Page 1

FOR

VOLTAGE REGULATOR

APR 63-5X

INTRODUCTION

The APR 63-5X Voltage Regulator controls

the dc field power of a conventional, 400 Hz

brushless generator that has a 63 Vdc field

to regulate the generator output voltage. The

APR 63-5X regulates the generator output

by sensing the generator output voltage,

converting it to a dc signal, and comparing

the signal to a reference voltage. An error

signal is developed and used to control the

dc field power in order to maintain a constant generator voltage.

The APR 63-5X is contained in an encapsulated, plastic case.

SPECIFICATIONS

Power Input

Configuration: 1-phase, 400 Hz

Range: 190 to 277 Vac, ±10%

Burden: 650 VA maximum

Dissipation: 25 W maximum

Sensing Voltage

Configuration: 1-phase, 400 Hz

Range

240 Vac: 190 to 240 Vac

480 Vac: 380 to 480 Vac

Burden: 5 VA

Power Output ∗

Continuous:63 Vdc, 5 Adc, 315 W

1-Min. Forcing: 105 Vdc, 8.5 Adc, 893 W

∗ With 240 Vac input power.

DC Exciter Field Resistance

12.6 to 100 Ω

Voltage Adjustment Range

Internal

170 to 264 Vac or 340 to 528 Vac using the

internal voltage adjust.

External

±10% of the nominal value determined by

the internal voltage adjust. A 1 kΩ, 2 W

potentiometer with a locking, screwdriveradjusted shaft is supplied with the APR 635X for remote mounting.

Regulation

Accuracy: ±0.5%

Voltage Drift: <±1% variation for a 50°C

(90°F) change

Response: <1 cycle

Voltage Buildup

Automatic voltage buildup from generator

residual voltage as low as 6 Vac.

Frequency Compensation

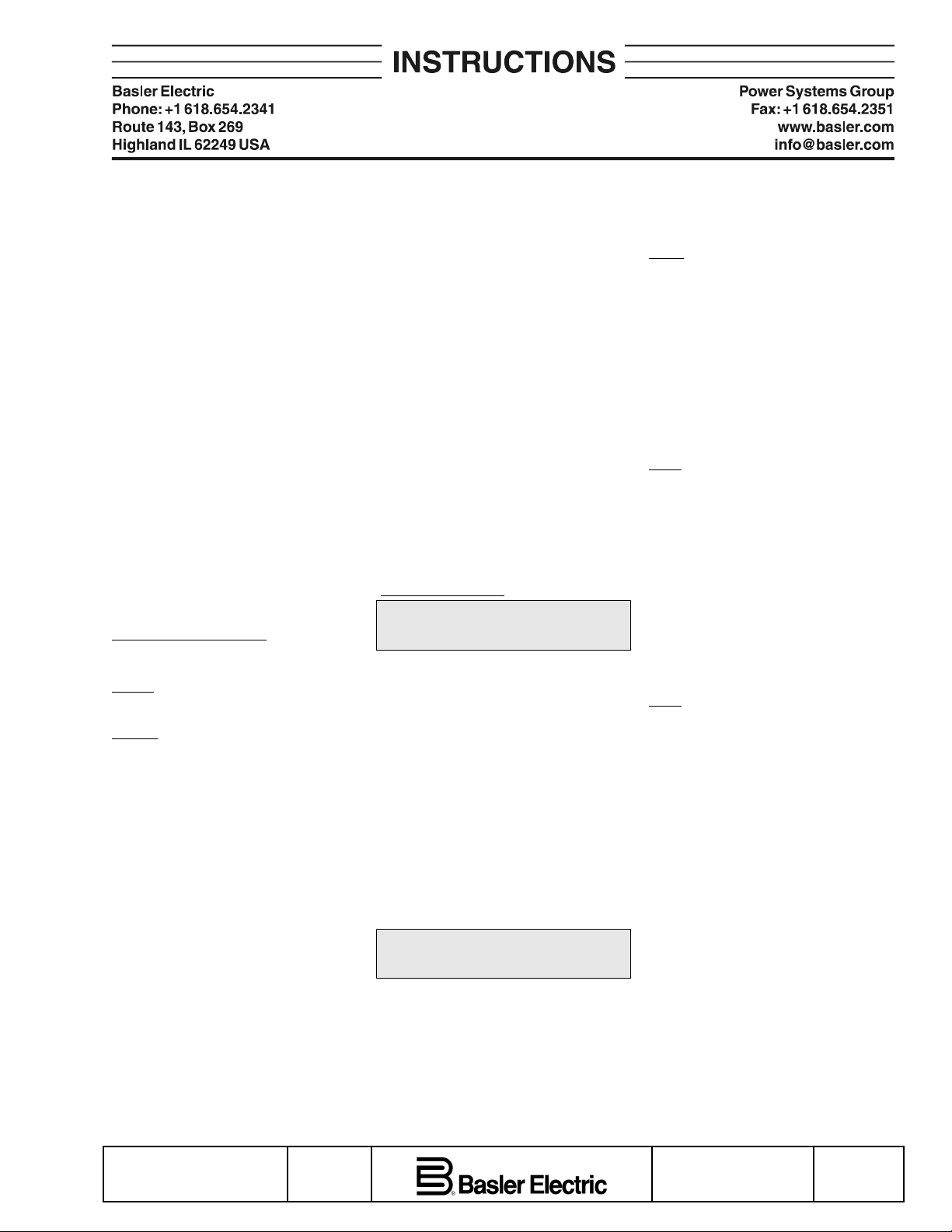

See Figure 1

Overexcitation Shutdown

See Figure 2. If the field voltage exceeds

100 ±5 Vdc, the APR 63-5X automatically

removes the field current after a time delay.

The time delay is inversely proportional to

the magnitude of the detected overvoltage

condition. At approximately 135 ±5 Vdc, the

field voltage is removed instantaneously.

Upon detection of overexcitation and the

resulting field voltage shutdown, the APR

63-5X will not reset or return to an opera-

tional condition until the generator output

drops to less than 6 Vac for 10 seconds.

Shock

Withstands up to 15 G in each of 3 mutually

perpendicular axes.

Vibration

5 to 26 Hz: 1.2 G

27 to 53 Hz: 0.036” double amplitude

54 to 1,000 Hz: 5.0 G

Temperature

Operating: –40 to 60°C (–40 to 140°F)

Storage: –65 to 85°C (–85 to 185°F)

Weight

1,110 g (2.5 lb)

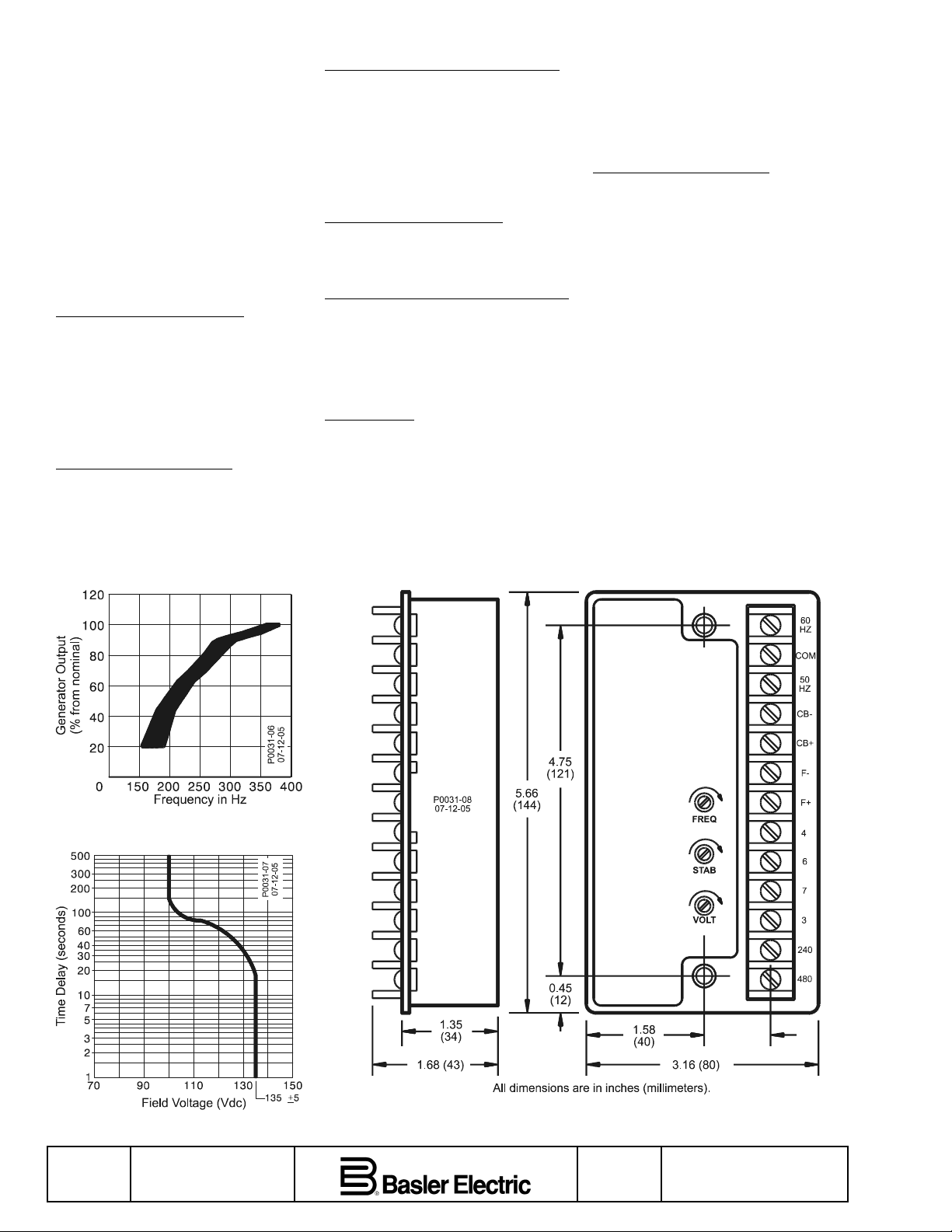

INSTALLATION

Mounting

The APR 63-5X may be mounted in any

position. The APR 63-5X may be mounted

directly on the generator using ¼” hardware.

Select the proper hardware to withstand any

expected transportation and operating conditions. Outline drawings are provided in

Figures 3 and 4.

Connections

APR 63-5X connection diagrams are provided in Figures 5 through 7.

Connecting Procedure

CAUTION

Do not make any connections to the 50 Hz,

60 Hz, or COM terminals.

1. Connect terminals F+ and F– to the field.

Observe proper polarity.

2. Connect terminals 3 and 4 to the generator output. Fuse both leads. If desired, install a shutdown switch.

3. Connect either the 240 or 480 terminal to

the sensing source. Sensing should be

connected line-to-line.

ADJUSTMENTS

Field Flashing

When the regulator is operated with the

generator for the first time, the polarity of the

residual magnetism may be incorrect or of

insufficient magnitude. If the residual voltage

at terminals 3 and 4 is greater than 6 Vac,

replace the regulator. If generator residual

voltage is less than 6 Vac, stop the prime

mover and proceed with the following steps.

CAUTION

The regulator may be damaged if the field is

flashed with the generator in motion.

1. With the prime mover at rest, apply an

ungrounded dc source of not more than

48 Vdc to terminals F+ and F– in series

with a limiting resistor. Use 1 Ω of resistance for each volt from the dc power

source with a power rating of at least 1 W

per ohm. For example, if using a 24 Vdc

source, use a 24 Ω, 24 W resistor.

2. Allow the field to be flashed for approximately 10 seconds before removing the

dc source.

3. If voltage does not build up after performing steps 1 and 2, verify the polarity of the

dc source and perform steps 1 and 2

again.

APR 63-5X Controls

FREQ

This control prevents generator and regulator damage by decreasing the generator

output voltage when the generator frequency decreases. To set the frequency rolloff, perform the following steps:

1. Adjust the generator rpm to the desired

frequency compensation (corner frequency roll-off) point.

2. Adjust the FREQ control until the output

voltage begins to drop-off.

3. Increase the generator rpm to nominal.

The output voltage should return to normal.

STAB

This control allows the generator response

time (and thus voltage stability) to be adjusted. Use an oscilloscope or other voltage

recording device to set the STAB control.

Clockwise rotation of the STAB control

slows response time and counterclockwise

rotation of the STAB control speeds response time. If the STAB control is rotated

too far counterclockwise, the generator voltage may oscillate (hunt).

When adjusting the generator response

time, rotate the STAB control counterclockwise until the system starts oscillating and

then rotate the control clockwise just past

the point where oscillation occurred.

VOLT

Clockwise rotation of the VOLT control increases the generator output voltage.

Replacing the jumper connected across

terminals 6 and 7 with a 1 kΩ, 2 W potentiometer allows a ±10% voltage range adjustment with the nominal level set by the

VOLT control. If a range less or greater than

that provided by the 1 kΩ potentiometer is

desired, a 2 W potentiometer of any value

from 50 to 5,000 Ω may be substituted.

OPERATION

Before proceeding with system startup,

confirm the following:

• Verify that the APR 63-5X specifications

conform with the requirements of the

generator system.

• Ensure that the APR 63-5X has been

installed and connected in accordance

with

Installation, Mounting

tions

.

During periods of prime mover idling, use

the shutdown switch to remove power from

the APR 63-5X.

System Startup

System startup is achieved by performing

the following steps. If the desired results are

not achieved during startup, refer to the

procedures listed under

and

Connec-

Troubleshooting

.

Publication

9168700992

Revision

D

First Printing: 08/93

Revised: 07/05

Copyright

2005

Page 2

1. Start the prime mover and bring it up to

rated speed.

2. Slowly adjust the VOLT control (or external potentiometer) until nominal generator

voltage is achieved.

3. Check stability by applying and removing

load.

4. Check regulation under normal operating

conditions.

5. Reduce the generator frequency to approximately 373 Hz. The generator output

should decrease from this point.

Troubleshooting

If the system does not operate as expected,

use the following information to determine

the cause and remedy.

Generator Voltage Does Not Build

There may be no or incorrect input voltage

applied to APR 63-5X terminals 3 and 4.

Verify the wiring and check the fuses and

shutdown switch.

The field may require flashing—flash the

field.

The overexcitation function may be shutting

the APR 63-5X off. Stop the prime mover

and then restart. Watch for high voltage.

Voltage Builds and then Decays

The voltage adjust circuit may be open. If an

external potentiometer is not used, verify

that a jumper is installed across terminals 6

and 7. If an external potentiometer is used,

the potentiometer may be defective or of the

wrong value. Check the potentiometer and

wiring and correct as necessary.

Voltage Does Not Build to the Rated Value

The jumper across APR 63-5X terminals

CB+ and CB– may be missing—install the

jumper.

Sensing may be connected to the wrong

terminal. Correct the sensing connections as

required.

The setting of the internal or external voltage

adjust may be incorrect. Adjust the VOLT

control or external potentiometer as needed.

Voltage High and Uncontrollable

Generator sensing may not be connected to

the APR 63-5X or may be connected to the

wrong terminal. Correct the sensing connections as needed.

Generator Response is Too Slow or Hunting

The generator load may be excessive or the

generator output may be shorted. Check the

generator load.

The STAB control may be improperly set.

Adjust the STAB control according to the

guidelines provided in

5X Controls, Stab

Adjustments, APR 63-

.

Poor Regulation

The resistance of the field may not be

matched to the capability of the APR 63-5X.

Compare the field resistance with the specified field resistance range of the APR 63-5X.

The APR 63-5X output rating does not meet

the requirement of the generator. Compare

the excitation requirement of the generator

with the specified output range of the APR

63-5X.

The speed of the prime mover may be too

low. Check the speed of the prime mover.

The voltmeter may not be connected at the

same point as the regulator sensing. Verify

the voltmeter connections. Also verify that

an average-sensing voltmeter is used—not

an rms-sensing voltmeter.

Frequency Roll-Off Not Working

The FREQ control may be improperly set.

Adjust the FREQ control according to the

guidelines provided in

5X Controls, Stab

Operational Test

To verify APR 63-5X functionality, perform

the following steps.

1. Connect the regulator as shown in Figure

8 and apply 240 Vac as shown.

2. Adjust the VOLT control fully counterclockwise. Observe that the lamp does

not light.

3. Adjust the VOLT control fully clockwise.

4. Adjust the VOLT control counterclockwise

until the lamp just goes out.

Regulator operation is satisfactory if the

above results are obtained. However, stability must be tested with the regulator and

generator operating.

Adjustments, APR 64-

.

Figure 1. Frequency Compensation Curves

Figure 2. Typical Inverse Time Delay

Characteristic Curves

Page 2 First Printing: 08/93

Revised: 07/05

Figure3. Mounting Dimensions

Revision

D

Publication

9168700992

Page 3

1.094

(27.78)

0.625

(15.88)

0.625

(15.88)

0.25

(6.35)

0.53

(13.49)

D2717-08

06-06-00

0.375

(9.53)

NOTE: All dimensions are in inches (millimeters).

0.125

(3.18)

0.81

(20.64)

Figure 4. External Voltage Adjust Potentiometer (Basler P/N 17727)

A

P0031-09

07-13-05

B

C

GEN

M

Field

1

250 V, 5 A fast acting, high

interrupting capacity fuses.

2

Shutdown switch.

External voltage adjust.

3

Jumper terminals 6 and 7 if

not used.

60

Hz

COM

50

Hz

1 1

2

3

CB- CB+ F- F+ 4 6 7 3 240 480

APR 63-5X

Figure 5. 240 Vac, Single-Phase Interconnection Diagram

Publication

9168700992

GEN

M

Field

1

250 V, 5 A fast acting, high

interrupting capacity fuses.

2

Shutdown switch.

External voltage adjust.

3

Jumper terminals 6 and 7 if

not used.

60

Hz

COM

50

Hz

Revision

D

1 1

2

3

CB- CB+ F- F+ 4 6 7 3 240 480

APR 63-5X

P0031-12

07-15-05

Figure 6. 480 Vac Interconnection Diagram

First Printing: 08/93

Revised: 07/05

A

B

C

N

Page

3

Page 4

GEN

M

Field

1 1

Isolation Tra nsformer

A

B

C

N

1

250 V, 5 A fast acting, high

interrupting capacity fuses.

2

Shutdown switch.

External voltage adjust.

3

Jumper terminals 6 and 7 if

not used.

60

Hz

COM

50

Hz

3

CB- CB+ F- F+ 4 6 7 3 240 480

APR 63-5X

2

P0031-13

07-15-05

Figure 7. Isolation Transformer Interconnection Diagram

60

Hz

J1

COM

Light Bulb

100 watts

10 ohms

10 watts

J3 J2

50

CB- CB+ 4 6 7 3 240 480

Hz

F- F+

APR 63-5X

240 Vac

P0031-14

07-15-05

Figure 8. Test Setup Diagram

Page 4 First Printing: 08/93

Revised: 07/05

Revision

D

Publication

9168700992

Loading...

Loading...