Page 1

Universal-Flap-Pocket-

Machine 100/58

Operating instructions

Version 2.1, 11-18-98

© 1998 – 1999 Beisler GmbH

Frohnradstr. 10 • D-63768 Hösbach • Phone-No. Service: +49-6021-501940 • Fax: +49-6021-540061

Page 2

These operating instructions contain the following parts:

Part 1: Operating instructions (pages 1-xx)

adresses to the operator of the machine, that means the person

who works at and with the machine

Part 2: Mechanics manual (pages 2-xx)

is used for the putting into operation, adjustment, troubleshooting

and maintenance of the machine and adresses to qualified staff

only

Part 3: T echnical manual (pages 3-xx)

contains information on the further adjustment, maintenance,

troubleshooting and repair of this machine and adresses to

especially trained and experienced staff only .

Please obtain all safety , warning and other hints and regulations in this manual.

Page 3

Part 1 Operating instructions

Hint

These operating instructions contain all information required for the operation

of the machine. It adresses to the operator of the machine, that is the person

that works at and with the machine. Please obtain all rules and regulations.

Contents Page

Part 1 Operating instructions ...................................................................................... 1-1

1 Security advice and warning hints ................................................................... 1-2

1.1 Classification........................................................................................................ 1-2

1.2 Range of validity .................................................................................................. 1-2

1.3 Authorized person................................................................................................ 1-2

1.4 General security advice and warning hints........................................................... 1-2

1.5 Copyright ............................................................................................................. 1-3

2 Preliminary remarks .......................................................................................... 1-4

2.1 Introduction .......................................................................................................... 1-4

2.2 Limitation of liability .............................................................................................. 1-4

2.3 Guarantee regulations ......................................................................................... 1-5

2.4 Use as agreed ..................................................................................................... 1-5

2.5 Description of the machine .................................................................................. 1-5

2.6 Main parts of the machine.................................................................................... 1-6

3 Security............................................................................................................... 1-7

3.1 Available security systems ................................................................................... 1-7

3.1.1 Program stop button ............................................................................................ 1-7

3.1.2 Mains /emergency stop button ............................................................................. 1-8

3.2 Security measures of the operator ....................................................................... 1-8

4 Operation of the machine.................................................................................. 1-9

4.1 Controls and indicators ........................................................................................ 1-9

4.1.1 Operation device................................................................................................ 1-10

4.1.2 Insertion station.................................................................................................. 1-13

4.1.3 Mains / emergency stop button .......................................................................... 1-13

4.1.4 Foot pedal machine sequence ........................................................................... 1-13

4.1.5 Foot pedal vacuum ............................................................................................ 1-13

4.1.6 Foot pedal stacker ............................................................................................. 1-13

4.1.7 Swing out the folder ........................................................................................... 1-14

4.1.8 Change folder .................................................................................................... 1-14

4.1.9 Change interface roll.......................................................................................... 1-15

4.1.10 Empty the stacker .............................................................................................. 1-16

4.2 Operation ........................................................................................................... 1-16

4.2.1 Machine sequence............................................................................................. 1-16

4.2.2 Program operation ............................................................................................. 1-16

4.2.3 Select a sewing program.................................................................................... 1-16

4.2.4 Enable/disable seams........................................................................................ 1-17

4.2.5 Change seam length.......................................................................................... 1-17

4.2.6 Remove and add seams .................................................................................... 1-17

5 Required cleanings.......................................................................................... 1-18

1-1

Page 4

1 Security advice and warning hints

1.1 Classification

Three different types of hints are used in this manual, which are indicated

with different symbols and signalling words:

DANGER

This indicates a possibly dangerous situation or action, which may cause

injuries to persons or severe damage to the machine.

ATTENTION

This indicates a situation or action, which may cause damage to the

machine.

Hint

This indicates hints for a better use and other helpful information or hints.

Please obey all rules and regulations.

1.2 Range of validity

This operating manual is valid for Pocket-Piping-Automatons manufactured

by Beisler named ‘Universal-Pocket-Piping-Automaton 100/58’.

This operating manual is not valid for the sewing head applied in the

machine. Please refer to the operating manual of the sewing head delivered

with the machine, for which we don’t take any liability .

Further security advice (verbal and written) for this machine or the

components will not be repealed by this manual.

1.3 Authorized person

Danger

Danger might arise for persons, things and environment by inappropriate

operation of this machine. Installation and maintenance duties may only be

carried out by authorized staff.

Persons are regarded as authorized, who are able to recognize possible

danger and judge the assigned duties from their technical education and

experience.

1-2

1.4 General security advice and warning hints

Danger

Danger might arise for persons, things and environment by inappropriate

operation of this machine. Installation and maintenance duties may only be

carried out by authorized staff.

Page 5

Danger

Danger of injuries in the range of the sewing head! Don’t grasp into the

affected area of the needle during the sewing process!

Danger

Before any operations at or with the machine (putting into operation,

operation, maintenance, repair, etc.) the person carrying out has to read and

understand this manual with each appendix completely .

Danger

Before carrying out maintenance or repair duties, the mains supply must be

cut off. Additionally pressure must be released from the pneu-matical system.

Attention

The machine will be destroyed by a connection to a wrong mains voltage!

See the section ‘Technical data’ before connecting the power supply.

1.5 Copyright

© 1997 Beisler GmbH, Hösbach

Pocket-Piping-Automaton

The Universal-Pocket-Piping-Automaton 100/58 and this operating manual

with all parts are protected on copyright. Manufacture without license will be

prosecuted by law. All rights reserved on this operating manual, including

reproduction in any thinkable way , either by copying, printing, on any data

recording media or in translated form. Reproduction of this operating manual

- even in extracts - only with written approval by Beisler GmbH.

This operating manual contains a description of the product, but no promise

of certain qualities or results of use. The operating manual has been proved

before delivery . The Beisler GmbH takes the liability, that this operating

manual if free of errors reducing its value for the estimated use. The editors

don’t take liability for consecuting damage arising through application of the

operating manual. We are always thankful for hints and ideas.

The technical standard of the common delivery of product and operating

manual by the Beisler GmbH is decisive, if not other information is given.

Technical changes without prior notice are reserved, previous operating

manuals loose validity .

The general conditions of sales and delivery of the Beisler GmbH are valid.

Do you have questions or problems with installation or putting into operation?

Don’t hesitate to call us.

Beisler GmbH

Frohnradstr. 10 - D-63768 Hösbach

Tel: (+49) 6021 / 50 19 0

Fax: (+49) 6021 / 50 19 10

1-3

Page 6

2 Preliminary remarks

2.1 Introduction

This operating manual adresses to the operator of the machine, that is the

person that works with the machine. It is not a technical manual. Please ask

questions exceeding the contents of this operating manual to our service

staff.

Attention

All service and maintenance duties at this Pocket-Piping-Automaton may only

be carried out by qualified staff (qualified electrical employee or electrotechnical instructed person according to IEC 364 and DIN EN 60204-1).

Machine operation may only be carried out by an instructed person, who had

read and understood this operating manual completely .

Attention

Any structural changes to the machine, either electrically , mechanically or

regarding the machine control, are suspect to the responsibility of the

machine owner.

The following documents are part of the documentation of the UniversalPocket-Piping-Automaton 100/58:

1. Electrical wiring plans

2. Parts list

Please check the documents delivered with the machine for completeness.

2.2 Limitation of liability

We guarantee the faultless functioning of our product in accordance with our

advertising, the product informations edited by the Beisler GmbH and this

manual. Further product-features are not guaranteed. We take no liability for

the economy and faultless function if the product is used for a different

purpose then that described in the chapter „Use as agreed“.

Compensation claims are generally impossible, except if intention or culpable negligence by the Beisler GmbH is proved, or if assured productfeatures are not provided. If this machine is used in environments, for which it

is not suited or which do not represent the technical standard, we are not

responsible for the consequences.

We don’t accept responsibility for damages at installations and systems in

the surroundings of this machine, which are caused by a fault of the product

or an error in this manual.

We are not responsible for the violation of patents and/or other rights of third

persons outside the Federal Republic of Germany .

We are not liable for damages, which result from improper operations

according to this manual. We are not liable for missed profit and for

consecuting damages due to non-regardance of security advices and

warning hints. We don’t accept liability for damages which resulted from the

use of tools and accessoires which are not delivered and/or approved by the

Beisler GmbH.

The prdocuts of the Beisler GmbH are designed for a long life. They

represent the standard of technique and science and were checked on all

functions individually before delivery . The electrical construction corresponds

to the current norms and regulations, particularly DIN 5713 / VDE 01 13.

Beisler GmbH is doing product and market research for the further

1-4

Page 7

development and permanent improvement of their products. In the case of

faults and/or technical trouble please contact the Beisler GmbH service staff.

We assure that suitable measures will be done immediately.

The Beisler GmbH guarantee regualtions are valid, which we will send to you

on demand.

2.3 Guarantee regulations

We guarantee the fault-free functioning of the Universal-Pocket-PipingAutomaton 100/58 according to this operating manual except the tools for a

time range of six months after delivery . If the machine is used in double- or

triple-shift operation, the term of guarantee is reduced to three or two

months.

The term of guarantee starts with the date of delivery to the customer,

independant from the time of putting into operation. Guarantee will be

spoiled, if the machine isn’t installed and operated according to this operating

manual and the regulations given by the Beisler GmbH staff. A cost-free

repair is only possible, if all regulations considering storage, transportation

and putting into operations have been obeyed.

Customers and third persons may only mesh with the machine after getting a

written approval by the Beisler GmbH. The Beisler GmbH takes no

responsibility for injuries and damages arising from non-obeyance of this

stipulation. All warranty will be spoiled in this case.

The Beisler GmbH takes no responsibility for faults of the machine as

consequence of defective or functional faulty equipment in the surrounding of

the machine or by the use of accessoires, which were not delivered by the

Beisler GmbH.

The general conditions of sale and delivery of the Beisler GmbH are valid.

2.4 Use as agreed

The Universal-Pocket-Piping-Automaton 100/58 has been developed for the

piping of pockets and the sewing in of pocket bags.

Danger

This machine has been developed and build for a certain purpose. Adaptions

may influence security equipments negatively . We recommend to contact our

service staff in such a case.

2.5 Description of the machine

The Universal-Pocket-Piping-Automaton 100/58 allows the automatic piping

of pockets. The machine is equipped with a cutting device, a clamp

transportation system, a sewing head and a stacking system for the

produced pieces.

All components of the machine are mounted on a base frame made of

square steel pipes and controlled by an innovative micro-processor system.

Machine operation is achieved with an operation device. Here you can open

several control programs, define new programs and check all machine

components individually for maintenance and repair duties.

1-5

Page 8

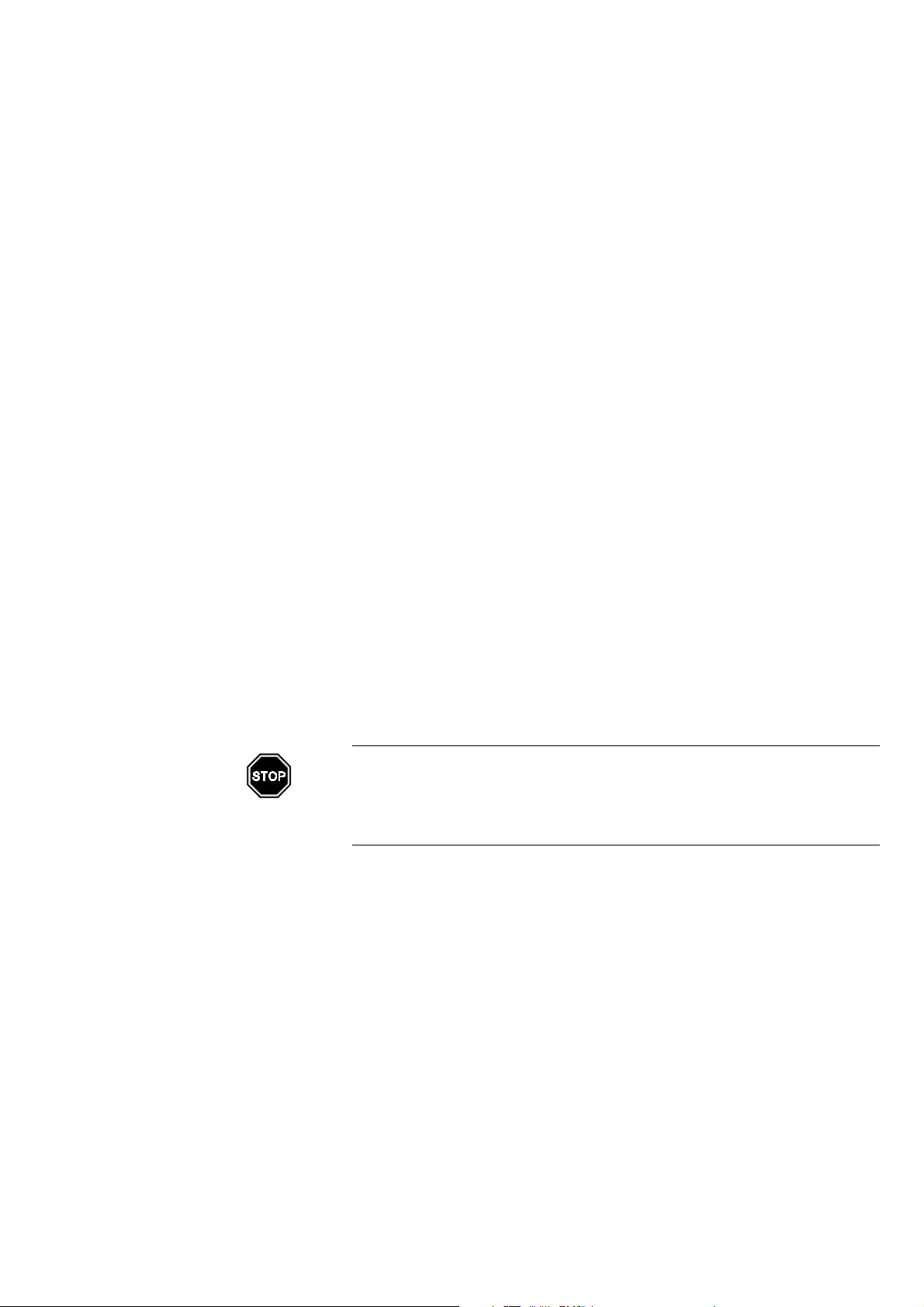

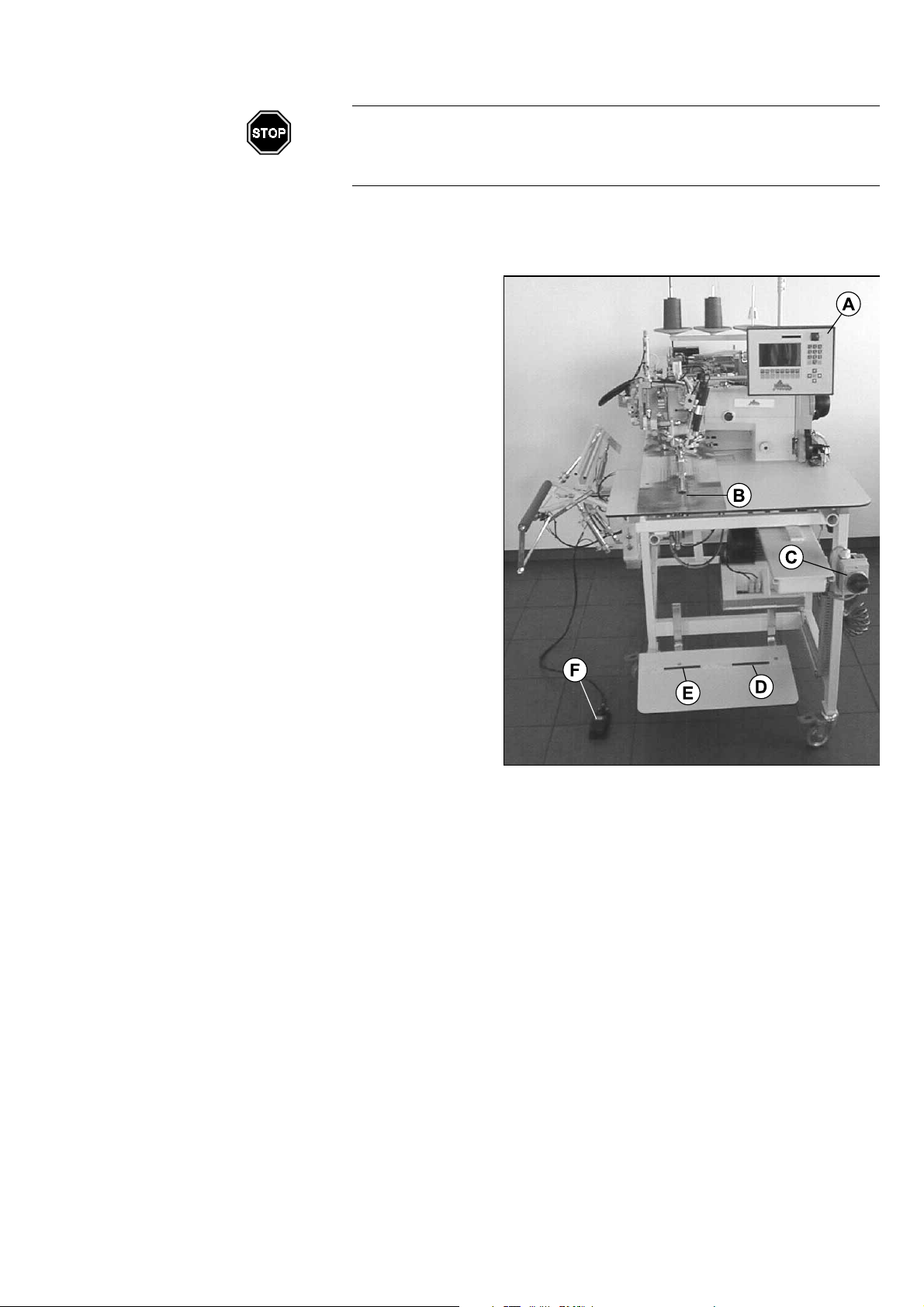

2.6 Main parts of the machine

A Sewing head

B Operation device

C Insertion station

D Clamp transportation

E Mitre knife

F Stacker

G Foot pedal sew sequence

H Sew motor

I Power / air supply

J Power distribution

K Spool rack

L Mains / emergency stop switch

M Foot pedal vacuum

N Foot pedal stacker

O Program stop button

The following chapters contain further information on the machine’s

components.

1-6

Page 9

3 Security

The topic of this chapter is the security exclusively . Please see chapter 1 for

the general security advice and warning hints and the security and warning

hints in the other chapters of this operating manual.

3.1 Available security systems

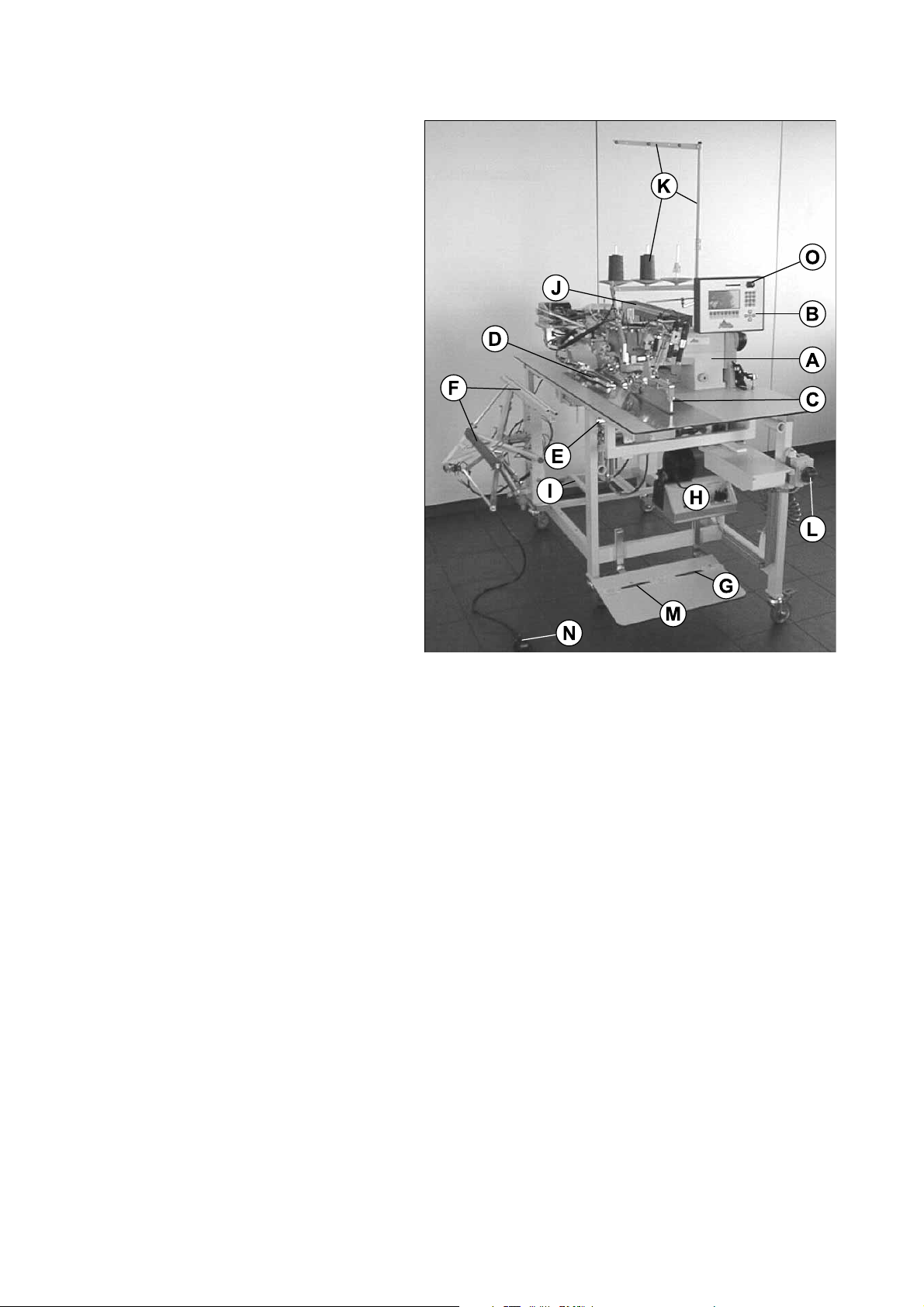

Danger

Check all security systems daily for functioning and effectivity!

Danger

Changes to the machine may influence function and effectivity of the security

systems negatively!

A Program stop button

B Mains / emergency stop button

3.1.1 Program stop button

The program stop button is mounted in the right upper corner of the operation

device. After pressing, all movements and the sewing process will be

stopped immediately .

Before a re-start the program stop button must be turned to the right to be

unlocked. With the release, the reset will be triggered.

1-7

Page 10

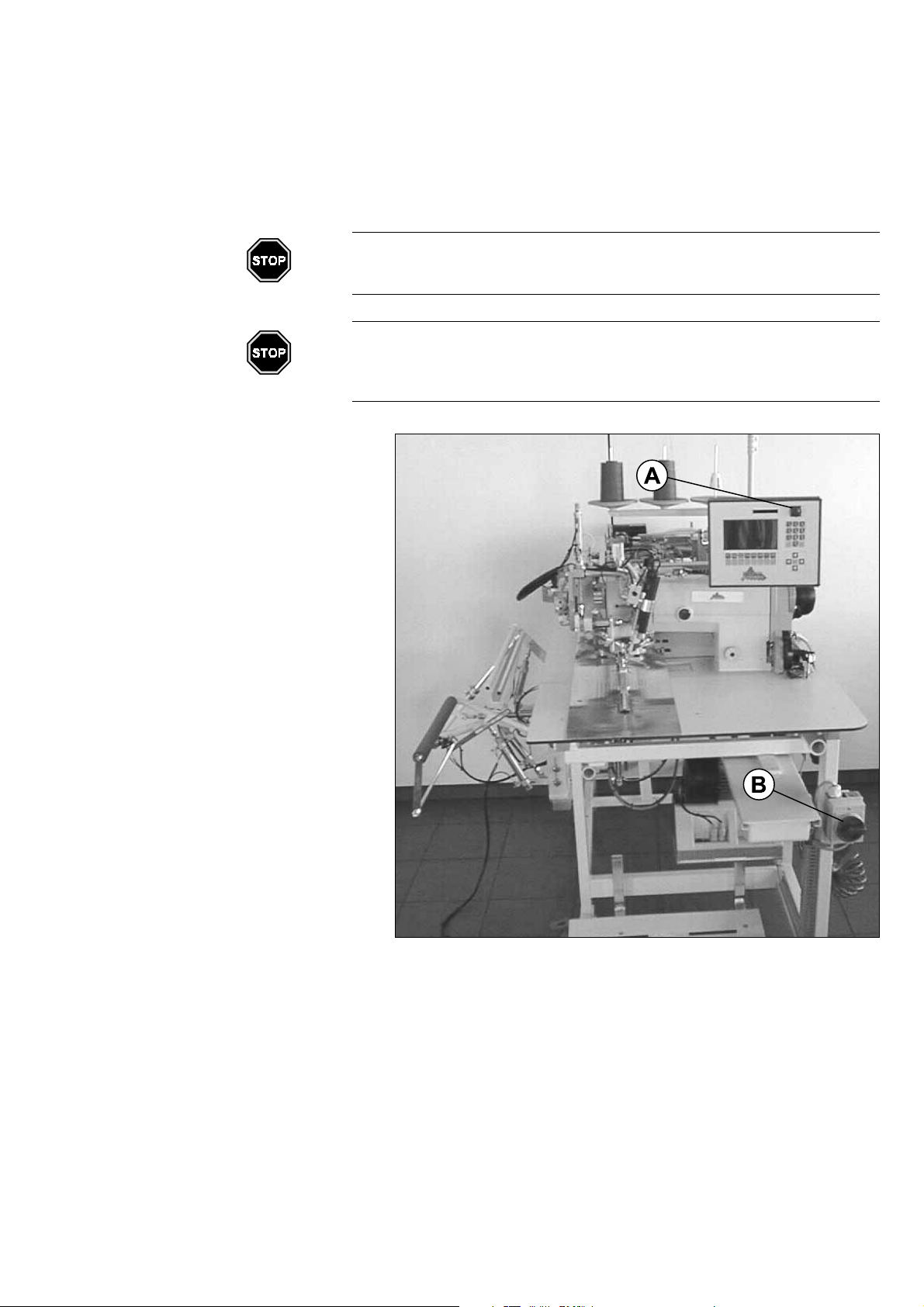

3.1.2 Mains /emergency stop button

The mains / emergency stop switch is mounted on the front side of the

machine, right-handed below the working plate. It can be used to cut-off the

power supply .

3.2 Security measures of the operator

The security systems of this machine work passively , that means that they

can only react on certain incidents. To achieve the required security for your

health and that of your collegues, active measures of the operator are

required.

Please obey the following general rules for the use of this machine:

1. Always work concetrated and avoid actions with a risk.

2. Don’t try to bridge existing security systems or to disable them in any way .

3. Check all security systems on function and effectivity before starting work.

4. Cut off the power supply before opening the switchbox.

5. Switch off the machine with the mains / emergency stop switch, before

executing cleaning and mainetenance duties.

1-8

Page 11

4 Operation of the machine

Danger

This machine may only be operated by qualified staff, who had read and

understood this operating manual completely .

4.1 Controls and indicators

A Operation device

B Insertion station

C Mains / emergency stop button

D Foot pedal machine sequence

E Foot pedal vacuum

F Foot pedal stacker

1-9

Page 12

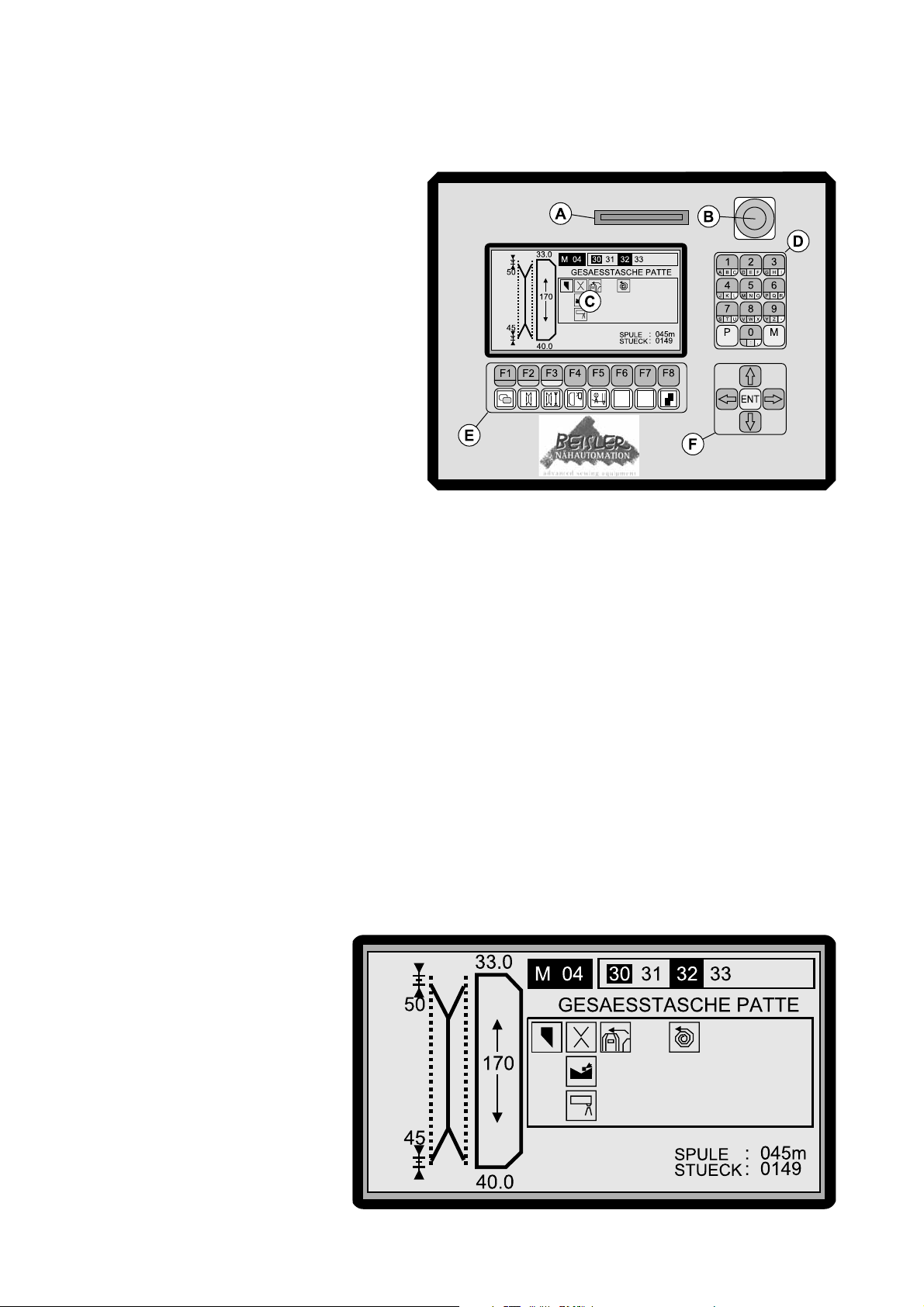

4.1.1 Operation device

During production the machine can be operated with the operating device;

existing programs can be called and new programmed. You will find the

program stop button at the device.

A Slot for the Memory card

B Program stop button

C Display

D Ten key pad with P- and M-key

E Function keys

F Arrow and enter keys

The elements of the operating devices have the following occupations:

4.1.1.1 Slot for the Memory card

The Memory card is used as a backup memory for software and programs of

the machine. You can load programs to the Memory card or read them after a

possible data loss into the machine.

4.1.1.2 Program stop button

By pressing the program stop button, all movements of the machine will be

stopped immediately . To continue production, you have to turn the button to

the right and release it.

4.1.1.3 Display

1-10

Page 13

All information required for the operation of the machine will be imaged in the

display . During normal production the display shows the following (see Pict.

6):

• the graphic on the left side images the mitre cut of the pocket; in the

shown example, the mitre cutter cuts the basic value 50 at the seam start

and 0.5 mm less at the end, that is the value 45

• the graphic to the right shows the seam or flap lenght of the pocket; the

value displayed above the flap (33.0) defines, how far the flap will be

pushed behind the needle, after the photocell has recognized the flap

(value for the seam start); the value displayed below the flap (40.0)

defines, how long the machine continues sewing, after the photocell has

recognized the end of the flap

• the most upper line shows the number of the selected program (M01) and

the seams assigned to this program (30, 31, 32 and 33); seams 30 and

32 are enabled (32 will be the next seam to be sewed), 31 and 33 are

disabled

• the name of the current seam is displayed to the right

• the square below contains the icons of the machine functions assigned to

the current seam

• below the square, the stock of bobbin thread (45 m) and the number of

produced parts (149) are displayed

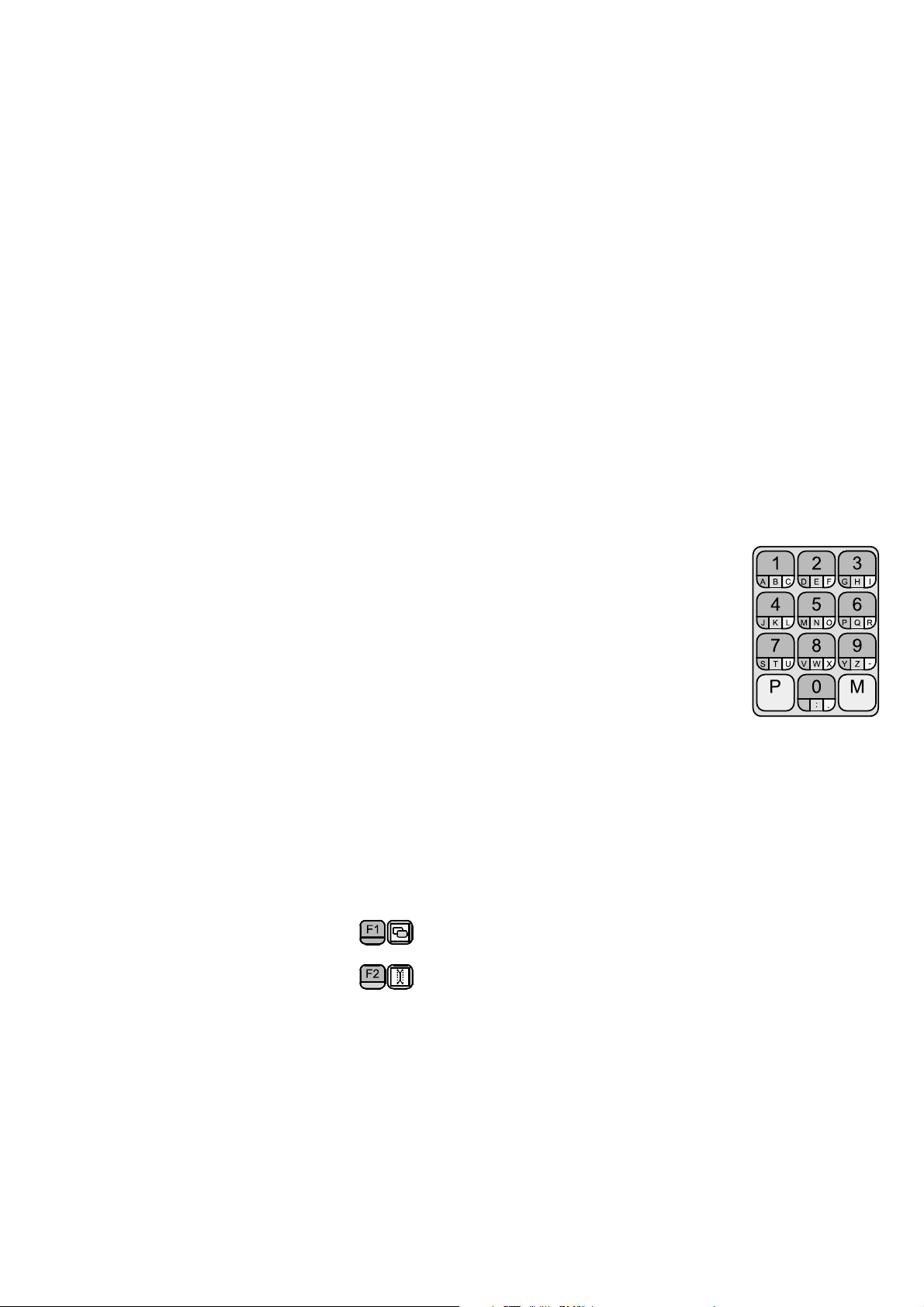

4.1.1.4 Ten key pad with P- and M-key

Numerical inputs can be done using the ten key pad.

The letters displayed below the digits can be entered, after the function key

with the corresponding color indication has been pressed before.

The P-key is used in several steps of the machine programming.

Sewing programs can be selected after pressing the M-key .

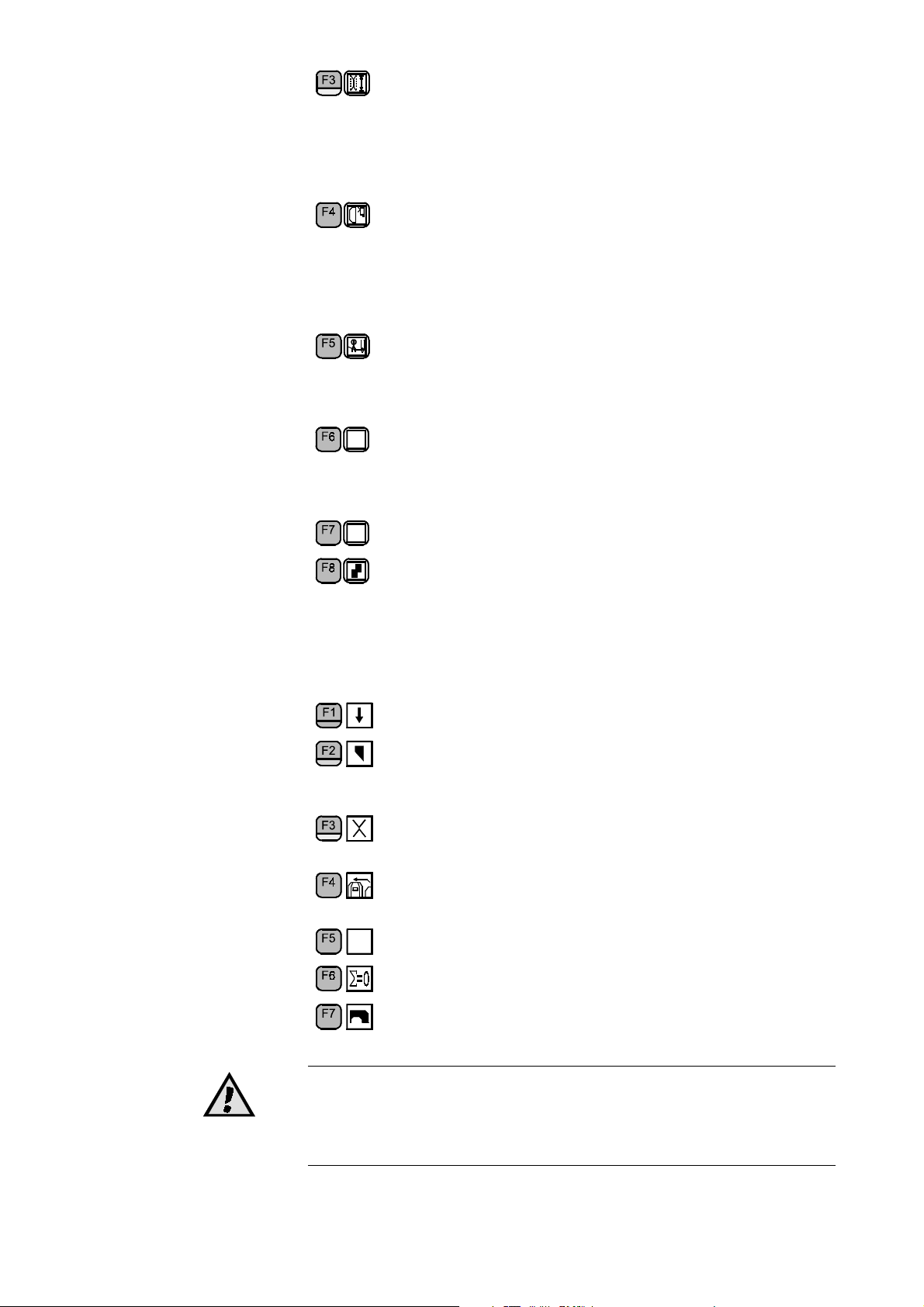

4.1.1.5 Function keys – lower occupation

The function keys are occupied as follows

switches to the upper occupation of the function keys

Mitre knife correction; press this key once to change the mitre

knife position at the seam start; press F1 and the cursor stands

on the seam start; press twice to change the position at the

seam end; after pressing F1, enter the new value using the ten

key pad, which will be displayed in the left-handed graphic; 50 =

middle value; the higher the value, the more far the mitre knife

cuts to the outside

e.g. old value 50, new value 56 and the mitre knife cuts 0.6 mm

more to the outside

e.g. old value 50, new value 22, the mitre knife cuts 2.8 mm

more to the inside

1-11

Page 14

Change pocket length; press F3 and enter the new value for the

length to be sewed; when producing with flap, this sets the

photo cell security length, too; e.g. security length 140 mm

allows the sewing of a flap length between 130 and 150 mm;

when producing flaps it is possible to disable the security length

by entering 999 here.

Sewing-over at seam start and end (only valid when sewing with

flap); press once to set the sewing-over at seam start, twice to

set it at seam end; enter the new value using the ten key pad

Seam start: the smaller the set value, the more the flap will be

sewed over; seam end: the bigger the set value, the more the

flap will be sewed over

Pick needle thread manually; after the first pressing, the main

clamp drives to end position, with the second pressing the

needle thread catcher will be enabled; it remains enabled, until

the key is released

Push interface forward manually (option); after changing the

interface roll, the interface will be cut with a key pressure and

then be pushed in position (only available if interface mode is

enabled)

reserved

Reset key; use this key to reset the program sequence step by

step; sets the clamp into starting position

4.1.1.6 Function keys – upper occupation

The function keys are double occupied. Press F1 to switch to the upper key

occupation. The icons will be displayed in the lower line.

switches back to the lower key occupation

Switch middle knife on/off; the knife is switched off, until it will be

switched on here; together with the middle knife, the mitre knife

is switched off

Switch mitre knife on/off; it remains switched off, until it will be

switched on here

Switch stacker on/off; it remains switched off until it will be

switched on here

Here without function

Sets counter to zero

Manual spooling; the sewing head runs with low revs, after a

second key press, it stops in the upper needle position

1-12

Attention

At machines with insertion station, the station must be swung out first (see

chapter 4.1.6); in any case, both threads must be removed from the needles

and the spools from the pickers.

Page 15

Reset spool thread length; when removing a half-full and

inserting a full spool, you can display the whole thread length by

pressing this key

4.1.1.7 Arrow and Enter-keys

Use the arrow keys to move the flashing cursor between the different

sections of a display . Confirm inputs using the Enter key.

4.1.2 Insertion station

The parts to be manufactured are inserted at the insertion station. Use the

marking lamps to align the parts exactly .

4.1.3 Mains / emergency stop button

With the mains / emergency stop button, you can cut-off the power supply of

the machine.

4.1.4 Foot pedal machine sequence

Use this foot pedal to trigger the steps of the machine sequence (see further

below).

4.1.5 Foot pedal vacuum

Press this foot pedal to enable the vacuum. The parts inserted at the

insertion station are fixed by the vacuum which will be disabled automatically ,

after the main clamp has picked up the parts.

4.1.6 Foot pedal stacker

Press the foot pedal stacker to open the stacker to be able to take out the

stacked parts.

1-13

Page 16

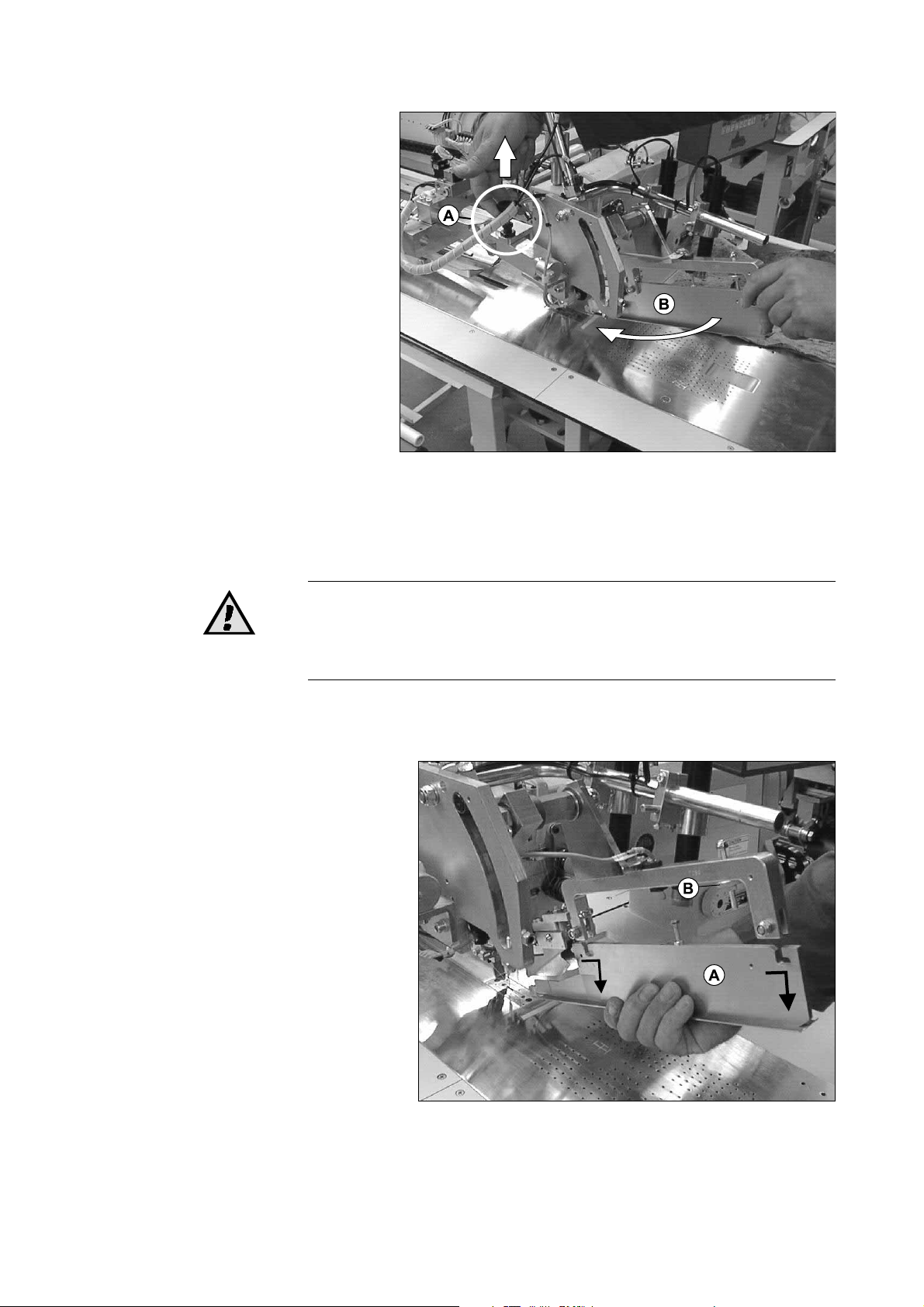

4.1.7 Swing out the folder

For several reasons (e.g. manual spooling), the folder must be swung out to

get access to the sewing head. Pull out the locking pin (A) and swing the

folder (B) to the left.

When swinging back, move the folder slowly to the right until the locking pin

inserts feelable.

Attention

The folder and the lamps of the crosshair attached to it are adjusted exactly

and are sensitive against violence. Therefore, swing the folder slowly and

without the use of power.

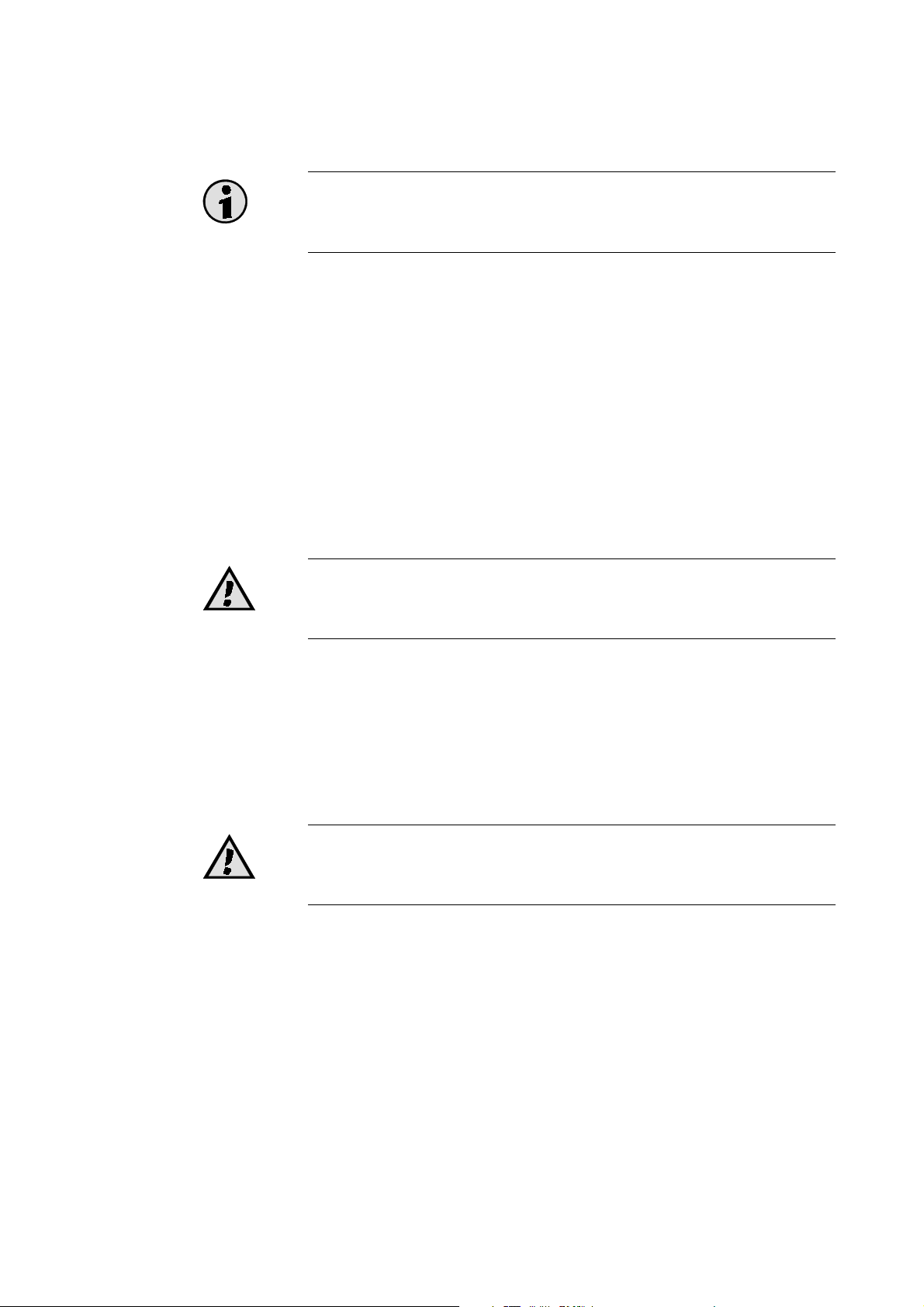

4.1.8 Change folder

1-14

Page 17

Different folders are needed for different pocket shapes (e.g. double/single

piping):

1. Open the locking (B) of the folder (A).

2. Pull the folder towards yourself and downwards to remove it.

3. Push in the new folder from the bottom side into the two attachments and

then push it forward.

4. Fix the locking (B).

4.1.9 Change interface roll

The interface roll is placed below the working plate and can be changed this

way:

1. Lift the insertion plate at the front side and push it to the left.

2. Remove all rests of the interface in the machine.

3. Insert the new interface roll.

4. Insert the interface over the roll into the interface guiding.

1-15

Page 18

5. Press F6 repeatedly , until the interface appears above the working plate.

6. Mount the insertion plate; be sure that the positioning pins are inserted

into the drill holes.

4.1.10 Empty the stacker

Press the foot pedal of the stacker, if it is full. The stacker will open and you

can remove the parts. Release the foot pedal to close the stacker.

4.2 Operation

4.2.1 Machine sequence

The production sequence is divided into several parts:

1. Machine sequence can start, if the machine is in starting position.

2. Insert the parts to be sewed and align them exactly .

3. Press the foot pedal machine sequence and the clamp comes forward.

4. Press the foot pedal again, the clamp will be lowered.

5. Press foot pedal, the folder is lowered and the fold pushers are driven to

the front.

6. Press foot pedal, the flap clamp closes.

7. Press foot pedal, the clamp pushes the part under the sewing head, it will

be sewed there, the mitres will be cut, the clamp opens and the sewed

part will be stacked.

The operator can trigger each step with a short pressing of the foot pedal, or

run an automatic process by keeping the foot pedal pressed.

Depending on the programming, different machine sequences might occur .

4.2.2 Program operation

The machine is operated with programs, which can be selected by the

operator. A program is stored at a memory location (e.g. ‘M01’) and contains

one or several seams (max. number is six).

The selected program and the assigned seams are imaged in the upper line

of the display . The machine executes all enabled seams of a program

sequentially . An enabled seam is displayed inverted (white on black).

Y ou can produce several pocket shapes and lengths sequentially, without

changing the sewing program. This allows to sew several pockets of a jacket

part.

The following operational actions are explained in this chapter:

• select a sewing program

• enable/disable seams

• change seam lengths

• change sewing programs

• create new sewing programs

• program new seams

4.2.3 Select a sewing program

The current sewing program is displayed in the upper line of the display . How

to select a program:

1. Press M-key .

2. Enter the number of the desired program using the ten key pad.

3. Press ENT-key .

1-16

Page 19

4.2.4 Enable/disable seams

Seams are assigned to every sewing program. All enabled seams are sewed

sequentially . Enabled seams are displayed inverted (white on black).

If a seams shall be skipped, it must be disabled. How to enable/disable a

seam:

1. Move the cursor on the desired seam using the arrow keys.

2. Press the ENT-key to enable/disable the seam.

4.2.5 Change seam length

Several parameters of the current seam are imaged in the left half of the

display (e.g. seam length, mitre knife position). You can change these

settings individually using the function keys.

All changes executed with the function keys are stored for all seams with the

same number, even if they are used in dif ferent programs.

Further information are contained in the chapter ‘4.1.1.5 Function keys’.

4.2.6 Remove and add seams

You can add seams to and remove them from sewing programs:

4.2.6.1 Remove seams

1. Select the sewing program to be changed.

2. Press the P-key .

3. Press F1.

4. Move the cursor on the seam to be removed using the arrow keys.

5. Press the M-key .

6. Repeat steps 4. and 5. for all seams to be removed.

4.2.6.2 Add seams

1. Select the sewing program to be changed.

2. Press the P-key .

3. Press F1.

4. Use the arrow keys to move the cursor to the place, where you want to

add a seam.

5. Press the ENT-key .

6. Enter the number of the desired seam.

7. Repeat steps 4. to 6. for all seams to be added to the current sewing

program.

8. Press the P-key to store the settings and leave the submenu.

1-17

Page 20

5 Required cleanings

To achieve the value and function of the machine, we recommend to keep it

always clean and free of spare materials and waste.

Blow off threats and cloth rests daily from the machine using the air

pistol.Below the air pistol you see a supply bottle for the oil needed in the

sewing head.

1-18

Page 21

Part 2 Mechanics manual

Hint

This part of the operating instructions contains all information required to put

the machine into operation and to do programming, troubleshooting and

maintenance. It adresses to trained technical personnel, which is able to

overview their tasks and recognize possible danger at an early moment. The

operating instructions given in part 1 of this manual are to be considered as

part of this mechanics manual.

Contents Page

Part 2 Mechanics manual............................................................................................. 2-1

1 Delivery , transportation, storage ...................................................................... 2-2

1.1 Delivery ................................................................................................................ 2-2

1.2 Transportation...................................................................................................... 2-2

1.3 Storage ................................................................................................................ 2-2

2 Installation.......................................................................................................... 2-3

2.1 Technical data...................................................................................................... 2-3

2.2 Mechanical installation......................................................................................... 2-3

2.2.1 Unpack and put up............................................................................................... 2-3

2.2.2 Connection of air supply....................................................................................... 2-4

2.3 Elektrical installation ............................................................................................ 2-4

2.4 First putting into operation.................................................................................... 2-5

3 Programming instructions ................................................................................ 2-6

3.1 Create new sewing programs .............................................................................. 2-6

3.1.1 Select a M-memory location................................................................................. 2-6

3.1.2 Add seams........................................................................................................... 2-6

3.1.3 Copy seams......................................................................................................... 2-6

3.1.4 Adjust seams ....................................................................................................... 2-6

3.1.5 Name seams........................................................................................................ 2-7

3.1.6 Delete seams....................................................................................................... 2-7

3.2 Seam functions .................................................................................................... 2-7

3.3 Seam parameters ................................................................................................ 2-9

3.3.1 Seam parameter 30: Flap clamp mode ...............................................................2-11

3.3.2 Working WITHOUT automatic clamp push-back................................................ 2-13

3.3.3 Working WITH automatic clamp push back ....................................................... 2-13

3.3.4 Working with INTERMEDIA TE ST OP of the main clamp.................................... 2-13

3.3.5 Working with automatic PICK UP P A RT using the main clamp.......................... 2-13

3.4 Seam images..................................................................................................... 2-14

3.4.1 Sewing with catch .............................................................................................. 2-14

3.4.2 Sewing with stitch condensation ........................................................................ 2-14

3.4.3 Sewing with stowing........................................................................................... 2-14

3.5 Basic parameters............................................................................................... 2-15

4 Troubleshooting hints ..................................................................................... 2-18

5 Maintenance of the machine........................................................................... 2-21

5.1 Water separator at air connector........................................................................ 2-21

5.2 Grease linear guiding......................................................................................... 2-21

5.3 Use of the Memory Card.................................................................................... 2-22

5.3.1 Saving seam data on the Memory Card............................................................. 2-22

5.3.2 Loading seam data from the Memory Card ........................................................ 2-22

5.4 Loading data from the EPROMs ........................................................................ 2-23

5.4.1 Loading the basic parameters............................................................................ 2-23

5.4.2 Loading seam parameters ................................................................................. 2-23

5.5 Test programs and diagnostics .......................................................................... 2-23

5.5.1 I/O-Test .............................................................................................................. 2-23

5.5.2 Diagnostics ........................................................................................................ 2-26

5.5.3 Service Code ..................................................................................................... 2-28

5.6 Preset sewing programs .................................................................................... 2-29

5.7 Diagram of the menu structure .......................................................................... 2-30

2-1

Page 22

1 Delivery, transportation, storage

1.1 Delivery

Hint

Check right after receiving the machine, whether all parts according to the

parts list are complete and without damage. Later claims can’t be accepted.

If you see damage to the transportation packing of the machine, which

indicates a possible damage to the delivered parts, don’t hesitate to claim this

to the transportation company .

1.2 Transportation

Generally it is possible to move the machine. Obey the following hints:

1. Cut off the power supply, release the pneumatical pressure.

2. Fix movable and loose parts.

3. Lift the base with a hoisting device and be sure to lift possible additional

devices (e.g. stacker). If the machine is equipped with transportation

casters (option), you will have to release the brakes at every caster.

4. Move the machine carefully to the new location.

Attention

Attention when moving the machine on sloping areas! Enormous pull power

arises from the machine weight.

1.3 Storage

If no other agreement is fixed, the following limitations have to be kept:

1. In closed rooms only .

2. Temperature range -10 ... +45 °C.

3. Humidity max. 80% non-condensing.

Attention

If stored or transported in improper environments, the machine can be

damaged severely . Damages may not be visible from the outside.

2-2

Page 23

2 Installation

Attention

Installation and putting into operation may only be carried out by mechanically

and electrically qualified staff. These people must read and understand the

complete operating manual before starting.

2.1 Technical data

Dimensions 1.600 x 750 x 1.300mm (LxWxH)

Table height 830 mm

Weight 220 kg

Mains power 220 V AC

Power consumption 0,7 kW

Fuse 10 A

Req. air pressure 6 bar

Req. air quality oil-free

Air consumption 5 NL/WD

2.2 Mechanical installation

Attention

Check before starting the installation, whether the desired location meets the

requirements (see chapter 2.1, technical data). This is very important

regarding the stability of the ground.

2.2.1 Unpack and put up

1. Remove the packing material and possible transportation protections.

2. Position the machine on a solid and horizontal ground.

3. Level the machine to a horizontal stand using the adjustable frame feet.

2-3

Page 24

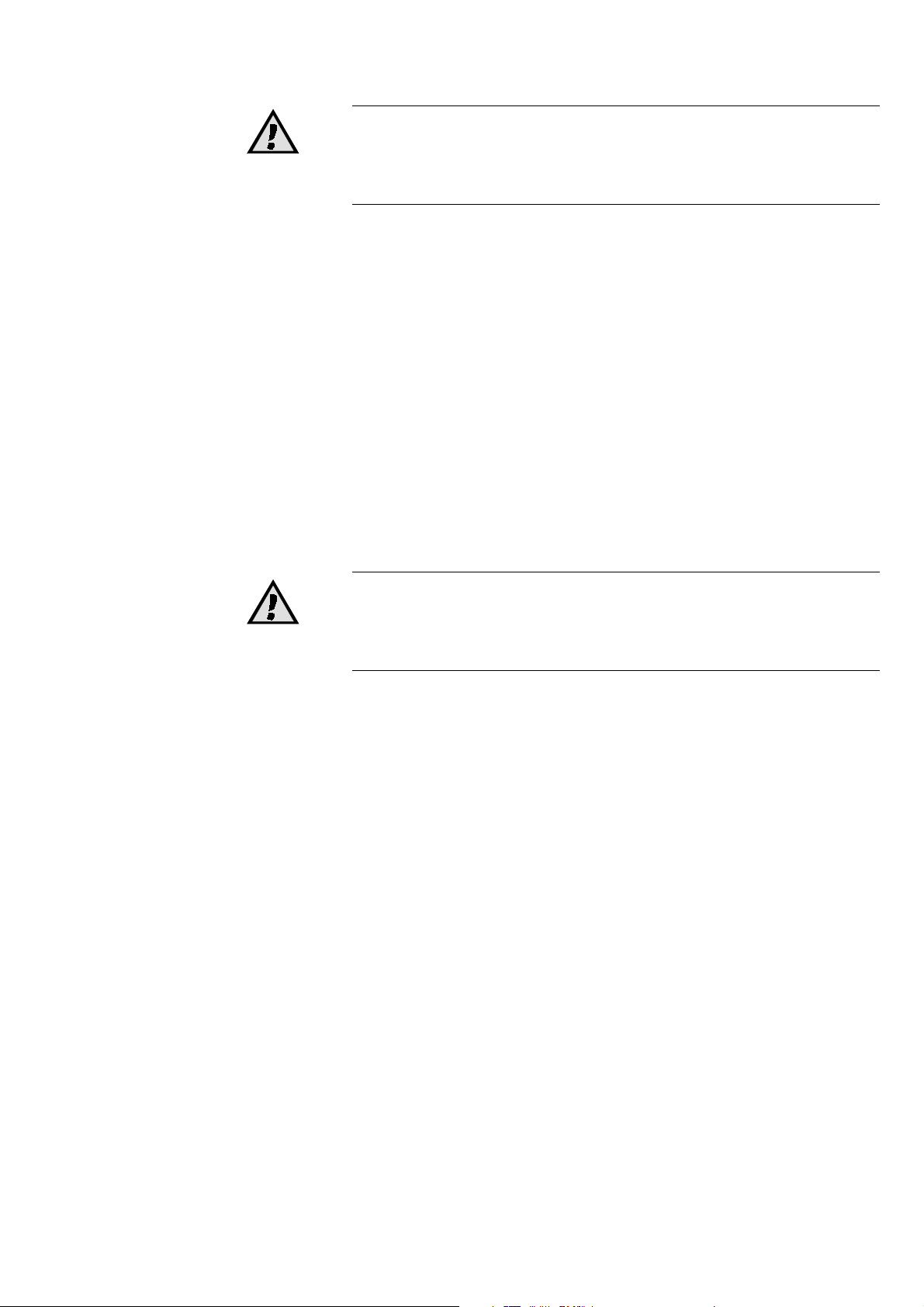

2.2.2 Connection of air supply

1. Connect the air pipe (A) to your air system.

2. Open the air supply of your air system.

3. Level the air pressure to 6 bar using the control (B); the air pressure can

be read at the scale (C).

Attention

We recommend to switch off the air supply when the machine is not in duty.

Use the black control (B).

2.3 Elektrical installation

Hint

All work at the electrical components of the machine may only be carried by

qualified staff (qualified electrical employee or instructed person according to

IEC 364 and DIN EN 60204-1).

Danger

Parts under electrical current! Without cutting off the power supply, you might

be injured severely . Please obey the security advice given in chapter 1.

2-4

Page 25

Attention

The machine will be destroyed by connecting to a wrong mains voltage!

Check, whether the requirements from chapter ‘Technical data’ meet the

local conditions.

1. Use the power cord located at the backside of the machine.

2. Plug it into a socket.

3. Lay the cord in a way , that the danger of stumbling is avoided.

Danger

Danger to life from unsufficient grounding! Do a grounding according to DIN

EN 60204-1.

2.4 First putting into operation

This machine has been configured to the individual requirements of the

customer. The first putting into operation can be done easily:

1. Adjust the machine to a horizontal stand.

2. Connect power and air supply .

3. Switch on the machine using the mains / emergency stop switch at the

front side of the machine.

4. Check all security systems for function and efficiency .

Danger

The machine may only be used for production purposes, after the security

systems have been checked. If a security doesn’t work adequately , it must be

repaired first.

As a factory setting, several production programs are contained in the buffer

of the machine. You may use one of them or create your own programs.

2-5

Page 26

3 Programming instructions

3.1 Create new sewing programs

The following steps are required to create a new sewing program:

1. Select memory location (Mxx).

2. Add or copy seams.

3. Adjust the seams.

3.1.1 Select a M-memory location

Due to customer-specific configuration, several M-memory locations are

occupied by sewing programs. There are enough memory locations available

for new sewing programs.

Select an available memory locationz:

1. Press the M-key .

2. Enter the number of the desired memory location (e.g. 09).

If the memory location is available, seam No. 50 is assigned six times.

3.1.2 Add seams

If existing seams shall be used in the new program, you can remove the

seams of the memory location and add the desired seams like described in

part 1 of this manual.

If you want to create new seams, you will first have to assign new numbers to

the seams, which are not used in another program.

3.1.3 Copy seams

If existing seams shall be manipulated for the new program, the seams can

be copied to a new seam number. This allows to keep the original seams

unchanged:

1. Move the cursor to the seam number, where you want to copy another

seam to (e.g. No. 45).

2. Press the P-key .

3. Press F1.

4. Press F2.

5. Enter the number of the seam, which you want to copy (e.g. 10).

6. Press the ENT-key .

Now seam No. 10 has been copied to No. 45, a new number has been

assigned. Seam No. 10 and 45 are identic. If you need more new seams, you

can assign further seam number to the program (e.g. 46, 47, 48, a.s.o.) and

copy existing seams to these numbers.

3.1.4 Adjust seams

The seams copied to the seam number 45, ... can now be manipulated

without changing the original seams (which are used in other programs).

The following items can be adjusted:

• mitre knife position, seam length, a.s.o.

• seam functions

• seam parameters

• seam name

2-6

Page 27

3.1.5 Name seams

To be able to distinguish seams, it is possible to define seam names. Follow

this procedure:

1. Press the P-key (opens the menu levels).

2. Press the key F5 (INIT-Parameter).

3. Press the key F1 (enter seam name).

4. The keys of the ten-key pad are occupied with letters, too. Each letter is

shown on its key with a color (blue, orange, green). Press one of the keys

F1...F3 together with a number key , to enter the desired letter (F1 blue, F2

orange, F3 green). Examples: A = F1 + 1; N = F2 + 5; U = F3 + 7.

5. Press the arrow keys to switch to the next or prior letter.

6. Press the P-key to terminate the entering and save the seam name.

3.1.6 Delete seams

An existing seam can be deleted.

ATTENTION

If a seam is used in several programs, it will be deleted in all programs. The

deletion of a seam can not be undone.

1. Press the P-key .

2. Press F5.

3. Press F5.

4. Enter the number of the seam to be deleted.

5. Press the P-key to delete the seam.

3.2 Seam functions

Several machine functions can be enabled/disabled for single seams. Follow

this procedure to enable/disable a machine function:

1. Select the seam number using the arrow keys.

2. Press the P-key .

3. Press F2.

4. Select the desired function using the arrow keys.

5. Press the ENT-key to enable/disable the function.

6. Repeat steps 4. and 5. for all desired functions.

7. Press the P-key to leave the menu.

An enabled function is displayed inverted (white on black), a disabled

function black on white.

The functions are visualized with icons:

Center knife

cuts the pocket between the seams; if the center knife is disabled,

the mitre knife will be disabled automatically

Mitre knife

cuts the pocket edges; if the center knife is disabled, the mitre knife

will be disabled, too

Stacker

stacks the sewed parts automatically

2-7

Page 28

Vacuum

keeps the parts in the insertion station, until the main clamp is

closed

Vylene

automatic supply with vylene

Stamp (option)

fixes the parts in the insertion station (3rd hand)

Piping blowing

piping is blown to the folder, to prevent a snapping during insertion;

should be enabled sewing thin parts

Folder up after seam end

increase of the production speed; earlier insertion of new parts is

possible

Flap clamp left

necessary if additional parts to the piping are inserted (e.g. pocket

bag, facing strips)

Flap clamp right

like flap clamp left (see above)

Seam shape trapeze jacket

breast welt production; left seam longer than right one

Seam form parallel

both needles work parallel

Seam shape trapeze troucers

left needle shorter than right one

Seam shape sloping pocket right

left seam with offset to the right one

Seam shape sloping pocket left

2-8

left seam with offset to the right one; mirrored to the right sloping

Piping pulling through (option)

turns the overlap of the piping (only during piping)

Photo cell left

necessary during sewing of left flap

Page 29

Photo cell right

necessary during sewing of right flap

Positioning point front

calculation point for the seam start during sewing without flap

Positioning point middle

calculation point for the seam start during sewing without flap

Positioning point rear

calculation point for the seam start during sewing without flap

Zipper scissor (option)

during sewing an endless zipper, this function gives a stop-

command to the machine to allow the cutting of the zipper

3.3 Seam parameters

Several seam-depending machine processes can be set:

1. Press the P-key .

2. Press F3.

3. Select the desired seam parameter using the arrow keys.

4. Press ENT-key .

5. Enter the desired value.

6. Repeat steps 3. to 5. for all desired seam parameters.

7. Press the P-key to leave the submenu.

During the selection of the parameters, you can scroll line per line using the

vertical arrow keys. You can also select the pages directly:

• Key 0: seam parameters 01 - 14

• Key 1: seam parameters 10 - 23

• Key 2: seam parameters 20 - 33

• Key 3: seam parameters 30 - 40

The seam parameters listed below can be changed. The factory-set default

configuration are shown in square brackets [ ], the possible settings in

rounded brackets ( ).

1 Change positioning point 135/225/315 mm

the set value defines the relation point of the seam

2 Insertion speed [60%] (10-90%)

clamp speed from the insertion position to the sew start position; when

photo cell is active, speed will be halved to allow a more exact

scanning; when producing with vylene, reduction to 1/3

3 Revs seam start [1500 rpm] (500 - 2000 rpm)

sewing head revs freely selectable, depending on needle- and center

knife setting

4 Revs during seam [2500 rpm] (500 - 3000 rpm)

freely programmable

5 Revs at seam end [1500 rpm] (500 - 2000 rpm)

freely programmable

6 Distance of seam start revs [5 mm] (0 - 99 mm)

distance with the revs of parameter 3

2-9

Page 30

7 Distance of seam end revs [5 mm] (0 - 99 mm)

distance with the revs of parameter 5

8 Stitch length seam start [1,5 mm] (0,5 - 3 mm)

stitch length at seam start for tack or stitch condensation

9 Stitch length in the seam [2,4 mm] (0,5 - 3,5 mm)

10 Stitch length seam end [1,5 mm] (0,5 - 3,0 mm)

freely selectable, effects on tack and stitch condensation at seam end

11 Distance stitch length seam start [10 mm] (0,5 - 99 mm)

distance with stitch length of parameter 8

12 Distance stitch length seam end [10 mm] (0,5 - 99 mm)

distance with stitch length of parameter 10

13 T ack length seam start [10 mm] (0 - 20 mm)

if this value is set to 0, stitch condensation will be sewed automatically

14 T ack length seam end [10 mm] (0 - 20 mm)

if this value is set to 0, stitch condensation will be sewed automatically

15 Slope at seam start [3 mm] ( 0 - 10 mm)

seam offset (difference left/right needle) at seam start

16 Slope at seam end [3 mm] (0 - 10 mm)

seam offset at seam end

17 Enable center knife [17 mm] (0 - 30 mm)

depending on seam and knife width, the center knife should cut est. 1

mm further than the mitre knife

18 Disable center knife [0 mm] (0 - 30 mm)

depending on seam and knife width, the center knife should cut est. 1

mm further than the mitre knife

19 Thread monitor on after [30 mm] (0 - 99 mm)

distance after which the thread monitor will be enabled; change this

parameter if seam length < 30 mm

20 Thread monitor filter [07] (00 - 99)

the smaller the digit, the more sensitive the upper thread monitor

reacts; 99: thread monitor disabled

21 Length vylene seam start [60 mm] (0 - 99 mm)

vylene overlay at seam start

22 Length vylene seam end [80 mm] (0 - 99 mm)

vylene overlay at seam end

23 Duration final roller [0,5 Sek.] (0 - 99 Sek.)

exact positioning of the work piece to be stacked

24 Intermediate stop selection + pos. [0 cm] (0 - 48 cm]

enter a position, where the main clamp shall be driven to after

stacking; 01 cm = main clamp is driven to the insertion station

25 Pick up part selection + pos. [0 cm] (0 - 48 mm)

if a value is defined, the main clamp pressure is released after mitre

cutting automatically and the work piece will be driven to the set

position; 01 cm = work piece is driven to the insertion station

26 Revs center knife [40%] (10 - 99%)

definition of the cutting speed

27 Revs final roller [99%] (10 - 99%)

a reduction achieves an optimized positioning for the stacking

30 Flap clamp mode >> see further below

31 Folding slide mode

00: left + right fold slider enabled

01: left fold slider enabled

02: right fold slider enabled

2-10

Page 31

32 Vacuum mode (option)

00: vacuum disabled

01: vacuum on with foot pedal vacuum (with display ‘enable

vacuum’ if not enabled with foot pedal)

02: vacuum on automatically if main clamp at insertion position

03: vacuum on with foot pedal advance

33 Main clamp mode

00: main clamp left/right down and tight

01: main clamp left down and tigh

02: main clamp right down and tight

03: main clamp both weak, before insertion both tight

35 Stacker mode

01: only final roller

02: only folding stacker

03: folding stacker and final roller

36 Push-back locking off

00: Push-back locking enabled

01: Push-back locking disabled

37 Folder as stamp [00] (00 - 01)

00: normal insertion process enabled

01: with the first step on the foot pedal, the folder is lowered and

fixes the work piece; next step drives main clamp to insertion position;

after clamp is closed, the folder is pushed up to allow the insertion of

the vylene; only required for trouser production with pocket automaton

100/58 without stamp

38 Flap clam mode

00: flap clamp active with foot pedal

01: flap clamp automatically active

39 Breast welt mode

the breast welt will swing in together with the flap station

00: folder down after flap clamp closed

01: folder down when left flap clamp closed

3.3.1 Seam parameter 30: Flap clamp mode

In the control, you can switch on/off the left or right flap clamp and select one

of eight modes additionally; dependant on the selection, the flap clamp

behave different. In the following table, the mode number is shown in the first

column, the behaviour of the flap clamps is indicated with graphics.

left clamp closed

right clamp closed

left clamp open

right clamp open

Left and right flap clamp switched on:

00: Insertion position

01: like 00

02: like 00

03: like 00

04: Insertion position

automatic with folding slide

05: like 04

06: like 04

07: like 04

2-11

Page 32

Left flap clamp switched on, right switched off:

00: Insertion position

with foot pedal pressure

01: like 00

02: Insertion position

automatic with folding slide

with foot pedal pressure

03: like 02

04: Insertion position

automatic with folding slide

with foot pedal pressure

05: like 04

06: like 04

07: like 04

Left flap clamp switched off, right switched on:

00: Insertion position

with foot pedal pressure

01: like 00

02: Insertion position

automatic with folding slide

with foot pedal pressure

03: like 02

04: Insertion position

automatic with folding slide

with foot pedal pressure

05: like 04

06: like 04

07: like 04

2-12

Page 33

Both flap clamps switched on:

00: Insertion position

with foot pedal pressure

with 2nd foot pedal pressure

01: Insertion position

with foot pedal pressure

02: Insertion position

automatic with folding slide

with foot pedal pressure

03: like 02

04: like 00

05: like 01

06: Insertion position

with foot pedal pressure

07: like 06

3.3.2 Working WITHOUT automatic clamp push-back

Seam parameter 24 INTERMEDIA TE STOP SELECTION + POS.

This parameter allows to define the positioning of the main clamp after

stacking.

Seam parameter 24 = 0 cm.

This setting causes the main clamp to wait on the mitre knife position, until

the foot pedal seam process is pressed.

3.3.3 Working WITH automatic clamp push back

Seam parameter 24 INTERMEDIA TE STOP SELECTION + POS.

Seam parameter 24 = 01 cm

With this setting the main clamp will be driven to the insertion position after

stacking. Pressing the foot pedal seam process closes the main clamp.

3.3.4 Working with INTERMEDIATE STOP of the main clamp

Seam parameter 24 = 20 cm

With this setting the main clamp will be driven until 20 cm before the insertion

position after stacking. Press the foot pedal seam process to drive the main

clamp to the insertion position.

If a different intermediate position of the main clamp is required, it can be

achieved by changing the SP 24. The higher the value the larger is the

distance between intermediate and insertion position.

3.3.5 Working with automatic PICK UP PART using the main clamp

Seam parameter 25 = PICK UP PART + POS.

Seam parameter 25 = 00 cm

Pick up part using the main clamp is disabled.

Seam parameter 25 = 01 cm

Pick up part using the main clamp until the insertion position.

The main clamps will be lifted after mitre cutting and SP 23 (duration final

roller) is carried out. The final roller pulls the work piece a little out of the

open main clamp. Now the main clamp is lowered after the time of basic

parameter 28 and drives with the work piece to the insertion position.

2-13

Page 34

Seam parameter 25 = 01 cm

When defining SP 23 (duration final roller) = 00 and NSP 23 = 00 sec., the

final roller won’t get active; the main clamp remains closed and drives without

clamp pressure to the insertion position.

Seam parameter 25 = 20 cm

Pic up parts with the main clamp until 20 cm before the insertion position.

3.4 Seam images

3.4.1 Sewing with catch

3.4.2 Sewing with stitch condensation

3.4.3 Sewing with stowing

2-14

Page 35

3.5 Basic parameters

The basic parameters contain the general settings of the machine. Changes

effect all programmed seams.

Attention

As a factory setting, the basic parameters are optimized. Improper changes

may cause faults in the machine process, which may lead to a reduction of

quality and damages to the machine.

Follow this procedure to changes basic parameters:

1. Press the P-key .

2. Press F4.

3. Select the desired basic parameter using the arrow keys.

4. Press ENT-key .

5. Enter the desired value.

6. Repeat steps 3. to 5. for all desired basic parameters.

7. Press the P-key to leave the submenu.

During the selection of the parameters, you can scroll line per line using the

vertical arrow keys. You can also select the pages directly:

• Key 0: basic parameters 01 - 14

• Key 1: basic parameters 10 - 23

• Key 2: basic parameters 20 - 33

• Key 3: basic parameters 30 - 40

The following basic parameters can be changed [factory-set values in square

brackets]:

01 Front positioning point [135 mm]

distance between insertion position and seam start; if seam length is

changed only the seam end is varied

02 Middle positioning point [225 mm]

with this setting the seam start is calculated that if the seam length is

changed, seam start and end are delayed the same; is used for back

pocket with dart, if dart shall be positioned in the middle of the pocket

03 Rear positioning point [315 mm]

distance between insertion position and seam end; if seam length is

changed, only the seam start is varied

Length of main clamp 165 mm set value 205 mm

245 mm 285 mm

290 mm 330 mm

Attention

This parameter defines the end of the main clamp. If this parameter is set too

large, there may be sewing problems while sewing flaps.

04 Folder up after [335 mm]

time of the folder lifting after the seam; if distance too short, folder gets

caught by the fold pushers

05 Thread length full spool [57 m]

a wrong thread length leads to incorrect values in the display of

remaining thread

08 Clamp down automatically

if defined, the main clamp closes after reaching the insertion position

and the set time

09 Time after clamp down

time delay between clamp down and next operation

2-15

Page 36

11 Before zipper (zipper clamp) clamp lateral (option)

16 Time before insertion

after the set time the main clamp drives from the insertion position to

sewing start (foot pedal machine process pressed)

17 Piping blowing off

piping and flap are blown to the folder, to prevent a tilt movement of

the piping; time may not be too long, since otherwise the thread will be

blown to the needle

18 ‘Thread clamp open’ at seam start (Beisler sewing head)

after the first two stitches the upper threads should be released from

the thread clamp; after the time defined here, the thread clamp opens

19 ‘Thread clamp open’ - duration

duration of ‘thread clamp open’ at seam start

20 Point stitches during sewing

allows one or several stitches at seam start and end to meet the end

point exactly

21 Cut til upper thread

time for catching and cutting of the upper thread

22 Upper thread cutting time

length of the threads after upper threads picked up

23 Scissor cutting time

influences the zipper scissor to cut the zipper completely before

moving to the end position

24 Drive to cutting

percentage of the clamp speed used by the main clamp to drive to the

mitre knifes

25 Mitre knife distance

distance between the mitre knifes

26 Mitre knifes cutting time

cutting time of the mitre knifes

27 Main clamp open

open the main clamp after mitre cutting; if time’s too short, the work

piece may slip out of the machine before taken by the stacker

28 T aking parts

when taking parts with weak clamp (inner pocket production) the main

clamp opens after mitre cutting, the final roller moves the part lateral

from the clamp; then the clamp is switched with this parameter, that

the main clamp detects the work piece faster and brings it to the

insertion position

29 T urn til final roller [0.1 sec.]

time for the start of the final roller

30 Time til final roller up [0.5 sec.]

keeping the work piece after rolling, until the stacker has taken the

work piece

31 Clamp speed [90%]

speed of the main clamp to the insertion position

32 Process step-by-step [00]

enter >01 to enable the switching of all machine functions

33 Remaining thread counter on/off [00] (option)

function can be enabled and disabled; 01 = remaining thread

monitoring on; this disables the spool thread counter

34 Thread cutter revs [250 Rpm]

positioning revs for threat cutting systems:

Beisler sewing head 250 Rpm

Pfaff sewing head 180 Rpm

Singer sewing head 250 Rpm

2-16

Page 37

35 Thread cutter position [45] (01 - 59)

start correction threat cutter impulse; the smaller the number, the

earlier the bobbin threat cutter is started

36 Threat cutter duration [0,1 Sek.]

duration of bobbin threat cutter should be minimized, otherwise the

main clamp is already driving

37 Piping turn delay [00 mm]

37: after the mitre cutting, the main clamp drives the distance set here

in mm.

38 Piping turn duration [0,0 Sek.]

05: impulse duration for the piping turn

2-17

Page 38

4 Troubleshooting hints

The following tables show possible error messages and the recommended

reactions of the operator. Error messages are imaged in the display of the

operating device.

Attention

Please obey the recommended actions in case of errors. Otherwise you

could damage the machine. In this case, producer’s warranty would be

spoiled. We won’t accept any liability for caused damage.

Error message Circumstances Recommended actions

Error 01: Sewing

program empty

Error 02: Seam not

enabled

Error 05: I/O communication error

Error 06: Path pulses

not valid

Error 07: No path pulses

from engine

current sewing program is empty ,

possibly distances and values are

not entered or the whole program is

deleted

current seam not enabled; No. is

shown black on white

transfer error between controls and

I/O module

wrong position of the clamp sledge check generator connection to clamp engine-

no path pulses from clamp engine;

if the clamp engine has done a

small movement, the path pulses

couldn’t be processes adequately

if the engine doesn’t work, the fault

is in the activation or the power part

of the clamp engine

enter program values manually if required; copy

from other programs or load from the memory

(INIT parameter)

Press ENT-key to enable the seam

check connecting wire; if not successful, change

controls and/or I/O module

check flat conductor plug of adaption module

9020020 > 9020013change adaption module

9020020

check connection to clamp enginechange clamp

enginechange adaption module 9020020

check condition of the diodes at the power card

(Berger); do further examinations according to the

Berger engine diagnosticscheck connection to

clamp engine (plug)check connection 9020020 >

power insert (plug)change adaption module

9020020

Error 08: Main clamp at

the stop

Error 09: Clamp can’t

leave the switch

Error 10: A piece is

inserted

Error 1 1: Enable vacuum before

Error 12: Interface end interface monitor (photo cell 21)

2-18

limitation switch ES01 or ES17 has

switched during clamp move,

although the clamp is at a distance

clamp sledge drives to the termination switch after initialisation but

cannot leave the switch (no change

of direction)

push back barrier (photo cell ES27)

is not lighted

vacuum enabled with mode Par32

= 01, but not switched on before

sewing start

detects interface end

check distance counter using the test program

(path steps); if counter defective, change clamp

engine or adaption board 9020020if counter OK,

check both switches and connections

enter a small speed with test program ‘Clamp

engine control’ and change direction using the

arrow keys; check if engine doesn’t change

direction:connection 9020020 > power insert

(plug)Berger power partif the engine changes

direction, check termination switch ES 17

check photo cell and film

switch on vacuum or change vacuum mode

insert new interface roll or check photo cell

Page 39

Error 13: Error clamp

position

difference between must and real

position (impulses from incremental

Gerber) of the clamp sledge is too

big; clamp sledge blocked

removed the blocking partcheck clamp sledge for

easy goingcheck engine piniontighten transport

belt

Error 14: Insertion /

seam length wrong

Error 15: Stamp not up stamp hasn’t reached the top

Error 16: Folder not

straight

Error 17: Folder not up folder hasn’t reached top position

Error 18: Folder not

down

Error 19: Folder not

sloping

Error 20: Knifes not

together

Error 21: Mitre knife notupmitre knife couldn’t reach top

back insertion point is selected;

seam length longer than the distance to the back insertion point

position after switching off

folder hasn’t reached middle

position within error time

within error time

folder hasn’t reached position within

error time

folder hasn’t reached position

‘sloping’ (for picking) within error

time

the mitre knife hasn’t reached start

position before sewing insertion

position within error time

program lengths correctly

check cylinder, gauge Y20, termination switch

ES19

check cylinder, gauge Y15, termination switch

ES05

check cylinder, gauges Y24 Y25, termination

switches ES03 ES04

check cylinder, gauges Y24 Y25, termination

switches ES03 ES04

check cylinder, gauge Y15, termination switch

ES06

check termination switch ES20check connection

to mitre knife engine (plug)check diodes on

Berger power cardcontinue search acc. to Berger

engine diagnostics

check cylinder, gauges Y03 Y48, termination

switch ES13

Error 22: Front mitre

knife not down

Error 23: Rear mitre

knife not down

Error 24: Scissor not up scissor couldn’t reach top position

Error 25: Scissor not

down

Error 26: Pinole not up the pinole for flap turning couldn’t

Error 27: Pinole not

down

Insert: see right-handed side

Error 52: Flap station

not in starting position

Error 53: Pocket bag

station not in starting

position

front mitre knifes (seam end)

couldn’t reach bottom position

within error time

rear mitre knifes (seam start)

couldn’t reach bottom position

within error time

within error time

scissor couldn’t reach cutting

position within error time

reach top position within error time

bottom position not reached within

error time

flap station couldn’t reach starting

position within error time

Pocket bag supply couldn’t reach

starting position within error time

check cylinder, gauge Y04, termination switch

ES19

check cylinder, gauge Y04, termination switch

ES18

check cylinder, gauges Y21 Y22, termination

switch ES14

check cylinder, gauges Y21 Y22, termination

switch ES15

check cylinder, gauge Y59, termination switch

ES41

check cylinder, gauge Y59, termination switches

ES39 ES40

check cylinder, gauge Y17, termination switch

ES07

check cylinder, gauges Y18 Y19, termination

switch ES1 1

Error 54: Station not

locked

folder station not locked lock stationcheck termination switch ES02

2-19

Page 40

Error 28: No impulses

from sewing engine

no impulses from sewing engine

after sewing start (engine doesn’t

work)

check sewing engine and synchronizationcheck

connection 9020013 > sewing engineread two

upper diodes at 9020013: left lights shortly if

needle in top position; right shows synchronizator

impulses (512 impulses per turn); if none lights

while turning the hand wheel, check power

supply; possibly change sewing engine

if diodes are working and engine doesn’t move

before error message, check connection 9020020

> sewing engine; possibly change 9020020 or

engineif engine works shortly before error message, check connection controls > I/O module;

possibly change components

Error 29: Sewing engine

too fast

Error 30: Thread cutter

position doesn’t come

Error 33: Sewing engine

doesn’t stop

Error 34: Needle not up needle couldn’t reach the top

Error 35: Thread broken threat monitor detects breakage

Error 36: Spool empty mode ‘Bottom thread counter’

during thread cutting the sewing

enginge couldn’t reach cutting

speed within error time

the sewing engine hasn’t reached

the position for thread cutting

engine doesn’t stop within error

time after thread cutting

position; with the error message the

control tries to put the needle into

the top position again

enabled; remaining length is zero

change sewing engine or synchronizator

set a slower cutting speedset an earlier cutting

positionchange sewing engine or synchronizator

set a slower cutting speed; set an earlier cutting

position; change sewing engine or synchronizator

check sewing engine and synchronizator; check

connection 9020013 > sewing engine; read two

upper diodes at 9020013: left lights shortly if

needle in top position; right shows synchronizator

impulses (512 impulses per turn); if none lights

while turning the hand wheel, check power supply;

possibly change sewing engine

if diodes are working and engine doesn’t move

before error message, check connection 9020020

> sewing engine; possibly change 9020020 or

engine

Error 37: Spool only

residual

Error 41: No flap automatic flap legth detection with

Error 42: Photo cell not

lighted

Error 43: Photo cell

lighted too early

Error 45 ... 48: I/O

DACI/O ULNI/O 485I/O

RES

Error 51: Flap station

doesn’t swing

Continuation: see bottom of left-handed side

2-20

one of the photo cells at the spool

capsule is lighted, the spool is

empty

phot cell is enabled but no flap is

detected

automatic flap length detection with

photo cell enabled; no flap within

the security length detected

automatic flap length detection with

photo cell enabled; photo cell

detected flap end too early

internal hardware errors during data

transfer to adaption board 9020020

flap station couldn’t reach the active

position within error time

if both spools are not empty , one photo cell

reflects the thread and must be set smaller

insert flapcheck photo cell ES31 and film

program a longer security lengthswitch off supervision (enter 250 mm as seam length)check photo

cell ES31 and film

program a shorter security lengthswitch off

supervision (enter 250 mm as seam length);

check photo cell ES31 and filmset photo cell

sensitivity smaller (reflections?)

change 9020020

check cylinder, gauge Y17, termination switch

ES08

Page 41

5 Maintenance of the machine

This machine works nearly free of maintenance. To achieve the maximum

ability of the machine for a long term, some regular maintenance duties are

required.

Danger

Before starting maintenance and repair duties, the following power down

procedures are to be executed. Otherwise there could be danger to life!

Cut off mains power

• switch the mains / emergency stop switch to '0' and assure that it can't be

switched on

• check whether the machine is without current and that there is no statical

loading

Switch off pneumatic system

• close the main gauge

• ventilate all pipes and gauges

5.1 Water separator at air connector

The air connector is equipped with an automatic water separator. If the air

supply looses pressure, the contained water will be let out automatically .

5.2 Grease linear guiding

At least once a year, the linear guiding must be greased with normal ballbearing grease:

2-21

Page 42

5.3 Use of the Memory Card

The Memory Card allows to save created seams and/or seam orders on a

removable data cartridge or load them back into the machine.

Hint

We strongly recommend to save own seams or seam orders on the Memory

Card, since otherwise they might get lost in case of an defective EPROM or

possbile other faults.

ATTENTION

The Memory Card contains a battery which is good for est. 2 to 3 years. If the

battery is empty , the saved data will get lost in a short period of time. Don’t

forget to change the battery in time and then save the machine data on the

Memory Card again.

5.3.1 Saving seam data on the Memory Card

1. Insert the Memory Card into the corresponding slot in the front panel of

the operating device (see operating instructions).

2. Press the P-key .

3. Press the F6-key .

4. Press the F2-key .

5. Press one of the keys F1, F3 or F5 (see further below).

6. Confirm by pressing the ENT-key .

You can use one of serveral possibilities to save data on the Memory Card.

Press the key

F1 to save the active seam (which is currently displayed in the

operating device) on the Memory Card;

F3 to save all seam orders;

F5 to save all variables.

If you want to save all your data on the Memory Card, you should press the

F5-key.

2-22

5.3.2 Loading seam data from the Memory Card

ATTENTION

Seam data from the Memory Card overwrite the data saved in the operating

device. If you have changed your seams, you will have to save them on the

Memory Card.

1. Insert the Memory Card into the corresponding slot in the front panel of

the operating device (see operating instructions).

2. Press the P-key .

3. Press the F6-key .

4. Press the F2-key .