Page 1

PT100 4-fold temperature measurement Beckhoff II/O System

PT100 4-fold temperature measurement

Technical description

Eiserstraße 5 Telephone: 05246/709-0

D-33415 Verl Fax: 05246/70980

Date : 12 March 97 Version : 1.1 Page 1 of 10

Page 2

PT100 4-fold temperature measurement Beckhoff II/O System

Table of contents

1. Hardware functional description ..................................................3

2. Software functional description.....................................................5

3. Technical specifications..................................................................7

4. Installation instructions..................................................................8

5. Terminal diagram.........................................................................10

Page 2 of 10 Version : 1.1 Date : 12 March 97

Page 3

PT100 4-fold temperature measurement Beckhoff II/O System

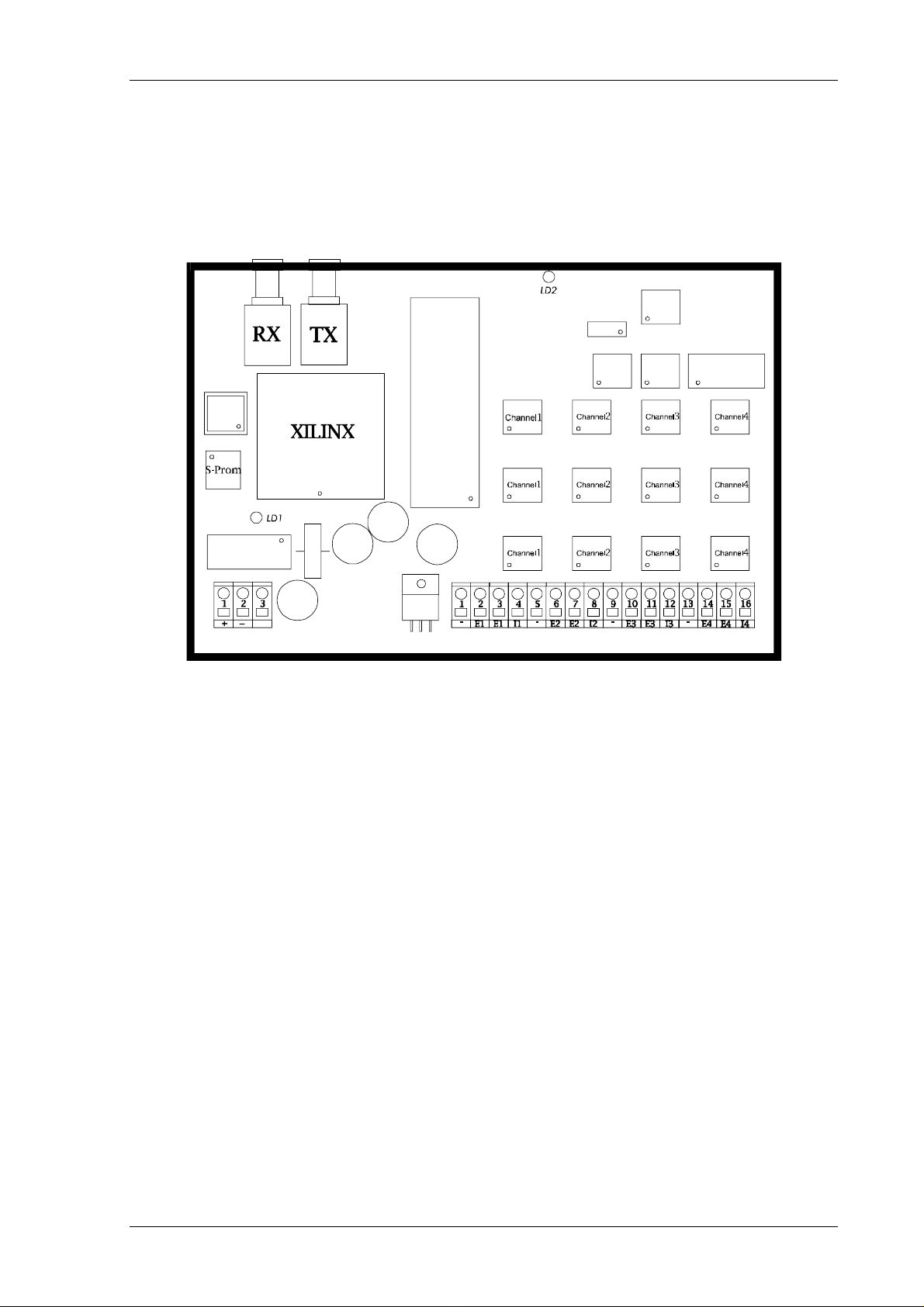

1. Hardware functional description

PT100

General information

The PT100 module is a temperature measurement module for use in an II/O system. Up to

four sensors (PT100) may be connected to each module.

A diagnostic LED is furnished for the II/O optical fibre guide ring:

LD1 The red ’ERROR’ LED is switched on after detection of an error message (check

sum, frame) and switched off after running three successive correct messages

(check sum, frame) have been run.

A match LED is furnished for initial matching:

LD2 The second (green) LED is used for control purposes when matching newly

connected sensors.

Date : 12 March 97 Version : 1.1 Page 3 of 10

Page 4

PT100 4-fold temperature measurement Beckhoff II/O System

Opt.Fibre

Opt.Fibre

Periphery controller

Processor

Converter

Block diagram

Page 4 of 10 Version : 1.1 Date : 12 March 97

Page 5

PT100 4-fold temperature measurement Beckhoff II/O System

2. Software functional description

Timing diagram:

Explanation of the timing diagram:

Signal assignment to II/O message data bytes:

Reset: D2.7

Select1 (priority 1): D2.0

Select2 (priority 2): D2.1

Select4 (priority 3): D2.2

Valid: D2.3

Data: D0.0 to D0.7

D1.0 to D1.7

The restart signal is used to reset the processor to the PT100 module. The signal remains at

"1" for continuous operation.

Date : 12 March 97 Version : 1.1 Page 5 of 10

Page 6

PT100 4-fold temperature measurement Beckhoff II/O System

Channels are pre-selected in accordance with Select 1-4 priorities.

Select1 Select2 Select4 Significance D0, D1

0 0 0 Measurement channel 1 is

selected.

1 0 0 Measurement channel 2 is

selected.

0 1 0 Measurement channel 3 is

selected.

1 1 0 Measurement channel 4 is

selected.

0 0 1 Control channel a is selected.

1 0 1 Control channel b is selected.

Pre-selection is valid with the falling edge (1=>0) of signal "Valid" D2.3.

Control channels a and b provide a specific bit pattern at selection. This allows for monitoring

of whether or not the microprocessor is active and properly operating.

Set value for control channel a: AA55 hex

Set value for control channel b: 55AA hex

The processor may be restarted by means of the D2.7 reset key if this alternating bit pattern is

not provided.

Page 6 of 10 Version : 1.1 Date : 12 March 97

Page 7

PT100 4-fold temperature measurement Beckhoff II/O System

3. Technical specifications

Number of channels

Resolution

Measurement value display

Converter range temperature

Monitoring

Connections

Data port

Transmission rate

Supply voltage

Four, (multiplex)

12 bit

2 byte, (ϑ x 10)

-50 to +150 degrees C

0 to +512 degrees C in progress

Display of two control channels for

monitoring the module,

reset via fibre-optic bus

Plug-in for PT100 sensor

(2-wire, 4-wire)

II/O system fibre-optic light guide

2.5 Mbaud, 25 µs for 32 bit

24 VDC (± 10%)

Power consumption

Casing type

Dimensions (W * H * D)

Weight

Operating temperature

Storage temperature

0.1 A

Open card carrier, snap-on device mounting

rail as specified in DIN EN 50022, 50035

168 * 111 * 65 mm

Approximately 550 g

±0..+55 øC

-20..+70 øC

Date : 12 March 97 Version : 1.1 Page 7 of 10

Page 8

PT100 4-fold temperature measurement Beckhoff II/O System

4. Installation instructions

Assembly

The PT100 module is connected to the II/O fibre-optical guide ring by means of fibre-optics

cable plug-in connectors (Toshiba). The maximum fibre-optical cable length to the adjacent

boxes should not exceed 45 m if plastic fibre-optical light guides are used and 600 m in the

case of glass-fibre. These values are only valid if bending radii of at least 30 mm are complied

with when running the fibre-optical cable. No special tools are required for attaching the

connectors if plastic fibre-optical light guides are used.

The Pt100 sensors are directly connected to the inputs (connecto r X 20) using two- or fourconductor cable (cf. wiring diagram).

Assembly of the PT100 module is performed by means of distributed configuration on the

unit or in the switchgear cabinet by simply snapping it onto a device mounting rail as

specified in DIN EN 50022 or DIN EN 50035.

Configuration

The D0 and D1 data bytes are entered into the configuration list as inputs and the D2 and D3

are entered as outputs.

The D0 and D1 data bytes of the II/O message contain the data of the four measurement

values (multiplexed).

Data byte D2 is used for selection and acceptance of the data of a m easurement channel. In

addition, the D2.7 key may be used to reset the microprocessor.

Data byte D3 is presently unassigned (spare slot).

Supply voltage

A tripolar connection terminal with ports for the control logic / analog portion is provided for

connecting 24V supply voltage (+) and ground (-) (connector X10). Connector X10 pin 3 is

unassigned.

Page 8 of 10 Version : 1.1 Date : 12 March 97

Page 9

Date : 12 March 97 Version : 1.1 Page 9 of 10

PT100 4-fold temperature measurement Beckhoff II/O System

PT100 4-fold temperature measurement

Optical-fibre transmitter

Optical-fibre receiver

Diagnose-LED

/' /('(UURU

S-Prom

/'

Channel

Channel

Channel

1

1

1

/'

LED alignment

/'

Channel

2

Channel

2

Channel

2

Channel

Channel

Channel

3

Channel

4

Channel

Channel

4

4

3

3

Plug-in connector

+24V

control logic/analog portion

Ground

Unassigned

Plug-in connector

GND for PT100 sensor

Input, PT100 sensor pick-off

Input, PT100 sensor pick-off

Constant-current source for PT100 sensor

Page 10

PT100 4-fold temperature measurement Beckhoff II/O System

5. Terminal diagram

Plug connection assignment and signal description

CONNECTOR X10

Plug Pin Signal

X10 1 +

X10 2 -

X10 3

Description

+24V supply voltage, control logic/analog

portion

Ground

Unassigned

CONNECTOR X10

Plug Pin Signal Description

X20 1 X20 2 E1

X20 3 E1

X20 4 I1

X20 5 X20 6 E2

X20 7 E2

X20 8 I2

X20 9 X20 10 E3

X20 11 E3

X20 12 I3

X20 13 X20 14 E4

X20 15 E4

X20 16 I4

GND for PT100 sensor

Input, PT100 se nsor pick-off

Input, PT100 se nsor pick-off

Constant-current source for PT100 sens or

(1mA)

GND for PT100 sensor

Input, PT100 se nsor pick-off

Input, PT100 se nsor pick-off

Constant-current source for PT100 sens or

(1mA)

GND for PT100 sensor

Input, PT100 se nsor pick-off

Input, PT100 se nsor pick-off

Constant-current source for PT100 sens or

(1mA)

GND for PT100 sensor

Input, PT100 se nsor pick-off

Input, PT100 se nsor pick-off

Constant-current source for PT100 sens or

(1mA)

Important: A bridge has to be inserted at the input for all of the unused channels. Open

inputs are capable of affecting the values of the other channels.

Example: If a PT100 sensor is not connected to channels 2 and 4, then pin 6 has to be

bridged with pin 7 and pin 14 with pin 15.

Page 10 of 10 Version : 1.1 Date : 12 March 97

Loading...

Loading...