Page 1

Oil

Model

AFII 85, AFII 100, AFII 150

Types ‘HLX’ & ‘FBX’ Air Tube Combinations

Voltage: 120 volts AC/60 Hz

AFII

Burner

AFII Burner with

Type ‘HLX’ Air Tube

WARNING

!

Incorrect installation, adjustment, or misuse of this burner could result in death, severe

personal injury, or substantial property damage.

To the Homeowner or Equipment Owner:

Please read and carefully follow all instructions

•

provided in this manual regarding your responsibilities in caring for your heating equipment.

Contact a professional, qualifi ed service agency

•

for installation, start-up or service work.

RWB 6104 BAFII R01 Page 1

Potential for Fire, Smoke and Asphyxiation Hazards

To the Professional, Qualifi ed Installer or

Service Agency:

Please read and carefully follow all instructions

•

provided in this manual before installing, starting,

or servicing this burner or heating system.

The Installation must be made in accordance with

•

all state and local codes having jurisdiction.

Page 2

Page 2 RWB 6104 BAFII R01

Page 3

Table of Contents

General Information

Hazard Defi nitions ........................................................................................................................................4

Owner’s Responsibility ................................................................................................................................4

Information To Be Used Only By Qualifi ed Service Technicians

General Information .........................................................................................................................................5

General Specifi cations………………………………………………………….. .................................................... 5

Notice Special Requirements ...........................................................................................................................5

Inspect/Prepare Installation Site .................................................................................................................5

Clearances to Burner and Appliance ...............................................................................................................5

Inspect Chimney or Direct Vent System .........................................................................................................6

Combustion Air Supply .....................................................................................................................................6

Direct/Sidewall Venting Application ................................................................................................................6

Fuel Line Installation .........................................................................................................................................6

Fuel Line Valves and Filters .............................................................................................................................6

Prepare the Burner ...........................................................................................................................................7

General .........................................................................................................................................................7

Low Fire Rate Baffl e (if specifi ed) ....................................................................................................................7

Mount Burner on Appliance .............................................................................................................................7

Connect Fuel Lines ...........................................................................................................................................7

Wiring Connection Diagram .............................................................................................................................8

Start the Burner and Set Combustion ......................................................................................................8

Start-up Burner ..................................................................................................................................................8

Set Combustion with Test Instruments ...........................................................................................................8

Trained Service Technician’s Regular Maintenance ........................................................................10

Removing Nozzle Line for Service .................................................................................................................10

Nozzle Installation ...........................................................................................................................................11

Check/Adjust Electrodes ................................................................................................................................13

Blower Wheel Replacement ...........................................................................................................................13

Replacement Parts ................................................................................................................. 14

Replacement Parts Diagram ...........................................................................................................................14

Replacement Parts List ...................................................................................................................................15

Beckett Limited Warranty Information ...................................................................................................16

RWB 6104 BAFII R01 Page 3

Page 4

General Information

!

!

General Information

To the Owner:

Thank you for purchasing a Beckett burner for

use with your heating appliance. Please pay attention

to the Safety Warnings contained within this instruction

manual. Keep this manual for your records and provide

it to your qualifi ed service agency for use in profession-

ally setting up and maintaining your burner

Your burner will provide years of effi cient operation if it

is professionally installed and maintained by a qualifi ed

service technician. If at any time the burner does not

appear to be operating properly, immediately contact

your qualifi ed service agency for consultation.

We recommend annual inspection/service of your

oil heating system by a qualifi ed service agency.

Hazard Defi nitions •

DANGER

!

avoided, will result in death, serious injury, or

property damage.

Indicates an imminently haz-

ardous situation, which, if not

WARNING

!

Incorrect installation, adjustment,

and use of this burner could result in

severe personal injury, death, or substantial property damage from fi re,

carbon monoxide poisoning, soot or explosion.

Contact a professional, qualifi ed service agency for the

installation, adjustment and service of your oil heating

system. This work requires technical training, trade experience, licensing or certifi cation in some states and the

proper use of special combustion test instruments.

Please carefully read and comply with the following in-

structions:

Never store or use gasoline or other fl ammable

•

liquids or vapors near this burner or appliance.

Never attempt to burn garbage or refuse in this

•

appliance.

Never attempt to light the burner/appliance by

•

throwing burning material into the appliance.

Never attempt to burn any fuel not specifi ed and

•

approved for use in this burner.

Never restrict the air inlet openings to the burner

•

or the combustion air ventilation openings in the

room.

Owner’s Responsibility

WARNING

!

if not avoided, could result in death, severe

personal injury, and/or substantial property

damage.

CAUTION

!

not avoided, may result in personal injury or

property damage.

Within the boundaries of the hazard warning,

there will be information presented describing

consequences if the warning is not heeded and

instructions on how to avoid the hazard.

Intended to bring special attention to information, but not

related to personal injury or property damage.

Indicates a potentially

hazardous situation, which,

Indicates a potentially hazardous situation, which, if

NOTICE

NOTICE

WARNING

!

Incorrect installation, adjustment,

and use of this burner could result

in severe personal injury, death, or

substantial property damage from

fi re, carbon monoxide poisoning, soot or explosion.

Please read and understand the manual supplied with

this equipment. This equipment must be installed, adjusted and put into operation only by a qualifi ed individual or

service agency that is:

Licensed or certifi ed to install and provide technical

•

service to oil heating systems.

Experienced with all applicable codes, standards and

•

ordinances.

Responsible for the correct installation and commis-

•

sion of this equipment.

Skilled in the adjustment of oil burners using combus-

•

tion test instruments.

The installation must strictly comply with all applicable

codes, authorities having jurisdiction and the latest revision of the National Fire Protection Association Standard

for the installation of Oil-burning Equipment, NFPA 31 (or

CSA B139 and B140 in Canada).

Regulation by these authorities take precedence over the

general instructions provided in this installation manual.

Professional Service

Required

Page 4 RWB 6104 BAFII R01

Page 5

General Specifi cation

•

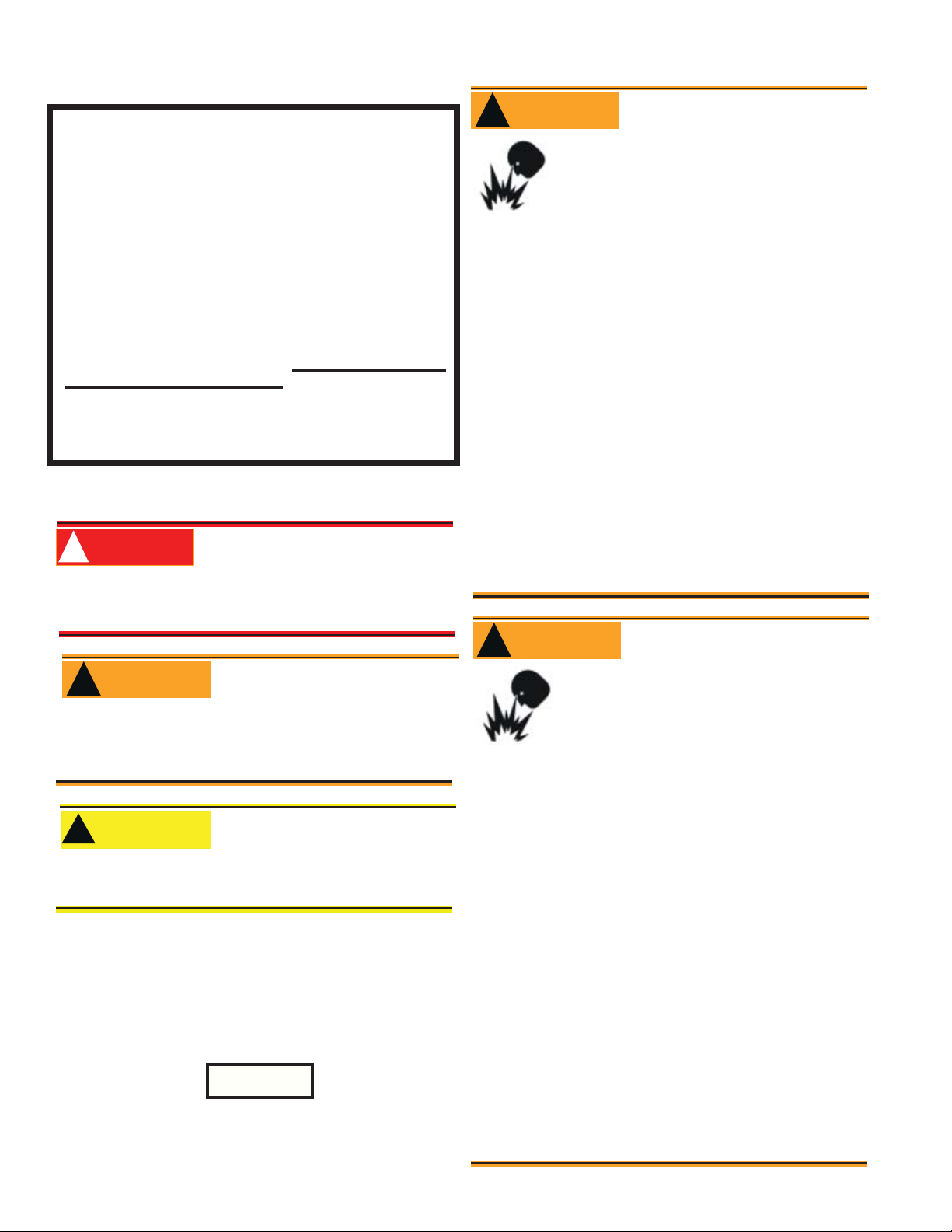

Table 1 – Burner Specifi cations

Capacity ‘HLX’ Heads

Firing rate: - 0.40 – 1.50 GPH

Input: Min./Max - 56,000 /210,000 Btu/h

‘FBX’ Heads

Firing rate: - 0.40 – 1.35 GPH

Input: Min./Max. - 56,000/189,000 Btu/h

Certifi cation/

Approvals

Fuels U. S No. 1 or No. 2 heating oil only (ASTM

Electrical Power supply - 120 volts AC, 60 Hz, single

Fuel pump Outlet pressure - Note 1

Air tube ATC code - See Table 2

Dimensions

(with cover)

*Note 1. See appliance manufacturer’s burner specifi cations for

recommended outlet pressure.

UL certifi ed to comply with ANSI/UL296 &

tested to CSA B140.0

D396)

Canada No. 1 stove oil or No. 2 furnace oil

only

phase

Operating load - 5.8 Amps max

Motor - 1/7 hp, 3450 rpm, NEMA 48M

frame PSC rotation CCW when

facing shaft end

Ignition - Continuous duty solid-state igniter

Height (maximum) - 13 inches

Width (maximum) - 14 inches

Depth - 6-11/16 inches

Air tube diameter - 3-1/2 inches

•

For recommended installation practice in Canada,

Concealed damage — If you discover damage to

When contacting Beckett for service information —

Inspect/Prepare Installation Site

•

Provide space around burner and appliance for

Table 2 – Air Tube Combinations (ATC) & Dimensions

ATC codes for usable air tube lengths dim. “A” (Figure 3) Firing rate range (gph)Min-Max

3” 5” 7” 9” ATC Code Head AFII 85 AFII 100 AFII 150

HLX30 HLX50 HLX70 HLX90 HB AF2-6 0.4-0.85 gph 0.65-1.00 gph 0.75-1.35 gph

HLX30 HLX50 HLX70 HLX90 HC AF2-9 N/A 0.65-1.00 gph 0.75-1.50 gph

w/stop

Adjustable

- Fixed

Head Design

HLX30 HLX50 HLX70 HLX90 HD AF2-6 0.40-0.85 gph 0.65-1.00 gph 0.75-1.10 gph

Design

screw Head

HLX30 HLX50 HLX70 HLX90 HE AF2-9 N/A 0.65-1.00 gph 0.75-1.35 gph

FBX30 FBX50 FBX70 FBX90 HFXS FB0 0.40-0.65 gph 0.55-0.75 gph 0.75-1.00 gph

FBX30 FBX50 FBX70 FBX90 HGXS FB3 0.55-0.85 gph 0.55-1.10 gph 0.85-1.20 gph

FBX30 FBX50 FBX70 FBX90 HHXS FB4 N/A 0.75-1.10 gph 1.10-1.25 gph

FBX30 FBX50 FBX70 FBX90 HIXS FB6 N/A 0.85-1.15 gph 1.15-1.35 gph

General Information

Notice Special Requirements

refer to the latest version of CSA Standard B139 &

B140.

the burner or controls during unpacking, notify the

carrier at once and fi le the appropriate claim.

Please record the burner serial number (and have

available when calling or writing). You will fi nd the

serial number on the silver label located on the left

rear of the burner. Refer to Figure 1.

Clearances to Burner and Appliance

ease of service and maintenance. Check the minimum clearances against those shown by the appliance manufacturer and by applicable building

codes.

HB 6 slot

RWB 6104 BAFII R01 Page 5

HC 9 slot

HD 6 slot

HE 9 slot

Page 6

Inspect/Prepare Installation Site

SK9642

Figure 1. Burner label location

SK9642

Inspect Chimney or Direct Vent System

•

Figure 2. Outside Air Connection

Inspect the chimney or vent. Make sure it is properly

sized and in good working condition. Follow the instructions supplied by the appliance manufacturer.

Combustion Air Supply Information

•

WARNING

!

Adequate Combustion

and Ventilation Air Supply

Required

Failure to provide adequate air supply could se-

riously affect the burner performance and result

4 inch Duct

Air

Inlet

Elbow

1/4”

Mesh

Screen

in damage to the equipment, asphyxiation, explosion or fi re hazards.

The burner cannot properly burn the fuel if it is not

•

supplied with a reliable combustion air source.

Follow the guidelines in the latest editions of the

•

NFPA 31 and CSA-B139 regarding providing adequate air for combustion and ventilation.

See NFPA Standard 31 for complete details.

Appliances located in confi ned spaces: All

confi ned spaces should have two (2) permanent

openings; one near the top of the enclosure and

one near the bottom of the enclosure. Each opening must have a free area of not less than one (1)

square inch per 1,000 BTU’s per hour of the total

input rating of all appliances within the enclosure.

The openings should have free access to the building interior, which should have adequate infi ltration

from the outside.

Exhaust fans and other air-using devices: Size

air openings large enough to supply all air-using

devices in addition to the minimum size required

for combustion air. If there is any possibility of the

equipment room developing a negative pressure

due to exhaust fans, clothes dryers, etc., either

pipe combustion air directly to the burner or provide

a sealed enclosure for the burner and supply it with

its own combustion air supply.

Inlet Ring

Direct/Sidewall Venting Application

•

· When sidewall venting appliances, carefully follow

appliance and power venter instructions for installation and wiring.

· AFII burners are equipped with a removable air inlet to allow use of a 4” duct to supply outside air

for combustion. Do not exceed 70 equivalent feet.

Allow 6 feet for each elbow.

1. Remove the inlet cover.

2. Insert 4” duct into the inlet ring.

3. Fasten duct into place using at least 3 sheet metal screws evenly spaced around the inlet ring.

Refer to Figure 2.

4. Remove the barometric draft control unless it is

in the same atmospheric pressure zone as the

inlet.

On the outside of the home use a 90° elbow pointed

downward with a 1/4” mesh screen over its opening.

The air inlet elbow must be located above the snow

line and in such a way as to prevent leaves and/or

other debris from blocking the air fl ow. Such debris

will prevent proper operation of the burner. Refer to

local codes for proper location of inlet.

SK8810

Page 6 RWB 6104 BAFII R01

Page 7

!

Inspect/Prepare Installation Site

GPH

10

0-15

0

PS

I

3450

R

P

M

A2EA-6

520

Mad

e

by

Su

nte

c

US

E

ONL

Y

WI

TH

Fuel Line Installation •

CAUTION

!

Damage to the pump could cause impaired burn-

er operation, oil leakage and appliance soot-up.

Never use Tefl on tape on fuel oil fi ttings.

•

T ape fragments can lodge in fuel line components

•

and fuel unit, damaging the equipment and preventing proper operation.

Use oil-resistant pipe sealant compounds.

•

For fuel line installation, continuous lengths of heavy

wall copper tubing are recommended. Always use

fl are fi ttings. Never use compression fi ttings.

Always install fi ttings in accessible locations. To

avoid vibration noise, fuel lines should not run

against the appliance or ceiling joists.

Fuel Line Valves and Filter

•

Install two high quality oil duty rated shutoff valves

in accessible locations on the oil supply line. Locate

one close to the tank and the other close to the

burner, upstream of the fi lter.

Do Not Use Tefl on Tape

Prepare the Burner

•

General

In most cases, the burner is ready to mount to the

appliance. There can be situations where the burner needs to be reconfi gured to perform properly in

the appliance. Review the appliance manufacturer’s specifi cations prior to installing to determine if

any modifi cation is required to properly confi gure

the burner.

Instruction on how to perform the following burner

preparation tasks can be found in the Professional

Maintenance section.

•

Remove / install burner nozzle

•

Check head/air adjusting plate

•

Mount Burner on Appliance

Verify that the air tube installed on the burner pro-

vides the correct insertion depth. Refer to Figure

3.

The end of the air tube should normally be

1/4” back

from the inside wall of the combustion chamber.

Never allow the leading edge of the retention ring

to extend into the chamber, unless otherwise specifi ed by the appliance manufacturer.

NOTICE

For protection in the event of fi re, some states require the

shutoff valves to be a fusible-handle design. R.W. Beckett Corporation recommends this design as good industry

practice for all installations.

NOTICE

To further protect the fuel supply system and reduce noz-

zle orifi ce plugging with fi ring rates below 0.75 gph, a dual

fi ltration system can be installed. This typically consists of

a 50 micron primary fi lter, located near the fuel tank and a

secondary fi lter rated for at least 10 microns located near

the burner.

Also install a generous capacity fi lter, rated for 50

microns or less, inside the building between the

fuel tank shutoff valve and the burner. Locate both

the fi lter and the valve close to the burner for ease

of servicing.

Bolt the burner to the appliance using the factory-

welded fl ange.

Figure 3. – Mounting Burner in Appliance

Beckett

T

E

L

IN

H

IT

W

Y

L

ON

E

S

U

Y

A

L

E

D

ON

E

V

L

VA

0

2

5

-6

A

E

2

A

M

P

R

0

5

4

3

I

S

P

0

5

1

-

0

0

1

H

P

4G

L

E

U

F

R

E

T

LIGH

&

O.2

N

M

P

0R

5

4

I3

S

P

0

0

2

-

0

5

1

H

P

3G

L

E

U

F

2

O.

N

S

S

A

P

Y

B

T

E

L

N

I

c

te

n

u

S

y

b

e

d

Ma

t

t

e

k

c

e

B

r

o

f

y

l

e

v

i

s

u

l

c

x

E

RWB 6104 BAFII R01 Page 7

Page 8

Start the Burner and Set Combustion

!

Connect Fuel Lines•

WARNING

!

Failure to comply could cause immediate pump

seal failure, pressurized oil leakage and the potential for a fi re and injury hazard.

The burner is shipped without the by-pass plug in-

•

stalled.

Install the by-pass plug in two-pipe oil supply systems

•

ONLY.

The burner is supplied with either a one-stage

pump or a two-stage pump based on the oil supply

system requirements. Consult the instructions provided with the pump for installation specifi cations.

CAUTION

!

Damage to the fi lter or pump seals could cause

oil leakage and a fi re hazard.

The oil supply inlet pressure to the burner cannot

•

exceed 3 psig.

Insure that a pressure limiting device is installed

•

in accordance with the latest edition of NFPA 31.

Gravity Feed Systems: Always install an anit-

•

siphon valve in the oil supply line or a solenoid

valve (RWB Part # 2182602U) in the pump/nozzle discharge tubing to provide backup oil fl ow

cut-off protection.

When installing a one-pipe system, connect the

inlet line to the pump inlet. The fuel pump may be

installed with gravity feed or lift. The maximum allowable lift for a single pipe installation is 8 ft.

When installing a two-pipe system, remove the

1/16” pipe by-pass plug from plastic bag attached

to fuel unit. Remove 1/4” plug from return port.

Insert and tighten the by-pass plug. Attach return

and inlet lines. The return line should terminate approximately 3 to 4 inches above supply line inlet.

Failure to do this may introduce air into the system

and could result in loss of prime.

•

Wiring Connections Diagram

Refer to the appliance manufacturer’s wiring dia-

gram prior to connecting the burner wiring. All wiring must be in accordance with the latest revision of

National Electric Code NFP A 70 and all local codes

and regulations.

Do Not Install By-pass Plug

with 1-Pipe System

Oil Supply Pressure

Control Required

The R7184 primary control with valve-on delay and

burner motor-off delay, shown in Figure 4, requires

a constant 120 volt AC power source supplied to

the black wire on the control. (Refer to the appliance manufacturer’s instructions. The red wire

goes to the appliance limit circuit. Please note that

other control manufacturers may use different wire

colors for power and limit connections.

Start the Burner and Set Combustion

Startup burner•

WARNING

!

Do not attempt to start the burner when excess oil

•

has accumulated in the appliance, the appliance

is full of vapor, or when the combustion chamber

is very hot.

Do not attempt to re-establish fl ame with the

•

burner running if the fl ame becomes extinguished

during start-up, venting, or adjustment.

Vapor-Filled Appliance: Allow the unit to cool off

•

and all vapors to dissipate before attempting another start.

Oil-Flooded Appliance: Shut off the electrical

•

power and the oil supply to the burner and then

clear all accumulated oil before continuing.

If the condition still appears unsafe, contact the

•

Fire Department. Carefully follow their directions.

Keep a fi re extinguisher nearby and ready for

•

use.

Open the shutoff valves in the oil supply line to

1.

the burner.

Open the air dial. This is an initial air setting for

2.

the pump bleeding procedure only . Additional adjustments must be made with instruments.

Set the thermostat substantially above room tem-

3.

perature.

Close the line voltage switch to start the burner.

4.

If the burner does not start immediately you may

have to reset the safety switch of the burner primary control.

Bleed air from the fuel unit as soon as burner mo-

5.

tor starts rotating. To bleed the fuel unit, attach

a clear plastic hose over the vent fi tting. Loosen

the fi tting and catch the oil in an empty container.

Tighten the fi tting when all air has been purged

from the oil supply system.

Failure to follow these instructions

could lead to equipment malfunction and result in heavy smoke

emission, soot-up, hot gas puffback, fi re and asphyxiation hazards.

Explosion and Fire Hazard

Page 8 RWB 6104 BAFII R01

Page 9

Start the Burner and Set Combustion

Figure 4. – Typical Wiring, R7184 Primary Control

SK9359

1. STANDBY. The burner is idle, waiting for a call for

heat. When a call for heat is initiated, there is a 310 second delay while the control performs a safe

start check.

2. VALVE-ON DELAY. The ignition and motor are

turned on for a 15 second valve-on delay.

3. TRIAL FOR IGNITION (TFI). The fuel valve is

opened. A fl ame should be established within the

15 second lockout time.

4. LOCKOUT. If fl ame is not sensed by the end of

7. RECYCLE. If the fl ame is lost while the burner is

fi ring, the control shuts down the burner , enters a 60

second recycle delay, and then repeats the above

ignition sequence. If fl ame is lost three times in a

row, the control locks out to prevent cycling with

repetitious fl ame loss due to poor combustion.

8. BURNER MOTOR-OFF DELAY. The fuel valve

is closed and the burner motor is kept on for the

selected motor-off delay time before the control returns the burner to standby.

the TFI, the control shuts down on safety lockout

and must be manually reset. If the control locks out

three times in a row, the control enters restricted

lockout.

5. IGNITION CARRYOVER. Once fl ame is estab-

lished, the ignition remains on for 10 seconds to

ensure fl ame stability before turning off. If the con-

trol is wired for intermittent duty ignition, the ignition

unit stays on the entire time the motor is running.

6. RUN. The burner runs until the call for heat is satifi ed. The burner is then sent to burner motor off

delay, if applicable, or it is shut down and sent to

standby.

Control System Features

Feature Interrupted

ignition

R7184A YES YES YES — — —

R7184B YES YES YES YES — —

R7184P YES YES YES YES YES Optional

Limited reset,

Limited recycle

Diagnostic LED,

cad cell indicator

Valve-on

delay

Burner motor

off delay

61351

Alarm Con-

tacts

RWB 6104 BAFII R01 Page 9

Page 10

Trained Service Technician’s Regular Maintenance

•

If the burner locks out on safety during bleeding, reset the safety switch and complete the

bleeding procedure. Note — Electronic safety

switches can be reset immediately; others may

require a three- to fi ve-minute wait.

•

If burner stops after fl ame is established, addi-

tional bleeding is probably required. Repeat the

bleeding procedure until the pump is primed

and a fl ame is established when the vent fi tting

is closed.

•

For R7184 primary controls, see Technician’s

Quick Reference Guide, part number 61351 or

61465, for special pump priming sequence.

•

Prepare for combustion tests by drilling a 1/4”

sampling hole in the fl ue pipe between the ap-

pliance and the barometric draft regulator.

6.

Initial air adjustment — Using a smoke tester,

adjust the air dial (and change fi ring pin on HLX

A TC’s, if necessary) to obtain a clean fl ame. Now

the additional combustion tests with instruments

can be made.

Set combustion with instruments

•

1.

Allow the burner to run for approximately 5 to 10

minutes.

2.

Set the stack or over-fi re draft to the level speci-

fi ed by the appliance manufacturer.

•

Natural Draft Applications; typically over-fi re

draft is -0.01” or -0.02” w.c.

•

Direct Venting; typically may not require draft

adjustment.

•

High Effi ciency/Positive Pressure Applianc-

es; also vary from traditional appliances (see

manufacturer’s recommendations).

Once combustion is set, tighten all fasteners on

4.

air dial, rear access door, and escutcheon plate.

Start and stop the burner several times to ensure

5.

satisfactory operation. Test the primary control

and all other appliance safety controls to verify

that they function according to the manufacturer’s specifi cations.

Trained Service Technician’s Regular

Maintenance

WARNING

!

Tampering with or making incorrect

adjustments could lead to equipment malfunction and result in

asphyxiation, explosion or fi re.

Do not tamper with the burner or controls or

•

make any adjustments unless you are a trained

and qualifi ed service technician.

To ensure continued reliable operation, a quali-

•

fi ed service technician must service this burner

annually.

More frequent service intervals may be required

•

in dusty or adverse environments.

Operation and adjustment of the burner requires

•

technical training and skillful use of combustion

test instruments and other test equipment.

The following guidelines are provided for routine

maintenance.

Annual Professional Ser-

vice Required

3.

Follow these four steps to properly adjust the

burner:

Step 1: Adjust the air dial until a trace of smoke is

achieved.

Step 2: At the trace of smoke level, measure the

Step 3: Increase the air to reduce the CO2 by 1.5

Step 4: Recheck smoke level. It should be Zero.

(or O2) . This is the vital reference point for

CO

2

further adjustments. Example: 13.5% CO

O2)

to 2 percentage points. (O2 will be increased by

approximately 2.0 to 2.7 percentage points.) Example: Reduce CO2 from 13.5% to 11.5% (2.6%

to 5.3% O2).

This procedure provides a margin of

•

reserve air to accommodate variable

conditions.

If the draft level has changed, recheck the

•

smoke and CO2 levels and readjust the burner

if necessary

(2.6%

2

Replace the oil supply line fi lter. The line fi lter

cartridge must be replaced to avoid contamination of the fuel unit and nozzle.

Inspect the oil supply system. All fi ttings should

be leak-tight. The supply lines should be free of

water, sludge and other restrictions.

Remove and clean the pump strainer if appli-

cable.

Replace the nozzle with an exact replacement

as specifi ed by the appliance manufacturer.

Clean and inspect the electrodes for damage,

replacing any that are cracked or chipped.

Check electrode tip settings. Replace elec-

trodes if tips are rounded.

Inspect the igniter cables and connections.

Clean the cad cell grid surface, if necessary.

Inspect all gaskets. Replace any that are dam-

aged or would fail to seal adequately.

Inspect the combustion head and air tube. Re-

move any carbon or foreign matter. Replace all

damaged units with exact parts.

Clean the blower wheel, air inlet, air guide,

burner housing and nozzle line assembly of

any lint or foreign material.

Page 10 RWB 6104 BAFII R01

Page 11

Trained Service Technician’s Regular Maintenance

If motor is not permanently lubricated, oil motor

with a few drops of SAE 20 nondetergent oil at

each oil hole. DO NOT over oil motor. Excessive oiling can cause motor failure.

Check motor current. The amp draw should

not exceed the nameplate rating by more than

10%.

Check all wiring for secure connections or in-

sulation breaks.

Check the pump pressure and cutoff function.

Check primary control safety lockout timing.

Check ignition system for proper operation.

Inspect the vent system and chimney for soot

accumulation or other restriction.

Clean the appliance thoroughly according to

the manufacturer’s recommendations.

Check the burner performance. Refer to the

section “Set combustion with test instruments”.

It is good practice to make a record of the ser-

vice performed and the combustion test results.

Removing Nozzle Line for Service

•

WARNING

!

Correct Nozzle and Flow

Rate Required

Incorrect nozzles and fl ow rates

could result in impaired combustion, under-fi ring, over-fi ring, soot-

ing, puff-back of hot gases, smoke

and potential fi re or asphyxiation hazards.

Use only nozzles having the brand, fl ow rate (gph), spray

angle and pattern specifi ed by the appliance manufactur-

er or Beckett Residential Burner OEM Spec Guide, Part

#6711.

Follow the appliance manufacturer’s specifi cations for the

required pump outlet pressure for the nozzle, since this

affects the fl ow rate.

Nozzle manufacturers calibrate nozzle fl ow rates

•

at 100 psig.

This burner utilizes pressures higher than 100

•

psig, so the actual nozzle fl ow rate will be greater

than the gph stamped on the nozzle body . (Example: A 1.00 gph nozzle @ 140 psig = 1.18 gph)

For typical nozzle fl ow rates at various pressures see ac-

companying chart.

Turn off power to burner before proceeding.

1.

Disconnect copper oil connector tube from noz-

2.

zle line.

Loosen the screw that fastens the rear access

3.

door.

Remove splined nut.

4.

5.

Remove the nozzle line assembly from the burner, being careful not to damage the electrodes or

insulators while handling. Stop halfway to remove

igniter/transformer wires.

6.

To replace the nozzle assembly, reverse the

above steps. “HLX” head air tubes – Be sure stop

screw is fastened securely. Seat stop screw on

back of choke ring to set the position of the head.

“FBX” head air tubes – Use T gauge to set the “Z”

dimension to 1-1/8” +/- 1/32”

Nozzle Installation

•

Perform the following steps when replacing a noz-

zle.

1.

Remove the nozzle line assembly to gain access

to the nozzle.

2.

Use a 3/4” open-end wrench to hold the nozzle

adapter. DO NOT attempt to remove or replace

the nozzle without securing the adapter, as nozzle alignment could be seriously affected.

3.

Do not squeeze the electrodes when handling

the nozzle line assembly. Excessive force could

change the electrode tip settings or damage the

ceramic electrode insulators.

4.

Use a 5/8” open-end wrench to carefully remove

the existing nozzle.

Nozzle Flow Rate by Size

Nozzle fl ow rate U. S. gallons per hour of No. 2 fuel oil when

pump pressure (psig) is:

Nozzle

size

(rated

at 100

psig)

0.40 0.45 0.47 0.49 0.53 0.56

0.50 0.56 0.59 0.61 0.66 0.71

0.60 0.67 0.71 0.74 0.79 0.85

0.65 0.73 0.77 0.80 0.86 0.92

0.75 0.84 0.89 0.92 0.99 1.06

0.85 0.95 1.01 1.04 1.13 1.20

0.90 1.01 1.07 1.10 1.19 1.27

1.00 1.12 1.18 1.23 1.32 1.41

1.10 1.23 1.30 1.35 1.46 1.56

1.20 1.34 1.42 1.47 1.59 1.70

1.25 1.39 1.48 1.53 - -

1.35 1.51 - - - -

125

psi

140 psi

(factory

std.)

150

psi

175

psi

200

psi

RWB 6104 BAFII R01 Page 11

Page 12

Trained Service Technician’s Regular Maintenance

Check/Adjust Electrodes

Figure 5a. HLX Air Tube

SK9639

•

Check the electrode tip settings, as shown in Figure

6a or 6b. If necessary , adjust by loosening the electrode clamp screw and slide/rotate the electrodes

as necessary. When the adjustment is complete,

securely tighten the clamp screw.

Figure 6a. Electrode Settings-HLX Air T ube Com-

binations

Figure 5b. FBX Air Tube

Inspect the nozzle adapter before installing the

5.

new nozzle. If it is grooved or scratched on the

sealing surface, replace the nozzle line assembly. If the surface is damaged, oil could leak at

the nozzle to adapter joint, causing serious combustion problems.

Protect the nozzle orifi ce and strainer when in-

6.

stalling. If the orifi ce gets dirt in it or is scratched,

the nozzle will not function properly.

SK9641

3/32”

Do NOT overtighten

Clamp Screw

1-1/2”

15/32”

Stop

Screw

5/32”

1/4”

5/32”

SK8263

Nozzle face to back of head

Figure 6b. Electrode Settings-FBX Air T ube Com-

binations

To install a new nozzle, place a 3/4” open-end

7.

wrench on the nozzle adapter. Insert the nozzle

into the adapter and secure fi nger tight. Finish

tightening with a 3/8” open-end wrench. Use care

to avoid bending the burner head support legs or

electrodes.

Do not over-torque the nozzle when install-

8.

ing. This will cause deep grooves in the nozzle

adapter, preventing a seal when a new nozzle is

installed.

Carefully check and realign the electrode tips af-

9.

ter replacing a nozzle, ensuring the electrode settings comply with Figure 6a or 6b.

If the head was removed when replacing the

10.

nozzle, carefully reconnect the head to the nozzle adapter. Push the head support until it stops

against the nozzle shoulder. Verify the dimension between the nozzle face and the back of the

head is 5/32”.

SK9461

Blower Wheel Re-

•

placement

For installation or re-

placement of a blower

wheel, insure that there

is a space between the

blower wheel and the

motor face of 0.062”

(1/16” + 1/64”). Refer to

Figure 7.

Figure 7. – Blower

Wheel Replacement

SK9190A

Page 12 RWB 6104 BAFII R01

Page 13

Trained Service Technician’s Regular Maintenance

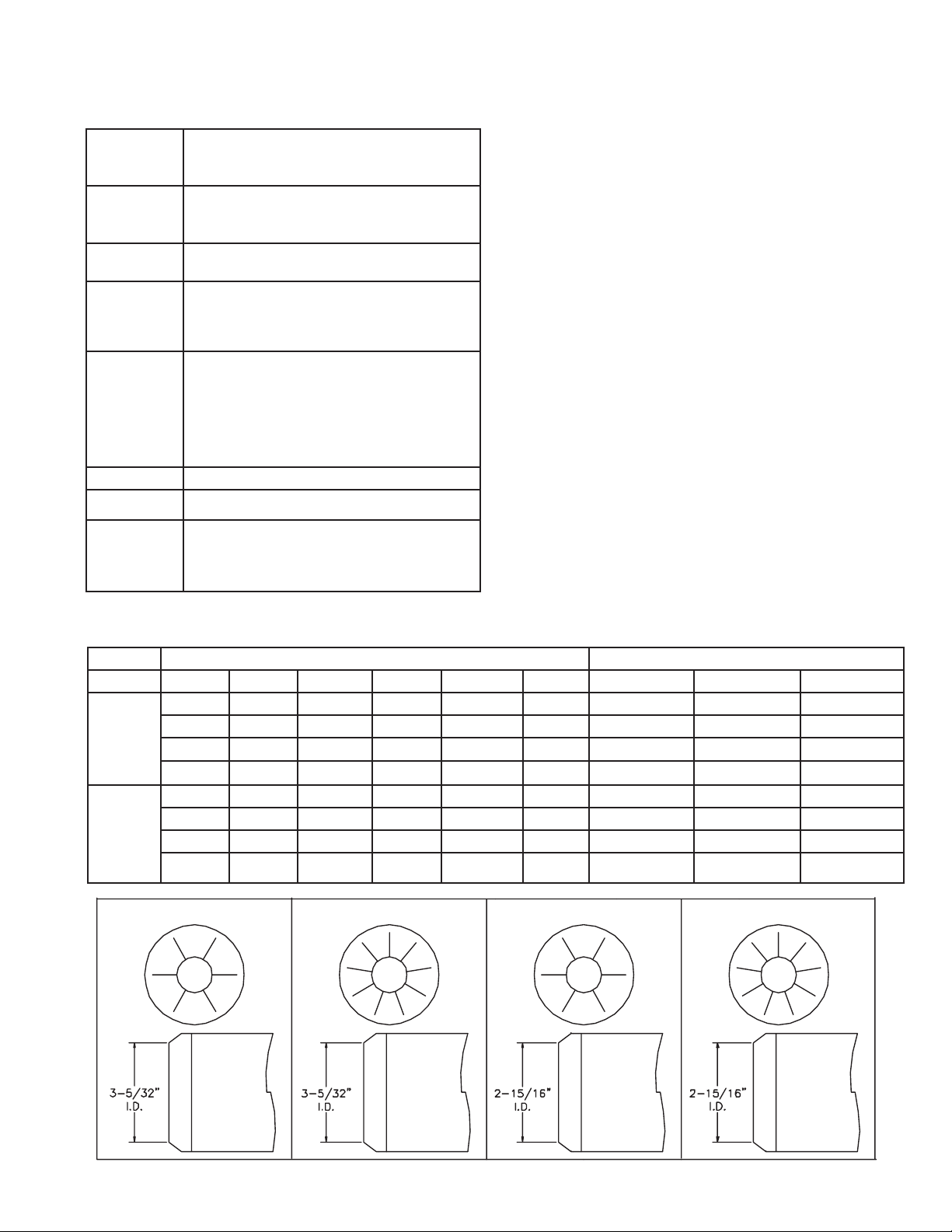

HLX Firing Rate

Stop

Screw

0 0.40-0.65 0.5-0.65 0.75-1.00

1 - 0.6-0.75 0.85-1.10

2 - 0.65-0.80 0.95-1.15

3 0.60-0.75 0.65-0.90 0.95-1.20

4 - 0.75-0.95 1.10-1.25

5 0.70-0.85 0.85-1.00 1.15-1.35

6 - 0.95-1.10 1.15-1.40

7 - - 1.25-1.50

8 - - 1.30-1.50

AFII 85 AFII 100 AFII 150

HLX Air Dial Setting

Firing Rate

@ 140 psig

0.40-0.65 3 - -

0.60-0.75 4 3 -

0.70-0.85 5 4 -

0.75-1.00 - 5 2

0.95-1.20 - - 3

1.15-1.35 - - 4

1.25-1.50 - - 5

AFII 85 AFII 100 AFII 150

FBX Firing Rate

Head AFII 85 AFII 100 AFII 150

FB0 0.40-0.65 0.55-0.75 0.75-1.00

FB3 0.55-0.85 0.55-1.10 0.85-1.20

FB4 - 0.75-1.10 1.10-1.25

FB6 - 0.85-1.15 1.15-1.35

FBX Air Dial Setting

Firing Rate @

140 psig

0.40-0.65 3 - -

0.60-0.75 4 3 -

0.70-0.85 5 4 -

0.75-1.00 - 5 2

0.95-1.20 - - 3

1.15-1.35 - - 4

1.25-1.50 - - 5

AFII 85 AFII 100 AFII 150

RWB 6104 BAFII R01 Page 13

Page 14

Replacement Parts Diagram

For best performance specify genuine Beckett replacement parts

10

11

1

16

17

8

21

12

19

3

20

14

23

22

7

4

Beckett

9

6

13

SK8265B

18

5

15 2

Page 14 RWB 6104 BAFII R01

Page 15

Replacement Parts List

Replacement Parts Diagram

Item Description Kit No.

1 Air tube combination Specify

2 Blower Wheel: AFII 85 (4-1/4”)

AFII 100 (4-1/2”)

AFII 150 (4-1/2”)

3 Electrical box 30613BK

4 Connector tube, 8” Copper 5394U

5 Coupling, Motor to Pump 21437U

6 Electrodes: HLX Heads

FBX Heads

7 Escutcheon Plate: AFII Blank

AFII 140psi

8 Flange Kit, (adjust. 3-1/2” ID w/gas-

ket)

9 Fuel Pump: Cleancut 2184404U

10 Gasket, fl ange 31658

11 Head: FBX:FB0, FB3, FB4, or FB6

HLX: AF2 6 Slot Head

AF2 9 Slot Head

Head insulator Kit (FB0, 3, 4, 6 only)

21439U

21438U

21438U

51484U

51670U

31623

3162302

51480

Specify

51671U

51672U

51685

Item Description Kit No.

12 Igniter, Electronic 51805U

13 Inlet air scoop, plastic, sound insu-

lated

14 Housing ass’y: AFII 85 & 100

AFII 150

15 Motor: 1/7 hp, 3450 rpm, 115V/60Hz 21444U

16 Nozzle adapter 213

17 Nozzle Line Electrode Head ass’y Specify

18 Pedestal Kit, AFII Mounting 51481

19 Primary control

R7184A Interrupted ignition

R7184B Valve-on Delay

R7184P Valve-on/Motor-off Delay

R7184P With Alarm Contacts

20 Rear Access Door 51424U

21 Stop Screw, Replacement kit 51483

22 Splined Nut 3666

23 Dial, Air Adjustment (UL approved) 187

51485

51584U

51476U

7455U

7456U

7457U

7458U

RWB 6104 BAFII R01 Page 15

Page 16

Limited Warranty Information

WARRANTY

For Residential, Commercial and Specialty Burners

The R. W. BECKETT CORPORATION (“Beckett”) warrants to persons who purchase its Beckett burners from Beckett for resale or for

incorporation into a product for resale (“Customers”) that its equipment is free from defects in material and workmanship under normal use and

service for 60 months from the date of manufacture for Residential Burners and 18 months from the date of manufacture for Commercial and

Specialty Burners. Residential burner models include: AF, AFG, AFII, NX, SF, SR and SMG. Commercial burner models include: CF375,

CF500, CF800, CF1400, CF2300A, CF2500, CF3500A, CG10, CG15, CG25 and CG50. Specialty burner models include: ADC, ADCP, ARV,

SDC and SM. The provisions of this warranty are extended to individual major burner components as follows:

a) 60 months from date of manufacture for all Beckett-branded major components, except for 12 Vdc components.

b) 18 months from date of manufacture for all non-Beckett-branded major components and Beckett branded 12 Vdc components.

Note: Normal service items found to be defective upon receipt by the customer are covered by this warranty.

THIS WARRANTY DOES NOT EXTEND TO EQUIPMENT SUBJECTED TO MISUSE, NEGLECT, OR ACCIDENT: NOR DOES THIS WARRANTY APPLY

UNLESS THE PRODUCT COVERED BY IT IS PROPERLY INSTALLED BY A QUALIFIED, COMPETENT TECHNICIAN, WHO IS LICENSED WHERE

STATE AND LOCAL CODES REQUIRE, AND WHO IS EXPERIENCED IN MAKING SUCH INSTALLATIONS, IN ACCORDANCE WITH THE LATEST

EDITION OF NFPA NO. 31 OF THE NATIONAL FIRE PROTECTION ASSOCIATION, THE LATEST EDITION OF THE NATIONAL FUEL GAS CODE (NFPA

NO. 54) AND IN ACCORDANCE WITH ALL APPLICABLE LOCAL, STATE AND NATIONAL CODES HAVING JURISDICTIONAL AUTHORITY.

Equipment, which is defective in material or workmanship and within the warranty period, may be returned for credit as follows:

Beckett Burners, Beckett-branded major components and non-Beckett-branded major components that came as original equipment on a Beckett burner

or were sold as a replacement part by Beckett should be returned, freight prepaid, to Beckett’s home office. Credit will be issued to the customer unless

the returned equipment is determined by Beckett to be out of warranty or damaged by user, in which case the equipment will be scrapped.

Note: Beckett is not responsible for any labor cost for removal and replacement of equipment.

THIS WARRANTY IS LIMITED TO THE PRECISE TERMS SET FORTH ABOVE, AND PROVIDES EXCLUSIVE REMEDIES EXPRESSLY IN LIEU OF ALL OTHER

REMEDIES, AND IN PARTICULAR THERE SHALL BE EXCLUDED THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE. IN NO EVENT WILL BECKETT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGE OF ANY NATURE.

authorizes any person to assume for Beckett any other liability or obligation in connection with the sale of this equipment, Beckett’s liability and Customer’s

exclusive remedy being limited to credit as set forth above.

Limited

Beckett neither assumes nor

R.W. BECKETT CORPORATION

P.O. Box 1289 Elyria, Ohio 44036

The Oilheat Manufacturers’ Association supports the use of low sulfur fuels as defi ned by ASTM D396, Grades No. 1 Low Sulfur

and No. 2 Low Sulfur, as the preferred heating fuel for the following reasons:

• Low sulfur fuels reduce deposits on heat exchanger surfaces, extending the service interval between cleanings.

• The reduced deposits increase the effi ciency of the appliance.

• Low sulfur fuels reduce particulate emissions.

Form No. 61545 R72905

R.W. BECKETT CORPORATION

U.S.A.: P.O. Box 1289 · Elyria, Ohio 44036

www.beckettcorp.com

Canada: R.W. Beckett Canada, Ltd. · Unit #3, 430 Laird Road · Guelph, Ontario N1G 3X7

Form Number 6104 BAFII R01

Printed in USA - 9/06

Page 16 RWB 6104 BAFII R01

Loading...

Loading...