THE WALL-MOUNT™ STEP CAPACITY AIR CONDITIONERS

Integrated Part Load Value (IPLV) Efficiency Up To 15.2 BTU/WATT

WA3S – WA5S Right Side Control Panel

GREEN REFRIGERANT

WL3S – WL5S Left Side Control Panel

3 to 5 Ton (35,400 to 56,500 Btuh) 60Hz

The Bard WA/L "S" Series is the world's most energy efficient wall mounted

air conditioner featuring a multi-step capacity compressor with

environmentally friendly non-ozone depleting refrigerant.

The Bard Wall-Mount Air Conditioner is a self contained energy efficient

system, which is designed to offer maximum indoor comfort at a minimal

cost without using valuable indoor floor space or outside ground space.

This unit is the ideal product for versatile applications such as: new

construction, modular offices, school modernization, telecommunication

structures, portable structures or correctional facilities. Factory or field

installed accessories are available to meet specific job requirements.

Engineered Features

Multi-Capacity Two-Stage:

Simple thermostatic control

seamlessly stages the compressor

and indoor airflow rate between high

and low capacity operations without

cycling the compressor. This helps

to maximize comfort, humidity

control, energy efficiency and overall

reduction in compressor cycling for

improved system life.

Multi-Step Capacity

Compressor:

Copeland step-capacity scroll

compressors are designed for

increased efficiency, quieter operation

and improved reliability for longer life.

R-410A Refrigerant:

Designed with R-410A (HFC) nonozone depleting refrigerant in

compliance with the Montreal

protocol and 2010 EPA requirements.

ECM Indoor Blower Motor:

Features a variable speed motor

providing super-high efficiency, low

sound levels and soft-start

capabilities.

adjusting to provide the proper airflow

rate for the staged capacity, and for

higher static pressure in ducted

installations without user adjustment

or wiring changes.

The motor is self-

Aluminum Finned Copper Coils:

Grooved tubing and enhanced

louvered fin for maximum heat

transfer and energy efficiency.

Twin Blowers:

Move air quietly. All models feature

variable speed blower motors

providing automatic airflow

adjustment for high static or free

blow (non-ducted) operation at a very

low sound level. Motor overload

protection is standard on all models.

Foil Faced Insulation:

Standard on all units.

Start Kit:

A PTCR compressor start assist

(Positive Temperature Coefficient

Resistor) is standard on all -A singlephase models to increase system

reliability. This helps to insure

compressor starts at adverse

conditions by increasing the

compressor starting torque.

Compressor Control Module:

Built-in off-delay timer adjustable

from 30 seconds to 5 minutes. 2minute on-delay if power interrupt.

120-second bypass for low pressure

control, and both soft and manual

lockouts for high and low pressure

controls. Alarm output for alarm

relay.

Liquid Line Filter Drier:

Standard on all units. Protects

system against moisture.

High & Low Pressure Switches are

Auto-Reset:

Standard on all units. Built-in lockout circuit resets from the room

thermostat. Provides commercial

quality protection to the compressor.

Crankcase Heaters:

Factory installed crankcase heaters

are standard on all models. This

helps to insure ease of start at low

temperatures and improves

compressor life.

Phase Rotation Monitor:

Standard on all 3 phase scroll

compressors. Protects against

reverse rotation if power supply is not

properly connected.

Galvanized 20 Gauge Zinc

Coated Steel Cabinet:

Cleaned, rinsed, sealed and dried

before the polyurethane primer is

applied. The cabinet is handsomely

finished with a baked on textured

enamel, which allows it to withstand

1000 hours of salt spray tests per

ASTM B117-03.

Galvanized 16 Gauge Zinc

Coated Unit Base:

The unit base is treated with the

same paint coatings as the cabinet

above, insuring years of service

without visible corrosion.

Drain Pan:

The evaporator drain pan is

constructed of stainless steel

material for maximum corrosion

resistance.

Electrical Components:

Are easily accessible for routine

inspection and maintenance through

a right side, service panel opening.

Features a lockable, hinged access

cover to the circuit breaker or toggle

disconnect switch.

R-410A

Electric Heat Strips:

Features line break automatic limit

and dual backup safety controls.

Heater packages can be factory or

field installed for all models.

Filter Service Door:

Separate service door provides easy

access for filter change.

Two-Inch, Pleated Disposable

Air Filters:

Are standard equipment.

Condenser Fan and Motor

Shroud Assembly:

Slides out for easy access.

Circuit Breakers/Rotary

Disconnect:

Standard on all versions of single (230/

208 volt) and three phase (230/208

volt) equipment. Rotary disconnects

are standard on all versions of three

phase (460 volt) equipment.

Slope Top:

Standard feature for water run-off.

Full Length Mounting Brackets:

Built into cabinet for improved

appearance and easy installation.

NOTE: Bottom mounting bracket

included to assist in installation.

Top Rain Flashing:

Standard feature on all models.

• Complies with efficiency requirements of ANSI/ASHRAE/IESNA 90.1-2010.

• Certified to ANSI/ARI Standard 390-2003 for SPVU (Single Package Vertical Units).

• Intertek ETL Listed to Standard for Safety Heating and Cooling Equipment ANSI/UL

1995/CSA 22.2 No. 236-05, Fourth Edition.

• Commercial Product - Not intended for Residential application.

Form No. S3378-1112

Supersedes S3378-712

Page 1 of 12

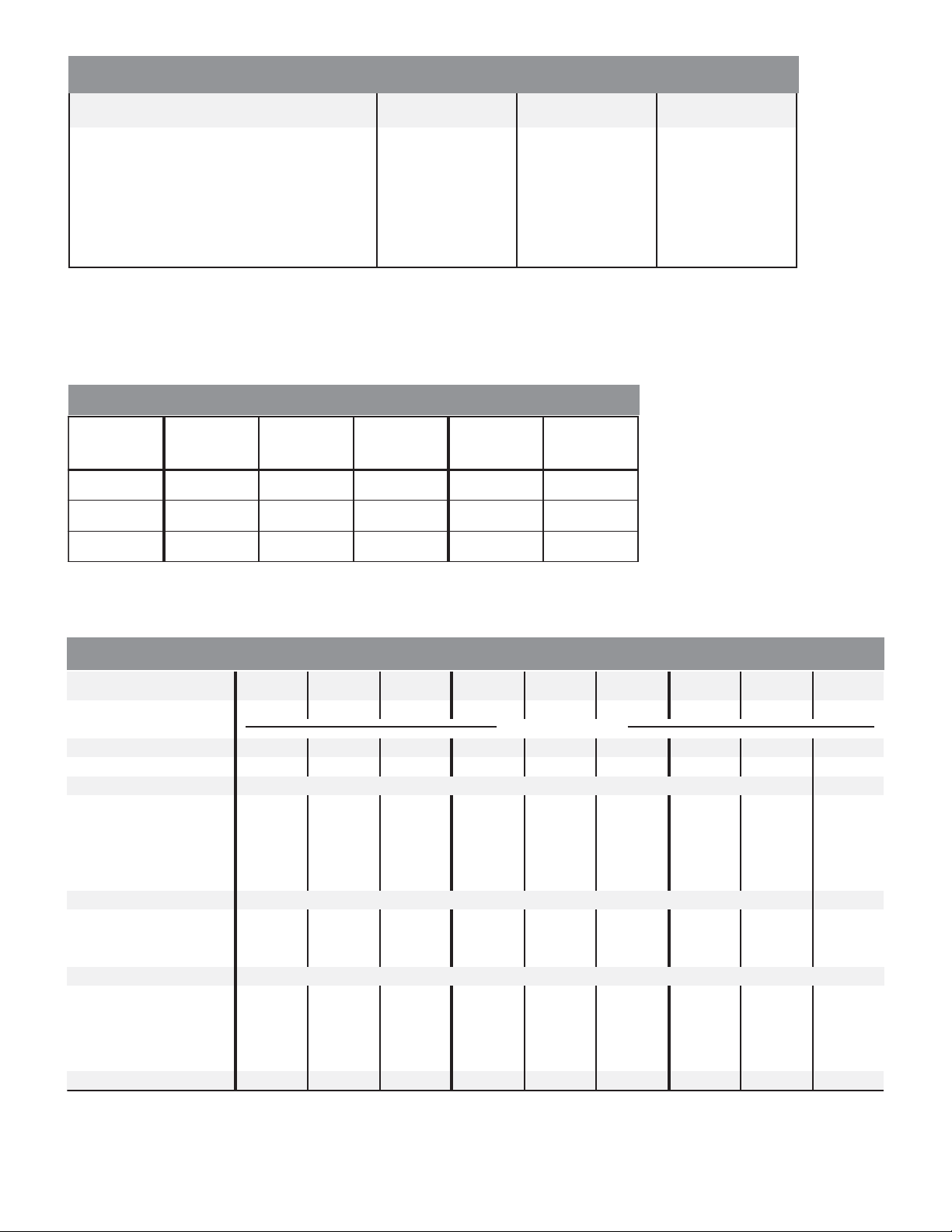

Capacity and Efficiency Ratings

c

1

SLEDOM

noitarepOegatSdn2,HUTByticapaCgnilooC

noitarepOegatSdn2REE 21

)lioCteW(MFCdetaR

noitarepOegatSts1,HUTByticapaCgnilooC

noitarepOegatSts1REE 2

)lioCteW(MFCdetaR

3S3AW

2S3LW

004,53

1.11

0011

000,42

7.11

008

3S4AW

2S4LW

000,64

2.11

0051

000,43

6.11

0011

3S5AW

2S5LW

005,65

1.01

0071

000,04

8.01

0031

VLPI 3 1.512.513.41

1 Certified in accordance with ANSI/ARI Standard 390-2003 for single package vertical units.

2 EER = Energy Efficiency Ratio - BTU/WATT efficiency.

3 Integrated Part Load Value - BTU/WATT efficiency and certified in accordance with ANSI/ARI Standard 390-2003.

All capacity, efficiency and cost of operation information is based on operation with fresh air cover plate. Cover plate is recommended for use to

obtain maximum energy efficiency where ventilation air is not required.

Indoor Blower Performance - CFM (0.00" through 0.80" H2O) 1

ylnOrewolBgnilooCegatSts1gnilooCegatSdn2

3S3AW

2S3LW

3S4AW

2S4LW

3S5AW

2S5LW

008008001100110041

5280011005100110051

0580031007100110051

cirtcelEWK01-5

taeH

1 These systems contain Variable Speed ECM Motor, which maintains airflow across static range at

dry and wet coil conditions.

irtcelEWK02-51

taeH

Specifications 3 Ton through 5 Ton

SLEDOM

yticapaCgnilooC004,53004,53004,53000,64000,64000,64005,65005,65005,65

yticapaCgnitaeH elbaTtaeHcirtcelEeeS

zH06--gnitaRlacirtcelE

egnaRegatloVgnitarepO352-791352-791605-414352-791352-791605-414352-791352-791605-414

AtiucriC--rosserpmoC

egatloV 802/032 802/032 064 802/032 802/032 064 802/032 802/032 064

spmAdaoLdetaR 6.41/3.21 9.7/7.6 6.3 1.91/1.61 21/1.01 8.4 6.62/9.12 9.81/5.51 8.7

tnerruCnoitceleStiucriChcnarB 7.61 6.11 7.5 2.12 0.41 5.6 1.72 9.81 0.9

spmArotoRkcoL3837834011.381435101125

epyTrosserpmoCllorcSllorcSllorcSllorcSllorcSllorcSllorcSllorcSllorcS

resnednoC&rotoMnaF

DPS-MPR-PH--rotoMnaF2-528-3/12-528-3/12-528-3/12-528-3/12-528-3/12-528-3/12-528-3/12-528-3/12-528-3/1

spmA--rotoMnaF5.25.23.15.25.23.15.25.23.1

MFC/AID--naF0072-"420072-"420072-"420082-"420082-"420082-"420082-"420082-"420082-"42

.pavE&rotoMrewolB

DPS-MPR-PH--rotoMrewolBelbairaV-2/1elbairaV-2/1elbairaV-2/1elbairaV-4/3elbairaV-4/3elbairaV-4/3elbairaV-4/3elbairaV-4/3elbairaV-4/3

spmA--rotoMrewolB3.53.53.58.68.68.68.68.68.6

gnilooCMFC

)lioCteW(retliF/w

.DTS)sehcni(seziSretliF2x03x022x03x022x03x022x03x022x03x022x03x022x03x022x03x022x03x02

.SBL--thgieWgnippihS

A-3S3AW

A-2S3LW

1-802/032 3-802/032 3-064 1-802/032 3-802/032 3-064 1-802/032 3-802/032 3-064

001100110011005100510051007100710071

035 035 035 035 035 035 035 035 035

B-3S3AW

B-2S3LW

C-3S3AW

C-2S3LW

A-3S4AW

A-2S4LW

B-3S4AW

B-2S4LW

C-3S4AW

C-2S4LW

A-3S5AW

A-2S5LW

B-3S5AW

B-2S5LW

C-3S5AW

C-2S5LW

Form No. S3378-1112

Supersedes S3378-712

Page 2 of 12

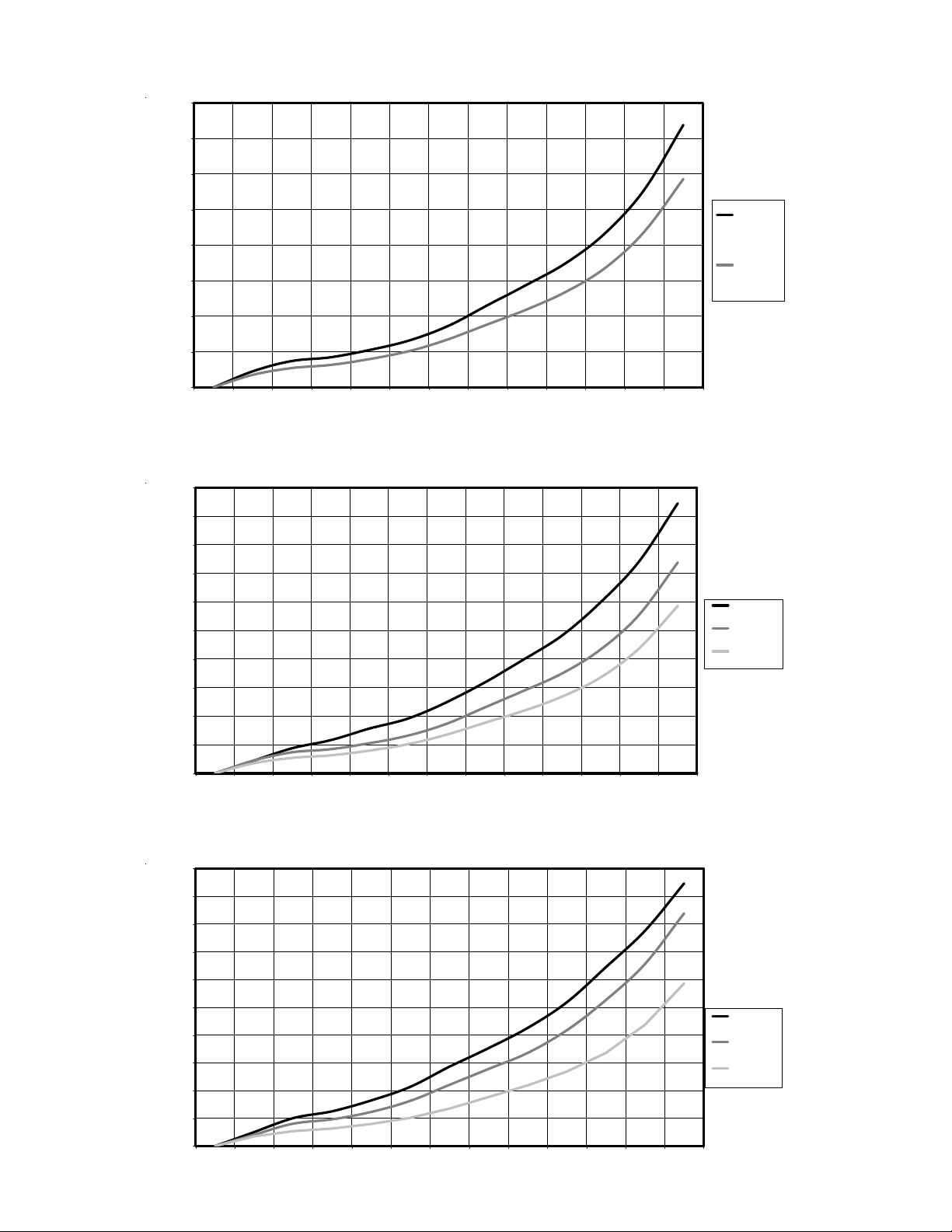

Ventilation System Packages

Bard Wall-Mounts are designed to provide optional ventilation packages to meet all of your ventilation and indoor air quality requirements. All

units are equipped with a blank off plate as the standard ventilation package. All ventilation packages can be built-in at the factory, or fieldinstalled at a later date.

BLANK OFF PLATE - BOP STANDARD

A blank off plate is installed on the inside of the service door. It covers the air inlet openings which restricts any

outside air from entering the unit. The blank off plate should be utilized in applications where outside air is not

required to be mixed with the conditioned air.

MOTORIZED FRESH AIR DAMPER - MFAD OPTIONAL

The motorized fresh air damper is internally mounted behind the service door and allows outside ventilation air,

up to 25% of the total airflow rating of the unit, to be introduced through the air inlet openings and to be mixed

with the conditioned air. The two position damper can be fully open or closed. The damper blade is powered

open by a 24VAC motor with spring return on power loss. The damper can be controlled by indoor blower

operation or can be field connected to be managed based on building occupancy.

Motorized Fresh Air Damper

COMMERCIAL ROOM VENTILATOR

NOTE: This vent system is intake only without built-in exhaust capability. Building will likely require separate field

installed barometric relief or mechanical exhaust elsewhere within the conditioned space. Other building systems will

govern actual amount of intake air.

COMMERCIAL ROOM VENTILATOR - CRVMP OPTIONAL

The built-in commercial room ventilator is internally mounted behind the service door and allows outside

ventilation air, up to 50% of the total airflow rating of the unit, to be introduced through the air inlet openings.

It includes a built-in exhaust air damper with integral bug screen. Automatic control is integrated to maintain

desired ventilation air at the various supply airflows.

The commercial room ventilator (CRV) is a simple and innovative approach to improving the indoor air quality by

providing fresh air intake and exhaust capability through the CRV. The damper can be easily adjusted to control

the amount of fresh air supplied into the building. The CRV can be controlled by indoor blower operation or field

controlled based on room occupancy. The CRV is power open - spring return on power loss. Complies with

ANSI/ASHRAE Standard 62.1 “Ventilation for Acceptable Indoor Air Quality.”

Economizer

ENERGY RECOVERY VENTILATOR

ECONOMIZER - ECONWM-Series OPTIONAL

The built-in economizer system is internally mounted behind the service door and allows outdoor air to be

introduced through the air inlet openings. The amount of outdoor air varies in response to the system controls and

settings defined by the end user. It includes a built-in exhaust air damper. The economizer is designed to provide

“free cooling” when outside air conditions are cool and dry enough to satisfy cooling requirements without running

the compressor. This in turn provides lower operating costs, while extending the life of the compressor.

• ECONWMT Equipment Building versions have extended air intake hood to deliver up to 100% of cooling rated airflow.

16" for ECONWMT-E2 or T2, and E3 or T3

18" for ECONWMT-E5 or T5

• ECONWMS Classroom versions have 3" air intake hood to deliver up to 75% of cooling rated airflow.

Standard Features:

•

Fully modulating

• Honeywell Direct Drive Hi-Torque Actuator

• No linkage required

• Simple single blade design

• Positive shut-off with non-stick gaskets

• Electronic DB and/or Enthalpy sensors depending upon version

• Honeywell JADE electronic economizer module with precision settings and diagnostics

• DB or Enthalpy economizer versions available

WALL-MOUNT ENERGY RECOVERY VENTILATOR - ERVF OPTIONAL

The wall-mount energy recovery ventilator (ERV) is a highly innovative approach to meeting indoor air quality

ventilation requirements as established by ANSI/ASHRAE Standard 62.1. The ERV allows from 200 to 450 CFM

(depending upon model) of fresh air and exhaust through the unit while maintaining superior indoor comfort and

humidity levels. In most cases this can be accomplished without increasing equipment sizing or operating costs.

Heat transfer efficiency is up to 67% during summer and 75% during winter conditions.

The ERV consists of a unique “rotary energy recovery cassette” that provides effective sensible and latent heat

transfer capabilities during summer and winter conditions. Various control schemes are addressed including

limiting ventilation during building occupancy only.

The ERV is designed to be internally mounted behind the service door in the WA/LS model wall-mount units. It

can be built-in at the factory or field installed as an option. ERVF-*5 can be independently adjusted for intake and

exhaust rates.

Manufactured under U.S. Patent Nos. 5,485,878; 5,301,744.

Form No. S3378-1112

Supersedes S3378-712

Page 3 of 12

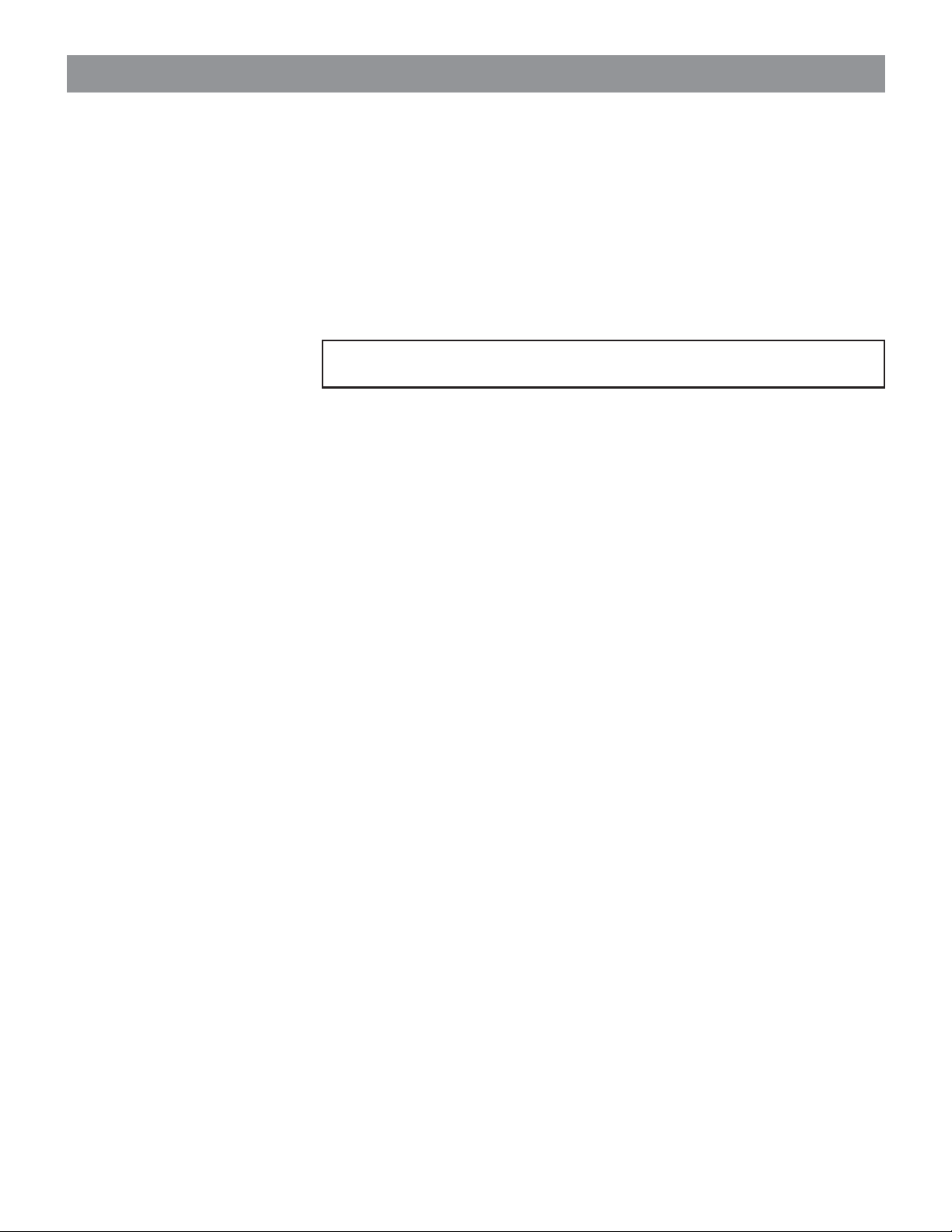

800

700

600

CRVMP-5

WA3S/WL3S Ventilation Airflow

500

400

300

Ventilation Airflow (CFM)

200

100

0

0 2.5 5 7.5 10 12.5 15 17.5 20 22.5 25 27.5 30

Vent Position

CRVMP-5

1000

900

800

700

600

500

400

Ventilation Airflow (CFM)

300

WA4S/WL4S Ventilation Airflow

Stage #2

Operation

Blower Only

& Stage #1

Operation

Stage #2

Operation

Stage #1

Operation

Blower Only

Ventilation Airflow (CFM)

Form No. S3378-1112

Supersedes S3378-712

Page 4 of 12

200

100

0

0 2.5 5 7.5 10 12.5 15 17.5 20 22.5 25 27.5 30

Vent Position

CRVMP-5

1000

900

800

700

600

500

400

300

200

100

0

0 2.5 5 7.5 10 12.5 15 17.5 20 22.5 25 27.5 30

WA5S/WL5S Ventilation Airflow

Vent Position

Stage #2

Operation

Stage #1

Operation

Blower Only

Performance and Application Data- WERV-*5

ECNAMROFREPGNILOOCREMMUS

)BW°26/BD°57SNOITIDNOCNGISEDROODNI(

tneibmA

.D.O

MFC054ETARNOITALITNEV MFC573ETARNOITALITNEV MFC003ETARNOITALITNEV

/BD

BW

F TLV SLV LLV TRH SRH LRH TLV SLV LLV TRH SRH LRH TLV SLV LLV TRH SRH LRH

575641208541488625931774957447887105121737550811810868730134102790954785921565703

0708541085410774977490 05121051210810881080027902790215621560

501

560854108541077

4977490 05121051210810881080027902790215621560

08 09513 05121 04491 33502 7987 53621 52362 52101 00261 47371 2866 29601 06012 0018 06921 01141 7245 3868

57 56412 05121 4139 25931 7987 4506 78871 52101 2677 50811 2866 3215 01341 0018 0126 7859 7245 0614

001

07 25321 05121 202 9208 7987 131 39201 52101 861 3976 2866 111 5328 0018 531 7155 7245 09

56 05121 05121 0 7987 7987 0 52101 52101 0 2866 2866 0 0018 0018 0 7245 7245 0

06 05121 05121 0 7987 7987 0 52101 52101 0 2866 2866 0 0018 0018 0 7245 7245 0

0809513027907812335028136512415236200185228147371543582021060120846085410114114348679

57564120279447112593181364367788710018787950811543595460134108460387785914346425

0725321027923629208813611713920100183912397654357441532808465571715514345711

59

56027902790813681360001800180543554350084608460

3414340

14

06027902790813681360001800180543554350084608460143414340

08 09513 0927 00342 33502 8374 49751 52362 5706 05202 47371 9004 56331 06012 0684 00261 01141 6523 45801

57 56412 0927 57141 25931 8374 3129 78871 5706 21811 50811 9004 6977 01341 0684 0549 7859 6523 1336

09

07 25321 0927 2605 9208 8374 0923 39201 5706 8124 3976 9004 4872 5328 0684 5733 7155 6523 1622

56 0927 0927 0 8374 8374 0 5706 5706 0 9004 9004 0 0684 0684 0 6523 6523 0

06 0927 0927 0 8374 8374 0 5706 5706 0 9004 9004 0 0684 0684 0 6523 6523 0

08095130684037623350295134737152362050457222473712762107410601204230287101141071293911

57564120684506612593195133970178871050473831508112762231901341042307011785907126147

0725321068429479208951307843920105043426397627620214532804235994715507126433

58

56068406840

139513005

95

0405040276227620042304230071207120

06068406840951395130050405040276227620042304230071207120

57 56412 0342 53091 25931 9751 27321 78871 5202 26851 50811 6331 96401 01341 0261 09621 7859 5801 2058

07 25321 0342 2299 9208 9751 9446 39201 5202 8628 3976 6331 7545 5328 0261 5166 7155 5801 2344

08

56 2524 0342 2281 4672 9751 4811 3453 5202 8151 8332 6331 2001 5382 0261 5121 9981 5801 418

06 0342 0342 0 9751 9751 0 5202 5202 0 6331 6331 0 0261 0261 0 5801 5801 0

072532102532192080920839201039201397603976532805328715507155

57

56252402524467204672345303453833208332538205382998109981

06000000000000000000

ECNAMROFREPGNITAEHRETNIW5*-VREW

)BDF°07SNOITIDNOCNGISEDROODNI(

tneibmA

.D.O

F°/BD LVW RHW LVW RHW LVW RHW

56034244915202046102618231

06068488830504082304236562

55092723855706029406845893

05027967770018165608463135

5405121027952101102800182466

04085414661105121148902790797

5301071806315714118411043118929

03044912555100261221310692172601

52078126947152281267410854155911

02003420449105202204610026148231

51037624831257222240810287121641

MFC054 MFC573 MFC003

ETARNOITALITNEV

LEGEND:

VLT = Ventilation Load - Total

VLS = Ventilation Load - Sensible

VLL = Ventilation Load - Latent

HRT = Heat Recovery - Total

HRS = Heat Recovery - Sensible

HRL = Heat Recovery - Latent

WVL = Winter Ventilation Load

WHR = Winter Heat Recovery

.noitacilpparetniwrofnwohssiylnoecnamrofrepelbisneS:ETON

Form No. S3378-1112

Supersedes S3378-712

Page 5 of 12

eriW

2 dnuorG

eziSeriW

rewoP

2 dleiF

01010101

010101

01

6

01010101

010101

601

01

6

601

01010101

010101

01

6

601

888

esuFlanretxE

.rkrB.tkCro

03060603

1 mumixaM

545454

62

yticapmA

tiucriC

3 muminiM

A.tkC B.tkC C.tkC A.tkC B.tkC C.tkC A.tkC B.tkC C.tkC A.tkC B.tkC C.tkC

eriW

2 dnuorG

eziSeriW

rewoP

tiucriCelgniS tiucriCelpitluM

2 dleiF

622525

53

010101

886

88663

53

53

010101

01

414121

01

01

2

414121

8

6

01

010101

01

88663

888

03060603

545454

62252562

737373

886

2

010101

01

01

888

03060603

050505

62252562

444444

01

212101

01

010101

212101

8

6

01

88663

886

2

010101

888

01

6

010101

010101

01

01

esuFlanretxE

.rkrB.tkCro

5454060709

1 mumixaM

yticapmA

tiucriC

135315

3 muminiM

dleiF.oN

stiucriC

rewoP

111

esahPdna

detaR

stloV

Z0A-

ledoM

Electrical Specifications

Form No. S3378-1112

Supersedes S3378-712

Page 6 of 12

50A-

511

311

16

78

2ro1

2ro1

3ro1

1-802/032

01A-

51A-

80A-

02A-

3S3AW

2S3LW

030304

527263

111

Z0B-

60B-

3S3AW

51

51

06

02

03

5454060709

5.31

31

91

55

1

3-802/032

111

3-064

82

8383353698

1

111

021

040404

06

020252

03

0505060709

511

929283

2ro1

2ro1

3ro1

111

1-802/032

3-802/032

65

1

51

61

111

12

3-064

03

6464353698

1

111

021

040404

511

434383

2ro1

2ro1

3ro1

111

1-802/032

525252

71

71

111

03

12

03

1

3-064

06

65

1

3-802/032

carrying conductors are in a raceway.

51C-

Z0C-

60C-

90B-

3S3AW

2S3LW

2S3LW

01A-

Z0A-

51A-

50A-

80A-

02A-

3S4AW

2S4LW

51B-

Z0B-

60B-

90B-

3S4AW

2S4LW

90C-

51B-

51C-

Z0C-

60C-

90C-

3S4AW

2S4LW

01A-

Z0A-

51A-

50A-

80A-

02A-

3S5AW

2S5LW

51B-

Z0B-

60B-

90B-

3S5AW

2S5LW

51C-

Z0C-

60C-

90C-

3S5AW

2S5LW

1 Maximum size of the time delay fuse or HACR type circuit breaker for protection of field wiring conductors.

2 Based on 75C copper wire. All wiring must conform to the National Electrical Code and all local codes.

3 These “Minimum Circuit Ampacity” values are to be used for sizing the field power conductors. Refer to the National Electrical code (latest version), Article 310 for power conductor sizing.

Caution: When more than one field power circuit is run through one conduit, the conductors must be derated. Pay special attention to note 8 of Table 310 regarding Ampacity Adjustment Factors when more than three (3) current

* Top outlet supply option is available only factory installed and only on the selected models.

IMPORTANT: While this electrical data is presented as a guide, it is important to electrically connect properly sized fuses and conductor wires in accordance with the National Electrical Code and all local codes.

•

•

N

(

(

•

•

Electric Heat Table

lanimo

WK

wKspmAhP-1spmAhP-3hutBwKspmAhP-1spmAhP-3hutBwKspmAhP-3hutBwKspmAhP-3hutB

0.50.58.02560,7157.30.81997,21

0.60.64.41874,0205.45.21953,510.62.7874,0225.59.6048,81

0.80.83.33403,7200.68.82874,02

0.90.97.12717,0357.67.81830,320.98.01717,0382.84.01062,82

0.010.017.14031,4305.71.63895,52

0.510.515.261.63591,1552.111.452.13693,830.510.81591,1508.313.71990,74

0.020.023.38062,8600.511.27591,15

)1(V042tA)1(V802tA)2(V084tA)2(V064tA

.ylnostinuV802/032nielbaliavaerasretaehcirtceleesehT)1

.ylnostinuV084nielbaliavaerasretaehcirtceleesehT)2

Heater Packages - Field Installed WA3, WA4 & WA5S

stinUWK0ottaeHcirtcelEgniddarofdengiseD

sledoMV802/032nodradnatSrekaerBtiucriC

renoitidnoCriA

sledoM

3S3AW

3S4AW

3S5AW

sledoM00A-

1-802/032

#ledoMretaeH WK #ledoMretaeH WK #ledoMretaeH WK

50A-S4AWHE

80A-S5AWHE

01A-S4AWHE

51A-S4AWHE

02A-S4AWHE

50A-S4AWHE

80A-S5AWHE

01A-S4AWHE

51A-S4AWHE

02A-S4AWHE

50A-S5AWHE

80A-S5AWHE

01A-S5AWHE

51A-S5AWHE

02A-S5AWHE

5

8

01

51

02

5

8

01

51

02

5

8

01

51

02

sledoM00B-

3-802/032

60B-S3AWHE

90B-S5AWHE

51B-S5AWHE

60B-S5AWHE

90B-S5AWHE

51B-S5AWHE

60B-S5AWHE

90B-S5AWHE

51B-S5AWHE

detsiLadanaC&SU–LTE•

sledoMV064nodradnatStcennocsiDyratoR•

sledoM00C-

3-064

6

9

51

6

9

51

6

9

51

60C-S5AWHE

90C-S5AWHE

51C-S5AWHE

60C-S5AWHE

90C-S5AWHE

51C-S5AWHE

60C-S5AWHE

90C-S5AWHE

51C-S5AWHE

6

9

51

6

9

51

6

9

51

Heater Packages - Field Installed WL3, WL4 & WL5S

stinUWK0ottaeHcirtcelEgniddarofdengiseD

sledoMV802/032nodradnatSrekaerBtiucriC

renoitidnoCriA

sledoM

2S3LW

2S4LW

2S5LW

sledoM00A-

1-802/032

#ledoMretaeH WK #ledoMretaeH WK #ledoMretaeH WK

L50A-S4AWHE

L80A-S5AWHE

L01A-S4AWHE

L51A-S4AWHE

L02A-S4AWHE

L50A-S4AWHE

L80A-S5AWHE

L01A-S4AWHE

L51A-S4AWHE

L02A-S4AWHE

L50A-S5AWHE

L80A-S5AWHE

L01A-S5AWHE

L51A-S5AWHE

L02A-S5AWHE

5

8

01

51

02

5

8

01

51

02

5

8

01

51

02

sledoM00B-

3-802/032

L60B-S3AWHE

L90B-S5AWHE

L51B-S5AWHE

L60B-S5AWHE

L90B-S5AWHE

L51B-S5AWHE

L60B-S5AWHE

L90B-S5AWHE

L51B-S5AWHE

detsiLadanaC&SU–LTE•

sledoMV064nodradnatStcennocsiDyratoR•

sledoM00C-

3-064

6

9

51

6

9

51

6

9

51

L60C-S5AWHE

L90C-S5AWHE

L51C-S5AWHE

L60C-S5AWHE

L90C-S5AWHE

L51C-S5AWHE

L60C-S5AWHE

L90C-S5AWHE

L51C-S5AWHE

6

9

51

6

9

51

6

9

51

Form No. S3378-1112

Supersedes S3378-712

Page 7 of 12

Return Air Acoustical Plenum

O

D

)

R

A

D

A

F

A

WAPR11

Free Blow Acoustical Plenum

WAPFB51

20 1/4"

42 3/8"

13 3/4"

34 1/4"

76"

12 1/8"

MIS-2208 A

Supply Air Acoustical Plenum

WAPS51-G

3 3/4"

1 1/2"

42 1/4"

44"

3 3/4"

1 1/2"

3/8"

9 7/8"

29 7/8"

18 1/2"

1 1/2"

MIS-2284 A

seirosseccAnoitallatsnIlanoitp

noitpircse

riAnrute

munelPlacitsuoc

riAylppuSdetcu

munelPlacitsuoc

riAylppuSwolBeer

munelPlacitsuoc

ledoM roloC

X-11RPAW

4-11RPAW

egieB

yarGeyekcuB

G-15SPAWdezinavlaG091

X-15BFPAW

4-15BFPAW

egieB

yarGeyekcuB

gnippihS

sbL(thgieW

812

46

12"

9 7/8"

5"

14"

14"

12" DIA. HOLES FOR DUCT COLLARS.

DUCT COLLARS FIELD SUPPLIED.

50 3/4"

29 7/8"

6"

MIS-2164

Typical installation with isolation curb, free blow, supply air acoustical plenum & return air acoustical plenum.

Form No. S3378-1112

Supersedes S3378-712

Page 8 of 12

WMICF5

ISOLATION CURB

WAPF51 FREE-BLOW

SUPPLY AIR PLENUM

WAPR11 RETURN AIR

ACCOUSTICAL PLENUM

WMICF5

ISOLATION CURB

WAPF51 FREE-BLOW

SUPPLY AIR PLENUM

WAPR11 RETURN AIR

ACCOUSTICAL PLENUM

Patent Pending

MIS-2604

Typical Sound Performance with Installation/Isolation Curbs & Acoustical Plenums

WA/L3S Sound Data Matrix (dBA @ 10 feet)

WA/L4S Sound Data Matrix (dBA @ 10 feet)

WA/L5S Sound Data Matrix (dBA @ 10 feet)

Unit Mounting Direct

Supply Air Treatment Grille

Return Air Treatment Grille

Blower Only Operation

Compressor Stage 1

Compressor Stage 2 with

ERV High Speed Operation

Indoor Integrated dBA 43.8 35.0 40.7 37.2 32.8 32.6

Compressor Stage 2

Outdoor Sound Level

Note 1: dBA is sound pressure measured 10 feet in front of unit and 5 feet above floor.

Note 2: Unit or isolation curb is mounted to frame construction.

Note 3: Results may vary depending upon other factors such as room size, type of construction and acoustical varianc es.

with CRV

Operation with CRV

Compressor

Stage 2 Operation

Unit Mounting Direct

37.8 30.7 33.6 33.6 27.4 27.6

51.8 40.7 49.9 41.7 39.7 38.7

52.3 41.4 50.8 42.4 40.8 39.9

52.7 41.7 51.7 ²²42.9

66.9 66.9 66.9 66.9 66.9 66.9

Free Blow Configuration Ducted Supply Configuration

Supply Air Treatment Grille

Return Air Treatment Grille

Blower Only Operation 40.1 38.9 38.4 34.5 32.8 28.2

Compressor

Stage 1 Operation

Compressor

Stage 2 Operation

Compressor Stage 2 with

ERV High Speed Operation

Indoor Integrated dBA 45.4 40.4 44.0 37.8 35.8 33.0

Compressor Stage 2

Outdoor Sound Level

Note 1: dBA is sound pressure measured 10 feet in front of unit and 5 feet above floor.

Note 2: Unit or isolation curb is mounted to frame construction.

Note 3: Results may vary depending upon other factors such as room size, type of construction and acoustical varianc es.

52.0 41.4 50.9 41.2 40.5 39.0

53.7 44.0 52.9 44.3 42.0 40.5

55.0 46.2 54.0 ²²44.8

65.0 65.0 65.0 65.0 65.0 65.0

WMICF-5

Isolation

Curb

WAPFB51

Free Blow

Supply Air

Plenum

WAPR11-X

Return Air

Silencer

WMICF-5

Isolation

Curb

WAPFB51

Free Blow

Supply Air

Plenum

WAPR11-X

Return Air

Silencer

Ducted Supply ConfigurationFree Blow Configuration

Direct Direct

Standard

Supply Duct

Grille

Direct Direct

Standard

Supply Duct

Grille

WMICF-5

Isolation

Curb

Standard

Supply Duct

WAPR11-X Return Air

Standard

Supply Duct

WAPR11-X Return Air

Supply Duct

Silencer

Supply Duct

Silencer

Standard

WMICF-5

Isolation

Curb

Standard

WMICF-5

Isolation

Curb

WAPS51-G

Supply Air

Silencer

WAPR11-X

Return Air

Silencer

WMICF-5

Isolation

Curb

WAPS51-G

Supply Air

Silencer

WAPR11-X

Return Air

Silencer

Unit Mounting Direct

Supply Air Treatment Grille

Return Air Treatment Grille

Blower Only Operation 40.3 33.3 35.1 34.8 33.5 31.1

Compressor

Stage 1 Operation

Compressor

Stage 2 Operation

Compressor Stage 2 with

ERV High Speed Operation

Indoor Integrated dBA 46.2 37.2 41.8 39.0 37.2 35.4

Compressor Stage 2

Outdoor Sound Level

Note 1: dBA is sound pressure measured 10 feet in front of unit and 5 feet above floor.

Note 2: Unit or isolation curb is mounted to frame construction.

Note 3: Results may vary depending upon other factors such as room size, type of construction and acoustical varianc es.

52.6 40.8 50.6 43.6 40.9 39.9

56.7 45.3 51.6 46.8 44.5 43.2

57.8 47.1 55.0 ²²45.4

65.4 65.4 65.4 65.4 65.4 65.4

WMICF-5

Isolation

Curb

WAPFB51

Free Blow

Supply Air

Plenum

WAPR11-X

Return Air

Silencer

Ducted Supply ConfigurationFree Blow Configuration

Direct Direct

Standard

Supply Duct

Grille

WMICF-5

Isolation

Curb

Standard

Supply Duct

WAPR11-X Return Air

Supply Duct

Silencer

Standard

WMICF-5

Isolation

Curb

WAPS51-G

Supply Air

Silencer

WAPR11-X

Return Air

Silencer

Form No. S3378-1112

Supersedes S3378-712

Page 9 of 12

otderiuqeRsecnaraelCmuminiM

slairetaMelbitsubmoC

SLEDOM 11

1

11

TCUDRIAYLPPUS

TEEFEERHTTSRIF

TENIBAC

S5L/AW,S4L/AW,S3L/AW"4/1"0

2nd Stage Cooling Application Data - Outdoor Temperature 1

ledoM

3S3AW

2S3LW

3S4AW

2S4LW

3S5AW

2S5LW

.B.W/.B.D

2

26/57

76/08

27/58

26/57

76/08

27/58

26/57

76/08

27/58

yticapaCgnilooC

RH/UTB

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

F°05 F°55 F°06 F°56 F°07 F°57 F°08 F°58 F°09 F°59 F°001 F°501 F°011 F°511

521,44

058,24

006,14

523,04

050,93

008,73

gnilooCelbisneS

573,23

058,13

003,13

577,03

522,03

051,94

576,74

571,64

576,44

gnilooCelbisneS

573,23

008,13

522,13

051,35

007,15

gnilooCelbisneS

570,23

520,65

gnilooCelbisneS

006,04

527,26

gnilooCelbisneS

057,14

524,96

gnilooCelbisneS

528,14

053,96

gnilooCelbisneS

056,94

057,47

gnilooCelbisneS

523,84

573,97

gnilooCelbisneS

524,64

052,05

055,13

050,13

001,35

575,15

001,04

054,93

008,85

579,65

003,14

574,14

007,66

008,46

005,14

527,04

525,76

007,56

578,84

001,84

577,27

008,07

055,74

057,64

056,77

059,57

578,54

053,54

002,34

056,03

570,03

008,84

053,74

525,03

520,03

050,05

525,84

577,83

521,83

051,55

523,35

056,93

008,83

009,26

000,16

529,93

051,93

009,36

570,26

523,74

575,64

008,86

528,66

579,54

571,54

522,47

525,27

528,44

572,44

055,63

007,92

002,92

007,14

521,04

005,92

498,82

009,54

574,44

005,92

000,92

004,84

059,64

003,73

527,63

006,35

007,15

006,73

007,63

009,95

579,75

009,73

001,73

052,06

524,85

008,54

570,54

058,46

577,26

004,44

005,34

008,07

572,96

057,34

572,34

1st Stage Cooling Application Data - Outdoor Temperature 1

ledoM

3S3AW

2S3LW

3S4AW

2S4LW

3S5AW

2S5LW

.B.W/.B.D

2

26/57

76/08

27/58

26/57

76/08

27/58

26/57

76/08

27/58

1 Below 50oF, unit requires a factory or field-installed low ambient control.

2 Return air temperature °F.

yticapaCgnilooC

RH/UTB

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

gnilooClatoT

F°05 F°55 F°06 F°56 F°07 F°57 F°08 F°58 F°09 F°59 F°001 F°501 F°011 F°511

052,03

572,92

003,82

053,72

573,62

004,52

gnilooCelbisneS

577,22

003,22

528,12

053,12

578,02

003,43

051,33

520,23

578,03

gnilooCelbisneS

570,32

575,22

050,22

009,73

007,63

gnilooCelbisneS

004,22

000,14

gnilooCelbisneS

576,92

573,54

gnilooCelbisneS

578,92

002,15

gnilooCelbisneS

526,03

573,05

gnilooCelbisneS

521,73

529,85

gnilooCelbisneS

009,63

055,26

gnilooCelbisneS

052,63

525,53

000,22

006,12

008,93

066,83

000,03

574,92

005,34

522,24

001,03

055,92

001,84

056,64

006,92

000,92

050,94

527,74

575,63

050,63

009,65

009,45

004,63

578,53

008,06

050,95

577,53

003,53

057,92

525,12

520,12

053,43

571,33

002,12

008,02

525,73

573,63

529,82

004,82

059,04

576,93

000,92

054,82

571,54

527,34

003,82

576,72

004,64

570,54

525,53

000,53

009,25

578,05

573,53

058,43

003,75

055,55

528,43

573,43

054,42

004,02

059,91

006,82

054,72

005,02

579,91

000,23

528,03

004,02

520,02

003,53

002,43

000,72

574,62

000,93

057,73

001,72

055,62

009,34

004,24

004,72

527,62

057,34

055,24

054,43

579,33

058,84

056,64

053,43

054,33

008,35

050,25

009,33

574,33

003,53

050,43

008,23

574,13

051,03

528,82

007,82

002,82

007,72

520,72

053,62

055,83

579,63

004,53

522,43

003,82

576,72

570,72

050,34

526,14

005,82

005,54

051,63

008,94

008,53

050,65

003,63

526,65

523,44

576,06

006,24

057,76

008,24

005,32

005,91

003,62

524,91

056,92

056,91

001,33

059,52

005,63

000,62

009,04

520,62

053,14

005,33

524,44

525,23

572,05

520,33

002,04

000,82

005,72

050,44

006,24

575,53

000,53

009,74

000,64

009,43

000,43

521,45

002,25

005,53

007,43

528,45

000,35

006,34

058,24

006,85

005,65

007,14

008,04

522,66

007,46

523,24

058,14

055,22

006,12

050,91

006,81

051,52

000,42

009,81

053,81

574,82

003,72

572,91

009,81

000,23

009,03

524,52

009,42

052,53

000,43

054,52

009,42

004,93

009,73

053,52

056,42

051,04

059,83

520,33

055,23

522,24

000,04

526,13

007,03

525,84

057,64

006,23

051,23

570,33

526,62

571,62

056,83

001,73

529,62

053,62

577,04

059,83

000,43

000,33

574,44

059,24

054,33

009,23

573,05

055,84

579,33

052,33

051,15

003,94

579,14

570,14

059,45

004,35

574,04

051,04

052,26

577,95

001,14

523,04

055,02

005,91

520,81

054,71

009,22

008,12

529,71

574,71

521,62

529,42

524,81

529,71

006,92

003,82

523,42

057,32

526,23

052,13

053,42

577,32

006,63

003,53

571,42

007,32

051,73

523,53

577,13

520,13

577,83

055,73

528,13

529,23

050,54

053,34

006,13

579,03

005,72

576,52

000,52

009,13

057,03

057,52

003,52

055,53

000,43

577,52

002,52

521,73

003,53

000,23

000,13

524,14

009,93

053,23

008,13

527,64

009,44

525,23

008,13

054,74

006,54

002,04

003,93

058,15

003,05

528,93

005,93

523,75

058,45

575,93

008,83

054,81

004,71

578,61

003,61

007,02

006,91

050,71

006,61

057,32

055,22

054,71

059,61

000,72

007,52

571,32

006,22

578,92

005,82

522,32

056,22

000,43

007,23

522,32

057,22

525,33

007,13

572,03

005,92

523,63

001,53

050,43

051,53

056,14

059,93

004,03

008,92

SLEDOM EDISTFEL EDISTHGIR

Form No. S3378-1112

Supersedes S3378-712

Page 10 of 12

S5L/AW,S4L/AW,S3L/AW"02"02

sseccAecivreSrofderiuqeRsecnaraelC

ekatnIwolfriAresnednoCetauqedAdna

1 Refer to the Installation Manual for more detailed information.

M

HTDIW

8

8

LEDO

)W(

3S3AW

2S3LW

3S4AW

2S4LW

3S5AW

2S5LW

HTPED

)D(

570.24234.22578.4888.988.9288.5188.9288.3465.3166.1300.0386.2349.6296.4334.2373.300.3488.3200.0144.100.6100.61

570.24234.22578.4988.988.9288.5188.9288.3465.3166.1400.0386.2449.6396.4434.2473.300.3488.3300.0144.100.1200.12

THGIEH

)H(

YLPPUS NRUTER

A B C B E F G I J K L M N O P Q R 1S 2S T

All dimensions are in inches. Dimensional drawings are not to scale.

)lanimoN(stnemeriuqeRnoitallatsnIdnalarutcetihcrAroftinUcisaBfosnoisnemiD

8.1

8.1

WA3-4-5S Models

W

5.88

F

G

Filter Access Panel

Ventilation Air

Condenser

Air Outlet

Front View

Built In

Rain Hood

4° Pitch

Heater

Access

Panel

Electric

C. Breaker/

Disconnect

Access Panel

(Lockable)

ERV and ECONWMS

only hood

Standard flush

vent door for

non-ERV/Econ.

models

Low Voltage

Electrical

Entrance

High Voltage

Electrical

Entrance

Equipment Building Hood

ECONWMT-E5, -T5 is 18"

Heat

3"

D

Cond.

Air

Inlet

Side View

2.13

J

Drain

E

O

.44

Side Wall

A

Mounting

Brackets

(Built In)

I

Top Rain

Flashing

Shipping

Location

Optional

H

C

Electrical

Entrances

K

L

M

P

N

Supply Air Opening

B

Return Air Opening

Q

Back View

Bottom Installation

Bracket

R

S1

S1

S1

S2

S2

T

MIS-3123

E

.44

R

S1

S1

S1

S2

S2

T

Bottom

Drain

Installation

Bracket

O

Supply Air Opening

B

Return Air Opening

Back View

D

Side Wall

Mounting

Brackets

(Built In)

Top Rain

Flashing

Shipping

Location

Optional

Electrical

Entrances

P

N

Q

2.13

A

I

C

H

L

K

M

Cond.

J

Air

Inlet

Side View

Built In

Rain Hood

4° Pitch

Electric

Heat

Heater

Access

Panel

C. Breaker/

Disconnect

Access Panel

(Lockable)

Standard flush

vent door for

non-ERV/Econ.

models

ERV and

ECONWMS

3"

only hood

Low Voltage

Electrical

Entrance

High Voltage

Electrical

Entrance

Equipment Building Hood

ECONWMT-E2, -T2, -E3, -T3 is 16"

ECONWMT-E5, T5 is 18"

WL3-4-5S Models

W

Filter Access Panel

Ventilation Air

Condenser

Air Outlet

Front View

Form No. S3378-1112

Supersedes S3378-712

Page 11 of 12

5.88

F

G

MIS-3124

Air Conditioning Wall-Mount Model Nomenclature

MODEL

NUMBER

WA – Right Hand

WL – Left Hand

CAPACITY

3S - 3 Ton

4S - 4 Ton

5S - 5 Ton

WA 3S 3 A 10 B P X X X X

REVISION

WA - 3

WL - 2

VOLTS & PHASE

A - 230/208/60/1

B - 230/208/60/3

C - 460/60/3

KW

VENTILATION OPTIONS

(See Chart Below)

FILTER OPTIONS

P - 2 inch Pleated

MERV 8

COLOR OPTIONS

X - Beige (Standard)

1 - White

4 - Buckeye Gray

5 - Desert Brown

8 - Dark Bronze

A - Aluminum

S - Stainless Steel

OUTLET OPTIONS

X - Front (Standard)

CONTROL MODULES

(See Chart Below)

COIL OPTIONS

X - Standard

1 - Phenolic Coated Evaporator

2 - Phenolic Coated Condenser

3 - Phenolic Coated Evaporator

& Condenser

Note: For 0KW and circuit breakers (230/208 Volt) or rotary disconnect (460 Volt) applications, insert 0Z in the KW field of the model number.

Ventilation Options

sledoM sledoMllA

noitpircseD

etalPffO-knalB B5-POB

repmaDriAhserFdezirotoM M5-DAFM

tsuahxEhtiwdezirotoM-rotalitneVlaicremmoC V5-PMVRC

yplahtnE,snoisreVloohcS-rezimonocE 4 S5E-SMWNOCE 32

yplahtnE,.gdlBtnempiuqE-rezimonocE 5 W5E-TMWNOCE 2

pmeTBD,.gdlBtnempiuqE-rezimonocE 5 T5T-TMWNOCE 2

tloV032-rotalitneVyrevoceRygrenE 3 R5A-FVRE 1

tloV064-rotalitneVyrevoceRygrenE 3 R5C-FVRE 1

)deriuqeR(FVREroftiKrooD A/N-5KDMW 3

1 Intake and exhaust can be independently adjusted.

2 Insert color to match unit ("X" = Beige; "4" = Buckeye Gray; etc.)

3 WMDK Door Kit must be ordered in addition to ERVF Assembly and ECONWMS & color matched to unit ("X" = Beige; "4" = Buckeye Gray; etc.)

4 Partial Full Flow (75% of Rated Cooling CFM). All ECONWMS versions have 3" deep intake hood.

5 Full Flow (100% of Rated Cooling CFM). ECONWMT2 and 3 have 16" deep intake hood; ECONWMT-5 has 18" deep intake hood.

dellatsnIyrotcaF

.oNedoC

dellatsnIdleiF

.oNtraP

seludoMlortnoCgninoitidnoCriA

SNOITPOLORTNOCELBALIAVA

CPH 1 CPL 2 MCC 3 CAL 4 RLA 5 KS 6 CDD 7

DTSDTSDTSDTSX

DTSDTSDTS

DTSDTSDTS

DTSDTSDTS

STD = Standard equipment for these specified models.

z

zz

zz

DTSH82-AMC

DTSJylnOyrotcaF

DTS

z

V 7 ylnOyrotcaF

sledoMllA

edoCdellatsnIyrotcaF traPdellatsnIdleiF

A/N

1 HPC. High pressure control is auto reset. Always used with compressor control module (CCM) which is included. See note 3.

2 LPC. Low pressure control is auto reset. Always used with compressor control module (CCM) which is included. See note 3.

3 CCM. Compressor control module has adjustable 30-second to 5-minute delay-on-break timer. On initial power-up, or any time the power is interrupted, the

delay-on-make will be 2-minutes plus 10% of the delay-on-break setting. There is no delay-on-make during routine operation of the unit. The module also

provides the lockout feature (with 1 retry) for high and/or low-pressure controls, and a 2-minute timed bypass for low-pressure control.

4 LAC. Low ambient control permits cooling operation down to 0°F.

5 ALR. The alarm relay has a set of normally open and normally closed dry contacts to provide the ability to signal a condition of shutdown on either high or low

pressure controls.

6 SK. Start kit standard on all -A single phase models only. Is not used or available for -B or -C three phase models.

7 DDC. Incorporates 4 additional sensors: discharge air temperature, indoor blower airflow, compressor current, and dirty filter. These sensing devices function

to input analog data such as temperature, as well as digital data such as airflow, compressor status or filter status.

Form No. S3378-1112

Supersedes S3378-712

Page 12 of 12

Bard Manufacturing Company, Inc.

Bryan, Ohio 43506

www.bardhvac.com

Due to our continuous product improvement

policy, all specifications subject to change

without notice.

Before purchasing this appliance, read important energy

cost and efficiency information available from your retailer.

Form No.

S3378

November, 2012

Supersedes: S3378-712

Loading...

Loading...