Page 1

www.basler.com

+1 618.654.2341 (USA)

info@basler.com

Model

AVC Sensing Module

9488800100

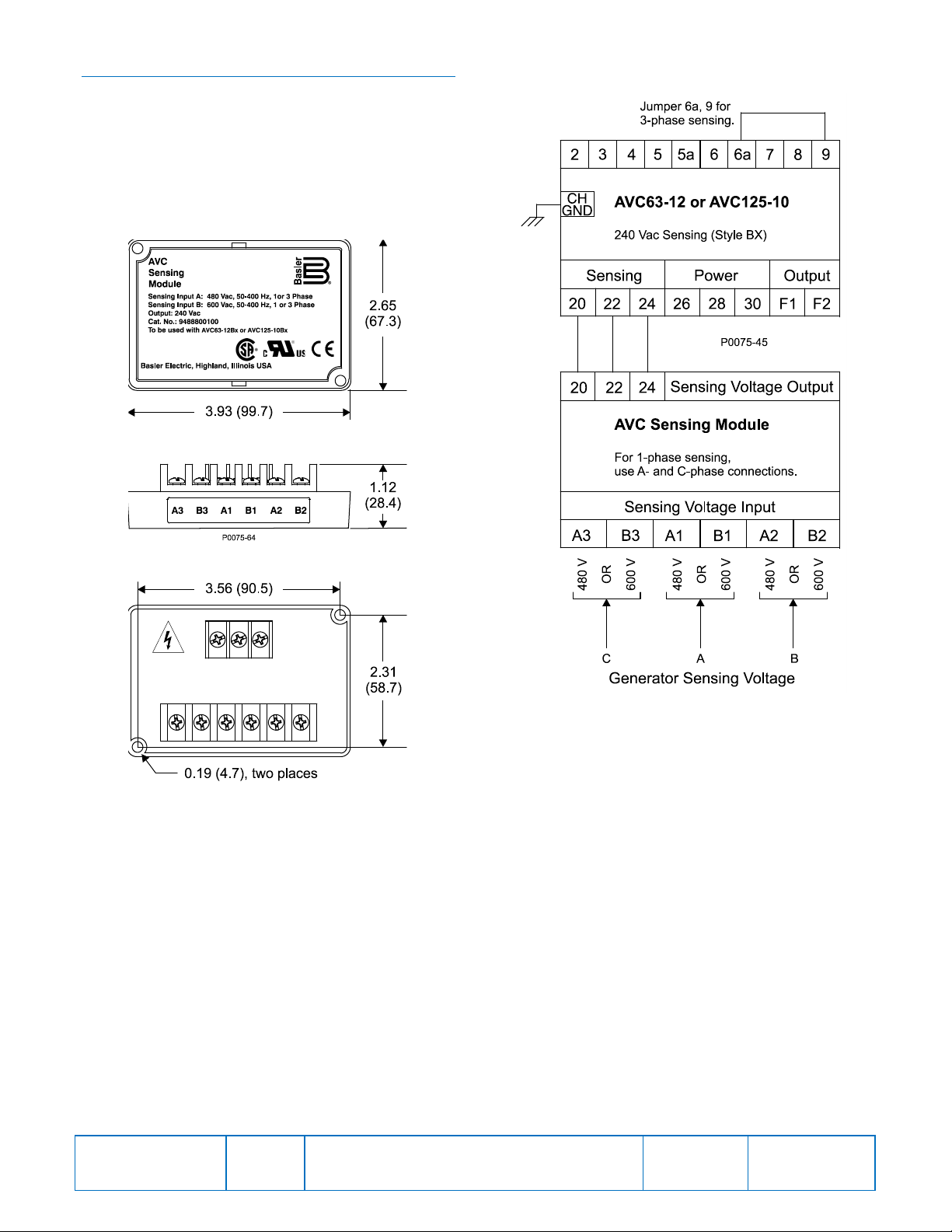

Term #

Description

A2

B-phase, 480 Vac nominal sensing voltage

input to AVC Sensing Module

A3

C-phase, 480 Vac nominal sensing voltage

input to AVC Sensing Module

A1

A-phase, 480 Vac nominal sensing voltage

input to AVC Sensing Module

B2

B-phase, 600 Vac nominal sensing voltage

input to AVC Sensing Module

B3

C-phase, 600 Vac nominal sensing voltage

input to AVC Sensing Module

B1

A-phase, 600 Vac nominal sensing voltage

input to AVC Sensing Module

22

A-phase sensing voltage output supplied to

AVC63-12/AVC125-10 terminal 22

24

B-phase sensing voltage output supplied to

AVC63-12/AVC125-10 terminal 24

20

C-phase sensing voltage output supplied to

AVC63-12/AVC125-10 terminal 20

Part Number

INTRODUCTION

The AVC Sensing Module provides a convenient and

cost-effective method for expanding the applica tio ns

where AVC63-12 and AVC125-10 voltage regulators

can be applied. The AVC Sensing Module incr eases

the nominal sensing voltage of style BX AVC63-12

and AVC125-10 voltage regulators from 200/240 Vac

to 480 Vac or 600 Vac. The AVC Sensing Module is

compatible with nominal sensing fr equ encies of

50/60 Hz and 400 Hz.

A compact, rugged (potted) case enables the AVC

Sensing Module to be mounted directly on the

generator. Other than making connections during

installation, the AVC Sensing Module requires no

adjustment or calibration.

SPECIFICATIONS

Sensing Voltage Inputs

Configuration: 1- or 3-phase

Burden: <1 VA

Nominal Frequency: 50, 60, or 400 Hz

Power Dissipation: 2.2 W

480 Vac Nominal Input

Range: 432 to 528 Vac

Terminal Assignments: A1, A2, A3

600 Vac Nominal Input

Range: 540 to 660 Vac

Terminal Assignments: B1, B2, B3

Sensing Voltage Output

Nominal: 200/240 Vac

Range: 180 to 264 Vac

Terminal Assignments: 20, 24, 22

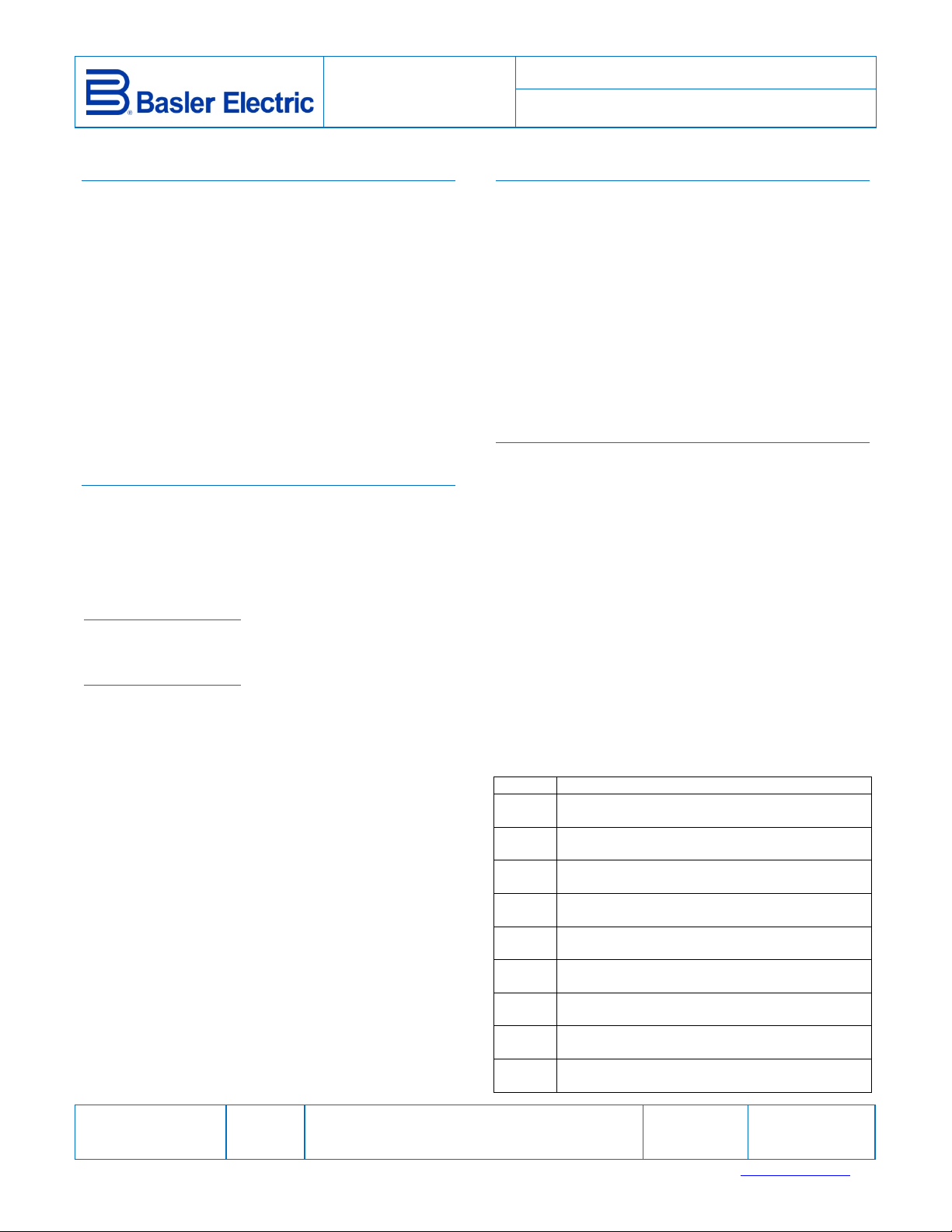

MOUNTING

The AVC Sensing Module is housed in a potted,

plastic case that can be mounted in any convenient

position. Overall module dimensions and panel

drilling dimensions are illust rated in Figure 1.

Mounting Hardware

The AVC Sensing Module can be mounted directly

on a genset using #10-32 or equivalent hardware. A

lock washer should be used between the screw head

and body of the module. Torque applied when

tightening the mounting hardware should not exceed

25 inch-pounds (2.8 N•m).

CONNECTIONS

All AVC Sensing Module connections are located on

the back panel. Sensing voltage is applied to the

lower, six-position terminal block. Sensing voltage is

supplied to the voltage regulator from the upper,

three-position terminal block. Connections consist of

#6 terminal screws. Each terminal accepts a

maximum wire size of 12 AWG (13 mm

2

). When

securing connections, apply no more than 9 in-lb

(1 N•m) of torque to each terminal screw.

Before connecting the module, review the terminal

descriptions listed in Table 1 and the connection

diagram of Figure 2. At any given time, only one of

the two sets of sensing voltage input terminals can be

used. Under no circumstance can both the 480 Vac

and 600 Vac sensing input terminals be connect e d to

a voltage source.

Table 1. Terminal Descriptions

Type Tests

Shock: Withstands 20 G in each of

three mutually perpendicular

planes

Vibration: Withstands 4.5 G at 18 to

2,000 Hz

Physical

Temperature: –40 to 70°C (–40 to 158°F)

operation and storage

Maximum Humidity: 95%, non-condensing

Approximate Weight: 160 g (6 oz.)

Publication

9488800990

For terms of service relating to this product and software, see the Commercial Terms of Products and Services document available at www.basler.com/terms.

Revision

A

Instructions

Date

07/14

Copyright

2014

Page 2

MAINTENANCE

A periodic inspection of the AVC Sensing Module

should be made to ensure that all connections are

clean and tight.

The AVC Sensing Module contains no serviceable

parts. If a failure occurs, replacement of the module

is recommended.

Figure 1. AVC Sensing Module Dimensions

Figure 2. AVC Sensing Module Connections

Publication

9488800990

Revision

A

Instructions

Date

07/14

Page

2 of 2

Loading...

Loading...