Page 1

EL9800 Base Board

Version: 3.07

Date: 2013-10-16

Page 2

Page 3

Content

Content

1 Legal Notice 5

1.1 Trademarks 5

1.2 Patent Pending 5

1.3 Disclaimer 5

1.4 Copyright 5

1.5 Safety Instructions 6

1.5.1 Delivery Status 6

1.5.2 Description of safety symbols 6

1.6 Documentation issue status 7

2 Product overview 8

2.1 Power Supply 9

2.2 Process Data Interface for EtherCAT postage stamps 10

2.2.1 Process data interface dependent pinout of the headers J202 and TP202 11

2.3 PDI-Selection 12

2.4 8/16 Bit µC-PDI-Interface 14

2.5 32 Bit Digital-PDI-Interface 17

2.6 PIC PDI-Interface 19

2.7 SPI-PDI-Interface 22

2.8 Distributed Clocks 22

2.9 FPGA-Programmer 23

2.10 PIC-Programmer 24

3 Altera Quartus II Programmer™ 26

3.1 Selecting the programming hardware 27

3.2 Conversion of a SOF-File in the JIC-file format 28

3.3 Choosing the programming file 30

3.4 Programming of the FPGA/EEPROM 30

4 Appendix 31

4.1 Support and Service 31

4.1.1 Beckhoff's branch offices and representatives 31

4.2 Beckhoff Headquarters 31

EL9800 1

Page 4

Content

TABLES

Table 1 Pinout of the headers J202 and TP202 ......................................................................................... 11

Table 2 Positions of the PDI-Selector ......................................................................................................... 12

Table 3 Pinout of the connectors TP208 and J208 .................................................................................... 16

Table 4 Pinout of the connector TP206 ...................................................................................................... 16

Table 5 Port configuration of the digital PDI ............................................................................................... 17

Table 6 Definition of the OE_CONF and OE_EXT signals ......................................................................... 17

Table 7 Pinout of the connectors TP207 and J207 .................................................................................... 18

Table 8 Pinout of the connector J900 ......................................................................................................... 19

Table 9 Location of the inputs and output ports on the PIC- ...................................................................... 20

Table 10 Connection of SPI-interface, EEPROM and programming interface with the PIC24H ............... 20

Table 11 Pinout of the connectors TP209 and J209 .................................................................................. 20

Table 12 Pinout of the connector J510 ....................................................................................................... 21

Table 13 Pinout of the connector J1005 ..................................................................................................... 21

Table 14 Pinout of the connectors TP204 and J204 .................................................................................. 22

2 EL9800

Page 5

Content

FIGURES

Figure 1 Overview about the EL9800 ............................................................................................................8

Figure 2 Power Supply ..................................................................................................................................9

Figure 3 Pinout of the header J1203 .............................................................................................................9

Figure 4 Header J1200 – Selection of the PDI header voltage .....................................................................9

Figure 5 Connection area fort he EtherCAT postage stamp ...................................................................... 10

Figure 6 Pinout of the connectors J202 and TP202 ................................................................................... 10

Figure 7 PDI-Selection Area ....................................................................................................................... 12

Figure 8 Pinout of the connector J1201 ..................................................................................................... 13

Figure 9 µ-Controller PDI-Interface ............................................................................................................ 14

Figure 10 Power pins on the connectors TP208 and J208 ........................................................................ 14

Figure 11 Digital IO PDI-Interface .............................................................................................................. 17

Figure 12 Voltages on the headers TP207 und J207 ................................................................................. 19

Figure 13 PIC PDI-Interface ....................................................................................................................... 19

Figure 14 Configuration and Status-Area of the Distributed Clocks .......................................................... 22

Figure 15 FPGA Programming Interface .................................................................................................... 23

Figure 16 PIC Programming Interface ........................................................................................................ 24

Figure 17 Quartus II Programmer™ ........................................................................................................... 26

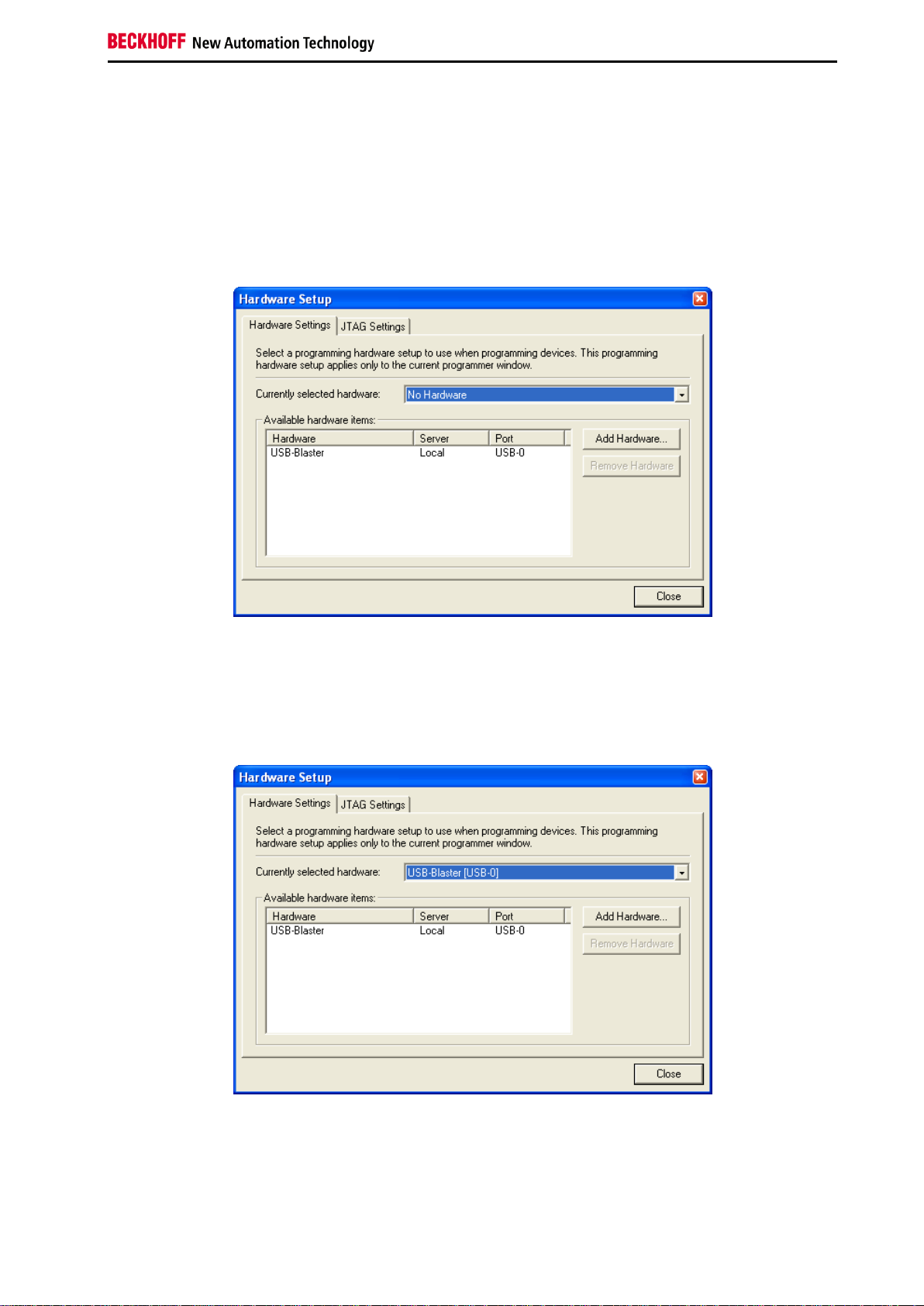

Figure 18 Hardware Setup Dialog .............................................................................................................. 27

Figure 19 Setup Dialog – USB Blaster selected......................................................................................... 27

Figure 20 Quartus II Programmer Dialog after „Auto-Detect“ processing .................................................. 28

Figure 21 Convert Programming Files ....................................................................................................... 29

Figure 22 Selection of the programming file ............................................................................................... 30

EL9800 3

Page 6

Content

DC

Direct Current

EEPROM

Electrically Erasable Programmable Read Only Memory. Non-volatile memory used

to store ESC configuration and description.

ESC

EtherCAT Slave Controller

EtherCAT

Real-time Standard for Industrial Ethernet Control Automation Technology

GND-Earth

Ground-Earth

LED

Light Emitting Diode, used as an indicator

PCB

Printed Circuit Board

PDI

Process Data interface

SPI

Serial Peripheral Interface

RJ45

FCC Registered Jack, standard Ethernet connector (8P8C)

ABBREVIATIONS

4 EL9800

Page 7

Legal Notice

1 Legal Notice

1.1 Trademarks

Beckhoff®, TwinCAT®, EtherCAT®, Safety over EtherCAT®, TwinSAFE® and XFC® are registered trademarks of and licensed by Beckhoff Automation GmbH. Other designations used in this publication may be

trademarks whose use by third parties for their own purposes could violate the rights of the owners.

1.2 Patent Pending

The EtherCAT Technology is covered, including but not limited to the following German patent applications and patents: DE10304637, DE102004044764, DE102005009224, DE102007017835 with corresponding applications or registrations in various other countries.

1.3 Disclaimer

The documentation has been prepared with care. The products described are, however, constantly under

development. For that reason the documentation is not in every case checked for consistency with performance data, standards or other characteristics. In the event that it contains technical or editorial errors,

we retain the right to make alterations at any time and without warning. No claims for the modification of

products that have already been supplied may be made on the basis of the data, diagrams and descriptions in this documentation.

1.4 Copyright

© Beckhoff Automation GmbH 05/2009.

The reproduction, distribution and utilization of this document as well as the communication of its contents

to others without express authorization are prohibited. Offenders will be held liable for the payment of

damages. All rights reserved in the event of the grant of a patent, utility model or design.

EL9800 5

Page 8

Legal Notice

DANGER

Acute risk of injury!

If you do not adhere the safety advise adjoining this symbol, there is immediate danger

to life and health of individuals!

WARNING

Risk of injury!

If you do not adhere the safety advise adjoining this symbol, there is danger to life and

health of individuals!

CAUTION

Hazard to individuals, environment and devices!

If you do not adhere the safety advise adjoining this symbol, there is obvious hazard to

individuals, environment and materials!

Note

Note or pointer

This symbol indicates information that contributes to better understanding.

1.5 Safety Instructions

Consider the following safety instructions and descriptions!

Product specific safety instructions are to be found on the following pages or in the areas mounting, wiring, commissioning etc.

1.5.1 Delivery Status

All the components are supplied in particular hardware and software configurations appropriate for the

application. Modifications to hardware or software configurations other than those described in the documentation are not permitted, and nullify the liability of Beckhoff Automation GmbH. Product specific safety

instructions are to be found on the following pages or in the areas mounting, wiring, commissioning etc.

1.5.2 Description of safety symbols

The following safety symbols are used in this documentation. They are intended to alert the reader to the

associated safety instructions.

6 EL9800

Page 9

Legal Notice

Version

Comment

3.0.0

First version

3.0.1

Pinout of headers J202 and TP202 added

3.0.2

CPU_CLK_IN added in Table 1

3.0.3

Signal level information added

3.0.4

Changed J1202 to J1201 in Figure 8

3.0.5

A13, nTA and nTS added in Table 3

3.0.6

Changes in chapter 2.10 related to hex file import

3.0.7

RB7 in Table 11 changed to “Not Connected”

1.6 Documentation issue status

EL9800 7

Page 10

Product overview

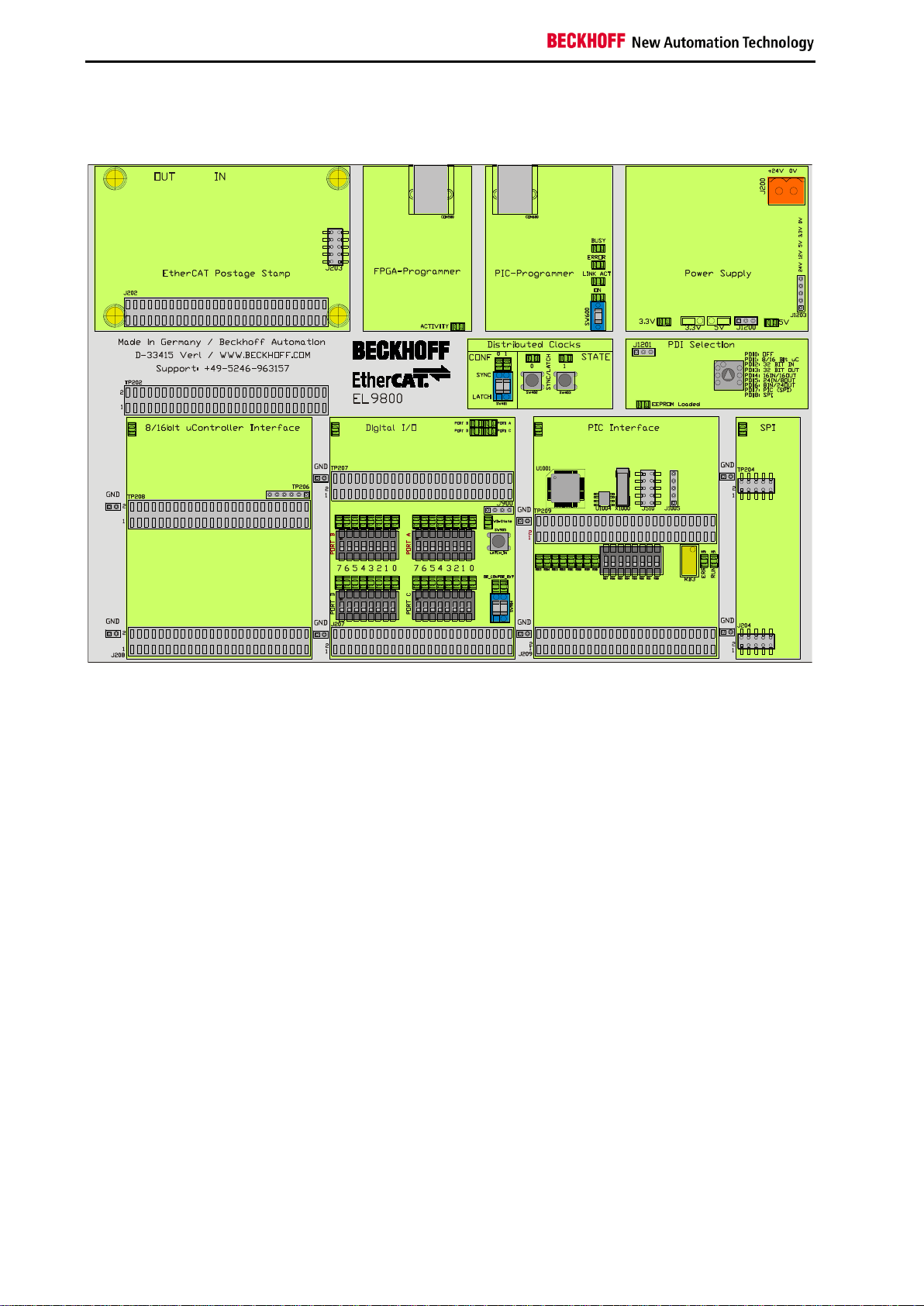

2 Product overview

Figure 1 Overview about the EL9800

On this EtherCAT Evaluation Kit base board all supported Process Data Interfaces (PDI) of the EtherCAT

Slave-Controllers (ESCs) can be evaluated and used for prototypic implementations. All EtherCAT postage stamps with the base name FB1XXX are compatible with this base board and can be used directly

without adaptation. Separate documentations for each EtherCAT piggy back controller board are available for download and can also be found on the EtherCAT Evaluation Kit CD.

Figure 1 gives an overview of the EL9800 base board that supports four physical, configurable Process

Data Interfaces. The following PDI variants area available

SPI-Interface

SPI-Interface with PIC

32 Bit digital interface

µ-Controller interface

As a user interface for changing the PDI to be used, a manual switch with eight different PDI configurations can be used.

For programming and debugging purposes different interfaces for FPGA-based EtherCAT piggy back

controller boards and the integrated PIC24, manufactured by Microchip, are integrated on the board. Furthermore an area for Sync/Latch configuration, monitoring and manipulation allows the user to interact

with the board. The integrated power supply is capable of powering extensive external hardware.

8 EL9800

Page 11

Product overview

J1203

24V

12V

5V

3.3V

GND

+3.3V 5V

V

CC Header

J1200

2.1 Power Supply

Figure 2 Power Supply

The EL9800 Base Board has to be supplied with 24V DC (J200). From this voltage all other voltages are

derived (12V, 5V, 3.3V). All these voltages are placed on the header J1203 and therefore available for

customer circuits. Indication of correct function of the DC-DC converters is provided by two LEDs, one for

3.3V, one for 5V.

Figure 3 Pinout of the header J1203

Placing a bridge on the left or right pin pairs header one can choose between 3.3V or 5V on the headers

of the µ-Controller, Digital IO and SPI process data interfaces.

All process data interface signals have 3.3V CMOS level. Except of the input signals of the PIC-PDI Interface (chapter 2.6) are all input signals 5V tolerant.

EL9800 9

Figure 4 Header J1200 – Selection of the PDI header voltage

Page 12

Product overview

2

9

20

27

38

45

48 50

49

VCC (5V)

+3.3V

GND

1 Pin Number

56

551

2.2 Process Data Interface for EtherCAT postage stamps

Figure 5 Connection area fort he EtherCAT postage stamp

Within this area all EtherCAT postage stamps are attached to the base board. Communication between

EtherCAT postage stamp and the EL9800 base boards takes place over the connector J202. In case of

FPGA-based EtherCAT Slave Controller boards configuration and debugging of the FPGA is done using

the connector J203. The headers J202 and TP202 pinouts are identical. Therefore all process data signals of any EtherCAT postage stamp can be measures without delay or be used for external customer

circuitry. The signal definition on the two connectors, despite of the power supply pins, may differ from

EtherCat postage stamp to EhterCAT postage stamp.

Figure 6 Pinout of the connectors J202 and TP202

Figure 6 shows the pinout of the connectors J202 and TP202 with power in- and outputs signals. Each

EtherCAT postage Stamp supplies its own IO-voltage of 3.3V on the pin 49 on the connectors J202 and

TP202.

Maximal transfer rates between an EtherCAT postage stamp and external circuitry can be achieved when

interfacing with the connector TP202. In this case direct communication between both devices is established, bypassing the PDIs bus drivers.

10 EL9800

Page 13

Product overview

Pin number

Digital IO

SPI

8/16bit sync./as. µC

1

I/O[0]

GPI[6]

A[0]

2

GND

3

I/O[2]

GPI[4]

A[2]

4

I/O[1]

GPI[5]

A[1]

5

I/O[4]

GPO[6]

A[4]

6

I/O[3]

GPO[7]

A[3]

7

I/O[6]

GPO[4]

A[6]

8

I/O[5]

GPO[5]

A[5]

9

GND

10

I/O[7]

GPI[3]

A[7]

11

I/O[9]

GPI[1]

A[9]

12

I/O[8]

GPI[2]

A[8]

13

I/O[11]

GPO[3]

A[11]

14

I/O[10]

GPI[0]

A[10]

15

I/O[13]

EEPROM Loaded

16

I/O[12]

GPO[2]

A[12]

17

I/O[15]

GPI[11]

CPU_CLK_IN

18

I/O[14]

GPO[1]

A[13]

19

I/O[16]

GPI[7]

D[0]

20

GND

21

I/O[18]

SPI_SEL

D[2]

22

I/O[17]

GPO[8]

D[1]

23

I/O[20]

GPO[11]

D[4]

24

I/O[19]

GPO[10]

D[3]

25

I/O[22]

SPI_INT

D[6]

26

I/O[21]

GPI[8]

D[5]

27

GND

28

I/O[23]

GPI[10]

D[7]

29

I/O[25]

GPO[13]

D[8]

30

I/O[24]

SPI_D_IN

D[8]

31

I/O[27]

GPO[15]

D[11]

32

I/O[26]

SPI_D_OUT

D[10]

33

I/O[29]

GPI[13]

D[13]

34

I/O[28]

GPI[12]

D[12]

35

I/O[31]

GPI[15]

D[15]

36

I/O[30]

GPI[14]

D[14]

37

WD_TRIGGER

SPI_CLK

nCS

38

GND

39

SOF

N.C.

RDnWR/nWR

40

OUT_VALID

N.C.

nTS/nRD

41

SYNC[0]/LATCH[0]

2.2.1 Process data interface dependent pinout of the headers J202 and TP202

The pinout of the headers J202 and TP202 are depending on the choice of the process data interface on

the EL9800 base board. In Table 1 the pinout of these headers are listed for the process interfaces Digital

IO, SPI and the different Microcontroller interfaces.

Table 1 Pinout of the headers J202 and TP202

EL9800 11

Page 14

Product overview

Pin number

Digital IO

SPI

8/16bit sync./as. µC

42

N.C.

N.C.

nBHE

43

LATCH_IN

N.C.

IRQ

44

SYNC[1]/LATCH[1]

45

GND

46

OE

N.C.

nTA/nBUSY

47

N.C.

48

VCC

49

3.3V Out

50

VCC (5V Input)

51

CLK25_OUT

N.C.

A[15]

52

OE_CONF

GPO[0]

A[14]

53

Not Used

54

Not Used

55

Not Used

56

Not Used

Note

Usage of the FB1111-0142 with differing PDIs

The usage of the FB1111-0142 with the PDIs SPI and µ-Controller is only supported

for evaluation purposes in combination with the EL9800 base board. Therefore the

pinout of the headers J202 and TP202 is not supported in these cases.

In custom devices the usage of postage stamps with the appropriate PDI is recommended.

Position

Process data interface

0

OFF

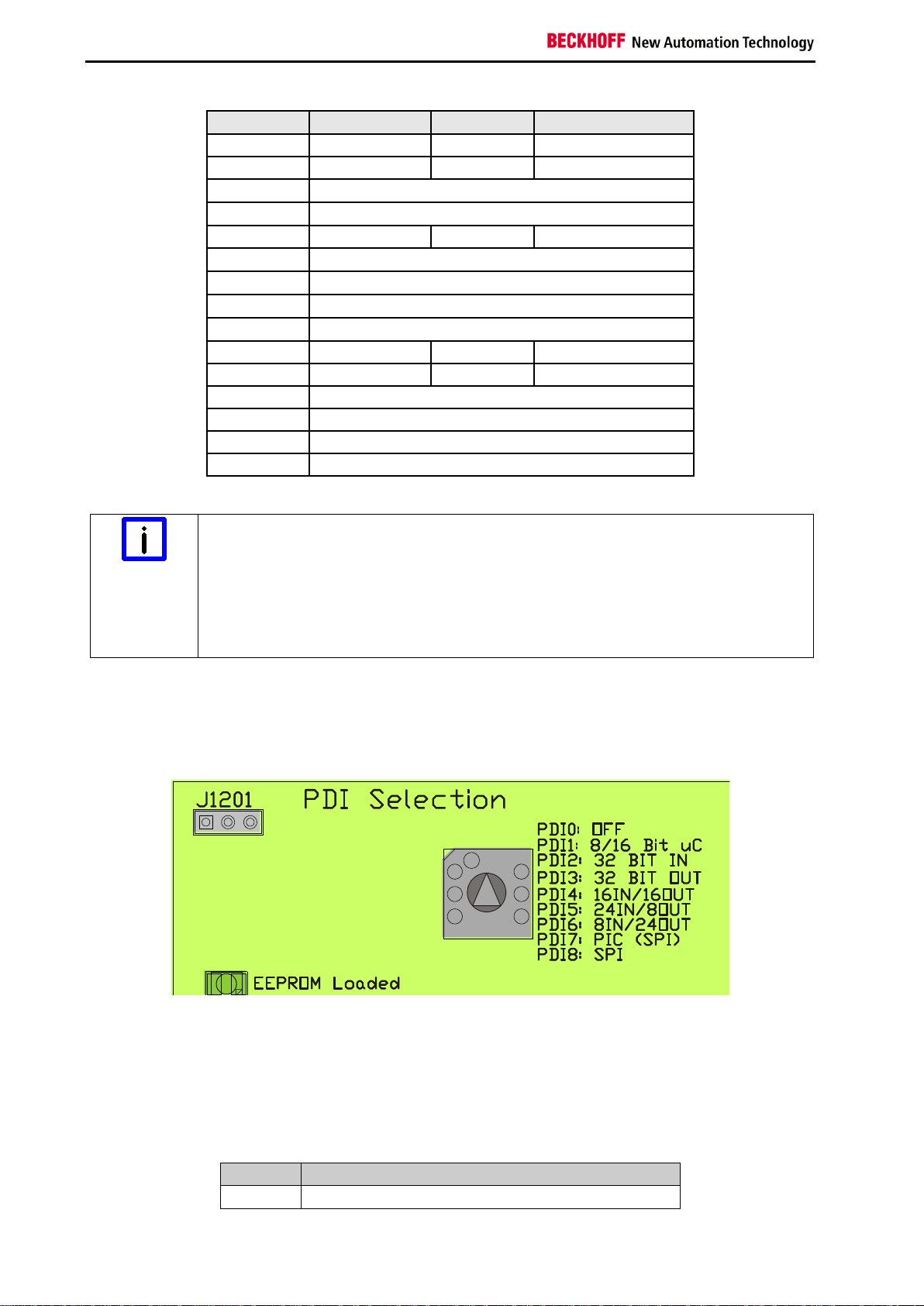

2.3 PDI-Selection

Figure 7 PDI-Selection Area

Selection of the different PDIs on the EL9800 takes place using a rotary selector in the PDI-Selection

Area. Based on the four physical PDIs all in all eight logical PDIs are selectable over the PDI-Selector.

The selector positions listed below activate the corresponding PDI shown in Table 2

Table 2 Positions of the PDI-Selector

12 EL9800

Page 15

Product overview

1

8/16 Bit µ-Controller Interface

2

32 Bit digital Interface - 32 Inputs

3

32 Bit digital Interface - 32 Outputs

4

32 Bit digital Interface - 16 Inputs / 16 Outputs

5

32 Bit digital Interface - 24 Inputs / 8 Outputs

6

32 Bit digital Interface - 8 Inputs / 24 Outputs

7

PIC (SPI)

8

SPI

+3.3V GND

FB-Detect

All postage stamps indicate successful loading of the EtherCAT configuration from the EEPROM with an

LED in the EL9800 base board.

The EL9800 base board supports automatic differentiation between FPGA-based postage stamps and

ASIC (e.g. ET1100) based ones. Therefore the programming voltage on the connector J203 is detected

and evaluated. In case of a missing programming voltage the behaviour of the EL9800 base board can be

configured using the connector J1202. Figure 8 shows the pinout of the connector J1202.

Figure 8 Pinout of the connector J1201

The delivery status of this connector is not bridged. FB-Detect has to be bridged to +3.3V, when FB1111140 and FB1111-141 postage stamps are used in combination with the EL9800 evaluation board. Precondition for correct communication between EtherCAT postage stamp and EL9800 base board is the

correct configuration of the EtherCAT device. As well on the IP-Core based FPGA postage stamps as on

ET1100-ASIC based postage stamps the process data interface has to be configured by loading the specific binary file into the configuration EEPROM (*bin).

EL9800 13

Page 16

Product overview

2

VCC

GND

1 Pin Number

50

491

2.4 8/16 Bit µC-PDI-Interface

Figure 9 µ-Controller PDI-Interface

Within this area customer specific µ-Controller hardware can be attached as well as the communication

between EtherCAT-Slave-Controller and µ-Controller can be monitored. µ-Controller with 8 and 16 bit

data with are supported by the EL9800 base board. An address space of 16 Bit is available on the connectors J208/TP208 and TP206. The logical levels are implemented in accordance with the Intel configuration (C166, SH1, etc.)

Figure 10 Power pins on the connectors TP208 and J208

Both of the connectors TP208 and J208 (Figure 10) have an identical signal and power pinout. While

connector TP208 is assigned to measuring purposes, the connector J208 is designated for interfacing

external hardware.

14 EL9800

Page 17

Product overview

Table 3 lists the pinout of the connectors TP208 and J208.

EL9800 15

Page 18

Product overview

Pin

Signal

Pin

Signal

1

GND

2 Vcc 3 A0 4

A1 5 A2 6

A3 7 A4 8

A5 9 A6 10

A7

11

GND

12

Vcc

13

A8 14

A9

15

A10

16

A11

17

A12

18

A13

19

GND

20

Vcc

21

D0 22

D1

23

D2 24

D3

25

D4 26

D5

27

D6 28

D7

29

GND

30

Vcc

31

D8 32

D9

33

D10

34

D11

35

D12

36

D13

37

D14

38

D15

39

GND

40

Vcc

41

nCS

42

nRD (nTS)

43

nWR

44

nBHE

45

nBUSY (nTA)

46

nINT

47

Port E4 (SYNC0)

48

Port E5 (SYNC1)

49

GND

50

Vcc

Pin

Signal

1

VCC

2

A14

3

A15

4

CPU_CLK_IN

5

EEPROM_Loaded

6

GND

Table 3 Pinout of the connectors TP208 and J208

Additional signals like the upper address lines of the µ-Controfller interface are lead through the connector TP206. The pinout of this connector is shown in Table 4.

Table 4 Pinout of the connector TP206

16 EL9800

Page 19

Product overview

Position

Process Data Interface

Port A

Port B

Port C

Port D

2

32 Bit digital Interface - 32 Inputs

IN

IN

IN

IN

3

32 Bit digital Interface - 32 Outputs

OUT

OUT

OUT

OUT

4

32 Bit digital Interface - 16 Inputs / 16 Outputs

IN

IN

OUT

OUT

5

32 Bit digital Interface - 24 Inputs / 8 Outputs

IN

IN

IN

OUT

6

32 Bit digital Interface - 8 Inputs / 24 Outputs

IN

OUT

OUT

OUT

Signal

Function

Polarity

OE_CONF

Output Configuration – Behavior of the output signals in case of a

falling edge of the WD_STATE signal. Or when OE_EXT is low respectively

Positive

OE_EXT

Output Enable – Enables the output of the output signals.

Positive

2.5 32 Bit Digital-PDI-Interface

Figure 11 Digital IO PDI-Interface

Additional to the input and output signals the digital process data interface contains configuration and

status signals. Using the PDI-Selector byte wise configuration of the 32 digital signals is supported. The

following combinations are selectable (Table 5).

Table 5 Port configuration of the digital PDI

Four LEDs in the top right edge of the digital PDI area are showing the configuration of the data bytes.

The LEDs are active, if the corresponding Byte (Port A to Port D) is configured as an output from the

EtherCAT postage stamps view. Furthermore eight LEDs and Switches are assigned to each port, for

input and output purposes respectively.

The lower right section of the digital PDI interface is assigned to configuration and status indication of the

digital PDI. The Switch SW904 configures the signals OE_CONG and OE_EXT according to Table 6.

Table 6 Definition of the OE_CONF and OE_EXT signals

Manual latching in of the input data can be controlled by activating the switch SW905. Furthermore the

state of the EtherCAT-Slave-Controllers (ESC) watchdog is indicated by the “WD-State” LED is active. In

EL9800 17

Page 20

Product overview

Pin

Signal

Pin

Signal

1

I/O 0

2 I/O 1

3

I/O 2

4 I/O 3

5

I/O 4

6 I/O 5

7

I/O 6

8 I/O 7

9

GND

10

Vcc

11

I/O 8

12

I/O 9

13

I/O 10

14

I/O 11

15

I/O 12

16

I/O 13

17

I/O 14

18

I/O 15

19

GND

20

Vcc

21

I/O 16

22

I/O 17

23

I/O 18

24

I/O 19

25

I/O 20

26

I/O 21

27

I/O 22

28

I/O 23

29

GND

30

Vcc

31

I/O 24

32

I/O 25

33

I/O 26

34

I/O 27

35

I/O 28

36

I/O 29

37

I/O 30

38

I/O 31

39

GND

40

Vcc

41

IN Valid

42

OUT valid

43

Port E2

44

Port E3

45

Port E4 (SYNC0)

46

Port E5 (SYNC1)

47

Port E6

48

Port E7

49

GND

50

Vcc

opposite the LED is inactive, if the watchdog has fallen off. Again the connectors TP207 (Measuring) and

J207 (external hardware) have an identical pinout, as shown in Table 7.

Table 7 Pinout of the connectors TP207 and J207

18 EL9800

Page 21

Product overview

Pin

Signal

1

VCC

2

WD_STATE

3

OE_CONF

4

GND

2

VCC

GND

1 Pin Number

50

491

Additional signals are available on the connector J900 (Table 8).

Table 8 Pinout of the connector J900

Figure 12 Voltages on the headers TP207 und J207

The headers TP208 and J208 (see Figure 12) have an identical signal layout. While header TP207 is

mostly used as test points, J207 can be used interfacing external circuits.

2.6 PIC PDI-Interface

Figure 13 PIC PDI-Interface

On the EL9800 base board a 24HJ128 PIC (U1001) from Microchip is integrated. Communication beEL9800 19

Page 22

Product overview

Port

Signal

Pin

Signal

RB8

Digital Output Bit 0

RD0

Digital Input Bit 0

RB9

Digital Output Bit 1

RD1

Digital Input Bit 1

RB10

Digital Output Bit 2

RD2

Digital Input Bit 2

RB11

Digital Output Bit 3

RD3

Digital Input Bit 3

RB12

Digital Output Bit 4

RD4

Digital Input Bit 4

RB13

Digital Output Bit 5

RD5

Digital Input Bit 5

RB14

Digital Output Bit 6

RD6

Digital Input 6

RB15

Digital Output Bit 7

RD7

Digital Input 7

SPI-Interface

EEPROM- Interface

Programming Signals

Port

Signal

Port

Signal

Port

Signal

RB2

SPI_SEL

RG2/SCL1

EE_CLK

RB0/PGD3

TARGET_DATA

RD8

SPI_IRQ

RG3/SDA1

EE_SDA

RB1/PGC3

TARGET_CLOCK

RF2

SPI_DOUT

MCLK#

TARGET_VPP

RF3

SPI_DIN

RF6

SPI_CLK

Port

Signal

Port

Signal

1

GND 2

3.3V

3

PGD3/RB0

4 PGC3/RB1

5

AN2/SS1/CN4/RB2

6 AN3/CN5/RB3

7

AN4/IC7/CN6/RB4

8 AN5/IC8/CN7/RB5

9

PGC1/RB6

10

not connected

11

GND 12

3.3V

13

U2CTS/AN8/RB8

14

AN9/RB9

15

TMS/AN10/RB10

16

TDO/AN11/RB11

17

TCK/AN12/RB12

18

TDI/AN13/RB13

tween PIC and EtherCAT postage stamp is realized using the SPI-Interface. Additionally an EEPROM

(U1004, Type: AT24C16A) is connected to the PIC using the I²C-Interface. Furthermore a crystal (X1000)

with 24 MHz resonant frequency is also connected with the PIC.

For demonstration and testing purposes digital in- and outputs and an analogue input connected with the

PIC are available. Eight LEDs and eight Switches each are building the digital interface of the PIC( pinout

see Table 9). The analogous input is connected to the Port RB3 of the PIC.

State and error indication is available by the LEDs connected to the ports RF1 (RUN) and RF0 (ERR) of

the PIC.

Table 9 Location of the inputs and output ports on the PIC-

SPI pinout, EEPROM pinout and the pinout of the programming interface are available (see Table 9).

Table 10 Connection of SPI-interface, EEPROM and programming interface with the PIC24H

The connectors TP209 and J209 are connected with the Port of the PICs and can be used as test points

and for interfacing with external hardware. The connectors TP209 and J209 pinout is shown in Table 11.

Table 11 Pinout of the connectors TP209 and J209

20 EL9800

Page 23

Product overview

19

U2RTS/AN14/RB14

20

AN15/OCFB/CN12/RB15

21

GND 22

3.3V

23

SCK2/CN8/RG6

24

SDI2/CN9/RG7

25

SDO2/CN10/RG8

26

SS2/T5CK/CN11/RG9

27

RG12 28

RG13

29

RG14 30

RG15

31

GND 32

3.3V

33

RF0 34

RF1

35

U1RX/SDI1/RF2

36

U1TX/SDO1/RF3

37

U2RX/SDA2/CN17/RF4

38

U2TX/SCL2/CN18/RF5

39

GND 40

3.3V

41

U1RTS/SCK1/INT0/RF6

42

IC1/INT1/RD8

43

EEPROM_Loaded

44

AN17/T3CK/T6CK/RC2

45

PGD2//RC13

46.

PGC2//RC14

47

GND 48

3.3V

49

IC3/INT3/RD10(SYNC0)

50

IC4/INT4/RD11 (SYNC1)

Pin

Signal

Pin

Signal

1

SPI_CLK_IN

2 3.3V

3

EEPROM_LOADED

4 SYNC0/LATCH0

5

SPI_DIN

6 SPI_SEL

7

SPI_DOUT

8 SYNC1/LATCH1

9

SPI_INTERRUPT

10

GND

Pin

Signal

1

3.3V

2

RC14/PGC2

3

RC13/PGD2

4

MCLR#

5

GND

The SPI-signals together with the Sync-Signals and the EEPROM_Loaded signal are additionally fed out

on the connector J510. The pinout of this header is listed in Table 12.

Table 12 Pinout of the connector J510

Table 13 Pinout of the connector J1005

EL9800 21

Page 24

Product overview

Pin

Signal

Pin

Signal

1

SPI_CLK_IN

2 3.3V

3

EEPROM_LOADED

4 SYNC0/LATCH0

5

SPI_DIN

6 SPI_SEL

7

SPI_DOUT

8 SYNC1/LATCH1

9

SPI_INTERRUPT

10

GND

2.7 SPI-PDI-Interface

Similar to the µ-Controller interface this interface only consists of two connectors (TP204 and J204),

which can as well be used as test points as for connection with external hardware. Again the pinout of

both connectors is identical and therefore listed in Table 14.

Table 14 Pinout of the connectors TP204 and J204

The maximum achievable data transfer rates using this interface are depending mainly from the EtherCAT-Slave-Controller used in combination with the EL9800 base board. Data transfer rates are also depending on the bus driver (SN74LVC245A from Texas Instruments) used on the base board. Details information about these rates can be found in both devices datasheets.

2.8 Distributed Clocks

Figure 14 Configuration and Status-Area of the Distributed Clocks

In the configuration area of the distributed clocks the user can switch from Sync- to Latch- signal configuration. That means using the switch SW401, one can switch from Sync0 to Latch0 and from Sync1 to

Latch1 separately. Switching from Sync to Latch configuration and vice versa, only changes the driving

direction of the bus drivers on the EL9800 base board. The EtherCAT postage stamp has to be configured equivalently in order to prevent damage either from the postage stamp as well as from the EL9800

base board. Sync configuration is indicated by activated LEDs above the switch SW401.

In the right section of the Distributed Clocks area the state of the Sync/Latch signals is indicated by LEDs,

which are active if the corresponding Sync/Latch signal has the logical state one. Additionally manual

chance of the Sync/Latch signal is possible by pressing the buttons SW402 and SW403

22 EL9800

Page 25

Product overview

2.9 FPGA-Programmer

Figure 15 FPGA Programming Interface

If FPGA-based EtherCAT postage stamps are used in combination with the EL9800 base board, these

postage stamps can be programmed and debugged using the integrated FPGA programming hardware

on the EL9800. The FPGA-Programmers USB-Port has to be connected with the PC using the USB cable, which is provided with this Evaluation Kit. A FPGA based EtherCAT postage stamp can as well be

programmed using the TwinCAT Systemmanager as well as the Altera Quartus II Programmer. The programming hardware on the EL9800 evaluation board supports programming of Altera FPGAs only (e.g.

FB1122).

Programming activity is indicated by the “ACTIVITY” LED on the board.

Detailed information about the programming operation using the Altera Quartus programmer is given in

chapter 3.

EL9800 23

Page 26

Product overview

CAUTION

Possible malfunction of the PIC Programming Interface

At the beginning of the programming sequence an operating system may be downloaded onto the programming interface. During the download operation neither power

may be cycled nor may the position of the switch SW600 be altered.

Not obeying this warning leads to an incomplete download of the operating system that

will cause the permanent malfunction of the programming interface.

2.10 PIC-Programmer

Figure 16 PIC Programming Interface

The PIC24H integrated on the EL9800 base board can be programmed using this interface. If its USBport is connected with the PC using the USB-cable delivered with this Evaluation Kit, the PIC can be programmed with the development software “MPLAB” from Microchip.

If power is supplied to the EL9800 base board then the PIC programming interface can be activated by

turning on the switch SW600. Different LEDs are showing the programming state during programming

operation. The “LINK-ACT”-LED is active if, the USB connection is established. The “BUSY”-LED indicat-

ed programming activity, while the “ERROR”-LED indicated configuration errors.

A freeware version of the development environment MPLAB can be found on the Evaluation Kit CD.

In order to achieve a successful programming of the PIC the steps listed below should be followed:

1. Turn on the power supply

2. Switch on the programming interface. Switch SW800 in „ON“-Position.

3. Connect the programming interface of the EL9800 with the PC, using the USB-Cable, delivered

together with this Evaluation KIT.

4. Start development environment MPLAB from Micochip

5. Select programming device

Choose „Select Programmer“ in the menue „Programmer“ and select MPLAB ICD2 as the

programming device.

24 EL9800

Page 27

Product overview

6. Connect with the programming device

Select „Connect“ in the menu „Programmer“. While connection to the programming device is

established, downloading of a new operating system onto the programming device may take

place. This procedure takes some time and my not be interrupted. Not following this advice,

will cause permanent malfunction of the programming interface.

7. Loading the programming file

The menu topic „Import“ in the „File“ menu has to be selected and then the file „el9800-spi-

VXXX.hex“ has to be loaded.

8. In the following it can be checked if the correct PIC has been selected. Normally the device type

will be automatically identified, when importing the programming file. In the sub menu “Select Device” of the menu “Configure” it can be checked, if the correct device is selected.

The device to be selected is: PIC24HJ128GP306

9. Programming operation is started by selecting „Programm“ in the „Programmer“ menu.

10. After completion of the programming operation the PIC will automatically stay hold in reset state.

Two way of releasing the device from reset are available. The first one is to switch off the switch

SW600. Alternatively the device can be release from reset by clicking on the button “Release

from Reset” in the symbol bar of the development environment MPLAB. In any case the switch

SW600 has to be in position “OFF” before the USB cable is disconnected from the EL9800 base

board.

EL9800 25

Page 28

Altera Quartus II Programmer™

3 Altera Quartus II Programmer™

Using the onboard FPGA-Programmer interface described in chapter 2.9, FPGAs from the manufacturer

Altera can be programmed with. Therefore the programming software Altera Quartus II Programmer™

can be downloaded from the Altera website (www.altera.com) for free, which runs independent from the

Quartus™ development environment.

Figure 17 Quartus II Programmer™

In the following the steps necessary to program a FPGA-based EtherCAT postage stamp are described:

1. Choose the programming hardware

2. Conversion of the SOF-File in the JIC format

3. Selecting the program file

4. Programming of a FPGA or EEPROM

26 EL9800

Page 29

Altera Quartus II Programmer™

3.1 Selecting the programming hardware

After starting the Altera Quartus Programmer™ the dialog shown in Figure 17 opens. At first the programming hardware hast to be selected. Therefore the dialog below has to be opened by clicking on the

button “Hardware-Setup”. “USB-Blaster” has to be chosen in the drop down menu “Currently selected

hardware” (see Figure 18).

Figure 18 Hardware Setup Dialog

In the following, it can be searched for FPGAs within the daisy chain. All devices in the chain are identi-

fied automatically by clicking on the button “Auto Detect”. When the identification process is completed,

all FPGAs/EEPROMs available are listed. As an example an Altera Cyclone III FPGA (EP3C25) with an

EEPROM (EPCS16) connected is shown in Figure 20.

Figure 19 Setup Dialog – USB Blaster selected

EL9800 27

Page 30

Altera Quartus II Programmer™

Figure 20 Quartus II Programmer Dialog after „Auto-Detect“ processing

3.2 Conversion of a SOF-File in the JIC-file format

In the example the EEPROM, connected with the FPGA, can be programmed using the “JTAG-Indirect”

Mode exclusively. Therefore the binary files generated from the Altera Quartus II™ have to be converted

in the JIC-format before programming of the EEPROM can take place. Selecting the “File” menu and

choosing „Convert Programming File…“ the „Convert Programming Files…” dialog (see Figure 21) is

opened. FPGA type, EEPROM, source and destination file format have to be set before the conversion

process can be started.

The steps below have to be followed to convert the programming file in the JIC-format:

1. „Programming file type“ JTAG Indirect Configuration File (.jic) auswählen

2. „Configuration device:“ EPCS16 (In case of the EtherCAT postage stamp FB1122)

3. „File Name:“ File and path name of the JIC-file has to be entered here.

4. Select „Flash Loader“ and click on „Add Device“. At this point select the FPAG-Type, which in this

case is the Cyclone III EP3C25.

5. Select „SOF Data“ and click on „Add File“ to select the SOF source file.

6. Start the conversion process by clicking on „Generate“ and confirm opening messages.

28 EL9800

Page 31

Altera Quartus II Programmer™

Figure 21 Convert Programming Files

EL9800 29

Page 32

Altera Quartus II Programmer™

3.3 Choosing the programming file

After successful conversion of the SOF-file, the programming of the EEPROM can take place. As shown

in Figure 22the EEPROM (EPCS16) has to be chosen. The programming file has then to be set by clicking on the button “Change File”.

Figure 22 Selection of the programming file

The last step is to configure the programming process, by setting check marks on “Program/Configure”

and “Verify”.

3.4 Programming of the FPGA/EEPROM

The programming process is then started by clicking on the button „Start“. In the message field the programming process is logged. And in case of a faulty programming process an error message is displayed

in this field.

30 EL9800

Page 33

Appendix

4 Appendix

4.1 Support and Service

Beckhoff and their partners around the world offer comprehensive support and service, making available

fast and competent assistance with all questions related to Beckhoff products and system solutions.

4.1.1 Beckhoff's branch offices and representatives

Please contact your Beckhoff branch office or representative for local support and service on Beckhoff

products!

The addresses of Beckhoff's branch offices and representatives round the world can be found on her

internet pages: http://www.beckhoff.com

You will also find further documentation for Beckhoff components there.

4.2 Beckhoff Headquarters

Beckhoff Automation GmbH

Eiserstr. 5

33415 Verl

Germany

phone: + 49 (0) 5246/963-0

fax: + 49 (0) 5246/963-198

e-mail: info@beckhoff.com

web: www.beckhoff.com

Beckhoff Support

Support offers you comprehensive technical assistance, helping you no only with the application of individual Beckhoff products, but also with other, wide-ranging services:

support

design, programming and commissioning of complex automation systems

and extensive training program for Beckhoff system components

hotline: + 49 (0) 5246/963-157

fax: + 49 (0) 5246/963-9157

e-mail: support@beckhoff.com

Beckhoff Service

The Beckhoff Service Center supports you in all matters of after-sales service:

on-site service

repair service

spare parts service

hotline service

hotline: + 49 (0) 5246/963-460

fax: + 49 (0) 5246/963-479

e-mail: service@beckhoff.com

EL9800 31

Loading...

Loading...