Page 1

CONTENTS

1. SAFETY PRECAUTIONS……………………………………………………….. 1

1.1 GENENRAL GUIDELINES……………………………………………………….. 1

2. PREVENTION OF ELECTRO STATIC DISCHARGE(ESD) TO ELECTROSTATICALLY

SENSITIVE(ES) DEVICES………………………………………………………. 1

3. PRECAUTION OF LASTER DIODE……………………………………………. 2

4. GENERAL DESCRIPTION……………………………………………………… 3

5. PREVENTION OF STATIC ELECTRICITY DISCHARGE…………………….. 5

5.1 GROUNDING FOR ELECTROSTATIC BREAKDOWN PREVENTION……… 5

5.1.1 WORKTABLE GROUNDING…………………………………………………… 5

5.1.2 HUMAN BODY GROUNDING…………………………………………………. 5

5.1.3 HANDING OF OPTICAL PICKUP……………………………………………… 5

5.2 HANDING PRECAUTIONS FOR TRAVERSE UNIT(OPTICAL PICKUP).. 5

6. ASSENBLING AND DISASSEMBLING THE MECHANISM UNIT…….. 6

6.1 DISASSEMBLY PROCEDURE………………………………………………… 6

6.2 TERMINAL P.C.B………………………………………………………………. 6

6.3 CLAMP PLATE UNIT………………………………………………………….. 7

6.4 TRAY…………………………………………………………………………… 7

6.5 TRAVERSE BLOCK…………………………………………………………… 8

6.6 TRAVERSE GEAR……………………………………………………………… 8

6.7 OPTICAL PICKUP UNIT……………………………………………………… 9

6.7.1 PRECAUTIONS IN OPTICAL PICKUP REPLACEMENT…………………… 9

6.8 DISASSEMBLING THE MIDDLE CHASSIS…………………………………. 11

6.9 DISASSENBLING THE TRAVERSE GRAR A………………………………... 11

6.10 DISASSEMBLING THE SPINDLE MOTOR UNIT…………………………… 11

7 Electrical Confirmation………………………………………………………….. 12

7.1 VIDEO OUTPUT(LUMINANCE SIGNAL) CONFIRMATION………………… 12

7.2 VIDEO OUTPUT(CHROMINANCE SIGNAL) CONFIRMATION

8. MPEG CHECK WAVEFORM 14

9 IC BLOCK DIAGRAM & DESCRIPTION………………………………….. 16

10 BLOCK DIAGRAM…………………………………………………………… 35

11 SCHEMATIC & PCB WIRING DIATRAM....................................................................36

12 EXPODED VIEWS…………………………………………………………….

13. SPARE PARTS LIST..................................................................................

13. SPARE PARTS LIST..................................................................................

……………. 13

49

50

54

Page 2

1.SAFETY PRICAUTIONS

1.1 GENERAL GUIDELINES

1.When servicing,observe the original lead dress.ifa short circuit is found,replace all parts which have

been overheated or damaged by the short circuit.

2.After servicing,see to it that all the protective devices such as insulation bamiers,insulation papers

shields are properly installed.

3.After servicing,make the following leakage current checks to prevent the customer from being exposed

to thock hazards.

2.PREVENTION OF ELECTRO STATIC DISCHARGE(ESD) TO ELECTROSTATECALLY

SENSITIVE(ES) DEVICES

Some semiconductor(solid state)devices can be damaged easily by static electricity.Such components

commonly are called Electrostatically Sensitive(ES)Devices.Examples of typical ES devices are integrated

circuits and some field-effect transistorsand semiconductor chip components.The following techniques

should be used to help reduce the incidence of component damage caused by electro static discharge(ESD).

1.Immediately before handling any semiconductor component or semiconductor-equipped assembly,drain

off any ESDon your body by touching a known earth ground.Alteatively,obtain and wear a commercially

availabel discharging ESD wrist strap,which should be removed for potential shock reasons prior to

applying power to the unit under test.

2.After removing an electrical assembly equipped with ES devices,place the assembly on a conductive

surface such as alminum foil,to prevent electrostatic charge buildup or exposure of the assembly.

3.Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4.Use only an anti-static solder removal device.Some solder removal devices not classified as anti-static

(ESD protected)can generate electrical charge sufficient to damage ES devices.

5.Do not use freon-propelled chemicals.These can generate electrical charges sufficient to damage ES

devices.

6.Do not remove a replacement ES device from its protective package until immediately before you are

ready to install if.(Most replacement ES devices are packaged with leads electrically shorted together by

conductive foam,alminum foil or comparable conductive material).

7.Immediately before removing the protective material from the leads of a aeplacement ES device,touch

the protective material to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit,and observe all other safety precautions.

8.Minimize bodily motions when handling unpackaged replacement ES devices.(Otherwise hamless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can

generate static electricity(ESD)

notice (1885x323x2 tiff)

1

Page 3

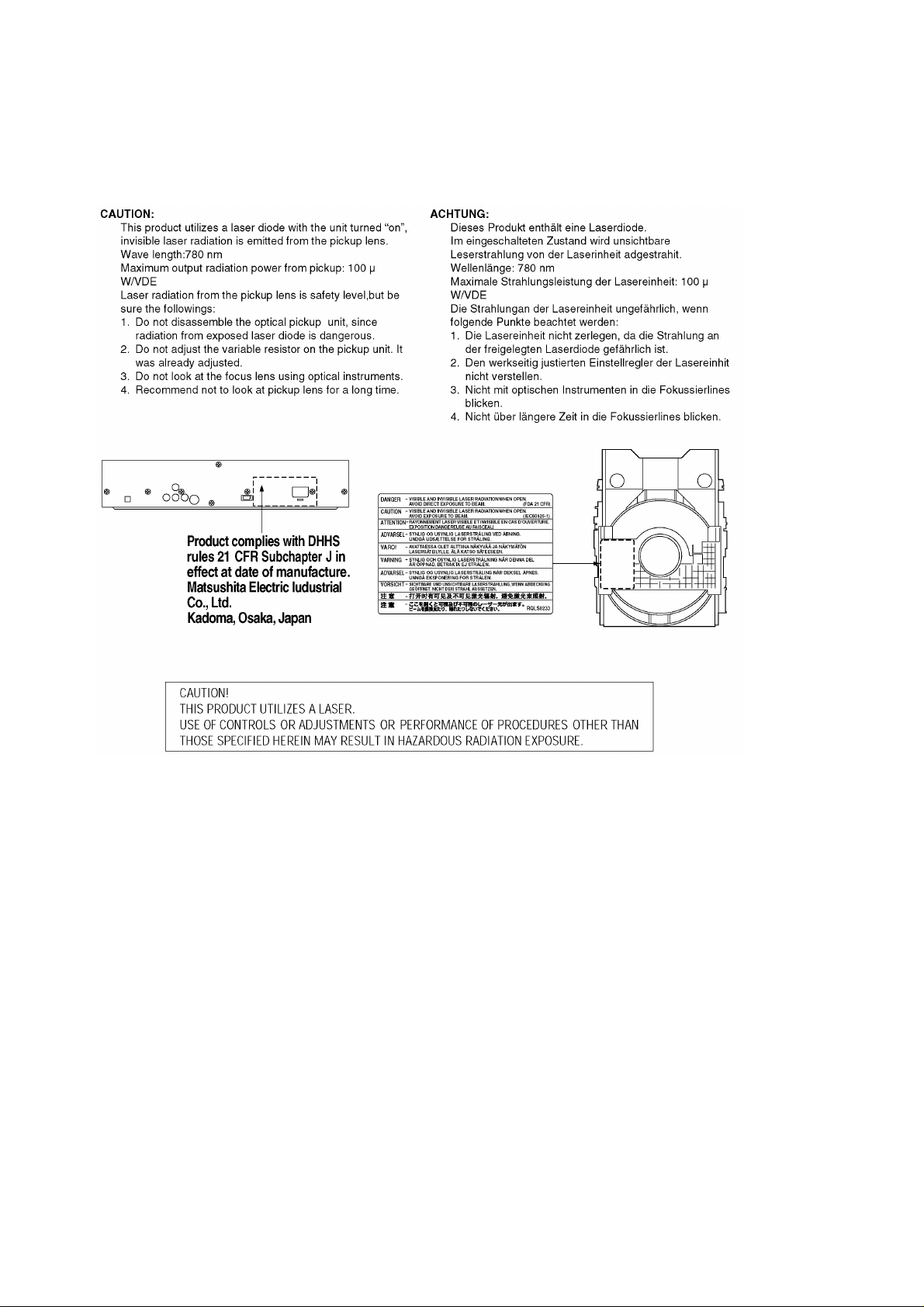

3. Precaution of L aster Diode

2

Page 4

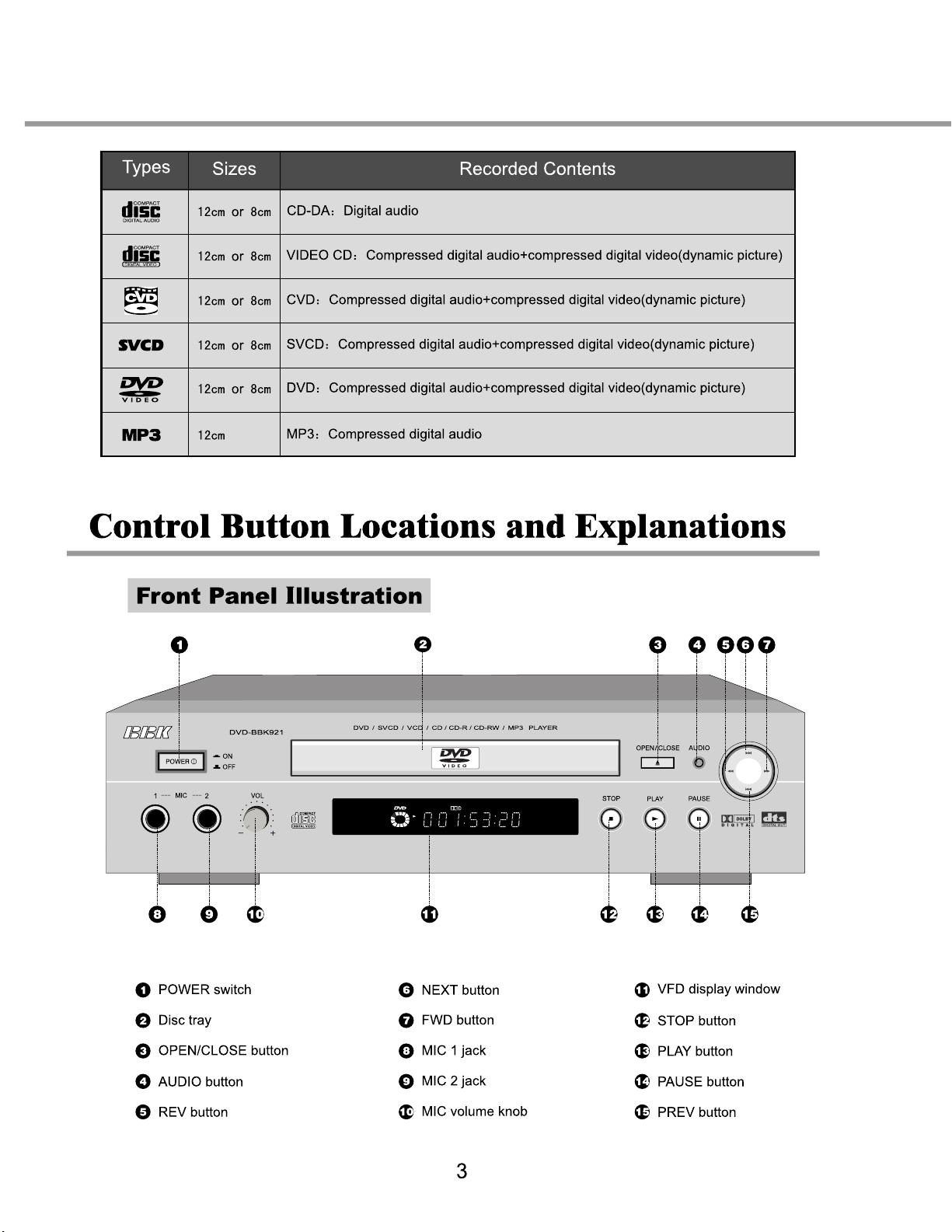

4.General Description

4.1 Compatible Disc Types

S

Page 5

4.2

Page 6

5.PREVERTION OF STATIC ELECTRICITY DISCHARGE

The laser diode in the traverse unit (optical pickup)may brake down due to static electricity of clothes or human body.

Some devices such as the DVD player use the optical pickup(laser diode)and the optical pickup will be damaged by

static electricity in the working environment.Proceed servicing works under the working environment where grounding

1.Put a conductive material(sheet)or iron sheet on the area where the optical pickup is placed,and ground the sheeet.

3.The flexible cable may be cut off if an excessive force is applied to it.Use caution when handling the cable.

Use due caution to electrostatic breakdown when servicing and handling the laser diode.

5.1.Grounding for electrostatic breakdown prevention

works is completed.

5.1.1. Worktable grounding

5.1.2.Human body grounding

1 Use the anti-static wrist strap to discharge the static electricity form your body.

safety_3 (1577x409x2 tiff)

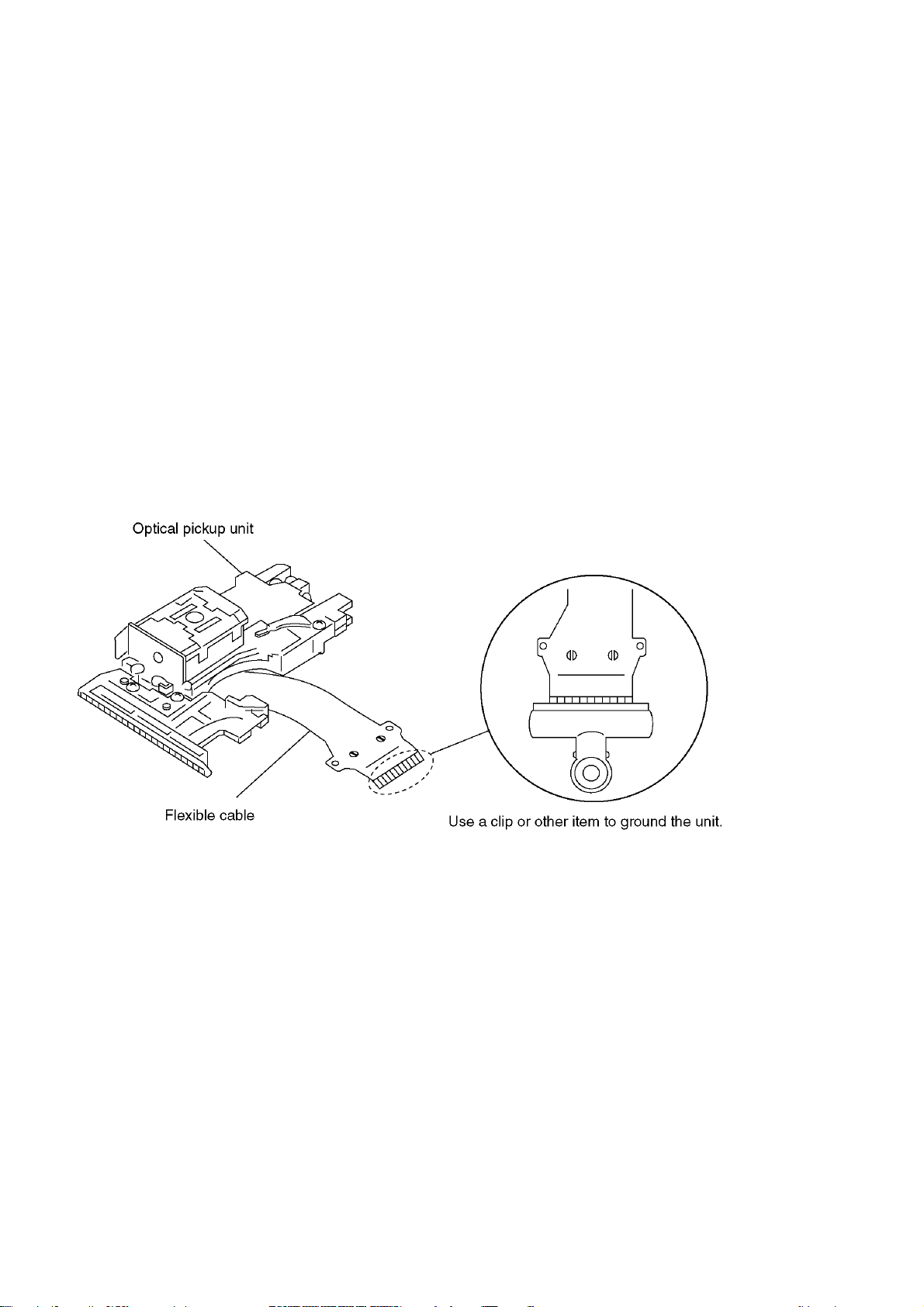

5.1.3.Handing of optical pickup

1.To keep the good quality of the optical pickup maintenance parts during transportation and before

installation,the both ends of the laser diode are short-circuited.After replacing the parts with new ones,

remove the short circuit according to the correct procedure.(See this Technical Guide).

2.Do not use a tester to check the laser diode for the optical pickup .Failure to do so willdamage the laser

diode due to the power supply in the tester.

5.2.Handing precautions for Traverse Unit (Optical Pickup)

1.Do not give a considerable shock to the traverse unit(optical pickup)as it has an extremely high-precise

structure.

2.When replacing the optical pickup,install the flexible cable and cut is short land with a nipper.See the

optical pickup replacement procedure in this Technical Guide.Before replacing the traverse unit,remove

the short pin for preventingstatic electricity and install a new unit.Connect the connector as short times as

possible.

4.The half-fixed resistor for laser power adjustment cannot be adjusted.Do not turn the resistor.

5

Page 7

6.ASSEMBLING AND DISASSENBLING THE MECHANISM UNIT

6

6.1Disassembly Procedure

6.2 Terminal P.C.B.

1.Unscrew the screws.

2.Remove the solders.

3.Remove the connectors

5

Page 8

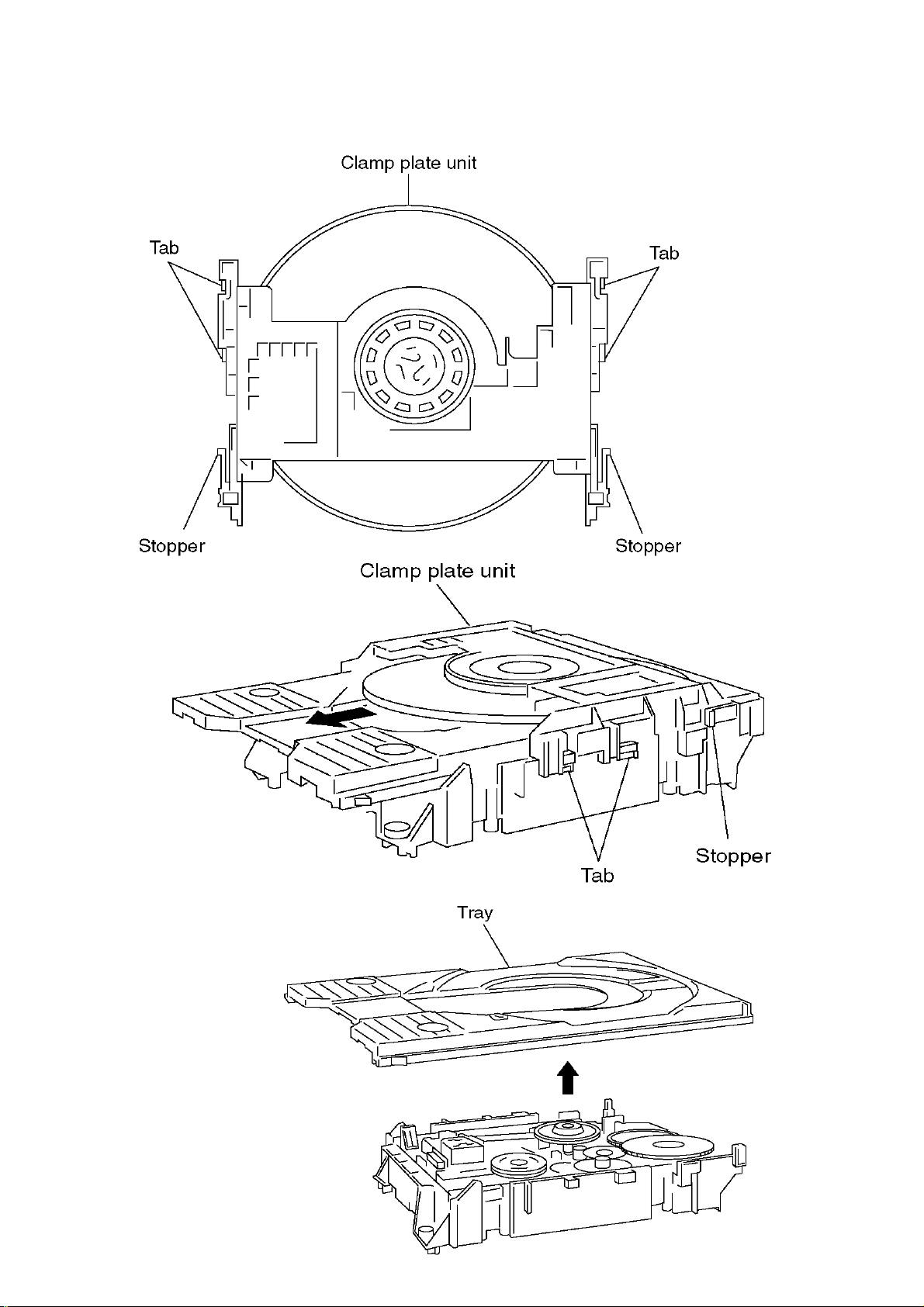

6.3 Clamp Plate Unit

7

1.Spread the stopper with hand to silde the tabs and remove the clamp plate unit.

6.4 Tray

1.Lift the tray.

6

Page 9

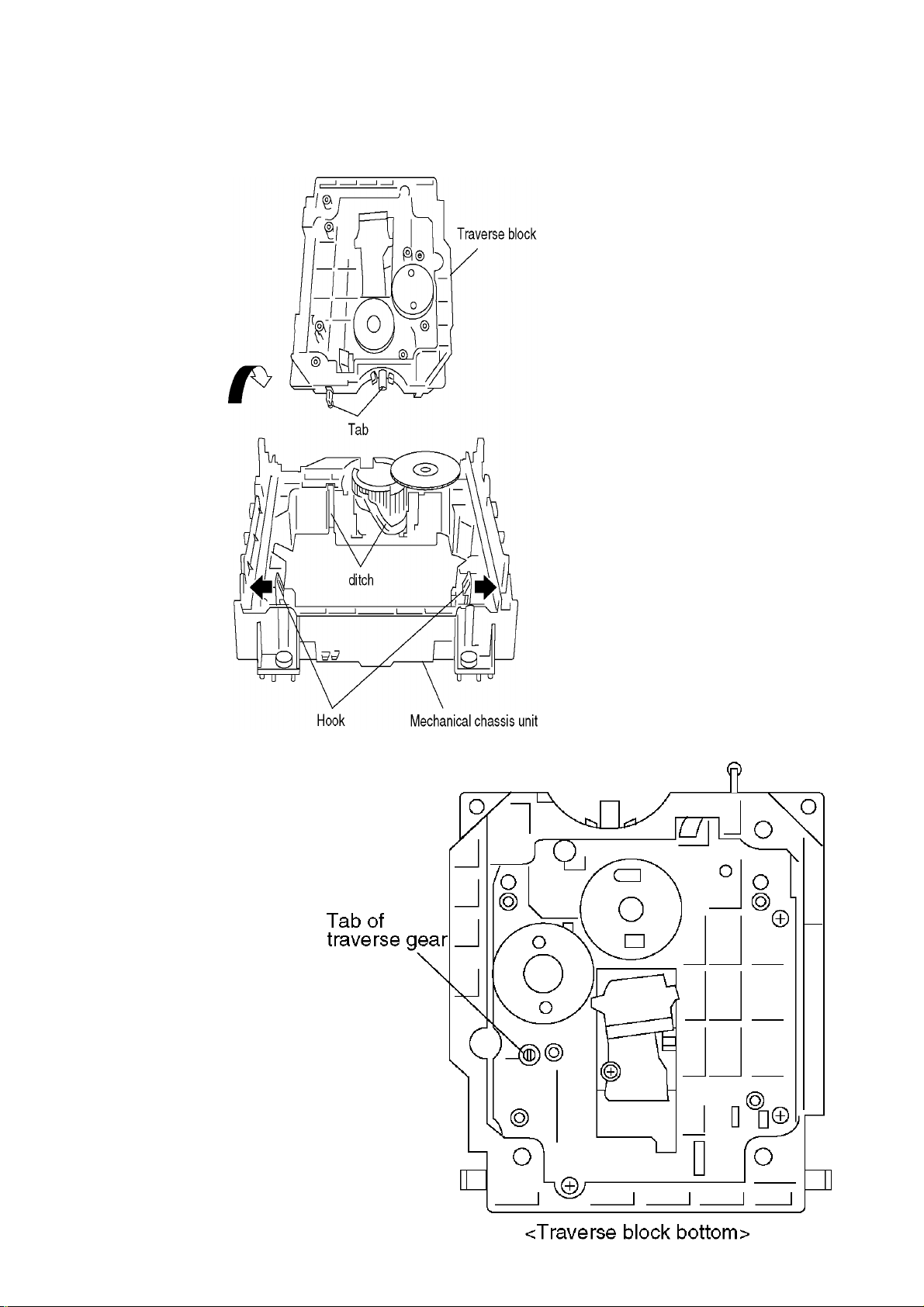

6.5 Traverse Block

8

1.Lift the traverse block while spreading the hook of the mechanical chassis chassis unit.

2.Disengage the tabs from the holes of the mechanical chassis unit.

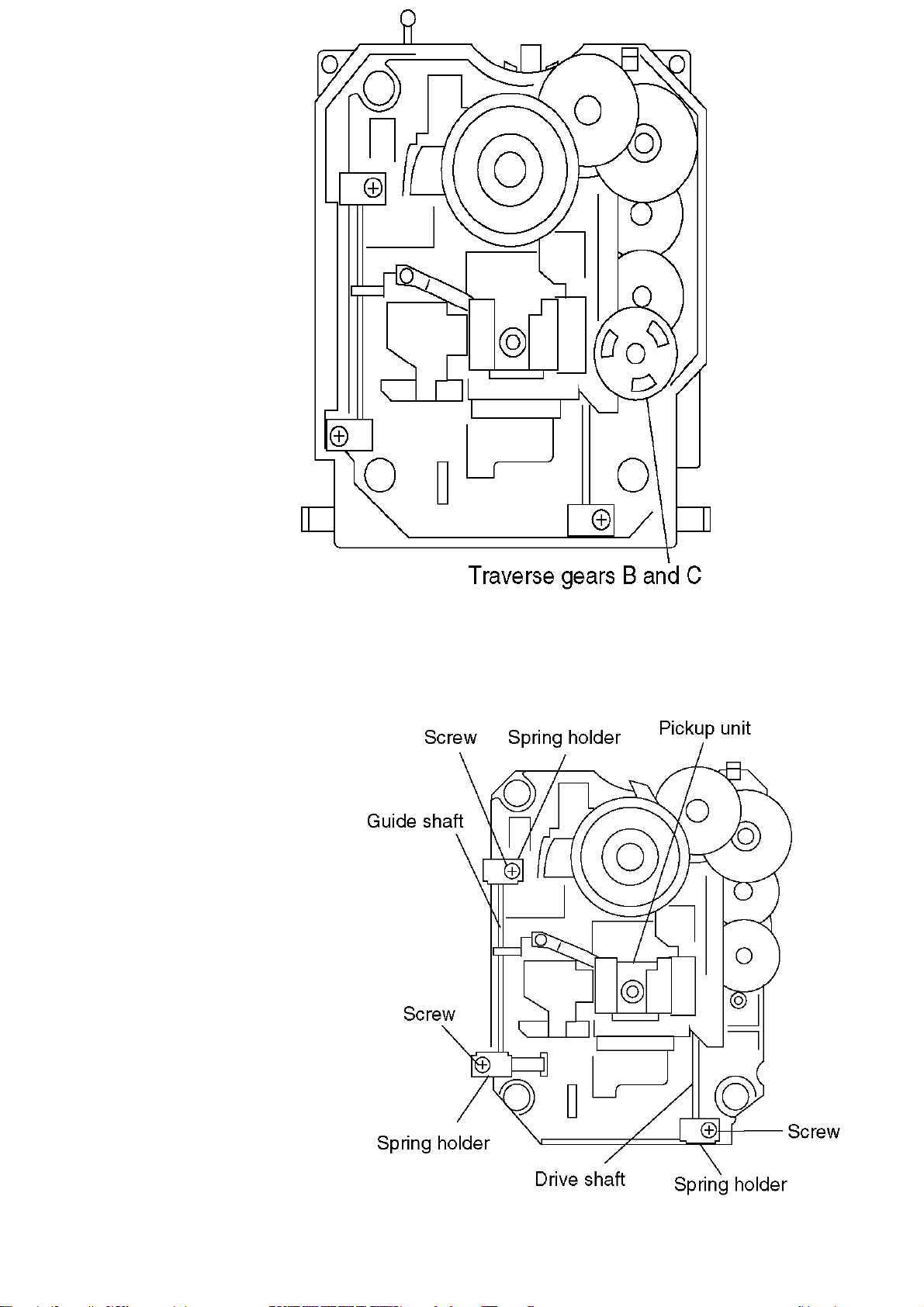

6.6. Traverse Gear

1.Disengage the tabs from the traverse gear

2.Remove the traverse gears B and C.

7

Page 10

5.6 Mechanism Unit

9

1.Unscrew the screws.

2.Remove the connectors.

6.7. Optical Pickup Unit

1. Unscrew the screws.

5.7 Terninal P.C.B.

2.Remove the spring holders and the springs.

3.Pull out of the drive shaft and guide shaft.

1.Unscrew the screws

2.Remove the solders.

3.Remove the connectors.

6.7.1. Precautions in optical pickup replacement

Page 11

The optical pickup can be damaged by static electricity from you body.Be sure to take static electricity countermeasures

when working around the optical pickup.(Refer to the related page in this Manual about the countermeasures.

3.The use of soldering iron with anti-static feature is recommended when providing short-circuit to laser diode or when

-When using the soldering iron without anti-static feature,short-circuit the flexible cable terminal with a clip before

-After intended repair is finished.remove the solder for short-circuit of laser diode in a correct way following the

procedures described in this Manual.

short-circuiting the land.

10

1.Do not touch laser diode,actuator and their peripheries.

2.Do not use tester to check laser diode.(Laser diode can be damaged easily.)

removing it.

4.Solder the land on flexible cable of optical pickup unit.

Page 12

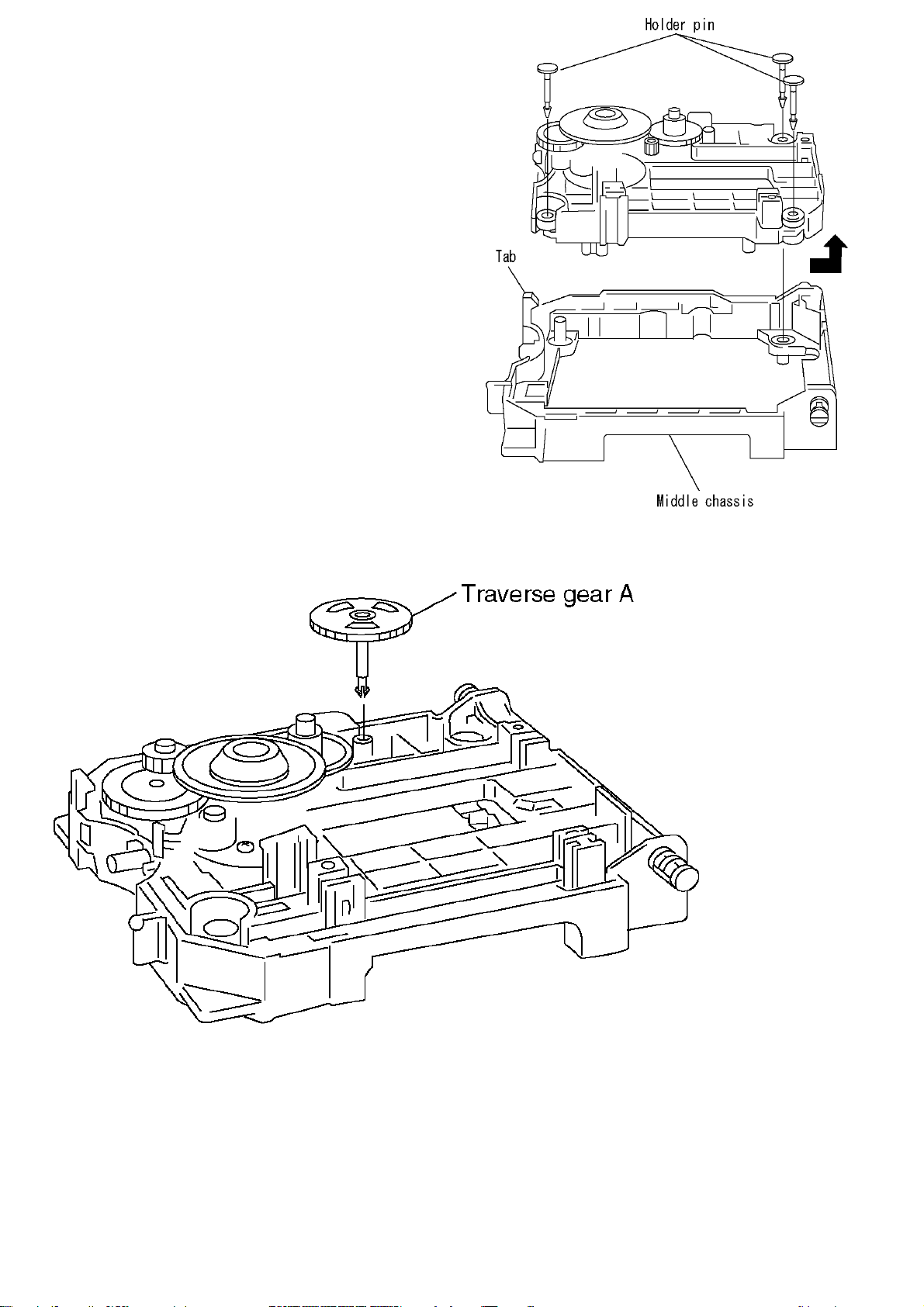

6.8. Disassenbling the Middle Chassis

11

1.Remove the holders pins.

2.Remove the tab.

3.It lifts while pulling it in the direction of the arrow.

6.9. Disassenbling the Traverse Gear A

1.Remove the traverse gear A.

Page 13

7. Electrical Confirmation

6.10. Disassembling the Sprindle Motor Unit

1.Remove the floating rubbers.

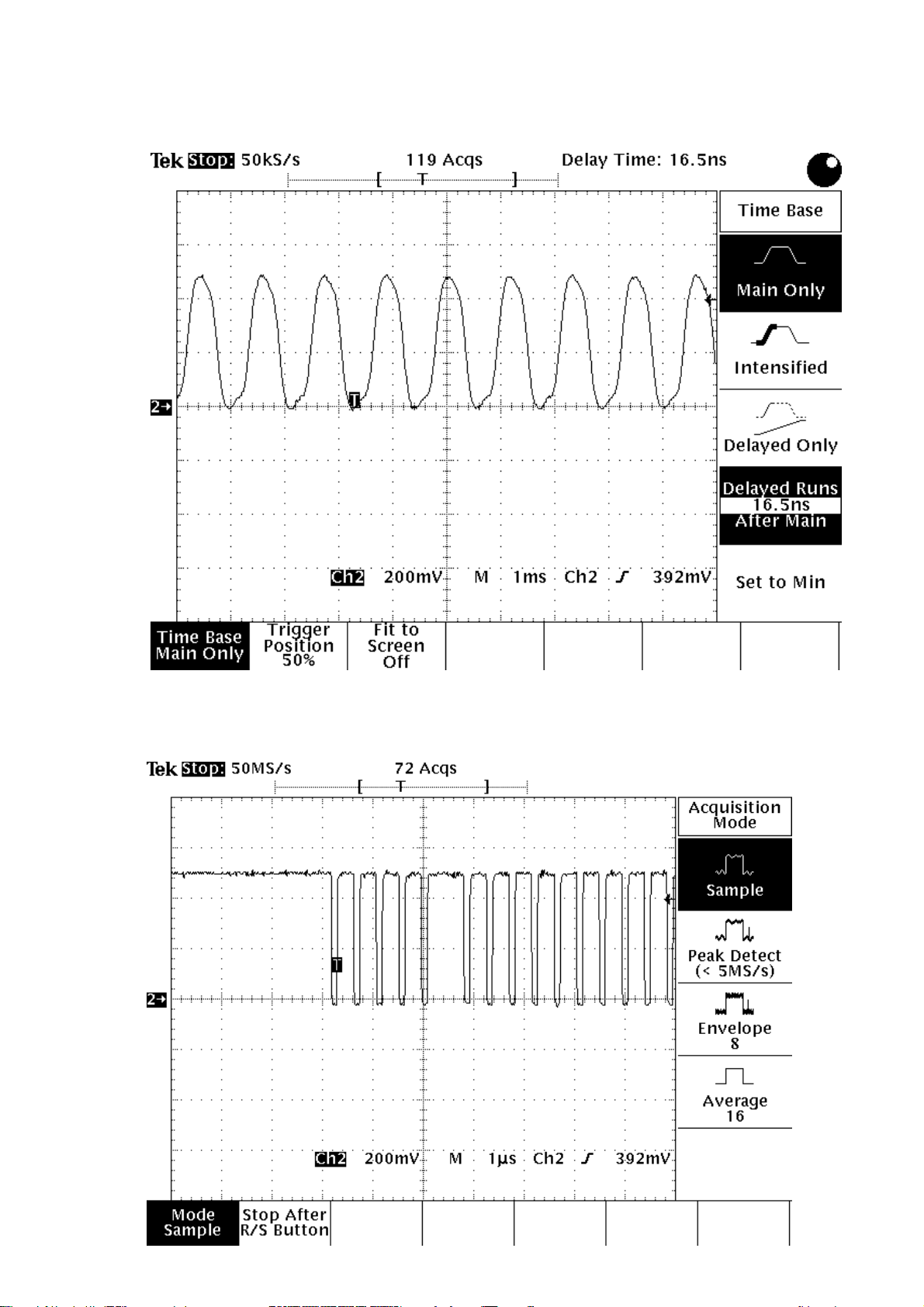

7.1. Video Output (Luminance Signal) Confirmation

DO this confirmation after replacing a P.C.B.

Measurement point

Mode Disc

Color bar 75%

Video output terminal

PLAY(Title 46):DVDT-S15

PLAY(Title 12):DVDT-S01

Measuring equipment,tools

200mV/dir,10 sec/dir

Confirmation value

1000mVp-p±30mV

Purpose:To maintain video signal output compatibility.

1.Connect the oscilloscope to the video output terminal and terminate at 75 ohms.

2.Confirm that luminance signal(Y+S)level is 1000mVp-p±30mV

DVDT-S15

or

DVDT-S01

12

Page 14

7.2. Video Output (Chrominance Signal) Confirmation

Screwdriver,Oscilloscope

13

Do the confirmation after replacing P.C.B.

Measurement point

Mode Disc

Color bar 75%

Video output terminal

PLAY(Title 46):DVDT-S15

PLAY(Title 12):DVDT-S01

Measuring equipment,tools Confirmation value

200mV/dir,10 sec/dir

621mVp-p±30mV

Purpose:To maintain video signal output compatibility.

1.Connect the oscilloscope to the video output terminal and terminate at 75 ohme.

2.Confirm that the chrominance signal(C)level is 621 mVp-p±30mV

DVDT-S15

or

DVDT-S01

Page 15

8. MPEG BOARD CHECK WAVEFORM

1.X204 WAVEFORM DIAGRAM

2.ZIVA-4.1 PIN.173/STRMCS WAVEFORM

14

Page 16

3.IC5L0380R PIN.2 WAVEFORM DIAGRAM

4.VIDEO OUPUT WAVEFORM DIAGRAM

15

Page 17

5.ZIVA-4.1PIN.172/DVDREQ WAVEFORM DIAGRAM

16

Page 18

Loader

IC U217 ZIVA-4.1

1 Typical ZiVA-4.1 DVD Decoder Application

9. IC BLOCK DIAGRAM & DESCRIPTION

17

SDRAM

Video Out

Front-End

Chip Set

ZiVA-4.1

ROM

Host

RAM

2 General Description

The ZiVA-4.1 DVD Decoder is the fourth generation in

C-Cube’s ZiVA family of highly integrated, high-performance

DVD decoders for the consumer DVD player market.

The ZiVA-4.1 maintains the same high-level application program interface (API) as earlier decoders. Therefore, system

host code developed for previous products is fully compatible with the ZiVA-4.1 API. This compatibility preserves software investment in designs and will be maintained in future

generations of the decoder family. Figure 2 shows the data

flow of the ZiVA-4.1 Decoder.

Digital Audio Input

2/6/2+6 Channel

Audio DAC

2/6/2+6

Channel

Out

0220c

SDRAM

Interface

Host

Interface

DVD/CD

Interface

Memory

Controller

Host

Interface

Control Logic

SecureView

CSS

Descrambling

Bus Key

Authentication

(optional)

Program

Stream

Decoder

OSD

Decoder

Subpicture

Decoder

MPEG Video

Decoder

CD-DA and LPCM

Decoder

Dolby Digital Audio

Decoder

MPEG Audio

Decoder

Figure 2 ZiVA-4.1 DVD Decoder Data Flow Diagram

Video

Mixer

Audio

DSP

Digital Audio Input

Digital

Video

Encoder

Digital

Audio

Interface

Video

Out

Audio

Interface

0221d

Page 19

A_VSS

3 Pin Descriptions

The ZiVA-4.1 decoder is packaged in a 208-pin Plastic Quad Flat Pack (PQFP) package. Figure 3 shows the

lists the pin number, pin name, and I/O voltage and I/O type.

IC BLOCK DIAGRAM & DESCRIPTION

18

SYSCLK

VCLK

A_VDD

DVD-DATA0/CD-DATA

DVD-DATA1/CD-LRCK

DVD-DATA2/ CD-BC K

DVD-DATA3/CD-C2P0

DVD-DATA4/ CDG-S DATA

DVD-DATA5/CDG-VFSY

DVD-DATA6/CDG-S0S1

DVD-DATA7/CDG-SCLK

VSS

VDD_3.3

VDACK

VREQUEST

VSTROBE

ERROR

VDD_3.3

RESERV ED

VDD_3.3

VSS

HADDR0

HADDR1

HADDR2

RESERV ED

RESERV ED

RESERV ED

VSS

VDD_2.5

RESERV ED

VSS

VDD_3.3

RESERV ED

RESERV ED

RESERV ED

RESERV ED

HDATA7

VSS

HDATA6

HDATA5

HDATA4

HDATA3

HDATA2

VDD_3.3

VSS

HDATA1

HDATA0

VDD_RREF

RREF

VSS_RREF

VDD_VIDEO

VDD_DAC

C/R/V

VSS_VIDEO

VSS_DACNCVDD_ VIDEO

VDD_DAC

Y/B/U

VSS_VIDEO

VSS_DACNCVDD_VIDEO

VDD_DAC

CVBS/G/Y

VSS_VIDEO

VSS_DACNCVDD_VIDEO

VDD_DAC

CVBS + sync

VSS_VIDEO

VSS_DACNCVSS

VDD_2.5

DA-IEC

DA-BCK

DA-XCK

VSS

VDD_3.3

DA-LRCK

DA-DATA0

DA-DATA1

DA-DATA2

DA-DATA3

DAI-DATA

VSS

VDD_3.3

DAI-BCK

DAI-LRCK

RESERVED

RESERVED

RESERVEDNCRESERVEDNCNC

RESERVED

156

155

154

153

152

151

150

149

148

147

146

145

144

143

142

141

140

139

138

137

136

135

134

133

132

131

130

129

128

127

126

125

124

123

122

121

120

119

118

117

116

115

114

113

112

111

110

109

108

107

106

105

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

NC

179

NC

180

NC

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

CS

208

123456789101112131415161718192021222324252627282930313233343536373839404142434445464748495051

ZiVA-4.1 Decoder

Top View

104

103

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

MADDR3

MADDR2

MADDR1

VSS

VDD_3.3

MADDR0

MADDR10

SD-BS

SD-CS1/MADDR11

SD-CS0

SD-RAS

VSS

VDD_3.3

SD-CAS

MWE

MADDR4

VSS

VDD_2.5

MADDR5

MADDR6

MADDR7

VSS

VDD_3.3

MADDR8

MADDR9

CLKSEL

SD-CLK

LDQM

MDATA8

VSS

VDD_3.3

MDATA9

MDATA10

MDATA11

MDATA12

MDATA13

VSS

VDD_2.5

MDATA14

VSS

VDD_3.3

MDATA15

MDATA7

MDATA6

MDATA5

MDATA4

MDATA3

MDATA2

VSS

VDD_3.3

MDATA1

MDATA0

RD

R/W

VDD_3.3

NCNCNC

NC

NCNCNC

VSS

INT *

RESET

WAIT*

VDD_3.3

VDD_2.5

NC

VSS

VSS

VDATA0

VDATA1

VDATA2

VDATA3

VDATA4

VDD_3.3

VSS

VSYNC

HSYNC

VDATA5

VDATA6

VDATA7

VSS

VDD_3.3

VDD_2.5

RESERV ED

RESERV ED

RESERV ED

RESERV ED

VSS

PIO0

PIO1

PIO2

PIO3

PIO4

PIO5

PIO6

RESERV ED

VDD_3.3

RESERV ED

RESERV ED

RESERV ED

PIO7

* These pins must be pulled up to 3.3 volts through an external 4.7K resistor

Page 20

Table 1 ZiVA-4.1 Decoder Pin List

IC BLOCK DIAGRAM & DESCRIPTION

19

Table 1 ZiVA-4.1 Decoder Pin List (Continued)

Pin No. Pin Name I/O Voltage I/O Type

1RD

2R/W

3 VDD_3.3 3.3V

4 WAIT 3.3V O, OD, PU

5RESET

6 VSS GROUND

7 VDD_3.3 3.3V —

8INT 3.3V O, OD, PU

9 NC No Connect O

10 NC No Connect O

11 NC No Connect O

12 NC No Connect O

13 VDD_2.5 2.5V

14 VSS GROUND —

15 NC No Connect O

16 NC No Connect O

17 NC No Connect O

18 NC No Connect O

19 VSS GROUND

20 VDD_3.3 3.3V —

21 VDATA0 3.3V O

22 VDATA1 3.3V O

23 VDATA2 3.3V O

24 VDATA3 3.3V O

25 VDATA4 3.3V O

26 VDATA5 3.3V O

27 VDATA6 3.3V O

28 VDATA7 3.3V O

29 VSYNC

30 HSYNC

31 VSS GROUND

32 VDD_3.3 3.3V —

33 RESERVED 3.3V I

34 RESERVED 3.3V I

35 RESERVED 3.3V I

36 VDD_2.5 2.5V

37 VSS GROUND —

38 RESERVED 3.3V I

39 RESERVED 3.3V I

40 RESERVED 3.3V I

41 RESERVED 3.3V I

42 RESERVED 3.3V I

43 PIO0 3.3V I/O

44 VSS GROUND

45 VDD_3.3 3.3V —

46 PIO1 3.3V I/O

47 PIO2 3.3V I/O

48 PIO3 3.3V I/O

3.3V I

3.3V I

—

3.3V I

—

—

—

3.3V I/O

ADV

3.3V I/O

—

—

—

Pin No. Pin Name I/O Voltage I/O Type

49 PIO4 3.3V I/O

50 PIO5 3.3V I/O

51 PIO6 3.3V I/O

52 PIO7 3.3V I/O

53 MDATA0 3.3V I/O

54 MDATA1 3.3V I/O

55 VDD_3.3 3.3V

56 VSS GROUND —

57 MDATA2 3.3V I/O

58 MDATA3 3.3V I/O

59 MDATA4 3.3V I/O

60 MDATA5 3.3V I/O

61 MDATA6 3.3V I/O

62 MDATA7 3.3V I/O

63 MDATA15 3.3V I/O

64 VDD_3.3 3.3V I/O

65 VSS GROUND I/O

66 MDATA14 3.3V I/O

67 VDD_2.5 2.5V

68 VSS GROUND —

69 MDATA13 3.3V I/O

70 MDATA12 3.3V I/O

NCE

71 MDATA11 3.3V I/O

A

72 MDATA10 3.3V I/O

73 MDATA9 3.3V I/O

74 VDD_3.3 3.3V

75 VSS GROUND —

76 MDATA8 3.3V I/O

77 LDQM 3.3V O

78 SD-CLK 3.3V O

79 CLKSEL 3.3V I

80 MADDR9 3.3V O

81 MADDR8 3.3V O

82 VDD_3.3 3.3V

83 VSS GROUND —

84 MADDR7 3.3V O

85 MADDR6 3.3V O

86 MADDR5 3.3V O

87 VDD_2.5 2.5V

88 VSS GROUND —

89 MADDR4 3.3V O

90 MWE

91 SD-CAS

92 VDD_3.3 3.3V

93 VSS GROUND —

94 SD-RAS 3.3V O

95 SD-CS0

96 SD-CS1

/MADDR11 3.3V O

3.3V O

3.3V O

3.3V O

—

—

—

—

—

—

Page 21

Table 1 ZiVA-4.1 Decoder Pin List (Continued)

IC BLOCK DIAGRAM & DESCRIPTION

20

Table 1 ZiVA-4.1 Decoder Pin List (Continued)

Pin No. Pin Name I/O Voltage I/O Type

97 SD-BS

98 MADDR10 3.3V O

99 MADDR0 3.3V O

100 VDD_3.3 3.3V

101 VSS GROUND —

102 MADDR1 3.3V O

103 MADDR2 3.3V O

104 MADDR3 3.3V O

105 RESERVED ANALOG GND

106 NC No connect O

107 NC No connect O

108 RESERVED 3.3V I

109 NC No connect O

110 RESERVED 3.3V I

111 RESERVED 3.3V ANALOG

112 RESERVED 3.3V I

113 DAI-LRCK 3.3V I/O

114 DAI-BCK 3.3V I/O

115 VDD_3.3 3.3V

116 VSS GROUND —

117 DAI-DATA 3.3V I/O

118 DA-DATA3 3.3V O

119 DA-DATA2 3.3V O

120 DA-DATA1 3.3V O

121 DA-DATA0 3.3V O

122 DA-LRCK 3.3V O

123 VDD_3.3 3.3V

124 VSS GROUND —

125 DA-XCK 3.3V I/O

126 DA-BCK 3.3V O

127 DA-IEC 3.3V O

128 VDD_2.5 2.5V

129 VSS GROUND —

130 NC No Connect O

131 VSS_DAC ANALOG GND

132 VSS_VIDEO ANALOG GND —

133 CVBS + sync 3.3V ANALOG O

134 VDD_DAC 3.3V ANALOG O

135 VDD_VIDEO 3.3V ANALOG

136 NC No Connect O

137 VSS_DAC ANALOG GND

138 VSS_VIDEO ANALOG GND —

139 CVBS/G/Y 3.3V ANALOG O

140 VDD_DAC 3.3V ANALOG

141 VDD_VIDEO 3.3V ANALOG —

142 NC No Connect O

143 VSS_DAC ANALOG GND

3.3V O

—

—

—

—

—

ADV

—

—

—

—

—

—

Pin No. Pin Name I/O Voltage I/O Type

144 VSS_VIDEO ANALOG GND —

145 Y/B/U 3.3V ANALOG O

146 VDD_DAC 3.3V ANALOG

147 VDD_VIDEO 3.3V ANALOG —

148 NC No Connect O

149 VSS_DAC ANALOG GND

150 VSS_VIDEO ANALOG GND —

151 C/R/V 3.3V ANALOG O

152 VDD_DAC 3.3V ANALOG

153 VDD_VIDEO 3.3V ANALOG —

154 VSS_RREF ANALOG GND —

155 RREF 3.3V ANALOG O

156 VDD_RREF 3.3V ANALOG

157 A_VSS GROUND —

158 SYSCLK 3.3V I

159 VCLK 3.3V I

160 A_VDD 3.3V ANALOG

161 DVD-DATA0/CD-DATA 3.3V I

162 DVD-DATA1/CD-LRCK 3.3V I

163 DVD-DATA2/CD-BCK 3.3V I

164 DVD-DATA3/CD-C2P0 3.3V I

165 DVD-DATA4/CDG-SDATA 3.3V I

NCE

166 VSS GROUND

A

167 VDD_3.3 3.3V —

168 DVD-DATA5/CDG-VFSY 3.3V I

169 DVD-DATA6/CDG-S0S1 3.3V I

170 DVD-DATA7/CDG-SCLK 3.3V I

171 VDACK 3.3V I

172 VREQUEST 3.3V O

173 VSTROBE 3.3V I

174 ERROR 3.3V I

175 VDD_3.3 3.3V

176 RESERVED GROUND —

177 VDD_3.3 3.3V —

178 VSS GROUND —

179 NC No connect O

180 NC No connect O

181 NC No connect O

182 HADDR0 3.3V I

183 HADDR1 3.3V I

184 HADDR2 3.3V I

185 RESERVED 3.3V I

186 RESERVED 3.3V I

187 RESERVED 3.3V I

188 VSS GROUND

189 VDD_2.5 2.5V —

190 RESERVED 3.3V I

—

—

—

—

—

—

—

—

Page 22

Table 1 ZiVA-4.1 Decoder Pin List (Continued)

IC BLOCK DIAGRAM & DESCRIPTION

21

Table 1 ZiVA-4.1 Decoder Pin List (Continued)

Pin No. Pin Name I/O Voltage I/O Type

191 VSS GROUND —

192 VDD_3.3 3.3V —

193 RESERVED 3.3V I

194 RESERVED 3.3V I

195 RESERVED 3.3V I

196 RESERVED 3.3V I

197 HDATA7 3.3V I/O

198 VSS GROUND

Note: The ZiVA-4.1 core operates at 2.5V ± 10%. Most I/O interface pins can be interfa ced with 3.3-V or 5-V devices depending on the voltage appli ed to the VDD pins associated

with them. Refer to the Application Note for more information.

—

Pin No. Pin Name I/O Voltage I/O Type

199 HDATA6 3.3V I/O

200 HDATA5 3.3V I/O

201 HDATA4 3.3V I/O

202 HDATA3 3.3V I/O

203 HDATA2 3.3V I/O

204 VDD_3.3 3.3V

205 VSS 3.3V —

206 HDATA1 3.3V I/O

207 HDATA0 3.3V I/O

208 CS

3.3V I

—

Signal Descriptions

Table 2 provides the pin name, pin number, type, and description of each signal.

Table 2 ZiVA-4.1 DVD Pin Descriptions

Name Pin No. Ty p e

RESET 5 I Active Low Reset. Assert for at least 5-milliseconds in the presence of clock to

SYSCLK 158 I Optional System Clock. Tie to A_VDD through a 1K Ohm resistor

CLKSEL 79 I Selects SYSCLK or VCLK as clock source. Normal operation is to tie HIGH.

VCLK 159 I System clock that drives internal PLLs and internal DENC. ZiVA-4 requires an

PIO[7:0] 52-46, 43 I/O Programmable I/O pins.

System Services

NC 181-179, 148, 142, 136, 130, 109, 107,

106, 18-15, 12-9

RESERVED 196-193, 190, 187-185, 176, 112, 111, 110,

108, 105, 42-38, 35-33

VDD_3.3 3, 7, 20, 32, 45, 55, 64, 74, 82, 92, 100, 115,

123, 167, 175, 177, 192, 204

VDD_2.5 13, 36, 67, 87, 128, 189 Power 2.5-V supply voltage for core logic

VDD_VIDEO 135, 141, 147, 153 Power 3.3-V Analog Video Power

VDD_DAC 134, 140, 146, 152 Power Analog Video DAC Power

A_VDD 160 Power 3.3-V Analog PLL Power

VDD_RREF 156 Power 3.3V Analog Video Power

VSS 6, 14, 19, 31, 37, 44, 56, 65, 68, 75, 83, 88,

Power and Grounds

VSS_VIDEO 132, 138, 144, 150 Ground Analog Video Ground

VSS_DAC 149, 143, 137, 131 Ground Analog Video DAC Ground

A_VSS 157 Ground Analog PLL Ground

VSS_RREF 154 Ground Video Analog Ground

93, 101, 116, 124, 129, 166, 178, 188, 191,

ADV

198, 205

1

reset the entire chip

Description

NCE

A

external 27-MHz TTL oscillator.

O No connect.

I Tie to VSS or VDD_3.3 as specified in Table 1.

Power 3.3-V supply voltage for I/O signals.

Ground Ground for core logic and I/O signals

Page 23

Table 2 ZiVA-4.1 DVD Pin Descriptions (Continued)

IC BLOCK DIAGRAM & DESCRIPTION

22

Name Pin No. Ty p e

CS 208 I Host chip select. Host asserts CS to select the decoder for a read or write oper-

HADDR[2:0] 184-182 I Host addr ess bus. 3-bit address bus selects one of eight host interface registers.

HDATA[7:0] 197, 199-203, 206, 207 I/O HDATA[7:0] is the 8-bit bi-directional host data bus through which the host

8 O, OD, PU Host interrupt. Open drain signal, must be pulled-up via 4.7kΩ to 3.3 volts.

INT

1 I Read strobe in I mode. Must be held HIGH in M Mode.

RD

Host Interface

2 I Read/write strobe in M mode. Write strobe in I mode. Host asserts R/W LOW

R/W

WAIT

DVD-DATA7/CDG-SCLK 170 I DVD parallel compressed da ta from DVD DSP. Or CD+G (Subcode) Clock indicat-

DVD-DATA6/CDG-S0S1 169 DVD pa rallel compressed data from DVD DSP. Or CD+G (Subcode) Block Sync

DVD-DATA5/CDG-VFSY 168 DVD parallel compressed dat a from DVD DSP. Or CD+G (Subcode) Frame Sync

DVD-DATA4/CDG-SDATA 165 DVD parallel compressed data from DVD DSP. Or CD+G (Subcode) data indicat-

DVD-DATA3/CD-C2P0 164 I Asserted HIGH indicates a corrupted byte. Decoder keeps the previous valid pic-

DVD-DATA2/CD-BCK 163 I CD bit clock. Decoder accept multiple BCK rates. This pin is shared with DVD

DVD-DATA1/CD-LRCK 162 I Programmable polarity 16-bit word synchronization to the decoder (right chan-

DVD-DATA0/CD-DATA 161 I Serial CD data. This pin is shared with DVD compressed data DVD-DATA0.

ERROR 174 I Error in input data. If ERROR signal is not available from the DSP it must be

Parallel DVD/CD or Serial CD Interface

VDACK 171 I In synchr onous mode, bitstream data ackn owledge. Asserted when DVD dat a is

VREQUEST 172 O Bitstream request. Decoder asserts VREQUEST to indicate that the bitstream

VSTROBE 173 I Bitstream strobe. Programmable dual mode pulse. Asynchronous and synchro-

SD-CAS 91 O Active LOW SDRAM Column Address

SD-RAS

SD-CS0

/MADDR11 96 O Active LOW SDRAM Chip Select 1 or use as MADDR11 for larger SDRAM

SD-CS1

LDQM 77 O SDRAM Lower or Upper Mask

SD-BS

SDRAM Interface

MADDR[10:0] 98, 80, 81, 84-86, 89, 104-102, 99 O SDRAM Address

MDATA[15:0] 63, 66, 69-73, 76, 62-57, 54, 53 I/O SDRAM Data

MWE

SD-CLK 78 O SDRAM Clock

4 O, OD , PU Transfer not complete / data acknowledge. Active LOW to indicate host initiated

ADV

94 O Active LOW SDRAM Row Address

95 O Active LOW SDRAM Chip Select 0

97 O SDRAM Bank Select

90 O SDRAM Write Enable

1

ation. The falling edge of this signal triggers the read or write operation.

writes data to the decoder Code FIFO. MSB of the 32-bit word is written first.

The host also reads and writes the decoder internal registers and local

SDRAM/ROM via HDATA[7:0].

Driven high for 10 ns before tristate.

to select Write and LOW to select Read for M Mode only.

transfer is not complete. WAIT

serted when decoder is ready to complete transfer cycle. Open drain signal,

must be pulled-up via 1kΩ to 3.3 volts. Driven high for 10 ns before tristate.

ing subcode data clock input or output.

indicating block-start synchronization input.

indicating frame-start or composite synchronization input.

ing serial subcode data input.

NCE

ture on-screen until the next valid picture is decoded. This pin is shared with

A

DVD compressed data DVD-DATA3.

compressed data DVD-DATA2.

nel HIGH). This pin is shared with DVD compressed data DVD-DATA1.

grounded.

valid. Polarity is programmable.

input buffer has available space. Polarity is programmable.

nous. In Asynchronous mode, an external source pulses VSTROBE to indicate

data is ready for transfer. In synchronous mode, VSTROBE clocks da ta.

(64 Mbits).

Description

is asserted after the falling edge of CS and reas-

Page 24

Table 2 ZiVA-4.1 DVD Pin Descriptions (Continued)

IC BLOCK DIAGRAM & DESCRIPTION

23

Name Pin No. Ty p e

C/R/V 151 Analog O DAC video output format. Macrovision encoded.

Y/B/U 145 Analog O DAC video output format. Macrovision encoded.

CVBS/G/Y 139 Analog O DAC video output format. Macrovision encoded.

CVBS + sync 133 Analog O DAC video output format: Composite + sync. Macrovision encoded.

RREF 155 Analog O Reference Resistor. Connecting to pin 154 through a 1.18K+/- 1% resistor is rec-

Analog Video Output

VCLK 159 I System clock that drives internal PLLs. ZiVA-4 requires an external 27-MHz TTL

HSYNC 30 I/O Horizontal sync. The decoder begins outputting pixel data for a new horizontal

VCLK 159 I Video clock. Clocks out data on input. VDATA[7:0]. Clock is typically 27 MHz.

VDATA[7:0] 28-21 O Video data bus. Byte serial CbYCrY data synchronous with VCLK. At power-up,

29 I/O Vertical sync. Bi-directional, the decoder outputs the top border of a new field

VSYNC

Digital Video Output

DA-DATA[3:0] 118, 119, 120, 121 O PCM Data Out. Eight channels. Serial audio samples relative to DA_BCK and

DA-BCK 126 O PCM Bit Clock. Divided by 8 from DA_XCK. DA_BCK can be either 48 or 32 times

DA-LRCK 122 O PCM Left Clock. Identifies the channel for each sample. The polarity is program-

DA-XCK 125 I/O Audio External Frequency Clock input or output. DA_BCK and DA_LRCK are

Audio Interface

DA-IEC 127 O PCM data out in IEC-958 format or compressed data out in IEC-1937 format.

DAI-DATA 117 I PCM data input.

DAI-BCK 114 I PCM input bit clock.

DAI-LRCK 113 I PCM left/right clock.

Digital Mic In

1. I - input, O - output, OD - open drain, PU - requires external pull-up resistor.

ADV

1

ommended

oscillator.

line after the falling (active) edge of HSYNC

the decoder does not drive VDATA. During boot-up, the decoder uses configuration parameters to drive or 3-state VDATA.

on the first HSYNC

synchronization or top/bottom field notification from an external source.

(VSYNC

DA_LRCK.

the sampling frequency

mable

NCE

derived from this clock. DA_XCK can be 384 or 256 times the sampling fre-

A

quency

Description

.

after the falling edge of VSYNC. VSYNC can accept vertical

HIGH = bottom field. VSYNC LOW = Top field)

Table 3 lists the pins that have Schmitt Trigger inputs when programmed as inputs.

Table 3 Schmitt Trigger Inputs

Pin No. Pin Name Pin No. Pin Name

173 VSTROBE 165 DVD-DATA4/CDG-SDATA

171 VDACK 168 DVD-DATA5/CDG-VFSY

174 ERROR 169 DVD-DATA6/CDG-S0S1

161 DVD-DATA0/CD-DATA 170 DVD-DATA7/CDG-SCLK

162 DVD-DATA1/CD-LRCK 5 RESET

163 DVD-DATA2/CD-BCK 29 VSYNC

164 DVD-DATA3/CD-C2P0 30 HSYNC

Page 25

IC BLOCK DIAGRAM & DESCRIPTION

IC U204 CY37032

24

UltraLogicTM 32-Macrocell ISRTM CPLD

Features

• 32 macrocells in two logic blocks

• In-Sy stem Reprogrammable™ (ISR™)

—JTAG-compliant on-board programming

—Design changes don’t cause pinout changes

—Design changes don’t cause timing changes

•Up to 32 I/Os

—Plus 5 dedicated inputs including 4 clock inputs

• High speed

= 222 MHz

—f

MAX

= 5.0 ns

—t

PD

—t

S

—t

CO

• Product-term clocking

• IEEE 1149.1 JTAG boundary scan

• Programmable slew rate control on individual I/Os

• Low power option on individual logic block basis

• 5V and 3.3V I/O capability

• User-Programmable Bus Hold capabilities on all I/Os

• Simple Timing Model

• PCI compl iant

• Available in 44-Lead TQFP and PLCC pack ages

• Pinout compatible with the CY37032V, CY37064/

CY37064V, CY7C371i

= 3.0 ns

= 4.0 ns

Logic Block Diagram

−

I/O

I/O

0

Pin Configurations

I/O

/TCLK

5

I/O

6

I/O

7

CLK2/I

0

JTAG

EN

GND

CLK0/I

1

I/O

8

I/O

9

I/O

10

I/O

11

44-Lead PLCC (J67)

65 34 2

7

8

9

10

11

12

13

14

15

16

17

18

19 20 2221 23 24 2726 2825

12

I/O

/TMS

I/O

Clock/

Input

Input

1

4

4

16 I/Os 16 I/Os

15

LOGIC

BLOCK

A

36

16

PIM

16

36

LOGIC

BLOCK

16

B

16

Top View

0

31

I/O2GND

I/O3I/O4I/O1I/O

14

CC

V

I/O15I/O

13

CCO

V

1

44

43 42 4041

16

GND

28

I/O29I/O30I/O

I/O

I/O27/TDI

39

I/O

38

26

I/O

25

37

I/O

24

36

CLK1/I

35

34

33

32

31

30

29

20

I/O

I/O18I/O17I/O

/TDO

19

I/O

GND

I

3

CLK3/I

I/O

23

I/O

22

I/O

21

37032-2

4

2

I/O5/TCLK

I/O

I/O

CLK2/I

JTAG

GND

CLK

I/O

I/O

I/O

I/O

0

44 43 42 4041 39 38 37 3536 34

1

6

2

3

7

4

0

5

EN

6

/I

7

1

8

8

9

9

10

10

11

11

12

I/O

TDI

TCLK

TMS

4

44-Lead TQFP (A44)

Top

View

0

I/O2GND

I/O3I/O4I/O1I/O

18 19 20 222113 14 15 171612

14

CC

V

GND

I/O15I/O

/TMS

13

I/O

JTAG Tap

Controller

JTAG

EN

−

I/O

I/O

16

31

CCO

V

16

28

I/O29I/O30I/O31I/O

33

32

31

30

29

28

27

26

25

24

23

37032–3

20

I/O

I/O18I/O17I/O

/TDO

19

I/O

I/O27/TDI

I/O

26

I/O

25

I/O

24

CLK1/I

GND

I

3

CLK3/I

I/O

23

I/O

22

I/O

21

TDO

37032-1

4

2

Selection Guide

CY37032-222 CY37032-200 CY37032-154 CY37032-125

Maximum Propagation Delay, tPD (ns) 5.0 6.0 7.5 10

Minimum Set-Up, tS (ns) 3.0 4 5 5.5

Maximu m Cl o ck to O u tp u t, t

T ypic al Supply Current, ICC (mA) in Low Power Mode 15 15 15 15

Shaded areas contain advance information.

(ns) 4.0 4 4.5 6.5

CO

Page 26

Electrical Characteristics

IC BLOCK DIAGRAM & DESCRIPTION

25

Over the Ope rating Range

Parameter Description Tes t Condi tions Min. Typ. Max. Unit

V

V

V

V

V

I

I

OH

OHZ

OL

IH

IL

IX

OZ

Output HIGH Voltage VCC = Min. IOH = –3.2 mA

(Com’l/Ind)

Output HIGH Voltage with Output Disabled

[6]

VCC = Max. IOH = 0 µA (Com’l)

IOH = 0 µA (Ind)

IOH = –50 µA (Com’l)

IOH = –100 µA (Ind)

Output LOW Voltage VCC = Min. IOL = 16 mA (Com’l/Ind)

Input HIGH Voltage Guaranteed Input Logical HI GH v oltage

for all input s

Input LOW Voltage Guaranteed In put Logical LOW voltage

for all input s

[4]

[4]

[2]

[3]

[3]

[3]

[3]

[2]

Input Load Current VI = GND OR VCC, Bushold Disabled

Output Leakage Current VO = GND or VCC, Output Disabled,

2.4 V

4.0 V

4.3 V

3.6 V

3.6 V

0.5 V

2.0 V

−0.5

−10

−50

CCmax

0.8 V

10

50

Bushold Disabl ed

I

OZBH

I

OS

I

BHL

Output Leakage Current VCC = Max., VO = 3.3V, Output

Disabled

Outp u t S h ort Cir cuit

[5, 6]

Current

Input Bus Ho ld LOW Sus taining

VCC = Max., V

VCC = Min., VIL = 0.8V +75

[3]

, Bus-Hold Enabled

= 0.5V

OUT

0

−30 −160

−70 −125 µA

Current

I

BHH

Input Bus Hold HIGH

VCC = Min., VIH = 2.0V

−75 µA

Sustaining Current

I

BHLO

Input Bus Hold LO W Over driv e

VCC = Max. +500

Current

I

BHHO

Input Bus Hold HIGH Overdriv e

VCC = Max. -500

Current

V

µA

µA

mA

µA

µA

µA

Inductance

[6]

Parameter Description Test Conditions 44-Lead TQFP 44-Lead PLCC Unit

L Maximum Pin Inductance VIN = 5.0V at f = 1 MHz 2 5 nH

Capacitance

[6]

Parameter Description Test Conditions Max. Unit

C

I/O

C

CLK

Endurance Characteristics

Input/Output Capacit ance VIN = 5.0V at f = 1 MHz at TA = 25°C 8 pF

Clock Signal Capacitance VIN = 5.0V at f = 1 MHz at TA = 25°C 12 pF

[6]

Parameter Description T est Conditions Min. Typ. Unit

N Minimum Reprogramm ing Cycles Normal Programming Conditions

Notes:

2. I

= –2 mA, IOL = 2 mA for TDO.

OH

3. When the I/O is output disabled, the bus-hold circuit can weakly pull the I/O to a maximum of 4.0V if no leakage current is allowed. This voltage is lowered

significantly by a small leakage current. Note that all I/Os are output disabled during ISR programming. Refer to the application note “Unde r sta ndi ng B u s Ho ld”

for additional information.

4. These are absolute values with respect to device ground. All overshoots due to system or tester noise are included.

5. Not more than one output should be tested at a time. Duration of the short circuit should not exceed 1 second. V

problems caused by tester ground degradation.

6. Tested initially and after any design or process changes that may aff ect these parameters.

[1]

1,000 10,000 Cycles

= 0.5V has been chosen to avoid test

OUT

Page 27

2 Megabit (256 K x 8-Bit)

IC BLOCK DIAGRAM & DESCRIPTION

IC U214 Am29F002B/Am29F002NB

26

CMOS 5.0 Volt-only Boot Sector Flash Memory

DISTINCTIVE CHARACTERISTICS

■ Single power supply operation

— 5.0 Volt-only operation for read, erase, and

program operations

— Minimizes system level requirements

■ Manufactured on 0.32 µm process technology

— Compatible with 0.5 µm Am29F002 device

■ High performance

— Access times as fast as 55 ns

■ Low power consumption (typical values at

5 MHz)

— 1 µA standby mode current

— 20 mA read current

— 30 mA program/erase current

■ Flexible sector architecture

— One 16 Kbyte, two 8 Kbyte, one 32 Kbyte, and

three 64 Kbyte sectors

— Supports full chip erase

— Sector Protecti on features:

A hardware method of locking a sector to

prevent any program or erase operations within

that sector

Sectors can be loc k ed v ia pr ogr ammi ng eq uipme nt

T emporary Sector Unprotect feat ure allows code

changes in previously locked sectors

■ Top or bottom boot block configurations a vaila ble

■ Embe dded Algorithms

— Embedded Erase algorithm automatically

preprograms and erases the entire chip or any

combination of designated sectors

— Embedded Progr am algorithm automatically

writes and verifies data at specified addresses

■ Minimum 1,000,000 write cycle guarantee per

sector

■ 20-year data retention at 125°C

— Reliable operation for the life of the system

■ Package option

— 32-pin PDIP

— 32-pin TSOP

— 32-pin PLCC

■ Compatibility with JEDEC standards

— Pinout and software compatible with

single-power supply Flash

— Superior inadver tent write protection

■ Data# Polling and toggle bits

— Provides a software method of detecting

program or erase operation completion

■ Erase Suspend/Erase Resume

— Suspends an erase oper ation to read data from,

or program data to, a sector that is not being

erased, then resumes the erase operation

■ Hardware reset pin (RESET#)

— Hardw are method to reset the device to reading

array data (not available on Am29F002NB)

Page 28

PRODUCT SELECTOR GUIDE

IC BLOCK DIAGRAM & DESCRIPTION

27

Family Part Number Am29F002B/Am29F002NB

= 5.0 V ± 5% -55

V

Speed Option

Max access time, ns (t

Max CE# access time, ns (t

Max OE# access time, ns (t

CC

= 5.0 V ± 10% -70 -90 -120

V

CC

)557090120

ACC

)557090120

CE

) 30303550

OE

Note: See “AC Characteristics” for full specifications.

BLOCK DIAGRAM

V

CC

V

SS

RESET#

n/a Am29F002NB

Sector Switches

Erase Voltage

Generator

DQ0

–

DQ7

Input/Output

Buffers

WE#

CE#

OE#

A0–A17

State

Control

Command

Register

VCC Detector

PGM Voltage

Generator

Timer

Chip Enable

Output Enable

STB

Logic

Address Latch

Y-Decoder

X-Decoder

STB

Data

Latch

Y-Gating

Cell Matrix

Page 29

CONNECTION DIAGRAMS

IC BLOCK DIAGRAM & DESCRIPTION

28

RESET#

NC

A16

A15

A12

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

DQ1

DQ2

V

SS

NC on Am29F002NB

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

PDIP

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

V

CC

WE#

A17

A14

A13

A8

A9

A11

OE#

A10

CE#

DQ7

DQ6

DQ5

DQ4

DQ3

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

5

6

7

8

9

10

11

12

13

14

A12

4

DQ1

15

A15

3

DQ2

A16

2

PLCC

17

SS

V

RESET#

VCCWE#

1

32

18

DQ3

DQ4

31 30

19 2016

NC on Am29F002NB

A17

A14

29

A13

28

A8

27

A9

26

A11

25

OE#

24

A10

23

CE#

22

DQ7

21

DQ6

DQ5

NC on Am29F002NB

A11

A9

A8

A13

A14

A17

WE#

V

CC

RESET#

A16

A15

A12

A7

A6

A5

A4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Standard TSOP

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

OE#

A10

CE#

DQ7

DQ6

DQ5

DQ4

DQ3

V

SS

DQ2

DQ1

DQ0

A0

A1

A2

A3

Page 30

PIN CONFIGURATION

IC BLOCK DIAGRAM & DESCRIPTION

29

A0–A17 = 18 addresses

DQ0–DQ7 = 8 data inputs/outputs

CE# = Chip enable

OE# = Output enable

LOGIC SYMBOL

18

A0–A17

8

DQ0–DQ7

WE# = Write enable

RESET# = Hardware reset pin, active low

(not available on Am29F002NB)

= +5.0 V single power supply

V

CC

(see Product Selector Guide for

device speed ratings and voltage

supply tolerances)

V

SS

= Device ground

NC = Pin not connected internally

CE#

OE#

WE#

RESET#

N/C on Am29F002NB

Page 31

4 Banks x 1M x 16Bit Synchronous DRAM

IC BLOCK DIAGRAM & DESCRIPTION

IC U206 SDRAM-HY57V65162B

30

DESCRIPTION

The Hyundai HY57V651620B is a 67,108,864-bit CMOS Synchronous DRAM, ideally suited for the Mobile applications which require low power consumption and extended temperature range. HY57V651620B is organized as 4banks

of 1,048,576x16.

HY57V651620B is offering fully synchronous operation referenced to a positive edge of the clock. All inputs and outputs are synchronized with the rising edge of the clock input. The data paths are internally pipelined to achieve very

high bandwidth. All input and output voltage levels are compatible with LVTTL.

Programmable options include the length of pipeline (Read latency of 2 or 3), the number of consecutive read or write

cycles initiated by a single control command (Burst length of 1,2,4,8 or Full page), and the burst count

sequence(sequential or interleave). A burst of read or write cycles in progress can be terminated by a burst terminate

command or can be interrupted and replaced by a new burst read or write command on any cycle. (This pipelined

design is not restricted by a `2N` rule.)

FEATURES

• Single 3.3V ± 10% power supply

• All device pins are compatible with LVTTL interface

• JEDEC standard 400mil 54pin TSOP-II with 0.8mm

of pin pitch

• All inputs and outputs referenced to positive edge of

system clock

• Data mask function by UDQM or LDQM

• Internal four banks operation

ORDERING INFORMATION

Part No. Clock Frequency Power Organization Interface Package

HY57V651620BTC-7I 143MHz

HY57V651620BTC-75I 133MHz

HY57V651620BTC-10SI 100MHz

HY57V651620BLTC-7I 143MHz

HY57V651620BLTC-75I 133MHz

HY57V651620BLTC-10SI 100Mhz

Normal

Power

• Auto refresh and self refresh

• 4096 refresh cycles / 64ms

• Programmable Burst Length and Burst Type

- 1, 2, 4, 8 or Full page for Sequential Burst

- 1, 2, 4 or 8 for Interleave Burst

• Programmable CAS Latency ; 2, 3 Clocks

power

4Banks x 1Mbits

x16

Lower

LVTTL 400mil 54pin TSOP II

This document is a general product description and is subject to change without notice. Hyundai Electronics does not assume any

responsibility for use of circuits described. No patent licenses are implied.

Rev. 0.4/Nov.00

Page 32

PIN CONFIGURATION

IC BLOCK DIAGRAM & DESCRIPTION

31

VDD

DQ0

VDDQ

DQ1

DQ2

VSSQ

DQ3

DQ4

VDDQ

DQ5

DQ6

VSSQ

DQ7

DD

V

LDQM

/WE

/CAS

/RAS

/CS

BA0

BA1

A10/AP

A0

A1

A2

A3

DD

V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

54pin TSOP II

400mil x 875mil

0.8mm pin pitch

VSS

54

DQ15

53

VSSQ

52

DQ14

51

DQ13

50

VDDQ

49

DQ12

48

DQ11

47

VSSQ

46

DQ10

45

DQ9

44

VDDQ

43

DQ8

42

SS

V

41

NC

40

UDQM

39

CLK

38

CKE

37

NC

36

A11

35

A9

34

A8

33

A7

32

A6

31

A5

30

A4

29

SS

V

28

PIN DESCRIPTION

PIN PIN NAME DESCRIPTION

CLK Clock

CKE Clock Enable

CS Chip Select Enables or disables all inputs except CLK, CKE and DQM

BA0,BA1 Bank Address

A0 ~ A11 Address

RAS, CAS, WE

LDQM, UDQM Data Input/Output Mask Controls output buffers in read mode and masks input data in write mode

DQ0 ~ DQ15 Data Input/Output Multiplexed data input / output pin

VDD/VSS Power Supply/Ground Power supply for internal circuits and input buffers

VDDQ/VSSQ Data Output Power/Ground Power supply for output buffers

NC No Connection No connection

Row Address Strobe,

Column Address Strobe,

Write Enable

The system clock input. All other inputs are registered to the SDRAM on the

rising edge of CLK

Controls internal clock signal and when deactivated, the SDRAM will be one

of the states among power down, suspend or self refresh

Selects bank to be activated during RAS activity

Selects bank to be read/written during CAS activity

Row Address : RA0 ~ RA11, Column Address : CA0 ~ CA7

Auto-precharge flag : A10

RAS, CAS and WE define the operation

Refer function truth table for details

Page 33

FUNCTIONAL BLOCK DIAGRAM

I/O Buffer & Logic

IC BLOCK DIAGRAM & DESCRIPTION

32

1Mbit x 4banks x 16 I/O Synchronous DRAM

Self refresh logic

CLK

CKE

CS

RAS

CAS

WE

UDQM

LDQM

& timer

Row active

State Machine

refresh

Column

Active

Internal Row

counter

Row

Pre

Decoders

Column

Pre

Decoders

1Mx16 Bank 3

X decoders

1Mx16 Bank 2

X decoders

X decoders

1Mx16 Bank 1

1Mx16 Bank 0

X decoders

Y decoders

Memory

Cell

Array

Sense AMP & I/O Gate

DQ0

DQ1

DQ14

DQ15

Bank Select

A0

A1

A11

BA0

BA1

Address buffers

Address

Registers

Mode Registers

Column Add

Counter

Burst

Counter

CAS Latency

Data Out Control

Pipe Line Control

Page 34

ABSOLUTE MAXIMUM RATINGS

IC BLOCK DIAGRAM & DESCRIPTION

33

Parameter Symbol Rating Unit

Ambient Temperature TA -40 ~ 85 °C

Storage Temperature TSTG -55 ~ 125 °C

Voltage on Any Pin relative to VSS VIN, VOUT -1.0 ~ 4.6 V

Voltage on VDD relative to VSS VDD, VDDQ -1.0 ~ 4.6 V

Short Circuit Output Current IOS 50 mA

Power Dissipation PD 1 W

Soldering Temperature ⋅ Time TSOLDER 260 ⋅ 10 °C ⋅ Sec

Note : Operation at above absolute maximum rating can adversely affect device reliability

DC OPERATING CONDITION (TA= -40 to 85°C)

Parameter Symbol Min Typ. Max Unit Note

Power Supply Voltage VDD, VDDQ 3.0 3.3 3.6 V 1

Input High Voltage VIH 2.0 3.0 VDDQ + 2.0 V 1,2

Input Low Voltage VIL VSSQ - 2.0 0 0.8 V 1,3

Note :

1.All voltages are referenced to VSS = 0V

2.VIH (max) is acceptable 4.7V AC pulse width with ≤3ns of duration

3.VIL (min) is acceptable -2.0V AC pulse width with ≤3ns of duration

AC OPERATING CONDITION (TA= -40 to 85°C, VDD=3.3V ± 0.3V, VSS=0V)

Parameter Symbol Value Unit Note

AC Input High / Low Level Voltage VIH / VIL 2.4/0.4 V

Input Timing Measurement Reference Level Voltage Vtrip 1.4 V

Input Rise / Fall Time tR / tF 1 ns

Output Timing Measurement Reference Level Voutref 1.4 V

Output Load Capacitance for Access Time Measurement CL 50 pF 1

Note :

1. Output load to measure access time is equivalent to two TTL gates and one capacitor (50pF)

For details, refer to AC/DC output circuit

Page 35

! 3-Termainal Regulators

IC WS7805

POSITIVE-VOLTAGE REGULATORS

25

V

)

WS7805DP

TO-220

WS7805CV

O

C

I

TO-252

IC BLOCK DIAGRAM & DESCRIPTION

34

! Output Current Up to 1.5 A

! No External Components

! Internal Thermal Overload Protection

! High Power Dissipation Capability

! Internal Shot-Circuit Current Limiting

! Output Transistor Safe-Area

Compensation

DESCRIPTION

This series of fixed-voltage monolithic integrated-circuit

voltage regulators designed for a wide range of

applications. These applications include on-card

regulation for elimination of noise and distribution

problems associated with single-point regulation. Each

of these regulators can deliver up to 1.5 amperes of

output current. The internal current limiting and thermal

shutdown features of these regulators make them

O

C

I

(TO-252)

essentially immune to overload.

ABSOLUTE MAXIMUM RATINGS OVER OPERATING TENPERATURE

RANGE (UNLESS OTHERWISE NOTE

WS7805 PARAMETER UNIT

Input voltage, V

Continuous total dissipati on at 25℃ free-air temperature

Lead temperature 1.6mm (1/16 inch) from case 10 seconds 260

Storage temperature range, T

I

stg

RECOMMEMDED OPERATING CONDITIONS

Input voltage, V

Output current, I

Operating virtual junction temperature, T

I

O

J

35 V

2W

-65 to 150

MIN MAX UNIT

7

1.5 A

070

℃

℃

℃

Page 36

35

10. Decode Board Block Diagram

Mixed Separate Dolby

2CH

S Complex Video

LPF

5.1CH

UDE

ITERFACE

BUFFER

MIC INPUT

ANALOG SIGNALS

STRMREQ

DSTROBE

STRMDMA

エョ

ソレ

8 Bit Data

CY37032

CS4228

I2S

DVDREQ CSTROBE

RAS/CAS

Simulate video

output

8 Bit host interface

LPF

ZiVA 4.1

27MHz

OSC

SDRAM

1 16Mbits

16 ホサ

SDRAM

1 16Mbits

REMOTE INPUT

V8000

3 LINE

OUTPUR FRONT

FLASH

DRAM

MMORY

I2C

DECODE BOARD DIAGRAM

Page 37

VFD401

11 SCHEMATIC & P.C.B WIRING DIAGRAM11 SCHEMATIC & P.C.B WIRING DIAGRAM11 SCHEMATIC & P.C.B WIRING DIAGRAM

36

FRONT SCHEMATIC DIAGRAM

11.1

VFD-32

5G

4G

3G

2G

1G

NC

NC

NC

NC

NC

P10

P11

P12

P13

P14

P15

P16

FIL+

1

F1

2

F1

GRID1

4

GRID2

5

GRID3

6

GRID4

7

GRID5

8

9

10

11

12

13

SEG16

14

P1

P2

P3

P4

P5

P6

P7

P8

P9

F2

F2

SEG15

15

SEG14

16

SEG13

17

SEG12

18

SEG11

19

SEG10

20

SEG9

21

SEG8

22

SEG7

23

SEG6

24

SEG5

25

SEG4

26

SEG3

27

SEG2

28

SEG1

29

31

FIL-

32

SEG9

SEG10

SEG11

SEG12

-25V

SEG13

SEG14

SEG15

SEG16

GRID5

23

24

25

26

27

28

29

30

31

32

33

S9

S10

S11

S12/G1

VEE

S13/G1

S14/G9

S15/G8

S16/G7

G6

G5

SEG8

SEG7

SEG6

SEG5

SEG4

SEG3

SEG2

SEG1

VCC

12

13

14S115S216S317S418S519S620S721S822

VDD

KEY4

U401

UPD16312

G434G335G236G137VDD38LED439LED340LED241LED142VSS43OSC

44

GRID4

GRID3

GRID2

GRID1

VCC

GND

KEY3

KEY2

KEY1

CLK

VSS

SW4

SW3

SW2

SW1

R405

33K

STB

DIN

DO

C401

104

R413

33K

C404

101

C405

104

KEY4

KEY3

KEY2

KEY1

R414

33K

VFDCK

VFDAT

C403

101

3

1

2

C407

100uF/16V

R417

10K

VCC

U403

HS0038A2

101

R401

R402

11

R403

10

R404

9

VFDST

8

7

GND

6

5

4

3

2

1

SW4

SW3

SW2

MSW

33K

33K

33K

33K

VCC C406

R411

R412

33K

VCC

10K

10K

10K

10K

10K

33K

IR

R415

100

R416

10K

R406

R407

R408

R409

R410

VCC

C402

100uF/16V

KEY1

KEY2

KEY3

KEY4

K401

K402

SEG1

1N4148

D401

K405

K406

K407K403

K408K404

SEG2

1N4148

D402

K409

SEG3

1N4148

D403

FIL+

R418

33R

VCC

GND

-25V

FIL-

IR

GND

VFDST

VFDCK

VFDAT

XS401

1

2

3

4

5

XS05

XS402

5

4

3

2

1

XS05

Page 38

37

FRONT P.C.B. WIRING DIAGRAM

11.2

Page 39

MIC601

P.W. & OK. SCHEMATIC DIAGRAM

38

11.3

OK

R609 10K

TC606

R603

560R

C603

103

R604

560R

C604

103

R607

1K

R608

1K

TC605

22uF/16V

9MIC602

8

7

6

5

4

3

2

1

9

8

7

6

5

4

3

2

1

L602

L601

TC601

4.7uF

R601

22K

TC602

4.7u

R602

22K

22uF/16V

R605

10k

6

5

R606

10K

C605 47p

2

3

8 4

+9VA

U601A

4558

R610

10K

C606

47p

U601B

4558

-9VA

1

VR601

R618

1K

R623

1K

10K

R611

4.7K

TC603

4.7uF/16V

TC604

4.7uF/16V

7

R613

24K

C607 100P

-9VA

2

3

8 4

+9VA

U602A

4558

1

4.7uF/16V

C608

102

TC613

R617

100K

+5V

R615

100K

R616

330

VD601

1N4148

VD603

VD602

1N4148

1N4158

TC611

47uF/16V

VOICE-DET

R620

1K

6

5

U602B

4558

R619

7

100

XS601

XS05

1

VOICE-DET

2

OK

3

AGND

4

+9V

5

-9V

R621

+9V +9VA -9V -9VA

10ohm1/6W

TC615

100uF/25V

C601

104

R622

10ohm1/6W

TC616

100uF/25V

C602

104

Page 40

BCN502

P.W. & OK. SCHEMATIC DIAGRAM

11.4

39

SW-SPST

~400V 102

!

L502

! !

BC501

L501

!

!

!

T1.6A/250V

!

D501 D502

D503 D504

~400V 102

~400V 102

!

!

F501

BCN501

~220V

!

BC502

BC503

C502

47uF/400V

BC505

~275V 104

BC504

~275V 104

RV501

07D471

R505

470K 2W

R501

120K/2W

3

VCC

U501

5L0380R

L503

2

D

FB

GND

C505

104

FB

R502

10K/2W

C503

101/1KV

R504

1M

4

1

C504

103/1KV

D505

HER107

C507

223

R503

10ohm

C509

47uF/50V

R507

270K/2W

D506

HER105

C506

101

!

2

3

4

6

7

8

!

U502

2501

BC506

~400V 221

T501

TRAX919-1

CN505

1

S+12V

2

L505

C516

470uF/25V

C501

470uF/25V

L507 10uH/2A

C522

1000uF/10V

C519

1000uF/10V

C524

100uF/50V

10uH/1A

L504

10uH/1A

L506

10uH/1A

330

R509

U503

LM431A

C517

470uF/25V

C514

470uF/25V

C521

1000uF/10V

C520

1000uF/10V

R514

1K

C527

104

K

R

R512

10K

R515

30K

R510

3.3K

R513

4.7K

+3.3V

-9V

5.1V

ZD501

VOICE-DET

VOICE-DET

+9V

L508

FB

OK

AGND

+9V

-9V

DGND

+5V

DGND

+3.3V

+3.3V

OK

AGND

+9V

-9V

+5V

DGND

-21V

FLFL+

+5V

1

2

3

4

5

6

7

8

9

10

1

2

3

4

5

5

4

3

2

1

C528

470uF/16V

CN503

XS10

CN504

XS05

CN501

C510

101

D508

HER105

C511

!

18

17

16

15

14

13

12

11

10

101

D507 HER105

D510

C536

101

C512

101

D509

HER303

D511

HER105

C537

101

D512

HER105

C538

101

220uF/16V

HER105

C525

AGND

DGND

SD+5V

DGND

SD+5V

AGND

SA+5V

AGND

S+8V

1

3

4

XS04

6

5

4

3

CN502

2

1

3

IN

OUT

GND

U504

LM7805

2

SA+5V

C508

100uF/16V

A

Page 41

P.W. & OK. WIRING DIAGRAM

11.5

40

Page 42

11.5

P.W. & OK. WIRING DIAGRAM

41

Page 43

VCC

MIAN SCHEMATIC DIAGRAM

11.6

42

R201 10K

TC201

47uF/16V

VD202

1N4148

Q211

S9015

TXD

R2105

RXD

R2106

R210

R209

47K

47K

RXD

TXD MSCK

/RD /RD1

R298

2.7k

GND

CPUCLK40

X2

CLKOUTA

P+5V VCC

L201

FB

P+5V

R219

4.7K

R213

FBSMT

R240

10K

33R

33R

R297

10K

ALE

S2

C212

151

DATA

R258

R204

R214

R207

R208

/CPU_RST

U205E

HC14

A19

A18

A17

A16

A15

A14

A13

A12

A11

A10

A9

1011

R202

33R

DATA

33R

1K

33RCLKSER

33R

33R

CLKOUTA1

P+5V

C202

104

C203

104

/WR1/WR

/CPU_RST

R253

4.7K

R252 33R

R257

0R

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

AD[15..0]

SDEN1

SDEN0

SCLK

BHE/ADEN

WR

RD

ALE

ARDY

S2

S1

S0

GND0

X1

X2

VCC0

CLKOUTA

CLKOUTB

GND1

A19

A18

VCC1

A17

A16

A15

A14

A13

A12

A11

A10

A9

P+5V

C201

104

AD15

AD7

AD14

AD13

AD12

AD5

AD6

MTXD

87

88

89

90

91

92

93

94

95

96

97

99

100

SDATA

UZI

AD7

TXD98RXD

AD15

AD14

AD6

VCC5

AD13

GND5

AD5

AD12

S6/CLKDIV2

U201

V8000-33KC

A831A732A633A534A435A336A237VCC238A139A040GND241WHB42WLB43HLDA44HOLD45SRDY46NMI47DT/R48DEN49MCS0

PA1

PA2

PA3

PA4

R21533R

R21633R

R21733R

R21833R

AD4

86

AD4

AD11

85

AD11

AD3

84

AD3

MNMI

R220

33R

AD2

AD9

AD10

82

83

AD981AD2

AD10

TMROUT0

TMROUT1

MCS3/RFCH

PCS5/A1

PCS6/A2

LCS/ONCE0

UCS/ONCE1

INT1/SELECT

INT2/INTA0

INT3/INTA1/IRQ

50

AD1

AD8

AD0

DRQ0

DRQ1

TMRIN0

TMRIN1

RES

GND4

MCS2

VCC4

PCS0

PCS1

GND3

PCS2

PCS3

VCC3

INT0

INT4

MCS1

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

57

56

55

54

53

52

51

R222

33R

C204

104

P+5V

C205

TC203

104

47uF/16V

AD1

AD8

AD0

STRMDMA

DVDREQ

SCK

/MSYSRST

/MLDR_RST

/CPU_RST

MCSADAC

/MROMACS

/MSTRMCS

/MDVDCS

/MLCS

/MUCS /UCS

DVDINT

/LDRRDY

MATN_FM

R239 33R

R238 1K

R2167 33R /H-RDY

R237 33R

R233

R231

R232

R230

R229

R250

R227 33R

R225

2.7K

LCS

33R

33R

33R

33R

33R

33R

0R

R241 22K

/SYSRST

/LDRRST

MCS2

SDA

CS

/ROMACS

/DMA0CS

/DVDCS

CSTROBER2168

LCS

VOICE-DET

MCS1

R226

1K

R242 22K

AD0

AD1

JP201

JP202

STRMDMA

DVDREQ

SCK

/SYSRST

MCS2

SDA

CS

/ROMACS

/DMA0CS

/DVDCS

CSTROBE

LCS

/UCS

VCC

S1_AD0

R248

S1_AD1

SDD[7..0]

DACK

XSTRMREQ

TXD

U205A

HC14

R247

/DEN16

LSBCLK

MSBCLK

/LDRRST

SDD0

12

22K

22K

L256

L257

L258

L259

L260

L261

L262

L264

L265

/DEN16

LSBCLK

MSBCLK

SDD7

SDD6

SDD5

SDD4

SDD3

SDD2

SDD1

SDD0

SDD0

SDD1

SDD2

SDD3

SDD4

SDD5

SDD6

SDD7

VCC

C2140

104

FB

FB

FB

FB

FB

FB

FB

FB

FB

1

11

2

3

4

5

6

7

8

9

1

11

2

3

4

5

6

7

8

9

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

XS202

XS22

C2141

104

U202

OC

CLK

1D

2D

3D

4D

5D

6D

7D

8D

74F574

U203

OC

CLK

1D

2D

3D

4D

5D

6D

7D

8D

74F574

L274

L273

L272

L271

L270

L267

L266

L202

L203

1Q

2Q

3Q

4Q

5Q

6Q

7Q

8Q

1Q

2Q

3Q

4Q

5Q

6Q

7Q

8Q

FBSMT

19

18

17

16

15

14

13

12

19

18

17

16

15

14

13

12

FB

FB

FB

FB

FB

FB

DSTROBE

FB

RXD

FB

/HOSTRDY

AD[15..0]

AD7

AD6

AD5

AD4

AD3

AD2

AD1

AD0

AD8

AD9

AD10

AD11

AD12

AD13

AD14

AD15

SDD7

SDD5SDD6

SDD3SDD4

SDD1SDD2

DSTROBE

A[3..1]

A[15..1]

XS203

XS06

/DVDWAIT

1

2

3

4

5

6

To VFD board

L241

L249

L251

L252

L253

FB

FB

FB

FB

FB

/CPU_RST

IR

GND

CS

SCK

DATA

/DVDWAIT

TC202

10uF/16V

VCC

U205C

IR 5 6

IR

A1

A2

A3

A4

A5

A6

A7

A8

/DVDINT

VCC

C206

104

U205B

2.2K

X2

R2172

C2150

20pF

X201

40MHz

C2151

20pF

CPUCLK40

3 4

HC14

7 14

/DVDINT

HC14

U205D

89

HC14

R223

33R

R224

0R

Page 44

PWR-U214

MIAN SCHEMATIC DIAGRAM

43

R254

0R

C215

104

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

LA16

LA17

LA18

/UCS

/RD

/WR

/CPU_RST

11

A0

10

A1

9

A2

8

A3

7

A4

6

A5

5

A6

4

A7

42

A8

41

A9

40

A10

39

A11

38

A12

37

A13

36

A14

35

A15

34

A16

3

A17

1

NC

12

/CE

14

/OE

43

/WE

44

/RESET

U214

AM29F800BT-120SC

D10

D11

D12

D13

D14

D15

A18

/BYTE

VCC

GND1

GND2

MADDR[10..0]

MDATA]15..0]

MDATA0

15

D0

D1

D2

D3

D4

D5

D6

D7

D8

D9

AD0

17

AD1

19

AD2

21

AD3

24

AD4

26

AD5

28

AD6

30

AD7

16

AD8

18

AD9

20

AD10

22

AD11

25

AD12

27

AD13

29

AD14

31

AD15

2

A18-U220 LA19

33

23

13

32

C213

102

R255

0R

PWR-U214

C217

104

TC237

47uF/16V

GND

/SD_BS

R2175

R2176

R2177

R2178

0R

100R

100R

1K

MDATA1

MDATA2

MDATA3

MDATA4

MDATA5

MDATA6

MDATA7 MDATA8

L/UDQM

/MWE

/SD_CAS

/SD_RAS

/SD_CS0

MADDR10

MADDR0

MADDR1

MADDR2

MADDR3 MADDR4

U206

1

VDD

2

DQ0

3

VDDQ

4

DQ1

5

DQ2

6

VSSQ

7

DQ3

8

DQ4

9

VDDQ

10

DQ5

11

DQ6

12

VSSQ

13

DQ7

14

VDD

15

LDQM

16

/WE

17

CAS

18

RAS

19

/CS

20

/SD-BS0

21

BS1

22

A10/AP

23

A0

24

A1

25

A2

26

A3

27

VDD

SDRAM-HY57V651620B

C228

C229

104

104

C230

104

VSS

DQ15

VSSQ

DQ14

DQ13

VDDQ

DQ12

DQ11

VSSQ

DQ10

DQ9

VDDQ

DQ8

VSS

UDQM

CLK

CKE

/SD-CS1

VSS

NC

NC

A9

A8

A7

A6

A5

A4

C231

104

54

53

52

51

50

49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

32

31

30

29

28

C232

104

C233

104

MDATA15

MDATA14

MDATA13

MDATA12

MDATA11

MDATA10

MDATA9

L/UDQM

SD_CLK

MADDR9

MADDR8

MADDR7

MADDR6

MADDR5

TC207

47uF/16V

R2179

100R

L207

FB

/SD_CS1

D+3V

D+3V

C226

104

TC205

47uF/16V

C209

102

LA[19..16]

VCC

L255

FBSMT

C210

102

TC240

47uF/16V

R234

0R

PWR-U214 PWR_HST_DRAM

L238

FB

LA19

LA18

TCLK

LA17

LA16

/ROMACS

JTAG

CLKOUTA

/CPU_RST

/RD

/DMA0CS

STRMDMA

R212

100R

/RD

MCS2

VCC

MCS1

/WR

LCS

L206

FBSMT

MSBCLK

LSBCLK

DACK

R2166

/DEN16

34

35

37

38

44

1

I/O5

2

I/O6

3

I/O7

4

CLK2/10

5

JTAG

6

GND

7

CLK0/11

8

I/O8

9

I/O9

10

I/O10

11

I/O11

39

I/O040I/O141I/O242I/O343I/O4

VCC

GND

U204

CY37032-QFP44

I/O3036I/O31

I/O28

I/O29

I/O27

I/O26

I/O25

I/O24

CLK1/14

GND

CLK3/12

I/O23

I/O22

I/O21

33

32

31

30

29

28

27

13

26

25

24

23

/HOSTRDY

/H-RDY

RXD

DSTB

STRMRQ

R2171

0R /UCS

ALE

0R

R235

0R

DSTROBE

XSTRMREQ

R236

33R

I/O1212I/O1313I/O1414I/O1515VCC16GND17I/O1618I/O1719I/O1820I/O1921I/O20

C211

22

R246

47K

22pF

/RD

MCS2

MCS1

PWR_HST_DRAM

AD0

AD1

AD2

AD3

AD4

AD5

AD6

AD7

/WR

LCS

A1

A3

A5

A7 A9

C219

102

10

11

12

13

14

15

16

17

18

19

20

U208

424260-70

1

2

3

4

5

6

7

8

9

VCC1

D0

D1

D2

D3

VCC2

D4

D5

D6

D7

NC1

NC2

WE

RAS

NC3

A0

A1

A2

A3

VCC3