Page 1

Manual | EN

TE1010

TwinCAT 3 | Realtime Monitor

2020-09-24 | Version: 1.3

Page 2

Page 3

Table of contents

Table of contents

1 Foreword ....................................................................................................................................................5

1.1 Notes on the documentation..............................................................................................................5

1.2 Safety instructions .............................................................................................................................6

2 Overview.....................................................................................................................................................7

3 Basic principles .........................................................................................................................................8

3.1 TwinCAT 3 Real-Time .......................................................................................................................8

3.2 Display in the Real-time Monitor......................................................................................................12

3.3 Use of cursors .................................................................................................................................16

4 Quick start................................................................................................................................................20

5 Reference, user interface........................................................................................................................22

5.1 Menu bar .........................................................................................................................................22

5.1.1 Project.............................................................................................................................. 22

5.1.2 User contexts................................................................................................................... 23

5.1.3 Tools ................................................................................................................................ 24

5.1.4 Info................................................................................................................................... 25

5.2 Toolbar - Real-time Monitor toolbar.................................................................................................25

5.3 Project tree ......................................................................................................................................26

5.4 Display window................................................................................................................................28

5.5 Properties window ...........................................................................................................................29

5.5.1 Project node..................................................................................................................... 29

5.5.2 Context node ................................................................................................................... 30

5.5.3 Marker group element...................................................................................................... 31

5.6 Cursor window.................................................................................................................................32

5.7 Event window ..................................................................................................................................32

6 PLC API.....................................................................................................................................................33

6.1 Function blocks................................................................................................................................33

6.1.1 FB_RTMon_LogMark ...................................................................................................... 33

6.1.2 FB_RTMon_LogMarkBase .............................................................................................. 36

6.2 Data types .......................................................................................................................................37

6.2.1 ST_RTMon_MarkDef....................................................................................................... 37

6.3 Global constants..............................................................................................................................38

6.3.1 TcMarkOption .................................................................................................................. 38

7 C++ API.....................................................................................................................................................39

7.1 Data types .......................................................................................................................................39

7.1.1 TcMark16......................................................................................................................... 39

7.2 Classes............................................................................................................................................39

7.2.1 CTcLogMark .................................................................................................................... 39

7.3 Constants ........................................................................................................................................41

TE1010 3Version: 1.3

Page 4

Table of contents

TE10104 Version: 1.3

Page 5

Foreword

1 Foreword

1.1 Notes on the documentation

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with applicable national standards.

It is essential that the documentation and the following notes and explanations are followed when installing

and commissioning the components.

It is the duty of the technical personnel to use the documentation published at the respective time of each

installation and commissioning.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development.

We reserve the right to revise and change the documentation at any time and without prior announcement.

No claims for the modification of products that have already been supplied may be made on the basis of the

data, diagrams and descriptions in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, EtherCAT G®, EtherCAT G10®, EtherCAT P®, Safety over EtherCAT®,

TwinSAFE®, XFC®, XTS® and XPlanar® are registered trademarks of and licensed by Beckhoff Automation

GmbH.

Other designations used in this publication may be trademarks whose use by third parties for their own

purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents:

EP1590927, EP1789857, EP1456722, EP2137893, DE102015105702

with corresponding applications or registrations in various other countries.

EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

TE1010 5Version: 1.3

Page 6

Foreword

1.2 Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

Description of symbols

In this documentation the following symbols are used with an accompanying safety instruction or note. The

safety instructions must be read carefully and followed without fail!

DANGER

Serious risk of injury!

Failure to follow the safety instructions associated with this symbol directly endangers the life and health of

persons.

WARNING

Risk of injury!

Failure to follow the safety instructions associated with this symbol endangers the life and health of persons.

CAUTION

Personal injuries!

Failure to follow the safety instructions associated with this symbol can lead to injuries to persons.

NOTE

Damage to the environment or devices

Failure to follow the instructions associated with this symbol can lead to damage to the environment or

equipment.

Tip or pointer

This symbol indicates information that contributes to better understanding.

TE10106 Version: 1.3

Page 7

Overview

2 Overview

The TwinCAT 3 Real-time Monitor enables precise diagnostics and optimization of the runtime behavior of

tasks in the TwinCAT 3 runtime. It offers a graphical representation of the temporal processing of real-time

tasks and their modules across all cores. In addition, user-defined processes and their dependencies can be

represented graphically through appropriate instrumentation of the control software.

The Real-time Monitor makes the time behavior of the control software on a target system completely

transparent and enables comprehensive time analysis. It thus supports both fault diagnosis and time

optimization of the configuration, especially on multi-core systems.

Installation

A separate installer is used for the installation. The license is activated as usual under TwinCAT 3.

Requirements

The Real-time Monitor can only be used for diagnosis of TwinCAT 3.1 runtimes from TwinCAT 3.1 version

4024.0 or higher.

It is suitable for Windows 10-based target systems, but not for target systems based on Windows CE.

Licensing

The TwinCAT 3 Real-time Monitor (TE1010) is an Engineering product. Licensing is therefore carried out

exclusively on the Engineering system.

There is no 7-day trial license available for this product.

TE1010 7Version: 1.3

Page 8

Basic principles

3 Basic principles

The following chapter describes the basic principles that should be read before using the TwinCAT 3 Realtime Monitor.

3.1 TwinCAT 3 Real-Time

According to the DIN 44300 standard, real-time / real-time operation is defined as follows:

Real-time operation is an operating mode of a computing system in which programs for the processing of

data are continuously operational in such a way that the processing results are available within a specified

period of time.

In other words, the output values of an application program (calculated based on the inner state and input

values) are available within a defined and guaranteed time. This defined time is also referred to as cycle

time.

The application program itself can consist of several program function blocks, which in turn call other

programs or function blocks etc. (see also IEC 61131-3 standard). The program blocks can be assigned to

real-time tasks, which in turn call them with a cycle time to be defined and a defined priority.

TwinCAT 3 Real-Time is a real-time extension that can be used in the current TwinCAT 3.1 version under

Microsoft Windows operating systems from Windows 7 or later. TwinCAT 3 Real-Time supports the following

features in order to meet the requirements described for the control of industrial processes:

• Real-time capable scheduling

• Parallel execution of processes

• Direct hardware access

In addition, TwinCAT 3 Real-Time also offers multi-core support to meet the ever-increasing demands for

high-performance and flexible/expandable control platforms. The available cores can either be used

exclusively for TwinCAT or shared with Windows. In the following sections, the cores are therefore referred

to as "isolated" or "shared.

Real-time capable scheduling:

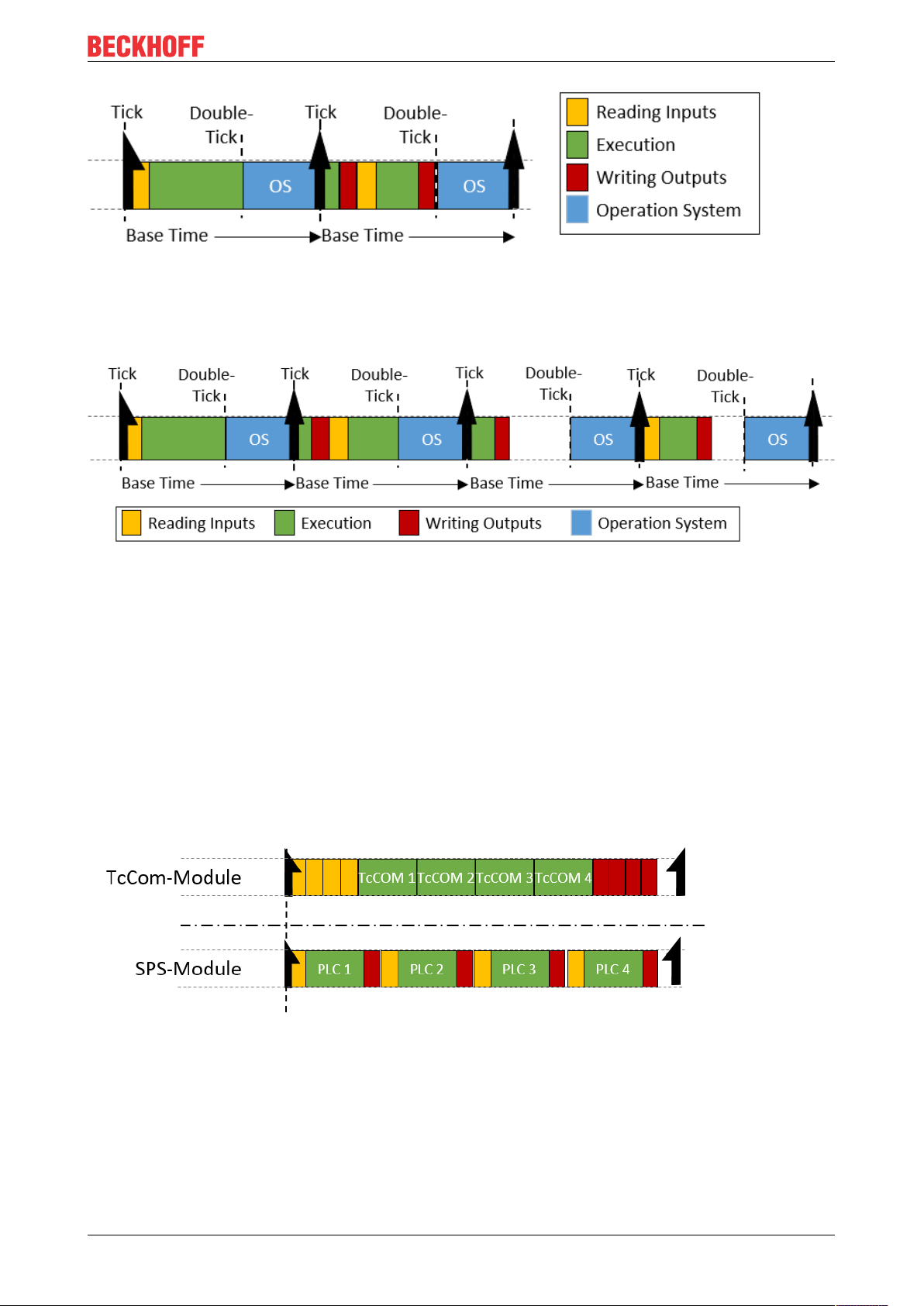

TwinCAT 3 Real-Time works with the double-tick method. This means that both switching to real-time mode

and switching back is triggered by an interrupt. The interrupt when switching to the real-time mode also

starts the scheduling at the same time. After an adjustable period of time, but no later than after 90% of the

set cycle time, TwinCAT only on shared cores switches back in non-real-time mode, so that the guest

operating system has sufficient computing time available to comply with the response times required for

hardware functions etc. The isolated cores are an exception.

Scheduling refers to the (system) process that determines the processing sequence and the processing time

of the individual tasks, based on the defined cycle time and the defined priority. Strict adherence to the

processing time ensures that the real-time compliance described above is guaranteed.

Triggered by a synchronous basic tick on all real-time kernels, the scheduling for each real-time kernel is

calculated independently in TwinCAT 3 Real-Time. This guarantees that real-time tasks running on different

cores do not interfere with each other (unless already explicitly prevented in the user program through the

use of interlocks).

Scheduling in which the priority of a task is derived from its cycle time is also known as rate-monotonic

scheduling. Activating the option "Automatic Priority Management" automatically sets TwinCAT 3 Real-Time

to this value. Since this is not always the best solution for every application, the priorities can be adjusted

manually.

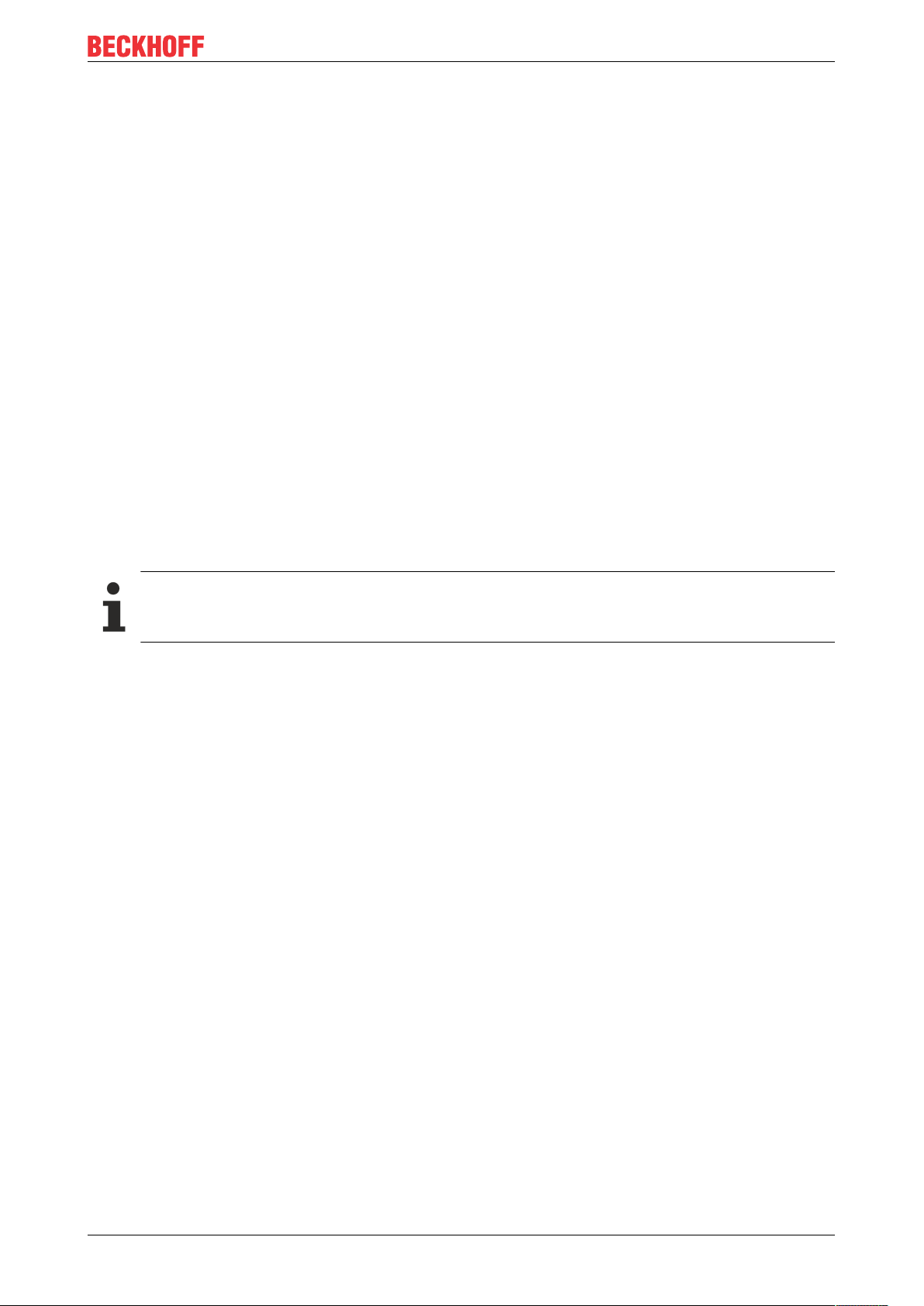

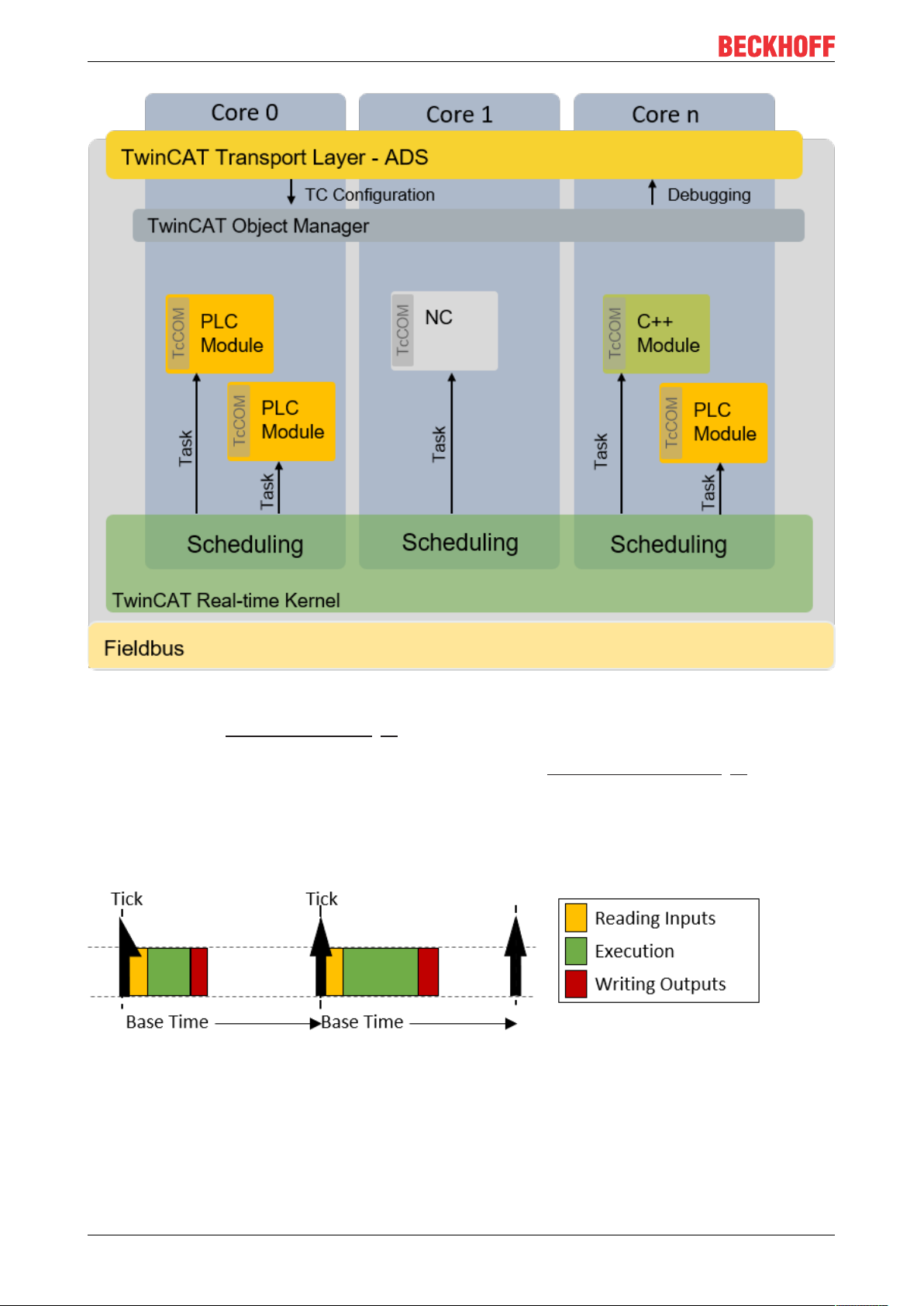

Exemplary representation of the call of a PLC task:

TE10108 Version: 1.3

Page 9

Basic principles

The figure shows the call of a PLC task. After the real-time tick has occurred, the PLC task is called by the

scheduler. This makes the current input values available to the PLC application (input update), followed by

processing of the application program (cycle update). Finally the results are written to the outputs (output

update). Once this has been completed, the device switches to non-real-time mode (double-tick). As shown

in the figure, the execution time of the user program may vary depending on which code is executed (based

on the internal state of the program). Thus the time when the outputs are written also varies. Depending on

which task a bus system is driven, this can cause the sending of the bus telegrams to vary (jitter) to the same

extent.

Sample call of a task with "IO at task start“

By using the "IO at task start" option, the processing sequence within a task can be changed so that after

reading the inputs, the outputs (of the previous cycle) are written directly before the application program is

executed. Although the outputs are not written until the next cycle, this setting has the advantage that the

time at which the outputs are written to the process/bus is exactly the same in each cycle.

Preemptive multitasking:

Preemptive multitasking means that the current state of a process (the CPU and floating point registers) is

saved in the event of an interrupt (e.g. by higher-priority processes), and the current process is paused. If

this happens, the scheduler determines the (new) process to be executed, based on the task priorities. Once

the process to be interrupted is complete, the process context is restored and the "old" process continues.

Direct hardware access:

In order to achieve deterministic (reproducible) real-time behavior, TwinCAT 3 Real-Time requires direct

hardware access. For this to be possible, TwinCAT 3 Real-Time must be executed in Windows kernel mode.

This makes it possible, among other things, for TwinCAT Real-Time to access the network ports directly and

send and receive real-time Ethernet telegrams (e.g. EtherCAT).

Schematic representation of the TwinCAT 3 runtime environment:

The following figure illustrates the structure of the TwinCAT 3.1 runtime environment in relation to

scheduling. The TwinCAT 3 runtime environment enables user modules to be executed in real-time. An

essential part of the TwinCAT 3 runtime environment therefore is the real-time driver, which is executed on

the cores that are activated for TwinCAT and handles the scheduling there. The latter takes place

independently on the individual cores.

TE1010 9Version: 1.3

Page 10

Basic principles

Isolated cores:

As described under Realtime scheduling [}8], TwinCAT uses a double-tick procedure to switch back to nonreal-time mode at a specified point in time. When switching between real-time mode and non-real-time

mode, the preceding process state is restored, as described under Preemptive multitasking [}9]. The

restoration takes some time, depending on how intensively the real-time and non-real-time programs use the

memory and in particular the cache. In order to eliminate these temporal effects, TwinCAT 3.1 Real-Time

allows cores to be isolated from the guest operating system. This eliminates the need to switch back,

resulting in more computing time for the real-time user program and better real-time quality (less jitter) by

avoiding the time effects associated with restoring the "old" process state.

Behavior when the cycle time is exceeded:

If the defined cycle time of a task is exceeded, processing of the "old" cycle continues in the next cycle. In

addition, the task exceed counter is incremented. Once processing of the old / previous cycle is complete,

the system immediately tries to start processing the tasks of the current cycle. If this is completed within the

current cycle, further processing is carried out as shown above.

TE101010 Version: 1.3

Page 11

Basic principles

If the second cycle that follows directly is also exceeded (in this case it is irrelevant whether the system is still

processing the first cycle or whether the second cycle has commenced), the current processing task is

completed, and processing of the next task does not commence until the next possible scheduled cycle start.

This means that several cycles may be lost. The exceedance counter is incremented accordingly.

Differences in execution between PLC and "TcCom" runtime modules:

Processing of a TwinCAT task, in relation to the execution of runtime modules, is based on the following

sequence:

1. Copying of the inputs to the process images of the runtime modules called by the task.

2. Executing the modules according to the sort order (in ascending order).

3. Output update, which makes the outputs available accordingly. If this task drives an EtherCAT fieldbus, the frame is provided and sent during the output process image.

4. Post-cycle update: this is used, among other things, to trigger a cycle update when the "I/O at task

start" option is active.

If runtime modules are added to a task, they "log on" to the respective calls of the task. The only exceptions

are PLC runtime modules. For reasons of compatibility with TwinCAT 2, the PLC runtime modules directly

update the inputs and outputs. The difference between the two behaviors is shown in the following figure.

Four runtime modules can be seen in each case. Standard TwinCAT 3 runtime modules log on to the

corresponding method calls of the task. This means that all input updates (yellow) and output updates (red)

are triggered by the task and take place one after the other directly at the start or end of task processing. If

two of these modules communicate with each other via a mapping, they do not receive the current values

until the next cycle.

The PLC runtime modules independently perform an input and output update. If two PLC runtimes

communicate with each other, the runtime module that is executed second directly receives the current

values from the first runtime module. Thus, there is no cycle offset in the communication direction from first

runtime module to second runtime module, but there such an offset does exist in the other direction.

TE1010 11Version: 1.3

Page 12

Basic principles

3.2 Display in the Real-time Monitor

In simple terms, the TwinCAT 3 Real-time Monitor enables the display of grouped events. In order to avoid

confusion with the messages or alarms stored in the TwinCAT EventLogger, the data handled by the

TwinCAT 3 Real-time Monitor are referred to as (time) markers.

These markers can be used to represent the temporal behavior of tasks or user processes. For this purpose,

the markers are assigned an ID, a marker type, a context and a timestamp. In addition, if required a userdefined date formatted as UINT can be provided, in order to include additional information in the display in

the real-time monitor (e.g. error number, state of a state machine etc.).

Marker ID:

The marker ID is used to identify the displayed task / process. In other words, all markers relating to the

same task/process should use the same marker ID.

Marker type:

The TwinCAT 3 Real-time Monitor enables the display of events or processes / operations over time. For the

representation of processes / operations, these are marked as a sequence. A sequence can be divided into

one or more intervals. Markers can be typed to define the start or end of sequences or intervals. In addition,

they can also show events within an application over time. A distinction is therefore made between the

following types of markers:

1. Marker:

The marker can be used to log an event, e.g. the time of an alarm or the change of a state etc.

2. Sequence start:

A sequence start indicates the time when a task / process is allowed to start (higher-priority tasks /

processes may result in a delay).

3. Interval start:

An interval start specifies the time when a task / process actually starts. Due to interruptions etc., a sequence may contain several interval starts.

4. Interval stop:

An interval stop specifies the time when a task / process is no longer executed. This can happen, for

example, due to interruptions caused by higher-priority tasks or unfulfilled dependencies.

5. Sequence stop:

A sequence stop indicates the point in time at which a task may no longer run or a process is terminated.

Context:

A context describes a summary of markers or marker groups.

For the system tasks, all tasks that are processed on a core are combined into one context (e.g. core 0).

Such a (real-time) context thus maps the scheduling within a real-time kernel. For these real-time contexts,

only one of the tasks assigned to a context is active at any one time. This restriction does not apply to userspecific marker groups.

When using simple markers (by using FB_Mark), the user-specific marker groups are automatically grouped

according to their application ports. For example, all markers stored from within a PLC project with port 851

are assigned to a context with context ID 851 (hexadecimal 0x353).

When using more complex markers (based on the function block FB_RTMon_LogMarkBase [}36]), contexts

(i.e. correlations) can be defined independently. This could be, for example, a grouping by process type or by

machine modules (functional units).

Display in the tree view:

As described above, all markers that describe the same task / process use the same marker ID. These

markers are combined into a marker group and are assigned an entry in the tree view of the TwinCAT 3

Real-time Monitor.

TE101012 Version: 1.3

Page 13

Basic principles

An entry with the corresponding task name is automatically created in the tree for the system tasks.

For user-related marker groups that describe processes, for example, this must be done manually. For each

detected user-specific marker group an entry NewGroup automatically appears in the tree, which can be

identified by the marker ID (corresponds to the group ID in the Properties window of the group). This group

can be renamed as required (see Context node [}30]).

As described under Display in the Real-time Monitor [}12], the individual marker groups are combined into

contexts. This happens automatically for the system tasks and when simple markers are used. When using

extended markers, the context ID that is transferred in the application code is used for this purpose.

The names of marker IDs (group IDs) and contexts can be exported for later reuse and subsequently re-imported.

In the chart display, a marker group (i.e. all markers of a task / process) is shown within one row. For more

information see Display in the Real-time Monitor [}13].

Chart display:

Symbols in the chart display:

TE1010 13Version: 1.3

Page 14

Basic principles

Sequence start

Sequence stop

Indicates an interval start or stop.

Marker

Example display:

The following diagram shows an example of a possible temporal behavior of a task. At time (1), the task

receives "permission" to run based on the set cycle time. The start may be delayed until time (2) due to

missing dependencies or due to higher priority tasks that are still active. At time (3) a marker was transferred.

This can be a "system event" marker or a user-defined marker. Detailed information is provided by a tooltip

associated with the marker. The marker itself has no influence on the temporal behavior of the task /

process. At time (4) the task is interrupted (once again for example due to an interlock or a higher-priority

task). At time (5) the task continues to run. At time (6) the task is finished.

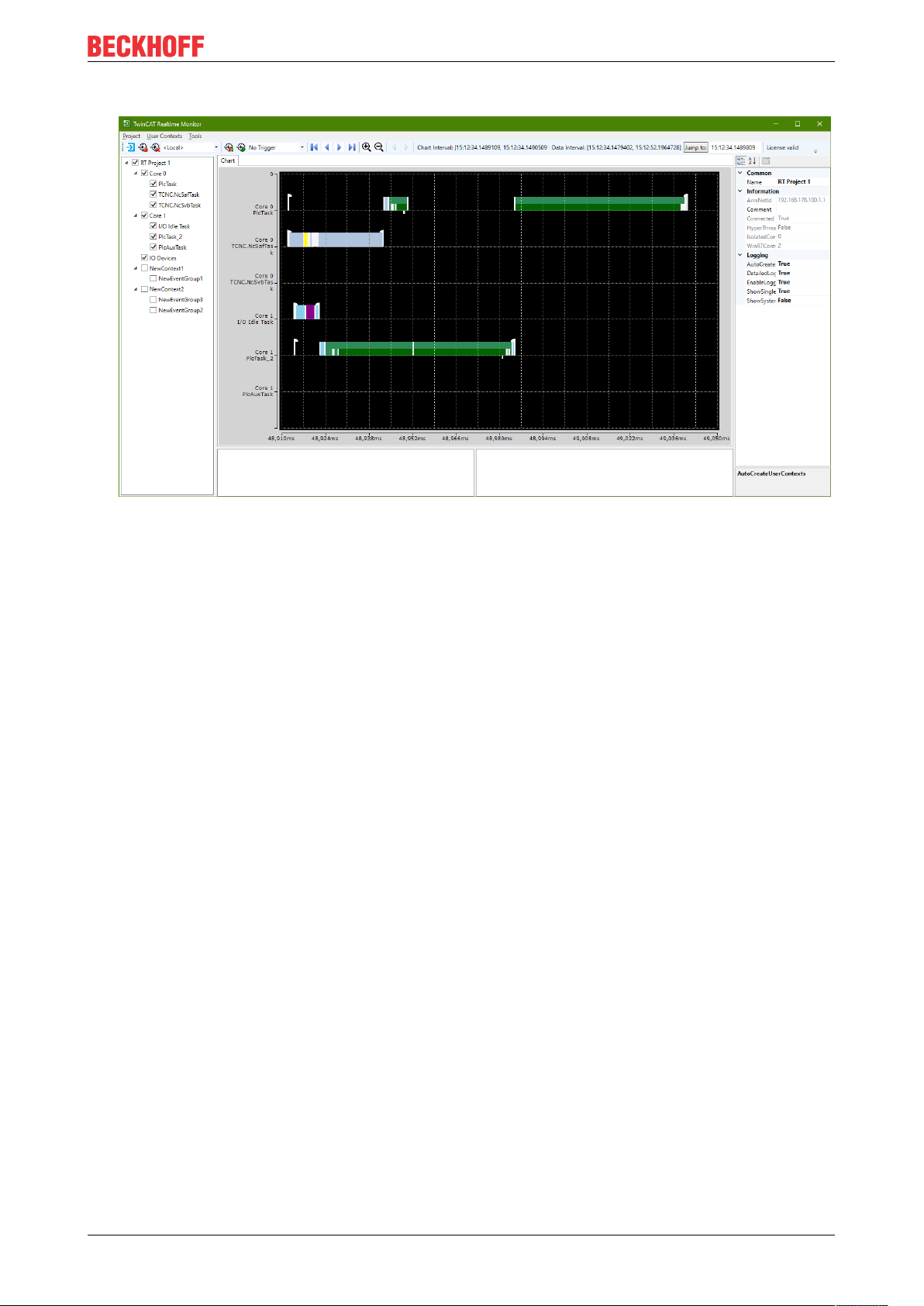

Illustration of the processing of a PLC runtime module:

As described in section TwinCAT 3 Real-Time [}11], each PLC runtime module calls the update of the inputs

and outputs itself. The complete processing of the PLC takes place in the cyclic update of the task calling it.

For this reason, if detailed logging is activated, processing of the PLC is mapped in the cyclic update of a

task. The following figure illustrates this by means of an example. Time (1) shows the execution of the input

update of the PLC runtime module. Cyclic processing of the PLC code takes place in area (2), which is

interrupted by another task in the example shown here. Once processing is completed, the output update of

the PLC runtime module takes place at time (3). In the example shown here, the task itself does not perform

an input or output update.

Detailed logging:

TE101014 Version: 1.3

Page 15

Basic principles

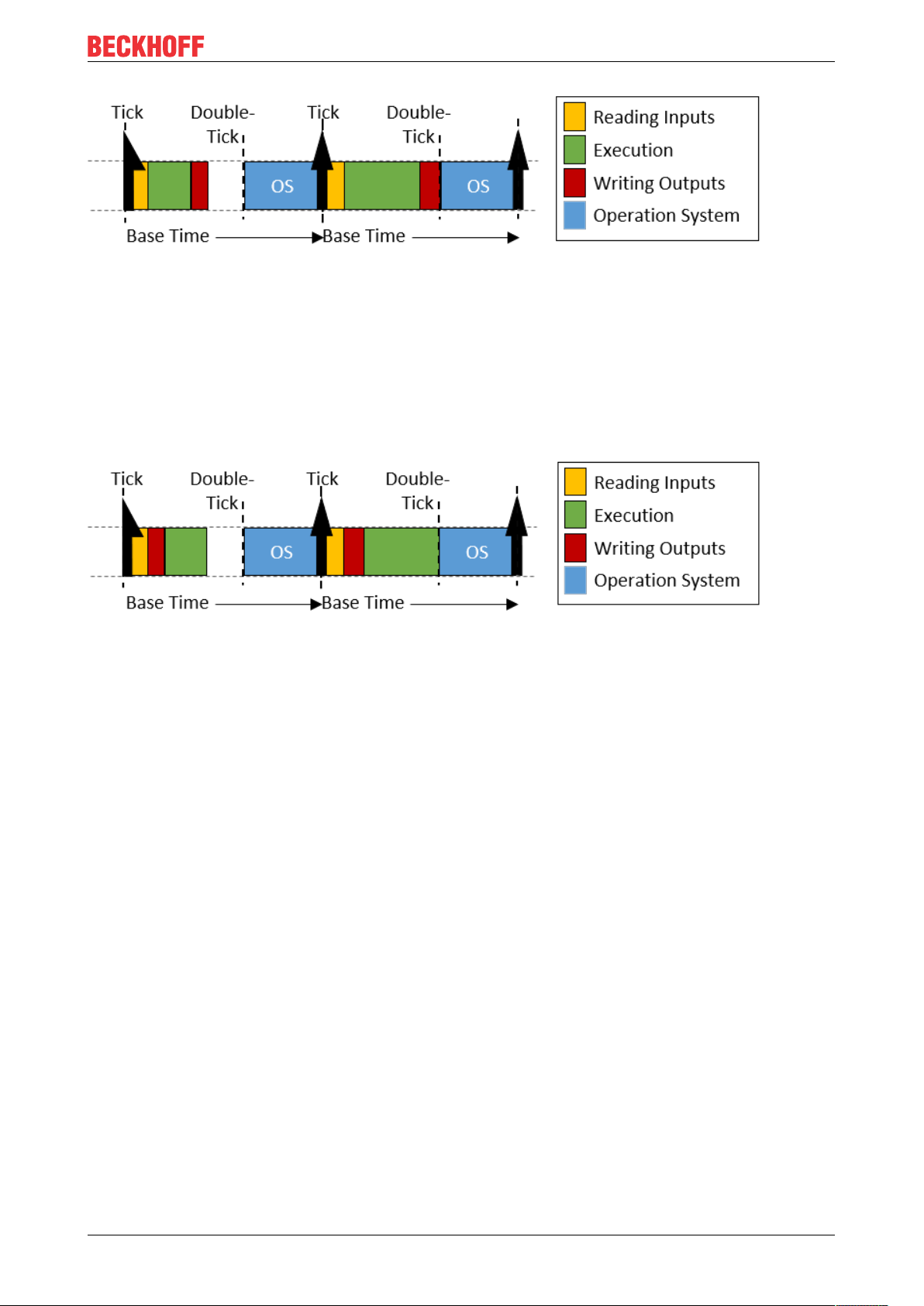

The option "detailedLogging" (see Project node [}29] or Context node [}30]) offers a detailed

representation of the execution of real-time tasks (also within a task). The following two figures illustrate the

difference.

Standard logging enabled:

DetailedLogging enabled:

Representation of the task references:

The option Show Task Reference (see Marker group element [}31]) enables the assignment of user

processes to the tasks on which they are executed to be made visible in the TwinCAT 3 Real-time Monitor.

This is represented by dashed lines. The following figure shows the assignment of the user process shown in

orange to a PLC task.

TE1010 15Version: 1.3

Page 16

Basic principles

3.3 Use of cursors

In order to measure times or to display all (system) events that occur at a particular time, cursors can be

used in the TwinCAT 3 Real-time Monitor.

Adding cursors

To add a cursor, proceed as follows:

1. Right-click within the display area of the chart.

ð A context menu opens, which contains the command Add Cursor as well as a command to delete all

existing cursors.

ð

2. Click Add Cursor.

ð A new cursor is created in the center of the chart.

TE101016 Version: 1.3

Page 17

Basic principles

Deleting cursors

There are two ways to delete a cursor:

Inside the chart

1. Right-click within the display area of the chart

ð A context menu opens which contains a command to delete all existing cursors.

2. Use the Remove Cursor command of the cursor you want to delete.

ð The cursor is deleted.

Inside the cursor window

1. Right-click the cursor you want to delete.

ð A context menu opens with a command to remove the cursor.

2. Use the command Remove Cursor to delete this cursor.

ð The cursor is deleted.

Navigating using the cursors

All cursors that were created are displayed in the cursor window.

TE1010 17Version: 1.3

Page 18

Basic principles

Double-clicking a cursor causes the display within the chart to jump to the exact position where the cursor is

positioned. The cursor is centered in the display area.

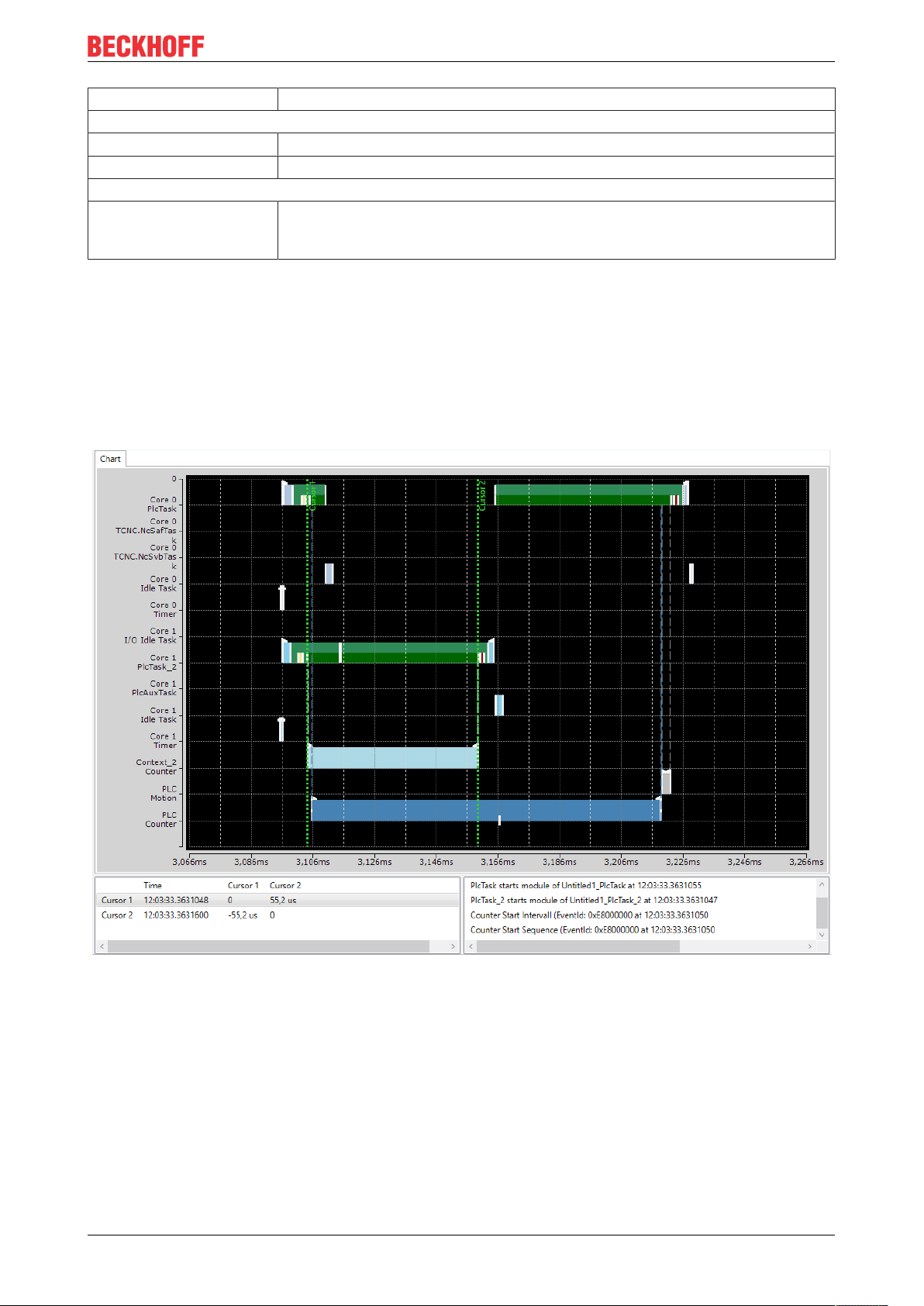

Measuring times

The cursors can be used to precisely determine the execution times of processes or the time of occurrence

of a user event. To do this, move one cursor to a relevant time within the display. The cursor automatically

"latches" to events and displays the events occurring at that time for the active cursor in the cursor window.

In the following figure, this is the application event Counter Start Interval for cursor 1.

To measure the duration of the process "Context_2_Counter", proceed as follows:

1. Create a cursor for the process start or use an existing cursor.

2. Move the cursor to the sequence / interval start marker of the process "Context_2_Counter" so that this

event is displayed in the Event window (see figure above).

3. Proceed accordingly with another cursor and move it to the sequence / interval stop marker of the

process "Context_2_Counter“.

ð The differences between all existing cursors are now displayed in tabular form in the cursor window.

4. Read the value for the cursor you are using directly from the table. For the example shown here, the

execution time is 55.5µs.

Cursor properties

The following properties are available for cursors.

TE101018 Version: 1.3

Page 19

Basic principles

Property Meaning

Cursor info

Color Allows you to change the color of the active cursor.

Text Shows the text displayed at the cursor.

Information

TriggerCursor Activates the property TriggerCursor, which causes a cursor in trigger mode to

remain at the same position in the chart window, rather than being latched to a

point in time (which would cause it to disappears from the display area).

Event window

The Event window shows all events taking place at this time for the active cursor. In the following figure,

these are the following events for cursor 1:

• The PlcTask starts processing of the runtime module Untitled1.

• PlcTask_2 also starts processing of the runtime module Untitled2.

• The Counter application process starts both the sequence and the interval.

TE1010 19Version: 1.3

Page 20

Quick start

4 Quick start

The following chapter is intended to provide an introduction to using the TwinCAT 3 Real-time Monitor.

ü The starting point is a project running on a TwinCAT 3.1 runtime version 3.1.4024.0 or later.

1. Open the Real-time Monitor.

2. Create a new project.

To do this, use the New Project option in the Project menu of the TwinCAT 3 Real-time Monitor. The

project name can be changed via the project properties (see Project node [}29]).

3. Now select the target system that you want to analyze. This is done via the toolbar of the TwinCAT 3

Real-time Monitor.

4. A prompt appears asking whether you want to load the configuration from the target system. Confirm

with "Yes“

ð The active configuration of the target system has been loaded and the contexts are displayed

hierarchically as a tree.

5. Select the tasks that you want displayed in the TwinCAT Real-time Monitor

6. Select the project in the tree view and set the Detailed Logging option in the Properties window to

"True" (see also Marker group element [}31]).

7. If you also want to automatically read the user contexts that may have been set in an application

program, set the AutoCreateUserContexts option to "True" as well.

8. Click the Start Log button in the toolbar of the TwinCAT 3 Real-time Monitor.

TE101020 Version: 1.3

Page 21

ð Recording of the real-time behavior begins.

Quick start

TE1010 21Version: 1.3

Page 22

Reference, user interface

5 Reference, user interface

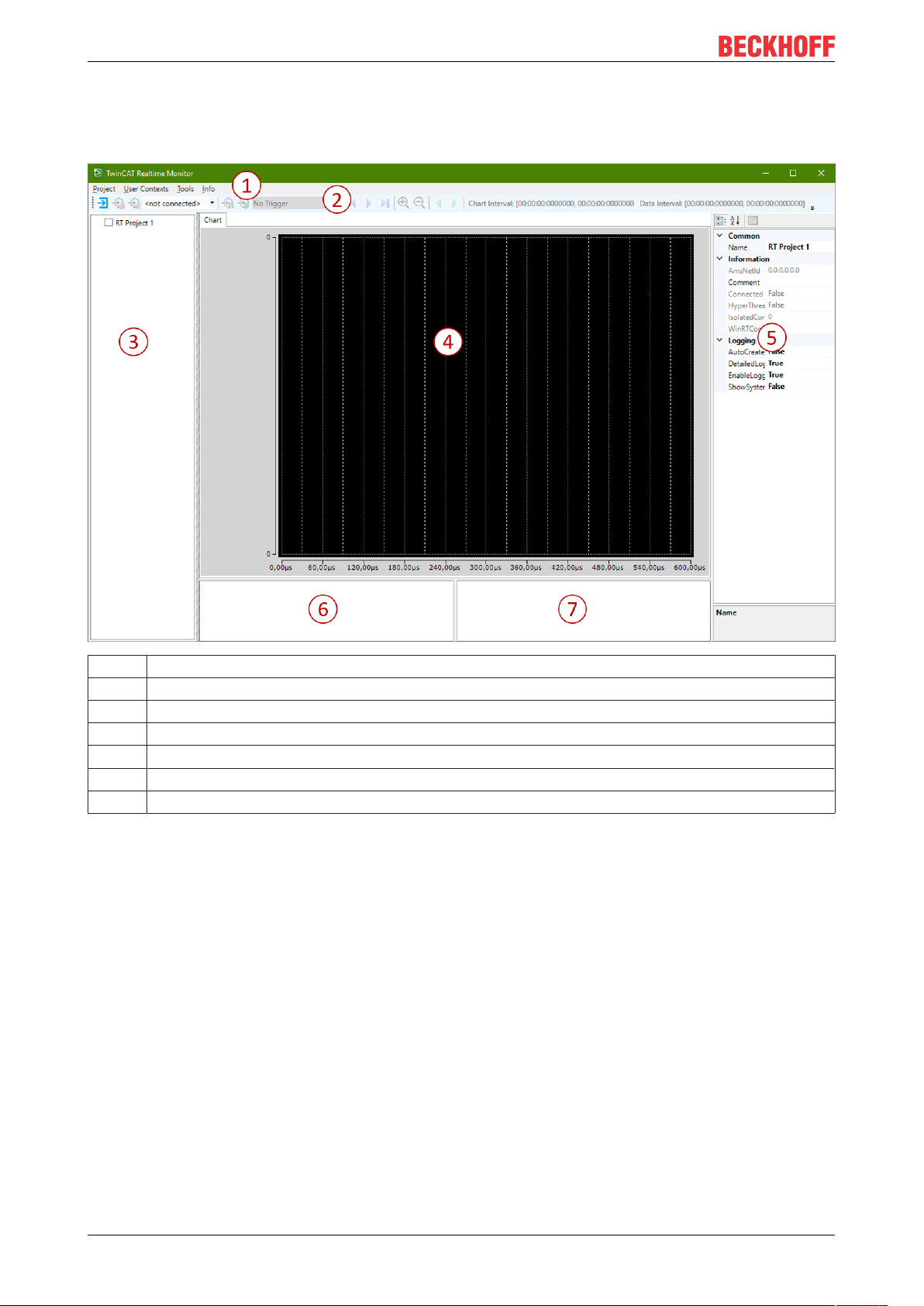

The user interface of the TwinCAT 3 Real-time Monitor consists of the following components:

1 Menu bar

2 Toolbar

3 Project tree

4 Display window

5 Properties window

6 Cursor window

7 Event window

Project tree: The various time contexts are displayed in the project tree of the TwinCAT 3 Real-time Monitor.

5.1 Menu bar

5.1.1 Project

new Project

Function: This command creates a new TwinCAT 3 Real-time Monitor project.

Call: Menu Project > new Project

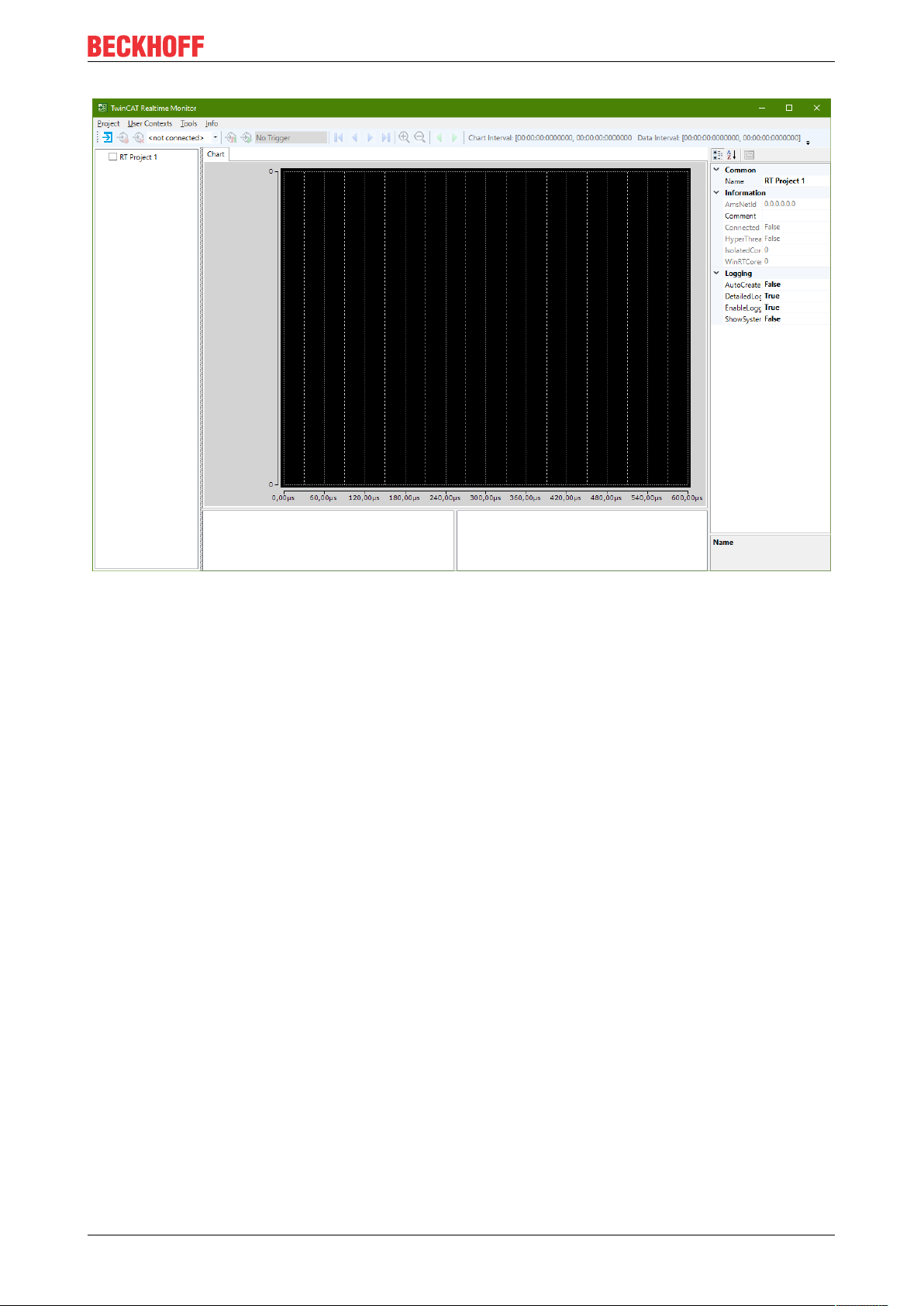

After a new project has been created, the TwinCAT 3 Real-time Monitor appears as follows:

TE101022 Version: 1.3

Page 23

Reference, user interface

open Project

Function: This command opens an existing TwinCAT 3 Real-time Monitor project.

Call: Menu Project > open Project

save Project

Function: This command saves an existing TwinCAT 3 Real-time Monitor project.

Call: Menu Project > save Project

close Project

Function: This command closes an existing TwinCAT 3 Real-time Monitor project.

Call: Menu Project > close Project

5.1.2 User contexts

Import User Contexts

Function: This command imports existing user contexts into a TwinCAT 3 Real-time Monitor project. If the

project contains previously (automatically) found contexts with the same event groups and event IDs, the

user is asked whether these should be replaced by the saved names and settings.

Call: Menu User Contexts > Import User Contexts

Export User Contexts

Function: This command exports existing user contexts from an open TwinCAT 3 Real-time Monitor project.

Call: Menu User Contexts > Export User Contexts

TE1010 23Version: 1.3

Page 24

Reference, user interface

Scan User Contexts

Function: This command scans for existing user contexts and inserts them into a TwinCAT 3 Real-time

Monitor project.

Call: Menu User Contexts > Scan User Contexts

5.1.3 Tools

Create Statistics

Function: The command evaluates the markers recorded with the TwinCAT 3 Real-time Monitor and

generates a statistic. This is displayed in the Statistics tab.

Call: Menu Tools > create Statistics

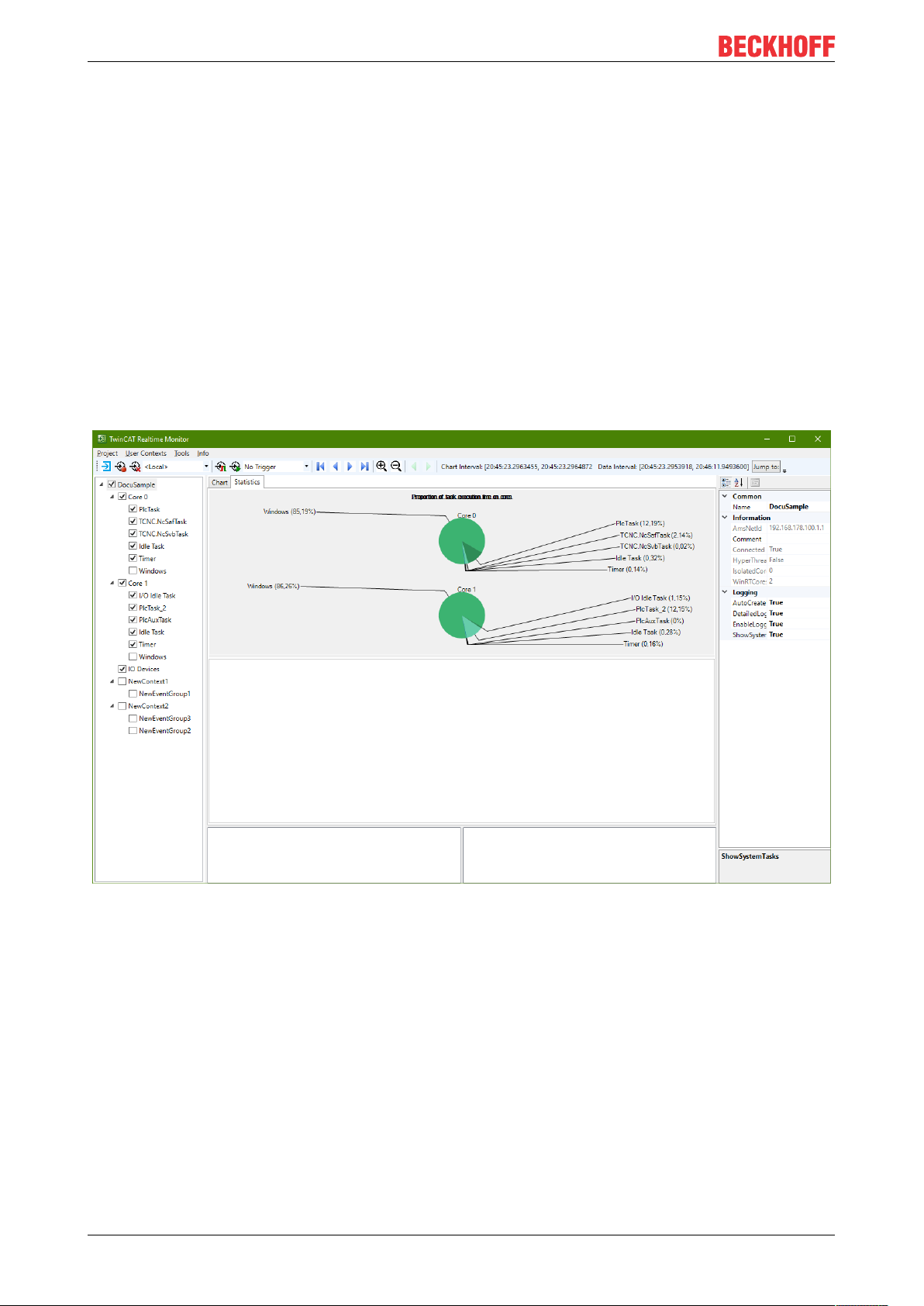

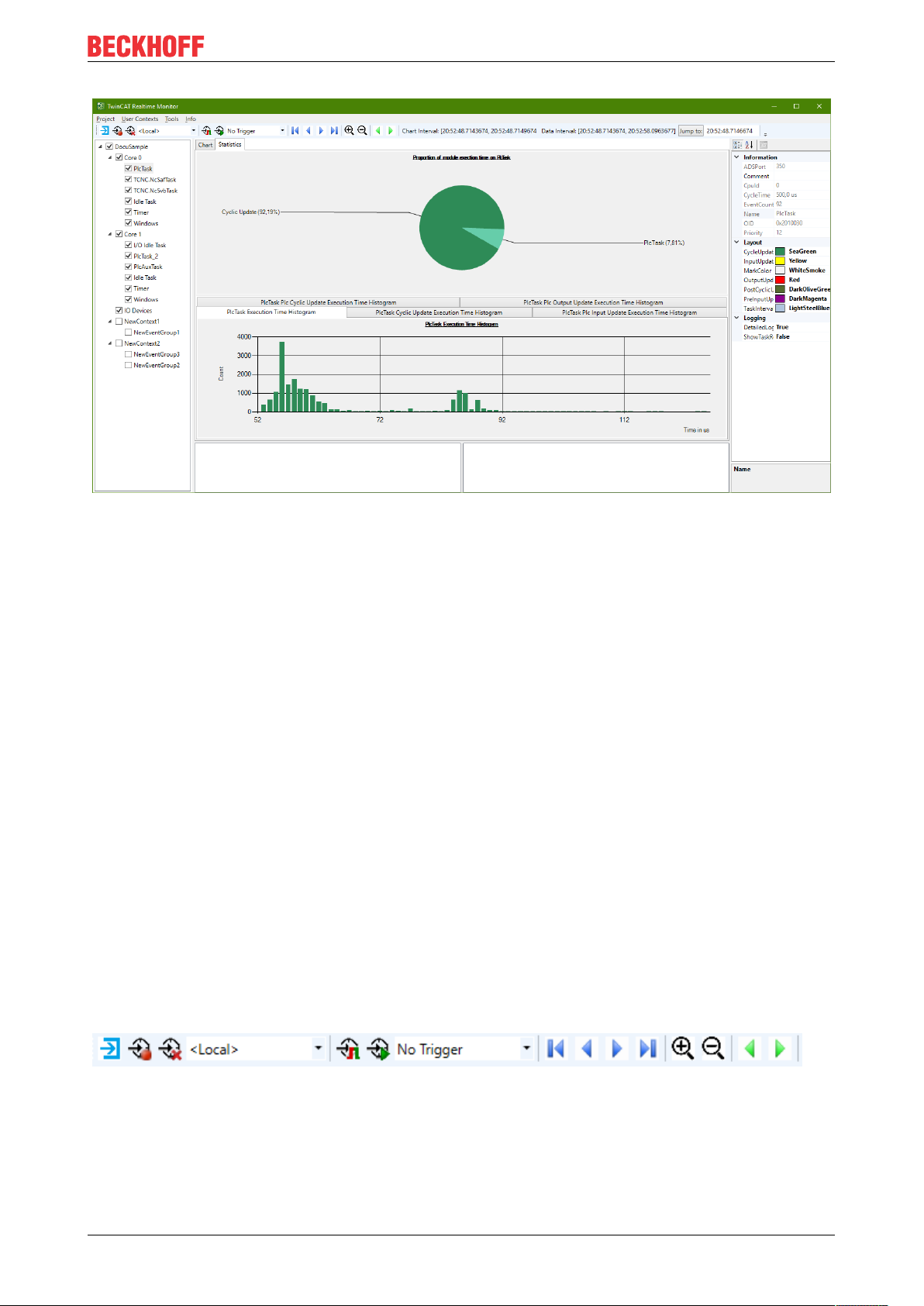

Examples of generated statistics:

TE101024 Version: 1.3

Page 25

Reference, user interface

Export Statistics

Function: The command exports the selected statistics to a CSV file.

Call: Menu Tools > Export Statistics

Set Trigger Prelude

Function: The command determines the prelude of a trigger. The values 1s, 10s, 30s and 1 min are

available.

Call: Menu Tools > Set Trigger Prelude

5.1.4 Info

Real-time Monitor

Function: The command opens a dialog window showing the version number of the installed TwinCAT 3

Real-time Monitor version.

Call: Menu Info > Real-time Monitor

5.2 Toolbar - Real-time Monitor toolbar

The TwinCAT 3 Real-time Monitor toolbar provides the following commands.

TE1010 25Version: 1.3

Page 26

Reference, user interface

Loading the project configuration from the set target system

Start recording

Stop recording

Deleting the displayed data and deleting the recorded data

Choose Target System

Start triggering on live data

Start triggering on recorded data

Selecting a trigger

Manual jump to next trigger event

Manual jump to previous trigger event

Jump to the start of the display

Move the display to the left

Move the display to the right

Jump to the end of the display

Zoom In

Zoom Out

Chart Interval Time interval of the area displayed in the current section

Data Interval Time interval of the recorded data

Jump to the time specified in the selection field after it

Input field for entering a time

5.3 Project tree

The project tree hierarchically displays all marker groups and their assignment to contexts. An entry with the

corresponding task name is automatically created in the tree for the system tasks. System tasks are grouped

into corresponding contexts once they have been assigned to cores.

An entry is also created in the project tree for user-related marker groups. Depending on the call used, the

assignment to contexts in the user program (see FB_RTMon_LogMark [}33] or FB_RTMon_LogMarkBase

[}36]) is made either in relation to the ADS port of the user program or based on a user-defined context ID.

TE101026 Version: 1.3

Page 27

Reference, user interface

The user-related nodes are created either manually by using the context menu entries (see Project tree

[}27]) or automatically if the AutoCreateUserContexts option (see Project node [}29]) is enable or the

User contexts [}24] option is called.

User-related nodes are named according to their Properties page (see Context node [}30] or Marker group

element [}31]).

Context menu entries in the project tree

The following table shows all context menu entries in the project tree (and the node type on which they are

available).

Command Node type Meaning

Add New User Context Project node Adds a user context.

Import User Context Project node Imports a user-related context including all

subelements.

Add New User Group User-related context node Adds a user-related marker group.

Remove User Context User-related context node Deletes a user-related context.

Export User Context User-related context node Exports a user-related context including all

subelements.

Remove User Group User-related marker group

node

Deletes a user-related marker group.

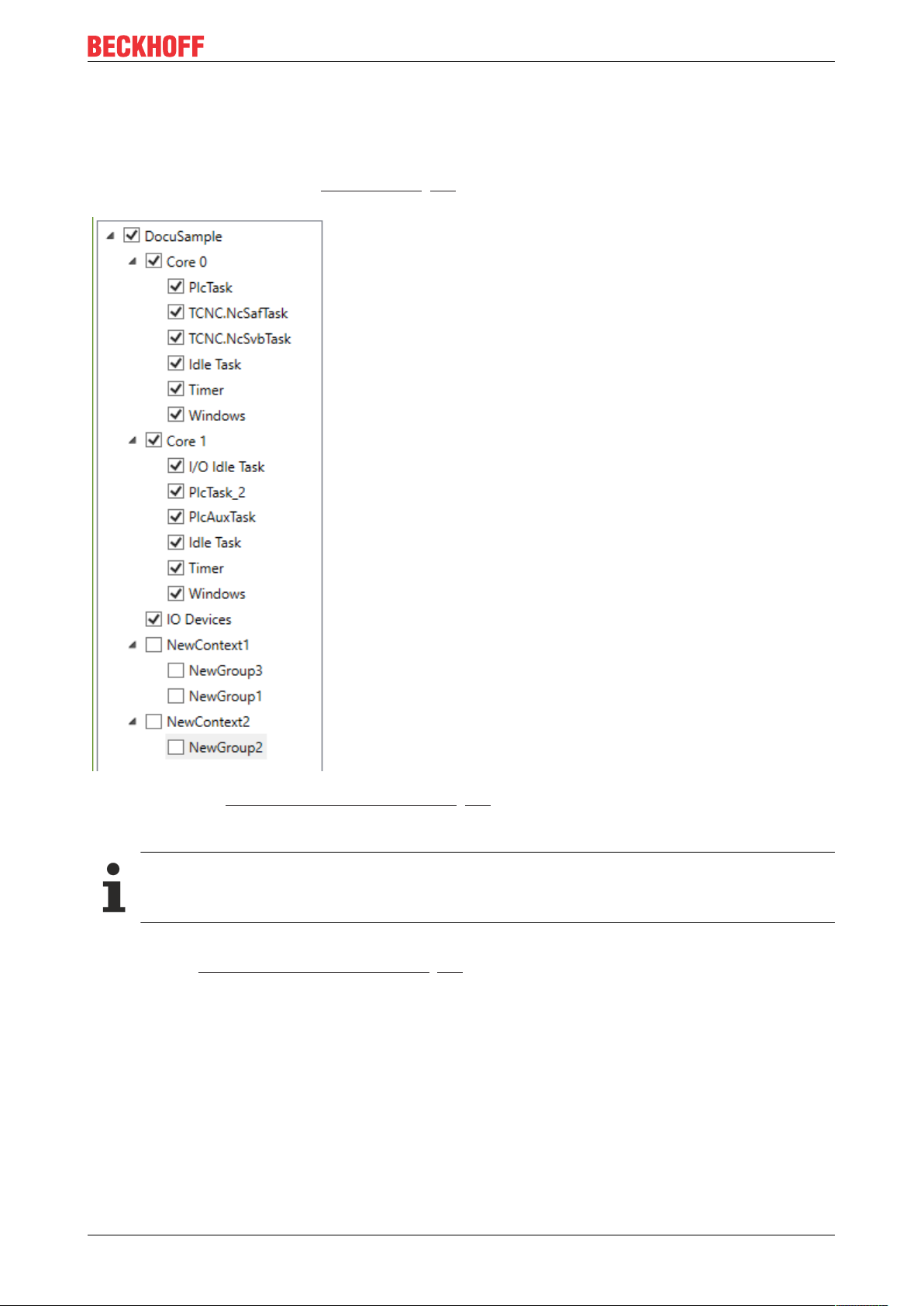

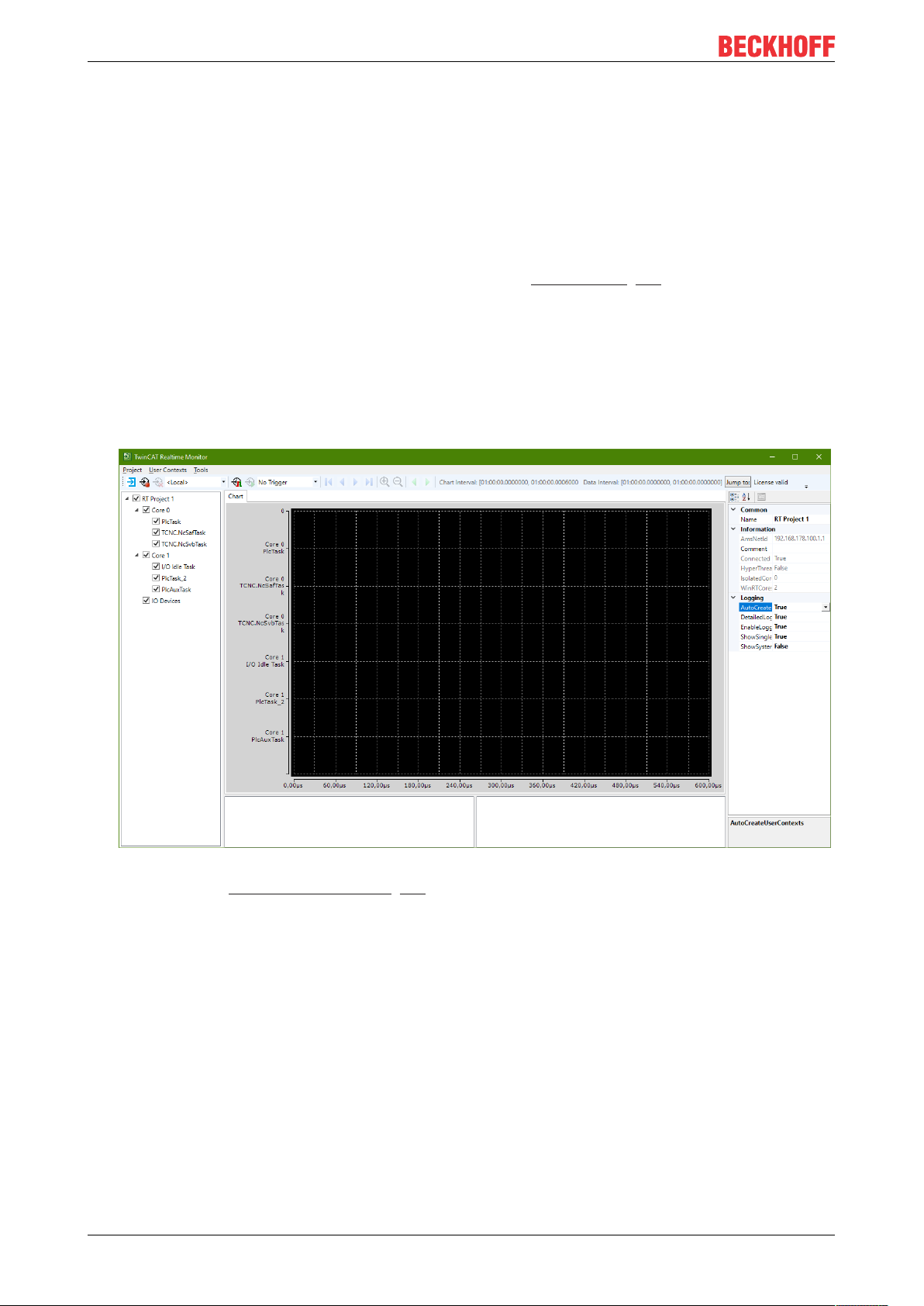

Example:

The following figure shows the representation of a project tree as it is automatically generated after the

recording is started (with the AutoCreateUserContexts option activated). In addition to the system tasks

distributed over Core 0 and Core 1, three user-related marker groups are generated, which have not yet

been named here.

TE1010 27Version: 1.3

Page 28

Reference, user interface

5.4 Display window

In the display window (chart) the (time) markers are displayed over time, sorted according to the individual

marker groups.

With the help of the functions in the toolbar (see Toolbar - Real-time Monitor toolbar [}25]) or accordingly

using the mouse or similar operating devices, you can navigate within the display window or enlarge / reduce

the display.

TE101028 Version: 1.3

Page 29

Reference, user interface

Via context menu entries in the display window it is possible to set, delete or move cursors to perform time

measurements or analyses (see Use of cursors [}16]).

5.5 Properties window

The Properties window shows the properties of the currently active (selected) element of the project tree.

The properties listed in the Logging area always apply to all subelements of the tree. The Different

Settings value indicates that the values of the subelements are different. By changing the value, the values

of the subelements are also changed.

5.5.1 Project node

The following settings are available on the project node of the TwinCAT 3 Real-time Monitor:

TE1010 29Version: 1.3

Page 30

Reference, user interface

Property Meaning

Common

Name Name of the project

Information

AmsNetId AmsNetId of the target system

Comment Comment on the project

Connected Connection status to target system

HyperThreading Indicates whether hyperthreading is active

Isolated cores Displays the number of isolated cores used in the project

WinRTCores Displays the number of Windows real-time cores used in

the project

Logging

DetailedLogging Enables detailed logging

EnableLogging Enables logging

ReduceOnZoom Reduces the display depth when zooming out (markers

lying directly adjacent to one another are combined as a

bar) in order to increase performance.

ShowSystemTasks Also shows the system tasks

The properties listed in the Logging area always apply to all subelements. In other words, these properties at

the project level apply to the entire Real-time Monitor project. If the value after one of the properties in the

Logging area is a "Different Settings", this means that the values in the individual sub-nodes differ. Changing

the value at the project level sets the values for all subelements.

5.5.2 Context node

The following settings are available on the context node of the TwinCAT 3 Real-time Monitor. These differ

according to real-time contexts (here the context corresponds to a computer core) and application contexts.

Real-time context:

Property Meaning

Information

BaseTime Base time of the core

Comment Comment

DefaultCore Indicates whether the core is the default core

Id Shows the ID of the core

Name Shows the name of the core

RT_Percentage Shows the set maximum real-time load

Type Shows the type of core (WindowsRT/ isolated core)

Logging

DetailedLogging Enables detailed logging

EnableLogging Turns logging on / off

Application context:

Property Meaning

Information

Comment Comment

ContextId ContextId that was transferred at the markers

Name Name of the context

TE101030 Version: 1.3

Page 31

Reference, user interface

If the function block FB_RTMon_LogMark [}33] is used, the port number of the PLC runtime module is automatically set as ContextId.

5.5.3 Marker group element

The following settings are available on the marker group / process nodes of the TwinCAT 3 Real-time

Monitor. They differ according to real-time tasks and application processes / markers.

Real-time tasks:

Property Meaning

Information

ADSPort ADS port of the task

Comment Comment

CpuId CpuId on which the task is executed

CycleTime Task cycle time

EventCount Number of executions (within the recording time)

Name Name of the task

OID ObjectId of the task

Priority Set priority

Layout

CycleUdateColor Color of the CycleUpdate of a task (default: green)

InputUpdateColor Color of the InputUpdate of a task (default: yellow)

MarkColor Marker color (default: white)

OutputUpdateColor Color of the output update of the task (default: red)

PostCyclicUpdateColor Color of the PostCyclicUpdate of the task (default: dark green)

PreInputUpdateColor Color of the PreInputUpdate of the task (default: magenta)

TaskIntervalColor Color of the task interval marker (default: light blue)

Logging

DetailedLogging Activate detailed logging

ShowTaskReference Displaying the task references

User processes:

Property Meaning

Information

Comment Comment

EventCount Number of executions (within the recording time)

GroupId ID of the marker group / process

Name Name of the process to be displayed

Layout

EventIntervalColor Color for the interval / active execution of the process (default: blue)

MarkColor Color of the markers (default: white)

Logging

ShowSingleMarker Enables the display of individual markers

ShowTaskReference Enables the display of task references (assignment of process markers to

real-time tasks by dashed lines)

TE1010 31Version: 1.3

Page 32

Reference, user interface

5.6 Cursor window

All cursors that were created are displayed in the cursor window.

Double-clicking a cursor causes the display within the chart to jump to the exact position where the cursor is

positioned. The cursor is centered in the display area.

The selected cursor can be deleted using the context menu entry Remove Cursor.

The use of cursors is described in detail under Use of cursors [}16].

5.7 Event window

The Event window shows all events taking place at this time for the active cursor. In the following figure,

these are the following events for cursor 1:

• The PlcTask starts processing of the runtime module Untitled1.

• PlcTask_2 also starts processing of the runtime module Untitled1.

• The Counter application process starts both the sequence and the interval.

TE101032 Version: 1.3

Page 33

PLC API

6 PLC API

6.1 Function blocks

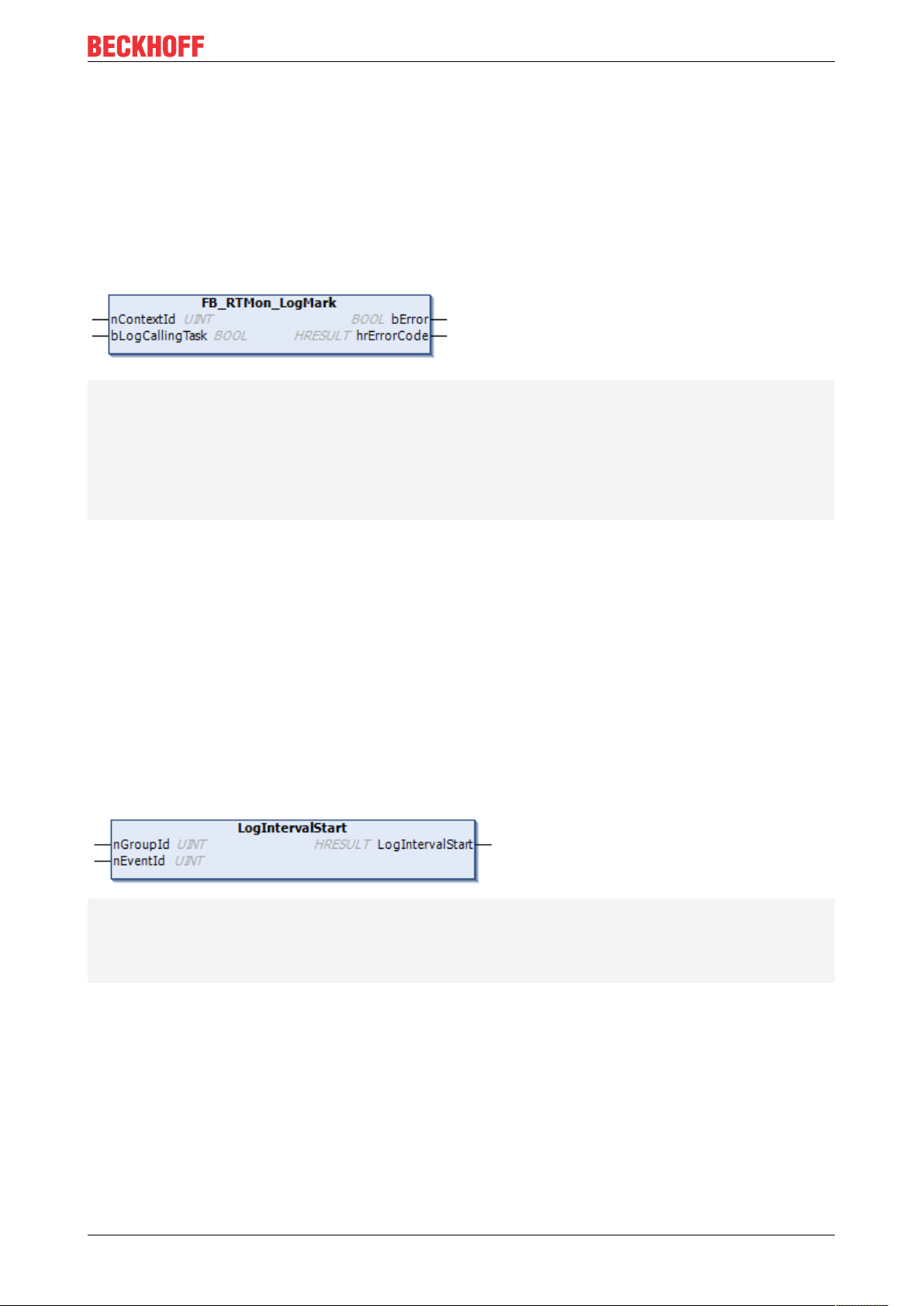

6.1.1 FB_RTMon_LogMark

FUNCTION_BLOCK FB_RTMon_LogMark

VAR_INPUT

nContextId: UINT := TwinCAT_SystemInfoVarList._AppInfo.AdsPort;

bLogCallingTask: BOOL:= TRUE; // specifies whether a reference to the calling task should be

set with each mark

END_VAR

VAR_OUTPUT

bError: BOOL; // TRUE if an error occurred

hrErrorCode: HRESULT; // outputs the error code which occurred

END_VAR

Description:

The FB_RTMon_LogMark is an extended function block that enables the setting of "simple" (time) markers.

For "simple" markers, the context of the calling user program is used automatically. The possible marker

types (sequence start & stop, interval start & stop or marker) are made available via individual methods. Only

the marker ID (marker group) must be transferred by the user. This is used to identify the process to be

displayed.

Optionally, an event ID is also available in which the user can transfer a user record (e.g. status of a state

machine, error message …)

6.1.1.1 LogIntervalStart

// Starts logging interval

METHOD LogIntervalStart : HRESULT

VAR_INPUT

nGroupId: UINT; // Defines the group to which the interval belongs

nEventId: UINT; // Set to distinguish different events inside the group

END_VAR

Description

The method creates a marker with an interval start for the transferred marker ID.

Parameter:

nGroupId: Marker ID (marker group) for which the marker is to be written.

nEventId: optional EventId.

TE1010 33Version: 1.3

Page 34

PLC API

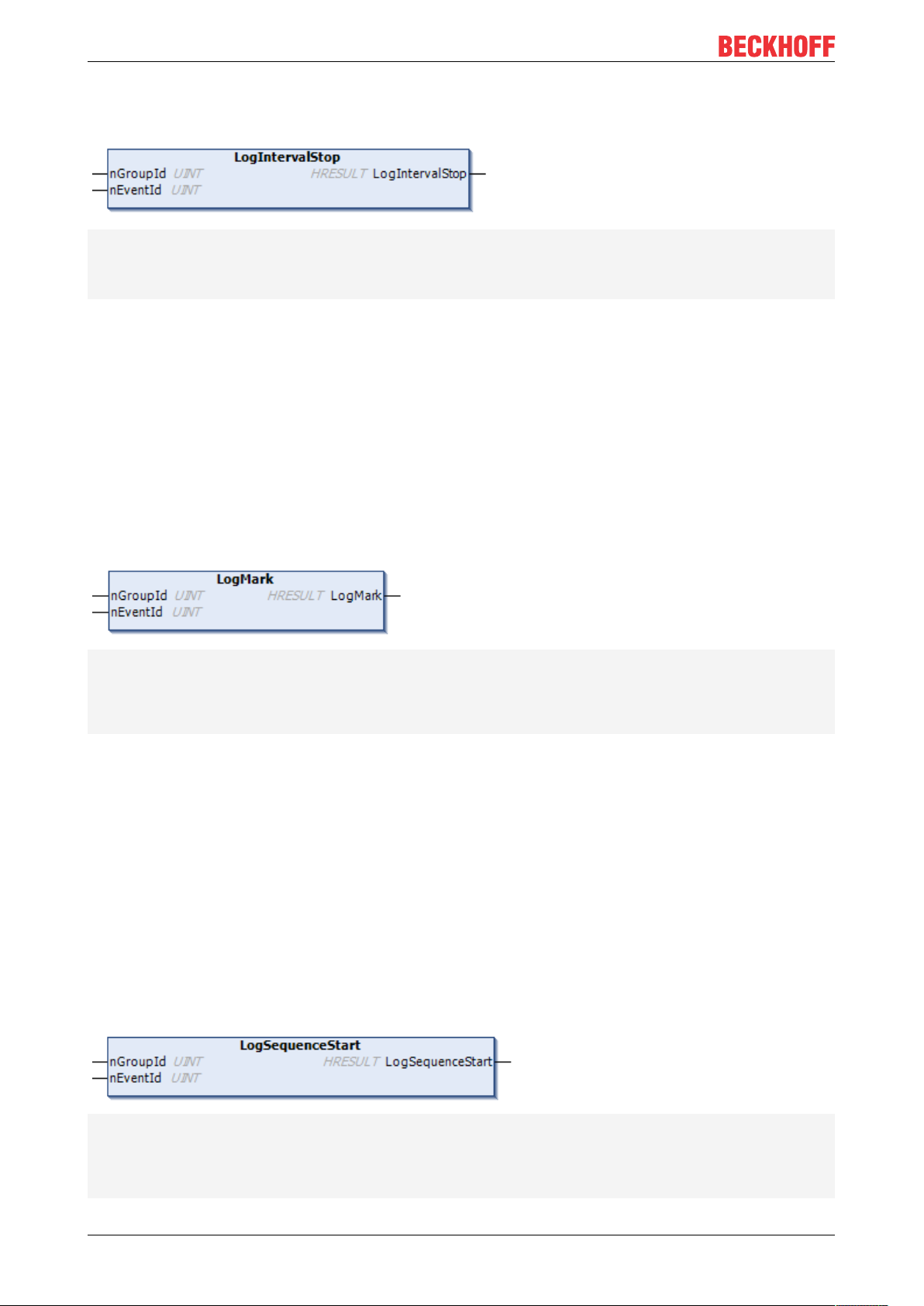

6.1.1.2 LogIntervalStop

METHOD LogIntervalStop : HRESULT

VAR_INPUT

nGroupId: UINT; // Defines the group to which the interval belongs

nEventId: UINT; // Set to distinguish different events inside the group

END_VAR

Description

The method creates a marker with an interval stop for the transferred marker ID.

Parameter:

nGroupId: Marker ID (marker group) for which the marker is to be written.

nEventId: optional EventId.

6.1.1.3 LogMark

// Logs a mark without start/stop

METHOD LogMark : HRESULT

VAR_INPUT

nGroupId: UINT; // Defines the group to which the mark belongs

nEventId: UINT; // Set to distinguish different events inside the group

END_VAR

Description

The method creates a marker for the marker ID that was transferred. Optionally, the event ID can be used to

distinguish between different user events or to display additional data (formatted as UINT) in the TwinCAT 3

Real-time Monitor display.

Parameter:

nGroupId: Marker ID (marker group) for which the marker is to be written.

nEventId: optional EventId.

6.1.1.4 LogSequenceStart

// Starts logging sequence

METHOD LogSequenceStart : HRESULT

VAR_INPUT

nGroupId: UINT; // Defines the group to which the sequence belongs

nEventId: UINT; // Set to distinguish different events inside the group

END_VAR

TE101034 Version: 1.3

Page 35

Description

The method creates a marker with a sequence start for the marker ID that was transferred.

Parameter:

nGroupId: Marker ID (marker group) for which the marker is to be written.

nEventId: optional EventId.

6.1.1.5 LogSequenceStop

// Stops logging sequence

METHOD LogSequenceStop : HRESULT

VAR_INPUT

nGroupId: UINT; // Defines the group to which the sequence belongs

nEventId: UINT; // Set to distinguish different events inside the group

END_VAR

PLC API

Description

The method creates a marker with a sequence stop for the marker ID that was transferred.

Parameter:

nGroupId: Marker ID (marker group) for which the marker is to be written.

nEventId: optional EventId.

6.1.1.6 LogStart

// Starts logging sequence and interval

METHOD LogStart : HRESULT

VAR_INPUT

nGroupId: UINT; // Defines the group to which the sequence and intervall belong

nEventId: UINT; // Set to distinguish different events inside the group

END_VAR

Description

The method creates a marker with a sequence and interval start for the transferred marker ID.

Thus this marker represents the time of a process at which it is immediately active / started.

Parameter:

nGroupId: Marker ID (marker group) for which the marker is to be written.

nEventId: optional EventId.

TE1010 35Version: 1.3

Page 36

PLC API

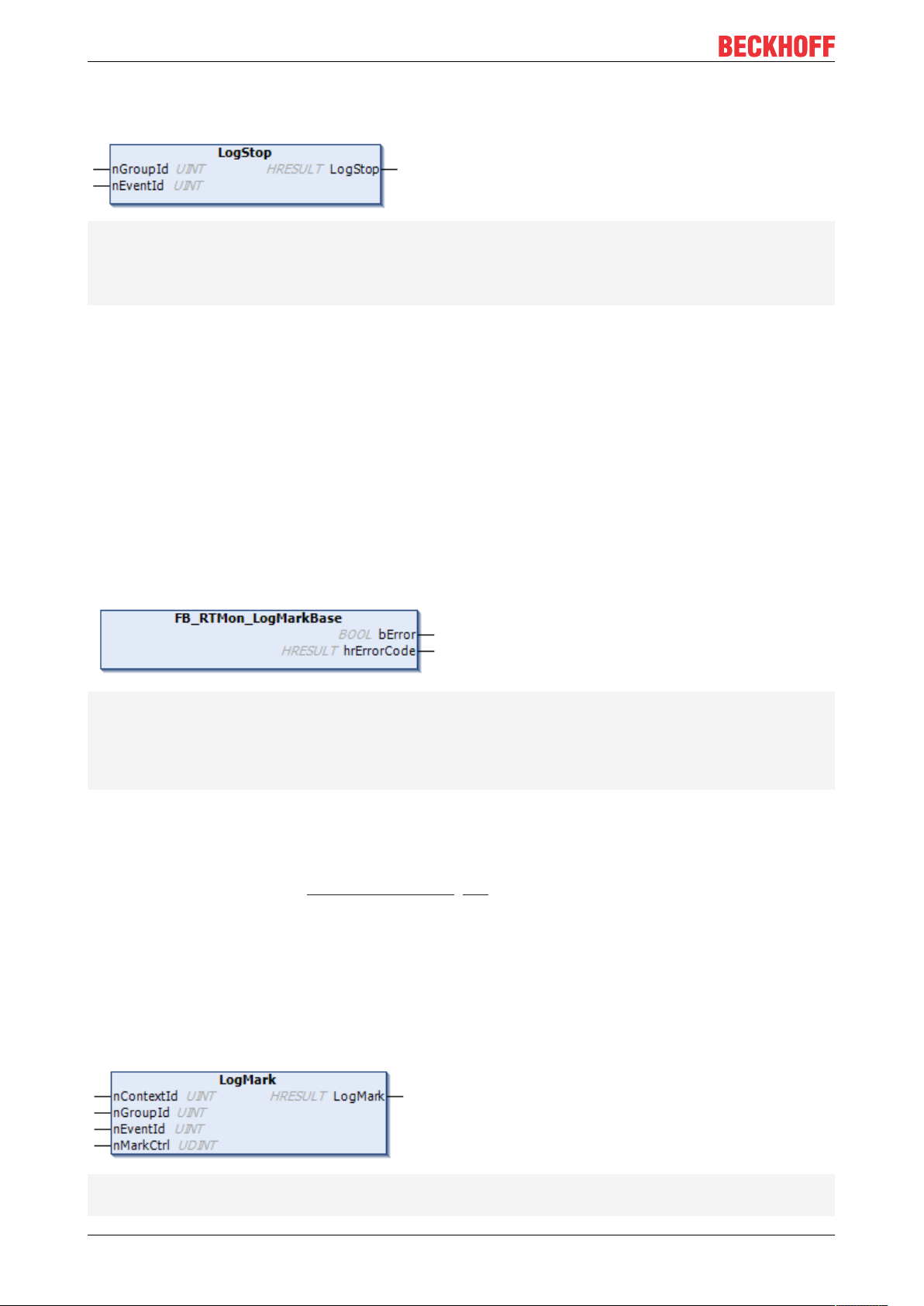

6.1.1.7 LogStop

// Stops logging sequence and interval

METHOD LogStop : HRESULT

VAR_INPUT

nGroupId: UINT; // Defines the group to which the sequence and intervall belong

nEventId: UINT; // Set to distinguish different events inside the group

END_VAR

Description

The method creates a marker with a sequence and interval stop for the transferred marker ID.

Thus, this marker represents the point in time of a process at which it is terminated directly.

Parameter:

nGroupId: Marker ID (marker group) for which the marker is to be written.

nEventId: optional EventId.

6.1.2 FB_RTMon_LogMarkBase

FUNCTION_BLOCK FB_RTMon_LogMarkBase

VAR_INPUT

END_VAR

VAR_OUTPUT

bError: BOOL; // TRUE if an error occurred

hrErrorCode: HRESULT; // outputs the error code which occurred

END_VAR

Description:

FB_RTMon_LogMarkBase is a basic function block that enables the setting of (time) markers.

In contrast to the function block FB_RTMon_LogMark [}33], the context ID itself must be transferred here.

This makes it possible to group the processes to be displayed (for example, by process type or functional

unit).

Optionally, an event ID is also available in which the user can transfer a user record (e.g. status of a state

machine, error message).

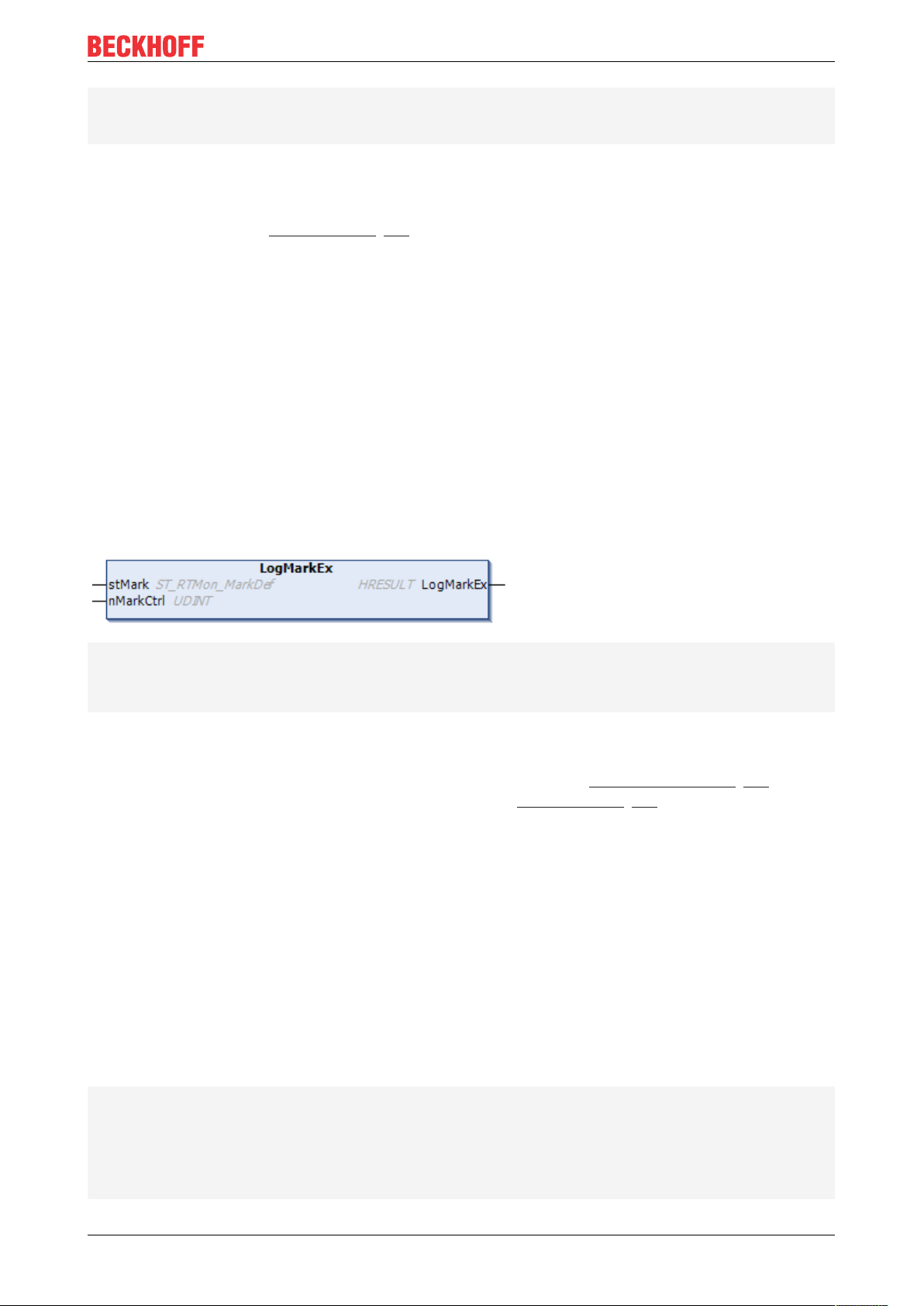

6.1.2.1 LogMark

METHOD LogMark : HRESULT

VAR_INPUT

nContextId: UINT; // defines the context

TE101036 Version: 1.3

Page 37

PLC API

nGroupId: UINT; // defines the group inside the context

nEventId: UINT; // defines the specific event inside the group

nMarkCtrl: UDINT; // mask for mark options (listed in TcMarkOption)

END_VAR

Description

The method creates a marker for the transferred marker group ID. The marker type is transferred using the

parameter nMarkCtrl (see TcMarkOption [}38]).

Optionally, the event ID can be used to distinguish between different user events or to display additional data

(formatted as UINT) in the TwinCAT 3 Real-time Monitor display.

Parameter:

nContextId: defines the context ID under which the marker is to be grouped in the TwinCAT 3 Real-time

Monitor.

nGroupId: Marker ID (marker group) for which the marker is to be written.

nEventId: optional EventId.

nMarkCtrl: defines the marker type.

6.1.2.2 LogMarkEx

METHOD LogMarkEx: HRESULT

VAR_INPUT

stMark: ST_RTMon_MarkDef;

nMarkCtrl: UDINT; // mask for mark options (listed in TcMarkOption)

END_VAR

Description

The method creates a marker. The marker is defined using the data type ST_RTMon_MarkDef [}37]. The

marker type is transferred using the parameter nMarkCtrl (see TcMarkOption [}38]).

Parameter:

stMark: Transfer parameter for a defined marker that is to be written.

nMarkCtrl: defines the marker type.

6.2 Data types

6.2.1 ST_RTMon_MarkDef

Data type that represents a marker.

// defines a mark

TYPE ST_RTMon_MarkDef:

STRUCT

nContextId: UINT; // defines the context

nGroupId : UINT; // defines the group inside the context

nEventId : UINT; // defines the specific event inside the group

END_STRUCT

END_TYPE

TE1010 37Version: 1.3

Page 38

PLC API

Description

Using this data type, it is possible to define a generic marker (without type). This is then transferred in the

method LogMarkEx [}37] of the function block FB_RTMon_LogMarkBase [}36] in addition to the marker type.

nContextId: Using the ContextId, marker groups, i.e. processes to be displayed, can be grouped (e.g. by

process type or functional unit).

nGroupId: Defines the process/ process event to be displayed.

nEventId: Optional user record. This can be used, for example, to display the status of a state machine or

error codes in the TwinCAT 3 Real-time Monitor.

Both the ContextId and the GroupId can be given names in the TwinCAT 3 Real-time Monitor.

These can be exported or imported using the User contexts [}23] or User contexts [}23] functions,

so that they are available for a further recording.

6.3 Global constants

6.3.1 TcMarkOption

The constants in this global variable list define the possible marker types (see Display in the Real-time

Monitor [}12]).

VAR_GLOBAL CONSTANT

Start: UDINT := 16#E0000000;

Stop: UDINT := 16#C0000000;

SequenceStart: UDINT := 16#A0000000;

SequenceStop: UDINT := 16#80000000;

IntervalStart: UDINT := 16#60000000;

IntervalStop: UDINT := 16#40000000;

RefToCaller: UDINT := 16#08000000; // reference to caller

END_VAR

In addition to the marker types, the option RefToCaller is defined, which enables the task references to be

displayed in the TwinCAT3 Real-Time Monitor. If this option is activated it must be ORed with the desired

marker type.

Sample:

fbLogMark.LogMarkEx(markCounter, TcMarkOption.Start OR TcMarkOption.RefToCaller);

The sample shows the setting of a marker, "markCounter", with the marker type "Start" and the option

"RefToCaller".

The option Show Task Reference (see Marker group element [}31]) must be activated if the task

references are to be displayed in the TwinCAT3 Real-Time Monitor.

Also see about this

2 FB_RTMon_LogMarkBase [}36]

TE101038 Version: 1.3

Page 39

C++ API

7 C++ API

7.1 Data types

7.1.1 TcMark16

Data type that represents a marker.

typedef struct {

USHORT ContextId;

USHORT GroupId;

USHORT EventId;

} TcMark16;

Description:

Using this data type, it is possible to define a generic marker (without type).

ContextId: Using the ContextId, marker groups, i.e. processes to be displayed, can be grouped (e.g. by

process type or functional unit).

GroupId: Defines the process/ process event to be displayed.

EventId: Optional user record. This can be used, for example, to display the status of a state machine or

error codes in the TwinCAT 3 Real-time Monitor.

Both the ContextId and the GroupId can be given names in the TwinCAT 3 Real-time Monitor.

These can be exported or imported using the User contexts [}23] or User contexts [}23] functions,

so that they are available for a further recording.

7.2 Classes

7.2.1 CTcLogMark

CTcLogMark(USHORT nContextId, ITComObjectServer* ipSrv = NULL);

Description:

The class CTcLogMark is a C++ class that makes it possible to set (time) markers from C++ application code

so that they can be displayed with the TwinCAT 3 Real-time Monitor.

7.2.1.1 LogIntervalStart

virtual HRESULT LogIntervalStart(USHORT GroupId, USHORT EventId);

Description:

The method creates a marker with an interval start for the transferred marker ID.

Parameter:

GroupId: Marker ID (marker group) for which the marker is to be written.

EventId: optional EventId.

TE1010 39Version: 1.3

Page 40

C++ API

7.2.1.2 LogIntervalStop

virtual HRESULT LogIntervalStop(USHORT GroupId, USHORT EventId);

Description:

The method creates a marker with an interval stop for the transferred marker ID.

7.2.1.3 LogMark

virtual HRESULT LogMark(USHORT GroupId, USHORT EventId, ULONG CtrlId);

Description:

The method creates a marker for the transferred marker group ID. The marker type is determined using the

constants from TcLogMark.h (see Constants [}41]).

Optionally, the event ID can be used to distinguish between different user events or to display additional data

(formatted as USHORT) in the TwinCAT 3 Real-time Monitor display.

Also see about this

2 TcMarkOption [}38]

7.2.1.4 LogMarkEx

virtual HRESULT LogMarkEx(TcMark16* pMark, ULONG CtrlId);

Description

The method creates a marker. The marker is defined using the data type TcMark16 [}39]. The marker type

is determined using the constants from TcLogMark.h (see Constants [}41]).

Also see about this

2 ST_RTMon_MarkDef [}37]

7.2.1.5 LogSequenceStart

virtual HRESULT LogSequenceStart(USHORT GroupId, USHORT EventId);

Description:

The method creates a marker with a sequence start for the marker ID that was transferred.

7.2.1.6 LogSequenceStop

virtual HRESULT LogSequenceStop(USHORT GroupId, USHORT EventId);

Description:

The method creates a marker with a sequence stop for the marker ID that was transferred.

7.2.1.7 LogStart

virtual HRESULT LogStart(USHORT GroupId, USHORT EventId);

TE101040 Version: 1.3

Page 41

Description:

The method creates a marker with a sequence and interval start for the transferred marker ID.

Thus this marker represents the time of a process at which it is immediately active / started.

7.2.1.8 LogStop

virtual HRESULT LogStop(USHORT GroupId, USHORT EventId);

Description

The method creates a marker with a sequence and interval stop for the transferred marker ID.

Thus, this marker represents the point in time of a process at which it is terminated directly.

7.2.1.9 SetContextId

virtual void SetContextId(USHORT nContextId);

Description:

C++ API

This method sets the context ID used.

7.2.1.10 InitLogMark

virtual HRESULT InitLogMark(ITComObjectServer* ipSrv);

Description:

Initializes the instance of the CTcLog marker class.

Parameter:

ipSrv: Interface pointer to the TcObjectServer.

7.2.1.11 ReleaseLogMark

virtual HRESULT ReleaseLogMark();

Description:

Releases the resources of the instance of the CTcLogMark class.

7.3 Constants

These constants - defined in TcLogMark.h - define the possible marker types [}12].

#define TCMARK_START 0xE0000000

#define TCMARK_STOP 0xC0000000

#define TCMARK_SEQ_START 0xA0000000

#define TCMARK_SEQ_STOP 0x80000000

#define TCMARK_IVAL_START 0x60000000

#define TCMARK_IVAL_STOP 0x40000000

#define TCMARK_REF_CALLER 0x08000000

TE1010 41Version: 1.3

Page 42

Page 43

More Information:

www.beckhoff.com/te1010

Beckhoff Automation GmbH & Co. KG

Hülshorstweg 20

33415 Verl

Germany

Phone: +49 5246 9630

info@beckhoff.com

www.beckhoff.com

Loading...

Loading...