or action, which may

cause injuries to persons or severe damage to the machine.

ATTENTION

This indicates a situation or action, which may cause damage to the

machine.

Hint

This indicates hints for a better use and other helpful information or

hints.

Please obey all rules and regulations.

Page 1-1

Page 6

Operating manual Automatic single head serging unit 1220/4

1.2 Range of validity

This operating manual is valid for Automatic single head serging units

manuactured by the Beisler GmbH named „Automatic single head

serging unit 1220/4“.

This operating manual is not valid for the sewing head applied in the

machine. Please refer to the operating manual of the sewing head

delivered with the machine, for which we don’t take any liability.

Further security advice (verbal and written) for this machine or the

components will not be repealed by this manual.

1.3 Authorized person

DANGER

Danger might arise for persons, things and environment by

inappropriate operation of this machine. Installation and maintenance

duties may only be carried out by authorized staff.

Persons are regarded as authorized, who are able to recognize possible

danger and judge the assigned duties from their technical education

and experience.

Page 1-2 © Beisler GmbH, Hösbach

Page 7

Chapter 1: Security advice and warning hints

1.4 General security advice and warning hints

DANGER

Danger might arise for persons, things and environment by

inappropriate operation of this machine. Installation and maintenance

duties may only be carried out by authorized staff.

GEFAHR

Danger of injuries in the range of the sewing head! Don’t grasp into

the affected area of the needle during the sewing process.

DANGER

Before any operations at or with the machine (putting into operation,

operation, maintenance, repair, etc.) the person carrying out has to

read and understand this manual with each appendix completely.

DANGER

Before carrying out maintenance or repair duties, the mains supply

must be cut off. Additionally pressure must be released from the pneumatical system.

ATTENTION

The machine will be destroyed by a connection to a wrong mains

voltage! See the section ‘Technical data’ before connecting the power

supply.

Page 1-3

Page 8

1.5 Copyright

© 1997-99 Beisler GmbH, Hösbach

Automatic single head serging unit

The Automatic single head serging unit 1220/4 and this operating

manual with all parts are protected on copyright. Manufacture without

license will be prosecuted by law. All rights reserved on this operating

manual, including reproduction in any thinkable way, either by

copying, printing, on any data recording media or in translated form.

Reproduction of this operating manual - even in extracts - only with

written approval by Beisler GmbH.

This operating manual contains a description of the product, but no

promise of certain qualities or results of use. The operating manual has

been proved before delivery. The Beisler GmbH takes the liability,

that this operating manual if free of errors reducing its value for the

estimated use. The editors don’t take liability for consecuting damage

arising through application of the operating manual. We are always

thankful for hints and ideas.

Operating manual Automatic single head serging unit 1220/4

The technical standard of the common delivery of product and

operating manual by the Beisler GmbH is decisive, if not other

information is given. Technical changes without prior notice are

reserved, previous operating manuals loose validity.

The general conditions of sales and delivery of the Beisler GmbH are

valid.

Do you have questions or problems with installation or putting into

operation? Don’t hesitate to call us:

Beisler GmbH

Frohnradstr. 10

D-63768 Hösbach

Tel: (+49) 6021 / 50 19 0

Fax: (+49) 6021 / 50 19 10

Page 1-4 © Beisler GmbH, Hösbach

Page 9

Chapter 2: Preliminary remarks

2 Preliminary remarks

2.1 Introduction

This operating manual adresses to the operator of the machine, that is

the person that works with the machine. It is not a technical manual.

Please ask questions exceeding the contents of this operating manual

to our service staff.

ATTENTION

All service and maintenance duties at this machine may only be carried

out by qualified staff (qualified electrical employee or electrotechnical instructed person according to IEC 364 and DIN EN 60204-

1). Machine operation may only be carried out by an instructed person,

who had read and understood this operating manual completely.

ATTENTION

Any structural changes to the machine, either electrically,

mechanically or regarding the machine control, are suspect to the

responsibility of the machine owner.

The following documents are part of the documentation of the

Automatic single head serging unit 1220/4:

1. Electrical wiring pans

2. Parts list

3. Operating manual of the sewing head

Please check the documents delivered with the machine for

completeness.

Page 2-1

Page 10

Operating manual Automatic single head serging unit 1220/4

2.2 Limitation of liability

We guarantee the faultless functioning of our product in accordance

with our advertising, the product informations edited by the Beisler

GmbH and this manual. Further product-features are not guaranteed.

We take no liability for the economy and faultless function if the

product is used for a different purpose then that described in the

chapter "Use as agreed".

Compensation claims are generally impossible, except if intention or

cul-pable negligence by the Beisler GmbH is proved, or if assured

product-features are not provided. If this machine is used in

environments, for which it is not suited or which do not represent the

technical standard, we are not responsible for the consequences.

We don't accept responsibility for damages at installations and systems

in the surroundings of this machine, which are caused by a fault of the

product or an error in this manual.

We are not responsible for the violation of patents and/or other rights

of third persons outside the Federal Republic of Germany.

We are not liable for damages, which result from improper operations

according to this manual. We are not liable for missed profit and for

consecuting damages due to non-regardance of security advices and

warning hints. We don't accept liability for damages which resulted

from the use of tools and accessoires which are not delivered and/or

approved by the Beisler GmbH.

The products of the Beisler GmbH are designed for a long life. They

represent the standard of technique and science and were checked on

all functions individually before delivery. The electrical construction

corresponds to the current norms and regulations, particularly DIN

5713 / VDE 0113. Beisler GmbH is doing product and market

research for the further development and permanent improvement of

their products. In the case of faults and/or technical trouble please

contact the Beisler GmbH service staff. We assure that suitable

measures will be done immediately.

The Beisler GmbH guarantee regualtions are valid, which we will send

to you on demand.

Page 2-2 © Beisler GmbH, Hösbach

Page 11

Chapter 2: Preliminary remarks

2.3 Guarantee regulations

We guarantee the fault-free functioning of the Automatic Single Head

Serging Unit, Series 1220/4 according to this operating manual except

the tools for a time range of six months after delivery. If the machine is

used in double- or triple-shift operation, the term of guarantee is

reduced to three or two months.

The term of guarantee starts with the date of delivery to the customer,

independant from the time of putting into operation. Guarantee will be

spoiled, if the machine isn’t installed and operated according to this

operating manual and the regulations given by the Beisler GmbH staff.

A cost-free repair is only possible, if all regulations considering

storage, transportation and putting into operations have been obeyed.

Customers and third persons may only mesh with the machine after

getting a written approval by the Beisler GmbH. The Beisler GmbH

takes no responsibility for injuries and damages arising from nonobeyance of this stipulation. All warranty will be spoiled in this case.

The Beisler GmbH takes no responsibility for faults of the machine as

consequence of defective or functional faulty equipment in the

surrounding of the machine or by the use of accessoires, which were

not delivered by the Beisler GmbH.

The general conditions of sale and delivery of the Beisler GmbH are

valid.

Page 2-3

Page 12

2.4 Use as agreed

The Automatic Single Head Serging Unit, Series 1220/4 has been

developed for the serging of trouser parts. The machine overcasts side

and crotch sews at front and back trousers and stacks the manufactured

parts automatically.

DANGER

This machine has been developed and build for a certain purpose.

Adaptions may influence security equipments negatively. We

recommend to contact our service staff in such a case.

Operating manual Automatic single head serging unit 1220/4

2.5 Description of the machine

The Automatic Single Head Serging Unit, Series 1220/4 allows the

serging of trouser parts. Side and crotch sews can be overcasted

automatically, while the overlapping is nearly complete.

All components of the machine are mounted on a base frame made of

square steel pipes and controlled by an innovative micro-processor

system.

Machine operation is achieved with an operation device. Here you can

open several control programs, define new programs and check all

machine components individually for maintenance and repair duties.

Page 2-4 © Beisler GmbH, Hösbach

Page 13

Chapter 2: Preliminary remarks

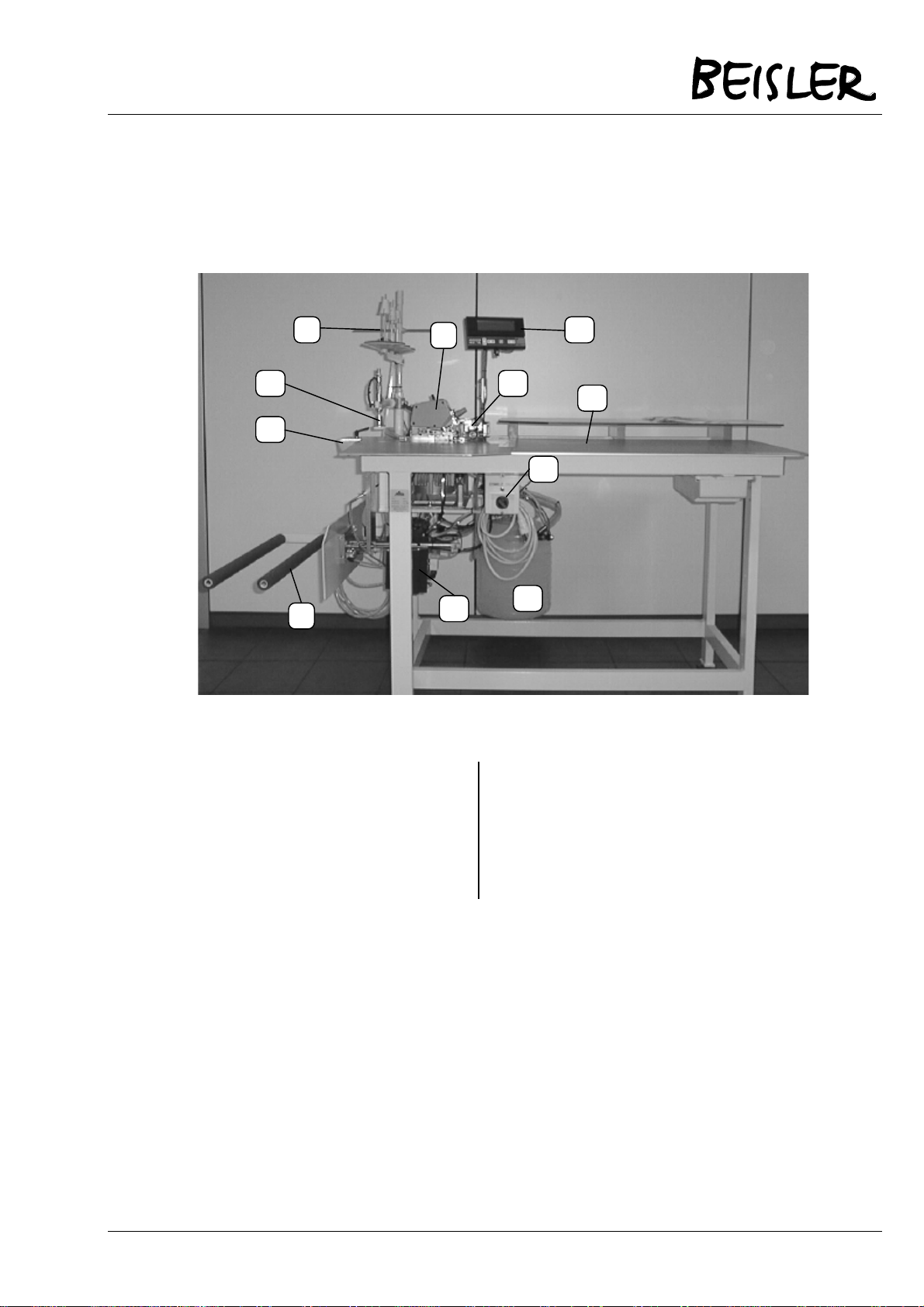

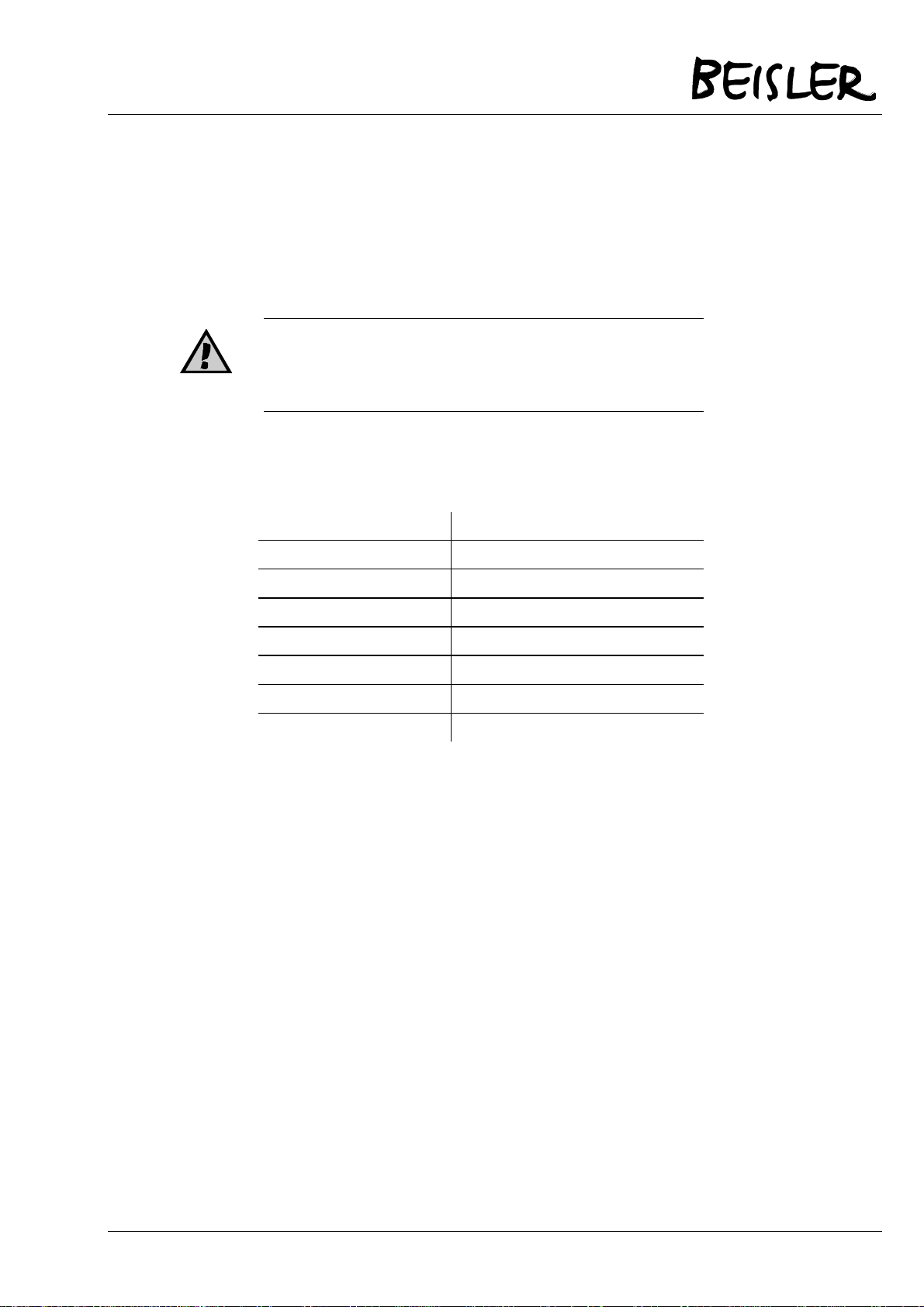

2.6 Major parts of the machine

L

K B

J

H

Pict. 1 Major parts of the machine

A Sewing head G Motor

A

G

F

C

D

E

B Contour guide H Stacker clamp

C Operation device J Blade with clamp lever

D Working table K Stamp

E Main switch L Spool rack

F Waste container

Further information on the components are contained in the coming

chapters.

Page 2-5

Page 14

Operating manual Automatic single head serging unit 1220/4

Page 2-6 © Beisler GmbH, Hösbach

Page 15

Chapter 3: Security

3 Security

The topic of this chapter is the security exclusively. Please see chapter

1 for the general security advice and warning hints and the security

and warning hints in the other chapters of this operating manual.

3.1 Available security systems

DANGER

Check all security systems daily for functioning and effectivity. The

machine may not be put into operation if the security systems and

installations hasn’t been checked previously.

DANGER

Changes to the machine may influence function and effectivity of the

security systems negatively.

Page 3-1

Page 16

Operating manual Automatic single head serging unit 1220/4

C

A

B

Pict. 2 Available security systems

A Main switch B Motor overload protection

3.1.1 Main switch

The main switch is located at the front side of the machine below the

working table. It is used to cut off the machine’s power supply.

3.1.2 Overload protection switch

If the motor is overloaded, the automatic protection switch reacts and

stops the sewing process. Check and repair the reason for the

overloading and put the machine into the starting position then.

switch

Page 3-2 © Beisler GmbH, Hösbach

Page 17

Chapter 3: Security

3.2 Security measures of the operator

The security systems of this machine work passively, that means that

they can only react on certain incidents. To achieve the required

security for your health and that of your collegues, active measures of

the operator are required.

Please obey the following general rules for the use of this machine:

1. Always work concetrated and avoid actions with a risk.

2. Don’t try to bridge existing security systems or to disable

them in any way.

3. Check all security systems on function and effectivity

before starting work.

4. Cut off the power supply before opening the power supply

unit.

5. Switch off the machine with the mains / emergency stop

switch, before executing cleaning and mainetenance duties.

Page 3-3

Page 18

Operating manual Automatic single head serging unit 1220/4

Page 3-4 © Beisler GmbH, Hösbach

Page 19

Chapter 4: Delivery, transportation, storage

4 Delivery, transportation, storage

4.1 Delivery

Hint

Check right after receiving the machine, whether all parts according to

the parts list are complete and without damage. Later claims can’t be

accepted.

If you see damage to the transportation packing of the machine, which

indicates a possible damage to the delivered parts, don’t hesitate to

claim this to the transportation company.

4.2 Transportation

Generally it is possible to move the machine. Obey the following

hints:

1. Cut off the power supply, release the pneumatical pressure.

2. Fix movable and loose parts.

3. Lift the base with a hoisting device and be sure to lift

possible additional devices (e.g. stacker). If the machine is

equipped with transportation casters (option), you will have

to release the brakes at every caster.

4. Move the machine carefully to the new location.

ATTENTION

Attention when moving the machine on sloping areas! Enormous pull

power arises from the machine weight.

Page 4-1

Page 20

4.3 Storage

If no other agreement is fixed, the following limitations have to be

kept:

1. In closed rooms only.

2. Temperature range -10 ... +45 °C.

3. Humidity max. 80% non-condensing.

ATTENTION

If stored or transported in improper environments, the machine can be

damaged severely. Damages may not be visible from the outside.

Operating manual Automatic single head serging unit 1220/4

Page 4-2 © Beisler GmbH, Hösbach

Page 21

Chapter 5: Installation

5 Installation

ATTENTION

Installation and putting into operation may only be carried out by

mechanically and electrically qualified staff. These people must read

and understand the complete operating manual before starting.

5.1 Technical data

Dimensions

Table height

Weight

Mains power

Power consumption

req. air pressure

req. air quality

Air consumption

1750 x 860 x 1700 mm (L x W x B)

940 mm, adjustable

120 kg

220 V AC

0,7 kW

6 bar

oil-free

20 NL/WD

Page 5-1

Page 22

Operating manual Automatic single head serging unit 1220/4

5.2 Mechanical installation

ATTENTION

Check before starting the installation, whether the desired location

meets the requirements (see chapter 5.1, technical data). This is very

important regarding the stability of the ground.

5.2.1 Unpack and put up

1. Remove the packing material and possible transportation

protections.

2. Position the machine on a solid and horizontal ground.

3. Level the machine to a horizontal stand using the adjustable

frame feet.

5.2.2 Connection of air supply

B

A

Pict.. 3 Connection of air supply (machine backside)

C

Page 5-2 © Beisler GmbH, Hösbach

Page 23

Chapter 5: Installation

1. Connect the air pipe (A) to your air system.

2. Open the air supply of your air system.

3. Level the air pressure to 6 bar using the control (B); the air

pressure can be read at the scale (C).

ATTENTION

We recommend to switch off the air supply when the machine is not in

duty. Use the black control (B in Pict. 3).

5.2.3 Electrical installation

Hint

All work at the electrical components of the machine may only be

carried by qualified staff (qualified electrical employee or instructed

person according to IEC 364 and DIN EN 60204-1).

DANGER

Parts under electrical current! Without cutting off the power supply,

you might be injured severely. Please obey the security advice given in

chapter 1.

ATTENTION

The machine will be destroyed by connecting to a wrong mains

voltage! Check, whether the requirements from chapter ‘Technical

data‘ meet the local conditions.

1. Use the power cord located at the backside of the machine.

2. Plug it into a socket.

3. Lay the cord in a way, that the danger of stumbling is

avoided.

Page 5-3

Page 24

Operating manual Automatic single head serging unit 1220/4

DANGER

Danger to life from unsufficient grounding! Do a grounding according

to DIN EN 60204-1.

5.3 First putting into operation

This machine has been configured to the individual requirements of

the customer. The first putting into operation can be done easily:

1. Adjust the machine to a horizontal stand.

2. Connect power and air supply.

3. Switch on the machine using the mains / emergency stop

switch at the front side of the machine.

4. Check all security systems for function and efficiency.

DANGER

The machine may only be used for production purposes, after the

security systems have been checked. If a security doesn’t work

adequately, it must be repaired first.

As a factory setting, several production programs are contained in the

buffer of the machine. You may use one of them or create your own

programs.

Page 5-4 © Beisler GmbH, Hösbach

Page 25

Chapter 6: Operation

6 Operation of the machine

DANGER

This machine may only be operated by qualified staff, who had read

and understood this operating manual completely.

6.1 Controls and indicators

A

B

C

Pict. 4 Controls and indicators

A Operating device C Main switch

B Reset key

Page 6-1

Page 26

6.1.1 Operating device

During production the machine can be operated with the operating

device; existing programs can be called and new programmed. You

will find the program stop button at the device.

Operating manual Automatic single head serging unit 1220/4

A

B C D

Pict. 5 Operating device

Display

A

Cursor keys

B

Special key

C

Minus / plus keys

D

The elements of the operating devices have the following occupations:

Display: all information required for the operation of the

machine are indicated here.

Cursor keys: use them to move the cursor and mark all

required commands and options.

Special key: press this key if additional information are

required for a setting.

Minus / plus key: are used to switch on/off functions, to increa-

se/reduce numerical values and to select programs.

Page 6-2 © Beisler GmbH, Hösbach

Page 27

Chapter 6: Operation

6.1.2 Reset key

The reset key can be used to reset a program, if an error occured

during insertion for a pre-seam. Insert the trouser part again and

execute the pre-seam.

The reset key is only enabled if it is pressed before the main seam.

6.1.3 Main switch

Use the main switch to enable/disable the power supply of the

machine.

6.2 Operation

6.2.1 Machine sequence

A

Pict. 6 Sewing area

B

C

Page 6-3

Page 28

Operating manual Automatic single head serging unit 1220/4

The production cycle of the machine is divided into several sections:

1. The operator inserts a trouser part from the right side (see

white arrow in Pict. 6) under contour guiding (C) and photo

cell (B).

2. After photo cell (B) switched dark, the sewing process starts

(needle Pos. (A) in Pict. 6); the contour guiding will be

lowered.

3. The trouser part will be sewed.

4. After the photo cell (B) switches light, the seam will be

ended and the stamp comes down.

5. The contour guiding drives up.

6. The stacker clamp advances to the front.

7. The stamp drives up.

8. The trouser part is stacked with an air-blow.

6.2.2 Program operation

The machine is operated with programs, which are stored in the

memory and can be opened by the operator. He can choose from

several possibilities:

he can select an existing program

he can change an existing program

he can create and adjust a new program

All possibilities will be explained in the following.

Page 6-4 © Beisler GmbH, Hösbach

Page 29

Chapter 6: Operation

6.2.3 Select a program

In the daily production process, the machine operator will only have to

select an existing program. The following programs exist as a factory

setting:

Program 1: 1 main seam

Program 2: 1 pre-seam with consecutive main seam

Program 3: 2 pre-seams with consecutive main seam

Program 4: 2 pre-seams, 1 seat seam with consecutive main

seam

Program 5: 1 seat seam, 2 pre-seams with consecutive main

seam

Program 6: 1 main seam without stop after photo cell lighted

The currently selected program is displayed in the left upper corner of

the display (program 1 is selected in Pict. 5).

To select a different program, you have to move the cursor on the

program number and press the ‘+’ / ‘-‘ keys repeatedly, until the

desired program number is displayed.

6.3 Create own programs

ATTENTION

The changing and creation of programs should be done by

experienced personell. The functionality of the machine can be

influenced badly by wrong programming.

Hint

All functions and options are displayed as icons in a rectangle in the

programs. Generally, a rectangle striked out twice means: function

disabled. If the rectangle isn’t striked out, the function is enabled.

To create an own program, you will first have to adjust the setup data

and then create the program. Setup data can only be displayed, if the

machine code has been entered before:

Page 6-5

Page 30

6.3.1 Enter machine code

ATTENTION

The machine code protects from unauthorized access to the setup

data. Wrong setup data affect the functionality of the machine

negatively. The machine code should not be accessible to unauthorized persons.

1. Move the cursor to the program number using the keys

.

Operating manual Automatic single head serging unit 1220/4

2. Press the key

3. Press the key

the key symbol.

4. Press

5. Press

disappears.

6.3.2 Set language

If you want to work with a different operation language, you can select

this on page „Setup -00“:

1. After entering the machine code, press

desired operation language using

2. Press

6.3.3 Adjust setup data

The setup data of this machine are contained on the pages ‘-01’, ‘-02’,

‘-03’ and ‘-10’:

repeatedly, until „Setup -00“ is displayed.

to place the cursor on the first ‚x‘ below

three times to change all ‘x’ to ‘0’.

to confirm the entered code. The key symbol

and select the

.

to place the cursor on „Setup -00“ again.

Page -01: machine type

Page -02: motor functions

Page -03: machine functions

Page -10: in- and outputs (switch on/off, program)

Use the

Page 6-6 © Beisler GmbH, Hösbach

key to select the page where you want to do changes.

Page 31

Chapter 6: Operation

6.3.3.1 Page -01: machine type

Press the

key after entering the machine code, until the setup page

-01 is displayed:

The machine type is a factory setting and may not be

changed. The selected type is marked with an arrow in

the list of available machine types.

6.3.3.2 Page -02: motor functions

After entering the machine code, press the

page -02 is displayed:

Motor functions like position actor, motor parameters

(turn direction, revs, a.s.o.) and pedal funtions.

The motor functions that can be changed on this setup page, are

gathered in three groups:

Turn direction, position actor

Place the cursor on this symbol and press the

special key. Now adjust the turn direction and

the needle-zero and -top position.

Motor parameters:

Here you can adjust revs and belt disc diameter.

key twice, until setup

Pedal functions:

Here you can assign several functions to the

pedal (not required here and therefor

deactivated).

Press the key until the desired symbol is marked and then the

key to open the adjustments.

Page 6-7

Page 32

Adjust turn direction

Operating manual Automatic single head serging unit 1220/4

Mark the symbol ‘Position actor’

Press the

SETUP-02

After opening the page, the cursor is placed on the icon of

the turn direction. Press the

turn direction (viewed on the belt disc).

Adjust needle zero and top position:

Use the arrow keys to move the cursor towards the right on

the zero position of the needle.

Turn the hand wheel of the sewing head some turns with

impetus, until the below the icon of the turn direction

changes.

Continue turning the hand wheel, until the needle top stands

at the upper edge of the stitch plate.

Press the

displayed in the needle position rectangle.

Use the arrow keys to move the cursor up on the symbol „II

Pos.“ and turn the hand wheel in turn direction, until the

needle stands in the desired top position.

Read the value displayed below the turn direction icon and

use the

Pos.“.

Move the cursor downwards on „I Pos.“ and enter the value

‚115‘ here.

Press the

key to enter this value into the rectangle of „II

.

key; the following will be displayed:

--290

0

115

key to accept the position. A ‚0‘ will be

key to close the page.

III POS.

II POS.

0

I POS.

key to select the desired

Page 6-8 © Beisler GmbH, Hösbach

Page 33

Chapter 6: Operation

Set motor parameters:

SETUP-02

RESET

MIN.:

MAX.:

Mark the symbol „Motor parameters“

Press the

key until the following will be displayed:

.

MIN.: 400

MAX.: 8000

[ 4500]

RESET

ON

5400

Pull: 75

100%

ACC.

67

Use the keys to mark the different values in

the window.

Use the

must be set to ‘ON’.

minimum revs of the sewing head; 400 is the optimized

value.

maximum revs of the sewing head:

Pegasus S52: 8000

keys to adjust the desired values:

80%

DEC.

PUL.:

ACC.:

DEC.:

KP:

mounted belt drive disc size; must be set to ‘75’

acceleration curve; must be set to ‘100%’

decrease parameter: must be set to 80%

add. motor break; must be set to 16

Press the key to close the page.

Page 6-9

Page 34

Operating manual Automatic single head serging unit 1220/4

6.3.3.3 Page -03: Machine functions

After entering the machine code, press

page -03 is displayed:

SETUP

-03

A

three times, until setup

S

Here you can edit several functions of the machine. Only four of them

are relevant for this machine:

Presser foot lifting:

Here, several time and voltage values for the

lifting, holding and lowering of the presser foot

can be adjusted.

Light barrier (Photo cell mode):

Here you can adjust several options for the

light barrier.

To adjust one of the machine functions, select the desired symbol

using the

‘Presser foot lifting’ is selected. Now press the

settings of the selected machine function.

Adjust presser foot lifting:

After selecting the symbol of the presser foot lifting and opening the

adjustment page, the following will be displayed:

keys. In the drawing shown above, the symbol

key to open the

Page 6-10 © Beisler GmbH, Hösbach

Page 35

Chapter 6: Operation

SETUP-02

30V

(max)

15 V

[ms]

150

00

120

Move the cursor on the time of maximum power (left value

in the lower line) and use the Plus-/Minus-keys to set the

value ‚150‘. This time is sufficient for the presser foot to be

lifted safely at seam end.

Move the cursor on the value with the holding voltage

(middle of the upper line) and set the value ‚15V‘. This

assures that the magnet valve of the foot lifting will not be

overloaded.

Move the cursor on the value of the start delay (lower line,

right value) and set ‚120‘ ms here. This time is needed that

the pressure foot rests safely on the fabrics after switching

the photo cell dark before sewing starts.

Move the cursor on the two presser foot icons on the right

of the display and use the Plus-key to set both on ‚presser

foot up‘ like shown in the drawing.

Press the

key to close the page.

Set light barrier (photo cell mode):

Use the arrow keys to select the symbol of the light barrier

then use the

press the

key to switch the photo cell to „switching dark“. Now

key.

and

After executing all settings on setup page –02, move the cursor on the

page number –02 and press the Minus-key to select setup page –10,

where you can activate and set inputs and outputs.

Page 6-11

Page 36

Operating manual Automatic single head serging unit 1220/4

6.3.3.4 Page -10: Inputs and outputs

Inputs a switches and keys and are named ‘M1’ ... ‘M6’. Outputs are

all available magnet valves and are named ‘F1’ ... ‘F7’.

The programmin of an input/output is done in three steps:

1. Switch on or off.

2. Set start mode.

3. Set time values.

The inputs and outputs are occupied as follows:

I/O Valve description Connector

Y0 Lift sewing foot A-1

F1 Y2 Table blowing A-3

F2 Y3 Contour guiding A-5

F3 Y13 Sucking nozzle A-5

F4 Y4 Contour roll A-7

F5 Y5 Kett-up A-9

F6 Y6 Holding stamp A-11

F7 Y7 Stacker impulse A-13

M1 Reset key below the operation device Pin 2-4

After you have selected setup page -10, the following will be

displayed:

SETUP

F5

F6

-10

F1

M1

F2

F3

M3M2

F4

M4

M5

F7

M6

Page 6-12 © Beisler GmbH, Hösbach

Page 37

Chapter 6: Operation

Use the keys to select the desired input/output and

switch them on/off using the

input/output switched off is crossed with two lines (M2-M6 in the

drawing).

6.3.4 Use of the storage module

A storage module KK195 is delivered together with the machine, on

which the factory-set programs and parameters are contained. After

replacing the machine control or a total loss of data, they can be read

into the machine.

You can save you individual sewing programs on an additional storage

module, to protect them from being lost. Storage module are available

from Beisler.

keys. The symbol of and

6.3.4.1 Re-load standard programs

The standard programs can be reloaded easily:

1. Switch off the machine using the mains switch.

2. Plug the storage module into the corresponding slot in the

operating device. This can be found at the right side of the

device.

3. Switch on the machine and use the

mark the entry ‘Setup / All programs’.

4. Press the

key.

5. The data will be read into the machine control.

6. Pull out the storage module. Now you will have to set the

needle position again (see section 6.3.3.2).

7. Then the machine is ready for sewing, sewing program 001

will be displayed.

keys to

Page 6-13

Page 38

Operating manual Automatic single head serging unit 1220/4

6.3.4.2 Save setup data on the storage module

1. Select the page ‚Setup –00‘.

2. Enter the access code (see section 6.3.1).

3. Move the cursor completely to the right onto the letter ‚W‘

(= write).

4. Plug the storage module KK195 into the slot on the right

side of the operating device.

5. Press the Plus-key to copy the setup data from the control

on the storage module.

6. Press the Special-key to terminate the procedure.

6.3.4.3 Read setup data into the machine control

1. Select the page ‚Setup –00‘.

2. Enter the access code (see section 6.3.1).

3. Move the cursor completely to the right onto the letter ‚R‘

(= read).

4. Plug the storage module KK195 into the slot on the right

side of the operating module.

5. Press the Plus-key to read the setup data from the storage

module into the machine control.

6. Press the Special-key to terminate the procedure.

6.3.4.4 Copy all sewing programs on the storage module

1. Select the page ‚Index 000‘.

2. Enter the access code (see section 6.3.1).

3. Press the Special-key.

4. Plug a storage module into the slot on the right side of the

operating device.

5. Move the cursor on the letter ‚W‘ (= write).

6. Press the Plus-key to copy all sewing on the storage

module.

7. Press the Special-key to terminate the procedure.

Page 6-14 © Beisler GmbH, Hösbach

Page 39

Chapter 6: Operation

6.3.4.5 Read all sewing programs into the machine control

ATTENTION

Before you read all sewing programs into the machine control, you

will first have to delete all sewing programs in the control. This

cannot be undone.

1. Select the page ‚Index 000‘.

2. Enter the access code (see section 6.3.1).

3. Press the Special-key.

4. Plug the storage module into the slot on the right side of the

operating device.

5. Move the cursor on the letters ‚PRG‘.

6. Press the Plus-key twice to delete all sewing programs from

the machine control.

7. Move the cursor on the letter ‚R‘ (= read).

8. Press the Plus-key to copy all sewing programs from the

storage module into the machine control.

9. Press the Special-key to terminate the process.

6.3.4.6 Copy single sewing programs on the storage module

Hint

To save single sewing programs, a separate storage module is

required for each sewing program to be saved.

1. Select the program, which you want to copy on the storage

module.

2. Press the Special-key.

3. Move the cursor on the letter ‚W‘ (= write).

4. Plug an empty storage module into the slot on the right side

of the operating device.

5. Press the Plus-key to write the program data to the storage

module.

6. Press the Special-key to terminate the process.

Page 6-15

Page 40

Operating manual Automatic single head serging unit 1220/4

6.3.4.7 Copy single sewing programs into the machine control

Hint

Before program data can be copied into the control, the data of the

desired program location must be deleted before. This cannot be

undone.

1. Select the program page, where you want to copy the

program data to.

2. Press the Special-key.

3. Move the cursor on the letters ‚PRG‘.

4. Press the Plus-key twice to delete possible program data

stored on the selected memory location.

5. Move the cursor on the letter ‚R‘ (= read).

6. Plug the storage module into the slot on the right side of the

operating device.

7. Press the Plus-key to write the program data into the

machine control.

8. Press the Special-key to terminate the process.

Page 6-16 © Beisler GmbH, Hösbach

Page 41

Chapter 6: Operation

6.4 Height adjustment of the contour guiding

The contour guiding achieves an evenly positioning of the trouser part

below the sewing head. Dependant on the thickness of the

manufactured cloth, the height of the contour guiding can be adjusted:

A

Pict. 11 Contour guiding height adjustment

1. Pull the adjusting wheel (A) a little backwards.

2. Set it to one of the four engage,emt position (1 = smallest

height, 4 = biggest height).

Page 6-17

Page 42

Operating manual Automatic single head serging unit 1220/4

6.5 Short operating instructions for the

sewing head

ATTENTION

The short operating instructions provided here are an excert of the

complete operating manual of the sewing head. This operating

manual must be read completely and all instructions must be obeyed.

The Beisler GmbH takes no responsibility for the correctness of the

following.

6.5.1 Adjust height of needle pole

The distance between needle top and stitch plate should be 9,7 to 9,9

mm in the upper endpoint.

Pict. 12 Adjust height of needle pole (1)

Page 6-18 © Beisler GmbH, Hösbach

Page 43

Chapter 6: Operation

Pict. 13 Adjust height of needle pole (2)

Pict. 14 Adjust height of needle pole(3)

1. Turn off the cover screws (1) and remove the cover (2).

2. Move the needle pole to the upper position by moving the

hand wheel.

3. Swing out the sewing foot and insert a new needle.

Page 6-19

Page 44

Operating manual Automatic single head serging unit 1220/4

4. Loosen screw (3) until the needle pole can be pushed hardly

only.

5. Push the needle pole that the distance between needle top

and stitch plate is 9.7 to 9.9 mm.

6. Tighten screw (3) in this position.

7. Fix the cover (2) again.

6.5.2 Distance of the left grab to the needle

Pict. 15 Distance of the left grab (1)

Pict. 16 Distance of the left grab (2)

Page 6-20 © Beisler GmbH, Hösbach

Page 45

Chapter 6: Operation

Pict. 17 Distance of the left grab (3)

6.5.2.1 Crosswise to the sewing direction

The distance between mid of the needle and grab top should be 2.3 to

2.5 mm on the left change point.

1. Remove the stitch plate, front transporter and the front and

rear needle protection.

2. Move the grab into its left change point.

3. Loosen screw (1) and move the grab to the stop (2).

4. Tighten screw (1).

5. Loosen screw (3) a little that the grab carrier (4) can be

turned hardly.

6. Turn the grab carrier that the distance between mid of

needle and grab top is 2.3 to 2.5 mm.

7. Do not tighten screw (3) yet.

6.5.2.2 In seam direction

The distance between grab top and needle should be 0 to 0.05 mm.

1. Turn the hand wheel in turn direction until the grab top

stands exactly in the middle of the needle.

2. Push the grab carrier (4) that the distance between grab

carrier and needle is 0 to 0.05 mm.

3. Check the adjustment crosswise to the seam direction;

possibly do some additional adjustments.

4. Tighten screw (3).

Page 6-21

Page 46

Operating manual Automatic single head serging unit 1220/4

6.5.3 Distance of the right grab to the needle

Pict. 18 Distance of the right grab to the needle (1)

Pict. 19 Distance of the right grab to the needle (2)

Page 6-22 © Beisler GmbH, Hösbach

Page 47

Chapter 6: Operation

Pict. 20 Distance of the right grab to the needle (3)

Pict. 21 Distance of the right grab to the needle (4)

6.5.3.1 Crosswise to the sewing direction

When the right grab stands in its upper change point, the distance

between grab top and middle of the needle should be 4.3 to 4.5 mm.

1. Remove thread guidings (1) (2) and cover (3).

2. Move the grab into its upper change position and loosen

screw (4) that the grab can be pushed hardly.

3. Push the grab that the grab shaft (5) stands levelled with the

side of the grab holder.

4. Loosen screw (6) a little.

5. Turn the lever (9) that there is a distance of 4.3 to 4.5 mm

between grab top and middle of the needle. Check that the

pole (7) moves easily in bearing (8).

6. Tighten screw (6).

7. Don’t tighten screw (4) now.

Page 6-23

Page 48

Operating manual Automatic single head serging unit 1220/4

6.5.3.2 In seam direction (to the left grab)

When the right grab crosses the left, distance ‘A’ shall be 0.5 mm and

distance ‘B’ 0.2 mm.

1. Turn the hand wheel in turn direction until the right grab

crosses the left.

2. Turn and push the right grab, that distance ‘A’ is 0.5 mm

and distance ‘B’ 0.2 mm.

3. Tighten screw (4) in this position.

4. Check all adjustements again and readjust them if required.

5. Mount threat guidings (1) (2) and cover (3).

6. Adjust the threat guidings according to the chapter ‘Threat

regulation of the ‘Überwendlich’ grabber’.

The right ‘Überwendlich’ grab depends on the thickness of the needle.

Use the grab with indication number 28 for needles 60-80 NM and

number 22 for needles 80-100 NM.

6.5.4 Rear needle protection

Pict. 22 Rear needle protection (1)

Page 6-24 © Beisler GmbH, Hösbach

Page 49

Chapter 6: Operation

Pict. 23 Rear needle protection (2)

Pict. 24 Rear needle protection (3)

When the top of the left grab stands in the middle of the needle, the

needle protection ((2) in Pict. 23 and (3) in Pict. 24) should push the

needle in a way, that a distance of 0 to 0.05 mm exists between grab

top and needle.

Page 6-25

Page 50

6.5.4.1 Movable versions

1. Turn the hand wheel in turn direction, until the grab top

stands in needle direction.

2. Loosen screw (1) and push the needle protection (2) in a

way, that there is a distance of 0 to 0.05 mm between grab

top and middle of the needle.

3. Tighten screw (4) in this position.

6.5.4.2 Fixed versions

1. Move the hand wheel in turn direction, until the grab top

stands in the middle of the needle.

2. Loosen screws (4) and push the needle protection (3) in a

way, that a distance of 0 to 0.05 mm exists between grab

top and middle of the needle.

3. Tighten screws (4) in this position.

Operating manual Automatic single head serging unit 1220/4

6.5.5 Front needle protection

Pict. 25 Front needle protection (1)

Page 6-26 © Beisler GmbH, Hösbach

Page 51

Chapter 6: Operation

Pict. 26 Front needle protection (2)

A distance of 0.03 to 0.05 mm should exist between needle protection

and needle in the bottom change point of the needle.

1. Turn the hand wheel in turn direction until the needle stands

in its bottom change point.

2. Loosen screw (1) and push the needle protection that there

is a distance of 0.03 to 0.05 mm between needle protection

and needle.

3. Tighten screw (1) in this position.

Page 6-27

Page 52

Operating manual Automatic single head serging unit 1220/4

6.5.6 Position of the transporter

Pict. 27 Position of the transporter (1)

Pict. 28 Position of the transporter (2)

The transporters should stand horizontally in their highest position.

Page 6-28 © Beisler GmbH, Hösbach

Page 53

Chapter 6: Operation

1. Remove cover (1) and cover plate (2).

2. Turn the hand wheel until the transporters stand in their

highest position.

3. Loosen screw (3).

4. Turn disc (4) that the transporters stand horizontally.

Consider that they may not be moved laterally.

5. Tighten screw (3) in this position.

6. Mount cover (1) and cover plate (2).

6.5.7 Transporter height

Pict. 29 Transporter height

When the transporters stand in their highest position, the cogs of the

main transporter (4) should stand 0.8mm, those of the differential

transporter (5) 0.9 to 1 mm and those of the additional transporters (6)

0.6 to 0.7 mm below the top edge of the stitch plate.

Page 6-29

Page 54

Operating manual Automatic single head serging unit 1220/4

1. Remove the stitch plate and loosen screws (1) (2) (3) a

little.

2. Turn the hand wheel until the transporters stand in their

highest positions.

3. Lay on the stitch plate.

4. Adjust the height of the transporters, that the cogs of the

main transporter stand 0.8mm, those of the differential

transporter (5) 0.9 to 1 mm and those of the additional

transporter (6) 0.6 to 0.7 mm above the top edge of the

stitch plate.

5. Tighten screws (1) (2) (3) in this position.

6. Mount the stitch plate.

6.5.8 Stroke of the presser foot

Pict. 30 Stroke of the presser foot (1)

Page 6-30 © Beisler GmbH, Hösbach

Page 55

Chapter 6: Operation

Pict. 31 Stroke of the presser foot (2)

Pict. 32 Stroke of the presser foot (3)

When the piston pole of the cylinder (7) is driven out, the lever (5)

should attach to screw (2) and the space between sewing foot and

stitch plate should be 5 mm. Additionally, a distance of est. 0.3 mm

should be between stop (11) and screw (10) in this position.

Page 6-31

Page 56

Operating manual Automatic single head serging unit 1220/4

1. Loosen nut (1) and turn screw (2) down completely.

2. Swing in the sewing foot and turn the hand wheel, until the

crogs of the transporter stand below the upper edge of the

stitch plate.

3. Loosen screw (3) and press ring (4) backwards til the stop.

4. Tighten screw (3) in this position. Be sure that ring (4) and

lever (5) show no axial play.

5. Press lever (6) down, until there is a distance of est. 5 mm

between sewing foot and stitch plate.

6. In this position you should bring screw (2) with lever (5) in

contact and fix them with nut (1).

7. If lever (5) gets no contact with screw (2) and piston pole of

cylinder (7) is driven out, loosen nut (8) and move cylinder

(7) correspondantly. Tighten nut (8) again.

8. Loosen screw (9).

9. Turn screw (10) in a way, that a distance of est. 0.3 mm is

between it and stop (11). Be sure that lever (6) is pressed

down to the stop.

10.Tighten screw (9) in this position.

6.5.9 Presser foot

Pict. 33 Presser foot (1)

Page 6-32 © Beisler GmbH, Hösbach

Page 57

Chapter 6: Operation

Pict. 34 Presser foot (2)

When the transporters stand in their lowest position, the presser foot

sole should stand up 0.1 to 0.2 mm in the front. Additionally, the hole

of the presser foot should be aligned with that of the stitch plate.

1. Bring the transporters into their lowest position.

2. Loosen screws (1) and (2).

3. Push the presser foot, that the stitch hole of the presser foot

is aligned with that of the stitch plate.

4. Tighten screws (1) and (2) in this position. Be sure that the

sole of the presser foot stands parallel above the stitch plate.

5. Adjust the presser foot by turning screw (3) in a way, that

the sole stands up 0.1 to 0.2 mm in the front.

Page 6-33

Page 58

6.5.10 Upper knife

Operating manual Automatic single head serging unit 1220/4

Pict. 35 Upper knife

In the lowest position of the knife, the front edge of the blade should

stand 0.5 to 1 mm below the upper edge of the stitch plate.

1. Bring the needle in its change point and swing out the

sewing foot.

2. Turn screw (1) out and take out the knife attachment (2)

completely with the knife.

3. Loosen screw (3) and take out the knife.

4. Insert a keen knife into the attachment (2) and fix screw (3)

a little.

5. Screw in knife attachment (2) with screw (1) a little.

6. Bring the knife in its lowest position.

7. Push the knife in a way, that it has a little contact to the

bottom knife and the front edge of the blade stands 0.5 to 1

mm below the upper edge of the stitch plate.

Page 6-34 © Beisler GmbH, Hösbach

Page 59

Chapter 6: Operation

8. Bring stops (4) and (5) in contact with the knife and tighten

screws (1) and (3).

9. Bring the knife into its highest position and loosen screw

(6).

10. Push the bottom knife attachment (7) to the left and let it

spring at the upper knife.

11.Tighten screw (6).

6.5.11 Bottom knife

Pict. 36 Bottom knife

The blade of the bottom knife should stand levelled with the upper

edge of the stitch plate.

1. Swing out sewing foot and cloth plate.

2. Loosen screw (1).

3. Push bottom knife attachment (2) to the left until the stop

and fix screw (1) a little.

4. Loosen screw (3) and remove the old knife.

Page 6-35

Page 60

Operating manual Automatic single head serging unit 1220/4

5. Insert a keen knife into the guiding (4) in a way, that the

blade stands levelled with the upper edge of the stitch plate.

6. Tighten screw (3) in this position.

7. Bring the upper knife into its highest position.

8. Loosen screw (1) and let the bottom knife attachment (2)

swing at the upper knife.

9. Tighten screw (1).

6.5.12 Thread regulation for ‘Überwendlich’ grab

Pict. 37 Thread regulation for ‘Überwendlich’ grab

The position of the threat guidings and pusher depends on the sewed

material, threat and stitch type. Therefore the following setting data

must be regarded as basic values.

1. Bring the right-handed grab into its upper change point.

2. Loosen screw (1) and push threat puller (2) in a way, that a

distance of est. 32 mm exists between screw-mid and loopmid.

Page 6-36 © Beisler GmbH, Hösbach

Page 61

Chapter 6: Operation

3. Tighten screw (1). Be sure that the threat puller (2) stands

vertically.

4. Loosen screws (3) and (4) a little.

5. Bring threat pullers (5) and (6) into the position shown in

Pict. 37.

6. Tighten screws (3) and (4) in this position.

7. Loosen screw (7) a little and bring the threat guiding (8)

into the position shown in Pict. 37.

8. Tighten screw (7) in this position.

9. Loosen screw (9) a little and push the threat guiding in a

way, that screw (9) stands in the middle of the long hole.

10.Tighten screw (9) in this position.

11.Adjust the threat pullers (5) and (6) in ‘+’ or ‘-‘ direction, if

more or less threat is necessary in the seam.

6.5.13 Oil filter changing

Pict. 38 Oil filter changing

Clean or change the oil filter every two years. Additionally, the oil

filter must be cleaned/changed, if the oil pressure indicator (5) doesn’t

move down while machine is working or the oil is polluted.

Reinigen bzw. wechseln Sie den Ölfilter alle 2 Jahre. Außerdem muß

der Ölfilter gereinigt/ausgetauscht werden, wenn Öldruckanzeiger (5)

sich bei laufender Maschine nicht nach unten bewegt oder das Öl

schmutzig ist.

Page 6-37

Page 62

1. Screw out screws (1) of the cover (2).

2. Turn a screw (1) into the filter and turn it out with it.

3. Clean the filter or change it.

4. Insert the seal (4), place the cover (2) and screw in screws

(1).

6.5.14 Oil changing

Operating manual Automatic single head serging unit 1220/4

Pict. 39 Oil changing (1)

Pict. 40 Oil changing (2)

Page 6-38 © Beisler GmbH, Hösbach

Page 63

Chapter 6: Operation

4 weeks after putting into operation and then every two years, the oil

of the sewing head must be changed.

1. Turn off release screw (1) and catch the oil in a receptacle.

2. Turn in release screw (1) again.

3. Turn off screw (2) and fill in oil, until the top of the oil

level indicator (3) has reached the upper mark in the oil

viewing glass (4).

4. We recommend Pfaff-sewing machine oil or oil with a

viscosity of 15 mm²/s at 50°C and a density of 0.865 g/cm³

at 15°C.

5. Turn in screw (2).

Page 6-39

Page 64

Operating manual Automatic single head serging unit 1220/4

Page 6-40 © Beisler GmbH, Hösbach

Page 65

Chapter 7: Cleaning and maintenance

7 Cleaning and maintenance

7.1 Maintenance of the machine

This machine works nearly free of maintenance. To achieve the

maximum ability of the machine for a long term, some regular

maintenance duties are required.

DANGER

Before starting maintenance and repair duties, the following power

down procedures are to be executed. Otherwise there could be

danger to life.

Cut off mains power

switch the mains / emergency stop switch to ‘0’ and assure

that it can’t be switched on

check whether the machine is without current and that there

is no statical loading

Switch off pneumatic system

close the main gauge

ventilate all pipes and gauges

Page 7-1

Page 66

Operating manual Automatic single head serging unit 1220/4

7.1.1 Water separator at air connector

Check the water separator (A) daily for

contained water. Release the water by

pressing the release button (B).

A

B

Pict. 41 Air maintenance

unit

7.1.2 Oil level in the sewing head

Pict. 42 Check oil level in the sewing head

Check the oil level in the sewing head regularly. The oil must stand at

least to the low mark in the left pillar. Consider the hints given in the

operating manual of the sewing head.

Page 7-2 © Beisler GmbH, Hösbach

Page 67

Chapter 7: Cleaning and maintenance

7.1.3 Check the drive belt

A

B

Pict. 43 Check the drive belt

The drive belt (A) must have tension at all time but show a certain play

(it must be possible to move it est. 1 cm up- and downwards).

If it is too loose, loosen the fixing screws of the motor (B) and push it

in a waym that the drive belt gets more tension. Tighten the fixing

screws again.

7.2 Required cleanings

To achieve the value and function of the machine, we recommend to

keep it always clean and free of spare materials and waste.

Blow off threats and cloth rests daily or use an industrial vacuum

cleaner.

Page 7-3

Page 68

Operating manual Automatic single head serging unit 1220/4

Page 7-4 © Beisler GmbH, Hösbach

Loading...

Loading...