Page 1

Documentation

KL5151/KS5151, KL5152/KS5152

Incremental Encoder Terminals

2.0.0

2016-03-15

Version:

Date:

Page 2

Page 3

Product overview: incremental encoder interface

1 Product overview: incremental encoder interface

KL5151-0000 [}8]: single-channel incremental encoder terminal

KL5151-0021 [}9]: single-channel incremental encoder terminal with comparator output

KL5151-0050 [}10]: two-channel incremental encoder terminal

KL5152-0000 [}10]: two-channel incremental encoder terminal

KL5151/KS5151, KL5152/KS5152 3Version: 2.0.0

Page 4

Table of contents

Table of contents

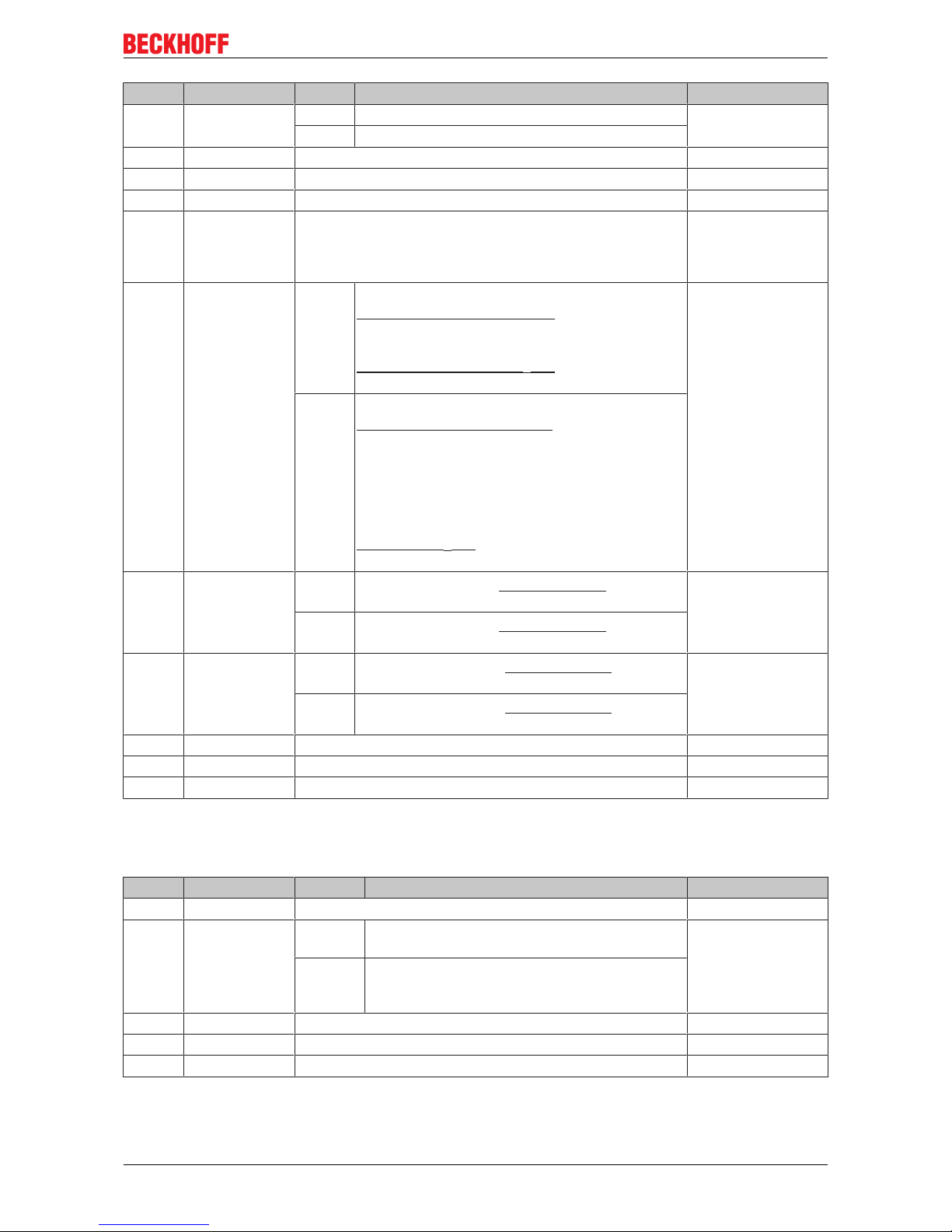

1 Product overview: incremental encoder interface .................................................................................3

2 Foreword ....................................................................................................................................................5

2.1 Notes on the documentation............................................................................................................. 5

2.2 Safety instructions ............................................................................................................................ 6

2.3 Documentation issue status.............................................................................................................. 7

3 Product overview.......................................................................................................................................8

3.1 KL5151-0000 - Introduction .............................................................................................................. 8

3.2 KL5151-0021 - Introduction .............................................................................................................. 9

3.3 KL5152-0000 (KL5151-0050) - Introduction ................................................................................... 10

3.4 Technical data ................................................................................................................................ 11

4 Mounting and wiring ...............................................................................................................................12

4.1 Installation on mounting rails .......................................................................................................... 12

4.2 Connection system ......................................................................................................................... 14

4.3 KL5151-0000 - Connection............................................................................................................. 18

4.4 KL5151-0021 - Connection............................................................................................................. 19

4.5 KL5152-0000 (KL5151-0050) - Connection.................................................................................... 20

4.6 ATEX - Special conditions .............................................................................................................. 21

4.7 ATEX Documentation ..................................................................................................................... 22

5 Configuration software KS2000 .............................................................................................................23

5.1 KS2000 - Introduction ..................................................................................................................... 23

5.2 Parameterization with KS2000 ....................................................................................................... 25

5.3 Settings........................................................................................................................................... 26

6 Access from the user program ..............................................................................................................28

6.1 KL5151-0000 .................................................................................................................................. 28

6.1.1 Process image ....................................................................................................................28

6.1.2 Control and status bytes .....................................................................................................29

6.1.3 Mapping ..............................................................................................................................31

6.2 KL5151-0021 .................................................................................................................................. 33

6.2.1 Process image ....................................................................................................................33

6.2.2 Control and status bytes .....................................................................................................33

6.3 KL5152-0000 (KL5150-0050) ......................................................................................................... 35

6.3.1 Process image ....................................................................................................................35

6.3.2 Control and status bytes .....................................................................................................38

6.3.3 Mapping ..............................................................................................................................40

6.4 Register .......................................................................................................................................... 44

6.4.1 Register overview ...............................................................................................................44

6.4.2 Register description ............................................................................................................45

6.4.3 Examples of Register Communication................................................................................48

7 Appendix ..................................................................................................................................................51

7.1 Support and Service ....................................................................................................................... 51

KL5151/KS5151, KL5152/KS51524 Version: 2.0.0

Page 5

Foreword

2 Foreword

2.1 Notes on the documentation

Intended audience

This description is only intended for the use of trained specialists in control and automation engineering who

are familiar with the applicable national standards.

It is essential that the following notes and explanations are followed when installing and commissioning

these components.

The responsible staff must ensure that the application or use of the products described satisfy all the

requirements for safety, including all the relevant laws, regulations, guidelines and standards.

Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development. For that reason the documentation is not in every case checked for consistency with

performance data, standards or other characteristics. In the event that it contains technical or editorial errors,

we retain the right to make alterations at any time and without warning. No claims for the modification of

products that have already been supplied may be made on the basis of the data, diagrams and descriptions

in this documentation.

Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE®, XFC® and XTS® are registered

trademarks of and licensed by Beckhoff Automation GmbH.

Other designations used in this publication may be trademarks whose use by third parties for their own

purposes could violate the rights of the owners.

Patent Pending

The EtherCAT Technology is covered, including but not limited to the following patent applications and

patents: EP1590927, EP1789857, DE102004044764, DE102007017835 with corresponding applications or

registrations in various other countries.

The TwinCAT Technology is covered, including but not limited to the following patent applications and

patents: EP0851348, US6167425 with corresponding applications or registrations in various other countries.

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH,

Germany

Copyright

© Beckhoff Automation GmbH & Co. KG, Germany.

The reproduction, distribution and utilization of this document as well as the communication of its contents to

others without express authorization are prohibited.

Offenders will be held liable for the payment of damages. All rights reserved in the event of the grant of a

patent, utility model or design.

KL5151/KS5151, KL5152/KS5152 5Version: 2.0.0

Page 6

Foreword

2.2 Safety instructions

Safety regulations

Please note the following safety instructions and explanations!

Product-specific safety instructions can be found on following pages or in the areas mounting, wiring,

commissioning etc.

Exclusion of liability

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

Personnel qualification

This description is only intended for trained specialists in control, automation and drive engineering who are

familiar with the applicable national standards.

Description of symbols

In this documentation the following symbols are used with an accompanying safety instruction or note. The

safety instructions must be read carefully and followed without fail!

DANGER

Serious risk of injury!

Failure to follow the safety instructions associated with this symbol directly endangers the

life and health of persons.

WARNING

Risk of injury!

Failure to follow the safety instructions associated with this symbol endangers the life and

health of persons.

CAUTION

Personal injuries!

Failure to follow the safety instructions associated with this symbol can lead to injuries to

persons.

Attention

Damage to the environment or devices

Failure to follow the instructions associated with this symbol can lead to damage to the environment or equipment.

Note

Tip or pointer

This symbol indicates information that contributes to better understanding.

KL5151/KS5151, KL5152/KS51526 Version: 2.0.0

Page 7

Foreword

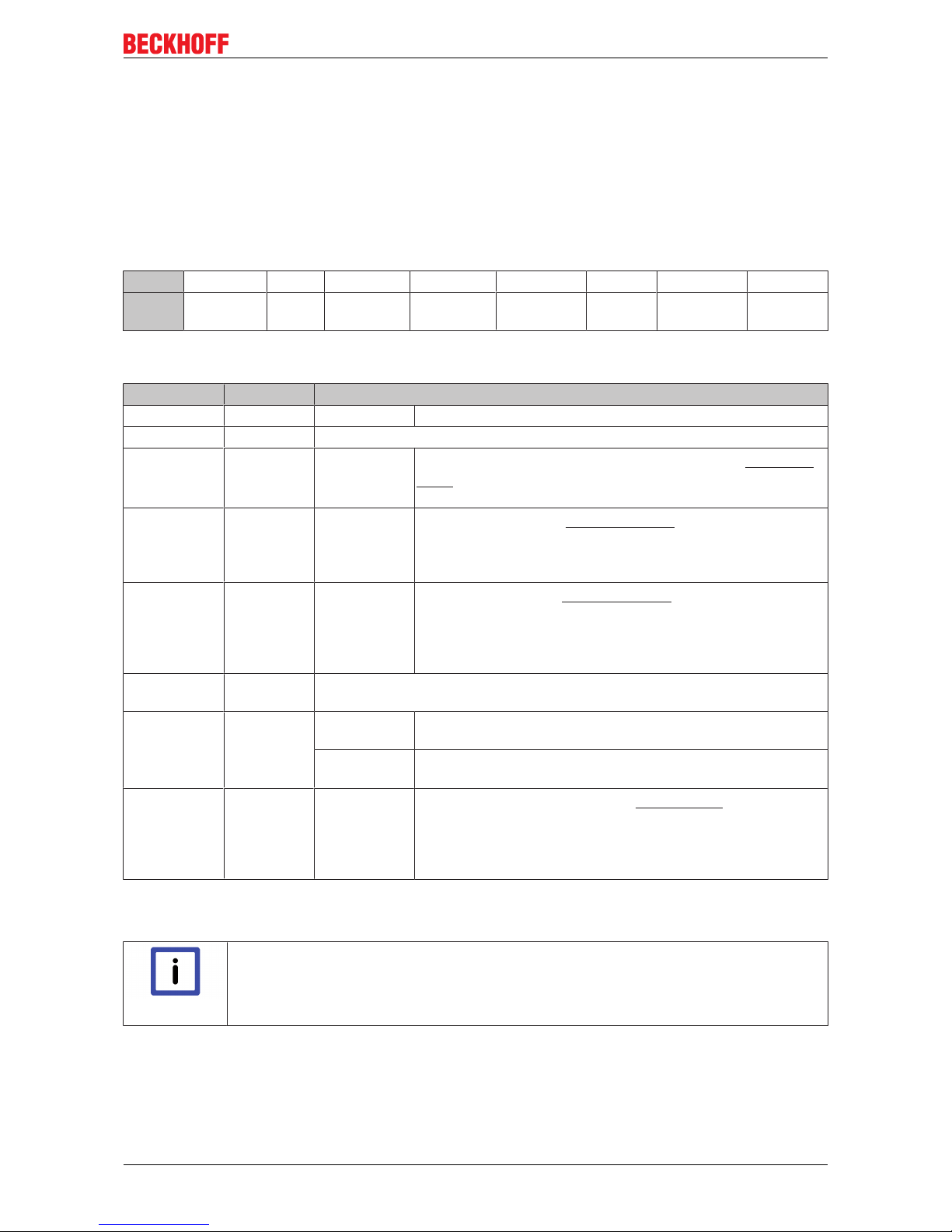

2.3 Documentation issue status

Version Comment

2.0.0 • Migration

• Update revision status

1.3.0 • Technical data updated

• ATEX notes added

• Extended temperature range for KL5151-0000

• Description of control and status bytes of the KL5151-0021 corrected

1.2.0 • Introduction updated

• Description of the parameterization of the KL5151 by means of KS2000

configuration software updated.

• Register description updated

• Mounting description expanded

• KL5151-0021 added

• KL5151-0050 now available as KL5152-0000

1.1.0 • Description of the process images expanded

• Mapping tables added

1.0 • KL5151-0050 added

• Description of the parameterization of the KL5151 by means of KS2000

configuration software added.

0.1 Preliminary version (KL5151-0000 only)

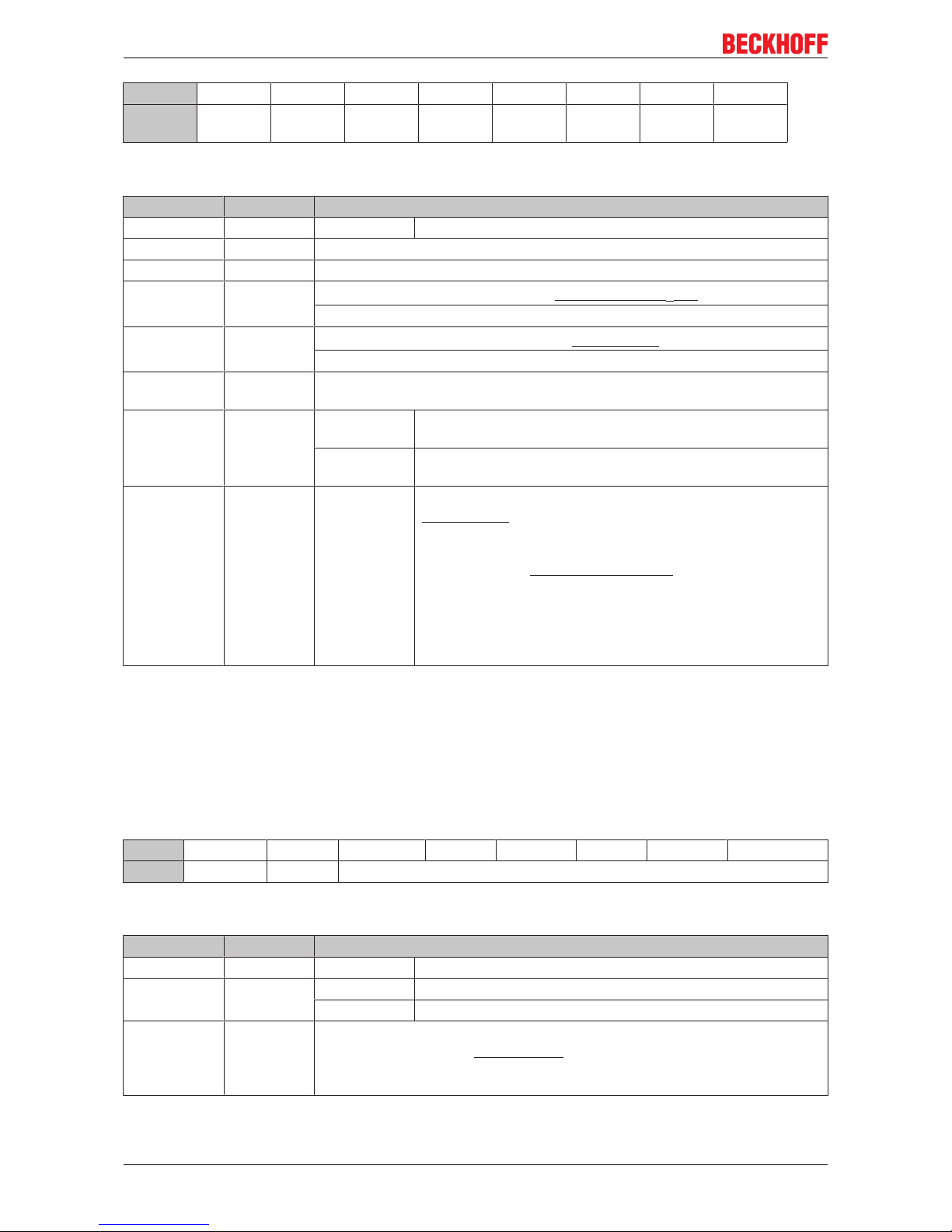

Firmware and hardware versions

Documentation

Version

KL5151-0000 KL5151-0021 KL5152-0000 (KL5151-0050)

Firmware Hardware Firmware Hardware Firmware Hardware

2.0.0 4E 09 14 08 4E 09

1.3.0 4C 07 13 07 4C 07

1.2.0 4C 07 13 07 4C 07

1.1.0 3A 02 - - 3A 02

1.0 3A 02 3A 02

0.1 3A 00 - -

The firmware and hardware versions (delivery state) can be taken from the serial number printed on the side

of the terminal.

Syntax of the serial number

Structure of the serial number: WWYYFFHH

WW - week of production (calendar week)

YY - year of production

FF - firmware version

HH - hardware version

Example with ser. no.: 35 04 3A 02:

35 - week of production 35

04 - year of production 2004

3A - firmware version 3A

02 - hardware version 02

KL5151/KS5151, KL5152/KS5152 7Version: 2.0.0

Page 8

Product overview

3 Product overview

3.1 KL5151-0000 - Introduction

Fig.1: KL5151

The KL5151-0000 Bus Terminal is an interface with 24 V inputs for the direct connection of incremental

encoders. A 32 bit counter with a quadrature decoder and a 32 bit latch for the zero pulse can be read, set or

enabled.

The KL5151-0000 Bus Terminal can also be used as a 32-bit up/down counter.

Table1: LED indicators

LED Function

Ch. A Lights up when a signal is present at input A.

Ch. B Lights up when a signal is present at input B.

Ch. C Lights up when a signal is present at input C (zero input).

Gate / Latch Lights up when a signal is present at the gate/latch input.

KL5151/KS5151, KL5152/KS51528 Version: 2.0.0

Page 9

Product overview

3.2 KL5151-0021 - Introduction

Fig.2: KL5151-0021

The KL5151-0021 Bus Terminal is an interface with 24 V inputs for the direct connection of incremental

encoders. A 32 bit counter with a quadrature decoder and a 32 bit latch for the zero pulse can be read, set or

enabled.

The KL5151-0021 Bus Terminal has an additional comparator output.

Table2: LED indicators

LED Function

Ch. A Lights up when a signal is present at input A.

Output Lights up when the comparator output is switched on.

Ch. B Lights up when a signal is present at input B.

Ch. C Lights up when a signal is present at input C (zero input).

Gate / Latch Lights up when a signal is present at the gate/latch input.

Operation

Referencing

Enter the reference value for referencing via the output double word DataOUT1 [}33] and set bits CB1.0

[}33] (EnLatchC) and CB1.2 [}33] (SetCnt) in the control byte. The reference value is now adopted by the

counter on a rising edge at input C.

Measuring the workpiece

At the beginning of the measurement the filter value is preset in the filter register R0 [}45].

Then set the release bit CB1.1 [}33] (EnMeas) in the control byte. If a plate has been successfully

measured, the terminal sets bit SB1.1 [}34] (MeasDone) in the status byte.

The measurement begins on an appropriate edge. If the level already exists, only the position of the end of

the board is determined. The start of the measurement is then taken as the start of the board.

Post-forming sawing

The output has a rise time of 10 µs and a 40 µs delay due to the optocoupler.

KL5151/KS5151, KL5152/KS5152 9Version: 2.0.0

Page 10

Product overview

3.3 KL5152-0000 (KL5151-0050) - Introduction

Fig.3: KL5151-0050

The KL5152-0000 (KL5151-0050) Bus Terminal is an interface with 24 V inputs for the direct connection of

two incremental encoders. The terminal can optionally be used as a single-channel or two-channel device.

Table3: LED indicators

Signal LED Function Encoder

Ch. A1 Lights up when a signal is present at input A1. 1

Ch. B1 Lights up when a signal is present at input B1.

Ch. A2 Lights up when a signal is present at input A2. 2

Ch. B2 Lights up when a signal is present at input B2.

KL5151/KS5151, KL5152/KS515210 Version: 2.0.0

Page 11

Product overview

3.4 Technical data

Technical data KL5151-0000 KL5151-0021 KL5152-0000 (KL5151-0050)

Sensor inputs (channels) 1 2

Encoder connection A, B, C, Gate, 24 V Channel 1: A1, B1

Channel 2: A2, B2

Encoder operating voltage 24 V

DC

Counter 1 x 32 bit binary 2 x 32 bit binary

Limit frequency 100 kHz

Quadrature decoder 4-fold evaluation

Commands read, set, latching,

Compare function for setting the output (KL5151-0021 only)

Supply voltage 24VDC (-15%/+20%)

Comparator output 0 1 0

Current consumption from

the power contacts

Typically 100 mA (without sensor load current)

Bit width in the K-bus I/O 4 x 16 bit user data, 1 x 8 bit control/status

Bit width in the input

process image

2 data words,

1 status byte

compact [}36] complete [}36]

4 data words 4 data words,

2 status bytes

Bit width in the output

process image

2 data words,

1 control byte

2 data words,

2 control bytes,

2 filler bytes

4 data words,

2 control bytes

Power supply for electronic via the K-bus

Current consumption from

K-bus

typically 50 mA

Weight approx. 50 g

Dimensions (W x H x D) approx. 15 mm x 100 mm x 70 mm

Mountin [}12]g

on 35 mm mounting rail conforms to EN 60715

Pluggable wiring [}14]

at all KSxxxx series terminals

Permissible ambient

temperature range during

operation

-25°C ... +60°C*

0°C ... +55°C (UL)

0°C ... +55°C (ATEX

[}21])

0°C ... + 55°C

Permissible ambient

temperature range during

storage

-40°C ... + 85°C -25°C ... + 85°C

Permissible relative

humidity

95%, no condensation

Vibration/shock resistance conforms to EN 60068-2-6 / EN 60068-2-27

EMC immunity/emission conforms to EN 61000-6-2 / EN 61000-6-4

Protection class IP20

Installation position variable

Approval

CE, cULus, ATEX [}21]

*) -25°C ... +60°C (extended temperature range)

0°C ... +55°C (according to cULus for Canada and the USA)

0°C ... +55°C (according to ATEX, see special conditions)

KL5151/KS5151, KL5152/KS5152 11Version: 2.0.0

Page 12

Mounting and wiring

4 Mounting and wiring

4.1 Installation on mounting rails

WARNING

Risk of electric shock and damage of device!

Bring the bus terminal system into a safe, powered down state before starting installation,

disassembly or wiring of the Bus Terminals!

Assembly

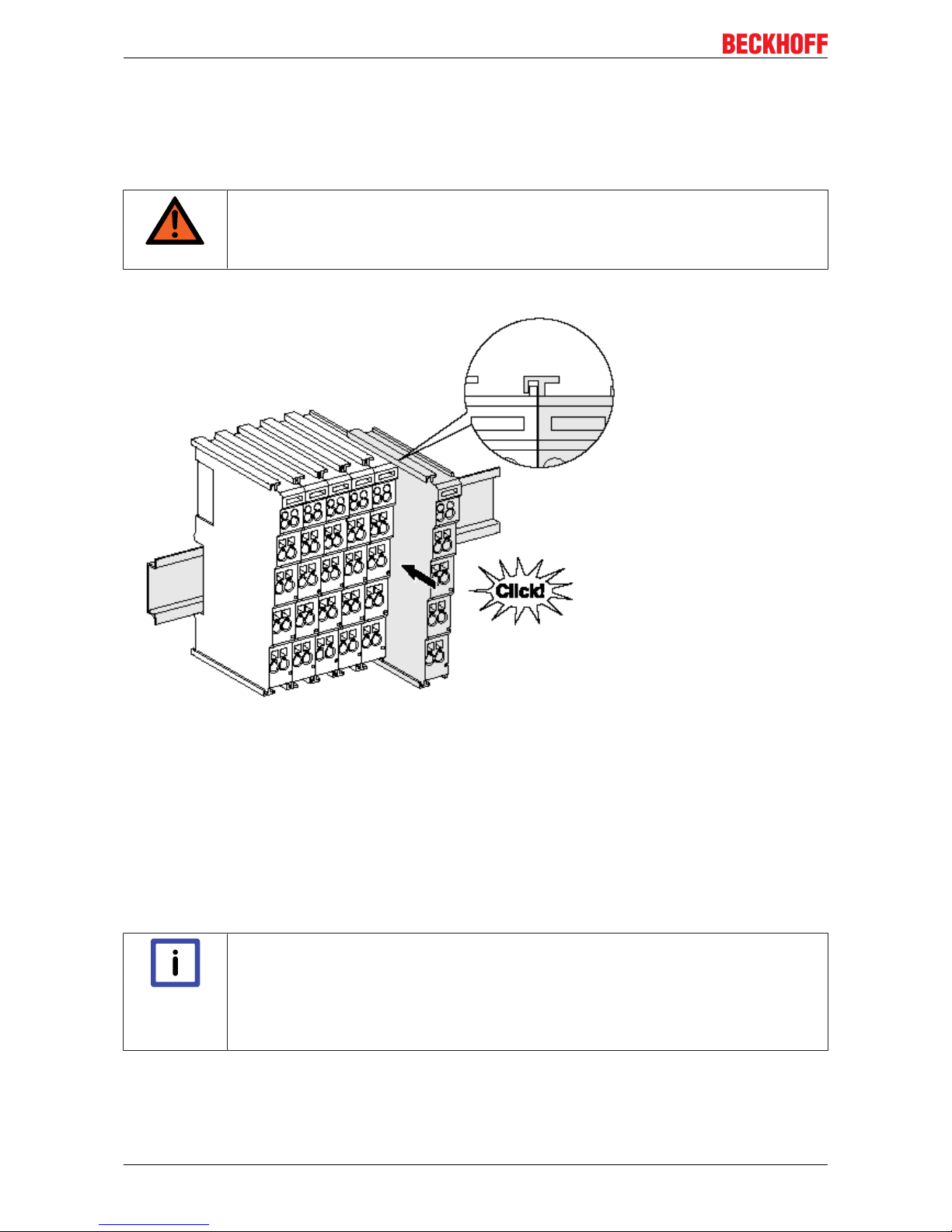

Fig.4: Attaching on mounting rail

The Bus Coupler and Bus Terminals are attached to commercially available 35mm mounting rails (DIN rails

according to EN60715) by applying slight pressure:

1. First attach the Fieldbus Coupler to the mounting rail.

2. The Bus Terminals are now attached on the right-hand side of the Fieldbus Coupler. Join the

components with tongue and groove and push the terminals against the mounting rail, until the lock

clicks onto the mounting rail.

If the Terminals are clipped onto the mounting rail first and then pushed together without tongue and

groove, the connection will not be operational! When correctly assembled, no significant gap should

be visible between the housings.

Note

Fixing of mounting rails

The locking mechanism of the terminals and couplers extends to the profile of the mounting

rail. At the installation, the locking mechanism of the components must not come into conflict with the fixing bolts of the mounting rail. To mount the mounting rails with a height of

7.5mm under the terminals and couplers, you should use flat mounting connections (e.g.

countersunk screws or blind rivets).

KL5151/KS5151, KL5152/KS515212 Version: 2.0.0

Page 13

Mounting and wiring

Disassembly

Fig.5: Disassembling of terminal

Each terminal is secured by a lock on the mounting rail, which must be released for disassembly:

1. Pull the terminal by its orange-colored lugs approximately 1cm away from the mounting rail. In doing

so for this terminal the mounting rail lock is released automatically and you can pull the terminal out of

the bus terminal block easily without excessive force.

2. Grasp the released terminal with thumb and index finger simultaneous at the upper and lower grooved

housing surfaces and pull the terminal out of the bus terminal block.

Connections within a bus terminal block

The electric connections between the Bus Coupler and the Bus Terminals are automatically realized by

joining the components:

• The six spring contacts of the K-Bus/E-Bus deal with the transfer of the data and the supply of the Bus

Terminal electronics.

• The power contacts deal with the supply for the field electronics and thus represent a supply rail within

the bus terminal block. The power contacts are supplied via terminals on the Bus Coupler (up to 24V)

or for higher voltages via power feed terminals.

Note

Power Contacts

During the design of a bus terminal block, the pin assignment of the individual Bus Terminals must be taken account of, since some types (e.g. analog Bus Terminals or digital 4channel Bus Terminals) do not or not fully loop through the power contacts. Power Feed

Terminals (KL91xx, KL92xx or EL91xx, EL92xx) interrupt the power contacts and thus represent the start of a new supply rail.

PE power contact

The power contact labeled PE can be used as a protective earth. For safety reasons this contact mates first

when plugging together, and can ground short-circuit currents of up to 125A.

KL5151/KS5151, KL5152/KS5152 13Version: 2.0.0

Page 14

Mounting and wiring

Fig.6: Power contact on left side

Attention

Possible damage of the device

Note that, for reasons of electromagnetic compatibility, the PE contacts are capacitatively

coupled to the mounting rail. This may lead to incorrect results during insulation testing or

to damage on the terminal (e.g. disruptive discharge to the PE line during insulation testing

of a consumer with a nominal voltage of 230V). For insulation testing, disconnect the PE

supply line at the Bus Coupler or the Power Feed Terminal! In order to decouple further

feed points for testing, these Power Feed Terminals can be released and pulled at least

10mm from the group of terminals.

WARNING

Risk of electric shock!

The PE power contact must not be used for other potentials!

4.2 Connection system

WARNING

Risk of electric shock and damage of device!

Bring the bus terminal system into a safe, powered down state before starting installation,

disassembly or wiring of the Bus Terminals!

Overview

The Bus Terminal system offers different connection options for optimum adaptation to the respective

application:

• The terminals of KLxxxx and ELxxxx series with standard wiring include electronics and connection

level in a single enclosure.

• The terminals of KSxxxx and ESxxxx series feature a pluggable connection level and enable steady

wiring while replacing.

• The High Density Terminals (HD Terminals) include electronics and connection level in a single

enclosure and have advanced packaging density.

KL5151/KS5151, KL5152/KS515214 Version: 2.0.0

Page 15

Mounting and wiring

Standard wiring

Fig.7: Standard wiring

The terminals of KLxxxx and ELxxxx series have been tried and tested for years.

They feature integrated screwless spring force technology for fast and simple assembly.

Pluggable wiring

Fig.8: Pluggable wiring

The terminals of KSxxxx and ESxxxx series feature a pluggable connection level.

The assembly and wiring procedure for the KS series is the same as for the KLxxxx and ELxxxx series.

The KS/ES series terminals enable the complete wiring to be removed as a plug connector from the top of

the housing for servicing.

The lower section can be removed from the terminal block by pulling the unlocking tab.

Insert the new component and plug in the connector with the wiring. This reduces the installation time and

eliminates the risk of wires being mixed up.

The familiar dimensions of the terminal only had to be changed slightly. The new connector adds about 3

mm. The maximum height of the terminal remains unchanged.

A tab for strain relief of the cable simplifies assembly in many applications and prevents tangling of individual

connection wires when the connector is removed.

Conductor cross sections between 0.08mm2 and 2.5mm2 can continue to be used with the proven spring

force technology.

The overview and nomenclature of the product names for KSxxxx and ESxxxx series has been retained as

known from KLxxxx and ELxxxx series.

High Density Terminals (HD Terminals)

Fig.9: High Density Terminals

The Bus Terminals from these series with 16 connection points are distinguished by a particularly compact

design, as the packaging density is twice as large as that of the standard 12mm Bus Terminals. Massive

conductors and conductors with a wire end sleeve can be inserted directly into the spring loaded terminal

point without tools.

KL5151/KS5151, KL5152/KS5152 15Version: 2.0.0

Page 16

Mounting and wiring

Note

Wiring HD Terminals

The High Density (HD) Terminals of the KLx8xx and ELx8xx series doesn't support steady

wiring.

Ultrasonically "bonded" (ultrasonically welded) conductors

Note

Ultrasonically “bonded" conductors

It is also possible to connect the Standard and High Density Terminals with ultrasonically

"bonded" (ultrasonically welded) conductors. In this case, please note the tables concern-

ing the wire-size width [}16] below!

Wiring

Terminals for standard wiring ELxxxx / KLxxxx and terminals for steady wiring

ESxxxx / KSxxxx

Fig.10: Mounting a cable on a terminal connection

Up to eight connections enable the connection of solid or finely stranded cables to the Bus Terminals. The

terminals are implemented in spring force technology. Connect the cables as follows:

1. Open a spring-loaded terminal by slightly pushing with a screwdriver or a rod into the square opening

above the terminal.

2. The wire can now be inserted into the round terminal opening without any force.

3. The terminal closes automatically when the pressure is released, holding the wire securely and

permanently.

Terminal housing ELxxxx, KLxxxx ESxxxx, KSxxxx

Wire size width 0.08 ... 2,5mm

2

0.08 ... 2.5mm

2

Wire stripping length 8 ... 9mm 9 ... 10mm

KL5151/KS5151, KL5152/KS515216 Version: 2.0.0

Page 17

Mounting and wiring

High Density Terminals ELx8xx, KLx8xx (HD)

The conductors of the HD Terminals are connected without tools for single-wire conductors using the direct

plug-in technique, i.e. after stripping the wire is simply plugged into the contact point. The cables are

released, as usual, using the contact release with the aid of a screwdriver. See the following table for the

suitable wire size width.

Terminal housing High Density Housing

Wire size width (conductors with a wire end sleeve) 0.14... 0.75mm

2

Wire size width (single core wires) 0.08 ... 1.5mm

2

Wire size width (fine-wire conductors) 0.25 ... 1.5mm

2

Wire size width (ultrasonically “bonded" conductors)

only 1.5mm2 (see notice

[}16]!)

Wire stripping length 8 ... 9mm

Shielding

Note

Shielding

Analog sensors and actors should always be connected with shielded, twisted paired wires.

KL5151/KS5151, KL5152/KS5152 17Version: 2.0.0

Page 18

Mounting and wiring

4.3 KL5151-0000 - Connection

WARNING

Risk of injury through electric shock and damage to the device!

Bring the Bus Terminals system into a safe, de-energized state before starting mounting,

disassembly or wiring of the Bus Terminals.

Fig.11: KL5151-0000

Pin assignment

Terminal point No. In the encoder interface operating mode*

Connection for

In the counter operating mode*

Connection for

A 1 Input A Counter input

+24 V 2 Power contact +24 V (internally connected to terminal point 6)

0 V 3 Power contact 0 V (internally connected to terminal point 7)

C 4 Input C or

zero input (in case bit 0 (EnLatchC [}29]) is set in the control byte, a

rising edge at this input causes the current counter value to be saved

in the latch register as a reference mark).

Counter enable (gate input for the

counter operating mode)

B 5 Input B Counting direction (high = down,

low = up)

+24 V 6 Power contact +24 V (internally connected to terminal point 2)

0 V 7 Power contact 0 V (internally connected to terminal point 3)

Gate/Latch 8 Gate input or

Latch input: if

• bit3 (EnLatchRise [}29]) is set in the control byte, a rising

edge

• bit 4 (EnLatchFall [}29]) is set in the control byte, a falling

edge

at this input causes the current counter value to be saved in the latch

register as a reference mark.

no function

*) The operating mode is set with bit R32.15 [}46] of the feature register.

KL5151/KS5151, KL5152/KS515218 Version: 2.0.0

Page 19

Mounting and wiring

4.4 KL5151-0021 - Connection

WARNING

Risk of injury through electric shock and damage to the device!

Bring the Bus Terminals system into a safe, de-energized state before starting mounting,

disassembly or wiring of the Bus Terminals.

Fig.12: KL5151-0021

Pin assignment

Terminal

point

No. Connection for

A 1 Input A

Output 2 Comparator output

0 V 3 Power contact 0 V (internally connected to terminal point 7)

C 4 Input C or

zero input (in case bit 0 (EnLatchC [}33]) is set in the control byte, a rising edge at

this input causes the current counter value to be saved in the latch register as a

reference mark).

B 5 Input B

+24 V 6 Power contact +24 V

0 V 7 Power contact 0 V (internally connected to terminal point 3)

Gate/Latch 8 Gate input or

Latch input: if

• bit3 (EnLatchRise [}33]) is set in the control byte, a rising edge

• bit 4 (EnLatchFall [}33]) is set in the control byte, a falling edge

at this input causes the current counter value to be saved in the latch register as a

reference mark.

KL5151/KS5151, KL5152/KS5152 19Version: 2.0.0

Page 20

Mounting and wiring

4.5 KL5152-0000 (KL5151-0050) - Connection

WARNING

Risk of injury through electric shock and damage to the device!

Bring the Bus Terminals system into a safe, de-energized state before starting mounting,

disassembly or wiring of the Bus Terminals.

Fig.13: KL5151-0050

Pin assignment

Terminal point No. Connection for

A1 1 Input A for encoder 1

+24 V 2 Power contact +24 V (internally connected to terminal point 6)

0 V 3 Power contact 0 V (internally connected to terminal point 7)

A2 4 Input A for encoder 2

B1 5 Input B for encoder 1

+24 V 6 Power contact +24 V (internally connected to terminal point 2)

0 V 7 Power contact 0 V (internally connected to terminal point 3)

B2 8 Input B for encoder 2

KL5151/KS5151, KL5152/KS515220 Version: 2.0.0

Page 21

Mounting and wiring

4.6 ATEX - Special conditions

WARNING

Observe the special conditions for the intended use of Beckhoff fieldbus

components in potentially explosive areas (directive 94/9/EU)!

ü Conditions

a) The certified components are to be installed in a suitable housing that guarantees a

protection class of at least IP54 in accordance with EN 60529! The environmental conditions during use are thereby to be taken into account!

b) If the temperatures during rated operation are higher than 70°C at the feed-in points of

cables, lines or pipes, or higher than 80°C at the wire branching points, then cables

must be selected whose temperature data correspond to the actual measured temperature values!

c) Observe the permissible ambient temperature range of 0 - 55°C for the use of Beckhoff

fieldbus components in potentially explosive areas!

d) Measures must be taken to protect against the rated operating voltage being exceeded

by more than 40% due to short-term interference voltages!

e) The individual terminals may only be unplugged or removed from the Bus Terminal sys-

tem if the supply voltage has been switched off or if a non-explosive atmosphere is ensured!

f) The connections of the certified components may only be connected or disconnected if

the supply voltage has been switched off or if a non-explosive atmosphere is ensured!

g) The fuses of the KL92xx/EL92xx power feed terminals may only be exchanged if the

supply voltage has been switched off or if a non-explosive atmosphere is ensured!

h) Address selectors and ID switches may only be adjusted if the supply voltage has been

switched off or if a non-explosive atmosphere is ensured!

Standards

The fundamental health and safety requirements are fulfilled by compliance with the following standards:

• EN 60079-0: 2006

• EN 60079-15: 2005

KL5151/KS5151, KL5152/KS5152 21Version: 2.0.0

Page 22

Mounting and wiring

Marking

The Beckhoff fieldbus components certified for potentially explosive areas bear one of the following

markings:

II 3 G Ex nA II T4 KEMA 10ATEX0075 X Ta: 0 - 55°C

or

II 3 G Ex nA nC IIC T4 KEMA 10ATEX0075 X Ta: 0 - 55°C

4.7 ATEX Documentation

Note

Notes about operation of the Beckhoff terminal systems in potentially explosive areas (ATEX)

Pay also attention to the continuative documentation Notes about operation of the Beckhoff

terminal systems in potentially explosive areas (ATEX) that is available in the download

area of the Beckhoff homepage http:\\www.beckhoff.com!

KL5151/KS5151, KL5152/KS515222 Version: 2.0.0

Page 23

Configuration software KS2000

5 Configuration software KS2000

5.1 KS2000 - Introduction

The KS2000 configuration software permits configuration, commissioning and parameterization of bus

couplers, of the affiliated bus terminals and of Fieldbus Box Modules. The connection between bus coupler/

Fieldbus Box Module and the PC is established by means of the serial configuration cable or the fieldbus.

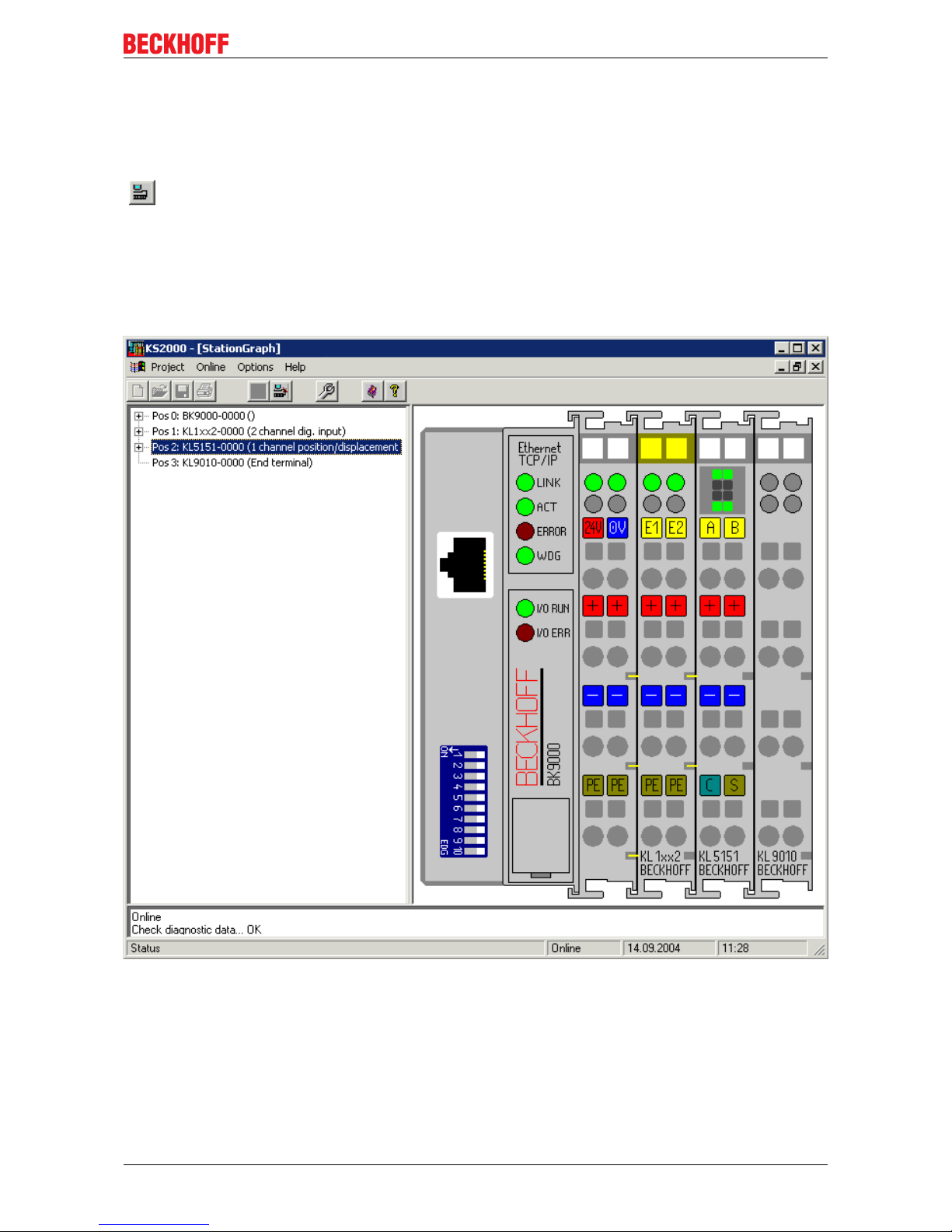

Fig.14: KS2000 configuration software

Configuration

You can configure the Fieldbus stations with the Configuration Software KS2000 offline. That means, setting

up a terminal station with all settings on the couplers and terminals resp. the Fieldbus Box Modules can be

prepared before the commissioning phase. Later on, this configuration can be transferred to the terminal

station in the commissioning phase by means of a download. For documentation purposes, you are provided

with the breakdown of the terminal station, a parts list of modules used and a list of the parameters you have

modified. After an upload, existing fieldbus stations are at your disposal for further editing.

Parameterization

KS2000 offers simple access to the parameters of a fieldbus station: specific high-level dialogs are available

for all bus couplers, all intelligent bus terminals and Fieldbus Box modules with the aid of which settings can

be modified easily. Alternatively, you have full access to all internal registers of the bus couplers and

intelligent terminals. Refer to the register description for the meanings of the registers.

KL5151/KS5151, KL5152/KS5152 23Version: 2.0.0

Page 24

Configuration software KS2000

Commissioning

The KS2000 software facilitates commissioning of machine components or their fieldbus stations: Configured

settings can be transferred to the fieldbus modules by means of a download. After a login to the terminal

station, it is possible to define settings in couplers, terminals and Fieldbus Box modules directly online. The

same high-level dialogs and register access are available for this purpose as in the configuration phase.

The KS2000 offers access to the process images of the bus couplers and Fieldbus Box modules.

• Thus, the coupler's input and output images can be observed by monitoring.

• Process values can be specified in the output image for commissioning of the output modules.

All possibilities in the online mode can be used in parallel with the actual fieldbus mode of the terminal

station. The fieldbus protocol always has the higher priority in this case.

KL5151/KS5151, KL5152/KS515224 Version: 2.0.0

Page 25

Configuration software KS2000

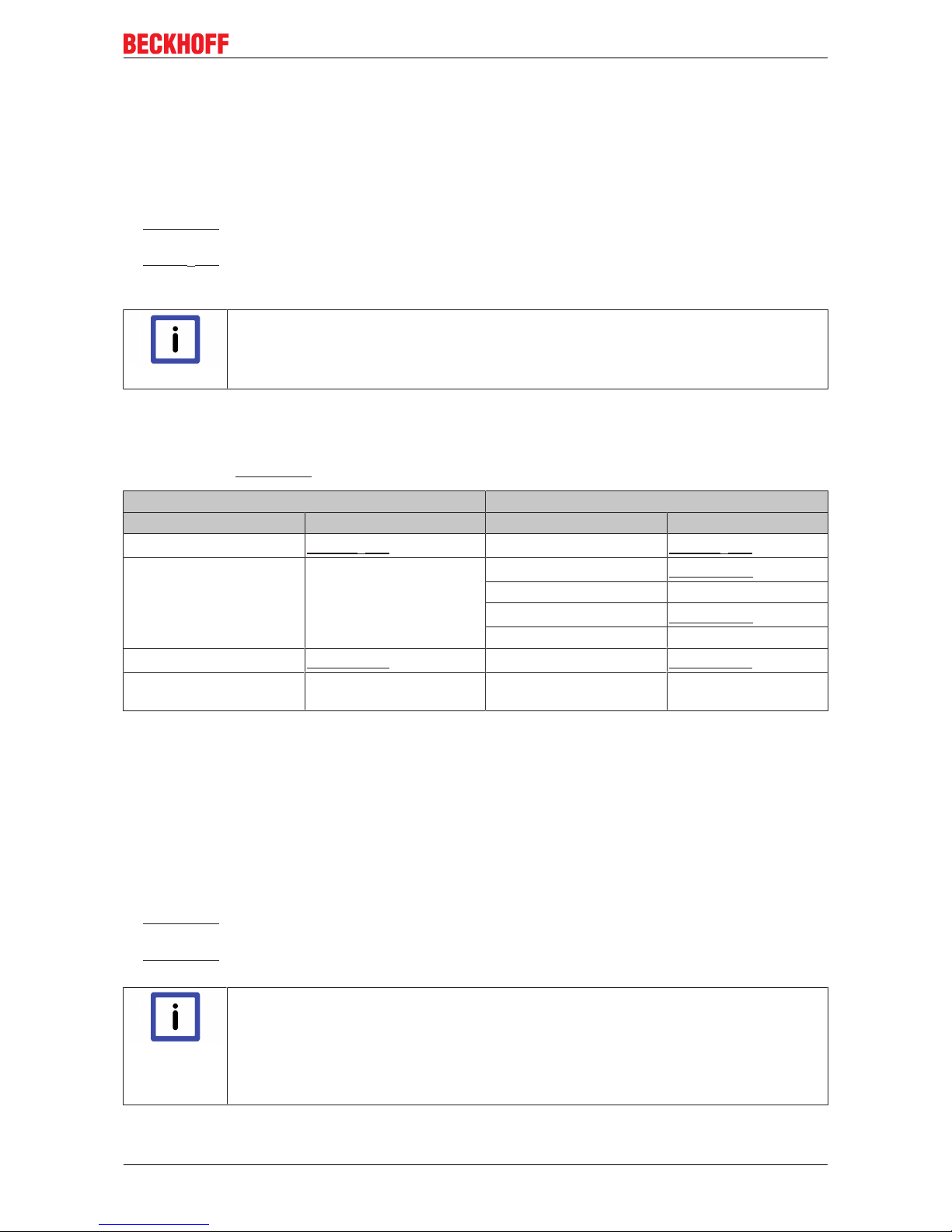

5.2 Parameterization with KS2000

Connect the configuration interface of your fieldbus coupler with the serial interface of your PC via the

configuration cable and start the KS2000 configuration software.

Click on the Login button. The configuration software will now load the information for the

connected fieldbus station.

In the example shown, this is

• a BK9000 Ethernet coupler

• a KL1xx2 digital input terminal

• a KL5151-0000 incremental encoder terminal

• a KL9010 bus end terminal

Fig.15: Display of the fieldbus station in KS2000

The left-hand KS2000 window displays the terminals of the fieldbus station in a tree structure.

The right-hand KS2000 window contains a graphic display of the fieldbus station terminals.

In the tree structure of the left-hand window, click on the plus-sign next to the terminal whose parameters

you wish to change (item 2 in the example).

KL5151/KS5151, KL5152/KS5152 25Version: 2.0.0

Page 26

Configuration software KS2000

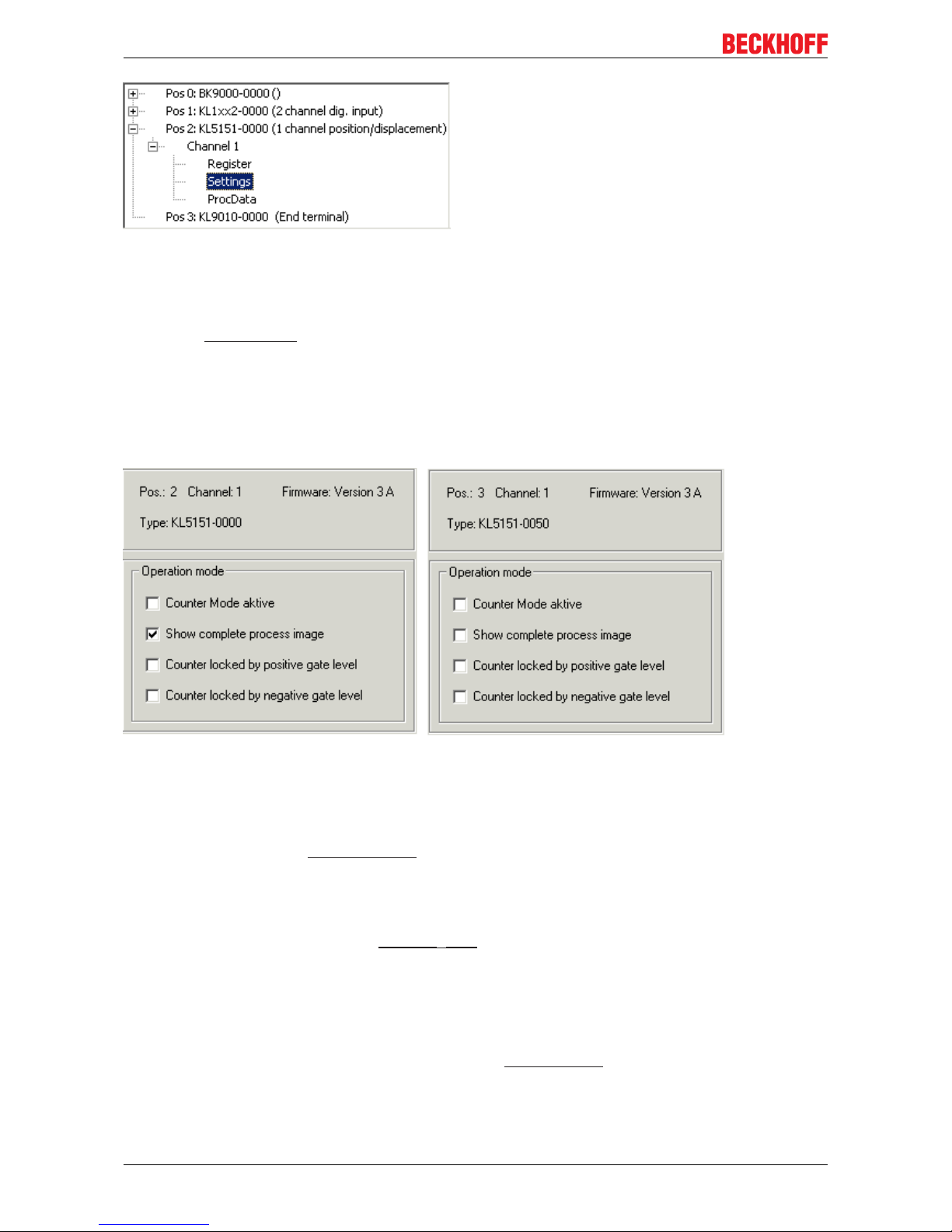

Fig.16: KS2000 tree branches for channel 1 of the KL5151

For the KL5151, the branches Register, Settings and ProcData are displayed:

• Register permits direct access to the registers of the KL5151.

• Under Settings [}26] you find dialog boxes for parameterizing the KL5151.

• ProcData displays the KL5151 process data.

5.3 Settings

The dialog mask for the parameterization of the KL5151-0000 or KL5151-0050 can be found under Settings.

Fig.17: Settings via KS2000

Operation mode

Counter mode active (R32.15 [}46])

You can activate counter mode here (default: inactive). When counter mode is activated, the KL5151-0000

operates as a 32 bit up/down counter.

Display whole process image (R32.6 [}46])

Meaningful operation of the KL5151-0000 is only possible with the full process image (default: active)!

The KL5151-0050 is factory-set to the small (compact) process image.

You can activate evaluation of the full process image for the KL5151-0050 here.

A positive level at the gate locks the counter (R32.5 [}46])

You can lock the counter by applying a positive level to the gate input (default: inactive).

KL5151/KS5151, KL5152/KS515226 Version: 2.0.0

Page 27

Configuration software KS2000

A negative level at the gate locks the counter (R32.4 [}46])

You can lock the counter by applying a negative level to the gate input (default: inactive).

KL5151/KS5151, KL5152/KS5152 27Version: 2.0.0

Page 28

Access from the user program

6 Access from the user program

6.1 KL5151-0000

6.1.1 Process image

In the process image, the KL5151 is represented with 5 bytes of input and output data. These are organized

as follows:

Format Input data Output data

Byte

SB [}30] CB [}29]

Double

word

DataIN DataOUT

Legend

SB: Status byte

CB: Control byte

DataIN: The current value of the 32-bit counter, or the one stored in the latch (the selection is made with bit

CB1.1 [}29] of the control byte)

DataOUT: Value specified for the 32 bit counter

• Please refer to the Mapping [}31] page for the allocation of the bytes and words to the addresses of

the controller.

• The meaning of the control and status bytes is explained on the Control and Status bytes [}29] page.

Note

No compact process image

Operation of the KL5151-0000 with compact process image (without control and status

bytes) is not possible, since the control and status bytes are required for useful process

data operation of the terminal. Even if you adjust your Bus Coupler to the compact process

image, the KL5151-0000 will still be represented with its complete process image!

KL5151/KS5151, KL5152/KS515228 Version: 2.0.0

Page 29

Access from the user program

6.1.2 Control and status bytes

Channel 1

Process data mode

Control byte 1 in process data mode

Control byte 1 (CB1) is located in the output image, and is transmitted from the controller to the terminal.

Bit CB1.7 CB1.6 CB1.5 CB1.4 CB1.3 CB1.2 CB1.1 CB1.0

Name RegAccess - RS_CNT_LATEnLatchFall EnLatchRise SetCnt ReadLatch EnLatchC

Legend

Bit Name Description

CB1.7 RegAccess 0

bin

Register communication off (process data mode)

CB1.6 - reserved

CB1.5 RS_CNT_LAT*1

bin

The counter is set to zero by an active edge at the latch input

[}18]. Bits CB1.4, CB1.3 and CB1.0 specify which edge of the

latch signal is active.

CB1.4 EnLatchFall* 1

bin

The falling edge of the latch input [}18] is active. The counter

value is stored in the latch register at the first external latch

impulse after the EnLatchFall bit becomes true. The

subsequent pulses do not have any effect on the latch register.

CB1.3 EnLatchRise*1

bin

The rising edge of the latch input [}18] is active. The counter

value is stored in the latch register on the first external latch

pulse after the EnLatchRise bit becomes true (this has priority

over EnLatchFall). The subsequent pulses do not have any

effect on the latch register.

CB1.2 SetCnt A rising edge at SetCnt will set the counter to the 32 bit value that is written by

the controller into the process output data.

CB1.1 ReadLatch 0

bin

The current value of the 32 bit counter is mapped to the

process input data.

1

bin

The 32 bit value stored in the latch counter is mapped to the

process input data.

CB1.0 EnLatchC* 1

bin

The rising edge of the zero input (input C [}18]) is active. The

counter value is stored in the latch register at the first external

latch impulse after the EnLatchC bit becomes true. The

subsequent pulses do not have any effect on the latch register.

(see note below)

*) Does not apply to KL5152-0000 (KL5151-0050), since the latch input and zero input are not available in

this case. Always set bits CB1.5, CB1.4, CB1.3 and CB1.0 of the KL5152-0000 (KL5151-0050) to 0

bin

!

Note

EnLatchC or EnLatchRise and EnLatchFall?

If bit CB1.0 (EnLatchC) is set, bit CB1.3 (EnLatchRise) and bit CB1.4 (EnLatchFall) must

not be set, otherwise you cannot know which event has caused a counter value to be

stored in the latch.

Status byte 1 in process data mode

The status byte 1 (SB1) is located in the input image, and is transmitted from terminal to the controller.

KL5151/KS5151, KL5152/KS5152 29Version: 2.0.0

Page 30

Access from the user program

Bit SB1.7 SB1.6 SB1.5 SB1.4 SB1.3 SB1.2 SB1.1 SB1.0

Name RegAccess- - StGate StLatchC SetCnt ReadLatchValLatchC

Legend

Bit Name Description

SB1.7 RegAccess 0

bin

Acknowledgement for process data mode

SB1.6 - reserved

SB1.5 - reserved

SB1.4 StGate

KL5151-0000: Status of the external gate/latch input [}18]

KL5152-0000 (KL5151-0050): reserved

SB1.3 StLatchC

KL5151-0000: Status of the zero input (input C [}18])

KL5152-0000 (KL5151-0050): reserved

SB1.2 SetCnt Acknowledgement that the data for setting the counter has been adopted by

the terminal.

SB1.1 ReadLatch 0

bin

The current value of the 32 bit counter has been mapped to the

process data.

1

bin

The 32 bit value stored in the latch counter has been mapped

to the process data.

SB1.0 ValLatchC* 1

bin

A zero-point latch has occurred: a rising edge at the zero input

(input C [}18]) has caused the current counter value to be

stored in the latch register as a reference mark.

Subsequent pulses do not have any effect on the latch register.

To reactivate the gate/latch input [}18] you must:

• set bit 0 (EnLatchC) in the control byte to 0

bin

.

• wait until this change has been acknowledged by

resetting bit 0 (ValLatchC) in the status byte.

• set bit 0 (EnLatchC) in the control byte to 1

bin

again.

*) Does not apply to KL5152-0000 (KL5151-0050), since the latch input and zero input are not available in

this case.

Register communication

Control byte 1 in register communication

Control byte 1 (CB1) is located in the output image, and is transmitted from the controller to the terminal.

Bit CB1.7 CB1.6 CB1.5 CB1.4 CB1.3 CB1.2 CB1.1 CB1.0

Name RegAccess R/W Reg. no.

Legend

Bit Name Description

CB1.7 RegAccess 1

bin

Register communication switched on

CB1.6 R/W 0

bin

Read access

1

bin

Write access

CB1.5 to

CB1.0

Reg. no. Register number:

Enter the number of the register [}44] that you

- want to read with input data word 0 or

- write to with output data word 0.

KL5151/KS5151, KL5152/KS515230 Version: 2.0.0

Page 31

Access from the user program

CAUTION

No valid process data during the register communication!

It is not possible to access the data registers during register communication! Process data

that may still be displayed is not valid!

Status byte 1 in register communication

The status byte 1 (SB1) is located in the input image, and is transmitted from terminal to the controller.

Bit SB1.7 SB1.6 SB1.5 SB1.4 SB1.3 SB1.2 SB1.1 SB1.0

Name RegAccess R Reg. no.

Legend

Bit Name Description

SB1.7 RegAccess 1

bin

Acknowledgement for register access

SB1.6 R 0

bin

Read access

SB1.5 to

SB1.0

Reg. no. Number of the register that was read or written.

Channel 2 (KL5152-0000 and KL5151-0050 only)

The control and status bytes of channel 2 (CB2 and SB2) have the same structure as the control and status

bytes of channel 1 [}29].

6.1.3 Mapping

The Bus Terminals occupy addresses within the process image of the controller. The assignment of process

data (input and output data) and parameterization data (control and status bytes) to the control addresses is

called mapping. The type of mapping depends on:

• the fieldbus system used

• the terminal type

• the parameterization of the Bus Coupler such as

- Intel or Motorola format

- word alignment switched on or off

The Bus Couplers (BKxxxx, LCxxxx) and Bus Terminal Controllers (BCxxxx, BXxxxx) are supplied with

certain default settings. The default setting can be changed with the KS2000 configuration software or with a

master configuration software (e.g. TwinCAT System Manager or ComProfibus).

The following tables show the mapping depending on different conditions. For information about the contents

of the individual bytes please refer to the pages Process image [}28] and Control and status byte [}29].

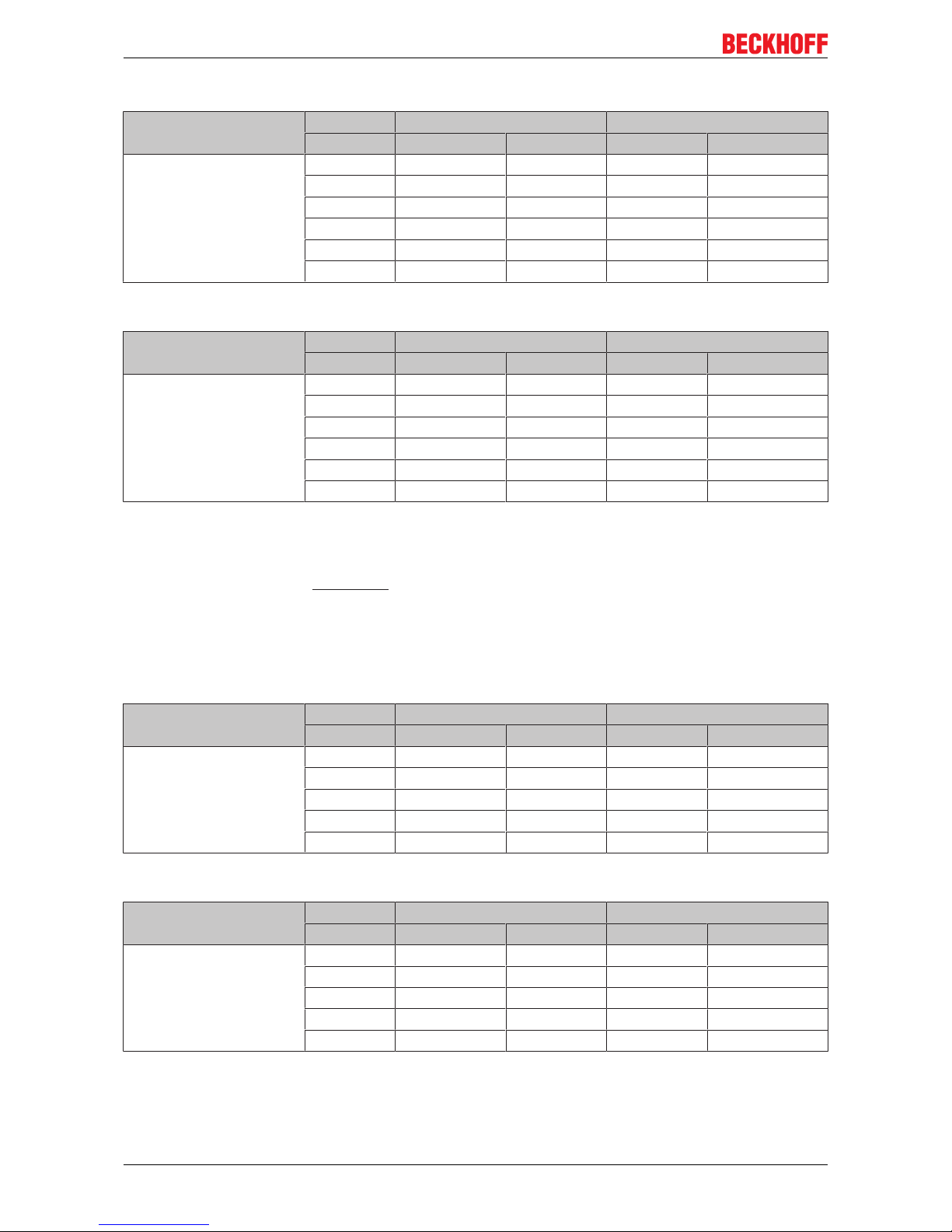

Complete evaluation

Control and status bytes can be accessed.

Complete evaluation in Intel format

Default mapping for CANopen, CANCAL, DeviceNet, ControlNet, Modbus, RS232 and RS485 coupler.

Parameterization

of the Bus Coupler

Address Input data Output data

Word offset High byte Low byte High byte Low byte

Complete evaluation: n/a

Motorola format: no

Word alignment: no

0 DataIN D0 SB DataOUT D0 CB

1 DataIN D2 DataIN D1 DataOUT D2 DataOUT D1

2 reserved DataIN D3 reserved DataOUT D3

KL5151/KS5151, KL5152/KS5152 31Version: 2.0.0

Page 32

Access from the user program

Complete evaluation in Motorola format

Parameterization

of the Bus Coupler

Address Input data Output data

Word offset High byte Low byte High byte Low byte

Complete evaluation: n/a

Motorola format: yes

Word alignment: no

0 DataIN D3 SB DataOUT D3 CB

1 DataIN D1 DataIN D2 DataOUT D1 DataOUT D2

2 reserved DataIN D0 reserved DataOUT D0

Complete evaluation in Intel format with word alignment

Default mapping for EtherCAT, Lightbus and Ethernet coupler as well as Bus Terminal Controllers (BCxxxx,

BXxxxx).

Parameterization

of the Bus Coupler

Address Input data Output data

Word offset High byte Low byte High byte Low byte

Complete evaluation: n/a

Motorola format: no

Word alignment: yes

0 reserved SB reserved CB

1 DataIN D1 DataIN D0 DataOUT D1 DataOUT D0

2 DataIN D3 DataIN D2 DataOUT D3 DataOUT D2

Complete evaluation in Motorola format with word alignment

Parameterization

of the Bus Coupler

Address Input data Output data

Word offset High byte Low byte High byte Low byte

Complete evaluation: n/a

Motorola format: yes

Word alignment: yes

0 reserved SB1 reserved CB1

1 DataIN D2 DataIN D3 DataOUT D2 DataOUT D3

2 DataIN D0 DataIN D1 DataOUT D0 DataOUT D1

Legend

Complete evaluation: In addition to the process data, the control and status bytes are also mapped into the

address space.

Motorola format: Motorola or Intel format can be set.

Word alignment: In order for the word address range to commence at a word boundary, empty bytes are

inserted into the process image as appropriate.

SB: Status byte (appears in the input process image)

CB: Control byte (appears in the output process image)

DataIN D0: Input double word, lowest significant data byte

DataIN D1: Input double word, ...

DataIN D2: Input double word, ...

DataIN D3: Input double word, highest significant data byte

DataOUT D0: Output double word, lowest significant data byte

DataOUT D1: Output double word, ...

DataOUT D2: Output double word, ...

DataOUT D3: Output double word, highest significant data byte

reserved: This byte occupies process data memory, although it has no function.

Compact evaluation

Note

No compact process image

Operation of the KL5151-0000 with compact process image (without control and status

bytes) is not possible, since the control and status bytes are required for useful process

data operation of the terminal. Even if you adjust your Bus Coupler to the compact process

image, the KL5151-0000 will still be represented with its complete process image!

KL5151/KS5151, KL5152/KS515232 Version: 2.0.0

Page 33

Access from the user program

6.2 KL5151-0021

6.2.1 Process image

In the process image, the KL5151 is represented with 5 bytes of input and output data. These are organized

as follows:

Format Input data Output data

Byte

SB1 [}33] CB1 [}33]

Double

word

DataIN1 DataOUT1

Byte SB2 CB2

Double

word

DataIN2 DataOUT2

Legend

SB1: Status byte 1

CB1: Control byte 1

SB1: Status byte 2 (not used)

CB1: Control byte 2 (not used)

DataIN1: The current value of the 32-bit counter, or the one stored in the latch (the selection is made with bit

CB1.1 [}33] of the control byte)

DataOUT1: Compare value for setting the comparator output (enabled by bit CB1.6 [}33] of the control

byte).

DataIN2: 32-bit latch

DataOUT2: Compare value for resetting the comparator output

• The meaning of the control and status bytes is explained on the Control and Status bytes [}33] page.

Note

No compact process image

Operation of the KL5151-0021 with compact process image (without control and status

bytes) is not possible, since the control and status bytes are required for useful process

data operation of the terminal. Even if you adjust your Bus Coupler to the compact process

image, the KL5151-0021 will still be represented with its complete process image!

6.2.2 Control and status bytes

Control byte 1 and status byte 1

Process data mode

Control byte 1 in process data mode

Control byte 1 (CB1) is located in the output image, and is transmitted from the controller to the terminal.

Bit CB1.7 CB1.6 CB1.5 CB1.4 CB1.3 CB1.2 CB1.1 CB1.0

Name RegAccess EnComp SetOut ReadLatchN ReadLatchP SetCnt EnMeas EnLatchC

KL5151/KS5151, KL5152/KS5152 33Version: 2.0.0

Page 34

Access from the user program

Legend

Bit Name Description

CB1.7 RegAccess 0

bin

Register communication off (process data mode)

CB1.6 EnComp 0

bin

Compare function for setting and resetting the output not enabled

1

bin

Compare function for setting and resetting the output enabled

CB1.5 SetOut 0

bin

sets output manually to 0 V SetOut only functions if EnComp =

0

bin

1

bin

sets output manually to 24 V

CB1.4 ReadLatchN 1

bin

Read the negative edge

CB1.3 ReadLatchP 1

bin

Read the positive edge

CB1.2 SetCnt A rising edge at SetCnt will set the counter to the 32 bit value that is written

by the controller into the process output data.

CB1.1 EnMeas 0

bin

Workpiece measurement

enabled

If the workpiece measurement is

enabled, it is read via CB1.3 and

CB1.4 and saved in two latch values.

1

bin

Workpiece measurement not

enabled

CB1.0 EnLatchC 1

bin

The rising edge of the zero input (input C [}19]) is active. The

counter value is stored in the latch register at the first external latch

impulse after the EnLatchC bit becomes true. The subsequent pulses

do not have any effect on the latch register. (see note below)

Note

EnLatchC or EnLatchRise and EnLatchFall?

If bit CB1.0 (EnLatchC) is set, bit CB1.3 (EnLatchRise) and bit CB1.4 (EnLatchFall) must

not be set, otherwise you cannot know which event has caused a counter value to be

stored in the latch.

Status byte 1 in process data mode

The status byte 1 (SB1) is located in the input image, and is transmitted from terminal to the controller.

Bit SB1.7 SB1.6 SB1.5 SB1.4 SB1.3 SB1.2 SB1.1 SB1.0

Name RegAccess - StOut StGate StLatchC SetCnt MeasDone ValLatchC

Legend

Bit Name Description

SB1.7 RegAccess 0

bin

Acknowledgement for process data mode

SB1.6 - reserved

SB1.5 StOut 0

bin

Status of the output is 0 V

1

bin

Status of the output is 24 V

SB1.4 StGate

Status of the external gate/latch input [}19]

SB1.3 StLatchC Status of the zero input (input C)

SB1.2 SetCnt Acknowledgement that the data for setting the counter has been adopted by

the terminal.

SB1.1 MeasDone 1

bin

Measurement done

SB1.0 ValLatchC 1

bin

A zero-point latch has occurred: a rising edge at the zero input (input

C [}19]) has caused the current counter value to be stored in the

latch register as a reference mark.

Subsequent pulses do not have any effect on the latch register. To

reactivate the gate/latch input [}19] you must:

• set bit 0 (EnLatchC) in the control byte to 0

bin

.

• wait until this change has been acknowledged by resetting bit 0

(ValLatchC) in the status byte.

• set bit 0 (EnLatchC) in the control byte to 1

bin

again.

KL5151/KS5151, KL5152/KS515234 Version: 2.0.0

Page 35

Access from the user program

Register communication

Control byte 1 in register communication

Control byte 1 (CB1) is located in the output image, and is transmitted from the controller to the terminal.

Bit CB1.7 CB1.6 CB1.5 CB1.4 CB1.3 CB1.2 CB1.1 CB1.0

Name RegAccess R/W Reg. no.

Legend

Bit Name Description

CB1.7 RegAccess 1

bin

Register communication switched on

CB1.6 R/W 0

bin

Read access

1

bin

Write access

CB1.5 to CB1.0 Reg. no. Register number:

Enter the number of the register [}44] that you

- want to read with input data word 0 or

- write to with output data word 0.

CAUTION

No valid process data during the register communication!

It is not possible to access the data registers during register communication! Process data

that may still be displayed is not valid!

Status byte 1 in register communication

The status byte 1 (SB1) is located in the input image, and is transmitted from terminal to the controller.

Bit SB1.7 SB1.6 SB1.5 SB1.4 SB1.3 SB1.2 SB1.1 SB1.0

Name RegAccess R Reg. no.

Legend

Bit Name Description

SB1.7 RegAccess 1

bin

Acknowledgement for register access

SB1.6 R 0

bin

Read access

SB1.5 to SB1.0 Reg. no. Number of the register that was read or written.

Control byte 2 and status byte 2

Control byte 2 and status byte 2 (CB2 and SB2) are not used.

6.3 KL5152-0000 (KL5150-0050)

6.3.1 Process image

The terminal can be operated with variously sized process images:

• compact process image

• compact process image on Bus Coupler that is set to complete process image (e.g. Lightbus)

• complete process image

The compact process image is activated in the delivery condition of the KL5151-0050. The size of the

process image can be specified through bit R32.6 [}46] of the feature register.

KL5151/KS5151, KL5152/KS5152 35Version: 2.0.0

Page 36

Access from the user program

Control byte, status byte and mapping

• The meaning of the control and status bytes is explained on the Control and Status bytes [}29] page.

• Please refer to the Mapping [}40] page for the allocation of the bytes and words to the addresses of

the controller.

Compact process image

For operation with compact process image, you must configure your Bus Coupler to compact mapping and

bit R32.6 [}46] of the feature register of the KL5151-0050 must be 1

bin

.

The KL5151-0050 is represented in the compact process image with 8 bytes of input data and 8 bytes of

output data. These are organized as follows:

Input data Output data

Format Contents Format Contents

Double

word

DataIN1 Byte

CB1PD [}29]

Byte reserved

Byte

CB2PD [}31]

Byte reserved

Double

word

DataIN2 Double

word

DataOUT

Legend

CB1PD: Control byte for process data operation of channel 1

CB2PD: Control byte for process data operation of channel 2

DataIN1: The current value of the 32-bit counter 1, or the one stored in the latch (the selection is made with

bit CB1.1 [}29] of the control byte 1)

DataIN2: The current value of the 32-bit counter 2, or the one stored in the latch (the selection is made with

bit CB2.1 [}31] of the control byte 2)

DataOUT: 32 bit specification of the value for counter 1 and counter 2

Note

No register communication possible

In this configuration the control bytes are suitable only for process data operation. Register

communication is not possible!

Complete process image

For operation with complete process image, you must configure your Bus Coupler to complete mapping and

bit R32.6 [}46] of the feature register of the KL5151-0050 must be 0

bin

.

The KL5151-0050 is represented in the complete process image with 10 bytes of input data and 10 bytes of

output data. These are organized as follows:

Input data Output data

Format Contents Format Contents

Byte

SB1 [}30]

Byte

CB1 [}29]

Double

word

DataIN1 Double

word

DataOUT1

Byte

SB2 [}31]

Byte

CB2 [}31]

Double

word

DataIN2 Double

word

DataOUT2

KL5151/KS5151, KL5152/KS515236 Version: 2.0.0

Page 37

Access from the user program

Legend

SB1: Status byte for channel 1

SB2: Status byte for channel 2

CB1: Control byte for channel 1

CB2: Control byte for channel 2

DataIN1: The current value of the 32-bit counter 1, or the one stored in the latch (the selection is made with

bit CB1.1 [}29] of the control byte 1)

DataIN2: The current value of the 32-bit counter 2, or the one stored in the latch (the selection is made with

bit CB2.1 [}31] of the control byte 2)

DataOUT1: 32 bit specification of the value for counter 1

DataOUT2: 32 bit specification of the value for counter 2

Note

Register communication possible

In this configuration you can use the control and status bytes alternatively for register communication or process data operation.

Compact process image on Bus Coupler that is set to complete process image

If the KL5151-0050 is operated on a Bus Coupler that is set by default to complete process image (e.g.

Lightbus), but bit R32.6 [}46] of the feature register is 1

bin

, the following process image results:

Input data Output data

Format Contents Format Contents

Byte

SB1RC [}31]

Byte

CB1RC [}30]

Double

word

DataIN1 Byte

CB1PD [}29]

Byte reserved

Byte

CB2PD [}31]

Byte reserved

Byte

SB2RC [}31]

Byte

CB2RC [}31]

Double

word

DataIN2 Double

word

DataOUT

Legend

SB1RC: Status byte for register communication with channel 1

SB2RC: Status byte for register communication with channel 2

CB1RC: Control byte for register communication with channel 1

CB2RC: Control byte for register communication with channel 2

CB1PD: Control byte for process data operation of channel 1

CB2PD: Control byte for process data operation of channel 2

DataIN1: The current value of the 32-bit counter 1, or the one stored in the latch (the selection is made with

bit CB1.1 [}29] of the control byte 1)

DataIN2: The current value of the 32-bit counter 2, or the one stored in the latch (the selection is made with

bit CB2.1 [}31] of the control byte 2)

DataOUT: 32 bit specification of the value for counter 1 and counter 2

Note

Register communication possible

In this configuration you have different control and status bytes for register communication

and process data operation. These are only suitable for the respectively specified purpose!

You can switch from process data operation to register communication with bit 7 of the control byte for register communication.

Bit 7 of the control byte for process data operation is not evaluated.

KL5151/KS5151, KL5152/KS5152 37Version: 2.0.0

Page 38

Access from the user program

6.3.2 Control and status bytes

Channel 1

Process data mode

Control byte 1 in process data mode

Control byte 1 (CB1) is located in the output image, and is transmitted from the controller to the terminal.

Bit CB1.7 CB1.6 CB1.5 CB1.4 CB1.3 CB1.2 CB1.1 CB1.0

Name RegAccess - RS_CNT_LATEnLatchFall EnLatchRise SetCnt ReadLatch EnLatchC

Legend

Bit Name Description

CB1.7 RegAccess 0

bin

Register communication off (process data mode)

CB1.6 - reserved

CB1.5 RS_CNT_LAT*1

bin

The counter is set to zero by an active edge at the latch input [}18].

Bits CB1.4, CB1.3 and CB1.0 specify which edge of the latch signal

is active.

CB1.4 EnLatchFall* 1

bin

The falling edge of the latch input [}18] is active. The counter value

is stored in the latch register at the first external latch impulse after

the EnLatchFall bit becomes true. The subsequent pulses do not

have any effect on the latch register.

CB1.3 EnLatchRise* 1

bin

The rising edge of the latch input [}18] is active. The counter value

is stored in the latch register on the first external latch pulse after the

EnLatchRise bit becomes true (this has priority over EnLatchFall).

The subsequent pulses do not have any effect on the latch register.

CB1.2 SetCnt A rising edge at SetCnt will set the counter to the 32 bit value that is written

by the controller into the process output data.

CB1.1 ReadLatch 0

bin

The current value of the 32 bit counter is mapped to the process

input data.

1

bin

The 32 bit value stored in the latch counter is mapped to the process

input data.

CB1.0 EnLatchC* 1

bin

The rising edge of the zero input (input C [}18]) is active. The

counter value is stored in the latch register at the first external latch

impulse after the EnLatchC bit becomes true. The subsequent pulses

do not have any effect on the latch register. (see note below)

*) Does not apply to KL5152-0000 (KL5151-0050), since the latch input and zero input are not available in

this case. Always set bits CB1.5, CB1.4, CB1.3 and CB1.0 of the KL5152-0000 (KL5151-0050) to 0

bin

!

Note

EnLatchC or EnLatchRise and EnLatchFall?

If bit CB1.0 (EnLatchC) is set, bit CB1.3 (EnLatchRise) and bit CB1.4 (EnLatchFall) must

not be set, otherwise you cannot know which event has caused a counter value to be

stored in the latch.

Status byte 1 in process data mode

The status byte 1 (SB1) is located in the input image, and is transmitted from terminal to the controller.

Bit SB1.7 SB1.6 SB1.5 SB1.4 SB1.3 SB1.2 SB1.1 SB1.0

Name RegAccess - - StGate StLatchC SetCnt ReadLatch ValLatchC

KL5151/KS5151, KL5152/KS515238 Version: 2.0.0

Page 39

Access from the user program

Legend

Bit Name Description

SB1.7 RegAccess 0

bin

Acknowledgement for process data mode

SB1.6 - reserved

SB1.5 - reserved

SB1.4 StGate

KL5151-0000: Status of the external gate/latch input [}18]

KL5152-0000 (KL5151-0050): reserved

SB1.3 StLatchC

KL5151-0000: Status of the zero input (input C [}18])

KL5152-0000 (KL5151-0050): reserved

SB1.2 SetCnt Acknowledgement that the data for setting the counter has been adopted

by the terminal.

SB1.1 ReadLatch 0

bin

The current value of the 32 bit counter has been mapped to the

process data.

1

bin

The 32 bit value stored in the latch counter has been mapped to the

process data.

SB1.0 ValLatchC* 1

bin

A zero-point latch has occurred: a rising edge at the zero input (input

C [}18]) has caused the current counter value to be stored in the

latch register as a reference mark.

Subsequent pulses do not have any effect on the latch register. To

reactivate the gate/latch input [}18] you must:

• set bit 0 (EnLatchC) in the control byte to 0

bin

.

• wait until this change has been acknowledged by resetting bit 0

(ValLatchC) in the status byte.

• set bit 0 (EnLatchC) in the control byte to 1

bin

again.

*) Does not apply to KL5152-0000 (KL5151-0050), since the latch input and zero input are not available in

this case.

Register communication

Control byte 1 in register communication

Control byte 1 (CB1) is located in the output image, and is transmitted from the controller to the terminal.

Bit CB1.7 CB1.6 CB1.5 CB1.4 CB1.3 CB1.2 CB1.1 CB1.0

Name RegAccess R/W Reg. no.

Legend

Bit Name Description

CB1.7 RegAccess 1

bin

Register communication switched on

CB1.6 R/W 0

bin

Read access

1

bin

Write access

CB1.5 to CB1.0 Reg. no. Register number:

Enter the number of the register [}44] that you

- want to read with input data word 0 or

- write to with output data word 0.

CAUTION

No valid process data during the register communication!

It is not possible to access the data registers during register communication! Process data

that may still be displayed is not valid!

KL5151/KS5151, KL5152/KS5152 39Version: 2.0.0

Page 40

Access from the user program

Status byte 1 in register communication

The status byte 1 (SB1) is located in the input image, and is transmitted from terminal to the controller.

Bit SB1.7 SB1.6 SB1.5 SB1.4 SB1.3 SB1.2 SB1.1 SB1.0

Name RegAccess R Reg. no.

Legend

Bit Name Description

SB1.7 RegAccess 1

bin

Acknowledgement for register access

SB1.6 R 0

bin

Read access

SB1.5 to SB1.0 Reg. no. Number of the register that was read or written.

Channel 2 (KL5152-0000 and KL5151-0050 only)

The control and status bytes of channel 2 (CB2 and SB2) have the same structure as the control and status

bytes of channel 1 [}38].

6.3.3 Mapping

The Bus Terminals occupy addresses within the process image of the controller. The assignment of process

data (input and output data) and parameterization data (control and status bytes) to the control addresses is

called mapping. The type of mapping depends on:

• the fieldbus system used

• the terminal type

• the parameterization of the Bus Coupler such as

- compact or full evaluation

- Intel or Motorola format

- word alignment switched on or off

• the parameterization of the KL5152-0000 (KL5151-0050) to compact or complete evaluation (bit R32.6

[}46] of the feature register)

The Bus Couplers (BKxxxx, LCxxxx) and Bus Terminal Controllers (BCxxxx, BXxxxx) are supplied with

certain default settings. The default setting can be changed with the KS2000 configuration software or with a

master configuration software (e.g. TwinCAT System Manager or ComProfibus).

The following tables show the mapping depending on different conditions. For information about the contents

of the individual bytes please refer to the pages Process image [}35] and Control and status byte [}29].

Compact evaluation

For operation with compact process image, you must configure your Bus Coupler to compact mapping and

bit R32.6 [}46] of the feature register of the KL5152-0000 (KL5151-0050) must be 1

bin

.

In this configuration the control bytes are suitable only for process data operation. Register communication is

not possible!

Compact evaluation in Intel format

Default mapping for CANopen, CANCAL, DeviceNet, ControlNet, Modbus, RS232 and RS485 coupler

KL5151/KS5151, KL5152/KS515240 Version: 2.0.0

Page 41

Access from the user program

Parameterization

of the Bus Coupler

Address Input data Output data

Word offset High byte Low byte High byte Low byte

Complete evaluation: no

Motorola format: no

Word alignment: n/a

0 DataIN1 D1 DataIN1 D0 reserved CB1PD

1 DataIN1 D3 DataIN1 D2 reserved CB2PD

2 DataIN2 D1 DataIN2 D0 DataOUT D1 DataOUT D0

3 DataIN2 D3 DataIN2 D2 DataOUT D3 DataOUT D2

Compact evaluation in Motorola format

Default mapping for PROFIBUS and Interbus coupler

Parameterization

of the Bus Coupler

Address Input data Output data

Word offset High byte Low byte High byte Low byte

Complete evaluation: no

Motorola format: yes

Word alignment: n/a

0 DataIN1 D2 DataIN1 D3 CB2PD reserved

1 DataIN1 D0 DataIN1 D1 CB1PD reserved

2 DataIN2 D2 DataIN2 D3 DataOUT D2 DataOUT D3

3 DataIN2 D0 DataIN2 D1 DataOUT D0 DataOUT D1

Complete evaluation

For operation with complete process image, you must configure your Bus Coupler to complete mapping and

bit R32.6 [}46] of the feature register of the KL5151-0050 must be 0

bin

.

In this configuration you can use the control and status bytes alternatively for register communication or

process data operation.

Complete evaluation in Intel format

Parameterization

of the Bus Coupler

Address Input data Output data

Word offset High byte Low byte High byte Low byte

Complete evaluation: yes

Motorola format: no

Word alignment: no

0 DataIN1 D0 SB1 DataOUT1 D0 CB1

1 DataIN1 D2 DataIN1 D1 DataOUT1 D2 DataOUT1 D1

2 SB2 DataIN1 D3 CB2 DataOUT1 D3

3 DataIN2 D1 DataIN2 D0 DataOUT2 D1 DataOUT2 D0

4 DataIN2 D3 DataIN2 D2 DataOUT2 D3 DataOUT2 D2

Complete evaluation in Motorola format

Parameterization

of the Bus Coupler

Address Input data Output data

Word offset High byte Low byte High byte Low byte

Complete evaluation: yes

Motorola format: yes

Word alignment: no

0 DataIN1 D3 SB1 DataOUT1 D3 CB1

1 DataIN1 D1 DataIN1 D2 DataOUT1 D1 DataOUT1 D2

2 SB2 DataIN1 D0 CB2 DataOUT1 D0

3 DataIN2 D2 DataIN2 D3 DataOUT2 D2 DataOUT2 D3

4 DataIN2 D0 DataIN2 D1 DataOUT2 D0 DataOUT2 D1

KL5151/KS5151, KL5152/KS5152 41Version: 2.0.0

Page 42

Access from the user program

Complete evaluation in Intel format with word alignment

Parameterization

of the Bus Coupler

Address Input data Output data

Word offset High byte Low byte High byte Low byte

Complete evaluation: yes

Motorola format: no

Word alignment: yes

0 reserved SB1 reserved CB1

1 DataIN1 D1 DataIN1 D0 DataOUT1 D1 DataOUT1 D0

2 DataIN1 D3 DataIN1 D2 DataOUT1 D3 DataOUT1 D2

3 reserved SB2 reserved CB2

4 DataIN2 D1 DataIN2 D0 DataOUT2 D1 DataOUT2 D0

5 DataIN2 D3 DataIN2 D2 DataOUT2 D3 DataOUT2 D2

Complete evaluation in Motorola format with word alignment

Parameterization

of the Bus Coupler

Address Input data Output data

Word offset High byte Low byte High byte Low byte

Complete evaluation: yes

Motorola format: yes

Word alignment: yes

0 reserved SB1 reserved CB1

1 DataIN1 D2 DataIN1 D3 DataOUT1 D2 DataOUT1 D3

2 DataIN1 D0 DataIN1 D1 DataOUT1 D0 DataOUT1 D1

3 reserved SB2 reserved CB2

4 DataIN2 D2 DataIN2 D3 DataOUT2 D2 DataOUT2 D3

5 DataIN2 D0 DataIN2 D1 DataOUT2 D0 DataOUT2 D1

Compact process image on Bus Coupler that is set to complete process image

If the KL5152-0000 (KL5151-0050) is operated on a Bus Coupler that is set by default to complete process

image (e.g. Lightbus), but bit R32.6 [}46] of the feature register is 1

bin

(default setting), the following process

image results:

In this configuration you have different control and status bytes for register communication and process data

operation. These are only suitable for the respectively specified purpose!

Intel format

Parameterization

of the Bus Coupler

Address Input data Output data

Word offset High byte Low byte High byte Low byte

Complete evaluation: yes

Motorola format: no

Word alignment: no

0 DataIN1 D0 SB1RC CB1PD CB1RC

1 DataIN1 D2 DataIN1 D1 CB2PD reserved

2 SB2RC DataIN1 D3 CB2RC reserved

3 DataIN2 D1 DataIN2 D0 DataOUT D1 DataOUT D0

4 DataIN2 D3 DataIN2 D2 DataOUT D3 DataOUT D2

Motorola format

Parameterization

of the Bus Coupler

Address Input data Output data

Word offset High byte Low byte High byte Low byte

Complete evaluation: yes

Motorola format: yes

Word alignment: no

0 DataIN1 D3 SB1RC reserved CB1RC

1 DataIN1 D1 DataIN1 D2 reserved CB2PD

2 SB2RC DataIN1 D0 CB2RC CB1PD

3 DataIN2 D2 DataIN2 D3 DataOUT D2 DataOUT D3

4 DataIN2 D0 DataIN2 D1 DataOUT D0 DataOUT D1

Intel format with word alignment

Default mapping for EtherCAT, Lightbus and Ethernet coupler as well as Bus Terminal Controllers (BCxxxx,

BXxxxx)

KL5151/KS5151, KL5152/KS515242 Version: 2.0.0

Page 43

Access from the user program

Parameterization

of the Bus Coupler

Address Input data Output data

Word offset High byte Low byte High byte Low byte

Complete evaluation: yes

Motorola format: no

Word alignment: yes

0 reserved SB1RC reserved CB1RC

1 DataIN1 D1 DataIN1 D0 reserved CB1PD

2 DataIN1 D3 DataIN1 D2 reserved CB2PD

3 reserved SB2RC reserved CB2RC

4 DataIN2 D1 DataIN2 D0 DataOUT D1 DataOUT D0

5 DataIN2 D3 DataIN2 D2 DataOUT D3 DataOUT D2

Motorola format with word alignment

Parameterization

of the Bus Coupler

Address Input data Output data

Word offset High byte Low byte High byte Low byte

Complete evaluation: yes

Motorola format: yes

Word alignment: yes

0 reserved SB1RC reserved CB1RC

1 DataIN1 D2 DataIN1 D3 CB2PD reserved

2 DataIN1 D0 DataIN1 D1 CB1PD reserved