Page 1

SERVICE MANUAL

BBK921D

Page 2

CONTENTS

1. SAFETY PRECAUTIONS

1.1 GENENRAL GUIDELINES

2. PREVENTION OF ELECTRO STATIC DISCHARGE(ESD)TO ELECTROSTATICALLY

SENSITIVE(ES) DEVICES

3. PRECAUTION OF LASTER DIODE

4. GENERAL DESCRIPTION

5. PREVENTION OF STATIC ELECTRICITY DISCHARGE

5.1 GROUNDING FOR ELECTROSTATIC BREAKDOWN PREVENTION

5.1.1 WORKTABLE GROUNDING

5.1.2 HUMAN BODY GROUNDING

5.1.3 HANDING OF OPTICAL PICKUP

5.2 HANDING PRECAUTIONS FOR TRAVERSE UNIT(OPTICAL PICKUP)

6. ASSENBLING AND DISASSEMBLING THE MECHANISM UNIT

6.1 DISASSEMBLY PROCEDURE

6.2 TERMINAL PCB

6.3 CLAMP PLATE UNIT

6.4 TRAY

2

2

2

3

4

6

6

6

6

6

6

7

7

7

8

8

6.5 TRAVERSE BLOCK

6.6 TRAVERSE GEAR

6.7 OPTICAL PICKUP UNIT

6.7.1 PRECAUTIONS IN OPTICAL PICKUP REPLACEMENT

6.8 DISASSEMBLING THE MIDDLE CHASSIS

6.9 DISASSENBLING THE TRAVERSE GRAR A

6.10 DISASSEMBLING THE SPINDLE MOTOR UNIT

7. ELECTRICAL CONFIRMATION

7.1 VIDEO OUTPUT(LUMINANCE SIGNAL)CONFIRMATION

7.2 VIDEO OUTPUT(CHROMINANCE SIGNAL)CONFIRMATION

8. MPEG CHECK WAVEFORM

9. IC BLOCK DIAGRAM & DESCRIPTION

10. SCHEMATIC & PCB WIRING DIAGRAM

11. SPARE PARTS LIST

9

9

10

10

12

12

13

13

13

14

15

16

32

45

1

Page 3

1.SAFETY PRICAUTIONS

1.1 GENERAL GUIDELINES

1.When servicing,observe the original lead dress.ifa short circuit is found,replace all parts which have

been overheated or damaged by the short circuit.

2.After servicing,see to it that all the protective devices such as insulation bamiers,insulation papers

shields are properly installed.

3.After servicing,make the following leakage current checks to prevent the customer from being exposed

to thock hazards.

2.PREVENTION OF ELECTRO STATIC DISCHARGE(ESD) TO ELECTROSTATECALLY

SENSITIVE(ES) DEVICES

Some semiconductor(solid state)devices can be damaged easily by static electricity.Such components

commonly are called Electrostatically Sensitive(ES)Devices.Examples of typical ES devices are integrated

circuits and some field-effect transistorsand semiconductor chip components.The following techniques

should be used to help reduce the incidence of component damage caused by electro static discharge(ESD).

1.Immediately before handling any semiconductor component or semiconductor-equipped assembly,drain

off any ESDon your body by touching a known earth ground.Alteatively,obtain and wear a commercially

availabel discharging ESD wrist strap,which should be removed for potential shock reasons prior to

applying power to the unit under test.

2.After removing an electrical assembly equipped with ES devices,place the assembly on a conductive

surface such as alminum foil,to prevent electrostatic charge buildup or exposure of the assembly.

3.Use only a grounded-tip soldering iron to solder or unsolder ES devices.

4.Use only an anti-static solder removal device.Some solder removal devices not classified as anti-static

(ESD protected)can generate electrical charge sufficient to damage ES devices.

5.Do not use freon-propelled chemicals.These can generate electrical charges sufficient to damage ES

devices.

6.Do not remove a replacement ES device from its protective package until immediately before you are

ready to install if.(Most replacement ES devices are packaged with leads electrically shorted together by

conductive foam,alminum foil or comparable conductive material).

7.Immediately before removing the protective material from the leads of a aeplacement ES device,touch

the protective material to the chassis or circuit assembly into which the device will be installed.

Caution

Be sure no power is applied to the chassis or circuit,and observe all other safety precautions.

8.Minimize bodily motions when handling unpackaged replacement ES devices.(Otherwise hamless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can

generate static electricity(ESD)

notice (1885x323x2 tiff)

2

Page 4

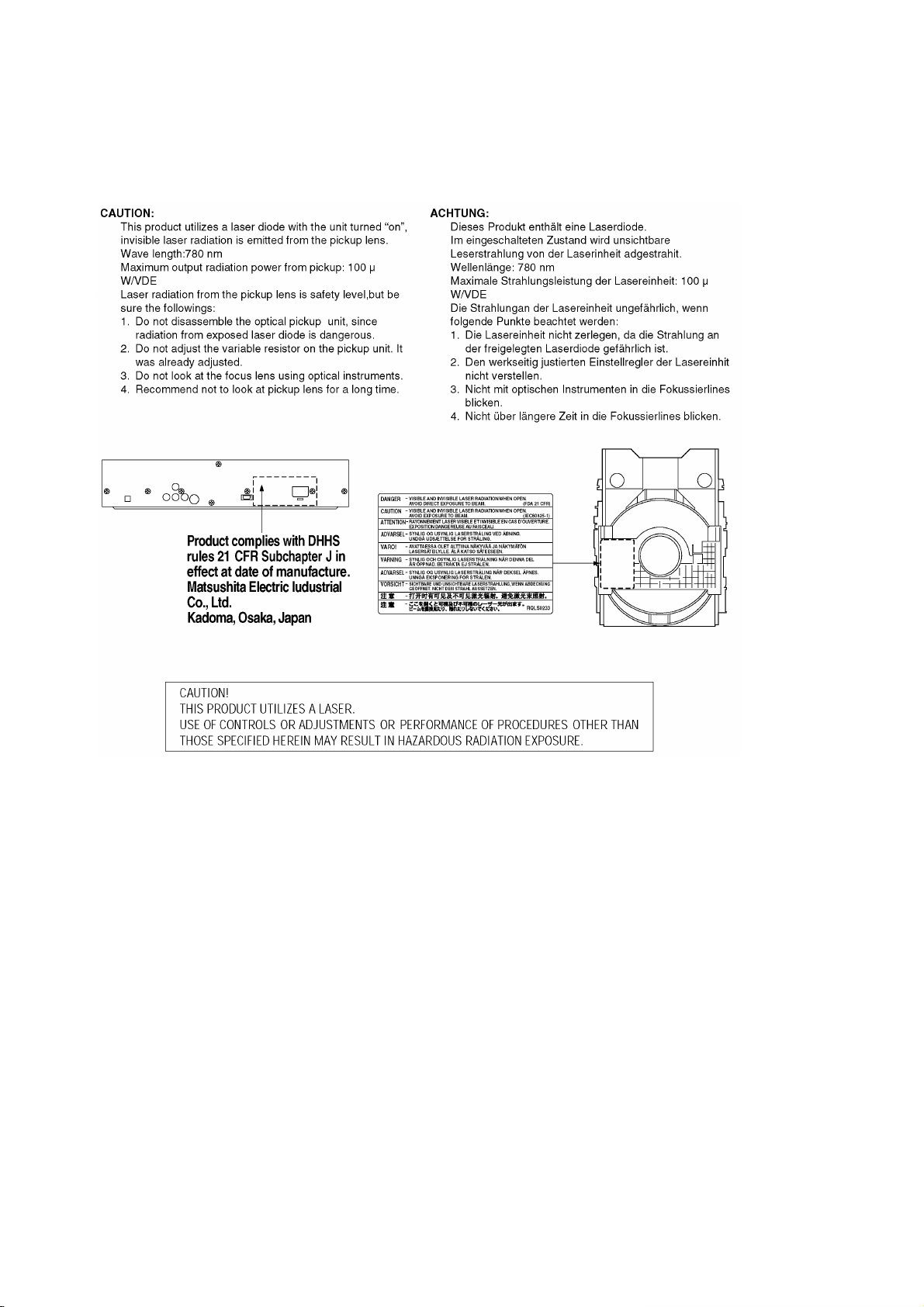

3. Precaution of L aster Diode

3

Page 5

4

Page 6

5

Page 7

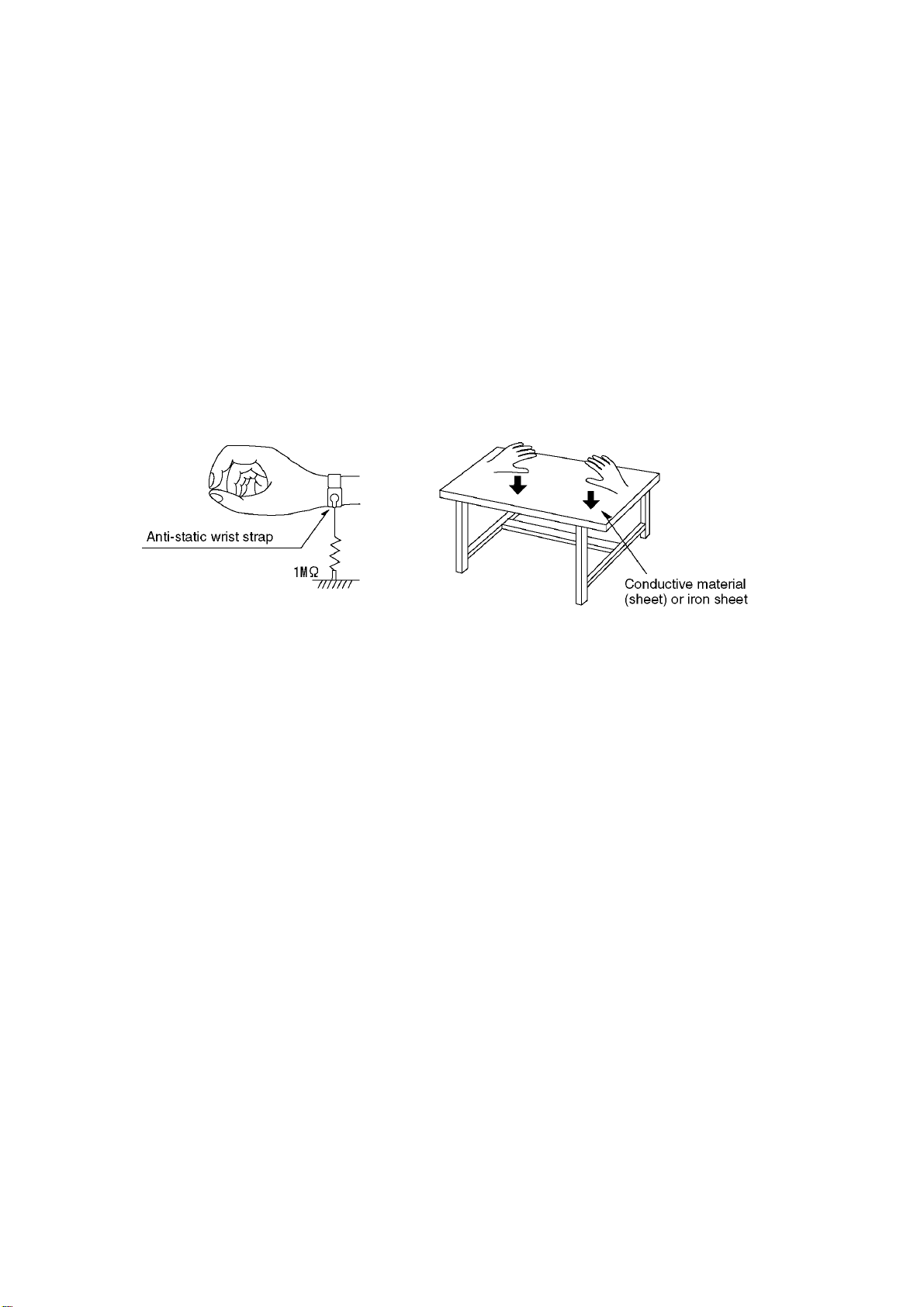

5.PREVERTION OF STATIC ELECTRICITY DISCHARGE

The laser diode in the traverse unit (optical pickup)may brake down due to static electricity of clothes or human

Some devices such as the DVD player use the optical pickup(laser diode)and the optical pickup will be damaged

by static electricity in the working environment.Proceed servicing works under the working environment where

1.Put a conductive material(sheet)or iron sheet on the area where the optical pickup is placed,and ground thesheet.

3.The flexible cable may be cut off if an excessive force is applied to it.Use caution when handling the cable.

6

body.Use due caution to electrostatic breakdown when servicing and handling the laser diode.

5.1.Grounding for electrostatic breakdown prevention

grounding works is completed.

5.1.1. Worktable grounding

5.1.2.Human body grounding

1 Use the anti-static wrist strap to discharge the static electricity form your body.

safety_3 (1577x409x2 tiff)

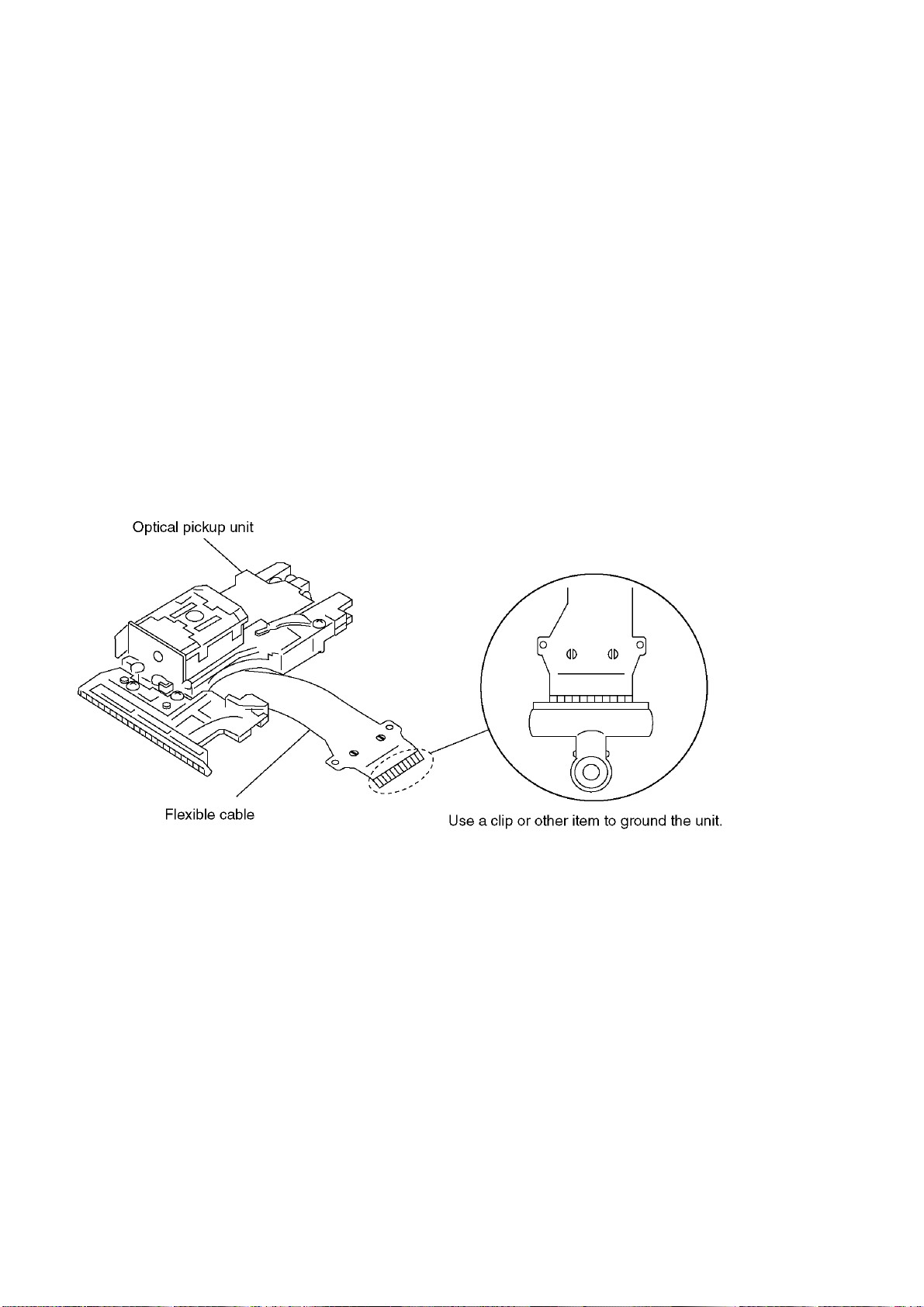

5.1.3.Handing of optical pickup

1.To keep the good quality of the optical pickup maintenance parts during transportation and before

installation,the both ends of the laser diode are short-circuited.After replacing the parts with new ones,

remove the short circuit according to the correct procedure.(See this Technical Guide).

2.Do not use a tester to check the laser diode for the optical pickup .Failure to do so willdamage the laser

diode due to the power supply in the tester.

5.2.Handing precautions for Traverse Unit (Optical Pickup)

1.Do not give a considerable shock to the traverse unit(optical pickup)as it has an extremely high-precise

structure.

2.When replacing the optical pickup,install the flexible cable and cut is short land with a nipper.See the

optical pickup replacement procedure in this Technical Guide.Before replacing the traverse unit,remove

the short pin for preventingstatic electricity and install a new unit.Connect the connector as short times as

possible.

4.The half-fixed resistor for laser power adjustment cannot be adjusted.Do not turn the resistor.

Page 8

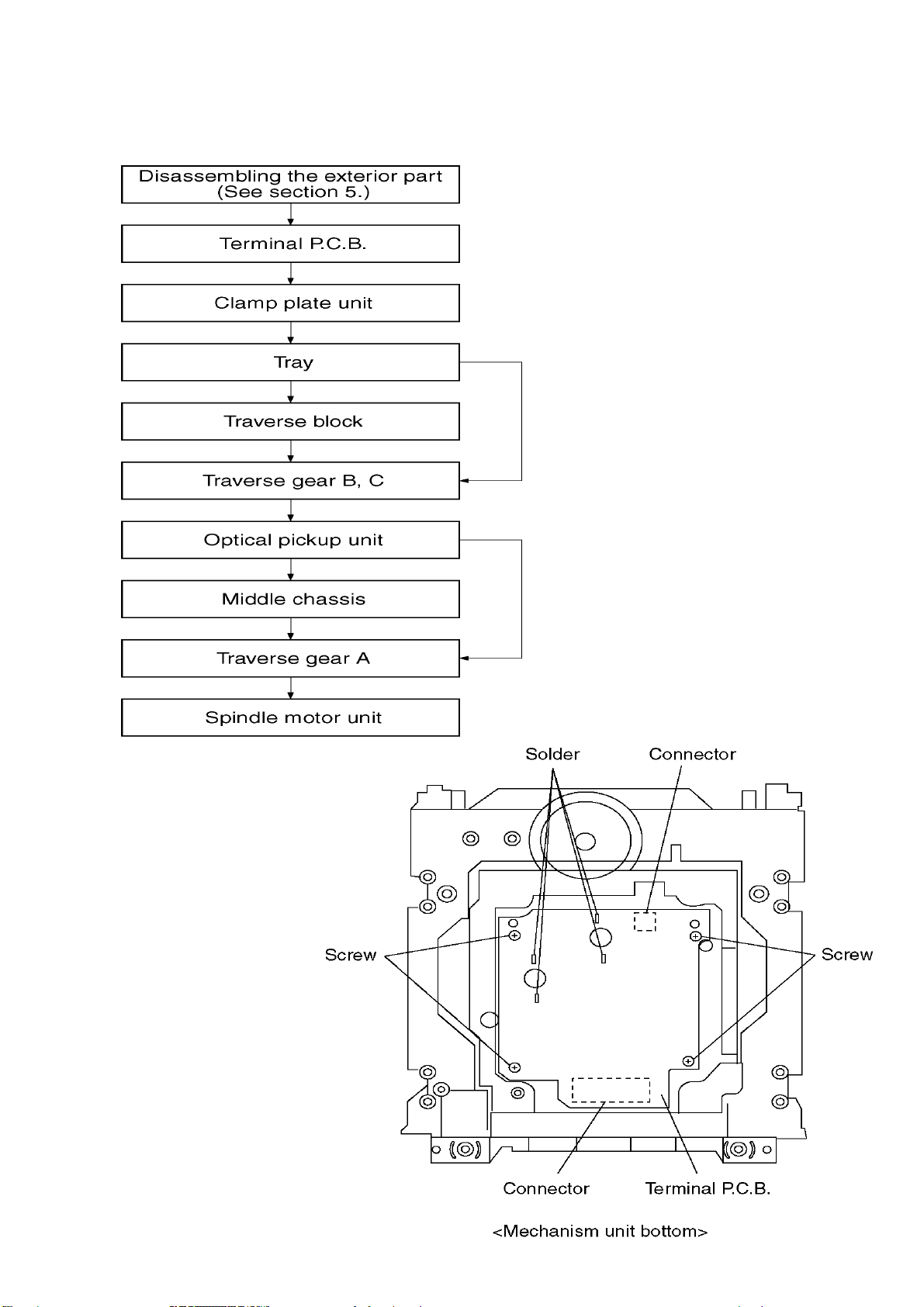

6.ASSEMBLING AND DISASSENBLING THE MECHANISM UNIT

7

6.1Disassembly Procedure

6.2 Terminal P.C.B.

1.Unscrew the screws.

2.Remove the solders.

3.Remove the connectors

5

Page 9

6.3 Clamp Plate Unit

8

1.Spread the stopper with hand to silde the tabs and remove the clamp plate unit.

6.4 Tray

1.Lift the tray.

6

Page 10

6.5 Traverse Block

9

1.Lift the traverse block while spreading the hook of the mechanical chassis chassis unit.

2.Disengage the tabs from the holes of the mechanical chassis unit.

6.6. Traverse Gear

1.Disengage the tabs from the traverse gear

2.Remove the traverse gears B and C.

7

Page 11

5.6 Mechanism Unit

10

1.Unscrew the screws.

2.Remove the connectors.

6.7 Optical Pickup Unit

1. Unscrew the screws.

5.7 Terninal P.C.B.

2.Remove the spring holders and the springs.

3.Pull out of the drive shaft and guide shaft.

1.Unscrew the screws

2.Remove the solders.

3.Remove the connectors.

Page 12

The optical pickup can be damaged by static electricity from you body.Be sure to take static electricity countermeasures

when working around the optical pickup.(Refer to the related page in this Manual about the countermeasures.

3.The use of soldering iron with anti-static feature is recommended when providing short-circuit to laser diode or when

-When using the soldering iron without anti-static feature,short-circuit the flexible cable terminal with a clip before

6.7.1. Precautions in optical pickup replacement

11

1.Do not touch laser diode,actuator and their peripheries.

2.Do not use tester to check laser diode.(Laser diode can be damaged easily.)

removing it.

4.Solder the land on flexible cable of optical pickup unit.

Page 13

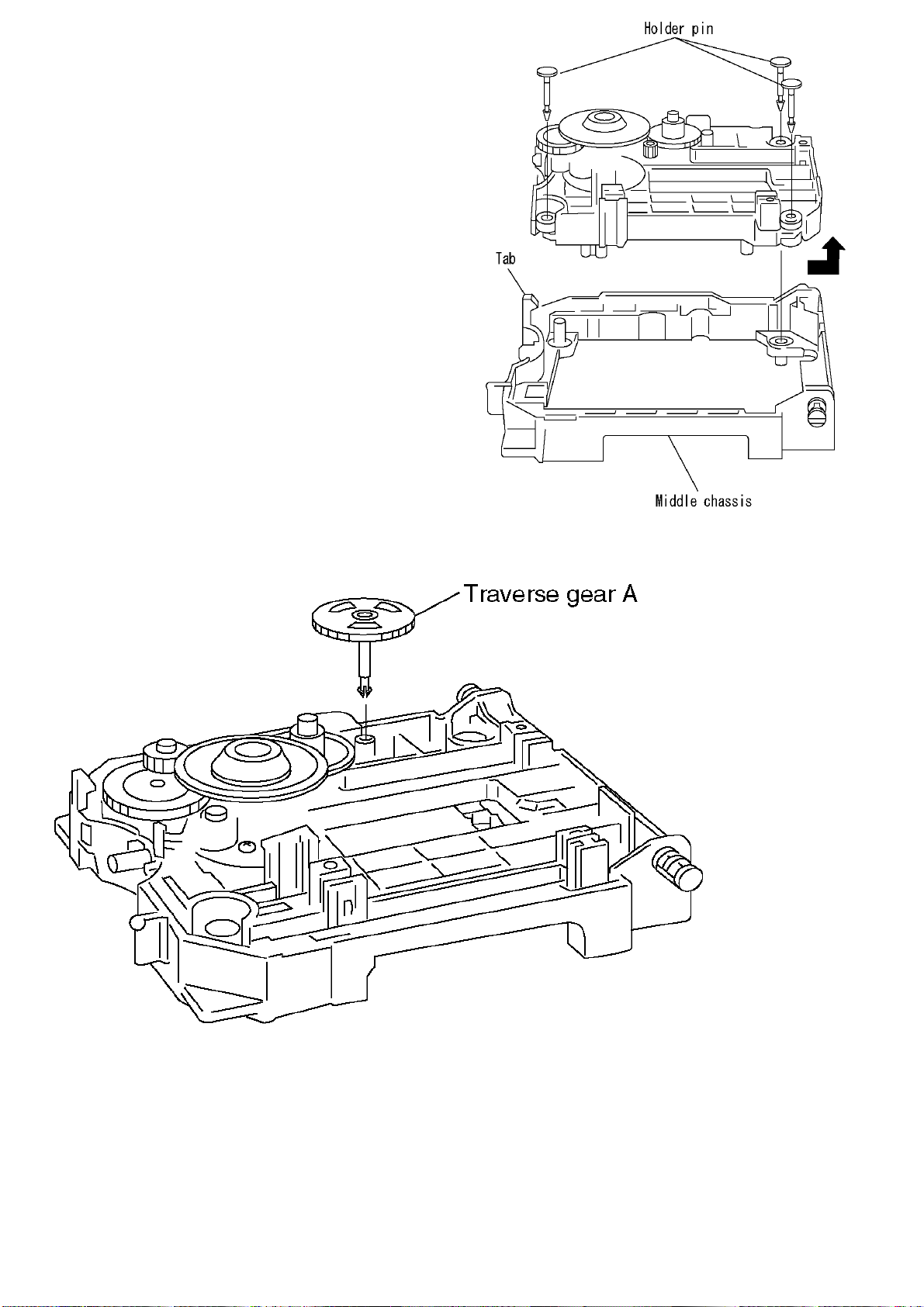

6.8. Disassenbling the Middle Chassis

12

1.Remove the holders pins.

2.Remove the tab.

3.It lifts while pulling it in the direction of the arrow.

6.9. Disassenbling the Traverse Gear A

1.Remove the traverse gear A.

Page 14

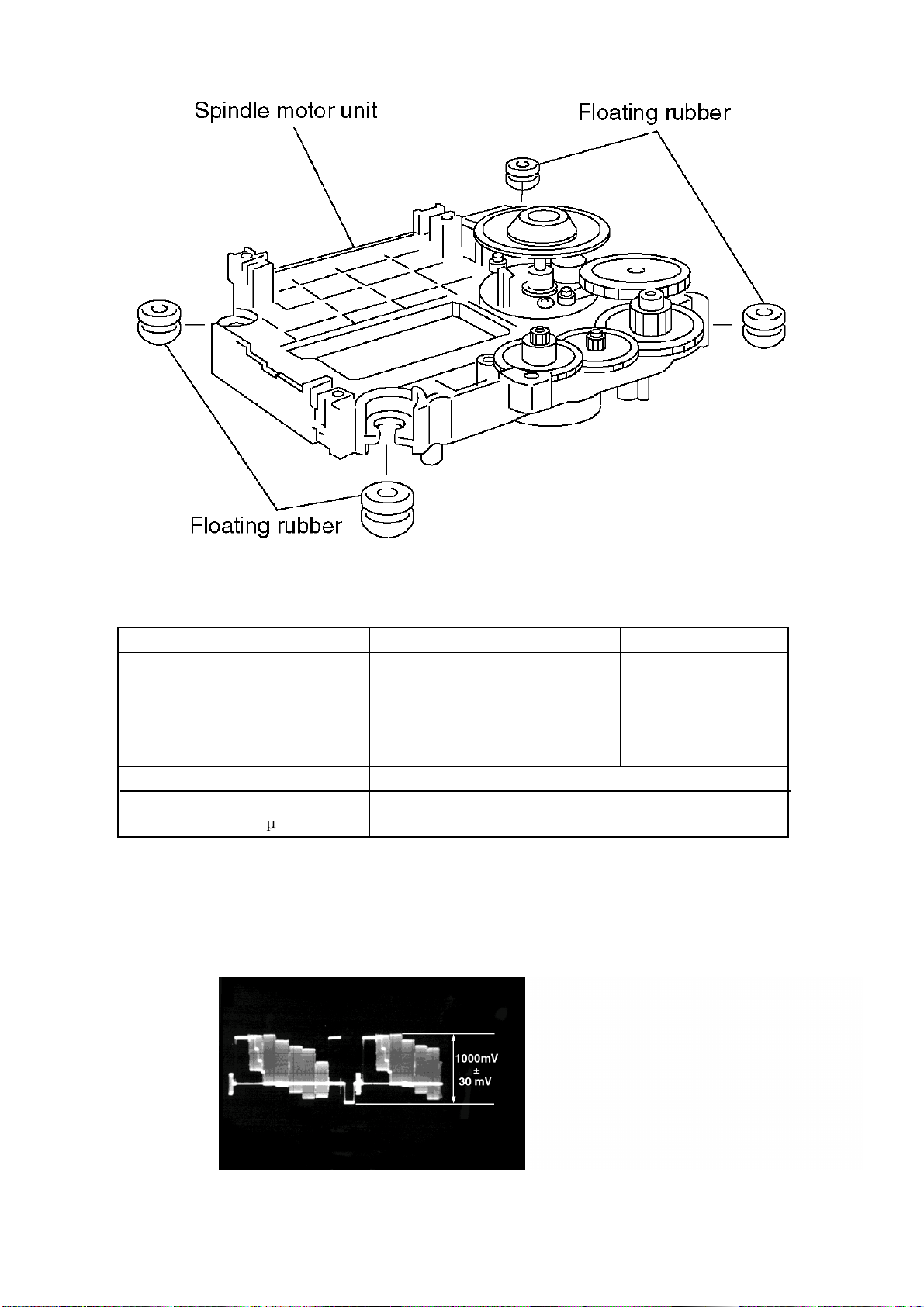

7. Electrical Confirmation

13

7.1. Video Output (Luminance Signal) Confirmation

DO this confirmation after replacing a P.C.B.

Measurement point

Mode Disc

Color bar 75%

Video output terminal

Measuring equipment,tools

200mV/dir,10 sec/dir

Purpose:To maintain video signal output compatibility.

1.Connect the oscilloscope to the video output terminal and terminate at 75 ohms.

2.Confirm that luminance signal(Y+S)level is 1000mVp-p±30mV

PLAY(Title 46):DVDT-S15

PLAY(Title 12):DVDT-S01

Confirmation value

1000mVp-p±30mV

DVDT-S15

or

DVDT-S01

Page 15

7.2. Video Output (Chrominance Signal) Confirmation

Screwdriver,Oscilloscope

141

Do the confirmation after replacing P.C.B.

Measurement point

Mode Disc

Color bar 75%

Video output terminal

Measuring equipment,tools Confirmation value

200mV/dir,10 sec/dir

Purpose:To maintain video signal output compatibility.

1.Connect the oscilloscope to the video output terminal and terminate at 75 ohme.

2.Confirm that the chrominance signal(C)level is 621 mVp-p±30mV

PLAY(Title 46):DVDT-S15

PLAY(Title 12):DVDT-S01

621mVp-p±30mV

DVDT-S15

or

DVDT-S01

Page 16

8.MPEG BOARD CHECK WAVEFORM

2. IC5L0380R PIN.2 WAVEFORM DIAGRAM

1. 27MHz WAVEFORM DIAGRAM

15

Page 17

PRELIMINARY

16

ES60X8 PINOUT DIAGRAM

The identical device pinouts for the ES6008, ES6018, ES6028

and ES6038 are shown in Figure 2.

HIOCS16#/CAMCLK/AUX3[4]

HA1/AUX4[3]

VSS

VEE

HA2

/AUX4[4]

VEE

AUX[0]

AUX[1]

AUX[2]/IOW#

VSS

VEE

AUX[3]/IOR#

AUX[4]

AUX[5]

AUX[6]

AUX[7]

LOE#

VSS

VCC

LCS0#

LCS1#

LCS2#

LCS3#

VSS

LD0

LD1

LD2

LD3

LD4

VEE

VSS

LD5

LD6

LD7

LD8

LD9

LD10

LD11

VSS

VEE

LD12

LD13

LD14

LD15

LWR LL#

LWRHL#

VSS

VEE

CAMIN0

CAMIN1

LA0

LA1

LA2

LA3

VSS

HA0/AUX4[2]

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

1

2 3 4 5 6 7 8 910111213141516171819202122232425262728293031323334353637383940414243444546474849505152

HWR#/DCI_CLK/AUX4[5]

HRD#/DCI_ACK#/AUX4[6]

HCS3FX#/AU X 3[6]

153

VEE

HCS1FX#/AU X 3[7]

152

VSS

HIORDY/AUX3[3]

HIRQ/DCI_ERR#/AUX4[7]

HRST#/AUX3[5]

HRRQ#/AUX4[0]

143

144

145

146

147

148

149

150

151

VSS

HD13/AUX2[5]/SP

HD12/AUX2[4]/C2PO

HD11/AUX2 [3]//IRQ

HD10/AUX2[2]/SQSK

HWRQ#/DCI_REQ#/AUX4[1]

HD15/A UX2[7]/IR

HD14/AUX2[6]/SQSI

VCC

138

139

140

141

142

HD9/AUX2[1]/SQSO

133

134

135

136

137

ES6008/18/28/38

208-Pin PQFP Package

HD8/DCI_FDS#/AUX2[0]/VFD_CLk

132

ES6008/18/28/38 DATA SHEET

ES60X8 PINOUT DIAGRAM

HD4/DCI4/AUX1[4]

HD5/DCI5/AUX1[5]

HD6/DCI6/AUX1[6]/VFD_DOUT

HD2/DCI2/AUX1[2]

HD3/DCI3/AUX1[3]

VSS

HD7/DCI7/AUX1[ 7 ]/VFD_DIN

VEE

128

129

130

131

HD1/DCI1/AUX1[1]

HD0/DCI0/AUX1[0]

VCC

VSS

HSYNC#/CAMIN7/AUX3[0]

PCLK2XSCN/CAMIN4

YUV7/CAMIN3

YUV6/VDAC

PCLKQSCN/CAMIN5/AUX3[2]

VSYNC#/CAMIN6/AUX3[1]

118

119

120

121

122

123

124

125

126

127

YUV5/YDAC

VSS

ADVEE

YUV4/RSET

YUV3/COMP

YUV2/CDAC

YUV1/VREF

YUV0/CAMIN2/UDAC

DCLK

105

106

107

108

109

110

111

112

113

114

115

116

117

104

103

102

101

100

96

94

93

91

57

99

98

97

95

92

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

64

63

62

61

60

59

58

56

55

54

53

VEE

VSS

DSCK

DQM

DCS0#

VEE

VSS

DCS1#

DB15

DB14

DB13

DB12

VEE

VSS

DB11

DB10

DB9

DB8

DB7

DB6

VSS

VCC

DB5

DB4

DB3

DB2

DB1

DB0

VSS

VEE

DMBS1

DMBS0

DRAS#

DWE#

DOE#/DSCK_EN

DCAS#

VEE

VSS

DMA11

DMA10

DMA9

DMA8

DMA7

DMA6

VSS

VEE

DMA5

DMA4

DMA3

DMA2

DMA1

DMA0

VEE

LA4

LA5

LA6

LA7

LA8

LA9

VSS

VCC

VSS

LA11

LA10

LA12

LA13

VEE

LA14

LA15

LA16

LA20

LA17

LA18

LA19

LA21

RESET#

TDMDX/RSEL

VSS

VEE

TDMDR

TDMCLK

VSS

VCC

TDMFS

TDMTSC#

TWS/SEL_PLL2

TSD2

TSD0/SEL_PLL0

TSD1/SEL_PLL1

NC

MCLK

TBCK

SPDIF/PLL3

VSS

TSD3

VCC

RSD

RWS

NC

RBCK

XIN

AVEE

XOUT

VSS

Figure 2 ES60x8 Pinout

SAM0400-100401 ESS Technology, Inc.

Page 18

ES6008/18/28/38 DAT A SHEET

17

PRELIMINARY

ES60X8 PIN DESCRIPTION

ES60X8 PIN DESCRIPTION

Table 1 lists the identical pin descriptions for the ES6008,

ES6018, ES6028 and ES6038.

Table 1 ES60x8 Pin Description

Name Number I/O Definition

VEE 1,18, 27, 59, 68,

75, 92, 99, 104,

130, 148, 157,

159, 164, 183,

193, 201

VSS 8, 17, 26, 34, 43 ,

52, 60, 67, 76,

84, 91, 98, 103,

112, 120, 129,

138, 147, 156,

163, 171, 177,

184, 192, 200,

208

LA[21:0] 23:19, 16:10,

7:2, 207:204

VCC 9, 35, 44, 83,

121, 139, 172

RESET# 24 I Reset input, active low.

TDMDX

RSEL I ROM Select.

25

I I/O power supply.

I Ground.

O Device address output.

I Core power supply.

O TDM transmit data.

RSEL Selection

016-bit ROM

1 8-bit ROM

TDMDR 28 I TDM receive data.

TDMCLK 29 I TDM clock input.

TDMFS 30 I TDM frame sync.

TDMTSC# 31 O TDM output enable.

TWS

O Audio transmit frame sync.

SEL_PLL2 I System and DSCK output clock frequency selection is made at the rising edge of

RESET#. The matrix belo w list s the avai lable c lock freque ncies and their res pective

PLL bit settings.

32

TSD0

SEL_PLL0 I Refer to the description and matrix for SEL_PLL2 pin 32.

33

TSD1

SEL_PLL1 I Refer to the description and matrix for SEL_PLL2 pin 32.

36

O Audio transmit serial data port 0.

O Audio transmit serial data port 1.

SEL_PLL2 SEL_PLL1 SEL_PLL0 Clock Type

0 0 0 VCO off.

0 0 1 DCLK

0 1 0 Bypass mode

0 1 1 DCLK x 2

1 0 0 DCLK x 4.5

1 0 1 DCLK x 3

1 1 0 DCLK x 3.5z

1 1 1 DCLK x 4

TSD[2] 37 O Audio transmit serial data output 2.

TSD[3] 38 O Audio transmit serial data output 3.

ESS Technology, Inc. SAM0400-100401

Page 19

PRELIMINARY

18

Table 1 ES60x8 Pin Description (Continued)

Name Number I/O Definition

MCLK 39 I/O Audio master clock for audio DAC.

TBCK 40 O Audio transmit bit clock.

SPDIF

SEL_PLL3 I Clock source select.

41

NC 42, 48 No connect pins. Leave open.

RSD 45 I Audio receiv e serial data.

RWS 46 I Audio receive frame sync.

RBCK 47 I Audio receive bit clock.

XIN 49 I Crystal input.

XOUT 50 O Crystal output.

AVEE 51 I Analog power for PLL.

DMA[11:0] 66:61, 58:53 O DRAM address bus [11:0].

DCAS# 69 O DRAM column address strobe.

DOE# 70 O DRAM output enable.

DSCK_EN O DRAM clock enable.

DWE# 71 O DRAM write enable.

DRAS# 72 O DRAM row address strobe.

DMBS0 73 O SDRAM bank select 0.

DMBS1 74 O SDRAM bank select 1.

DB[15:0] 96:93, 90:85,

82:77

DCS[1:0]# 97,100 O SDRAM chip select [1:0].

DQM 101 O Data input/output mask.

DSCK 102 O Output clock to SDRAM.

DCLK 105 I 27 MHz clock input to PLL.

YUV0

CAMIN2 I Camera input 2.

UDAC O Video DAC output.

O S/PDIF output.

SEL_PLL3 Clock Source

0 Crystal oscillator

1 DCLK input

I/O DRAM data bus [15:0].

O YUV0 pixel output data.

ES6008/18/28/38 DATA SHEET

ES60X8 PIN DESCRIPTION

Mode YDAC UDAC VDAC CDAC

A Y C Composite C

B Y Composite Composite C

C Y U Composite V

106

DYUCV

Y: Luma component for YUV and Y/C processing.

C: Chrominance signal for Y/C processing.

U: Chrominance component signal for YUV mode.

V: Chrominance component signal for YUV mode.

SAM0400-100401 ESS Technology, Inc.

Page 20

ES6008/18/28/38 DAT A SHEET

19

ES60X8 PIN DESCRIPTION

PRELIMINARY

Table 1 ES60x8 Pin Description (Continued)

Name Number I/O Definition

YUV1 107 O YUV1 pixel output data.

VREF I Internal voltage reference to video DAC. Bypass to ground with 0.1 µF capacitor.

YUV2

CDAC O Video DAC output. Refer to description and matrix for UDAC pin 106.

YUV3 109 O YUV3 pixel output data.

COMP I Compensation input. Bypass to ADVEE with 0.1 µF capacitor.

YUV4 110 O YUV4 pixel output data.

RSET I DAC current adjustment resistor input.

ADVEE 111 I Analog power for video DAC.

YUV5 113 O YUV5 pixel output data.

YDAC O Video DAC output. Refer to description and matrix for UDAC pin 106.

YUV6 114 O YUV6 pixel output data.

VDAC O Video DAC output. Refer to description and matrix for UDAC pin 106.

YUV7 115 O YUV7 pixel output data.

CAMIN3 I Camera YUV 3.

PCLK2XSCN 116 I/O 27-MHz video output pixel clock.

CAMIN4 I Camera YUV 4.

PCLKQSCN 1 17 O 13.5-MHz video output pixel clock.

CAMIN5 I Camera YUV 5.

VSYNC# 118 I/O Vertical sync, active low.

CAMIN6 I Camera YUV 6.

HSYNC# 119 I/O Horizontal sync, active low.

CAMIN7 I Camera YUV 7.

HD[5:0]

DCI[5:0] I/O DVD channel data I/O [5:0].

AUX1[5:0] I/O Aux1 data I/O [5:0].

HD[6]

DCI[6] I/O DVD channel data I/O [6].

AUX1[6] I/O Aux1 data I/O [6].

VFD_DOUT I VFD data output.

HD[7]

DCI[7] I/O DVD channel data I/O [7].

AUX1[7] I/O Aux1 data I/O [7:0].

VFD_DIN I VFD data input.

HD[8]

DCI_FDS# I/O DVD input sector start.

AUX2[0] I/O Aux2 data I/O 0.

VFD_CLK I VFD clock input.

HD[9]

AUX2[1] I/O Aux2 data I/O [1] when selected.

SQSQ I Subcode-Q data.

HD[10]

AUX2[2] I/O Aux2 data I/O [2] when selected.

SQSK I Subcode-Q clock.

108

127:122

128

131

132

133

134

O YUV2 pixel output data.

I/O Host data I/O [5:0].

I/O Host data I/O [6].

I/O Host data I/O [7].

I/O Host data bus 8.

I/O Host data bus line 9.

I/O Host data bus line10.

ESS Technology, Inc. SAM0400-100401

Page 21

PRELIMINARY

20

Table 1 ES60x8 Pin Description (Continued)

Name Number I/O Definition

HD[11]

AUX2[3] I/O Aux2 data I/O [3] when selected.

IRQ O IRQ output.

HD[12]

AUX2[4] I/O Aux2 data I/O [4] when selected.

C2PO I C2PO error correction flag from CD-ROM.

HD[13]

AUX2[5] I/O Aux2 data I/O [5] when selected.

SP I 16550 UART serial port input.

HD[14]

AUX2[6] I/O Aux2 data I/O [6] when selected.

SQSI I Subcode-Q sync.

HD[15]

AUX2[7] I/O Aux2 data I/O [7] when selected.

IR I IR remote control input.

HWRQ#

DCI_REQ# O DVD control interface request.

AUX4[1] I/O Aux4 data I/O 1.

HRRQ# 143 O Host read request.

AUX4[0] I/O Aux4 data I/O 0.

HIRQ

DCI_ERR# I/O DVD channel data error.

AUX4[7] I/O Aux4 data I/O 7.

HRST# 145 O Host reset.

AUX3[5] I/O Aux3 data I/O 5.

HIORDY 146 I Host I/O ready.

AUX3[3] I/O Aux3 data I/O 3.

HWR#

DCI_CLK I/O DVD channel data clock.

AUX4[5] I/O Aux4 data I/O 5.

HRD#

DCI_ACK# O DVD channel data valid.

AUX4[6] I/O Aux4 data I/O 6.

HIOCS16#

CAMCLK I Camera port pixel clock input.

AUX3[4] I/O Aux3 data I/O 4.

HCS1FX# 152 O Host select 1.

AUX3[7] I/O Aux3 data I/O 7.

HCS3FX# 153 O Host select 3.

AUX3[6] I/O Aux3 data I/O 6.

HA[2:0] 158, 155:154 I/O Host address bus.

AUX4[4:2] I/O Aux4 data I/Os [4:2].

AUX[1:0] 160 I/O Auxiliary ports 1:0.

135

136

137

140

141

142

144

149

150

151

I/O Host data bus line11.

I/O Host data bus line12.

I/O Host data bus line13.

I/O Host data bus line14.

I/O Host data bus line15.

O Host write request.

I/O Host interrupt.

I/O Host write.

OHost read.

I Device 16-bit data transfer.

ES6008/18/28/38 DATA SHEET

ES60X8 PIN DESCRIPTION

SAM0400-100401 ESS Technology, Inc.

Page 22

ES6008/18/28/38 DAT A SHEET

21

LICENSING REQUIREMENTS

PRELIMINARY

Table 1 ES60x8 Pin Description (Continued)

Name Number I/O Definition

AUX[2] 162 I/O Auxiliary port 2.

IOW# O I/O Write strobe.

AUX[3] 165 I/O Auxiliary port 3.

IOR# O I/O Read strobe.

AUX[7:3] 169:166 I/O Auxiliary ports 7:3.

LOE# 170 O Device output enabl e.

LCS[3:0]# 176:173 O Chip select [3:0].

LD[15:0] 197:194,

191:185,

182:178

LWRLL# 198 O Device low-byte write enable.

LWRHL# 199 O Device high-byte write enable.

CAMIN0 202 I Camera YUV 0.

CAMIN1 203 I Camera YUV 1.

I/O EPROM device data bus.

LICENSING REQUIREMENTS

Dolby Digital Licensing

Dolby Digital audio enabling softwa re is provid ed with the

Vibrat to seri es of DVD proc essors. Dolby is a tra demark of

the Dolby Labora tories. Supply of th is implementation of

Dolby Technology does not convey a license or imply a

right under any patent, or any other Industrial or

Intellectual Property Ri ght of Dolby Laboratories, to use

this implementation i n any end-user or ready-to -use final

product. Companies planning to us e this implementation

in products must obtain a license from Dolby Laboratories

Licensing Corporation before designing such products.

Additional per-chip royalties may be required and are to be

paid by the purchaser to Dolby Labor atories, Inc. Details

of the OEM Dolby Digital license may be obtained by

writing to:

Dolby Laboratories Inc.

Dolby Laboratories Licensing Corporation

Attn.: Intellectual Property Manager

100 Potrero Avenue

San Francisco, CA 94103-4813

Macrovision Licensing

Macrovision Copy Protection is su pported in the Vibratto

series of DVD processors. The use of Macrovision’s Copy

Protection technology in the device must be authorized by

Macrovision and is intended for home and other limited

pay-per-view uses only, unless otherwise authorized in

writing by Macrovision.

Reverse engineering or disassembly is prohibited. A valid

Macrovision license must be in effect between the Vibratto

purchaser and Macrovision Corporation. Additional perchip royalties ma y be required and are to be paid by th e

purchaser to Macrovision Corporation. Details of the

Macrovision license may be obtained by writing to:

Macrovision Corporation

1341 Orleans Avenue

Sunnyvale, CA 94089

ESS Technology, Inc. SAM0400-100401

Page 23

PRELIMINARY

22

FUNCTIONAL DESCRIPTION

Figure 3 shows the internal block diagram for the basic Vibratto DVD processor.

SRAM

Interface

ESS RISC

Processor

DMA

Controller

Host/ATAPI/UDF

Loader Interface

Serial Audio

Interface

DCI Loader

Interface

MPEG

Decoder

System

Demultiplexer

DVD

Descramble

Interface

2Kx32 ROM

512x32 SRAM

Processor

Video Output

On Screen

Display

Sub-Picture

Decoder

Encoder

Processor

Interface

Host/ATAPI

UDF

Interface

HCS[1,3]FX#

Serial

Audio

Interface

DCI

Interface

LA[21:0]

LCS#[3:0]

LD[15:0]

LWRHL#

LWRLL#

LOE#

HA[2:0]

HD[15:0]

HWRQ#

HRDQ#

HIRQ#

HRST#

HIORDY

HWR#

HRD#

HIOCS16#

RSD

RWS

RBCK

SPDIF

TBCK

MCLK

TSD[3:0]

TWS

DCI_ACK#

DCI_CLK

DCI_ERR#

DCI_REQ#

DCI_FDS#

DCI[7:0]

DRAM

Video

Video

ES6008/18/28/38 DATA SHEET

FUNCTIONAL DESCRIPTION

DSCK_EN

DSCK

DQM

DCS#[1:0]

DMA[11:0]

DWE#

DOE#

DRAS#[2:0]

DB[I5:0]

DCAS#

YUV[7:0]

PCLK2XSCN

PCLKQSCN

VSYNC#

HSYNC#

DRAM

Screen

Display

CDAC

YDAC

UDAC

VDAC

VREF

COMP

RSET

TDM

Interface

TDMCLK

TDMDR

TDMDX

TDMFS

TDMTSC#

TDM

Interface

Registers

Clock

AUX[7:0]

RESET#

XIN

XOUT

Clock,

Aux Ports

and Reset

Figure 3 Vibratto Block Diagram

Vibratto Device Architecture

The Vibratto device architecture includes a RISC

processor, CRT controller, transport mechanism, video

encoder, memory controller, on-screen display (OSD)

controller and video processor.

ESS RISC Processor

Embedded in the Vibratto is a 32-bit data pipelin ed RISC

processor, with a combined 16 kb instruction and data

done mostly in C. Fo r applications involving an external

host processor the communication between a host

processor and the Vibratto is ha ndled by a host inte rface

module. The host interface can also be used for high

speed data input and output.

The ESS RISC processor instruction and data cache

subsystem is organ iz ed as a t wo- way s et a ss ocia tiv e. O n

a cache load-miss and write-miss, the cache lines are

allocated into the cache memory.

cache subsystem. Programming of the RISC processor is

SAM0400-100401 ESS Technology, Inc.

Page 24

2 Megabit (256 K x 8-Bit)

IC BLOCK DIAGRAM & DESCRIPTION

IC U214 Am29F002B/Am29F002NB

23

CMOS 5.0 Volt-only Boot Sector Flash Memory

DISTINCTIVE CHARACTERISTICS

■ Single power supply operation

— 5.0 Volt-only operation for read, erase, and

program operations

— Minimizes system level requirements

■ Manufactured on 0.32 µm process technology

— Compatible with 0.5 µm Am29F002 device

■ High performanc e

— Access times as fast as 55 ns

■ Low power consumption (typical values at

5 MHz)

— 1 µA standby mode current

— 20 mA read current

— 30 mA program/erase current

■ Flexible sector architecture

— One 16 Kbyte, two 8 Kbyte, one 32 Kbyte, and

three 64 Kbyte sectors

— Supports full chip erase

— Sector Protection features:

A hardware method of locking a sector to

prevent any program or erase operations within

that sector

Sectors can be loc k ed v ia pr ogr ammi ng eq uipme nt

T emporary Sector Unprotect feat ure allows code

changes in previously locked sectors

■ Top or bot tom boot blo ck co nfigurations a vaila ble

■ Embedded Algorithms

— Embedded Erase algorithm automatically

preprograms and erases the entire chip or any

combination of designated sectors

— Embedded Program algorithm automatically

writes and verifies data at specified addresses

■ Minimum 1,000,000 write cycle guarantee per

sector

■ 20-year data retention at 125°C

— R eliable operation for the life of the system

■ Package option

— 32-pin PDIP

— 32-pin TSOP

— 32-pin PLCC

■ Compatibility with JEDEC standards

— Pinout and software compatible with

single-power supply Flash

— Super ior inadvertent write protection

■ Data# Polling and toggle bits

— Provides a software method of detecting

program or erase operation completion

■ Erase Suspend/Erase Resume

— Suspends an erase operation to read data from,

or program data to, a sector that is not being

erased, then resumes the erase operation

■ Hardware reset pin (RESET#)

— Hardware method to reset the device to reading

array data (not available on Am29F002NB)

Page 25

PRODUCT SELECTOR GUIDE

IC BLOCK DIAGRAM & DESCRIPTION

24

Family Part Number Am29F002B/Am29F002NB

= 5.0 V ± 5% -55

V

Speed Option

Max access time, ns (t

Max CE# access time, ns (t

Max OE# access time, ns (t

CC

= 5.0 V ± 10% -70 -90 -120

V

CC

)557090120

ACC

)557090120

CE

) 30303550

OE

Note: See “AC Characteristics” for full specifications.

BLOCK DIAGRAM

V

CC

V

SS

RESET#

n/a Am29F002NB

Sector Switches

Erase Voltage

Generator

DQ0

–

DQ7

Input/Output

Buffers

WE#

CE#

OE#

A0–A17

State

Control

Command

Register

VCC Detector

PGM Voltage

Generator

Timer

Chip Enable

Output Enable

STB

Logic

Address Latch

Y-Decoder

X-Decoder

STB

Data

Latch

Y-Gating

Cell Matrix

Page 26

CONNECTION DIAGRAMS

IC BLOCK DIAGRAM & DESCRIPTION

25

RESET#

NC

A16

A15

A12

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

DQ1

DQ2

V

SS

NC on Am29F002NB

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

PDIP

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

V

CC

WE#

A17

A14

A13

A8

A9

A11

OE#

A10

CE#

DQ7

DQ6

DQ5

DQ4

DQ3

A7

A6

A5

A4

A3

A2

A1

A0

DQ0

5

6

7

8

9

10

11

12

13

14

A12

4

15

DQ1

A15

3

DQ2

A16

2

PLCC

17

SS

V

NC on Am29F002NB

RESET#

VCCWE#

31 30

1

32

19 2016

18

DQ3

DQ4

DQ5

A17

29

28

27

26

25

24

23

22

21

DQ6

A14

A13

A8

A9

A11

OE#

A10

CE#

DQ7

NC on Am29F002NB

A11

A9

A8

A13

A14

A17

WE#

V

CC

RESET#

A16

A15

A12

A7

A6

A5

A4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Standard TSOP

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

OE#

A10

CE#

DQ7

DQ6

DQ5

DQ4

DQ3

V

SS

DQ2

DQ1

DQ0

A0

A1

A2

A3

Page 27

PIN CONFIGURATION

IC BLOCK DIAGRAM & DESCRIPTION

26

A0–A17 = 18 addresses

DQ0–DQ7 = 8 data inputs/outputs

CE# = Chip enable

OE# = Output enable

LOGIC SYMBOL

18

A0–A17

8

DQ0–DQ7

WE# = Write enable

RESET# = Hardware reset pin, active low

(not available on Am29F002NB)

= +5.0 V single power supply

V

CC

V

SS

NC = Pin not connected internally

(see Product Selector Guide for

device speed ratings and voltage

supply tolerances)

= Device ground

CE#

OE#

WE#

RESET#

N/C on Am29F002NB

Page 28

4 Banks x 1M x 16Bit Synchronous DRAM

IC BLOCK DIAGRAM & DESCRIPTION

IC U206 SDRAM-HY57V65162B

27

DESCRIPTION

The Hyundai HY57V651620B is a 67,108,864-bit CMOS Synchronous DRAM, ideally suited for the Mobile applications which require low power consumption and extended temperature range. HY57V651620B is organized as 4banks

of 1,048,576x16.

HY57V651620B is offering fully synchronous operation referenced to a positive edge of the clock. All inputs and outputs are synchronized with the rising edge of the clock input. The data paths are internally pipelined to achieve very

high bandwidth. All input and output voltage levels are compatible with LVTTL.

Programmable options include the length of pipeline (Read latency of 2 or 3), the number of consecutive read or write

cycles initiated by a single control command (Burst length of 1,2,4,8 or Full page), and the burst count

sequence(sequential or interleave). A burst of read or write cycles in progress can be terminated by a burst terminate

command or can be interrupted and replaced by a new burst read or write command on any cycle. (This pipelined

design is not restricted by a `2N` rule.)

FEATURES

• Single 3.3V ± 10% power supply

• All device pins are compatible with LVTTL interface

• JEDEC standard 400mil 54pin TSOP-II with 0.8mm

of pin pitch

• All inputs and outputs referenced to positive edge of

system clock

• Data mask function by UDQM or LDQM

• Internal four banks operation

ORDERING INFORMATION

Part No. Clock Frequency Power Organization Interface Package

HY57V651620BTC-7I 143MHz

HY57V651620BTC-75I 133MHz

HY57V651620BTC-10SI 100MHz

HY57V651620BLTC-7I 143MHz

HY57V651620BLTC-75I 133MHz

HY57V651620BLTC-10SI 100Mhz

Normal

• Auto refresh and self refresh

• 4096 refresh cycles / 64ms

• Programmable Burst Length and Burst Type

- 1, 2, 4, 8 or Full page for Sequential Burst

- 1, 2, 4 or 8 for Interleave Burst

• Programmable CAS Latency ; 2, 3 Clocks

power

4Banks x 1Mbits

x16

Lower

Power

LVTTL 400mil 54pin TSOP II

This document is a general product description and is subject to change without notice. Hyundai Electronics does not assume any

responsibility for use of circuits described. No patent licenses are implied.

Rev. 0.4/Nov.00

Page 29

PIN CONFIGURATION

IC BLOCK DIAGRAM & DESCRIPTION

28

VDD

DQ0

VDDQ

DQ1

DQ2

VSSQ

DQ3

DQ4

VDDQ

DQ5

DQ6

VSSQ

DQ7

DD

V

LDQM

/WE

/CAS

/RAS

/CS

BA0

BA1

A10/AP

A0

A1

A2

A3

DD

V

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

54pin TSOP II

400mil x 875mil

0.8mm pin pitch

VSS

54

DQ15

53

VSSQ

52

DQ14

51

DQ13

50

VDDQ

49

DQ12

48

DQ11

47

VSSQ

46

DQ10

45

DQ9

44

VDDQ

43

DQ8

42

SS

V

41

NC

40

UDQM

39

CLK

38

CKE

37

NC

36

A11

35

A9

34

A8

33

A7

32

A6

31

A5

30

A4

29

SS

V

28

PIN DESCRIPTION

PIN PIN NAME DESCRIPTION

CLK Clock

CKE Clock Enable

CS Chip Select Enables or disables all inputs except CLK, CKE and DQM

BA0,BA1 Bank Address

A0 ~ A11 Address

RAS, CAS, WE

LDQM, UDQM Data Input/Output Mask Controls output buffers in read mode and masks input data in write mode

DQ0 ~ DQ15 Data Input/Output Multiplexed data input / output pin

VDD/VSS Power Supply/Ground Power supply for internal circuits and input buffers

VDDQ/VSSQ Data Output Power/Ground Power supply for output buffers

NC No Connection No connection

Row Address Strobe,

Column Address Strobe,

Write Enable

The system clock input. All other inputs are registered to the SDRAM on the

rising edge of CLK

Controls internal clock signal and when deactivated, the SDRAM will be one

of the states among power down, suspend or self refresh

Selects bank to be activated during RAS activity

Selects bank to be read/written during CAS activity

Row Address : RA0 ~ RA11, Column Address : CA0 ~ CA7

Auto-precharge flag : A10

RAS, CAS and WE define the operation

Refer function truth table for details

Page 30

FUNCTIONAL BLOCK DIAGRAM

I/O Buffer & Logic

IC BLOCK DIAGRAM & DESCRIPTION

29

1Mbit x 4banks x 16 I/O Synchronous DRAM

Self refresh logic

CLK

CKE

CS

RAS

CAS

WE

UDQM

LDQM

& timer

Row active

State Machine

refresh

Column

Active

Internal Row

counter

Row

Pre

Decoders

Column

Pre

Decoders

1Mx16 Bank 3

X decoders

1Mx16 Bank 2

X decoders

X decoders

1Mx16 Bank 1

1Mx16 Bank 0

X decoders

Memory

Y decoders

Cell

Array

Sense AMP & I/O Gate

DQ0

DQ1

DQ14

DQ15

Bank Select

A0

A1

A11

BA0

BA1

Address buffers

Address

Registers

Mode Registers

Column Add

Counter

Burst

Counter

CAS Latency

Data Out Control

Pipe Line Control

Page 31

ABSOLUTE MAXIMUM RATINGS

IC BLOCK DIAGRAM & DESCRIPTION

30

Parameter Symbol Rating Unit

Ambient Temperature TA -40 ~ 85 °C

Storage Temperature TSTG -55 ~ 125 °C

Voltage on Any Pin relative to VSS VIN, VOUT -1.0 ~ 4.6 V

Voltage on VDD relative to VSS VDD, VDDQ -1.0 ~ 4.6 V

Short Circuit Output Current IOS 50 mA

Power Dissipation PD 1 W

Soldering Temperature ⋅ Time TSOLDER 260 ⋅ 10 °C ⋅ Sec

Note : Operation at above absolute maximum rating can adversely affect device reliability

DC OPERATING CONDITION (TA= -40 to 85°C)

Parameter Symbol Min Typ. Max Unit Note

Power Supply Voltage VDD, VDDQ 3.0 3.3 3.6 V 1

Input High Voltage VIH 2.0 3.0 VDDQ + 2.0 V 1,2

Input Low Voltage VIL VSSQ - 2.0 0 0.8 V 1,3

Note :

1.All voltages are referenced to VSS = 0V

2.VIH (max) is acceptable 4.7V AC pulse width with ≤3ns of duration

3.VIL (min) is acceptable -2.0V AC pulse width with ≤3ns of duration

AC OPERATING CONDITION (TA= -40 to 85°C, VDD=3.3V ± 0.3V, VSS=0V)

Parameter Symbol Value Unit Note

AC Input High / Low Level Voltage VIH / VIL 2.4/0.4 V

Input Timing Measurement Reference Level Voltage Vtrip 1.4 V

Input Rise / Fall Time tR / tF 1 ns

Output Timing Measurement Reference Level Voutref 1.4 V

Output Load Capacitance for Access Time Measurement CL 50 pF 1

Note :

1. Output load to measure access time is equivalent to two TTL gates and one capacitor (50pF)

For details, refer to AC/DC output circuit

Page 32

! 3-Termainal Regulators

IC WS7805

POSITIVE-VOLTAGE REGULATORS

25

V

)

WS7805DP

TO-220

WS7805CV

O

C

I

TO-252

IC BLOCK DIAGRAM & DESCRIPTION

31

! Output Current Up to 1.5 A

! No External Components

! Internal Thermal Overload Protection

! High Power Dissipation Capability

! Internal Shot-Circuit Current Limiting

! Output Transistor Safe-Area

Compensation

DESCRIPTION

This series of fixed-voltage monolithic integrated-circuit

voltage regulators designed for a wide range of

applications. These applications include on-card

regulation for elimination of noise and distribution

problems associated with single-point regulation. Each

of these regulators can deliver up to 1.5 amperes of

output current. The internal current limiting and thermal

shutdown features of these regulators make them

O

C

I

(TO-252)

essentially immune to overload.

ABSOLUTE MAXIMUM RATINGS OVER OPERATING TENPERATURE

RANGE (UNLESS OTHERWISE NOTE

WS7805 PARAMETER UNIT

Input voltage, V

Continuous total dissipati on at 25℃ free-air temperature

Lead temperature 1.6mm (1/16 inch) from case 10 seconds 260

Storage temperature range, T

I

stg

RECOMMEMDED OPERATING CONDITIONS

Input voltage, V

Output current, I

Operating virtual junction temperature, T

I

O

J

35 V

2W

-65 to 150

MIN MAX UNIT

7

1.5 A

070

℃

℃

℃

Page 33

101

32

10. SCHEMATIC & P.C.B WIRING DIAGRAM

FRONT SCHEMATIC DIAGRAM

R417

10K

VCC

VFDCK

VFDAT

KEY1

KEY2

KEY3

KEY4

33K

33K

R401

R402 33K

R403 33K

R404

11

12

13

14

VCC

15

SEG1

16

SEG2

17

SEG3

18

SEG4

19

SEG5

20

SEG6

21

SEG7

22

SEG8

KEY3

KEY4

VDD

S1

S2

S3

S4

S5

S6

S7

S8

R414

33K

33K

R413

R412

33K

R411

33K

R416

10K

VCC C406

GND

VFDST

4DO5

8

9

STB

DIN6VSS7CLK

KEY110KEY2

U401

UPD16312

SW11SW22SW33SW4

U403

HS0038A2

123

101

C403

101

C404

10K

R406

R407 10K

SW4

SW3

SW2

MSW

OSC

VSS

LED1

LED2

LED3

LED4

VDD

G1

G2

G3

G4

C405

IR

10K

10K

R408 10K

R409

R410

R405

33K

44

43

42

41

40

39

38

37

36

35

34

C407

100uF/16V

104

R415

100

VCC

VCC

C402

100uF/16V

104

C401

GND

VCC

GRID1

GRID2

GRID3

GRID4

XS401

23415

VCC

-25V

FIL-

GND

R418

33R

FIL+

VCC

R419

470R

12

LED401

XS402

XS05

IR

GND

XS05

23415

VFDST

VFDCK

VFDAT

S923S1024S1125S12/G126VEE27S13/G128S14/G929S15/G830S16/G731G632G5

33

-25V

SEG11

SEG10

SEG9

SEG12

SEG13

GRID1

GRID2

GRID3

GRID4

FIL+

1

F12F1

GRID5

4

5G

91G82G73G64G5

NC

SEG16

GRID5

SEG14

SEG15

SEG16

FIL-

SEG1

SEG2

SEG3

SEG4

SEG5

SEG6

SEG7

SEG8

SEG9

SEG10

SEG11

SEG12

SEG13

SEG14

SEG15

31

29

P1225P1124P10

P1326P1427P15

28

F232F2

P16

23P922P821P720P619P518P417P316P215P114NC13NC12NC11NC10

D403

1N4148

SEG3

D402

SEG2

D401

SEG1

K409

1N4148

K408K404

K405

1N4148

K401

K407K403

K406

K402

KEY4

KEY3

KEY2

KEY1

VFD401

VFD-32

Page 34

33

FRONT SCHEMATIC DIAGRAM

Page 35

CN503

34

POWER BOARD SCHEMATIC DIAGRAM

XS10

TC508

100uF/16V

SA+5V

2341568

9107

CN504

23415

XS06

6

3

CN502

CN505

1

SD+5V

234

DGND

DGND

L505

10uH/1A

C507

XS04

+12V

+9V

101

XS06

23415

6

SD+5V

SA+5V

DGND

C508

TC504

TC503

+9V

DGND

DGND

104

470uF/16V

470uF/16V

D508

HER105

OUT

U504

LM7805

GND

2

IN

1

TC507

470uF/10V

L508

FB

TC511

C510

+5V

TC506

1000uF/10V

L507 10uH/2A

TC505

1000uF/10V

HER303

C509

101

D510

+3.3V

104

TC510

1000uF/10V

L506

10uH/2ABC502

TC509

1000uF/10V

C511

101

D509

SR303

D512

100uF/16V

101

C513

HER105

D511

-9V

DGND

+3.3V

+5V

DGND

+9VOKAGND

VOICE-DET

-9V

R511

220R/1W

HER105

C514

+3.3V

ZD502

9.1V/1W

TC513

100uF/16V

5.1V

ZD501

R510

4.7K

R508

3.3K

R507

1K

330

R506

TC512

47uF/50V

101

-9V

+9V

AGNDOKDET

+5V

CN501

FL+

C515

104

23415

FL-

-21V

DGND

K

U503

XS05

+5V

R509

10K

R

A

LM431A

10

11

16T501

!

C502

103/1KV

R503

39K/2W

R502

120K/2W

D504

D503

1N4007

D502

1N4007

D501

12

13 14 15

2 3 4 6

D505

HER107

C503

101/1KV

TC501

1N4007

47uF/400V

1N4007

9

EI28/8

7

C505

101

D506

HER105

R505

TC502

33ohm

47uF/50V

R504

1M

C504

104

FB

L503

~275V 104

4

1

FB

D

2

3

GND

VCC

U501

5L0380R

!

U502

2501

C506

223

BC501

~275V 104

RV501

07D471

R501

680K 2W

BC503

~400V 221

!

!

!

~220V

BCN501

F501

!

L502

L501

!

!

!

T1.6A/250V

!

BCN502

SW-SPST

Page 36

35

POWER BOARD SCHEMATIC DIAGRAM

Page 37

C619

36

OK SCHEMATIC DIAGRAM

102

R626

1K

TC610

4.7uF/16V

7

U602B

27K

C620 101

R629

R628

4.7K

TC611

R613

-9VA

30K

C607 101

4558

C616

5

6

4.7uF/16V

392

C608

R614

15K

TC613

4.7uF/16V

1

U602A

4558

8 4

+9VA

TC621

2

4.7uF/16V

R612

10K

103

C615

392

C614

R621

10K

C613

R624

10K

C612

R618

15K

10K

R616 5.6K

R617 10K

R623

50K

R620

C610

R622 4.7K

TC607

U603

PT2399

9

104

10

11

104

12

13

561

14

15

16

561

4.7uF/16V

XS601

XS06

23415

6

OK

GND

+9V

-9V

DET

OP1-OUT

OP1-IN

OP2-IN

OP2-OUT

LPF2-IN

LPF2-OUT

LPF1-OUT

LPF1-IN

+5V

C623

CC2

8

CC1

7

VCO

6

CLKO

5

DGND

4

AGND

3

REF

2

VDD

1

+5V

104

C622

104

R615

18K

TC609

47uF/16V

C609

104

TC608

100uF/25V

VR601

10K

TC603

4.7uF/16V

1

U601A

4558

8 4

+9VA 3

R609 30K

C605 101

R607

1K

OK

TC605

22uF/16V

3

2

R603

560R

TC601

4.7uF/16V

9MIC602

L602

54321

678

R605

10K

C603

103

R601

22K

FB

1K

R619

R610

R611

1K

TC604

4.7uF/16V

7

U601B

30K

R608

1K

TC606

4558

C606

101

R606

10K

5

6

C604

R604

560R

22uF/16V

TC602

4.7uF/16V

L601

FB

54321

678

9

103

R602

22K

R632

R633

C602

104

TC616

10R/0.25W

10R/0.25W

100uF/25V

C601

104

TC615

100uF/25V

+9V +9VA -9V -9VA

DET

MIC601

Page 38

37

OK SCHEMATIC DIAGRAM

Page 39

R224

38

MIAN SCHEMATIC DIAGRAM

0R(DNS)

C284

104

VCC5A

VCC5A

3

OUT

U211

R245

GND

+9V

1

2

IN

GND

4.7K(OPEN)

5

VCC5A

VDD

NC1GND2NC

U210

78L05

UPA[20..0]

VCC

R206

4.7K

MA1

MA2

MA3

R2165 22R

R2166 22R

R2167 22R

R2168 22R

TC201

10uF/16V

C215

104

C214

104

C213

104

C212

104

C211

104

C210

104

C209

104

C208

104

C207

104

C206

104

VCC3.3

C205

104

C204

104

C203

104

VCC VCC VCC

VCC

R2169 22R

DMA0 MA0

DMA1

DMA2

DMA3

DMA4 MA4

TC209

10uF/16V

C286

104

VCC3.3E

TC203

10uF/16V

VCCVCC

C223

104

VCC

TC202

10uF/16V

C222

104

C221

104

C220

104

C219

104

C218

104

VCC2.5

C217

104

C216

104

AUX1

AUX0

R208

1K

R207

1K

8

7

6

5

SCL

VCC

SDA

RST/WP

U202

AT24C01/X4050

DC/NC1RST_/NC2WP/RST_3VSS

C289

102

4

WRLL#

R221

0R

AUX2

RST#

C242

C224

104

VCC

4

C290

104

RES

V6300

3

R246

0R(OPEN)

R211

Q201

9015C(OPEN)

AUX2

MA5

MA6

MA7

R2170 22R

R2171 22R

R2172 22R

R2173 22R

DMA5

DMA6

DMA7

DMA8 MA8

VGND

R2189

4.7K

R2191

4.7K

TC208

C285

VCC3.3P

VCC2.5

Q203

8050

L250

FBSMT

L249

FBSMT

VCC3.3 VCC3.3VCC3.3P VCC3.3E

RST#

101(OPEN)

44WE43A842

RESET

U203

RY/BY1A182A173A65A56A38A29A011CE

4.7K

R210 0R(OPEN)

R209

10K(OPEN)

MA9

MA10

33RTSD2 TSD2-

33R

33RTSD1 TSD1-

R249

R247

R248

R2174 22R

R2175 22R

DMA9

DMA10

TSD0 TSD0-

R2190

4.7K(OPEN)

R2192

4.7K(OPEN)

10uF/16V

104

159

172

139

121

83

44

35

9

201

193

183

164

157

148

130

111

104

99

92

75

68

59

51

27

18

1

29

30

28

25

31

LA9

WR#

LA19

LA18

RAS0#

R2177 22R

DRAS0#

LA10

LA12

LA13

LA11

41

38

A9

A1040A1139A1337A1436A16

A7

4

7

LA8

LA7

LA6

LA5

CAS#

WE#

R2178 22R

R2179 22R

DCAS#

DWE#

C201

MCLK

RBCK

TSD0

RWS

39

40

32

TBCK

MCLK

TWS/SEL_PLL1

VPP

VCC25

VCC25

VCC25

VCC25

VCC25

VCC25

VCC25

VCC33

VCC33

VCC33

VCC33

VCC33

VCC33

VCC33

VCC33

VCC33

VCC33

VCC33

VCC33

VCC33

VCC33

VCC33

VCC33

VCC33

VCC33

TDMFS

CLK

RESET24LCS0

105

173

174

LA14

LA15

LA16

LA17

LA0

LD7

LD6

LD5

LD4

DB15

DB14

DB13

DB12

DB11

DB10

VCC3.3VCC3.3

46

52

54

49

30

29

31

32

34

33

A1535VSS

A12

BYTE

A110VSS

A4

13

12

0R(OPEN)

R212

LA4

LA3

LA2

LA1

LCS2#

LCS3#

BANK0

BANK1

R216 33RDQM DQMX

R217 33R

R218 33R

DBANK0

DBANK1

22pF

25

24

23

27

VCC

DQ526DQ628DQ7

DQ4

DQ14

DQ12

DQ13

DQ15/A_1

DQ219DQ117DQ015DQ816OE

DQ9

14

18

DQ1020DQ321DQ11

LD[0..7]

8M_FLASH/16M_FLASH

22

0R

R213

LD0

LD1

LD2

LD3

LEO#

CKE

R220 33R

R222 33R

R223 33R

DMA11 MA11

DCKE

DCS0# CS0#

C2140

104

VCC3.3E

C2141

TSD1

TSD2

SPDIF

RSD

R292 33R

36

38

47

46

45

41

42

RSD

RWS

RBCK

TSD237TSD3

TSD0/SEL_PLL033TSD1/SEL_PLL2

TDMCLK

TDMDR

TDMDX/RSEL

TDMTSC

LCS1

LCS2

LCS3

175

176

SPDIF_DOBM

LWRLL

LWRHL

LOE

LA0

LA1

LA2

LA3

198

199

170

204

205

206

207

104

HSYNC

VSYNC

R2193

UDAC

VREF

CDAC

YDAC

116

117

119

118

106

107

108

109

110

113

YUV0

YUV1

YUV2

YUV3

YUV4

HSSCN

VSSCN

PCLKQSCN

PCLK2XSCN

SPDIF_DIBM

LA42LA53LA64LA75LA86LA97LA1010LA1111LA1212LA1313LA1414LA1515LA1616LA1719LA1820LA1921LA2022LA2123LD0

53

DB[0..15]

U204

SDRAM-HY57V651620B

VSS

VDD

DQ02VDDQ3DQ25VSSQ6DQ48VDDQ9DQ611VSSQ

1

DB0

VSSQ

VSSQ

VDDQ

DQ1

DQ3

4

7

10

DB1

DB2

DB3

DB4

DB5

DCLK

IORDY

INTRQHIRQ

4.7K

47R

47RHIOCS16# /IOCS16

47RHIORDY

R225

R227

R228

R226

VCC

4.7K

R229

DSCK

VGND

DCS0#

DRAS0#

240R

VDAC

114

115

100

97

DCS0

DCS1

YUV5

YUV6

YUV7

DBANK0

DRAS072DRAS173DRAS2

DBANK1

DCAS#

74

69

DWE#

DCKE

DQM

71

70

101

DWE

DCAS

10R

DMA[0..11]

R214

DMA0

DMA1

DMA2

102

DQM

DSCK

DMA053DMA154DMA255DMA457DMA356DMA558DMA661DMA762DMA863DMA9

DOE/DSCK_EN

U201

SWAN ES4438

LD1

LD2

LD3

LD4

LD5

LD6

LD7

178

179

180

181

182

185

186

187

188

DSCK

C226

15pF

DB9

DB8

DQMX

CKE

39

38

40

43

41

44

DQ1045DQ1147DQ1248DQ1350DQ1451DQ15

DQ5

DB6

37

NC

CLK

VSS

DQ842DQ9

UDQM

VDDQ

VDD

DQ7

16

14

13

12

DB7

DQMX

WE#

CAS#

RAS0#

MA5

MA6

MA7

MA8

MA9

MA11

34

36

35

NC

CKE

RAS18CAS17LDQM15/WE

/CS

19

CS0#

BANK0

28

A429A530A631A732A833A9

/SD-CS1

/SD-BS020BS1

VSS

A023A124A225A3

A10/AP

VDD

26

22

27

21

MA10

MA1

MA2

MA3 MA4

MA0

BANK1

TC204

10uF/16V

C233

104

C232

104

C231

104

C230

104

C229

104

MA[0..11]

C228

104

C227

104

VCC3.3

C240

151(OPEN)

XIN

HCS1FX

10uF/16V

R242

DB6

153

10K(OPEN)

DB7

HCS3FX

144

U205C

Q202

DB8

DB9

88

HIRQ/DCI_ERR

HA0

154

155

RST#

R244

HCU04

5 6

9015C(OPEN)

TC237

10uF/16V(OPEN)

DB10

DB11

DB12

DB13

DB1089DB1190DB1293DB1394DB1495DB1596AUC0

HA1

HA2

HD0/DCI[0]

HD1/DCI[1]

158

122

123

124

C241

15pF

AUDCLKMCLK

33R(OPEN)

R235

220R

R243

10K(OPEN)

XIN

C239 102(OPEN)

R282 33R

C292

L207 3.3uH(OPEN)

R281

4.7K(OPEN)

20pF(OPEN)

DCLK

DB14

DB15

AUX0

AUX1

AUX2

AUX3

AUX4

AUX5

AUX6

AUX7

160

161

162

165

167

166

168

169

AUX1

AUX2

AUX3

AUX5

AUX4

AUX6

HD2/DCI[2]

HD3/DCI[3]

HD4/DCI[4]

HD5/DCI[5]

HD6/DCI[6]

HD7/DCI[7]

HD8/DCI_FDS

HD10

HD9

HD11

125

126

127

128

131

132

134

133

135

136

C291

20pF(OPEN)

27MHz(OPEN)

X202

R219 0R(OPEN)

49

50

48

C202

151(OPEN)

XIN

AUX7

XOUT

APLLCAP

VSS

208

VSS

200

VSS

192

VSS

184

VSS

171

VSS

163

VSS

156

VSS

147

VSS

138

VSS

129

VSS

120

VSS

177

VSS

112

VSS

103

VGND

VSS

98

VSS

91

VSS

84

VSS

76

VSS

67

VSS

60

VSS

52

VSS

43

VSS

34

VSS

26

VSS

17

VSS

8

NC

203

NC

202

HD12

HD13

HD14

HD15

137

140

141

C238

15pF

R231

FBSMT C237

C236

VCC

R230

X201

27MHz

121

R232

FBSMT

U205B

HCU04

104

7 14

3 4

TC205

VCC

C235

20pF

100R

U205A

HCU04

VD201

1 2

1N4148(OPEN)

C234

20pF

DB[0..15]

DMA3

DMA4

DMA5

DMA6

DMA7

DMA8

DMA9

DMA10

DMA11

DB0

DB1

DB2

DB3

DB4

DB5

64

66

DB077DB178DB279DB380DB481DB582DB685DB786DB887DB9

DMA1065DMA11

LD8

LD10

LD9

LD11

LD12

LD13

LD14

LD15

HRST

HRD/DCI_ACK

HWR/DCI_CLK

HRDQ

HWRQ/DCI_REQ

HIORDY

HIOCS16

191

189

192

194

195

196

197

145

150

149

143

142

146

151

152

VCC

DCLK

TDMDX

R205 4.7K(DNS)

R204 4.7K

R203 4.7K(DNS)

R202 4.7KTDMDX

R201 4.7KRWS

R2101 4.7K(DNS)

TSD0

RST#

LCS3#

WRLL#

LEO#

LA0

LA1

LA2

LA3

LA4

LA5

LA6

LA7

LA8

LA9

LA10

LA11

LA12

LA13

LA14

LA15

LA16

LA17

LA18

LA19

LA20

LA21

LD0

LD1

LD2

LD3

LD4

LD5

LD6

LCS2#

LA[0..21]

LD7

LD[0..7]

HRST#

HRD#

HWR#

HIORDY

HIOCS16#

HCS1#

HCS3#

HIRQ

HA0

HA1

HA2

HD0

HD1

HD2

HD3

HD4

HD5

HD6

HD7

HD8

HD9

HD10

HD11

HD12

HD13

HD14

HD15

HA[0..2]

HD[0..15

Page 40

BLUE

39

MIAN SCHEMATIC DIAGRAM

111013

C276

FBSMT

U

VIDEO_U

20pF(OPEN)

R276

VD212

1N4148

REDV

JK202

S-VIDEO

JK201

V-OUT2

VGND

C277

L222

FBSMT

20pF(OPEN)

75R

20pF(OPEN)

VIDEO_V

C268

101

L214

1.8uH

C266

101

L247

0R

VGND VGND

VD213

1N4148

VCC3.3

YDAC

3

L216

VIDEO_Y

C270

20pF(OPEN)

VD210

1N4148

CDAC

1 2

C273

4

L217

FBSMT

FBSMT

VIDEO_C

C271

L215

1.8uH

C269

L248

0R

R280

VD211

1N4148

20pF(OPEN)

VGND

C272

20pF(OPEN)

101

101

VGND VGND

75R

WHITE

21

18

Lt

RED

BLACK

VIN1VCC2GND

JK202

JK204

JK201

V-OUT3

171619

20

Rt

VCC

R257

R256 330R

C252

1011

U205E

1213

U205F

R254

10M(OPEN)

C253

R253

R252

VCC

91R

AGND

104

89

HCU04

U205D

HCU04

HCU04

R255

1M(OPEN)

104

330R

100R

3

OPTICAL

R2103

68R

C261

VCC3.3

V-OUT5

576

C274

L219

FBSMT

R250

2.2R

TC210

220uF

C262

101

L212

1.8uH

20pF(OPEN)

VD216

1N4148

C260

L245

0R

R270

VD217

1N4148

UDAC

VGND

20pF(OPEN)

101

C264

20pF(OPEN)

R273

VGND VGND

75R

VD214

1N4148

VCC3.3

GREEN

15

12

14

C275

20pF(OPEN)

L220

FBSMT

L221

Y

VIDEO_Y

VIDEO

C265

101

L213

1.8uH

C263

101

C267

L246

0R

75R

VDAC

VGND VGND

VD215

1N4148

VCC3.3

SPDIF

CS

SCK

DATA

#OKA

C257

104

C256

104

C255

104

C254

104

AUX4

GND

AUX6

AUX7

AUX3

R2104

4.7K

L239 FBSMT

IR

IRCSSCK

23415

L240 FBSMT

L241 FBSMT

L242 FBSMT

DATA

XS201

XS05

VCC

VCC

+9V-9V +5V VCC3.3

VOICE-DET

OKA

#OKA

L201 FBSMT

L202 FBSMT

2341568910711

GND

L204 FB

L203 FB

TC207

220uF/16V

C244

104

TC206

220uF/16V

C243

104

C245

104

C246

104

MGND

A5V

L205 FB

L206 FB

12

XS202

XS12

LD[0..7]

LD0

LD1

VCC

D013D114D215D317D418D519D620D7

A012A111A210A39A48A57A66A75A827A926A10

U208

LA0

LA1

LD2

LD3

LD4

LD5

LD6

LD7

2

21

LA2

LA3

LA4

LA5

LA6

LA7

LA8

LA9

A11

A124A1328A1429A153A162A1730A1831A19

23

25

LA10

LA11

LA12

LA13

LA[0..21]

32

16

VCC

GND

OE24CE

27C080

1

22

LA14

LA15

LA16

LA17

LLA18

LLA19

LEO#

OPEN

OPEN

OPEN

R21070RR2108

R21800RR2181

R21820RR2183

LA18

WR#

LA19

LA18

LCS3#

LCS2#

4

CLK

ADDR

RESET

WE

U209

ROM-4

1

3

RST#

WR#

LA21

Page 41

+9V

40

MIAN SCHEMATIC DIAGRAM

VD206

1N4148

TC235

47uF/16V

VCC5A

VCC

VCC3.3

TC236

10uF/16V

R2185

0R(OPEN)

C297

104

LLLSRR

LFERSCC

MUTE1

R2184

0R

R233

0R

R234

0R(DNS)

MUTE2

28

27

26

25

MUTEC1

AOUTB1

AOUTA1

VLS1SDIN12SDIN23SDIN34SCLK5LRCK6MCLK7VD8GND9RST10SCL11SDA12CS13VLC

U207

C2139

104

TC231

10uF/16V

TSD2-

TSD1-

TSD0-

C225

104

OKA

C2116

R2132

22K

22K

C2111 101

R2129

MUTE3

24

23VA22

21

20

19

18VQ17

GND

MUTEC2

RBCK

102

+9V

MUTEC3

AOUTB2

AOUTB3

AOUTA2

AOUTA3

RWS

AUDCLK

AUX1

AUX0

AUX5

AGND

R2136 6.8K

C2122

122

C2112

102

R2131

4.7K

R2130

4.7K

3

2

U219A

4580

4 8

-9V

1

TC232

10uF/16V

TC233

10uF/16V

C288

104

C2137

104

AGND

16M215

FILT+

CS4360

14

R287

0R

R2148 6.8K

R2156

22K

R2135

4.7K

AGND

R2134

4.7K

6

22K

C2114 101

+9V

R2133

7

RRRSLL

10uF/16V

TC22510uF/16V

TC226

683

C2132

R

L

6.8K

C2129

122

C2115

102

AGND

22K

5

U219B

4580

4 8

R2137

-9V

C2130

122

R2152

C2118

R2139

4.7K

R2138

4.7K

3

2

U220A

C2117 101

+9V

1

LS

TC227

TC228

10uF/16V

10uF/16V

SR

683

C2119

683

C2131

R21536.8K

102

AGND

4580

4 8

-9V

R2143

R2142

22K

R2141

C2120 101

+9V

LFE

TC229

10uF/16V

SL

SW

C2138

683

C2133

122

C2121

102

4.7K

AGND

4.7K

22K

5

6

U220B

4580

R2145

4 8

-9V

7

VOICE-DET

CC

TC230

10uF/16V

C

6.8K

R2154

C2135

122

R2147

4.7K

C2124

R2146

4.7K

3

2

U221A

C2123 101

+9V

1

Q219

1015C2134

MUTE-1

VD205

1N4148

Q218

1015

Q212

2SC1815-Y

R241

R240

102

4580

4 8

-9V

1K

1K

+9V

VCC

AGND

R2149

Q211

TC238

2.2uF/16V

1K

R2105

R2106

VD207

1N4148

VD208

1N4148

MUTE1

MUTE2

683

6.8K

R2155

R2151

R2150

C2126

22K

101

6

+9V

7

VD204

1N4148

AGNDR236

R239

150R

R238

10K

AGND

TC234

47uF/16V

10K

R237

330R

-9V

1015

1K

VD209

1N4148

MUTE3

683

C2128

C2136

122

4.7K

C2127

102

4.7K

5

U221B

4580

4 8

-9V

AGND

AGND

TC240

10uF/16V

TC224

TC223

TC222

TC221

TC241

10uF/16V

CH-L

CH-R

R2117

1K

Q205

2SC1815-Y

ROUT

L232

FBSMT

Rt

7

JK201

R2119

R2118

C2100

R2111

C299

1K

1K

C2102

102

100K

R2112

100K

AGND

C2101

47pF

47pF

Lt

9

8

10uF/16V

CH-SR

R21211KR2120

1K

Q206

2SC1815-Y

102

LOUT

L234

FBSMT

L233

FBSMT

4

MUTE-1

R2123

R2122

1K

Q207

2SC1815-Y

C2104

102

R2113

100K

AGND

C2103

47pF

5

10uF/16V

CH-SL

1K

R2124

1K

R2125

1K

R2126

1K

Q208

2SC1815-Y

C2106

102

R2114

100K

C2105

47pF

L235

FBSMT

6

Q209

C2108

102

R2115

100K

C2107

47pF

L236

FBSMT

1

10uF/16V

CH-SW

R2127

1K

R2128

1K

2SC1815-Y

2SC1815-Y

C2110

102

R2116

100K Q210

AGND

C2109

47pF

L237

FBSMT

3

2

A/V-O3

10uF/16V

CH-C

C280

104

C279

104

C278

104

+9V

C283

104

C282

104

C281

104

-9V

AGND

AGND

Page 42

VHALF

41

MIAN SCHEMATIC DIAGRAM

LDCUR

C335

104

A+3.3V

D+3.3V

FB

L322

TC301

100uF/16V

47K

GND

C334

104

C333

104

C332

104

C331

104

DMV

FBSMT

4.7K

47K

15K

C329 102

R331

R333

VD301 1N4148 L321

R332

RFENVASTE

GND

15K

15K

4.7M

R327

R328

R329

R330

C326 102

C327 102

C328 472

FE

15K

15K

15K

TE

GND

NARF

ARF

FODRV

R324

R325

R326

C319 222

C321 821

C322 102

C323 331

C324 331

C325 102

8.2K

8.2K

C318 222

C320 102

R322

R323

VREF2

TRDRV

C317 682

C316 681

C313 224

1M

C315 104

C314 47pF

R320 15K

R321

VHALF

C359

104

GND

C312 153

68K

R319

C311 103

C310

104

1K

C309

103

R318

GND GND

A+3.3V

108

107

106

105

104

103

102

101

100

99

98

97

96

95

94

93

92

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

VSS

VDD3

MONI0

MONI1

MONI2

MONI3

NDASP

NCS3FX

NCS1FX

DA2

DA0

DA1

/IOCS16

INTRQ

NDMACK

IORDY

NIORD

NIOWR

HDD15

HDD0

HDD14

HDD1

HDD13

HDD2

HDD12

HDD3

HDD11

HDD4

HDD10

HDD5

HDD9

HDD6

HDD8

HDD7

VDDH

MASTER

C330

R335 0R

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

104

NCS3FX

NCS1FX

DA2

DA0

NPDIAG

DA1

NOSCS16

INTRQ

NDMACK

VDD3

VSS

IORDY

NIORD

NIOWR

DMARQ

HDD15

HDD0

HDD14

VDD18

PO

DATASEL

VSS

VDD3

HDD1

HDD13

HDD2

HDD12

HDD3

VDD3

VSS

HDD11

HDD4

HDD10

HDD5

HDD9

VDD3

VSS

HDD6

HDD8

HDD7

VDDH

NRESET

MASTER

MINTO1NINT12VDD33VSS4MINT25WAITODC6NMRST7DASPST8CPUADR179CPUADR1610CPUADR1511CPUADR1412CPUADR1313CPUADR1214CPUADR1115CPUADR1016CPUADR917VDD1818VSS19DRAMVDD1820DRAMVSS21CPUADR822CPUADR723CPUADR624CPUADR525CPUADR426CPUADR327CPUADR228CPUADR129CPUADR030VDD331VSS32DRAMVDD3333NCS34INWR35NDR36CPUDT737CPUDT638CPUDT539CPUDT440CPUDT341CPUDT242CPUDT143CPUDT0

R304 47K

R303 47K

R302 47K

R301 47K

NINTO

ODCIRQ

NEOECT

NTRYCL

NDASP

TECAPA

ADSCIRQ

WAITSODC

RST

CPUADR17

CPUADR16

AD0

AD1

AD2

AD3

AD4

AD5/CAPAC2

AD6/CAPAC1

CPUADR15

CPUADR14

CPUADR13

CPUADR12

CPUADR11

CPUADR10

ARF

NARF

DAC0

DAC1

AVSS

AVDD

U301

CPUADR9

AVDD

JITOUT

MN103S26EGA

C377

104

C376

104

TC211

10uF/6.3V

R251

0R

CPUADR8

CPUADR7

CPUADR6

GND

RV1

PLPG

AVSS

DSLF1

DSLF2

VREFH

VHALF

CPUADR5

CPUADR4

CPUADR3

CPUADR2

CPUADR1

RFDIF

AVDD

PLFLT1

PLFLT2

NSODCCS

NWEL

CPUADR0

91

AVSS

LRFIN

HPFIN

CMPIN

CSLFLT

LRFOUT

HPFOUT

NRD

CPUDT7

CPUDT6

CPUDT5

CPUDT4

CPUDT3

CPUDT2

CPUDT1

GND

89

TRCRS90VCOF

AVDD

88

LOUT

87

ROUT