Page 1

Operating instructions for

EP1908

TwinSAFE EtherCAT Box with eight fail-safe inputs

Version: 1.2.1

Date: 2015-03-11

Page 2

Page 3

Table of contents

Table of contents

1 Foreword 3

1.1 Notes on the manual 3

1.1.1 Disclaimer 3

1.1.2 Brands 3

1.1.3 Patents 3

1.1.4 Copyright 3

1.1.5 Delivery conditions 3

1.2 Safety instructions 4

1.2.1 Delivery state 4

1.2.2 Operator's obligation to exercise diligence 4

1.2.3 Description of safety symbols 5

1.2.4 Origin of the document 5

1.2.5 Documentation issue status 5

2 System description 6

2.1 EtherCAT Box Modules 6

3 Product description 7

3.1 EP1908-0002 7

3.2 Intended use 8

3.3 Technical data 9

3.4 Safety parameters 10

3.5 Dimensions 10

4 Operation 11

4.1 Installation 11

4.1.1 Safety instructions 11

4.1.2 Transport / storage 11

4.1.3 Address settings on the TwinSAFE EtherCAT Box 12

4.1.4 Mounting 13

4.1.5 Connection 14

4.2 Operating modes 21

4.3 EP1908 process image 23

4.4 Diagnostics 24

4.4.1 Run LED diagnostics 24

4.4.2 Diagnostic objects 25

EP1908-0002 1

Page 4

Table of contents

4.5 EL1908 configuration in the TwinCAT System Manager 27

4.5.1 Adding an EtherCAT device 27

4.5.2 Adding a EP1908 27

4.5.3 Entering a TwinSAFE address and parameters in the System Manager 28

4.6 Maintenance 37

4.6.1 Cleaning 37

4.6.2 Service life 37

4.7 Decommissioning 38

4.7.1 Disposal 38

5 Appendix 39

5.1 Protection classes according to IP code 39

5.1 Beckhoff Support and Service 40

5.1.1 Beckhoff branches and partner companies Beckhoff Support 40

5.1.2 Beckhoff company headquarters 40

5.2 Certificate 41

2

EP1908-0002

Page 5

Foreword

1 Foreword

1.1 Notes on the manual

This description is only intended for the use of trained specialists in control and automation technology

familiar with the applicable national standards. It is essential that the following notes and explanations are

followed when installing and commissioning these components.

The responsible staff must ensure that the application or use of the products described satisfy all the

safety requirements, including all the relevant laws, regulations, guidelines and standards.

1.1.1 Disclaimer

This documentation has been prepared with care. The products described are, however, constantly under

development. For this reason, the documentation may not always have been fully checked for

consistency with the performance data, standards or other characteristics described.

If it should contain technical or editorial errors, we reserve the right to make changes at any time and

without notice.

No claims for the modification of products that have already been supplied may be made on the basis of

the data, diagrams and descriptions in this documentation.

1.1.2 Brands

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE® and XFC® are registered

trademarks of and licensed by Beckhoff Automation GmbH.

The use by third parties of other brand names or trademarks contained in this documentation may lead to

an infringement of the rights of the respective trademark owner.

1.1.3 Patents

The EtherCAT technology is patent protected, in particular by the following applications and patents:

EP1590927, EP1789857, DE102004044764, DE102007017835 with the corresponding applications and

registrations in various other countries.

The TwinCAT technology is patent protected, in particular by the following applications and patents:

EP0851348, US6167425 with the corresponding applications and registrations in various other countries.

1.1.4 Copyright

©

Beckhoff Automation GmbH & Co. KG.

The copying, distribution and utilization of this document as well as the communication of its contents to

others without express authorization is prohibited. Offenders shall be held liable for damages. All rights

conferred by patent grant or registration of a utility model or registered design are reserved.

1.1.5 Delivery conditions

In addition, the general delivery conditions of the company Beckhoff Automation GmbH & Co. KG apply.

EP1908-0002 3

Page 6

Foreword

1.2 Safety instructions

1.2.1 Delivery state

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the

documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH & Co. KG.

1.2.2 Operator's obligation to exercise diligence

The operator must ensure that

• the TwinSAFE products are only used as intended (see section Product description);

• the TwinSAFE products are only operated in sound condition and in working order (see chapter

Cleaning).

• the TwinSAFE products are operated only by suitably qualified and authorized personnel.

• the personnel is instructed regularly about relevant occupational safety and environmental

protection aspects, and is familiar with the operating instructions and in particular the safety

instructions contained herein.

• the operating instructions are in good condition and complete, and always available for reference

at the location where the TwinSAFE products are used.

• none of the safety and warning notes attached to the TwinSAFE products are removed, and all

notes remain legible.

4

EP1908-0002

Page 7

Foreword

1.2.3 Description of safety symbols

The following safety symbols are used in these operating instructions. They are intended to alert the

reader to the associated safety instructions.

Serious risk of injury!

DANGER

WARNING

CAUTION

Attention

Note

Failure to follow the safety instructions associated with this symbol directly endangers

the life and health of persons.

Caution - Risk of injury!

Failure to follow the safety instructions associated with this symbol endangers the life

and health of persons.

Personal injuries!

Failure to follow the safety instructions associated with this symbol can lead to injuries

to persons.

Damage to the environment or devices

Failure to follow the instructions associated with this symbol can lead to damage to the

environment or equipment.

Tip or pointer

This symbol indicates information that contributes to better understanding.

1.2.4 Origin of the document

The operating instructions for the EP1908-0002 EtherCAT Box were originally written in German. All other

languages are derived from the German original.

1.2.5 Documentation issue status

Version Comment

1.2.1

1.2.0

1.1.2

1.1.1

1.1.0

• Certificate updated

• Company address amended

• Documentation versions added

• DateCode description added

• HFT and element classification according to EN 61508:2010 added

• Clock output currents in the technical data amended

• Notes regarding the M8 and M12 connectors expanded

• Reference to EN 60068-2-29 removed

• First released version

EP1908-0002 5

Page 8

System description

2 System description

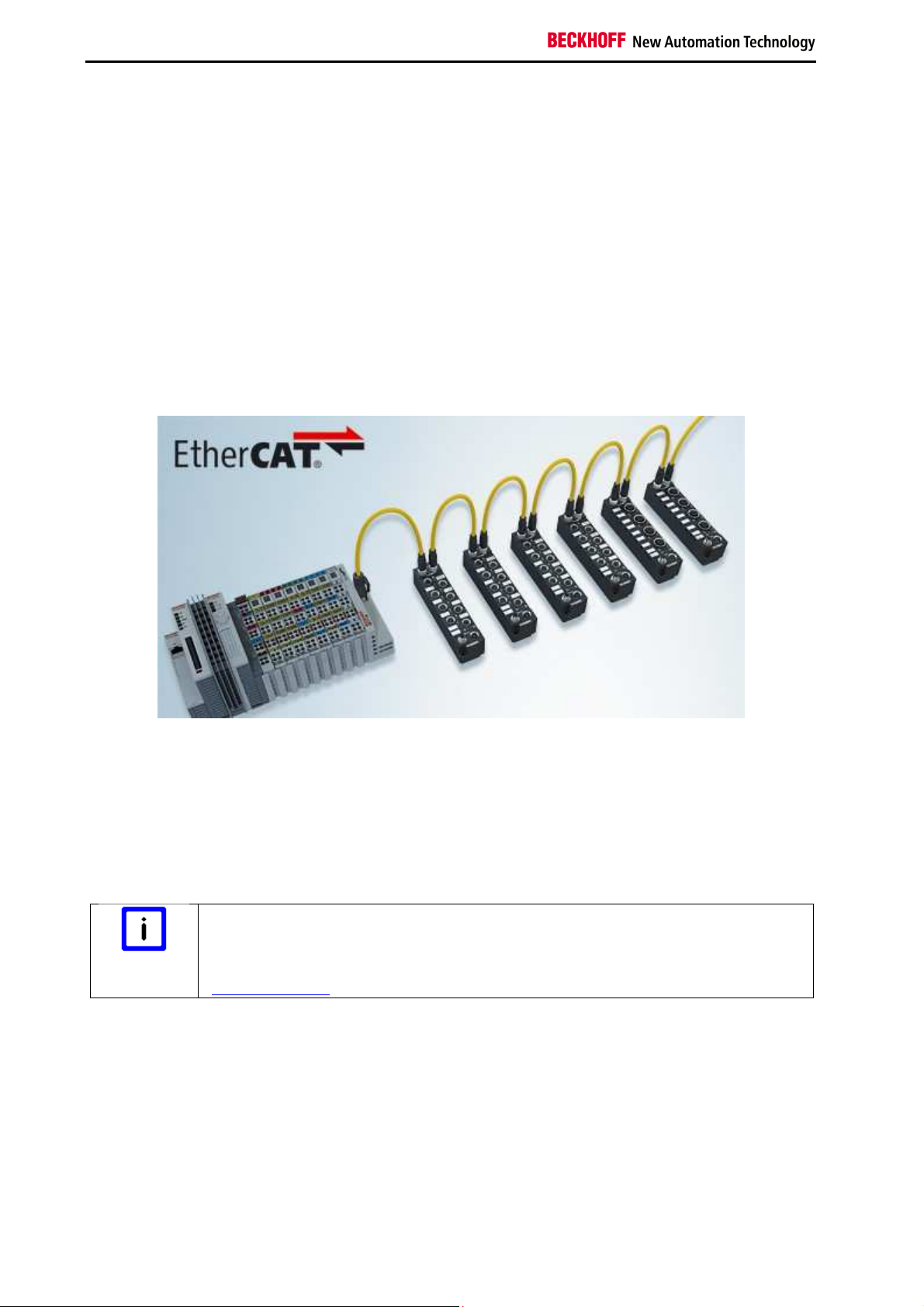

2.1 EtherCAT Box Modules

The EtherCAT system has been extended with EtherCAT Box modules with protection class IP 67.

Through the integrated EtherCAT interface the modules can be connected directly to an EtherCAT

network without an additional Coupler Box. The high-performance of EtherCAT is thus maintained into

each module.

The extremely low dimensions of only 126 x 30 x 26.5 mm (H x W x D) are identical to those of the

Fieldbus Box extension modules. They are thus particularly suitable for use where space is at a premium.

The small mass of the EtherCAT modules facilitates applications with mobile I/O interface (e.g. on a robot

arm). The EtherCAT connection is established via screened M8 connectors.

The robust design of the EtherCAT Box modules enables them to be used directly at the machine.

Control cabinets and terminal boxes are now no longer required. The modules are fully sealed and

therefore ideally prepared for wet, dirty or dusty conditions.

Pre-assembled cables significantly simplify EtherCAT and signal wiring. Very few wiring errors are made,

so that commissioning is optimized. In addition to pre-assembled EtherCAT, power and sensor cables,

field-configurable connectors and cables are available for maximum flexibility. Depending on the

application, the sensors and actuators are connected through M8 or M12 connectors.

Basic EtherCAT documentation

Note

You will find a detailed description of the EtherCAT system in the Basic System

Documentation for EtherCAT, which is available for download from our website

(www.beckhoff.de) under Downloads.

6

EP1908-0002

Page 9

Product description

3 Product description

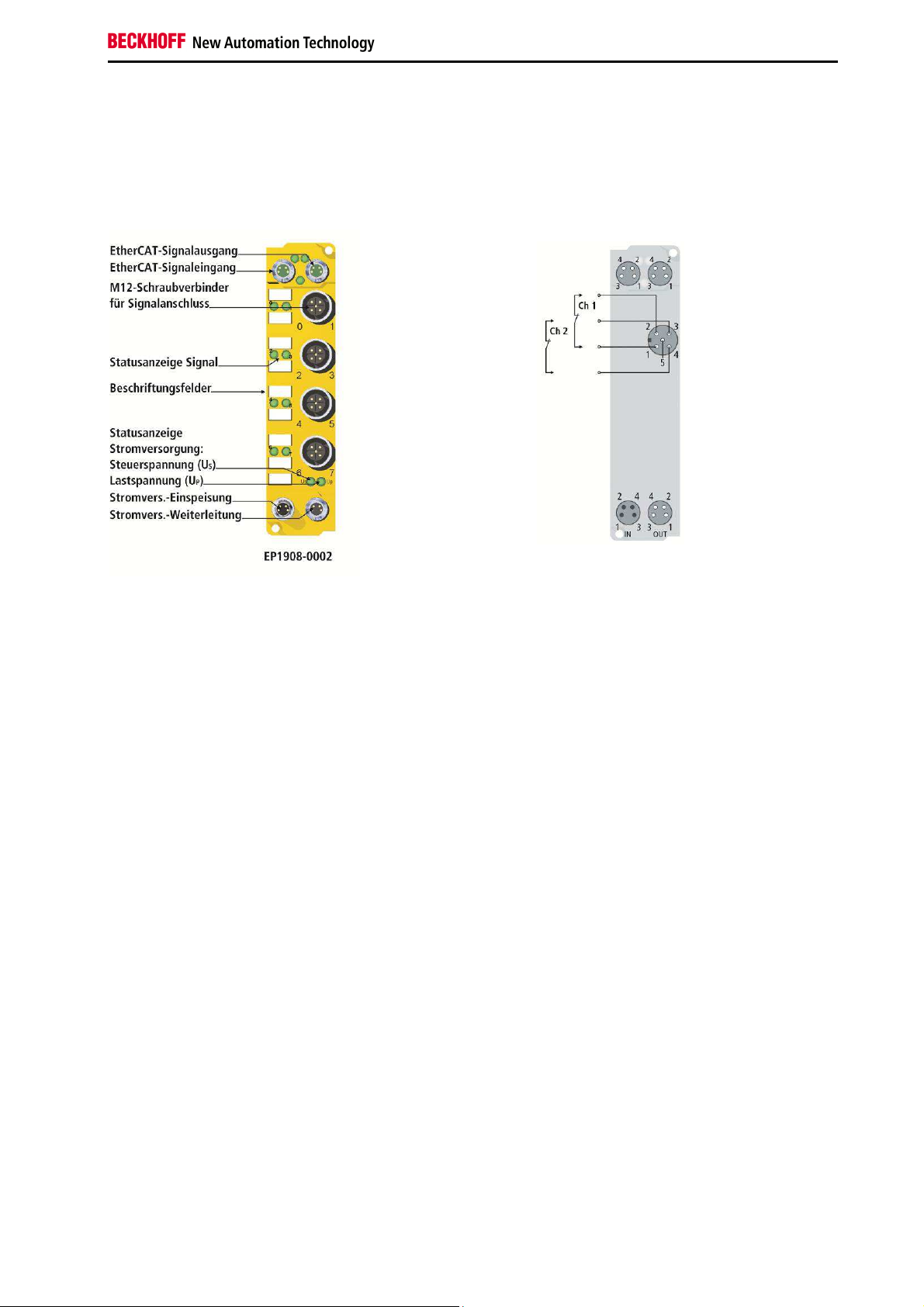

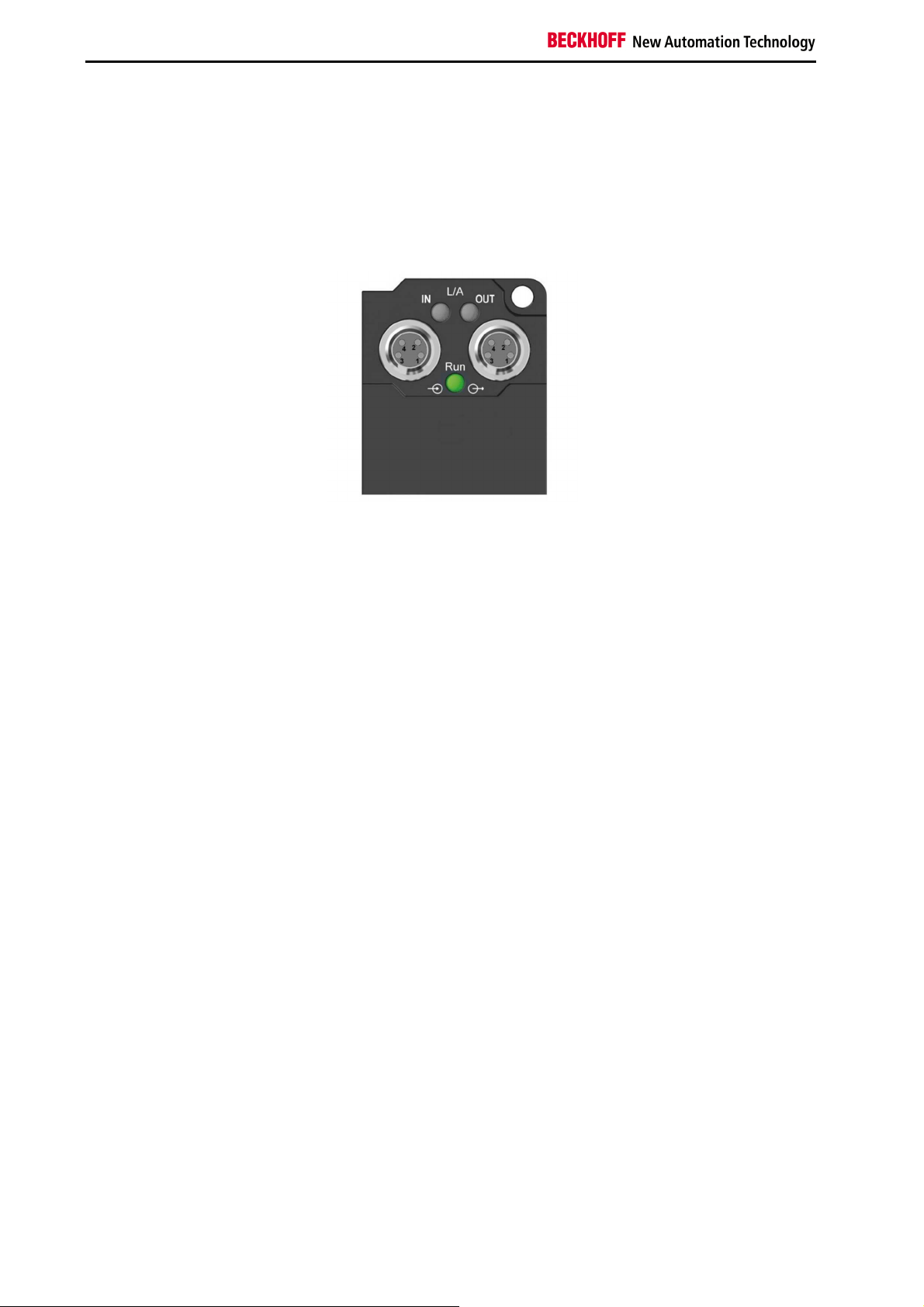

3.1 EP1908-0002

The EP1908-0002 is an EtherCAT Box with digital inputs for 24 VDC encoders or for potential-free

contacts. The EtherCAT Box has eight fail-safe inputs.

In addition to the possibility to read potential-free contacts, the EP1908-0002 also supports the

connection of encoders with OSSD signals whose test pulse length does not exceed 350 µs and of safety

mats that operate based on the cross-circuit principle.

Frequency measurement is also supported, in order to enable standstill and speed monitoring. The

frequency below which a logical 1 is reported at the input is specified in steps of 0.1 Hz. The module

supports a minimum frequency of 2 Hz and a maximum frequency of 500Hz. Frequencies above of 500

Hz result in a diagnostic message for the module. In this case all inputs are set to safe state (logical 0).

This message can be reset through a rising edge of the safe output signal ErrAck of the EP1908-0002.

With a two-channel connection, the EP1908-0002 meets the requirements of EN 61508-1:2010 SIL 3 and

DIN EN ISO 13849-1:2006 (Cat 4, PL e).

The control voltage US supplies the module electronics. The sensors are supplied from the control voltage

Up.

The TwinSAFE EtherCAT Box has the typical design of an EtherCAT Box.

EP1908-0002 7

Page 10

Product description

3.2 Intended use

Caution - Risk of injury!

WARNING

The TwinSAFE EtherCAT Box expands the application range of the Beckhoff system with functions that

enable it to be used for machine safety applications. The TwinSAFE Boxes are designed for machine

safety functions and directly associated industrial automation tasks. They are therefore only approved for

applications with a defined fail-safe state. This safe state is the wattless state. Fail-safety according to the

relevant standards is required.

The TwinSAFE EtherCAT Box allows the connection of:

• 24 VDC sensors such as

emergency stop push buttons, pull cord switches, position switches, two-hand switches, safety

mats, light curtains, light barriers, laser scanners etc.

• initiators and encoders for speed measurement (frequency) with a signal voltage of 24 VDC

WARNING

The TwinSAFE EtherCAT Box may only be used for the purposes described below!

The fail-safe principle

The basic rule for a safety system such as TwinSAFE is that failure of a part, a system

component or the overall system must never lead to a dangerous condition. The safe

state is always the switched off and wattless state.

Follow the machinery directive

CAUTION

CAUTION

The TwinSAFE EtherCAT Box may only be used in machines that meet the

requirements of the Machinery Directive.

Ensure traceability

The buyer has to ensure the traceability of the device via the serial number.

8

EP1908-0002

Page 11

Product description

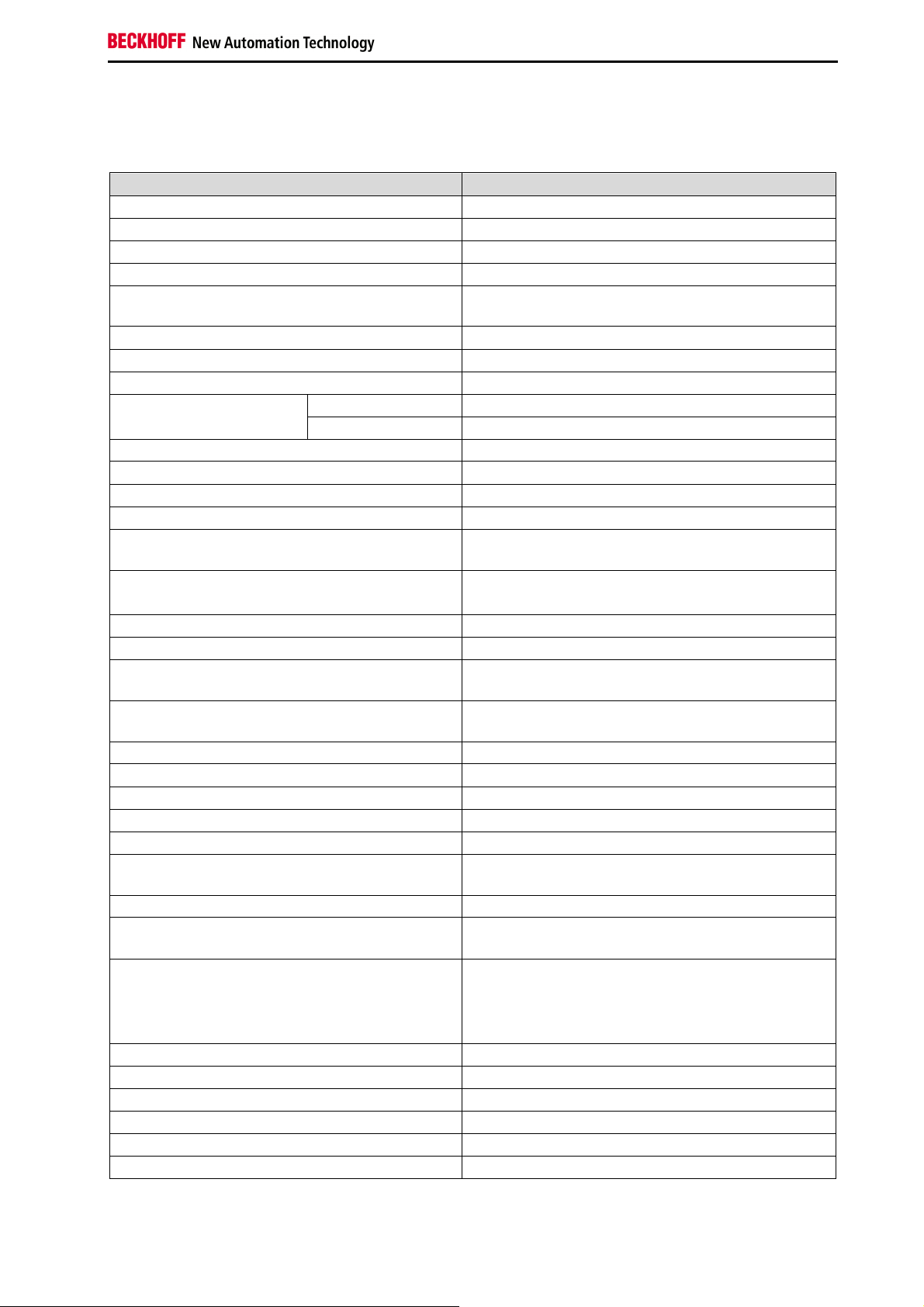

3.3 Technical data

Product designation EP1908-0002

Fieldbus EtherCAT

Number of inputs 8

Connecting the inputs M12

Status display 8 (one green LED per input)

Reaction time

(Read input/write to E-bus)

Watchdog time adjustable from 2 ms to 60 s

Error reaction time ≤ watchdog time

Frequency range for speed measurement 2 Hz to 500 Hz

Cable length between

sensor and EtherCAT Box

(unshielded) 30 m max.(at 0.75 or 1 mm²)

(shielded) 30 m max.(at 0.75 or 1 mm²)

Output current of the clock outputs typically 10 mA, max. 15 mA

Input process image 6 byte

Output process image 6 byte

Supply voltage for the EP1908 24 VDC (-15%/+20%)

Power consumption Us

(connected with eight potential-free contacts)

Current consumption UP

(connected with eight potential-free contacts)

Power dissipation of the EtherCAT Box typically 3 watts

Electrical isolation (between the channels) no

Electrical isolation (between the channels and

EtherCAT)

Insulation voltage (between the channels and

EtherCAT, under common operating conditions)

Dimensions (W x H x D) 30 mm x 126 mm x 26.5 mm

Housing material PA6-F (polyamide)

Sealing compound polyurethane

Weight approx. 170 g

Permissible ambient temperature (operation) -25 ℃ to +70 ℃

Permissible ambient temperature

(transport/storage)

Permissible air humidity 5 % to 95 %, non-condensing

Permissible air pressure

(operation/storage/transport)

Impermissible operating conditions

EMC immunity/emission according to EN 61000-6-2 / EN 61000-6-4

Vibration / shock resistance according to EN 60068-2-6 / EN 60068-2-27

Shocks 15 g with pulse duration 11 ms in all three axes

Protection class (when screwed together) IP65, IP66, IP67 (according to EN 60529)

Permissible installation position Variable

Approvals CE, TÜV SÜD

typically: 4 ms,

maximally: see error reaction time

8 channels occupied: typically 87 mA

0 channels occupied: typically 80 mA

8 channels occupied: approx. 27 mA

0 channels occupied: approx. 6 mA

yes

insulation tested with 500 VDC

-40 ℃ to +85 °C

750 hPa to 1100 hPa

TwinSAFE EtherCAT boxes must not be used under

the following conditions:

• under the influence of ionizing radiation

• in corrosive environments

EP1908-0002 9

Page 12

Product description

3.4 Safety parameters

Key figures EP1908-0002

Lifetime [a] 20

Prooftest Intervall [a] not required 1)

PFH 1.56E-09

%SIL3 1.56%

PFD 1.06E-04

%SIL3 10.59%

MTTFd [a] >100

Performance level PL e

Category 4

HFT 1

Element classification* Type A

*) Classification according to EN 61508-2:2010 (see chapters 7.4.4.1.2 and 7.4.4.1.3)

The EP1908-0002 EtherCAT Box can be used for safety-related applications according to IEC 61508 up

to SIL3 and EN ISO 13849-1 up to PL e (Cat4).

1)

Special proof tests throughout the service life of the EtherCAT Box are not required.

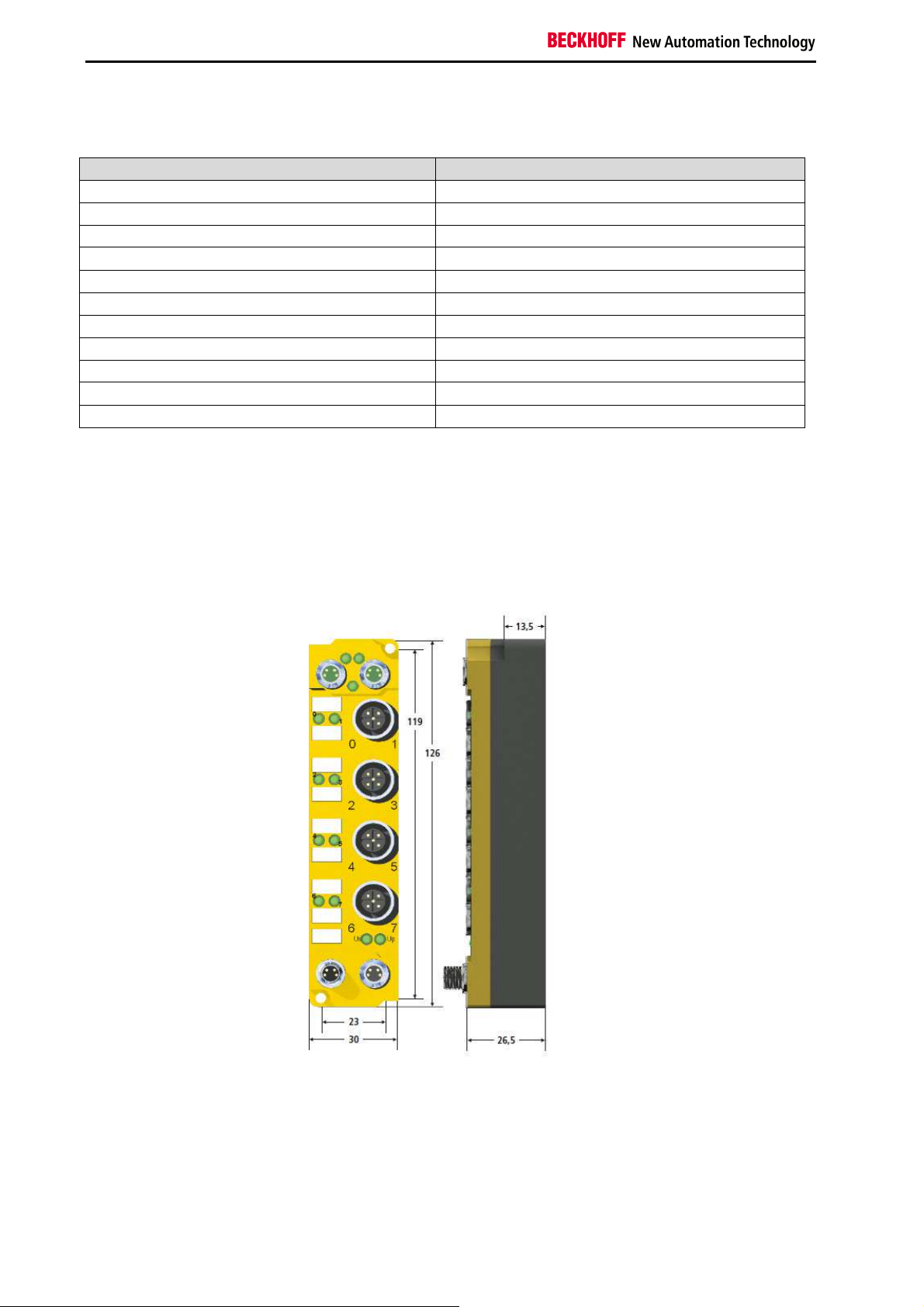

3.5 Dimensions

The EP1908 module has the following dimensions.

Width: 30 mm

Height: 126 mm

Depth: 26.5 mm

When fully wired, the connected cables increase the total depth of the module.

10

EP1908-0002

Page 13

Operation

4 Operation

Please ensure that the TwinSAFE Boxes are only transported, stored and operated under the specified

conditions (see technical data)!

Caution - Risk of injury!

The TwinSAFE EtherCAT boxes must not be used under the following conditions:

WARNING

4.1 Installation

4.1.1 Safety instructions

Read the safety notes in the Foreword of this document before installing and commissioning the

TwinSAFE EtherCAT Box.

• under the influence of ionizing radiation

• in corrosive environments

4.1.2 Transport / storage

When transporting or storing the TwinSAFE EtherCAT Box, always use the original packaging in which it

was delivered.

Note the specified environmental conditions

CAUTION

Please ensure that the digital TwinSAFE EtherCAT Boxes are only transported and

stored under the specified environmental conditions (see technical data).

EP1908-0002 11

Page 14

Operation

4.1.3 Address settings on the TwinSAFE EtherCAT Box

The TwinSAFE address of the box must be set using the three rotary switches at the bottom of the

EP1908-0002 TwinSAFE EP Box. TwinSAFE addresses between 1 and 4095 are available.

Rotary switch Address

1 (left) 2 (centre) 3 (right)

0 0 1 1

0 0 2 2

0 0 3 3

… … … …

0 0 F 15

0 1 0 16

0 1 1 17

… … … …

0 F F 255

1 0 0 256

1 0 1 257

… … … …

F F F 4095

Unique TwinSAFE address

Each TwinSAFE address may only be used once within a network! The address 0 is

WARNING

not a valid address.

12

EP1908-0002

Page 15

Operation

4.1.4 Mounting

Protect connectors against soiling

Note

The modules are mounted with two M3 screws. The bolts must be longer than 15 mm. The fixing holes

are not threaded. Note when mounting that the overall height is increased further by the fieldbus

connections.

4.1.4.1 Mounting rail ZS5300-0001

The mounting rail ZS5300-0001 (500 mm x 129 mm) allows time-saving configuration of the modules.

The rail is made of 1.5 mm thick stainless steel (V2A) and features ready-made M3 threads. Use M5

screws (5.3 mm oblong holes) to attach the rail to the machine.

Protect all connections from contamination during module installation!

Protection class IP67 can only be guaranteed if all cables and connectors are

connected!

Unused connections must be protected with the appropriate connectors (connector

sets see catalog)!

The rail is 500 mm long and enables the installation of 15 modules, with a distance of 2 mm between

them. It can be shortened as required for your particular application.

EP1908-0002 13

Page 16

Operation

4.1.5 Connection

4.1.5.1 Tightening torque for plug connectors

The plug connectors should be tightened with the recommended torque.

Type Connection Nm ft-lb

M8 Power supply, EtherCAT 0.4 0.3

M12 Input signals 0.6 0.44

Torque wrench

Ensure the proper torque is used

Note

Use torque wrenches available from Beckhoff to tighten the plug connectors (see

accessories)!

14

EP1908-0002

Page 17

Operation

4.1.5.2 EtherCAT connection

The EtherCAT Box (EPxxxx) has two M8 connectors marked green for the incoming and outgoing

EtherCAT connection.

Assignment

There are various different standards for the assignment and colors of connectors and cables for

EtherCAT.

EtherCAT Connector Cable Standard

Signal Description M8

ZB9010, ZB9020,

ZK1090-6292

ZB903x,

ZK1090-31xx

TIA-568B

Tx + Transmit Data+ Pin 1 yellow1 orange/white2 white/orange

Tx - Transmit Data- Pin 4 orange1 orange2 orange

Rx + Transmit Data- Pin 2 white1 blue/white2 white/green

Rx - Receive Data- Pin 3 blue1 blue2 green

Screen Shield Housing Screen Screen Screen

1

) Wire colors according to EN 61918

2

) Wire colors

EP1908-0002 15

Page 18

Operation

4.1.5.3 EtherCAT- Fieldbus LEDs

LED displays

LED Display Meaning

IN L/A off no connection to the preceding EtherCAT module

lit LINK: connection to the preceding EtherCAT module

flashing ACT: communication with the preceding EtherCAT module

OUT

L/A

off no connection to the following EtherCAT module

lit LINK: connection to the following EtherCAT module

flashing ACT: Communication with the following EtherCAT module

Run - see section 4.4.1

4.1.5.4 EtherCAT cables

For connecting EtherCAT devices only Ethernet cables that meet the requirements of at least category 5

(CAT5) according to EN 50173 or ISO/IEC 11801 should be used.

Wiring recommendations

Note

Detailed recommendations for EtherCAT wiring can be found in the documentation

"Design recommendations for EtherCAT/Ethernet infrastructure", which is available for

download from www.Beckhoff.com.

EtherCAT uses four cable wires for signal transmission. Due to automatic cable detection (auto-crossing)

symmetric (1:1) or cross-over cables can be used between EtherCAT devices from BECKHOFF.

16

EP1908-0002

Page 19

Operation

4.1.5.5 Power Connection

Two M8 connectors at the low-end of the modules are used for feeding and routing the supply voltages:

• IN: left M8 connector for feeding the supply voltages

• OUT: right M8 connector for routing the supply voltages

• Earthing screw: The earthing screw is installed in the factory. An additional M3 ring cable lug and

the earthing cable are required for the installation.

Pin assignment

Voltage

Contact

1 Control voltage Us, +24 VDC

2 Peripheral voltage Up, +24 VDC

3 GNDS

4 GNDP

Earthing connection

The contacts of the M8 plug connectors can conduct a maximum

current of 4 A.

Two LEDs indicate the status of the supply voltages.

Do not confuse the power port with EtherCAT port!

Attention

Never connect the power cables (M8, 24 VDC) to the green-marked EtherCAT sockets

of the EtherCAT Box Modules. This can cause the destruction of the modules!

Control voltage US: 24VDC

The control voltage US supplies the logic and communication parts of the module. It is galvanically

isolated from the fieldbus part.

Peripheral voltage UP: 24VDC

The peripheral voltage Up supplies the digital inputs; it can be brought in separately. If the load voltage is

switched off, the fieldbus function is preserved, but the input signals switch to safe state.

Redirection of the supply voltages

The power IN and OUT connections are bridged in the module. Hence, the supply voltages Us and Up can

be passed from EtherCAT Box to EtherCAT Box in a simple manner.

Note the maximum current!

Attention

Ensure that the maximum permitted current of 4 A for the M8 plug connectors is not

exceeded when routing the supply voltages US and UP!

EP1908-0002 17

Page 20

Operation

4.1.5.6 Status-LEDs for the power supply

LED Display Meaning

US (control voltage) off the power supply voltage, US, is not present

green

the power supply voltage, US, is present

illuminated

red

illuminated

The sensor supply was switched off due to an overload (current

> 0.5 A).

UP (peripheral voltage) off the power supply voltage, UP, is not present

green

The power supply voltage, UP, is present

illuminated

18

EP1908-0002

Page 21

Operation

4.1.5.7 Signal connection

M12 connection Contact Channel Signal

1 1 1 Pulse output 1

2 Input 1

3 2 Pulse output 2

4 Input 2

5 - not connected

2 1 3 Pulse output 3

2 Input 3

3 4 Pulse output 4

4 Input 4

5 - not connected

3 1 5 Pulse output 5

2 Input 5

3 6 Pulse output 6

4 Input 6

5 - not connected

4 1 7 Pulse output 7

2 Input 7

3 8 Pulse output 8

4 Input 8

5 - not connected

Configurable inputs

Note

The inputs 1 to 8 can be occupied as you want with normally closed contacts or

normally open contacts. The corresponding analysis is carried out in the safety PLC.

EP1908-0002 19

Page 22

Operation

Permitted cable length

When connecting a single switching contact via a dedicated continuous cable (or via a non-metallic

sheathed cable), the maximum permitted cable length is 30 m if a sensor test is active.

Route the signal cable separately

Attention

The signal cable must be routed separately from potential sources of interference, such

as motor supply cables, 230 VAC power cables etc.!

Interference caused by cables routed in parallel can influence the signal form of the

test pulses and thus cause diagnostic messages (e.g. sensor errors).

The common routing of signals together with other clocked signals in a common cable also reduces the

maximum propagation, since crosstalk of the signals can occur over long cable lengths and cause

diagnostic messages. The test pulses can be switched off (sensor test parameter) if the connection of a

common cable is unavoidable. However, this then leads to a reduction in the degree of diagnostic cover

when calculating the performance level.

The use of contact points, plug connectors or additional switching contacts in the cabling also reduces the

maximum propagation.

The typical length of a test pulse (switching from 24 V to 0 V and back to 24 V) is 350 µs and takes place

approx. 250 times per second.

20

EP1908-0002

Page 23

Operation

4.2 Operating modes

Operating mode Description

Single logic channel x/y Each channel is evaluated individually

Asynchronous analysis

OSSD, sensortest

deactivated

Any pulse repetition OSSD,

sensortest deactivated

Short cut channel x/y is no

module fault

Velocity control channel x /

Single logic channel y

Single logic channel x /

Velocity control channel y

Velocity control channel x/y

Two channel sync. Velocity

control channel x/y

Mode for connecting devices with OSSD signals. The test pulses of the

OSSD devices must not occur simultaneously. The maximum

supported test pulse length is 350 µs.

In this mode the sensor test must be switched off for the input pair

used.

Mode for connecting devices with OSSD signals. The test pulses of the

OSSD devices may occur simultaneously. The maximum supported

test pulse length is 350 µs.

In this mode the sensor test must be switched off for the input pair

used.

Mode for connecting safety mats. In this mode the two inputs of the

input pair used are monitored for cross-circuit. If a cross-circuit occurs

a person has walked on the safety mat, and the inputs report logical 0

in pairs.

The sensor test must be switched on for the inputs used.

Speed monitoring channel x / individual evaluation channel y

The first channel (x) returns a logical 1 if the current frequency is below

the frequency set under Velocity limit channel x.

The second channel (y) supplies the current signal state at input y.

The minimum supported frequency is 2 Hz. Values below this are

shown as 0. The maximum supported frequency is 500 Hz. Values

above this result in a diagnostic message of the EP1908-0002. This

message can be reset through a rising edge of the safe output signal

ErrAck of the EP1908-0002.

Individual evaluation channel x / Speed monitoring channel y

The first channel (x) reports the current signal state of input x.

The second channel (x) returns a logical 1 if the current frequency is

below the frequency set under Velocity limit channel y.

The minimum supported frequency is 2 Hz. Values below this are

shown as 0. The maximum supported frequency is 500 Hz. Values

above this result in a diagnostic message of the EP1908-0002. This

message can be reset through a rising edge of the safe output signal

ErrAck of the EP1908-0002.

Speed monitoring channel x / speed monitoring channel y

The first channel (x) returns a logical 1 if the current frequency is below

the frequency set under Velocity limit channel x.

The second channel (x) returns a logical 1 if the current frequency is

below the frequency set under Velocity limit channel y.

The minimum supported frequency is 2 Hz. Values below this are

shown as 0. The maximum supported frequency is 500Hz. Values

above this result in a diagnostic message of the EP1908-0002. This

message can be reset through a rising edge of the safe output signal

ErrAck of the EP1908-0002.

Two-channel evaluation of the frequency, whereby at least one input

signal always has to be at logical 1. The frequencies and the upper

limit frequencies have to be the same.

The two channels return logical 1 if the current frequency is below the

frequency set under Velocity limit channel x/y.

The minimum supported frequency is 2 Hz. Values below this are

shown as 0. The maximum supported frequency is 500 Hz. Values

above this result in a diagnostic message of the EP1908-0002. This

message can be reset through a rising edge of the safe output signal

ErrAck of the EP1908-0002.

EP1908-0002 21

Page 24

Operation

Operating mode Description

Two channel encoder

velocity control channel x/y

Two-channel evaluation of the frequency. The upper limit frequencies

are specified separately, but should but the same. The same

frequencies have to be supplied, whereby all states are permitted that

may occur at the encoder interface.

The two channels return logical 1 if the current frequency is below the

frequency set under Velocity limit channel x/y.

The minimum supported frequency is 2 Hz. Values below this are

shown as 0. The maximum supported frequency is 500 Hz. Values

above this result in a diagnostic message of the EP1908-0002. This

message can be reset through a rising edge of the safe output signal

ErrAck of the EP1908-0002.

Two channel async. velocity

control channel x/y

Two-channel evaluation of the frequencies. In this mode is only the

compliance with the limits for the two channels is monitored. The upper

limit frequencies are specified separately.

The two channels return logical 1 if both frequencies are below the

frequency set under Velocity limit channel x/y.

The minimum supported frequency is 2 Hz. Values below this are

shown as 0. The maximum supported frequency is 500 Hz. Values

above this result in a diagnostic message of the EP1908-0002. This

message can be reset through a rising edge of the safe output signal

ErrAck of the EP1908-0002.

Note

Speed / frequency measurement

The permitted frequency range is between 2 Hz and 500 Hz. Values below are

reported as 0 Hz, values above result in a diagnostic message of the EP1908-0002.

This diagnostic message can be reset through a rising edge at the safe output signal

ErrAck of the EP1908-0002.

22

EP1908-0002

Page 25

Operation

4.3 EP1908 process image

The process image of the EP1908-0002 consists of 6 bytes of input data and 6 bytes of output data.

These data contain the Safety over EtherCAT protocol. The eight safe input channels of the EP19080002 are contained in the safe input data. The first channel of the safe output data contains the ErrAck

signal, which can be used to reset a diagnostic message of the EP1908, such as exceeding of the

maximum allowable frequency.

EP1908-0002 23

Page 26

Operation

4.4 Diagnostics

4.4.1 Run LED diagnostics

The Run LED shows diagnostic information for the EP1908-0002.

4.4.1.1 Run LED (green)

The Run LED lights green when the EP1908-0002 has booted without error.

4.4.1.2 Run LED (red)

The Run LED lights red when the TwinSAFE EtherCAT Box has detected an error, such as cross-circuit,

external feed or exceeding of the maximum frequency.

24

EP1908-0002

Page 27

Operation

4.4.2 Diagnostic objects

The CoE objects indicate additional diagnostic information.

Do not change CoE objects!

Do not change any of the CoE objects in the TwinSAFE EtherCAT Boxes! Changes

CAUTION

4.4.2.1 CoE objects 0xA008 and 0xA009

(e.g. using the TwinCAT System Manager) in the CoE objects would permanently set

the TwinSAFE EtherCAT Boxes to Fail-Stop state!

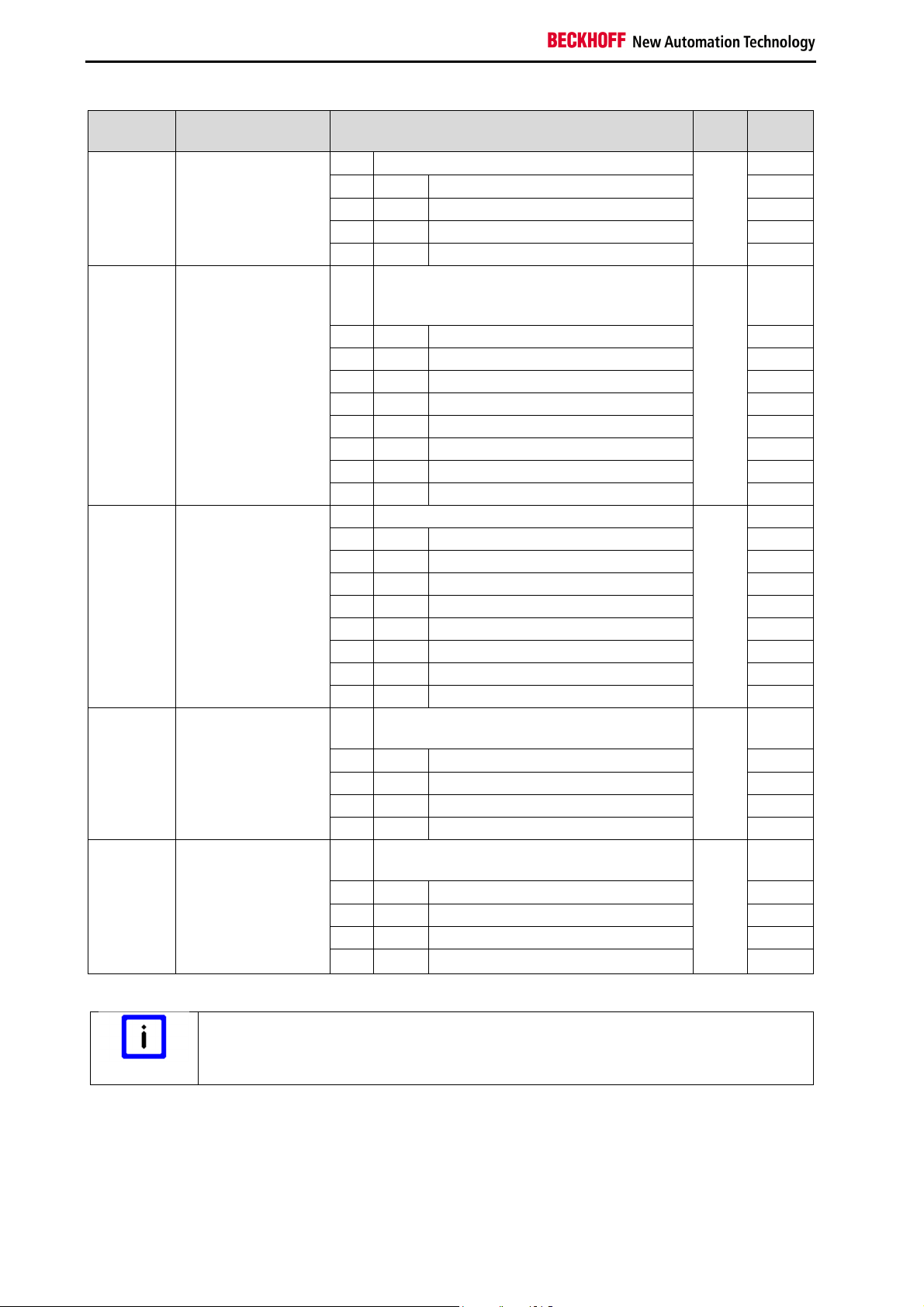

Index Name Meaning Flags

0xA008:0 FSOE Velocity

The following sub-indices contain the currently

RO

measured frequencies in 0.1 Hz.

0xA008:01 0xA008:08

0xA009:0

Velocity 1 -

Velocity 8

FSOE max

Velocity

Frequency at channels 1 to 8 in 0.1 Hz RO

The following sub-indices contain the maximum

RO

frequencies (in 0.1 Hz) determined since the last

startup of the TwinSAFE communication with the

EP1908-0002.

0xA009:01 0xA009:08

maxVelocity 1 maxVelocity 8

Maximum frequency at channels 1 to 8 in 0.1 Hz RO

4.4.2.2 CoE object 0x800E: diagnostic objects

Index Name Meaning Flags

800E:0 FSoE Internal Data

The following sub-indices contain detailed

RO

diagnostic information.

800E:0A Sensor test error Bit

Error during sensor test. This may be an

RO

external feed, for example.

800E:0B

Error during twochannel evaluation

0 1

1 1

2 1

3 1

4 1

5 1

6 1

7 1

Bit

Error at input 1 0

bin

Error at input 2 0

bin

Error at input 3 0

bin

Error at input 4 0

bin

Error at input 5 0

bin

Error at input 6 0

bin

Error at input 7 0

bin

Error at input 8 0

bin

Error during the contiguous evaluation of

RO

two channels, i.e. the two channels

contradict each other.

0 1

1 1

2 1

3 1

Error in the first input pair 0

bin

Error in the second input pair 0

bin

Error in the third input pair 0

bin

Error in the fourth input pair 0

bin

Default

value

Default

value

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

EP1908-0002 25

Page 28

Operation

Index Name Meaning Flags

800E:0C

800E:0D

800E:13

800E:14

800E:15

Error in the safety

mat operating

mode: input pair

disagree

Error in the safety

mat operating

mode: external

supply

Speed monitoring

error: Overspeed

Error in operating

mode: Two

Channel Sync

Velocity Control

Error in operating

mode: Two

Channel Sync

Velocity Control

and Two Channel

Encoder Velocity

Control

Bits Error in the input pair RO

1, 0 11

3, 2 11

5, 4 11

7, 6 11

Bit

Error in the first input pair 00

bin

Error in the second input pair 00

bin

Error in the third input pair 00

bin

Error in the fourth input pair 00

bin

Error in the test pulses in the safety mat

RO

operating mode; i.e. the EtherCAT Box has

detected an external supply.

0 1

1 1

2 1

3 1

4 1

5 1

6 1

7 1

Error at input 1 0

bin

Error at input 2 0

bin

Error at input 3 0

bin

Error at input 4 0

bin

Error at input 5 0

bin

Error at input 6 0

bin

Error at input 7 0

bin

Error at input 8 0

bin

Bit Overspeed was detected at an input. RO

0 1

1 1

2 1

3 1

4 1

5 1

6 1

7 1

Bit

Speed at input 1 is too high 0

bin

Speed at input 2 is too high 0

bin

Speed at input 3 is too high 0

bin

Speed at input 4 is too high 0

bin

Speed at input 5 is too high 0

bin

Speed at input 6 is too high 0

bin

Speed at input 7 is too high 0

bin

Speed at input 8 is too high 0

bin

Both inputs of an input pair were read with

RO

inactive state.

0 1

1 1

2 1

3 1

Bit

Error in the first input pair 0

bin

Error in the second input pair 0

bin

Error in the third input pair 0

bin

Error in the fourth input pair 0

bin

Different speeds were identified for the two

RO

inputs of an input pair.

0 1

1 1

2 1

3 1

Error in the first input pair 0

bin

Error in the second input pair 0

bin

Error in the third input pair 0

bin

Error in the fourth input pair 0

bin

Default

value

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

bin

26

Note

Differing diagnostic messages possible

Due to the variable order or execution of the test series, diagnostic messages differing

from those given in the table above are possible.

EP1908-0002

Page 29

Operation

4.5 EL1908 configuration in the TwinCAT System Manager

Do not change the register values!

Do not change any of the CoE objects in the TwinSAFE EtherCAT Boxes. Any

CAUTION

4.5.1 Adding an EtherCAT device

See TwinCAT automation software documentation.

4.5.2 Adding a EP1908

An EP1908-0002 is added in exactly the same way as any other Beckhoff EtherCAT Box. In the list open

the item Safety Terminals and select the EP1908-0002.

modifications (e.g. via the System Manager) of the CoE objects would permanently set

the EtherCAT Boxes to the Fail-Stop state!

EP1908-0002 27

Page 30

Operation

4.5.3 Entering a TwinSAFE address and parameters in the System Manager

The TwinSAFE address set at the rotary switch must be entered under the tab Safe Parameters (FSoE

Address entry) below the EP1908-0002. All other parameters can also be set there. They can also be

found under the respective TwinSAFE connection on the tab Safe Parameters.

28

EP1908-0002

Page 31

Operation

The connection-specific parameters are set in the respective TwinSAFE connection on the Connection

tab.

EP1908-0002 29

Page 32

Operation

Safe parameters overview

Parameter name Meaning Values

FSoE_Address

Address of the rotary switch or the setting

1 to 4095

in the EP1908

Operating Mode Digital Digital

Sensor test channel 1

active

Sensor test channel 2

active

Sensor test channel 3

active

Sensor test channel 4

active

Sensor test channel 5

active

Sensor test channel 6

active

Sensor test channel 7

active

Sensor test channel 8

active

The clock signal of channel 1 (pin 1) is

checked at the channel 1 input (pin 2).

The clock signal of channel 2 (pin 3) is

checked at the channel 2 input (pin 4).

The clock signal of channel 3 (pin 3) is

checked at the channel 1 input (pin 2).

The clock signal of channel 4 (pin 3) is

checked at the channel 4 input (pin 4).

The clock signal of channel 5 (pin 5) is

checked at the channel 1 input (pin 2).

The clock signal of channel 6 (pin 3) is

checked at the channel 6 input (pin 4).

The clock signal of channel 7 (pin 7) is

checked at the channel 1 input (pin 2).

The clock signal of channel 8 (pin 3) is

checked at the channel 8 input (pin 4).

TRUE / FALSE

TRUE / FALSE

TRUE / FALSE

TRUE / FALSE

TRUE / FALSE

TRUE / FALSE

TRUE / FALSE

TRUE / FALSE

Logic channel 1 and 2 Logic of channels 1 and 2 see operating modes table

Logic channel 3 and 4 Logic of channels 3 and 4 see operating modes table

Logic channel 5 and 6 Logic of channels 5 and 6 see operating modes table

Logic channel 7 and 8 Logic of channels 7 and 8 see operating modes table

Velocity limit channel 1 Upper frequency limit for channel 1 Frequency in 1/10 Hz

Velocity limit channel 2 Upper frequency limit for channel 2 Frequency in 1/10 Hz

Velocity limit channel 3 Upper frequency limit for channel 3 Frequency in 1/10 Hz

Velocity limit channel 4 Upper frequency limit for channel 4 Frequency in 1/10 Hz

Velocity limit channel 5 Upper frequency limit for channel 5 Frequency in 1/10 Hz

Velocity limit channel 6 Upper frequency limit for channel 6 Frequency in 1/10 Hz

Velocity limit channel 7 Upper frequency limit for channel 7 Frequency in 1/10 Hz

Velocity limit channel 8 Upper frequency limit for channel 8 Frequency in 1/10 Hz

Store Code

This parameter is required for the

0x0000

TwinSAFE Restore Mode

Project CRC

This parameter is required for the

0x0000

TwinSAFE Restore Mode

Identity internal use (read only)

Detected Modules internal use (read only)

30

EP1908-0002

Page 33

Operation

4.5.3.1 EP1908-0002 configuration for light barriers, light grids, light curtains, etc.

The EP1908-0002 also supports direct connection of contact-free protective devices with two self-testing

outputs such as light barriers, light grids, light curtains, laser scanners, etc.

Sensors with self-testing outputs

Only sensors with self-testing outputs and a maximum sensor self-test duration of

CAUTION

350 µs may be connected to the EP1908-0002.

Parameter

To connect these sensors please set the following parameters for the EP1908-0002 in the TwinCAT

System Manager:

• Connect the two sensor signals either to channels 1, 2 & 3 and 4, 5 & 6 or channels 7 & 8 and

activate asynchronous repetition OSSD or any pulse repetition for the two inputs used under

parameter Logic for channel x and y. The difference between these settings is that with any pulse

repetition simultaneous tests of the OSSD signals up to 350 µs are allowed.

• For the two inputs used set the sensor test for the EL1908-0002 to false.

4.5.3.2 EP1908-0002 configuration for safety switching mats

The EP1908-0002 also supports direct connection of safety mats that operate based on the cross-circuit

principle.

Parameter

To connect these safety mats please set the following parameters for the EP1908-0002 in the TwinCAT

System Manager:

• Connect the two sensor signals either to channels 1, 2 & 3 and 4, 5 & 6 or channels 7 & 8 and

activate the entry short cut channel x/y is no module fault for the two inputs used under

parameter Logic for channel x and y.

EP1908-0002 31

Page 34

Operation

4.5.3.3 Configuration of the EP1908-0002 for mode Velocity Control Channel x

The TwinSAFE EtherCAT Box also supports direct connection of initiators and encoders for speed

measurement or frequency (24 VDC).

If mode Velocity Control Channel x is set, a frequency is determined from two consecutive falling edges of

the respective input signal. This mode can be set for each channel individually.

If the current frequency is below the set limit frequency, the corresponding input channel returns a logical

1. If the frequency is above the set limit frequency, the corresponding channel returns a logical 0.

The minimum supported frequency is 2 Hz. Values below this are shown as 0. The maximum supported

frequency is 500 Hz. Values above this result in a diagnostic message of the EP1908-0002. This

message can be reset through a rising edge of the safe output signal ErrAck of the EP1908-0002.

Parameter:

• Connect the signals of the sensors used to the respective channel(s).

• Switch off the sensor test for the inputs used

(Sensor test Channel x active = FALSE)

• Set the parameter "Logic of Channel x and y" to

"velocity control channel x / single logic channel y" or

"single logic channel x / velocity control channel y" or

"velocity control channel x/y",

depending on which channel(s) of the input pair is to be used for this mode.

• Set the parameter Velocity limit channel x of the used channel to the required value. The entered

value has the unit 0.1 Hz.

Example for an input signal curve:

32

EP1908-0002

Page 35

Operation

Read the corresponding current frequencies via CoE Online (0xA008:01 to 0xA008:08).

EP1908-0002 33

Page 36

Operation

4.5.3.4 Configuration of the EP1908 for mode Two Channel Sync Velocity Control

The TwinSAFE EtherCAT Box also supports direct connection of initiators and encoders for speed

measurement or frequency (24VDC).

The set mode Two Channel SyncVelocity Control Channel x/y determines a frequency from the signals of

an input pair of the EP1908-0002, whereby one input signal always has to be set to logical 1. The

frequencies of the two input signals must be the same.

If the current frequency is below the limit frequency set for both channels (Velocity limit channel x/y), the

corresponding input pair returns a logical 1. If the frequency is above the set limit frequency, the

corresponding input pair returns a logical 0. The limit frequencies must be the same.

The minimum supported frequency is 2 Hz. Values below this are shown as 0. The maximum supported

frequency is 500 Hz. Values above this result in a diagnostic message of the EP1908-0002. This

message can be reset through a rising edge of the safe output signal ErrAck of the EP1908-0002.

Parameter:

• Connect the signals of the used sensors to input pairs 1 and 2, 3 and 4, 5 and 6 or 7 and 8

• Switch off the sensor test for the inputs used

(Sensor test Channel x active = FALSE)

• Set the parameter "Logic of Channel x and y" to

"Two Channel SyncVelocity Control Channel x/y"

• Set the parameters Velocity limit channel x and Velocity limit channel y of the used channels to

the required value. The entered value has the unit 1/10 Hz.

Example for a signal curve of the input signals:

34

EP1908-0002

Page 37

Operation

4.5.3.5 Configuration of the EP1908 for mode Two Channel Encoder Velocity Control

The TwinSAFE EtherCAT Box also supports direct connection of initiators and encoders for speed

measurement or frequency (24V DC).

The set mode Two Channel Encoder Velocity Control Channel x/y is used to determine a frequency from

the signals of an input pair of the EP1908-0002. The upper limit frequencies are specified separately, but

should but the same. The same frequencies have to be supplied, whereby all states are permitted that

may occur at the encoder interface.

If the current frequency is below the limit frequency set for both channels (Velocity limit channel x/y), the

corresponding input pair returns a logical 1. If the frequency is above the set limit frequency, the

corresponding input pair returns a logical 0.

The minimum supported frequency is 2 Hz. Values below this are shown as 0. The maximum supported

frequency is 500 Hz. Values above this result in a diagnostic message of the EP1908-0002. This

message can be reset through a rising edge of the safe output signal ErrAck of the EP1908-0002.

Parameter:

• Connect the signals of the used sensors/encoders to input pairs 1 and 2, 3 and 4, 5 and 6 or 7

and 8

• Switch off the sensor test for the inputs used (Sensor test Channel x active = FALSE)

• Set the parameter "Logic of Channel x and y" to

"Two Channel SyncVelocity Control Channel x/y"

• Set the parameters Velocity limit channel x and Velocity limit channel y of the used channels to

the required value. The entered value has the unit 1/10 Hz.

Example for a signal curve of the input signals:

EP1908-0002 35

Page 38

Operation

4.5.3.6 Configuration of the EP1908-0002 for mode Two Channel Async Velocity Control

The TwinSAFE EtherCAT Box also supports direct connection of initiators and encoders for speed

measurement or frequency (24VDC).

The set mode Two Channel AsyncVelocity Control Channel x/y is used to determine a frequency from the

signals of an input pair of the EP1908-0002. In this mode is only the compliance with the limits for the two

channels is monitored. The upper limit frequencies are specified separately.

The two channels return logical 1 if both frequencies are below the frequency set under Velocity limit

channel x/y.

If the current frequency of the two channels is below the set limit frequency (Velocity limit channel x/y) for

the respective channel, the corresponding input pair returns a logical 1. If the current frequency of a

channel is above the set limit frequency for this channel, the corresponding input pair returns a logical 0.

The minimum supported frequency is 2 Hz. Values below this are shown as 0. The maximum supported

frequency is 500 Hz. Values above this result in a diagnostic message of the EP1908-0002. This

message can be reset through a rising edge of the safe output signal ErrAck of the EP1908-0002.

Parameter:

• Connect the signals of the used sensors to input pairs 1 and 2, 3 and 4, 5 and 6 or 7 and 8

• Switch off the sensor test for the inputs used (Sensor test Channel x active = FALSE)

• Set the parameter "Logic of Channel x and y" to

"Two Channel Async Velocity Control Channel x/y"

• Set the parameters Velocity limit channel x and Velocity limit channel y of the used channels to

the required value. The entered value has the unit 1/10 Hz.

Example for a signal curve of the input signals:

36

EP1908-0002

Page 39

Operation

4.6 Maintenance

The TwinSAFE EtherCAT boxes are maintenance free!

Observe the specified environmental conditions!

WARNING

If the EtherCAT Box is operated outside the permitted temperature range it will switch to Global Fault

state. The state Global Fault can only be exited by switching the EtherCAT Box off and on again.

Please ensure that the TwinSAFE EtherCAT Boxes are only transported, stored and

operated under the specified conditions (see technical data)!

4.6.1 Cleaning

Protect the TwinSAFE EtherCAT Boxes from unacceptable soiling during operation and storage!

If the TwinSAFE EtherCAT Boxes were exposed to unacceptable soiling, they may no longer be

operated!

Have soiled EtherCAT Boxes checked!

WARNING

Cleaning of the TwinSAFE EtherCAT Boxes by the user is not allowed!

Please send soiled EtherCAT Boxes to the manufacturer for inspection and cleaning!

4.6.2 Service life

The TwinSAFE EtherCAT Boxes have a service life of 20 years.

Due to the high diagnostic coverage within the lifecycle no special proof tests are required.

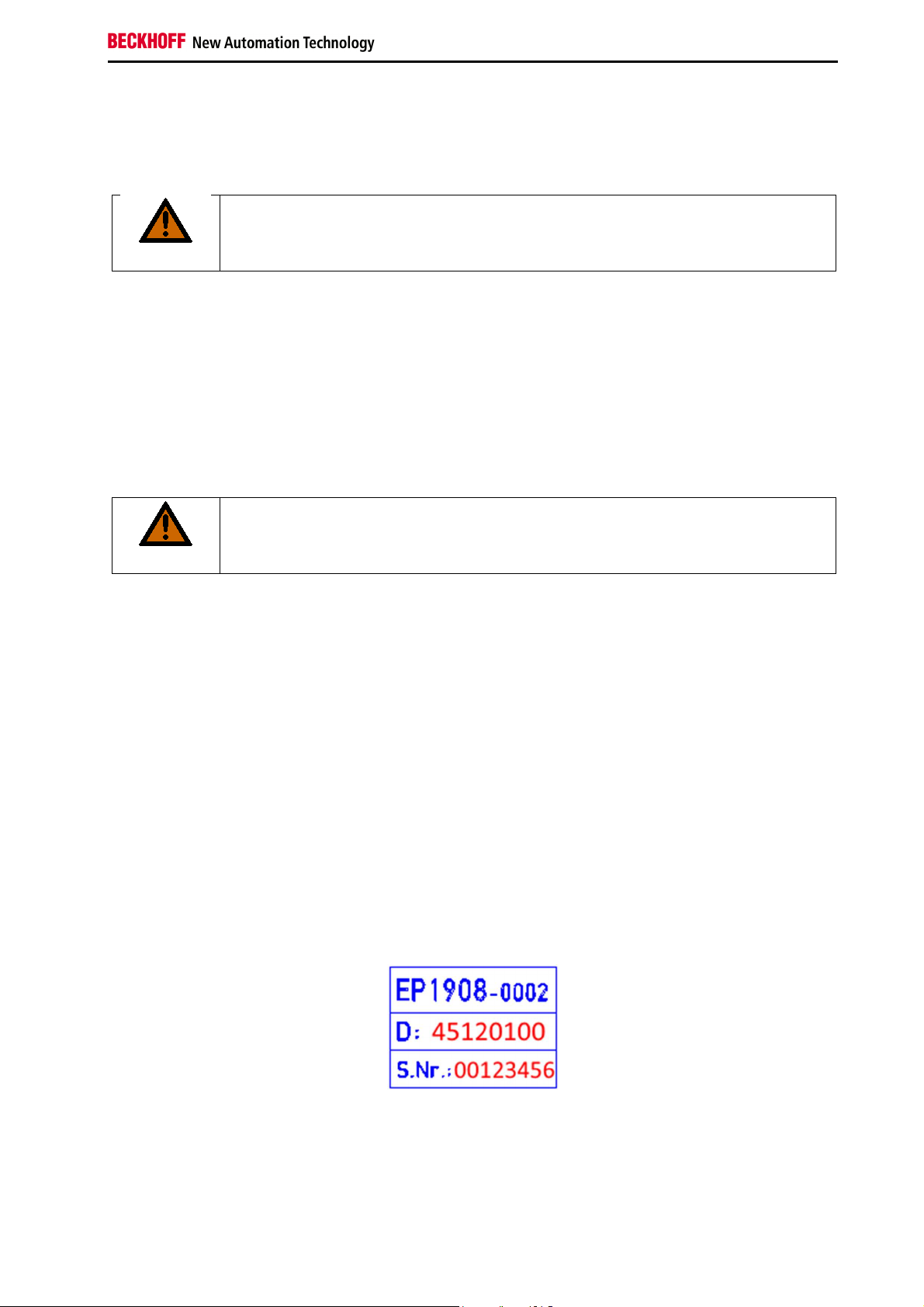

The TwinSAFE EtherCAT Boxes have a date code (D:), which is structured as follows:

Date code: CW YY SW HW

Legend:

CW: Calendar week of manufacture

YY: Year of manufacture

SW: Software version

HW: Hardware version

In addition, the TwinSAFE EtherCAT Boxes have a unique serial number (S.No.:).

Example: Date code 45 12 01 00

Calendar week: 45

Year: 2012

Software version: 01

Hardware version: 00

EP1908-0002 37

Page 40

Operation

4.7 Decommissioning

Serious risk of injury!

DANGER

Bring the bus system into a safe, de-energized state before starting disassembly of the

EtherCAT Boxes!

4.7.1 Disposal

The device must be removed for disposal.

• Housing parts (polyamide PA6-F) are suitable for plastics recycling

• Sealing compound (polyurethane resin)

• Metal parts can be sent for metal recycling.

• Electronic parts such as disk drives and circuit boards must be disposed of in accordance with

national electronics scrap regulations.

38

EP1908-0002

Page 41

Appendix

5 Appendix

5.1 Protection classes according to IP code

Protection classes defining different degrees of protection are specified in IEC 60529 (DIN EN 60529) as

follows:

1st digit: Protection

against ingress of

dust and access to

hazardous parts

0 Non-protected

1

2

3

4

5

6

2nd digit: Protection

against ingress of

water*

0 Non-protected.

1 Protection against dripping water.

2 Protection against dripping water when housing tilted up to 15°.

3

4

5 Protection against jetting.

6 Protection against powerful jetting.

7

*) These protection classes only define protection against water, not against other liquids.

Meaning

Protection against access to hazardous parts with back of hand. Protection

against ingress of solid foreign objects = 50 mm diameter

Protection against access to hazardous parts with a finger. Protection against

ingress of solid foreign objects = 12.5 mm diameter

Protection against access to hazardous parts with a tool. Protection against

ingress of solid foreign objects = 2.5 mm diameter

Protection against access to hazardous parts with a wire. Protection against

ingress of solid foreign objects = 1 mm diameter

Protection against access to hazardous parts with a wire. Protection against

ingress of dust. Ingress of dust is not prevented completely, although the

quantity of dust able to penetrate is limited to such an extent that the proper

function of the device and safety are not impaired

Protection against access to hazardous parts with a wire. Dust-proof. No

ingress of dust

Meaning

Protection against spraying. Water sprayed at an angle of up to 60° from

vertical must not have any adverse effect.

Protection against splashing. Water splashing against the housing from any

direction must not have any adverse effects.

Protection against the effects of temporary immersion. The quantity of water

being able to penetrate if the housing is submerged in water for 30 minutes at

a depth of 1 m must not have any adverse effects.

EP1908-0002 39

Page 42

Appendix

5.1 Beckhoff Support and Service

Beckhoff and their partners around the world offer comprehensive support and service, making available

fast and competent assistance with all questions related to Beckhoff products and system solutions.

5.1.1 Beckhoff branches and partner companies Beckhoff Support

Please contact your Beckhoff branch office or partner company for local support and service on Beckhoff

products!

The contact addresses for your country can be found in the list of Beckhoff branches and partner

companies: www.beckhoff.com. You will also find further documentation for Beckhoff components there.

5.1.2 Beckhoff company headquarters

Beckhoff Automation GmbH & Co.KG

Huelshorstweg 20

33415 Verl

Germany

Phone: + 49 (0) 5246/963-0

Fax: + 49 (0) 5246/963-198

E-mail: info@beckhoff.com

Web: www.beckhoff.com

Beckhoff Support

Support offers you comprehensive technical assistance, helping you not only with the application of

individual Beckhoff products, but also with other, wide-ranging services:

• world-wide support

• design, programming and commissioning of complex automation systems

• and extensive training program for Beckhoff system components

Hotline: + 49 (0) 5246/963-157

Fax: + 49 (0) 5246/963-9157

E-mail: support@beckhoff.com

Beckhoff Service

The Beckhoff Service Center supports you in all matters of after-sales service:

• on-site service

• repair service

• spare parts service

• hotline service

Hotline: + 49 (0) 5246/963-460

Fax: + 49 (0) 5246/963-479

E-mail: service@beckhoff.com

40

EP1908-0002

Page 43

Appendix

5.2 Certificate

EP1908-0002 41

Loading...

Loading...