Page 1

Manual | EN

TE3520

TwinCAT 3 Analytics Service Tool

8/12/2020 | Version: 1.0

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................5

1.1 Notes on the documentation..............................................................................................................5

1.2 Safety instructions .............................................................................................................................6

2 Overview.....................................................................................................................................................7

3 Installation..................................................................................................................................................8

3.1 System requirements.........................................................................................................................8

3.2 Installation and licensing ...................................................................................................................8

3.3 Licensing .........................................................................................................................................11

4 Analytics Workflow - First Steps............................................................................................................14

4.1 Recording data from the machine ...................................................................................................14

4.2 Communication................................................................................................................................17

4.3 Historicize data ................................................................................................................................18

4.4 Analyse data....................................................................................................................................23

5 Technical introduction ............................................................................................................................28

5.1 Basic concept ..................................................................................................................................28

6 Configuration ...........................................................................................................................................30

6.1 Networks..........................................................................................................................................30

6.2 Algorithms........................................................................................................................................31

6.2.1 Analytics - Base ............................................................................................................... 33

6.2.2 Analytics - Classification .................................................................................................. 62

6.2.3 Analytics - Compare ........................................................................................................ 83

6.2.4 Analytics - Math ............................................................................................................... 95

6.2.5 Analytics - Training Base ............................................................................................... 100

6.2.6 Analytics - XTS .............................................................................................................. 102

6.2.7 Analytics - WT................................................................................................................ 106

6.2.8 Analytics - XY Path Analysis.......................................................................................... 108

6.3 Interaction with Scope ...................................................................................................................117

6.4 Working with Historical Data..........................................................................................................121

7 Appendix ................................................................................................................................................124

7.1 FAQ - frequently asked questions and answers............................................................................124

TE3520 3Version: 1.0

Page 4

Table of contents

TE35204 Version: 1.0

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning the components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCAT G®, EtherCAT G10®, EtherCAT P®, Safety over EtherCAT®,

TwinSAFE®, XFC®, XTS® and XPlanar® are registered trademarks of and licensed by Beckhoff Automation

GmbH.

Other designations used in this publication may be trademarks whose use by third parties for their own

purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents:

EP1590927, EP1789857, EP1456722, EP2137893, DE102015105702

with corresponding applications or registrations in various other countries.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

TE3520 5Version: 1.0

Page 6

Foreword

1.2 Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

Description of symbols

In this documentation the following symbols are used with an accompanying safety instruction or note. The

safety instructions must be read carefully and followed without fail!

DANGER

Serious risk of injury!

Failure to follow the safety instructions associated with this symbol directly endangers the life and health of

persons.

WARNING

Risk of injury!

Failure to follow the safety instructions associated with this symbol endangers the life and health of persons.

CAUTION

Personal injuries!

Failure to follow the safety instructions associated with this symbol can lead to injuries to persons.

NOTE

Damage to the environment or devices

Failure to follow the instructions associated with this symbol can lead to damage to the environment or

equipment.

Tip or pointer

This symbol indicates information that contributes to better understanding.

TE35206 Version: 1.0

Page 7

2 Overview

Overview

The TwinCAT3 Analytics Service Tool is used for commissioning the machine and for service engineers.

Live and historical data can be retrieved for an analysis via the IoT connection or offline via file copy. The

analysis is configured in Microsoft Visual Studio where the user has access to a toolbox of algorithms for

implementing the relevant life time, cycle time, envelope or component counter analysis. The outputs of the

algorithms can be used as inputs for other algorithms or can be output as a result directly in the graphical

editor. Signal paths can be visualised with ease by means of parallel recording with the TwinCAT Scope.

Analysis results can be dragged by the user from the analytics configurator and dropped in the charting tool

so as to mark the significant positions in the data stream. The interaction between the product components

offers advantages in particular for diagnosing machine behavior and can highlight optimisation potential. The

user’s location is immaterial owing to the IoT technologies used, which means that service technicians can

perform system and machine diagnostics from practically any location.

Components

• Analytics configurator

• Base Analytics algorithm

• Analytics Storage Provider Recorder

• TwinCAT Scope (TE1300 and TF3300)

• IoT Connectivity

TE3520 7Version: 1.0

Page 8

Installation

3 Installation

3.1 System requirements

The following system requirements must be fulfilled for proper function of TwinCAT Analytics.

Supported operating systems

Windows 7, Windows 8.1 and Windows 10

TwinCAT

Minimum is TwinCAT 3.1 Build 4022.29 for engineering with TwinCAT Analytics Service Tool and

Workbench.

.NET Framework

For the engineering a .NET Framework 4.6.2 is required.

Visual Studio development environment

• Microsoft Visual Studio ® 2013 Update 5

• Visual Studio® 2015

• Visual Studio® 2017

• TwinCAT XAE Shell

In general, it is enough to use the Visual Studio® Shell. If you choose the “Full” setup it will install

automatically the TwinCAT XAE Shell. The “Update” setup provides just an update of the Analytics sources

and no Visual Studio® Shell.

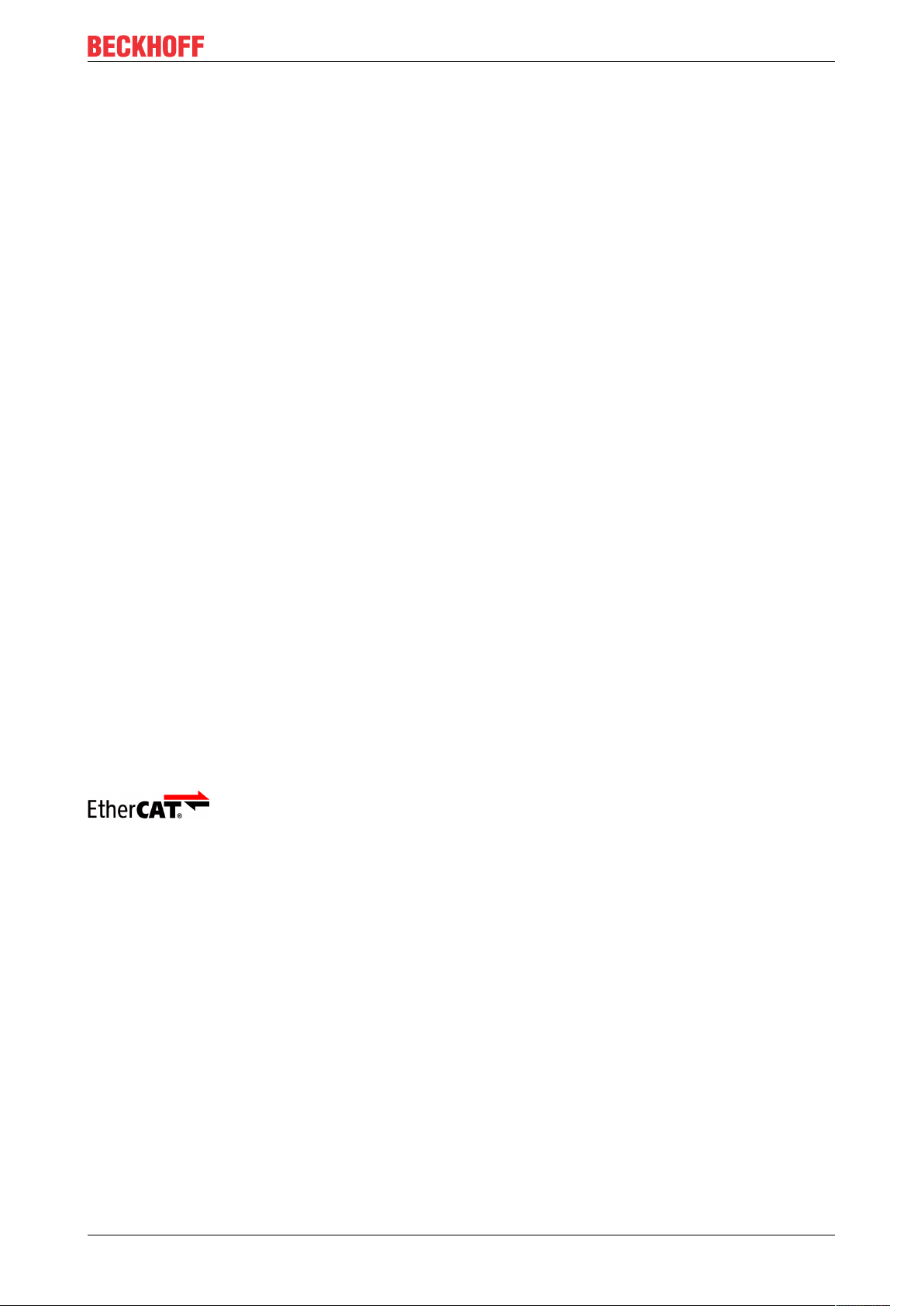

3.2 Installation and licensing

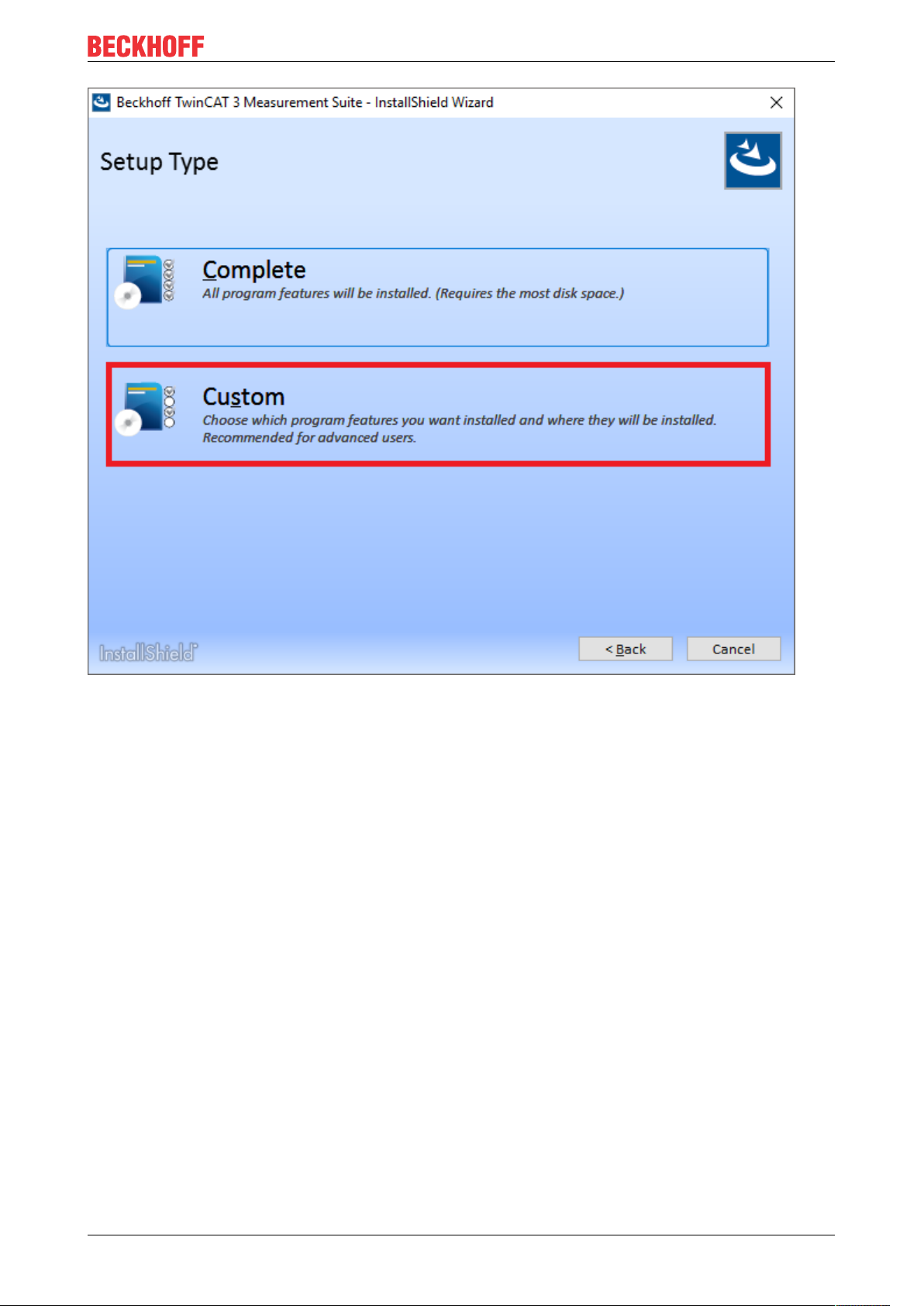

The TwinCAT Analytics setup is part of the TwinCAT Measurement Suite setup. You will be able to choose

the Analytics option only by a click on Custom setup.

TE35208 Version: 1.0

Page 9

Installation

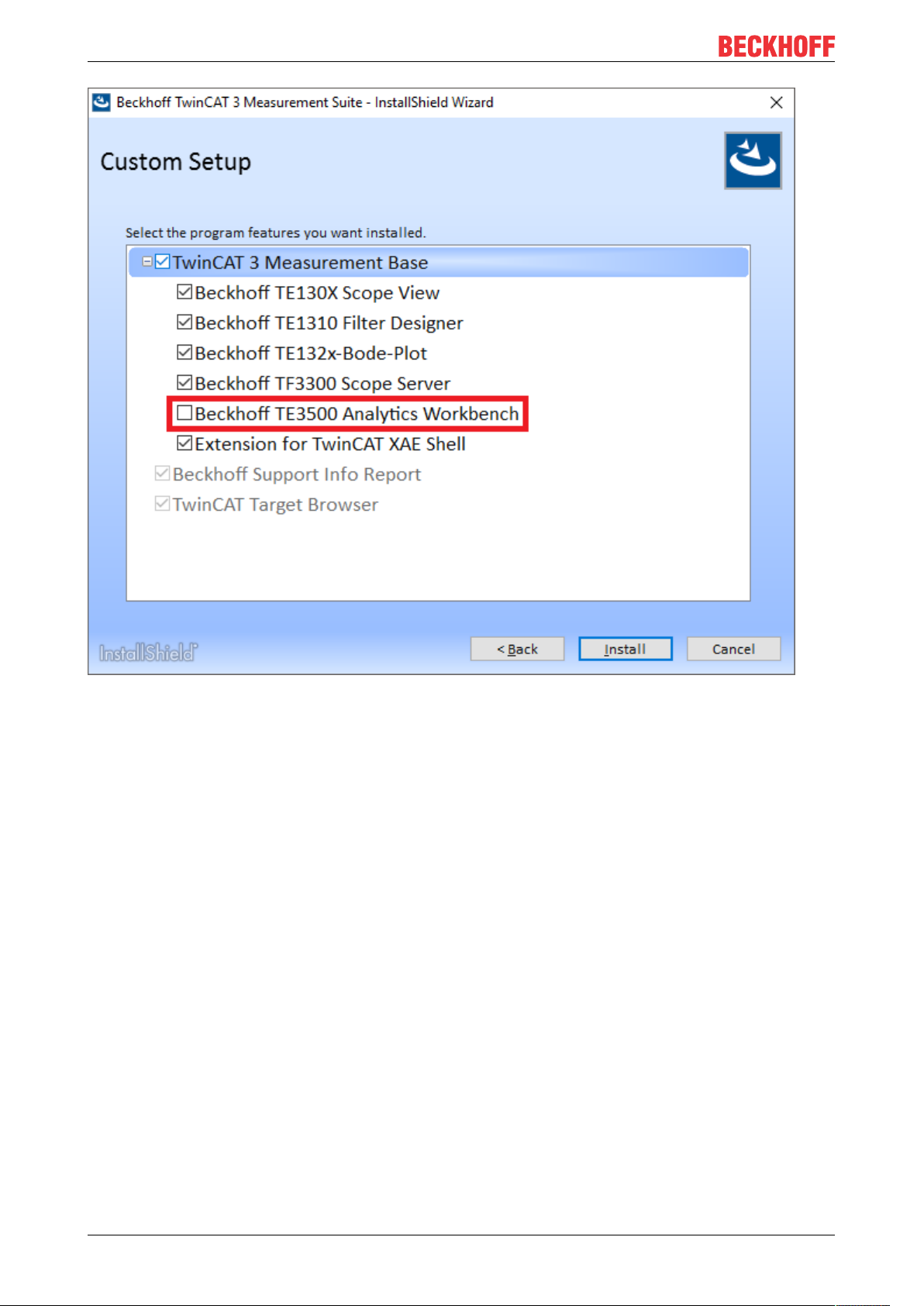

You can enable the option “Beckhoff TE35xx Analytics Engineering”. Depending on the license it provides

later the function of the Analytics Workbench or Service Tool.

TE3520 9Version: 1.0

Page 10

Installation

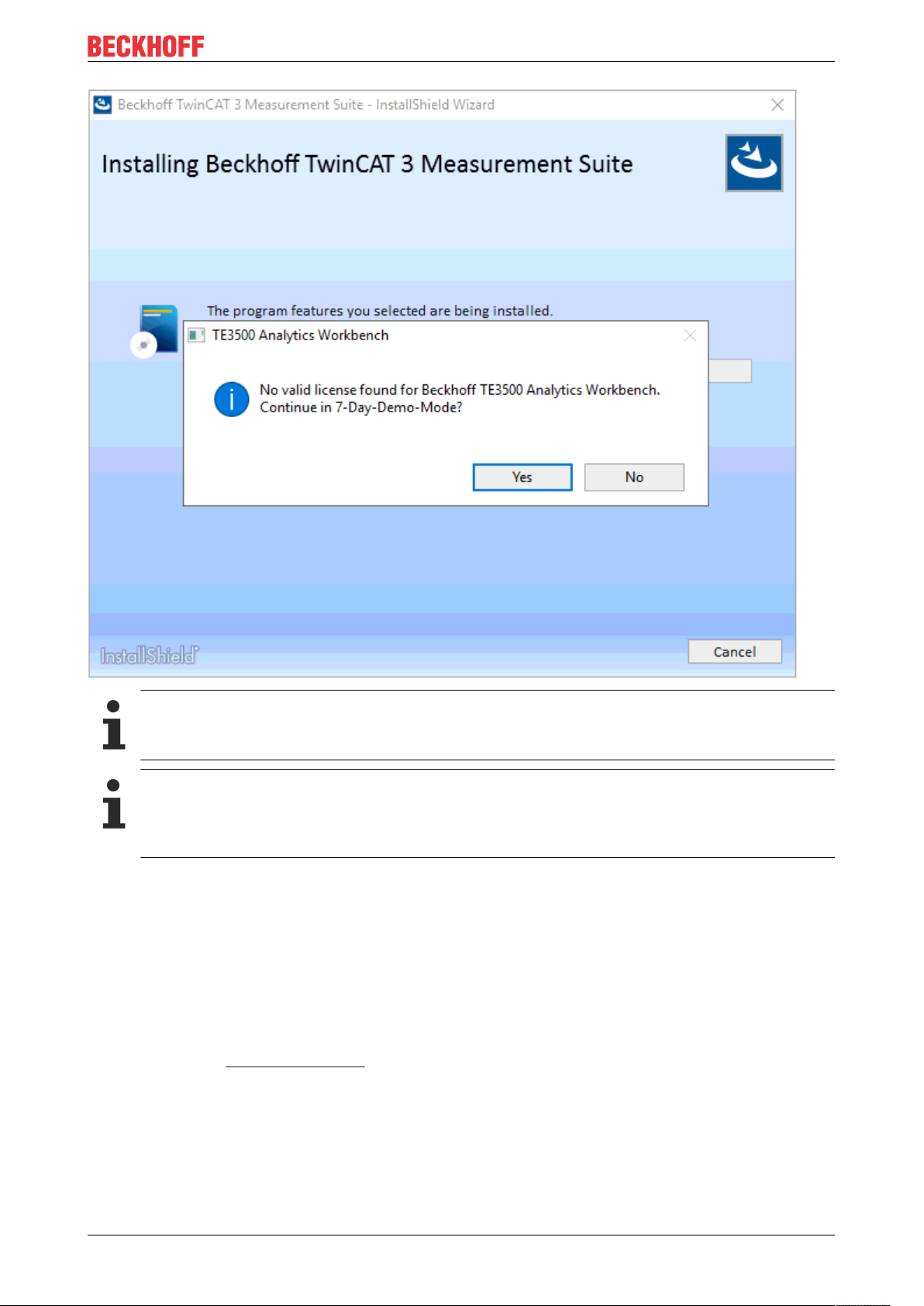

The Analytics setup will check during the process if your system provides the necessary licenses. If not, then

a demo can be activated. This demo can be extended as often as desired, however, no update of the

software/setup on this system is possible. For this purpose, a license must be acquired.

TE352010 Version: 1.0

Page 11

Installation

Setup needs license

Updates of TwinCAT Analytics engineering tools are only possible with a valid maintenance license!

TwinCAT 3 licenses for non-Beckhoff devices

If you use an IPC from a manufacturer other than Beckhoff (TwinCAT 3 plattform level >= 90),

aTwinCAT 3 licencse dongle is highly recommended, if not a prerequisite for successful licensing of

TwinCAT Analytics!

3.3 Licensing

The TwinCAT3function can be activated as a full version or as a 7-day test version. Both license types can

be activated via the TwinCAT 3 development environment (XAE).

Licensing the full version of a TwinCAT3Function

A description of the procedure to license a full version can be found in the Beckhoff Information System in

the documentation "TwinCAT3Licensing".

Licensing the 7-day test version of a TwinCAT3Function

Note: A 7-day test version cannot be enabled for a TwinCAT 3 license dongle.

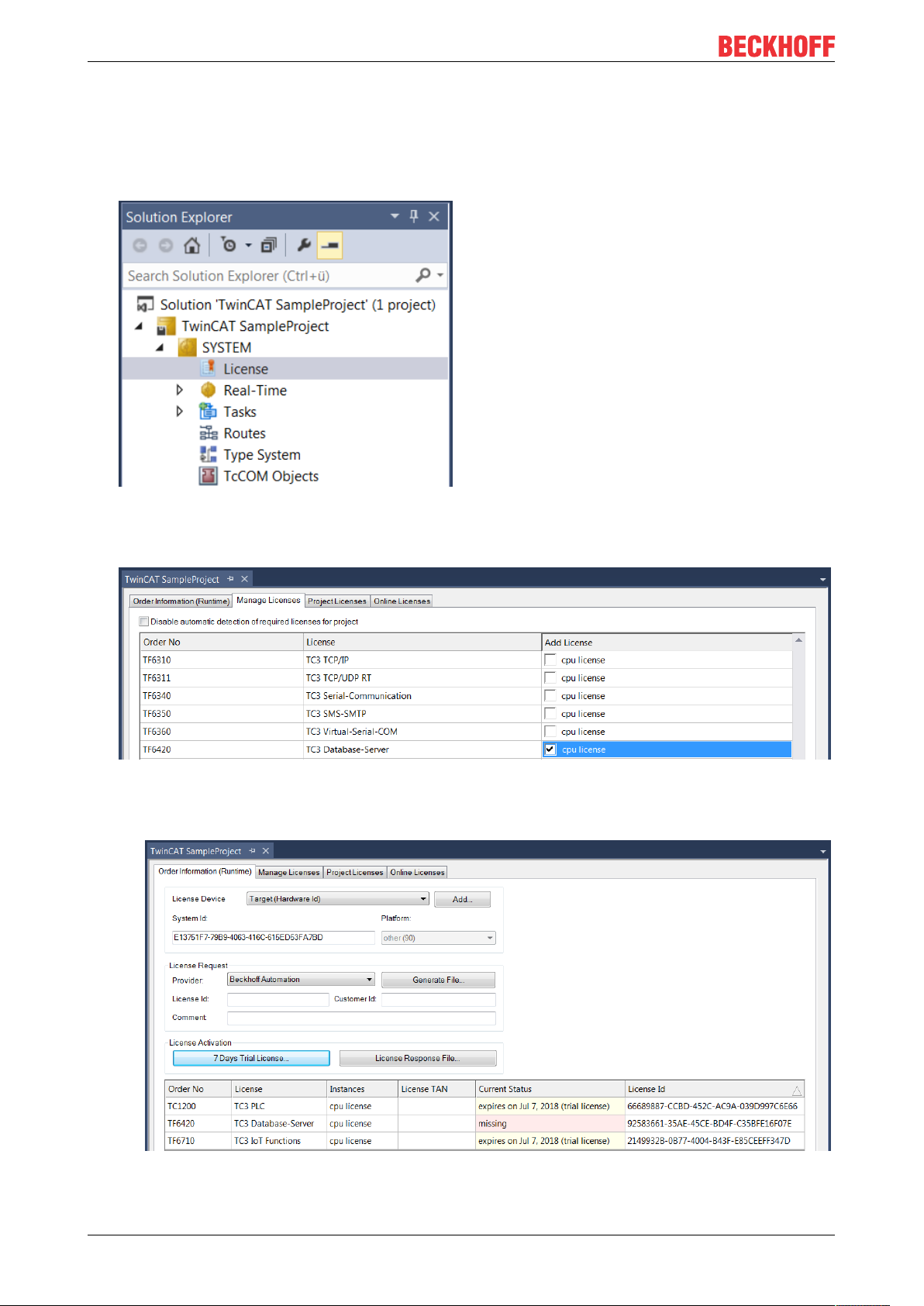

1. Start the TwinCAT 3 development environment (XAE).

2. Open an existing TwinCAT 3 project or create a new project.

TE3520 11Version: 1.0

Page 12

Installation

3. If you want to activate the license for a remote device, set the desired target system. To do this, select

the target system from the Choose Target System drop-down list in the toolbar.

ð The licensing settings always refer to the selected target system. When the project is activated on

the target system, the corresponding TwinCAT 3 licenses are automatically copied to this system.

4. In the Solution Explorer, double-click License in the SYSTEM subtree.

ð The TwinCAT 3 license manager opens.

5. Open the Manage Licenses tab. In the AddLicense column, check the check box for the license you

want to add to your project (e.g."TF6420:TC3DatabaseServer").

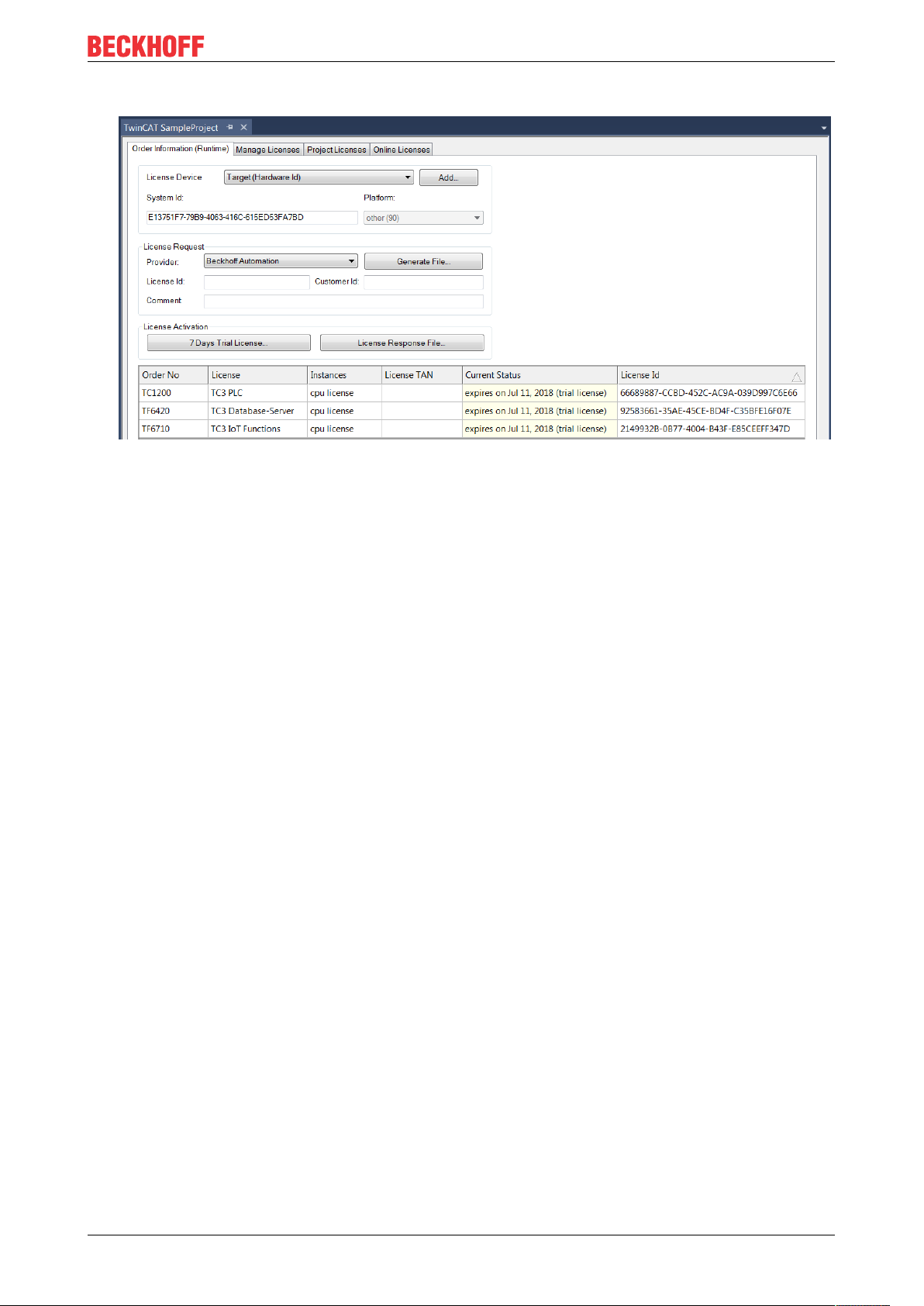

6. Open the Order Information (Runtime) tab.

ð In the tabular overview of licenses, the previously selected license is displayed with the status

“missing”.

TE352012 Version: 1.0

Page 13

Installation

7. Click7-DayTrialLicense... to activate the 7-day trial license.

ð A dialog box opens, prompting you to enter the security code displayed in the dialog.

8. Enter the code exactly as it appears, confirm it and acknowledge the subsequent dialog indicating

successful activation.

ð In the tabular overview of licenses, the license status now indicates the expiry date of the license.

9. Restart the TwinCAT system.

ð The 7-day trial version is enabled.

TE3520 13Version: 1.0

Page 14

Analytics Workflow - First Steps

4 Analytics Workflow - First Steps

This step by step documentation presents the complete TwinCAT Analytics workflow. From the data

acquisition over the communication and historizing up to the evaluation and analysis of the data and to the

presentation of the data in web-based dashboard.

4.1 Recording data from the machine

On the machine side is the Analytics Logger the recorder of process data from the machine image, PLC, NC

and so on. The Logger is working in the real-time context of TwinCAT.

The TwinCAT Analytics Logger is installed with TwinCAT XAE and XAR. The Logger can act as MQTT Client

to communicate the recorded data to a native MQTT Message Broker or store the data in the same data

format in a local binary file. By the usage as MQTT Client the Logger is able to bypass short disconnects to

the Message Broker with a ring buffer functionality. You can configure a ring buffer as well for the local

binary file storage.

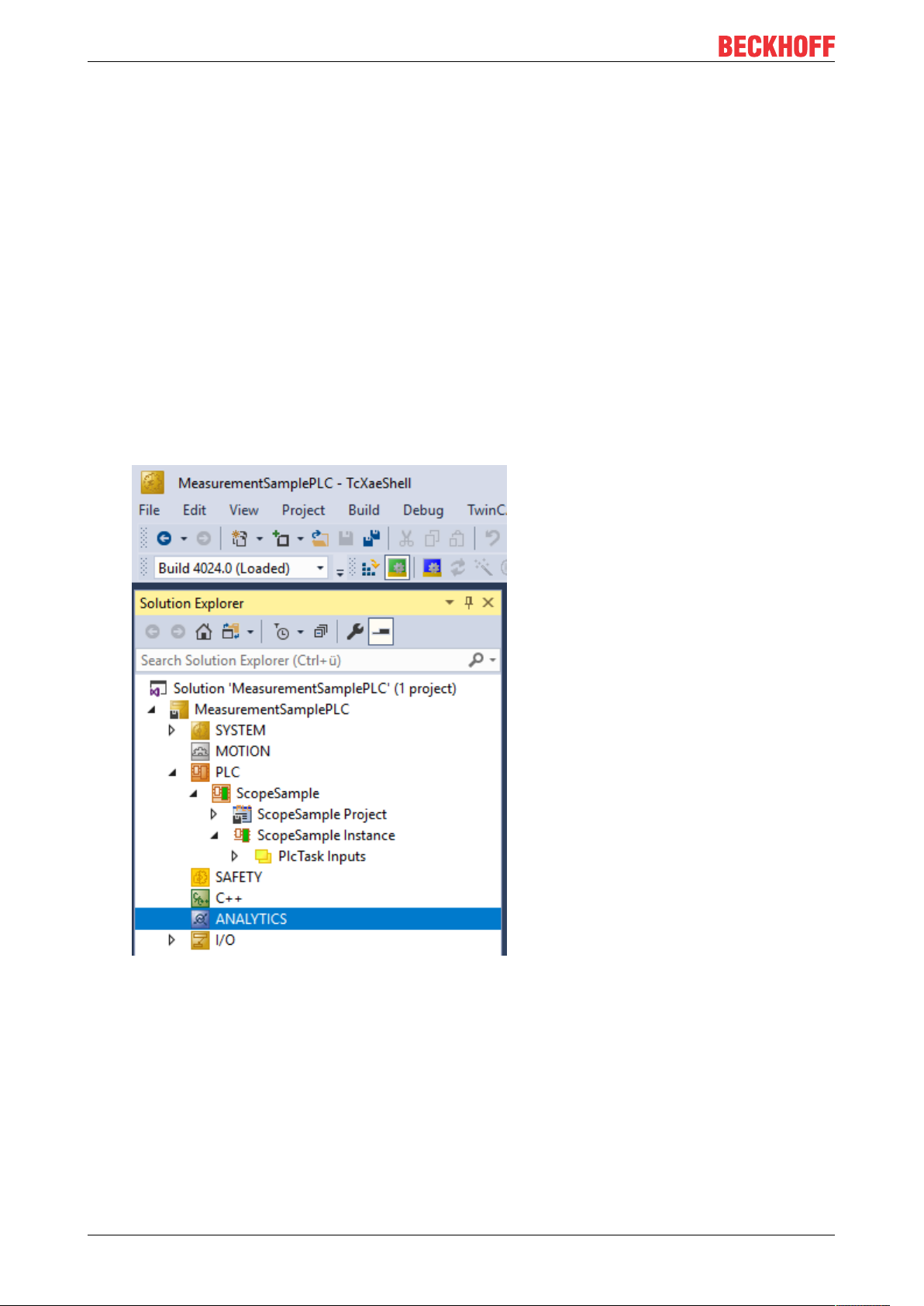

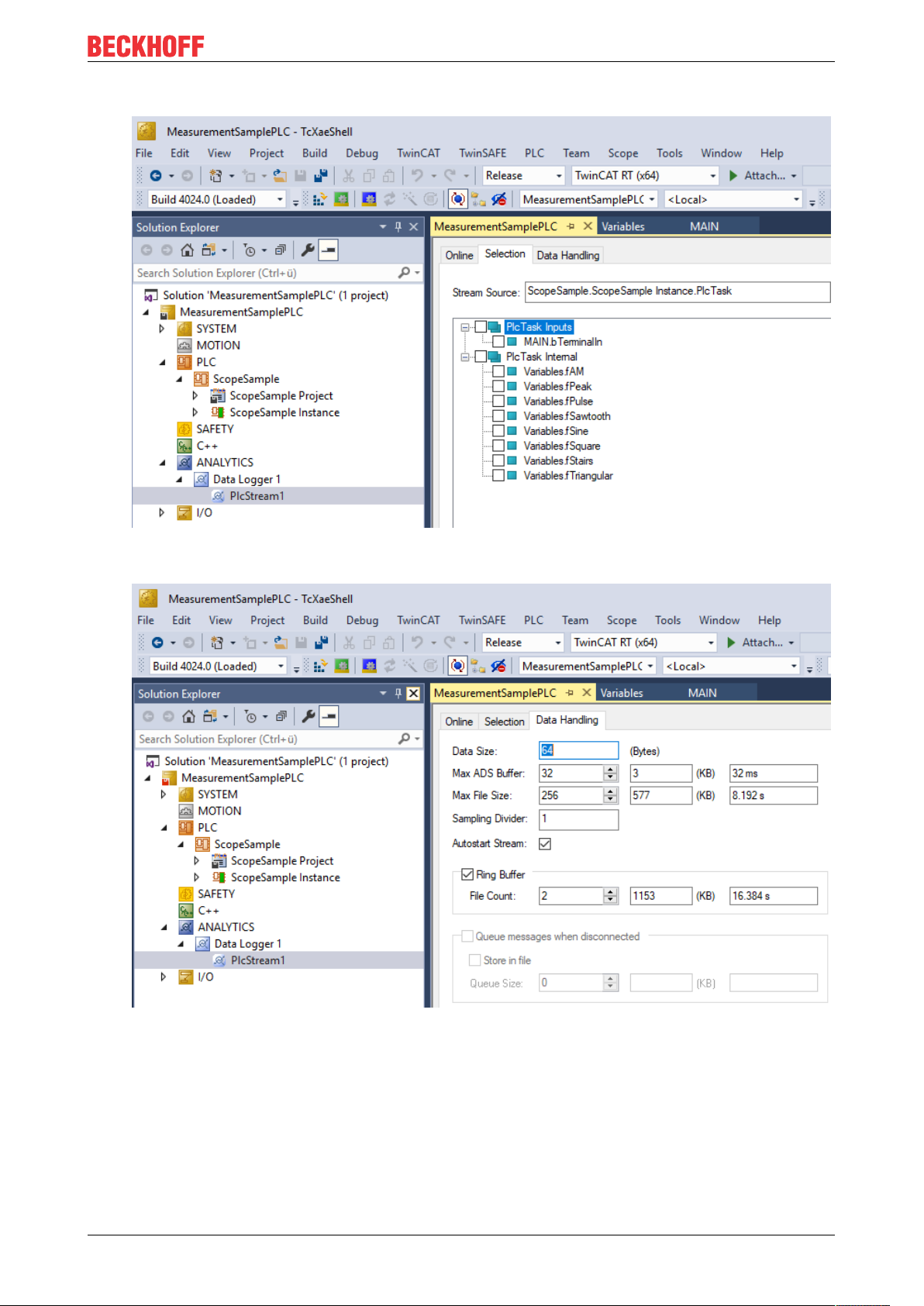

• To configure the Analytics Logger you have to navigate in your existing TwinCAT Project to the

Analytics tree node

TE352014 Version: 1.0

Page 15

Analytics Workflow - First Steps

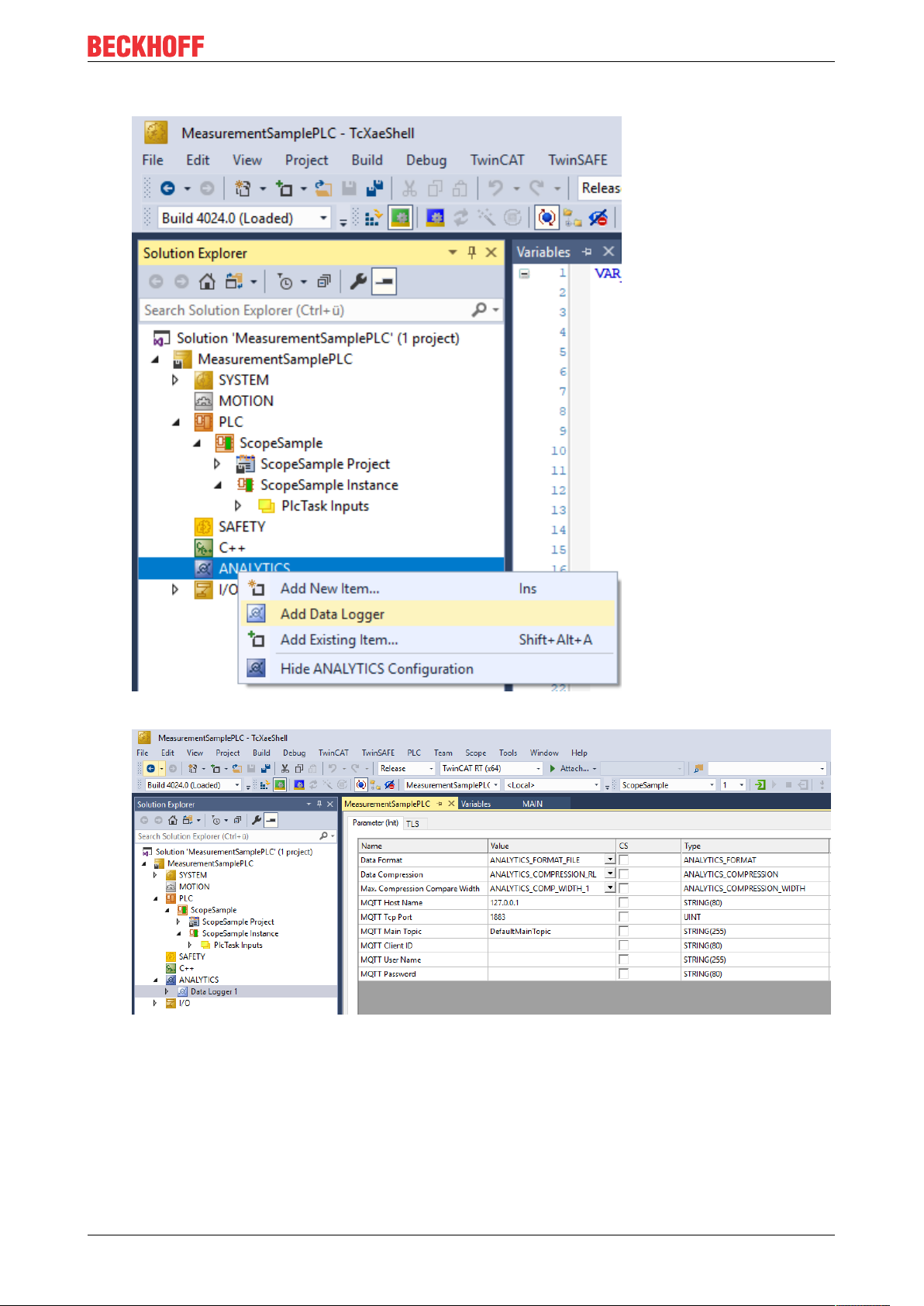

• Right click on this node and click on “Add Data Logger” to add one new instance to your configuration

• For configuring the base settings, please double click on the new tree item

You can make your specific Analytics Logger settings

-Data Format: Binary file or MQTT stream

-FILE format: Analytics Logger stores the data in local binary files and all other settings are not

necessary anymore. The files will be stored in C:\TwinCAT\3.1\Boot\Analytics.

-BINARY: Data will be sent to the configured MQTT Message Broker. You can have multiple Logger in

one TwinCAT project to communicate data to different MQTT Message Broker.

-Data Compression: on (default) or off

TE3520 15Version: 1.0

Page 16

Analytics Workflow - First Steps

-Max Compression: mode of the compression

-MQTT host name

-MQTT Tcp port

-MQTT main topic for own hierarchical levels to keep the identification easy

-MQTT Client ID should be unique in the network

-MQTT username

-MQTT password to make authentication at the message broker

-At the TLS (Transport Layer Security) tab, security settings can be configured. TLS is a secure

communication channel between client and server. By the usage of certificates, the TCP port 8883 is

exclusively reserved for MQTT over TLS. Analytics Logger is supporting the modes CA Certificates, CA

Certificates & Client Certificate and Preshared Key (PSK) mode.

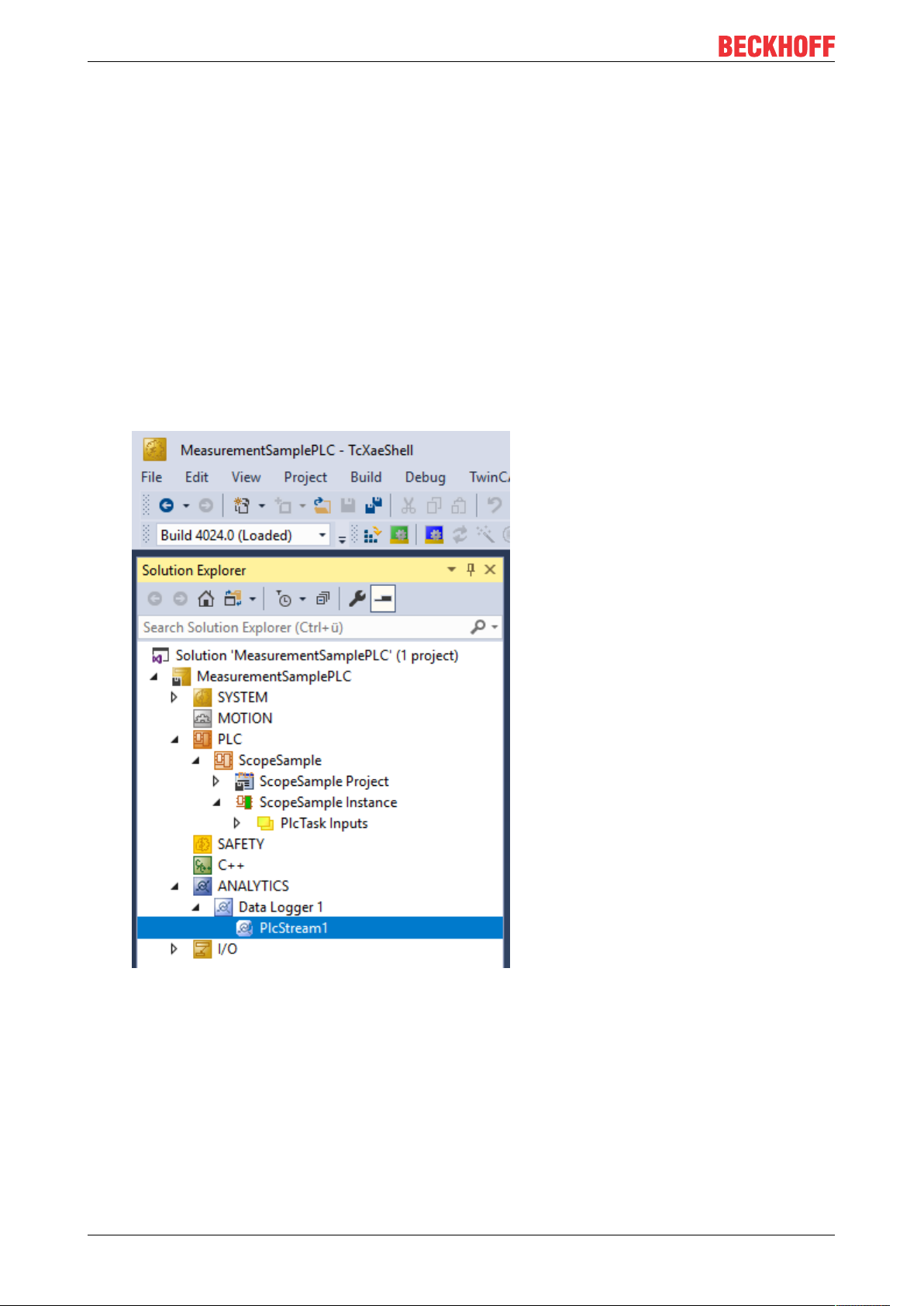

• If variables in your PLC application are marked in the declaration with the attribute {attribute

'TcAnalytics'} they will be shown automatically as a stream below the Data Logger tree node.

An additional device stream will be shown if your configuration provides an EtherCAT Process Image.

TE352016 Version: 1.0

Page 17

Analytics Workflow - First Steps

• In the stream a Selection tab is available to choose the variables that should be recorded

• Finally it is possible to change the package size for the frames or to configure the ring buffer for

disconnects and file in the Data Handling tab.

4.2 Communication

Currently, the Analytics workflow is fully mappable via MQTT. The engineering tools can also access the

data of the machines via ADS and carry out analyzes.

TE3520 17Version: 1.0

Page 18

Analytics Workflow - First Steps

If you choose for the IoT communication protocol MQTT you have to setup a native MQTT Message Broker

somewhere in the network (VM in a cloud system is also possible). This Message Broker provides a

decoupling of the different applications in the Analytics Workflow.

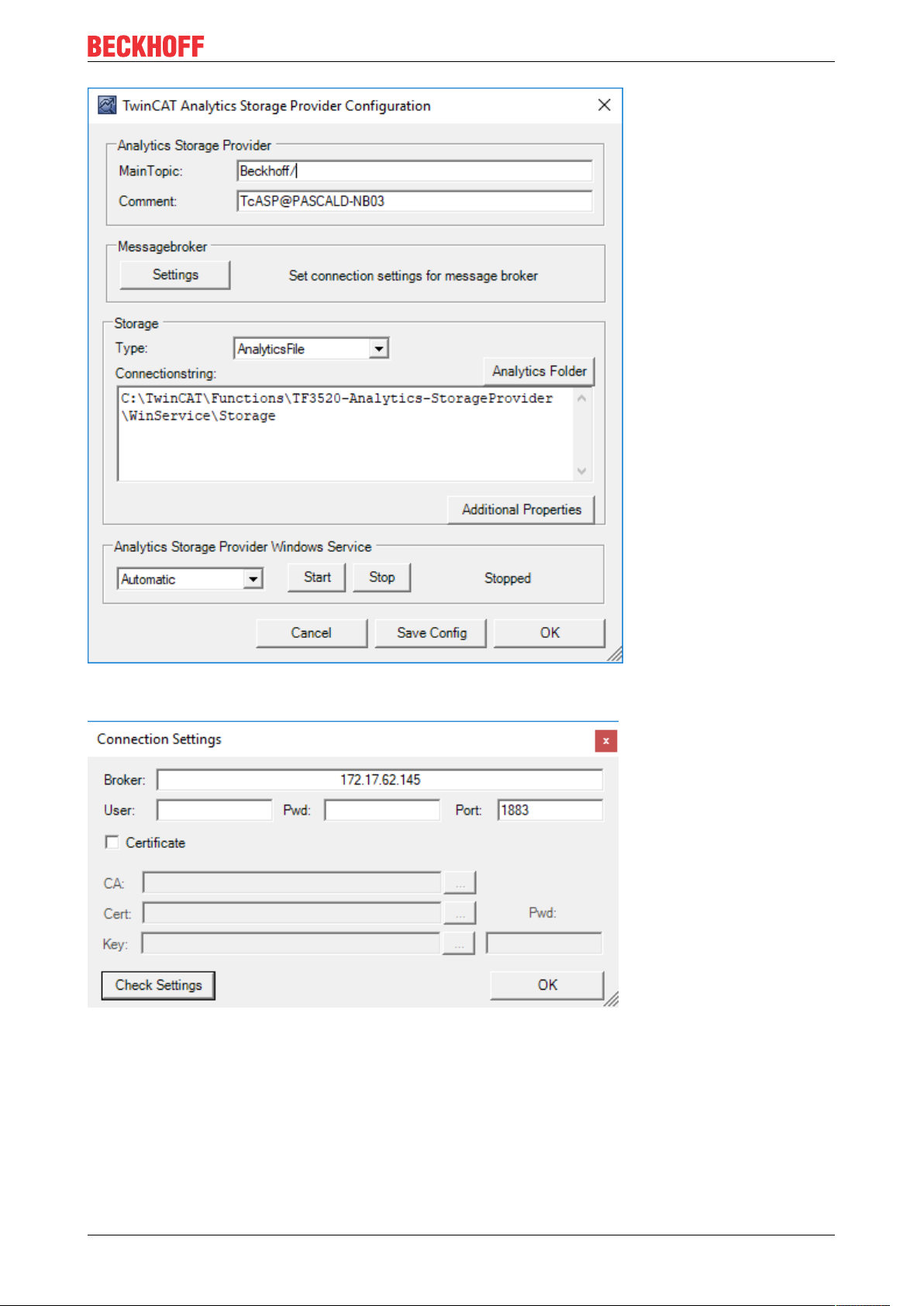

4.3 Historicize data

After installation of the TwinCAT Analytics Storage Provider you are able to configure the service running in

the background. You will find therefore the TcAnalyticsStorageProvider_Config application in the folder C:

\TwinCAT\Functions\TF3520-Analytics-StorageProvider\WinService.

TE352018 Version: 1.0

Page 19

Analytics Workflow - First Steps

The main part of the topic can be set in the configuration as well as the comment which will be used for

identification if more than one Storage Provider is registered at the Message Broker.

You are able to provide the Message Broker settings and to decide for storage type:

• Analytics File (binary file)

• Microsoft SQL

• Microsoft Azure Blob (Azure Cloud necessary)

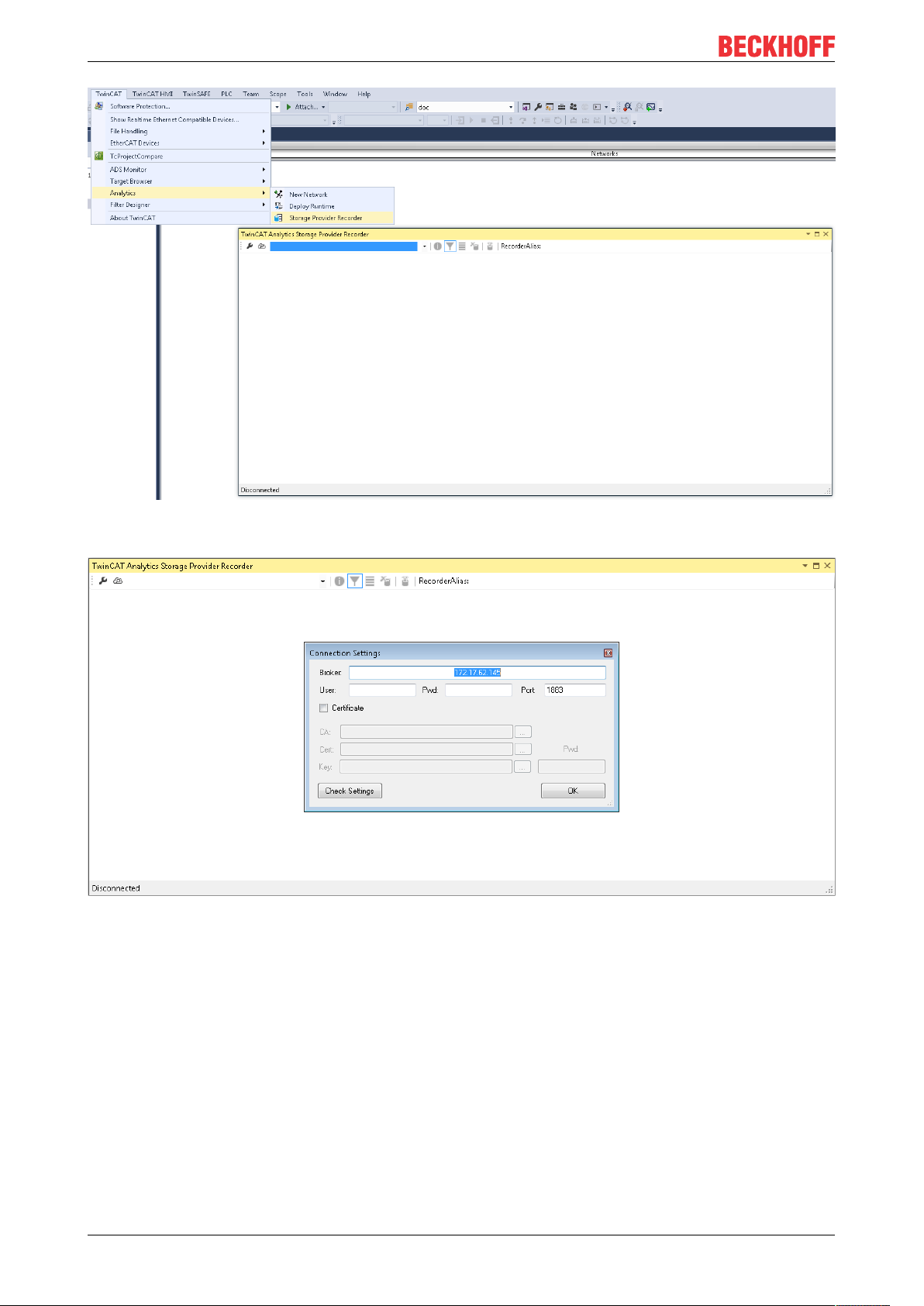

Finally, you can save the config and start the service. The next step is the configuration of the specific

record. Therefore you should choose in your development environment the Storage Provider Recorder.

TE3520 19Version: 1.0

Page 20

Analytics Workflow - First Steps

The recorder has also to connect to the Message Broker. So you have to provide the same settings as for

the background service.

After this you can click to icon with the small cloud to search Storage Providers at the configured Message

Broker. Here you will find also the comment you gave already by the service configuration to identify your

Storage Provider.

TE352020 Version: 1.0

Page 21

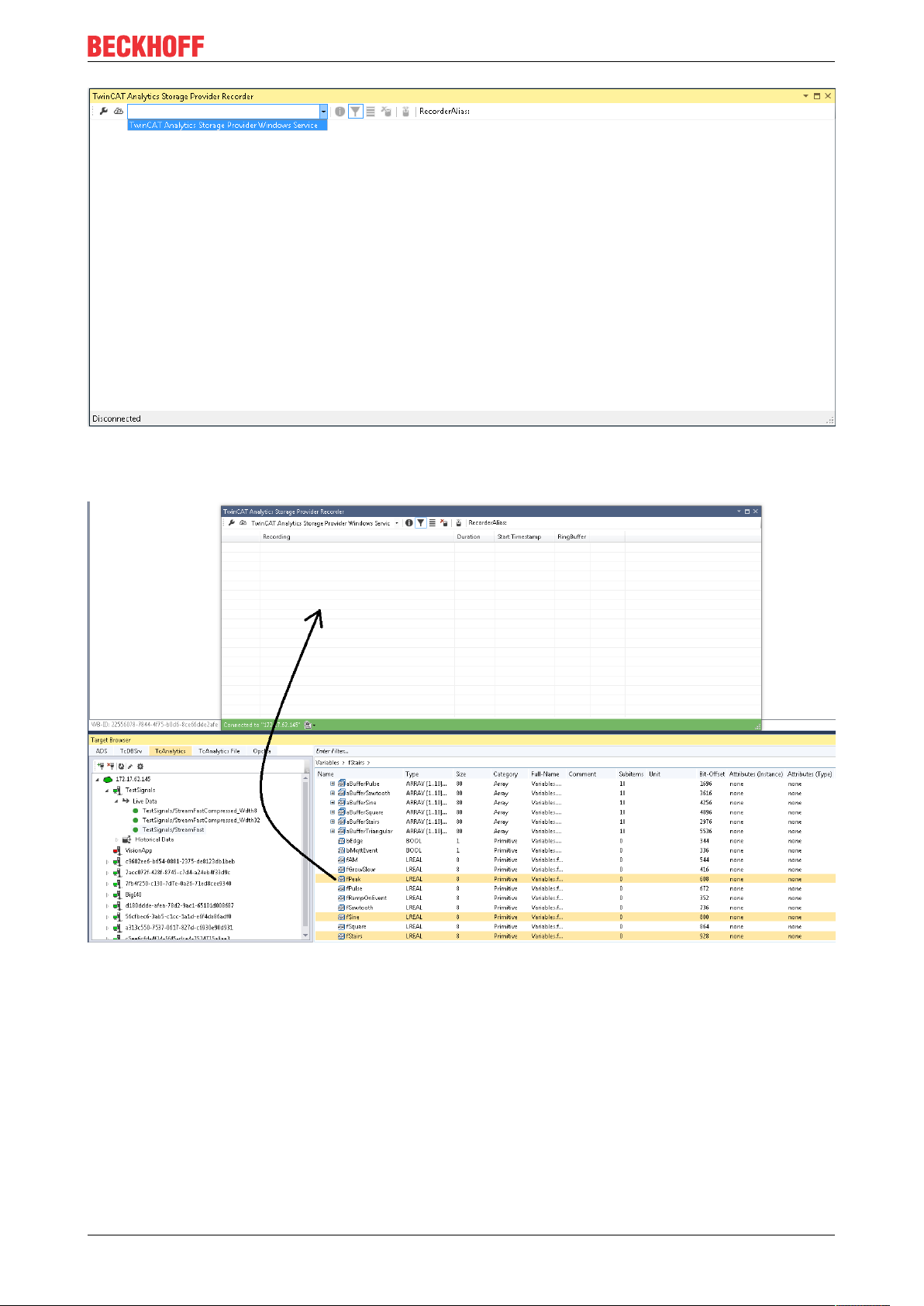

Analytics Workflow - First Steps

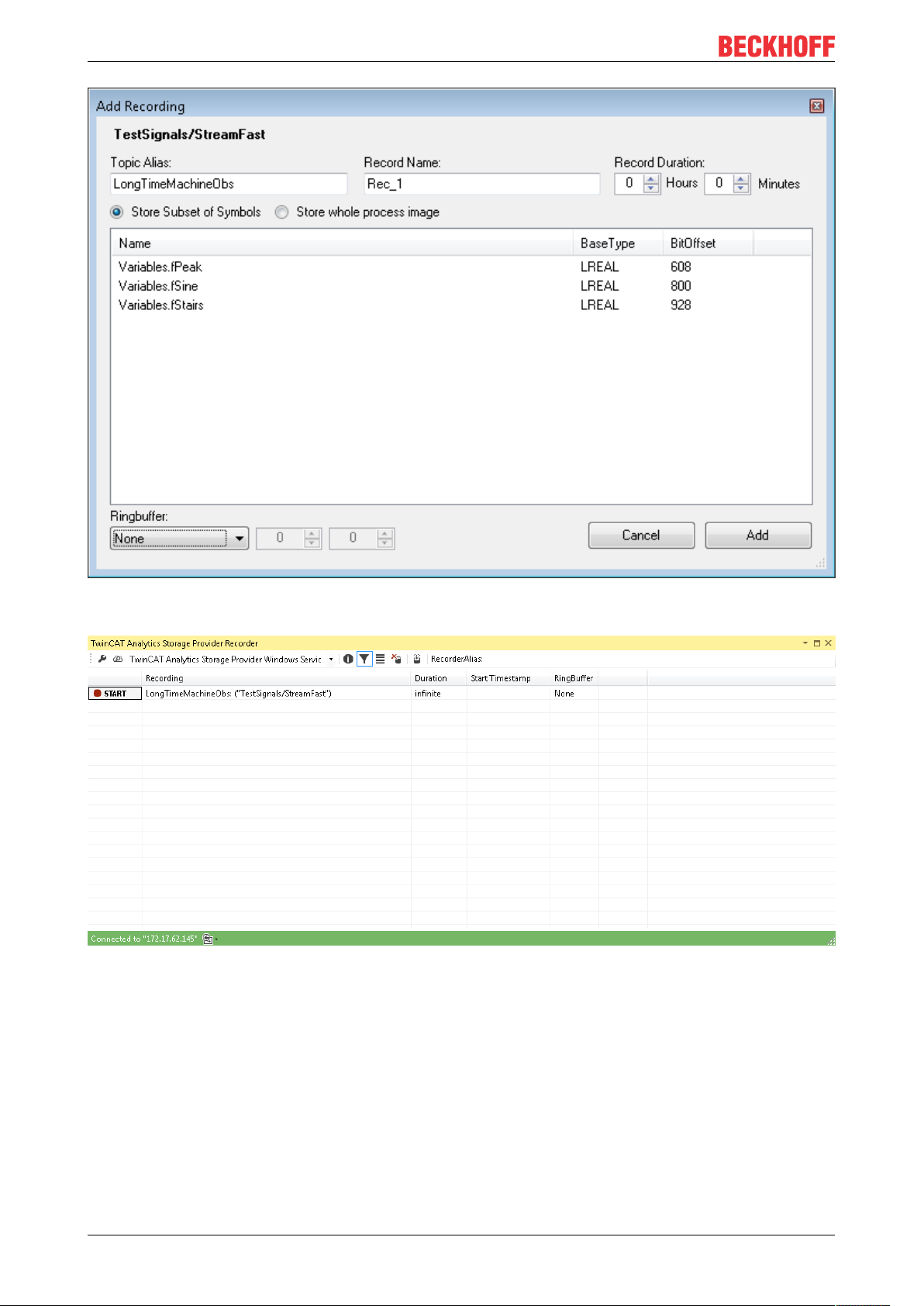

The configuration of the record is very easy. You have just to choose your target in the Target Browser. Click

on Live data and choose one or more variables by multiselect and put them by drag and drop to the recorder

window.

The recorder will ask you if you like to add just the chose variables or the complete source process image of

the variables.

TE3520 21Version: 1.0

Page 22

Analytics Workflow - First Steps

You can also configure record names and a duration (otherwise endless until manual stop). A ringbuffer can

be set by memory or time.

Click the Start button to start the record. After this you can also disconnect the recorder, because the

background service do the work. It is also possible that someone else connect to this Storage Provider

service and control the running record.

TE352022 Version: 1.0

Page 23

Analytics Workflow - First Steps

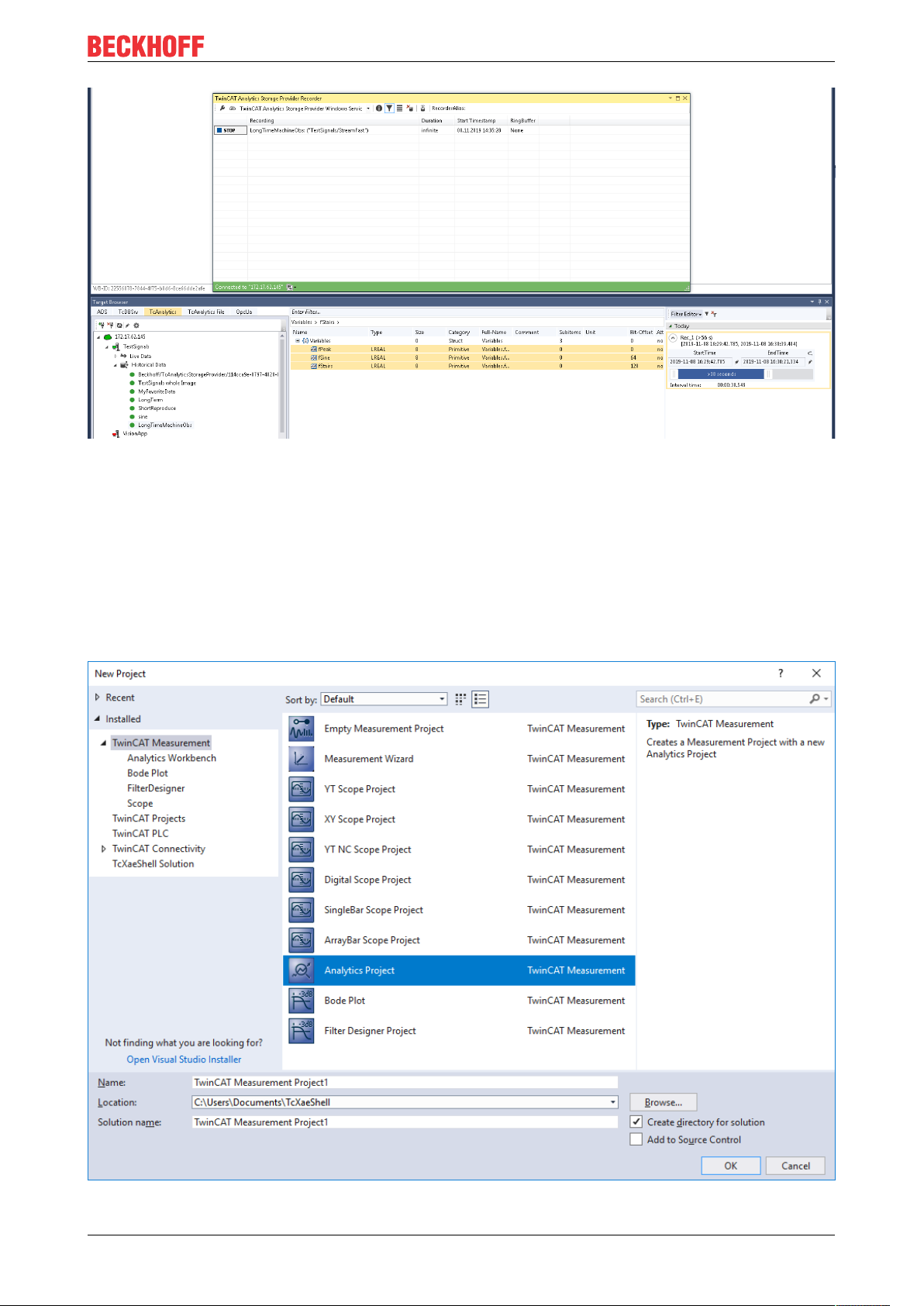

After and also during the record you can choose the historical data as input for your analysis in the Target

Browser. In the Target Browser you will find for historical data a new control on the right hand site. There you

can choose the time span for your data.

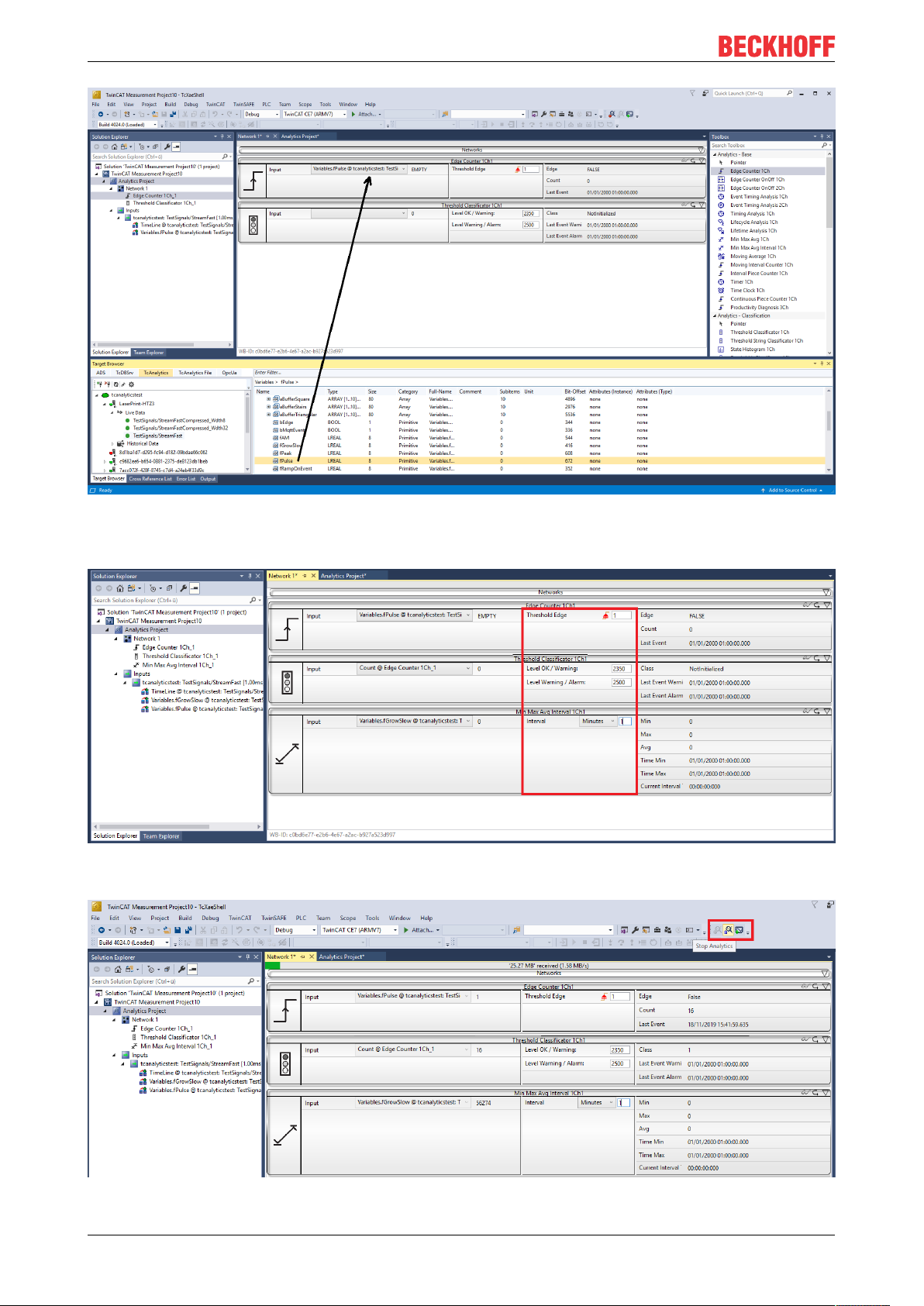

4.4 Analyse data

Open your TwinCAT engineering environment to start the analysis of the data.

Open Visual Studio® >> File >> New >> Project…

Choose from TwinCAT Measurement the Analytics project template.

TE3520 23Version: 1.0

Page 24

Analytics Workflow - First Steps

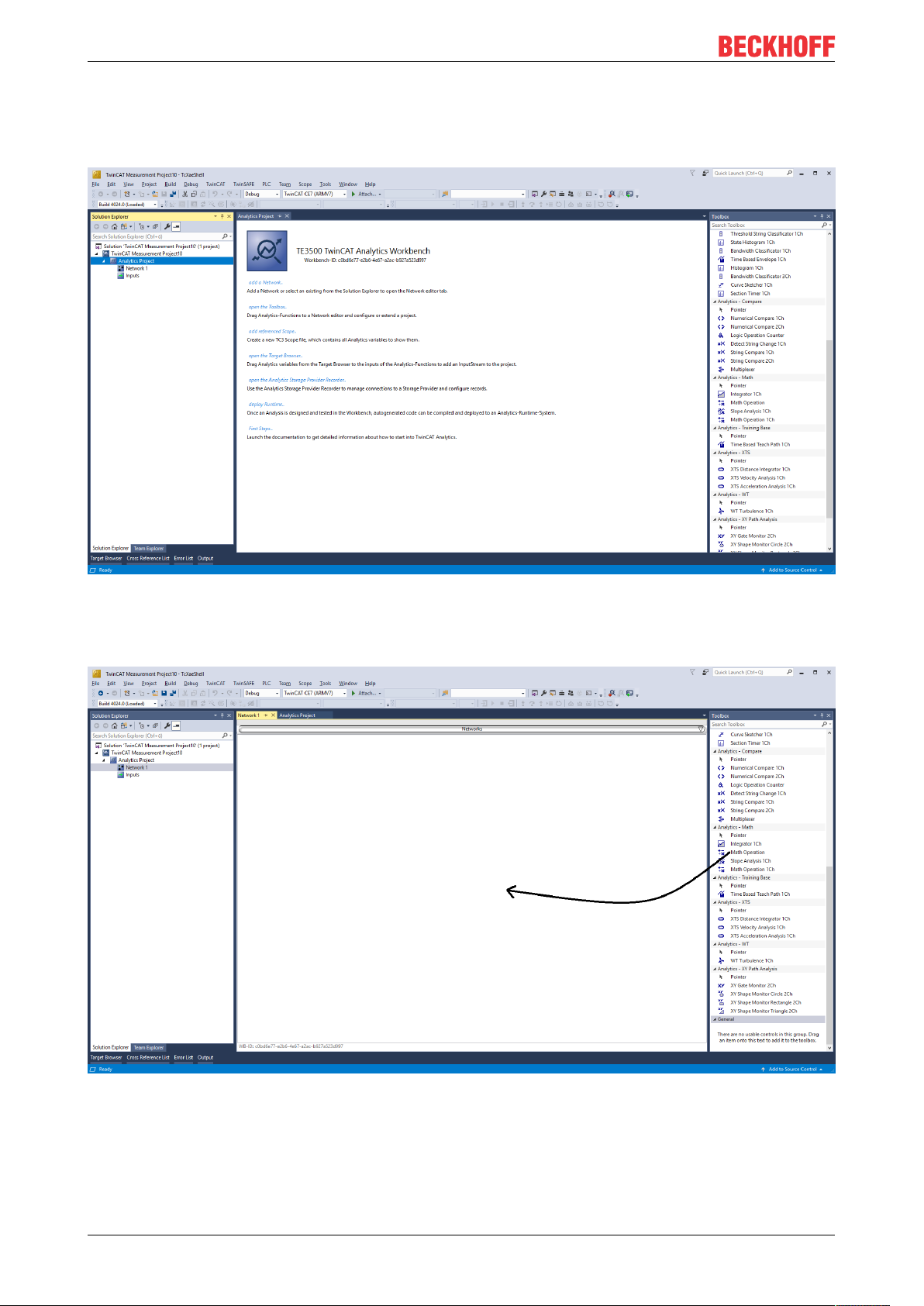

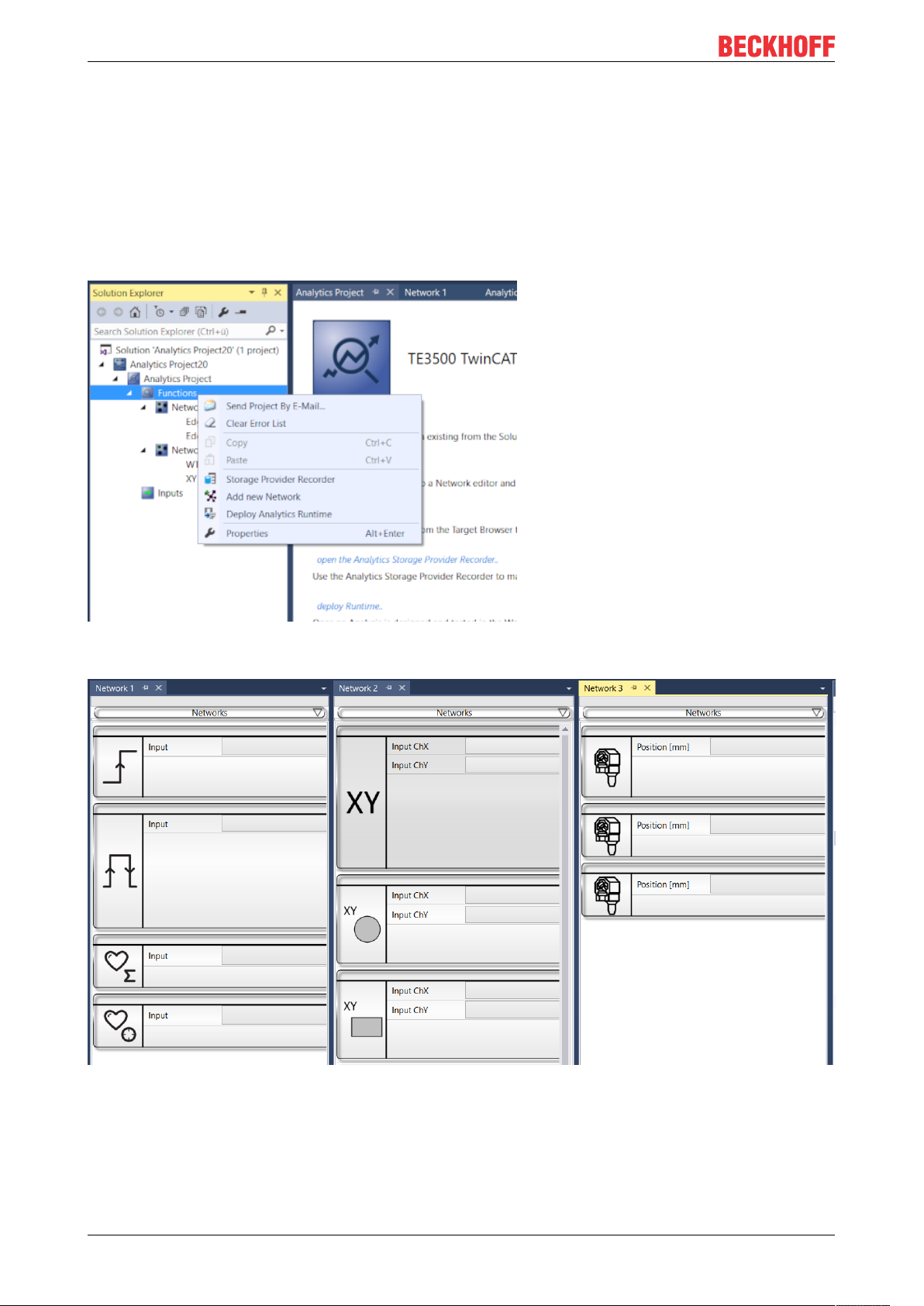

The new project will be shown in the Solution Explorer. After a click on the Analytics Project tree node item a

start window opens where you can select your first action. From here, you can add a Network, open the

Toolbox, open the Target Browser or open the Analytics Storage Provider Recorder. You will do all these

actions in the following steps.

It makes sense to open in a first step the Toolbox of Visual Studio®. There you will find all the supported

algorithm of TwinCAT Analytics. Algorithm must be organized and grouped into networks. Right click on the

Analytics Project to add a new Network or add a Network using the start page. The first Network is always

generated by default.

If you click on the Network an editor will be open. Now you can take the algorithm you like by drag and drop

into the editor surface. After choosing the algorithm you need to connect input variables to the modules

(algorithm). Therefor open the Target Browser.

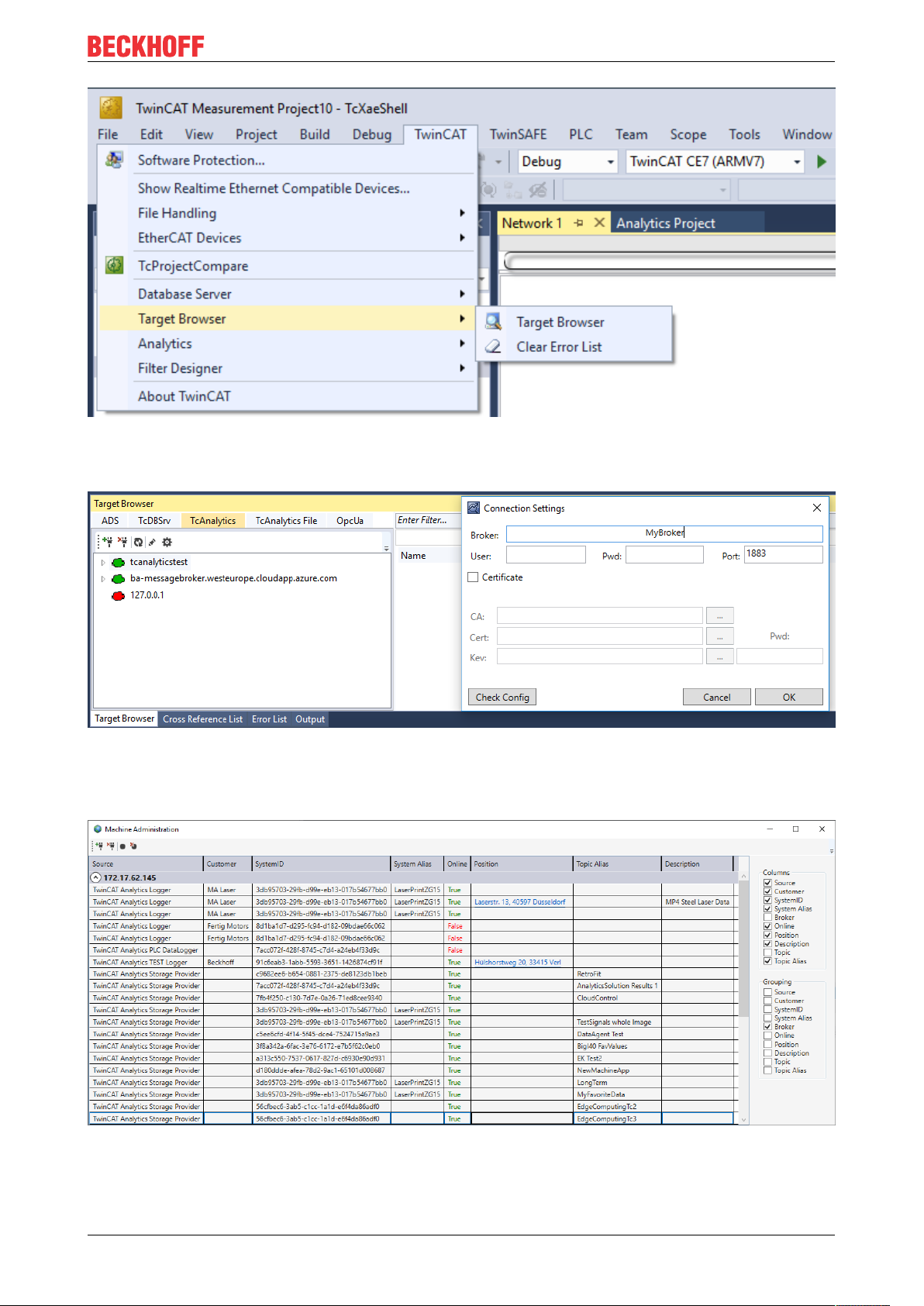

TwinCAT >> Target Browser >> Target Browser

TE352024 Version: 1.0

Page 25

Analytics Workflow - First Steps

Choose now the TcAnalytics or TcAnalyticsFile tab in the Target Browser. We go ahead with the TcAnalytics

tab (MQTT). Click on the green marked icon in the toolbar of this Analytics extension. A window will be open

where you can provide your Message Broker connectivity data.

Choose your MQTT Analytics client (TwinCAT Analytics Logger, TwinCAT IoT Data Agent or Beckhoff

EK9160). For each controller you have a unique ID. This ID is shown in the Target Browser. Not very legible,

of course. Therefore, click on the icon with the gear to get to the machine administration page. Here you can

provide a System Alias name which is shown in the Target Browser instead of the GUID.

In the next step you can choose between Live Data and Historical Data for each MQTT Analytics client.

Historical Data are only provided by the TwinCAT Analytics Storage Provider.

TE3520 25Version: 1.0

Page 26

Analytics Workflow - First Steps

You can take the variables by drag and drop into the inputs of the specific algorithm. For the most algorithm

it is possible to set conditions like thresholds, time intervals, logic operators and so on. You can do these

settings in the middle of each module.

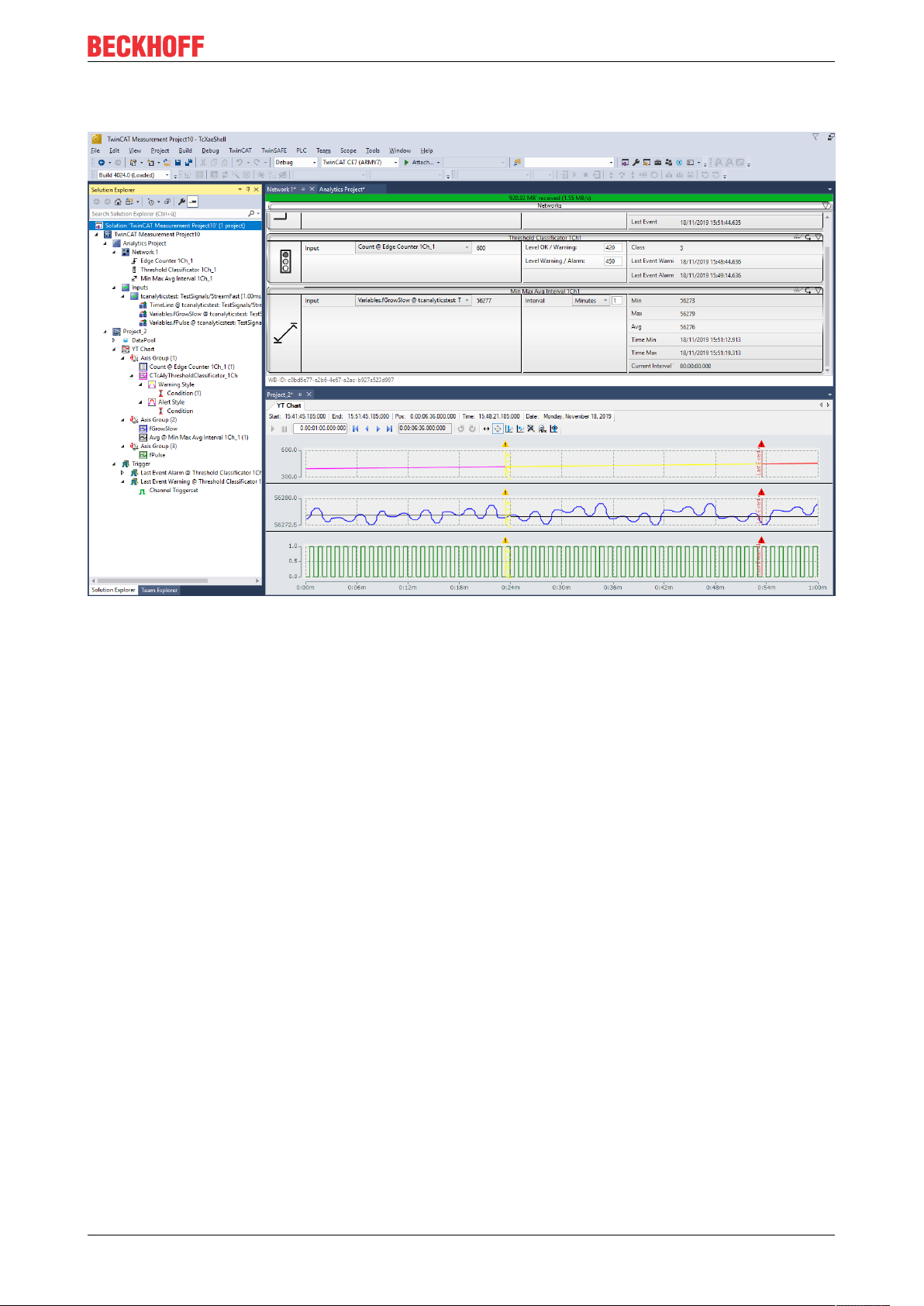

Finally, your first Analytics Project is finished. To start the analysis, click on “Start Analytics”. To stop the

analysis, click on “Stop Analytics”.

TE352026 Version: 1.0

Page 27

Analytics Workflow - First Steps

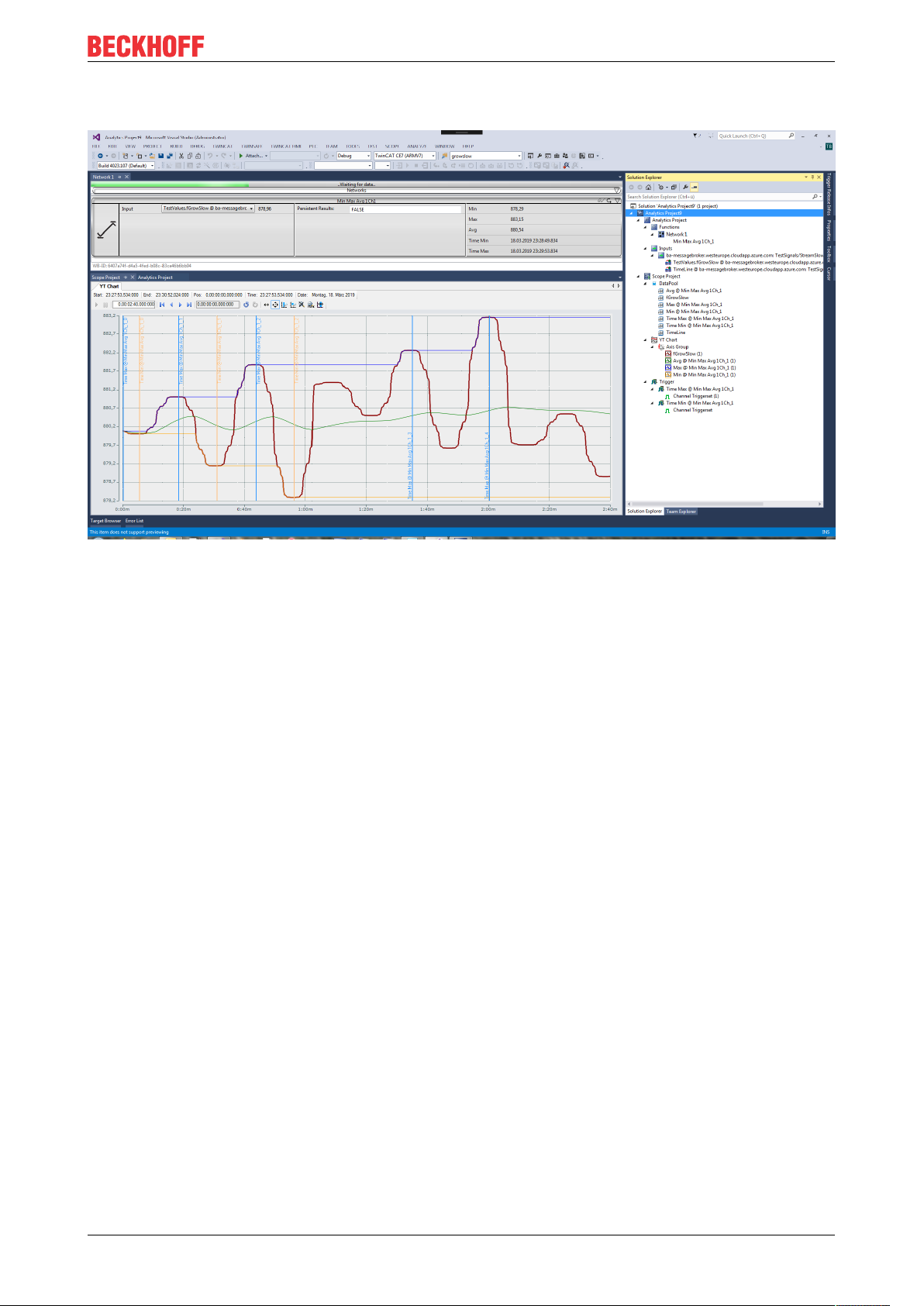

Before starting Analytics or also during the runtime you can click on the button “Add Reference Scope”. A

Scope configuration is automatically built to fit your Analytics project.

Results of the analysis can be show in the Scope View charts by drag and drop. For example, an average

value can be shown as new channel in the view. Timestamps as Marker at the x-axes to show significant

values.

TE3520 27Version: 1.0

Page 28

Technical introduction

5 Technical introduction

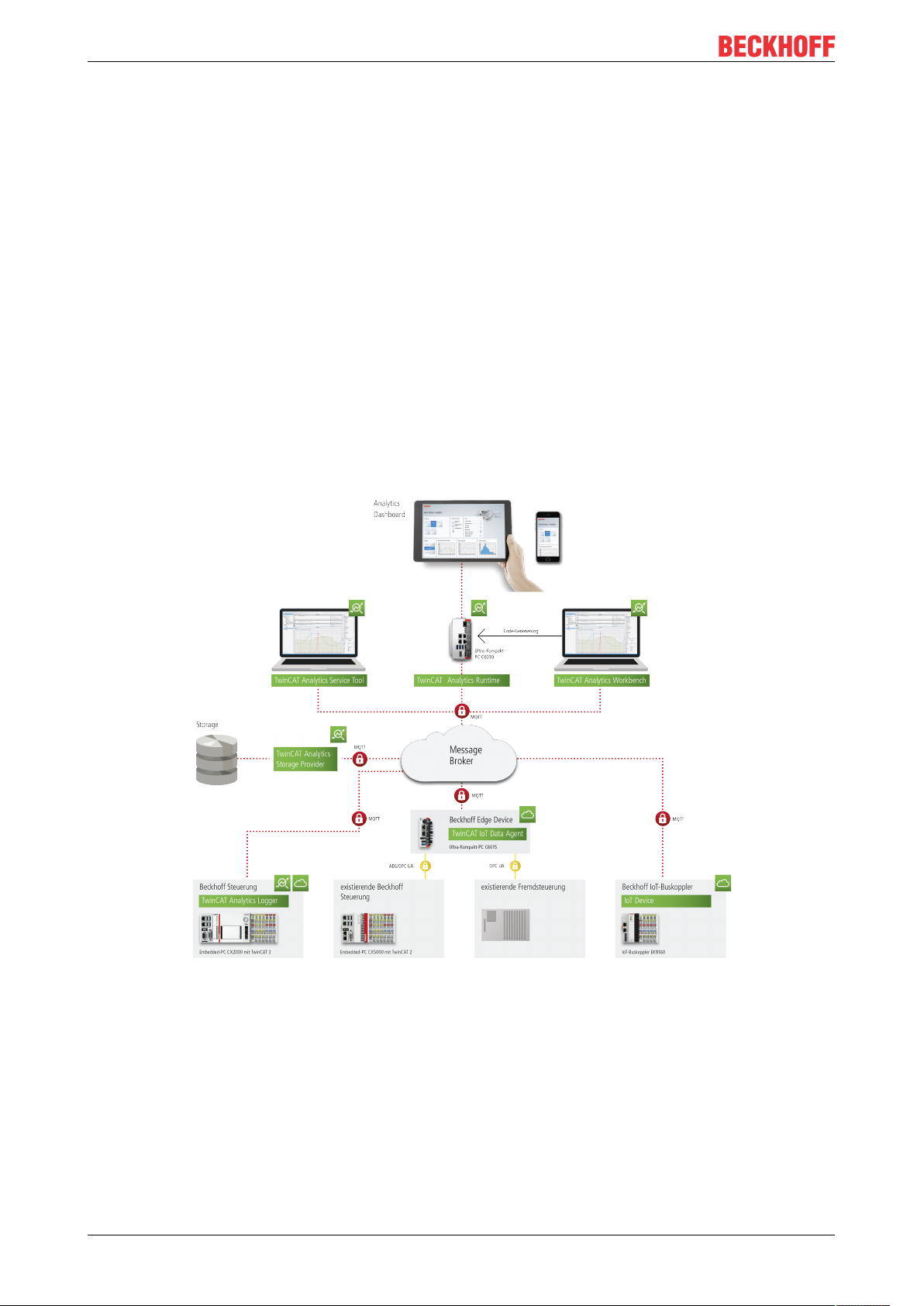

5.1 Basic concept

The following picture shows the basic concept of TwinCAT Analytics from the data source up to the Analytics

dashboard based on TwinCAT 3 HMI. The communication in an Analytics scenario is realized by the IoT

communication protocol MQTT.

Data sources:

Currently there are three different data sources for TwinCAT Analytics. All these sources are able to

communicate with TwinCAT Analytics specific binary data format. This format is necessary to reach this high

performance.

• TwinCAT 3 controller with TF3500 TwinCAT Analytics Logger

• TwinCAT 2, TwinCAT 3 and third party controller together with a gateway of TF6720 TwinCAT IoT

Data Agent

• All EK9160 IoT Coupler devices

Storage:

With TwinCAT Analytics it is possible to analyze live and historical data. The TwinCAT Analytics Storage

Provider is the interface between native MQTT Message Broker to different stores. As storage TwinCAT

Analytics is supporting an Azure Blob store and a Microsoft SQL database. The configuration of the stores is

done automatically by the Storage Provider. Thus, it is not necessary to use classic SQL commandos to

realize the communication. The user also does not need to setup a special table structure.

Analysis:

For service technicians and machine commissioning

TE352028 Version: 1.0

Page 29

Technical introduction

The TE3520 TwinCAT Analytics Service Tool is the perfect tool for experts who like to analyze TwinCAT

Analytics data sources. It is integrated into the Microsoft Visual Studio®. The user is able to make his

analytics configuration in a graphical configurator choosing from a wide pool of different algorithms. A

parallel interaction with the Scope View is also possible. The user is able to find significant values easily by

drag and drop from the configurator into the data stream of our Scope View.

For continues 24/7 machine analysis

The TE3500 TwinCAT Analytics Workbench has the same functionality as the Service Tool. In addition, it is

possible to make an automatic PLC code generation based on the realized analytics configuration in the

configurator. The PLC code is ready to use. So you can start the data analysis immediately like in the

configurator. But now for 24 hours 7 days per week if necessary. The auto generated code can be

downloaded into the TF3550 TwinCAT Analytics Runtime. This runtime can be on a classic IPC or

Embedded-PC, but also in a virtual machine. In the generated PLC project, the user is also able to realize

his Analytics Dashboard by the TwinCAT 3 HMI.

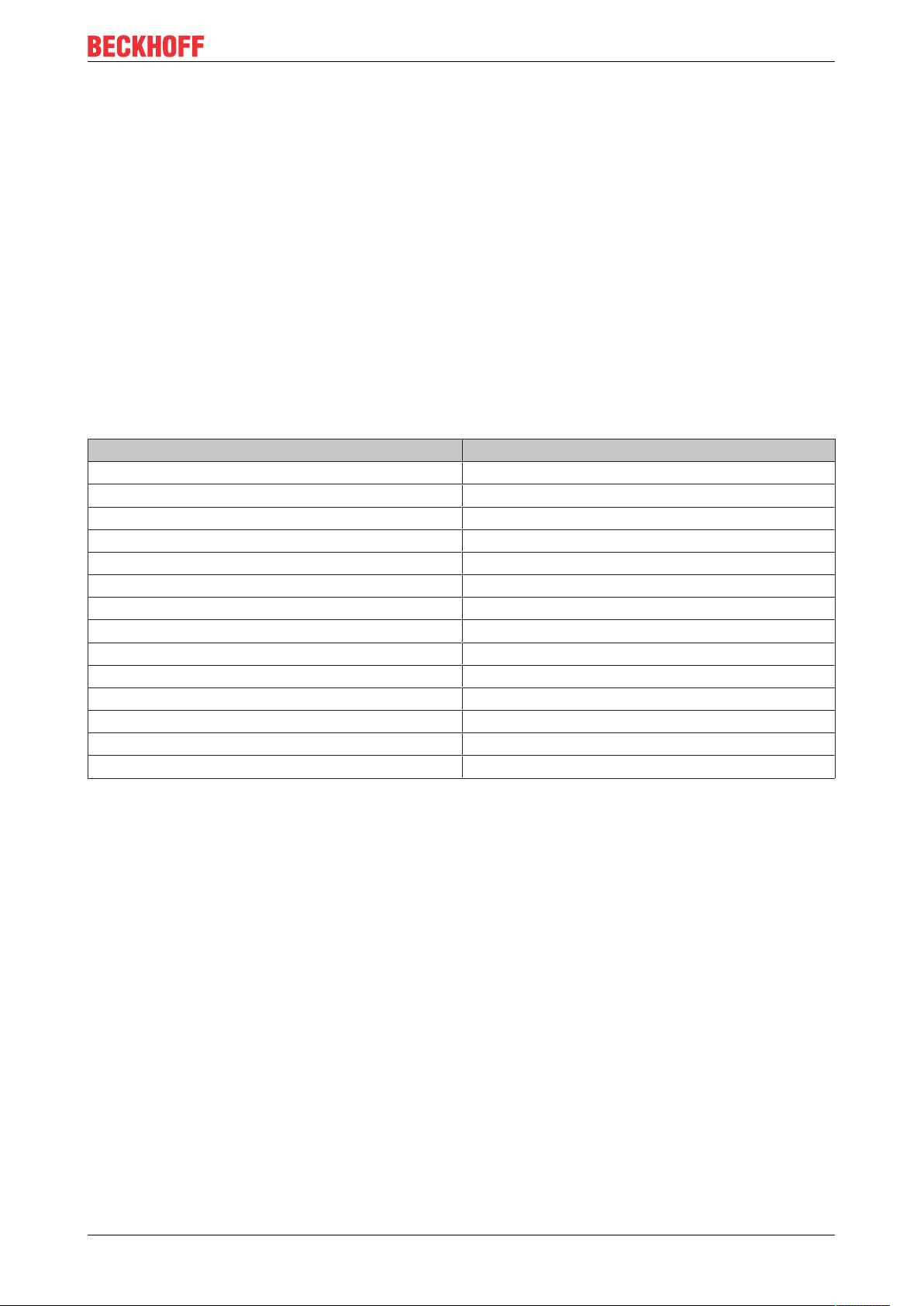

Products:

We have different single products in the TwinCAT Analytics Workflow. See therefore the following list with all

products

Product Number Product Name

TE3500 Analytics Workbench

TE3520 Analytics Service Tool

TF3500 Analytics Logger

TF3510 Analytics Library

TF3520 Analytics Storage Provider

TF3550 Analytics Runtime

TF3560 Analytics Controller Pack 4

TF3561 Analytics Controller Pack 8

TF3562 Analytics Controller Pack 16

TF3563 Analytics Controller Pack 32

TF3564 Analytics Controller Pack 64

TF3565 Analytics Controller Pack 128

TF6720 IoT Data Agent

EK9160 IoT Coupler

The minimal meaningful configuration is the usage of TF3500/TF6720/EK9160 together with TE3520

Analytics Service Tool. Also possible is just to use the TF3510 Analytics Library in a TwinCAT system.

TE3520 29Version: 1.0

Page 30

Configuration

6 Configuration

6.1 Networks

The networks serve as containers of the analytics algorithms. Thereby an analytics configuration can be

structured easily into different areas to allow greater clarity.

You can add a network directly from the analytics project start page or via the context menu.

Each network is represented in a single tab page. This allows you to view the networks separately, stacked

horizontally or stacked vertically.

Furthermore, you have the possibility to rename the networks (F2 on selected network element in solution

explorer). For example because you want to create networks for different machines, machine parts or other

content-based connections.

TE352030 Version: 1.0

Page 31

Configuration

6.2 Algorithms

The TwinCAT Analytics Workbench Configurator includes different Analytics algorithms, which you can find

in the toolbox. If the toolbox is empty, you have to select the Analytics project to see the algorithms.

TE3520 31Version: 1.0

Page 32

Configuration

Currently there are eight different groups of algorithms: Analytics-Base, Analytics-Classification, AnalyticsCompare, Analytics-Math, Analytics–Training Base, Analytics-XTS, Analytics-XY Path Analysis and

Analytics-WT. In the following all of them are described.

Each algorithm has the same three icons on the upper right corner:

TE352032 Version: 1.0

Page 33

Configuration

• Glasses: If you click on the glasses icon you can see the optional parameter Enable Execution. You

can select a boolean signal for this parameter, so that the algorithm is just active, if the value of the

selected signal is TRUE.

• Reset Arrow: If you click on the arrow the output values of the specific algorithm will be reseted.

• Minimize Arrow: if you click on the minimize arrow on the right, the algorithm will be folded.

6.2.1 Analytics - Base

The algorithms of the category Analytics-Base provide base functionalities for analyzing process and

application data. For example threshold detection, timing analysis or calculation of minimum, maximum and

average values.

6.2.1.1 Edge Counter 1Ch

The Edge Counter 1Ch counts the amount of raised events. An event is raised when the signal of the input

channel passes the configured edge at a specific threshold.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

Configuration Options

• Type of the edge: Indicates whether the edge counter should react to a rising or a falling edge.

• Threshold: Threshold of the signal at the respective edge. If the signal passes this threshold, the

event is raised.

Output Values

• Edge: Shows TRUE in the moment the event is raised, otherwise FALSE.

• Count: Counts the amount of raised events.

• Last Event: Indicates the point of time of the last raised event → the event can be pulled into the

scope chart by Drag & Drop to show it as a trigger-event.

Standard HMI Controls

The following HMI controls are available for the Edge Counter 1Ch algorithm to generate an Analytics

Dashboard:

1.The SingleValue control visualizes the Count and Last Event output values.

2.The Table control visualizes all output values: Edge, Count, Last Event.

TE3520 33Version: 1.0

Page 34

Configuration

Alternatively, custom HMI controls can be mapped to the Edge Counter 1Ch algorithm using the Mapping

Wizard.

6.2.1.2 Edge Counter On Off 1Ch

The Edge Counter On Off 1Ch counts the amount of raised on- and off-events. An on-event is raised when

the signal of the input channel passes the configured edge at a specific on-threshold and an off-event is

raised when the off-threshold is passed by the same signal.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

Configuration Options

• Type of the edge: Indicates whether the edge counter should react to a rising or a falling edge.

• Threshold On: Threshold of the signal at the respective edge. If the signal passes this threshold, the

on-event is raised.

• Threshold Off: Threshold of the signal at the respective edge. If the signal passes this threshold, the

off-event is raised.

Output Values

• Is On: Shows TRUE within the time range between on-event and off-event, otherwise FALSE.

• Edge On: Shows TRUE if there is a raising edge.

• Edge Off: Shows TRUE if there is a falling edge.

• Count On: Counts the amount of raised on-events.

• Count Off: Counts the amount of raised off-events.

• Last Event: Indicates the point of time of the last raised event → the event can be pulled into the

scope chart by Drag & Drop to show it as a trigger-event.

TE352034 Version: 1.0

Page 35

Configuration

Standard HMI Controls

The following HMI controls are available for the Edge Counter On Off 1Ch algorithm to generate an Analytics

Dashboard:

1.The EdgeCounterOnOff control visualizes the Is On, Count On, Count Off and Last Event output values.

2. The SingleValue control visualizes the Count On and Last Event output values.

3.The BinaryStare controls visualizes the Is On output value.

4. The Table control visualizes all output values: Edges (Is On, Edge On, Edge Off), Count On, Count Off,

Last Event.

TE3520 35Version: 1.0

Page 36

Configuration

Alternatively, custom HMI controls can be mapped to the Edge Counter On Off 1Ch algorithm using the

Mapping Wizard.

6.2.1.3 Edge Counter On Off 2Ch

The Edge Counter On Off 2Ch counts the amount of raised on- and off-events. An on-event is raised when

the signal of the first input channel passes the configured edge at a specific on-threshold and an off-event is

raised when the off-threshold is passed by the signal of the second channel.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

Configuration Options

• Type of the edge: Indicates whether the edge counter should react to a rising or a falling edge.

• Threshold On: Threshold of the signal at the respective edge. If the signal passes this threshold, the

on-event is raised.

• Reset On Multiple On: If the checkbox is ticked off, the "Count On"-counter is increased on every onevent. Otherwise the on-events are just counted after a reset of the counter (off-event).

• Threshold Off: Threshold of the signal at the respective edge. If the signal passes this threshold, the

off-event is raised.

TE352036 Version: 1.0

Page 37

Configuration

Output Values

• Is On: Shows TRUE within the time range between on-event and off-event, otherwise FALSE.

• Edge On: Shows TRUE if there is a raising edge.

• Edge Off: Shows TRUE if there is a falling edge.

• Count On: Counts the amount of raised on-events.

• Count Off: Counts the amount of raised off-events.

• Last Event: Indicates the point of time of the last raised event → the event can be pulled into the

scope chart by Drag & Drop to show it as a trigger-event.

Standard HMI Controls

The following HMI controls are available for the Edge Counter On Off 2Ch algorithm to generate an Analytics

Dashboard:

1.The EdgeCounterOnOff control visualizes the Is On, Count On, Count Off and Last Event output values.

2. The SingleValue control visualizes the Count On and Last Event output values.

3.The BinaryStare controls visualizes the Is On output value.

4. The Table control visualizes all output values: Edges (Is On, Edge On, Edge Off), Count On, Count Off,

Last Event.

TE3520 37Version: 1.0

Page 38

Configuration

Alternatively, custom HMI controls can be mapped to the Edge Counter On Off 2Ch algorithm using the

Mapping Wizard.

6.2.1.4 Event Timing Analysis 1Ch

The Event Timing Analysis 1Ch measures time differences between on- and off-event and counts the

amount of raised events. An on-event is raised when the signal of the input channel passes the configured

edge at a specific on-threshold and an off-event is raised when the off-threshold is passed by the same

signal.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

Configuration Options

• Type of the edge: Indicates whether the edge counter should react to a rising or a falling edge.

TE352038 Version: 1.0

Page 39

Configuration

• Threshold On: Threshold of the signal at the respective edge. If the signal passes this threshold, the

on-event is raised.

• Threshold Off: Threshold of the signal at the respective edge. If the signal passes this threshold, the

off-event is raised.

Output Values

• Is On: Shows TRUE within the time range between on-event and off-event, otherwise FALSE.

• Current Interval: Shows the time of the current interval.

• On Min: Shows the minimal time the "Is On"-value is TRUE.

• On Max: Shows the maximal time the "Is On"-value is TRUE.

• On Avg: Shows the average time the "Is On"-value is TRUE.

• On Total: Shows the total time the "Is On"-value is TRUE.

• Off Min: Shows the minimal time the "Is On"-value is FALSE.

• Off Max: Shows the maximal time the "Is On"-value is FALSE.

• Off Avg: Shows the average time the "Is On"-value is FALSE.

• Off Total: Shows the total time the "Is On"-value is FALSE.

• Count On: Counts the amount of raised on-events.

Standard HMI Controls

The following HMI controls are available for the Event Timing Analysis 1Ch algorithm to generate an

Analytics Dashboard:

1. The EventTiming control visualizes the Is On, Count On, Current Interval, On Min, On Max, On Avg, On

Total, Off Min, Off Max, Off Avg, Off Total output values.

2. The SingleValue control visualizes the Count On output value.

TE3520 39Version: 1.0

Page 40

Configuration

3. The Table control visualizes all output values: Is On, Count On, Current Interval, On Min, On Max, On

Avg, On Total, Off Min, Off Max, Off Avg, Off Total.

Alternatively, custom HMI controls can be mapped to the Event Timing Analysis 1Ch algorithm using the

Mapping Wizard.

TE352040 Version: 1.0

Page 41

Configuration

6.2.1.5 Event Timing Analysis 2Ch

The Event Timing Analysis 2Ch measures time differences between on- and off-event and counts the

amount of raised events. An on-event is raised when the signal of the first input channel passes the

configured edge at a specific on-threshold and an off-event is raised when the off-threshold is passed by the

signal of the second channel.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

Configuration Options

• Type of the edge: Indicates whether the edge counter should react to a rising or a falling edge.

• Threshold On: Threshold of the signal at the respective edge. If the signal passes this threshold, the

on-event is raised.

• Reset On Multiple On: If the checkbox is ticked off, the "Count On"-counter is increased on every onevent. Otherwise the on-events are just counted after a reset of the counter (off-event).

• Threshold Off: Threshold of the signal at the respective edge. If the signal passes this threshold, the

off-event is raised.

Output Values

• Is On: Shows TRUE within the time range between on-event and off-event, otherwise FALSE.

• Current Interval: Shows the time of the current interval.

• On Min: Shows the minimal time the "Is On"-value is TRUE.

• On Max: Shows the maximal time the "Is On"-value is TRUE.

• On Avg: Shows the average time the "Is On"-value is TRUE.

• On Total: Shows the total time the "Is On"-value is TRUE.

• Off Min: Shows the minimal time the "Is On"-value is FALSE.

• Off Max: Shows the maximal time the "Is On"-value is FALSE.

• Off Avg: Shows the average time the "Is On"-value is FALSE.

• Off Total: Shows the total time the "Is On"-value is FALSE.

• Count On: Counts the amount of raised on-events.

Standard HMI Controls

The following HMI controls are available for the Event Timing Analysis 2Ch algorithm to generate an

Analytics Dashboard:

1. The EventTiming control visualizes the Is On, Count On, Current Interval, On Min, On Max, On Avg, On

Total, Off Min, Off Max, Off Avg, Off Total output values.

TE3520 41Version: 1.0

Page 42

Configuration

2. The SingleValue control visualizes the Count On output value.

3. The Table control visualizes all output values: Is On, Count On, Current Interval, On Min, On Max, On

Avg, On Total, Off Min, Off Max, Off Avg, Off Total.

TE352042 Version: 1.0

Page 43

Configuration

Alternatively, custom HMI controls can be mapped to the Event Timing Analysis 2Ch algorithm using the

Mapping Wizard.

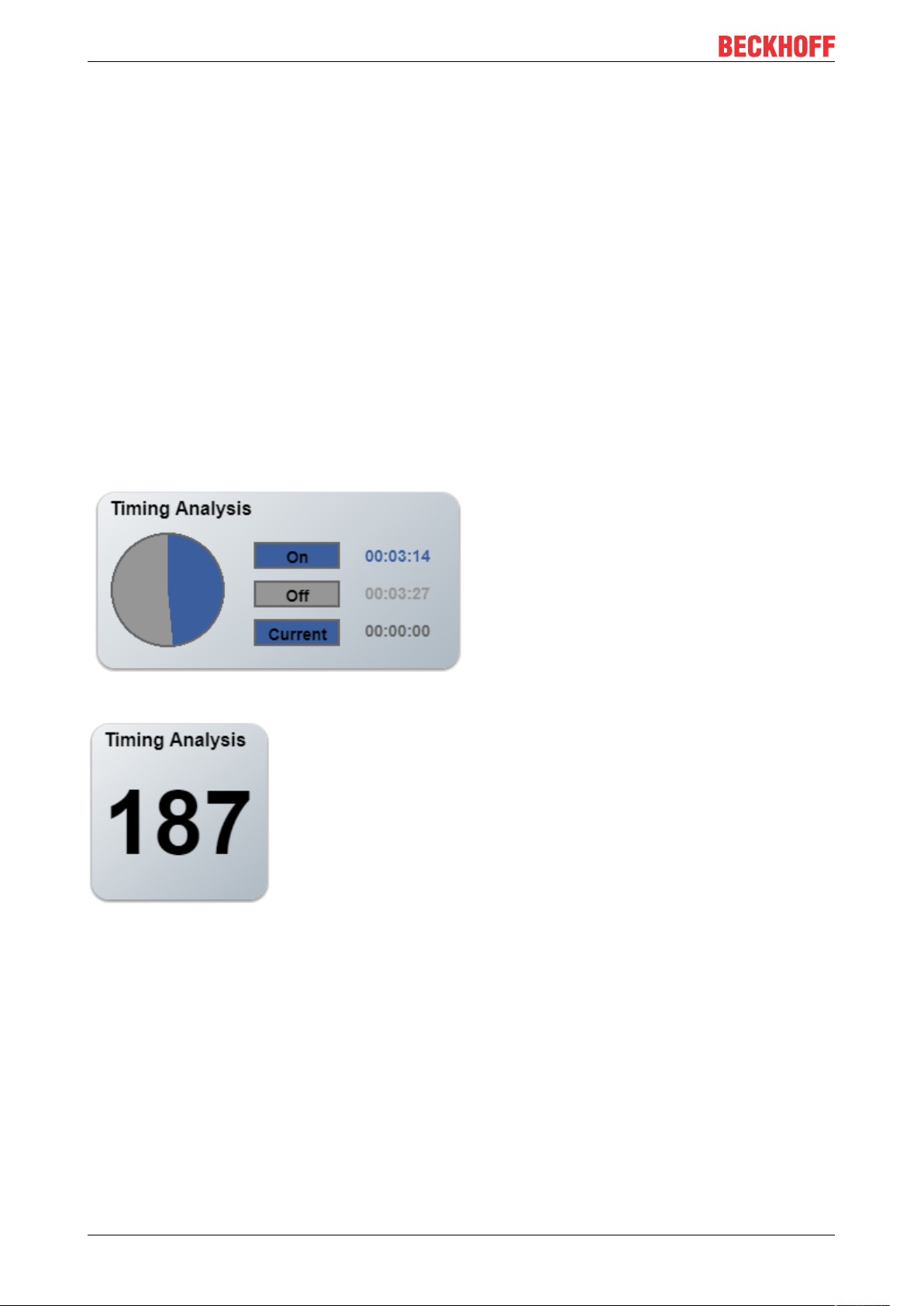

6.2.1.6 Timing Analysis 1Ch

The Timing Analysis 1Ch measures time differences between on- and off-periods and counts the amount of

on-periods. The on-period starts when the condition of operator and threshold is met.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

TE3520 43Version: 1.0

Page 44

Configuration

Configuration Options

• Operator: Indicates whether the input value should be greater, greater or equal, equal, less or equal,

less or not equal than the Threshold.

• Threshold: Threshold of the signal.

Output Values

• Is On: Shows TRUE within the time range of the on-period, otherwise FALSE.

• Current Interval: Shows the time of the current interval.

• On Total: Shows the total time the "Is On"-value is TRUE.

• Off Total: Shows the total time the "Is On"-value is FALSE.

• Count On: Counts the amount of raised on-events.

Standard HMI Controls

The following HMI controls are available for the Timing Analysis 1Ch algorithm to generate an Analytics

Dashboard:

1.The TimingAnalysis controls visualizes the Is On, On Total, Off Total and Current Interval output values.

2. The SingleValue control visualizes the Count On output value.

3.The Table control visualizes all output values: Is On, Count On, Current Interval, On Total, Off Total.

TE352044 Version: 1.0

Page 45

Configuration

Alternatively, custom HMI controls can be mapped to the Timing Analysis 1Ch algorithm using the Mapping

Wizard.

6.2.1.7 Lifecycle Analysis 1Ch

The Lifecycle Analysis 1Ch calculates the elapsed and the estimated remaining cycles of a device. When the

signal of the input channel passes the configured edge at a specific threshold, the elapsed cycles are

increased and the remaining cycles are decreased.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

Configuration Options

• Type of the edge: Indicates whether the edge counter should react to a rising or a falling edge.

• Threshold: Threshold of the signal at the respective edge. If the signal passes this threshold, an event

is raised.

• Estimated Cycles: Estimated cycles in the lifetime of the respective device.

Output Values

• Elapsed Cycles: Counts the amount of cycles which are already elapsed.

• Remaining Cycles: Shows the remaining cycles of the device as the difference of estimated and

elapsed cycles.

Standard HMI Controls

The following HMI controls are available for the Lifecycle Analysis 1Ch algorithm to generate an Analytics

Dashboard:

1.The Process controls visualizes the Elapsed Cycles and Remaining Cycles output values.

TE3520 45Version: 1.0

Page 46

Configuration

2. The Table control visualizes all output values: Elapsed Cycles, Remaining Cycles.

Alternatively, custom HMI controls can be mapped to the Lifecycle Analysis 1Ch algorithm using the

Mapping Wizard.

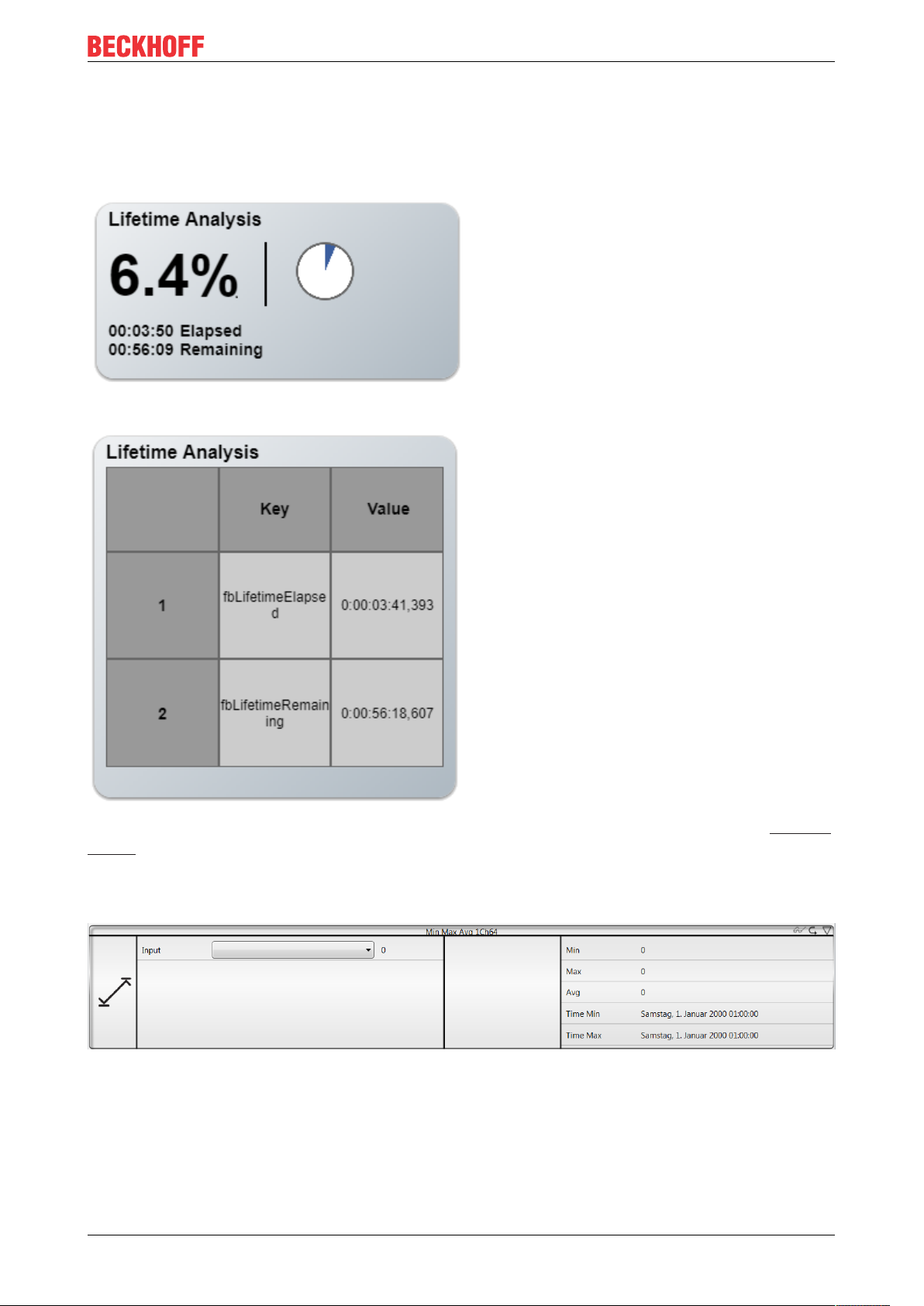

6.2.1.8 Lifetime Analysis 1Ch

The Lifetime Analysis 1Ch calculates the elapsed and the estimated remaining lifetime of a device. If the

input value met the configured condition the lifetime will be reduced.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

Configuration Options

• Operator: Indicates whether the input value should be greater, greater or equal, equal, less or equal,

less or not equal than the Threshold.

• Threshold: Threshold of the signal.

• Estimated Lifetime: Estimated lifetime of the respective device.

Output Values

• Elapsed Lifetime: Shows the lifetime which is already elapsed.

• Remaining Lifetime: Shows the remaining lifetime of the device as the difference of estimated and

elapsed lifetime.

TE352046 Version: 1.0

Page 47

Configuration

Standard HMI Controls

The following HMI controls are available for the Lifetime Analysis 1Ch algorithm to generate an Analytics

Dashboard:

1. The Process controls visualizes the Elapsed Lifetime and Remaining Lifetime output values.

2. The Table control visualizes all output values: Elapsed Lifetime, Remaining Lifetime.

Alternatively, custom HMI controls can be mapped to the Lifetime Analysis 1Ch algorithm using the Mapping

Wizard.

6.2.1.9 Min Max Avg 1Ch

The Min Max Avg 1Ch calculates the minimum, maximum and the average of the input values from the

beginning of the analysis up to the current moment. Furthermore, the time values of minimum and maximum

are shown.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

TE3520 47Version: 1.0

Page 48

Configuration

Output Values

• Min: Shows the minimum of the input values.

• Max: Shows the maximum of the input values.

• Avg: Shows the average of the input values.

• Time Min: Shows the time value of the minimum → this event can be pulled into the scope chart by

Drag & Drop to show it as a trigger-event.

• Time Max: Shows the time value of the maximum → this event can be pulled into the scope chart by

Drag & Drop to show it as a trigger-event.

Standard HMI Controls

The following HMI controls are available for the Min Max Avg 1Ch algorithm to generate an Analytics

Dashboard:

1.The MinMaxAvg control visualizes the Min, Max, Avg, Time Min and Time Max output values and the data

input value.

2. The Table control visualizes all output values: Min, Max, Avg, Time Min, Time Max.

TE352048 Version: 1.0

Page 49

Configuration

Alternatively, custom HMI controls can be mapped to the Min Max Avg 1Ch algorithm using the Mapping

Wizard.

6.2.1.10 Min Max Avg Interval 1Ch

The Min Max Avg Interval 1Ch calculates the minimum, maximum and the average of the input values for the

time period of the configured Interval. Furthermore the time values of minimum and maximum are shown.

Note that all values are from the relative last interval and that they will only be updated when the interval is

over. The calculation restarts when the time of the interval has elapsed.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

Configuration Options

• Interval: Time Interval in which the values should be calculated.

Output Values

• Min: Shows the minimum of the input values in the last time interval.

• Max: Shows the maximum of the input values in the last time interval.

• Avg: Shows the average of the input values in the last time interval.

• Time Min: Shows the time value of the minimum in the last time interval → this event can be pulled

into the scope chart by Drag & Drop to show it as a trigger-event.

• Time Max: Shows the time value of the maximum in the last time interval → this event can be pulled

into the scope chart by Drag & Drop to show it as a trigger-event.

• Current Interval Time: Shows the timespan, that already proceeded from the current interval.

Standard HMI Controls

The following HMI controls are available for the Min Max Avg Interval 1Ch algorithm to generate an Analytics

Dashboard:

1. The MinMaxAvg control visualizes the Min, Max, Avg, Time Min and Time Max output values and the data

input value.

TE3520 49Version: 1.0

Page 50

Configuration

2. The Table control visualizes all output values: Min, Max, Avg, Time Min, Time Max, Current Interval Time.

Alternatively, custom HMI controls can be mapped to the Min Max Avg Interval 1Ch algorithm using the

Mapping Wizard.

TE352050 Version: 1.0

Page 51

Configuration

6.2.1.11 Moving Average 1Ch

The Moving Average 1Ch calculates the moving average, the minimum and the maximum of the most recent

input values in an interval of specified length. Furthermore the time values of minimum and maximum are

shown. The calculation of the moving average depends on the configuration parameters Num Values and

Startup Behaviour.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

Configuration Options

• Num Values: Amount of values which will be included in the calculation of the moving average, the

minimum and the maximum.

• Startup Behaviour: Calculation behaviour at the beginning of the analysis before at least Num Values

input values exist.

ZeroPadding: The missing values are filled with zeros.

UseFirstValue: The first value is used until the amount of values is equivalent to Num Values.

WaitUntilFilled: The first result is calculated when the amount of values is equivalent to Num

Values.

AvgOverExisting: The average will be calculated with the already existing values until the amount

of values is equivalent to Num Values.

Output Values

• Moving Avg: Shows the current average value.

• Moving Min: Shows the minimum of the last n input values.

• Moving Max: Shows the maximum of the last n input values.

Standard HMI Controls

The following HMI controls are available for the Moving Average 1Ch algorithm to generate an Analytics

Dashboard:

1. The MinMaxAvg control visualizes the Moving Min, Moving Max and Moving Avg output values and the

data input value.

TE3520 51Version: 1.0

Page 52

Configuration

2. The Table control visualizes all output values: Moving Min, Moving Max, Moving Avg.

Alternatively, custom HMI controls can be mapped to the Moving Average 1Ch algorithm using the Mapping

Wizard.

6.2.1.12 Moving Interval Counter 1Ch

The Moving Interval Counter 1Ch counts the amount of raised events within a configured interval. An event

is raised when the signal of the input channel passes the configured edge at a specific threshold. The

calculation restarts when the time of the interval has elapsed.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

TE352052 Version: 1.0

Page 53

Configuration

Configuration Options

• Type of the edge: Indicates whether the edge counter should react to a rising or a falling edge.

• Threshold: Threshold of the signal at the respective edge. If the signal passes this threshold, the

event is raised.

• Interval: Time Interval in which the values should be calculated.

• Count Limit: Limits the number of edges that can be counted in an interval.

Output Values

• Edge: Shows TRUE in the moment the event is raised, otherwise FALSE.

• Limited: Shows TRUE if the number of edges in the current interval exceeds the set Count Limit.

• Counts in Interval: Shows the amount of raised events in the current interval.

• Time First Count: Indicates the point of time of the first raised event → the event can be pulled into

the scope chart by Drag & Drop to show it as a trigger-event.

• Time Last Count: Indicates the point of time of the last raised event → the event can be pulled into the

scope chart by Drag & Drop to show it as a trigger-event.

Standard HMI Controls

The following HMI controls are available for the Moving Interval Counter 1Ch algorithm to generate an

Analytics Dashboard:

1. The MovingIntervalCounter control visualizes the Counts in Interval, Time First Count and Time Last

Count output values.

2. The Table control visualizes all output values: Edge, Counts in Interval, Time First Count, Time Last

Count, Limited.

TE3520 53Version: 1.0

Page 54

Configuration

Alternatively, custom HMI controls can be mapped to the Moving Interval Counter 1Ch algorithm using the

Mapping Wizard.

6.2.1.13 Interval Piece Counter 1Ch

The Interval Piece Counter 1Ch counts the amount of raised events within a configured interval, which starts

when the value of the start interval flag is TRUE. An event is raised when the signal of the input channel

passes the configured edge at a specific threshold. The calculation restarts when the time of the interval has

elapsed and the value of the start interval flag is True again.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

Configuration Options

• Type of the edge: Indicates whether the edge counter should react to a rising or a falling edge.

• Threshold: Threshold of the signal at the respective edge. If the signal passes this threshold, the

event is raised.

• Reset On Multiple Start: If the checkbox is ticked off, the interval restarts when the start interval flag

gets TRUE again. Otherwise the interval restarts automatically when the time has elapsed.

• Interval: Time interval in which the values should be calculated.

Output Values

• Executing Interval: Shows True, if the calculation is active and the interval is running, otherwise

False.

• Num Intervals: Shows the number of Intervals.

• Count Last Interval: Shows the amount of raised events in the last interval.

• Count Current Interval: Shows the amount of raised events in the current interval or if the calculation

is currently inactive, the amount of raised events in the last interval.

• Count Min: Shows the minimum of raised events in an interval.

• Count Max: Shows the maximum of raised events in an interval.

• Time Count Min: Shows the time value of the minimum → this event can be pulled into the scope

chart by Drag & Drop to show it as a trigger-event.

• Time Count Max: Shows the time value of the maximum → this event can be pulled into the scope

chart by Drag & Drop to show it as a trigger-event.

• Current Interval Time: Shows the time of the current interval → this event can be pulled into the

scope chart by Drag & Drop to show it as a trigger-event.

Standard HMI Controls

The following HMI controls are available for the Interval Piece Counter 1Ch algorithm to generate an

Analytics Dashboard:

1.The PieceCounter control visualizes the Num Intervals, Count Last Interval, Count Current Interval, Count

Min, Count Max, Time Count Min, Time Count Max and Time Current Interval output values.

TE352054 Version: 1.0

Page 55

Configuration

2. The Table control visualizes all output values: Num Intervals, Count Last Interval, Count Current Interval,

Count Min, Count Max, Time Count Min, Time Count Max, Time Current Interval.

Alternatively, custom HMI controls can be mapped to the Interval Piece Counter 1Ch algorithm using the

Mapping Wizard.

TE3520 55Version: 1.0

Page 56

Configuration

6.2.1.14 Timer 1Ch

The Timer 1Ch starts a timer which can be configured by timer mode and interval. According to the specific

timer mode the timer is started, if the configured condition becomes TRUE (TON, TP) or the condition

becomes FALSE (TOF).

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

Configuration Options

• Operator: Indicates whether the input value should be greater, greater or equal, equal, less or equal or

less than the Threshold.

• Threshold: Threshold of the signal.

• Timer Mode: Mode of the timer:

TON: The TON timer is a turn on delay timer that enables the output after the threshold condition

becomes TRUE and the timespan specified in the interval has elapsed.

TOF: The TOF timer is a turn off delay timer that disables the output after the threshold condition

becomes FALSE and the timespan specified in the interval has elapsed.

TP: The TP timer is a pulse generator that enables the output for the amount of time specified in

the interval after the threshold condition becomes TRUE.

• Interval: Time interval of the configured timer.

Output Values

• Output: Shows the output value which is affected by the configured timer.

• Elapsed Time: Shows the elapsed time of the timer.

Standard HMI Controls

The following HMI controls are available for the Timer 1Ch algorithm to generate an Analytics Dashboard:

1. The Timer control visualizes the Elapsed Time output value.

2. The Table control visualizes all output values: Output, Elapsed Time.

TE352056 Version: 1.0

Page 57

Configuration

Alternatively, custom HMI controls can be mapped to the Timer 1Ch algorithm using the Mapping Wizard.

6.2.1.15 Time Clock 1Ch

The Time Clock 1Ch executes a time switch which can be configured with switch-on time, switch-off time and

the days of the week on which the time switch should be active. As reference value a timestamp is required,

because the algorithm needs a time context, in which it should work. This reference timestamp is set

automatically, if there is another algorithm in the configuration. Therefore it is not possible to use the Time

Clock 1Ch stand alone.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

Configuration Options

• Time On: Switch-on time.

• Time Off: Switch-off time.

• Day of Week Mask: The days of the week on which the time switch should be active.

Output Values

• Is On: Shows TRUE, if the time switch is on, otherwise FALSE.

• Next Switch: Shows the remaining time up to the next switch.

Standard HMI Controls

The following HMI controls are available for the Time Clock 1Ch algorithm to generate an Analytics

Dashboard:

1. The Timer control visualizes the Next Switch output value.

TE3520 57Version: 1.0

Page 58

Configuration

2. The Table control visualizes all output values: Output, Next Switch.

Alternatively, custom HMI controls can be mapped to the Time Clock 1Ch algorithm using the Mapping

Wizard.

6.2.1.16 Continuous Piece Counter 1Ch

The Continuous Piece Counter 1Ch counts the number of pieces within the configured interval. The counter

is increased when the signal of the input channel passes the configured edge at a specific threshold. The

calculation restarts when the time of the interval has elapsed. The algorithm provides the amount of pieces,

the minimal and the maximal number of pieces as well as the time values of minimum and maximum.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

Configuration Options

• Type of the edge: Indicates whether the edge counter should react to a rising or a falling edge.

• Threshold: Threshold of the signal at the respective edge. If the signal passes this threshold, the

counter is increased.

• Interval: Time interval in which the values should be calculated.

TE352058 Version: 1.0

Page 59

Configuration

Output Values

• Num Interval: Shows the number of intervals.

• Count Last Interval: Shows the amount of pieces in the last interval.

• Count Current Interval: Shows the amount of pieces in the current interval.

• Count Min: Shows the minimal number of pieces in an interval.

• Count Max: Shows the maximal number of pieces in an interval.

• Time Count Min: Shows the time value of the minimum.

• Time Count Max: Shows the time value of the maximum.

• Current Interval Time: Shows the time of the current interval.

Standard HMI Controls

The following HMI controls are available for the Continuous Piece Counter 1Ch algorithm to generate an

Analytics Dashboard:

1. The PieceCounter control visualizes the Num Intervals, Count Last Interval, Count Current Interval, Count

Min, Count Max, Time Count Min, Time Count Max and Time Current Interval output values.

2. The Table control visualizes all output values: Num Intervals, Count Last Interval, Count Current Interval,

Count Min, Count Max, Time Count Min, Time Count Max, Time Current Interval.

TE3520 59Version: 1.0

Page 60

Configuration

Alternatively, custom HMI controls can be mapped to the Continuous Piece Counter 1Ch algorithm using the

Mapping Wizard.

6.2.1.17 Productivity Diagnosis 3Ch

The Productivity Diagnosis 3Ch calculates the productivity of the process during a configured interval. The

interval can be started and stopped by the input level Producing. Executing the production interval the

production cycles are considered. Each production cycle is started with an edge at Input Start Cycle and

stopped with an Edge at Input Stop Cycle. The productivity over the whole production internal (Productivity)

and the productivity of the last production cycle (ProductivityLastCycle) are provided as output values. The

algorithm can be configured with the setpoint of produced pieces within a configured interval e.g. 1 piece per

30 seconds or 50 pieces per hour.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

Configuration Options

• Type of the Edge: Indicates whether the algorithm should react to a rising or a falling edge. It can be

configured for every Threshold individually.

• Threshold Level Producing: Threshold of the Input Producing at the respective edge. If the signal

passes this threshold, the Production Time Interval is started.

TE352060 Version: 1.0

Page 61

Configuration

• Threshold Edge Start Cycle: Threshold of the Input Start Cycle at the respective edge. If the signal

passes this threshold, the production cycle is started.

• Threshold Edge Stop Cycle: Threshold of the Input Stop Cycle at the respective edge. If the signal

passes this threshold, the production cycle is stopped.

• Produced Pieces: Setpoint of produced pieces during the configured time interval (Production Time).

• Production Time: Time interval of the production time. It can be configured in days, hours, minutes or

seconds.

Output Values

• Producing: Indicates if the Production Time Interval is currently running.

• Productivity: Shows the productivity over the whole production as a percentage.

• Productivity Last Cycle: Shows the productivity of the last production cycle as a percentage.

Standard HMI Controls

The following HMI controls are available for the Productivity Diagnosis 3Ch algorithm to generate an

Analytics Dashboard:

1. The ProductivityDiagnosis control visualizes the Productivity and Productivity Last Cycle output values.

2. The Table control visualizes all output values: New Result, Producing, Cycle Finished, Productivity,

Productivity Last Cycle.

Alternatively, custom HMI controls can be mapped to the Productivity Diagnosis 3Ch algorithm using the

Mapping Wizard.

TE3520 61Version: 1.0

Page 62

Configuration

6.2.1.18 Downsampling Buffer 1Ch

The Downsampling Buffer 1Ch buffers values of the input channel with a configurable down sampling factor.

The size of the buffer, which corresponds to the number of output channels, is configurable as well.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

Configuration Options

• Buffer Size: Indicates the number of values that are stored and returned as output. The number of

output channels equals the buffer size.

• Downsampling Factor: The number of cycles that pass between two values being saved to the buffer.

If the Downsampling Factor is set to one, all values are buffered.

• Sample Mode: The values from the buffer can be passed to the output channels in two different

modes:

◦ Flow: The buffer is filled like a ring buffer. At the start of the analysis all output values are set to

zero. Each change to the ring buffer is transferred to the output channels immediately. The New

Result flag is set to TRUE, once all output channels got assigned a value and is always true, when

a new value is saved in the buffer (each down sampling factor cycles).

◦ Wait: At the start of the analysis or after reset all output channels are set to zero. Only after the

internal buffer is full. These values are transferred to the output channels and the New Result flag

is set to true. These values stay as output values until all the values in the internal buffer are

renewed. Only then they are transferred to the output channels.

Output Values

• Output Value 00..n: Results of the down sampling buffer, according to the sample mode.

6.2.2 Analytics - Classification

The algorithms of the category Analytics-Classification provide functionalities for classification and state

detection.

6.2.2.1 Threshold Classificator 1Ch

The Threshold Classificator 1Ch classifies the input values into three different classes. OK, Warning and

Alarm according to the configured thresholds.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

Configuration Options

• Level Ok / Warning: The input values which are smaller than the configured threshold are classified

into into the OK class and the input values which are equal to or greater than the configured threshold

are classified into the Warning class.

• Level Warning / Alarm: The input values which are smaller than the configured threshold are

classified into into the Warning class and the input values which are equal to or greater than the

configured threshold are classified into the Alarm class.

TE352062 Version: 1.0

Page 63

Configuration

Output Values

• Class: Shows the class to which the input values belong to.

• Last Event Warning: Indicates the point of time of the last raised warning event → the event can be

pulled into the scope chart by Drag & Drop to show it as a trigger-event.

• Last Event Alarm: Indicates the point of time of the last raised alarm event → the event can be pulled

into the scope chart by Drag & Drop to show it as a trigger-event.

Standard HMI Controls

The following HMI controls are available for the Threshold Classificator 1Ch algorithm to generate an

Analytics Dashboard:

1.The TrafficLight control visualizes the Class, Last Event Warning and Last Event Alarm output values and

the data input value.

2.The MultiState control visualizes the Class output value.

3.The Table control visualizes all output values: Class, Last Event Warning Last Event Alarm.

TE3520 63Version: 1.0

Page 64

Configuration

Alternatively, custom HMI controls can be mapped to the Threshold Classificator 1Ch algorithm using the

Mapping Wizard.

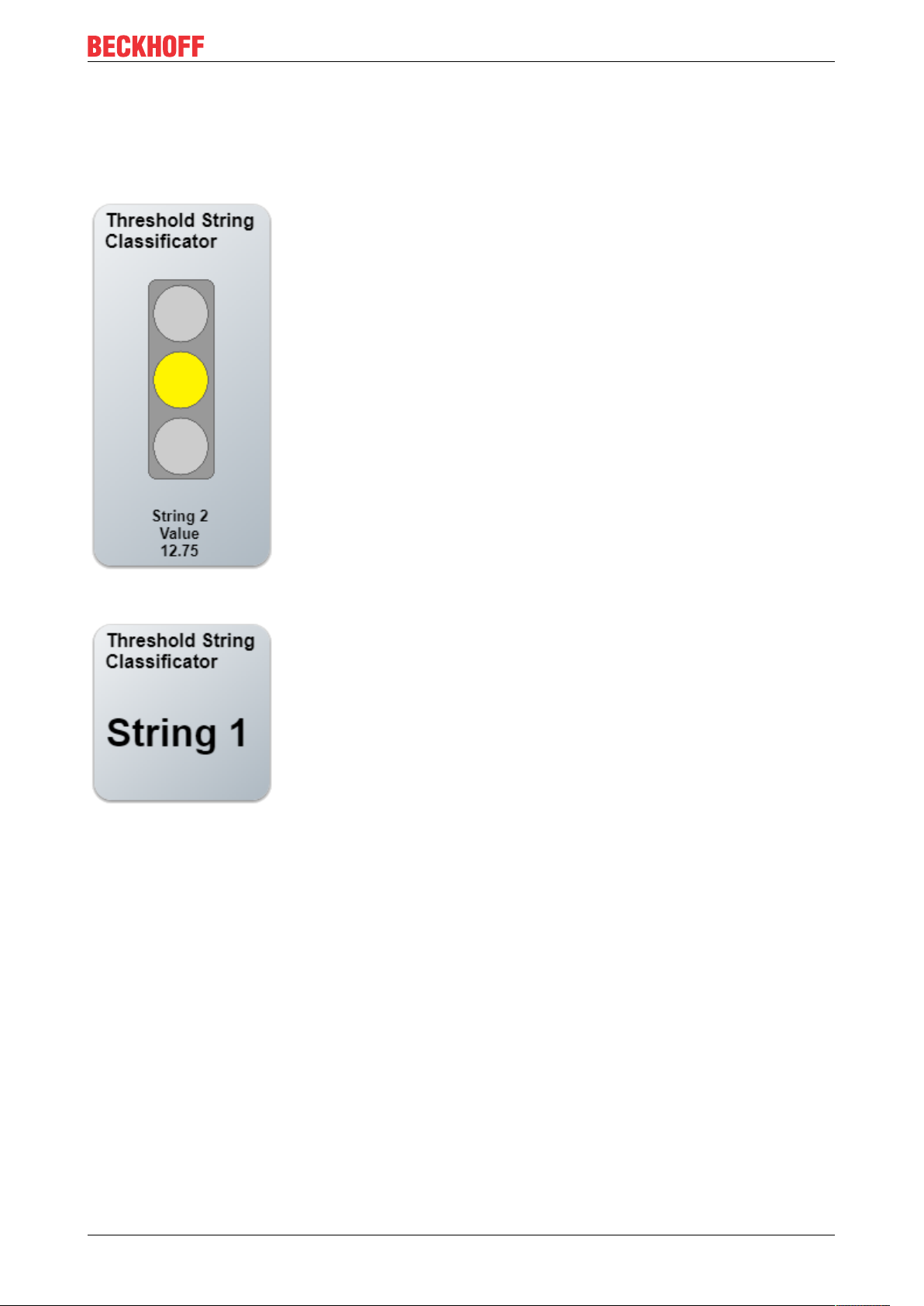

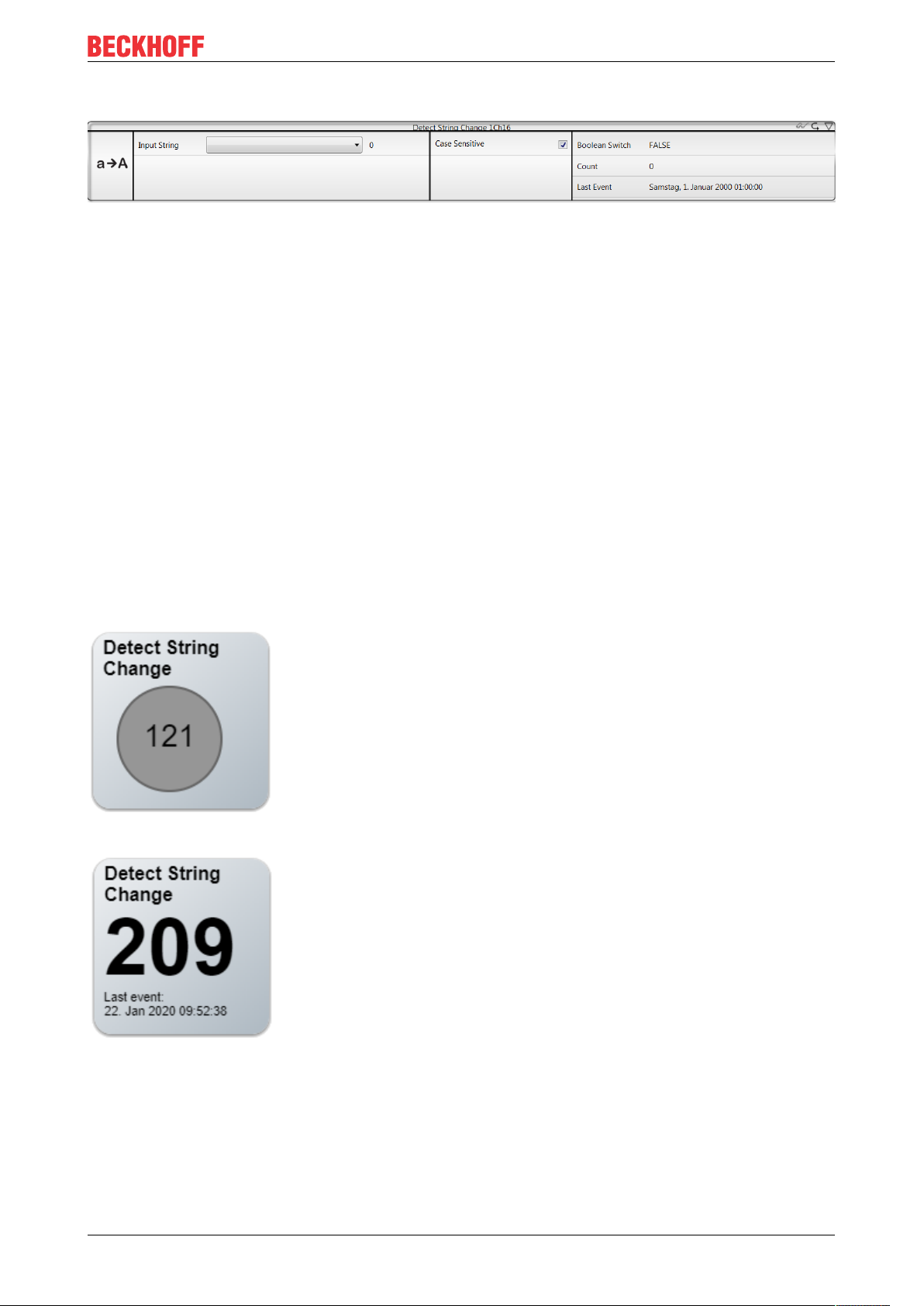

6.2.2.2 Threshold String Classificator 1Ch

The Threshold String Classificator 1Ch classifies the input values into three different classes according to the

configured thresholds. The class names (output string) can be configured individually as String 1, String 2

and String 3.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

Configuration Options

• Level 1 / 2: The input values which are smaller than the configured threshold are classified into into the

first class and the input values which are equal to or greater than the configured threshold are

classified into the second class.

• Level 2 / 3: The input values which are smaller than the configured threshold are classified into into the

second class and the input values which are equal to or greater than the configured threshold are

classified into the third class.

• String 1: Name of the first class.

• String 2: Name of the second class.

• String 3: Name of the third class.

Output Values

• Output String: Shows the class to which the input values belong to.

• Last Event: Indicates the point of time of the last raised event → the event can be pulled into the

scope chart by Drag & Drop to show it as a trigger-event.

TE352064 Version: 1.0

Page 65

Configuration

Standard HMI Controls

The following HMI controls are available for the Threshold String Classificator 1Ch algorithm to generate an

Analytics Dashboard:

1.The TrafficLight control visualizes the Output String and Last Event output values and the data input value.

2.The SingleValue controls visualizes the Output string output value.

3.The Table control visualizes all output values: Output String, Last Event.

TE3520 65Version: 1.0

Page 66

Configuration

Alternatively, custom HMI controls can be mapped to the Threshold String Classificator 1Ch algorithm using

the Mapping Wizard.

6.2.2.3 State Histogram 1Ch

The State Histogram 1Ch counts how often the input signal (INT) has a specific value between the

configured minimum and maximum and shows the distribution in a histogram. The first bar represents the

boundary values which are smaller than the minimum and the last bar represents the boundary values which

are greater than the maximum. The State Histogram 1Ch is suitable for state-machines to show how often

the different states are executed.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

Configuration Options

• Hist Mode The operating mode of the histogram. You can select between "eAbs" for absolute Values

and "eRel" for relative values to show the percentage distribution.

• Min: Minimal value which should be analyzed.

• Max: Maximal value which should be analyzed.

Output Values

• Num Values: Shows the whole amount of executed states between the configured boarders.

• Histogram: Below the Num Values the Histogram is shown. On each bar the respective value is

displayed.

Standard HMI Controls

The following HMI controls are available for the State Histogram 1Ch algorithm to generate an Analytics

Dashboard:

1.The PieChart control visualizes the Histogram output value.

TE352066 Version: 1.0

Page 67

2. The StateHistogram control visualizes the Histogram output value.

Configuration

3. The Table control visualizes all output values: Num Values, Histogram.

Alternatively, custom HMI controls can be mapped to the State Histogram 1Ch algorithm using the Mapping

Wizard.

TE3520 67Version: 1.0

Page 68

Configuration

6.2.2.4 Bandwidth Classificator 1Ch

The Bandwidth Classificator 1Ch determines whether the input signal is within the configured bounds,

smaller or bigger than the bounds.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

Configuration Options

• Lower Bound: Lower Bound for the comparison.

• Upper Bound: Upper Bound for the comparison.

Output Values

• Class: Shows the class to which the input values belong to (WithinBounds / Smaller / Bigger).

• Last Event: Indicates the point of time of the last raised event → the event can be pulled into the

scope chart by Drag & Drop to show it as a trigger-event.

Standard HMI Controls

The following HMI controls are available for the Bandwidth Classificator 1Ch algorithm to generate an

Analytics Dashboard:

1.The BandwidthClassificator control visualizes the Class and Last Event output values and the Lower

Bound and Upper Bound Configuration options.

2.The MultiStates control visualizes the Class output value.

3.The Table control visualizes all output values: Class, Last Event.

TE352068 Version: 1.0

Page 69

Configuration

Alternatively, custom HMI controls can be mapped to the Bandwidth Classificator 1Ch algorithm using the

Mapping Wizard.

6.2.2.5 Time Based Envelope 1Ch

The Time Based Envelope 1Ch compares, if the periodic input data are within a configured bandwidth of

values, which are read from a file. The comparison starts if the signal of the start period flag is TRUE. It is

recommended not to use the Time Based Envelope 1Ch simultaneously with the Time Based Teach Path 1Ch

[}100] due to concurrent file access.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

Configuration Options

• File Path: Path to the previously teached data file.

• Band Mode: Mode of the band operation (use absolute or relative values).

• Band: Bandwidth of the band operation.

Output Values

• Executing Comparison: Shows TRUE when the algorithm processes the envelope, otherwise FALSE.

The envelope process starts if the start period flag is TRUE.

• Lower Band: Shows the value of the lower band depending on band mode.

• Upper Band: Shows the value of the upper band depending on band mode.

• Within Band: Shows TRUE, if the current values are within the band, otherwise FALSE.

• Compare Result: Result of the current comparison. Shows if the current values are within the band,

smaller or greater than the band.

TE3520 69Version: 1.0

Page 70

Configuration

• Current Compared Cycles: Number of cycles that have been compared.

• Count Within Band: Counts the amount of times, the values were within the band.

• Count Smaller: Counts the amount of times, the values were smaller than the band.

• Count Bigger: Counts the amount of times, the values were greater than the band.

• Value Number: Shows the value number of the data point in the file, that is currently compared.

Standard HMI Controls

The following HMI controls are available for the Time Based Envelope 1Ch algorithm to generate an

Analytics Dashboard:

1.The TimeBasedEnvelope control visualizes the Executing Comparison, Lower Band, Upper Band, Within

Band, Compare Result, Count Within Band, Count Smaller, Count Bigger, Current Compared Cycles, State

and Value Number output values.

2. The Table control visualizes all output values: Executing Comparison, State, Lower Band, Upper Band,

Within Band, Compare Result, Current Compared Cycles, Count Within Band, Count Smaller, Count Bigger,

Value Number.

TE352070 Version: 1.0

Page 71

Configuration

Alternatively, custom HMI controls can be mapped to the Time Based Envelope algorithm using the Mapping

Wizard.

6.2.2.6 Histogram 1Ch

The Histogram 1Ch calculates the distribution of a single channel input value cyclically. It can be configured

with minimal bin, maximal bin and the total amount of bins. The dimension of the output array is the number

of bins + 2. Because values that are less than the minimal bin are stored in the first array element and values

greater than the maximal bin are stored in the last array element.

Optional a boolean signal for Enable Execution can be selected, so that the algorithm is just active, if the

value of the selected signal is TRUE.

TE3520 71Version: 1.0

Page 72

Configuration

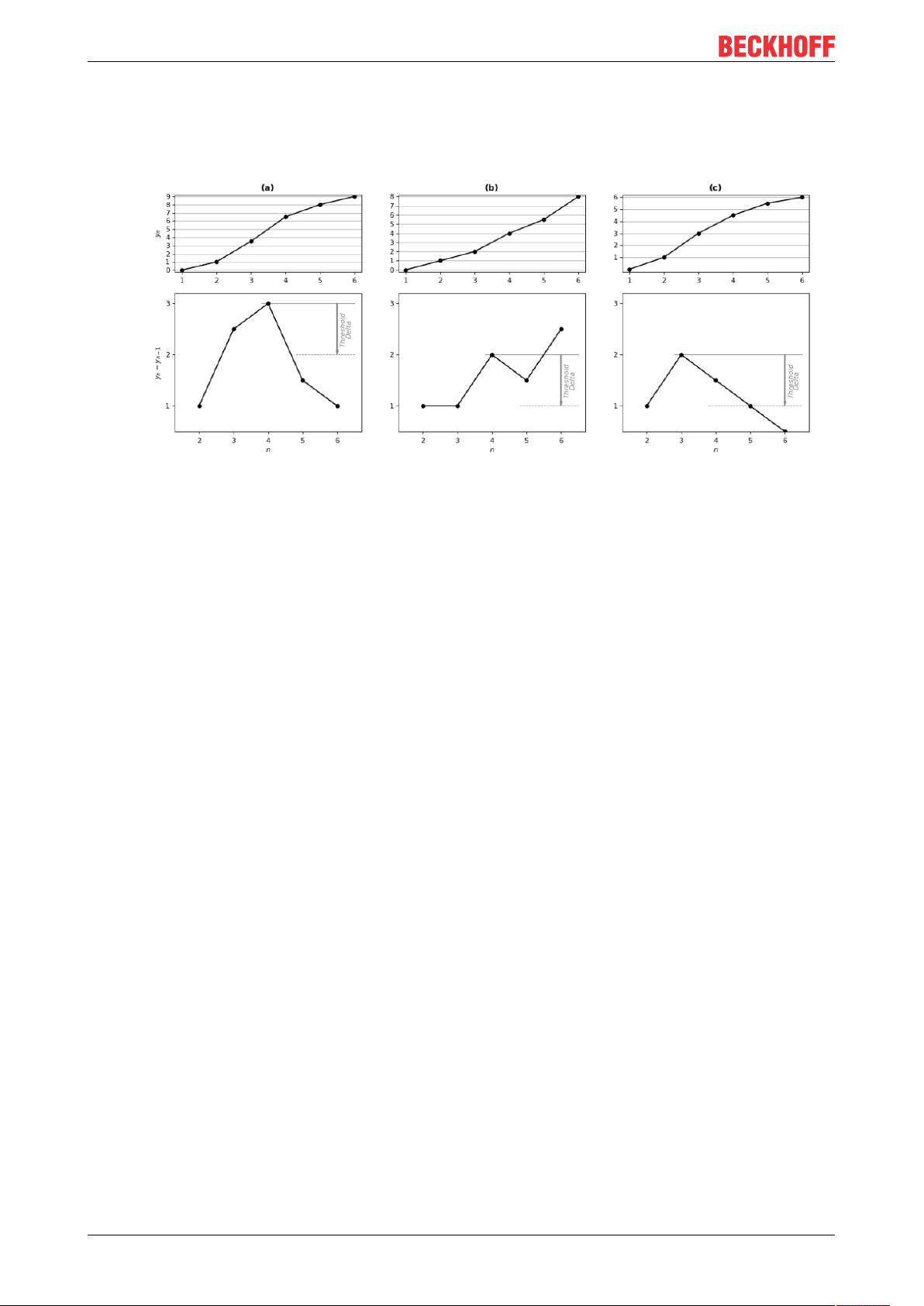

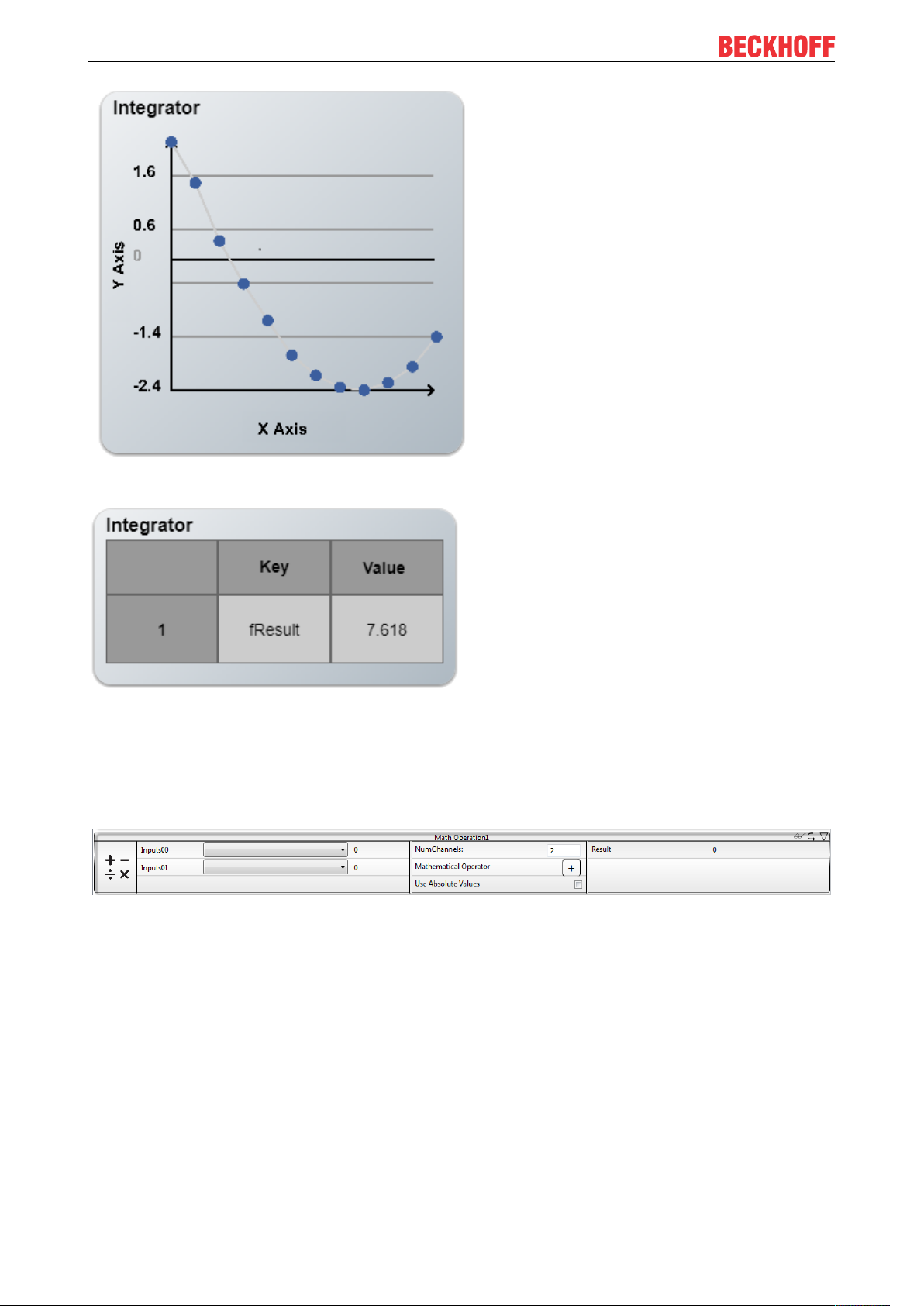

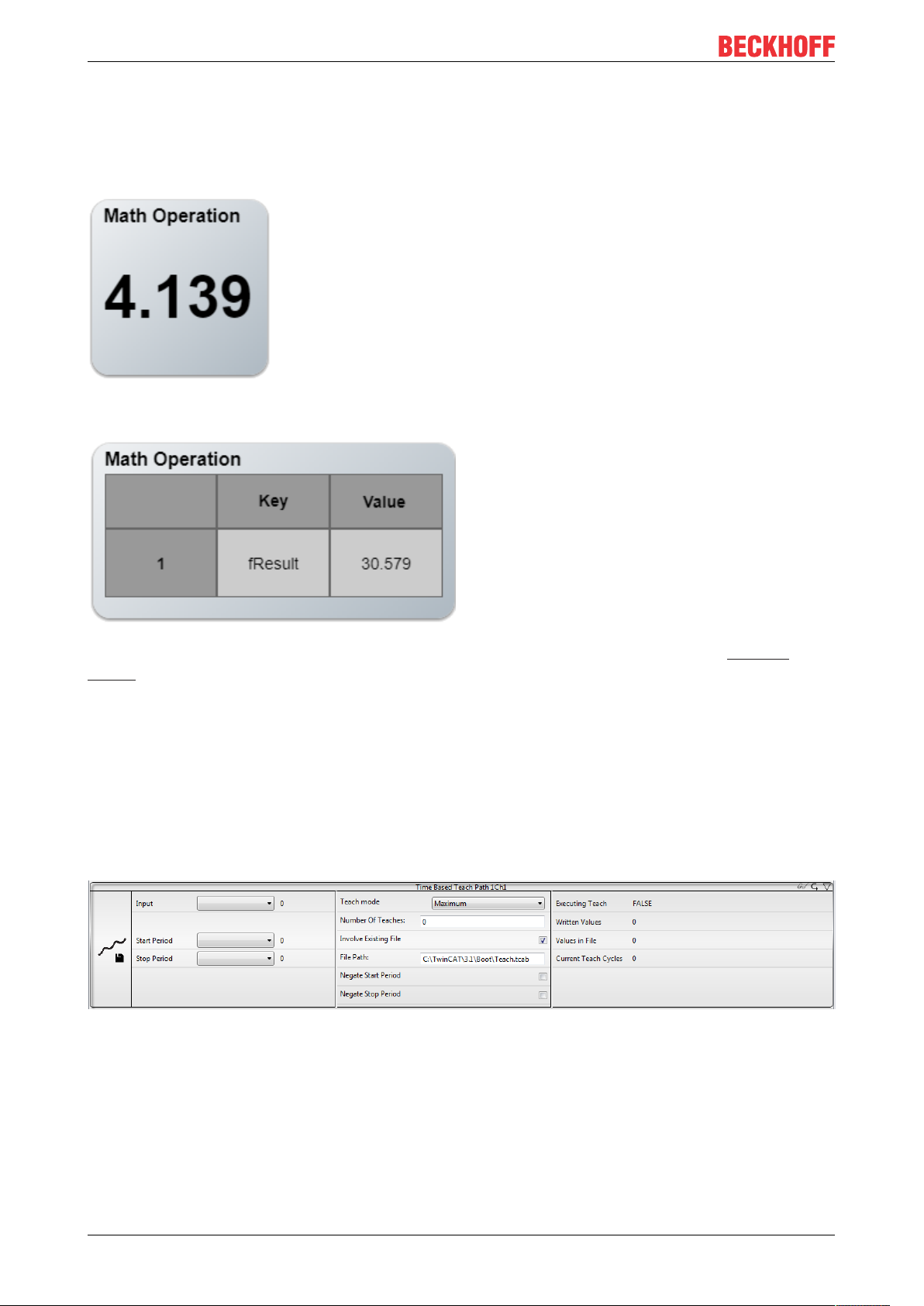

Configuration Options