Page 1

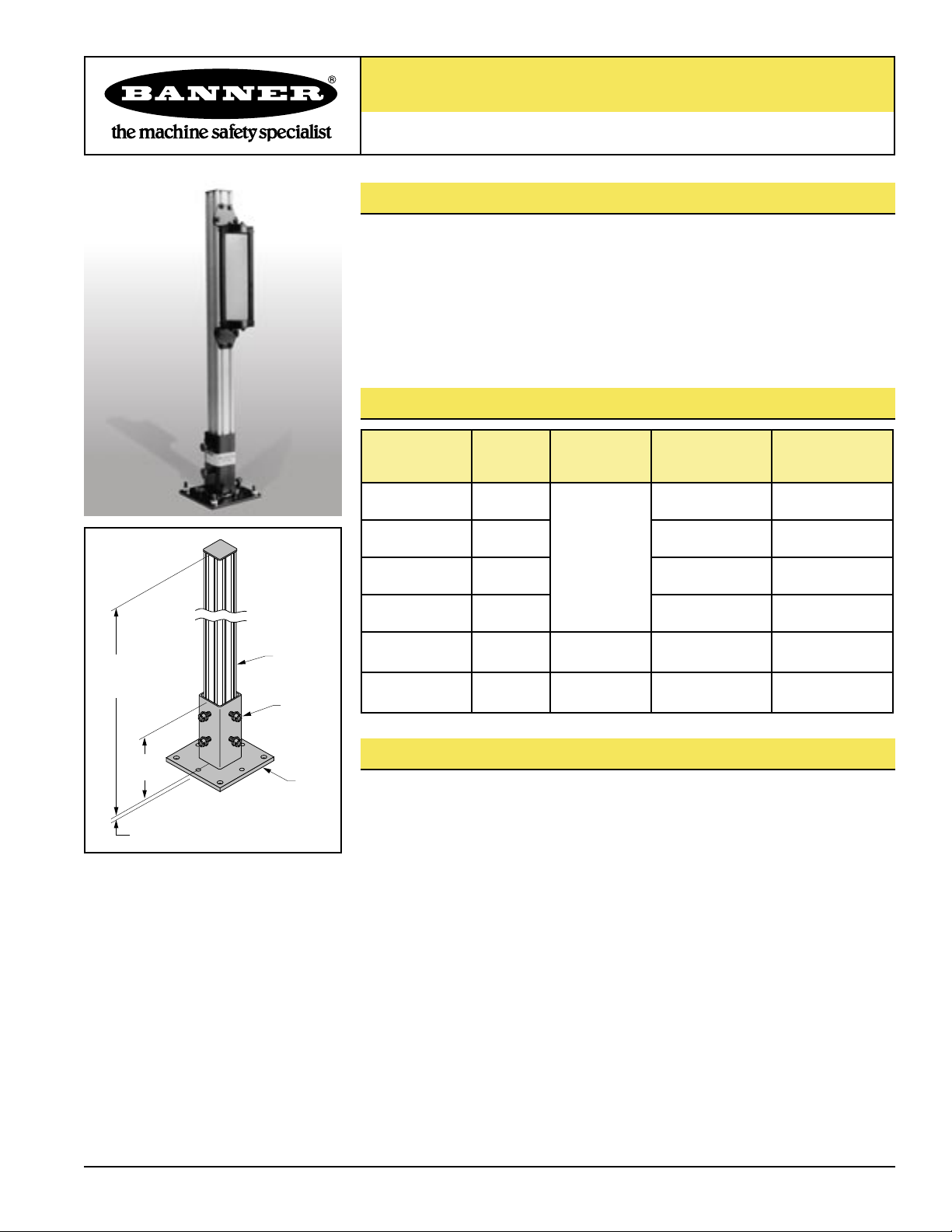

MSA Series Stands

(4) M10 Bolt

Pole

40 mm

(1.58") Square

Height L

(see Models

table)

Base

6.4 mm (0.25")

127 mm

(5")

For Optical Safety System Sensors or Corner Mirrors

Features

• Easy to assemble

• Available in four pole heights

• Solidly supports emitter, receiver or corner mirror

• Strong extruded and anodized aluminum poles

• Dual-channel design for accurate sensor/mirror adjustment

Models

Figure 1. Assembled stand

Model

MSA-S24-1

MSA-S42-1

MSA-S66-1

MSA-S84-1

SPKA-AG12-1

SPKA-AG30-1

Part

Number

43174

43175 42" 37"

43176 66" 61"

52397 84" 79"

73229

73230

For Use

With

Light Screens

and Mirrors as

Noted Below

SFP12

Safety Point

SFP30

Safety Point

Height “L”

(Figure 1)

24" 19"

42" 37"

42" 37"

Useable Stand

Height

Overview

Banner MSA Series stands are designed specifically for use with Banner optical safety

system emitters and receivers, and corner mirrors. The poles are constructed of strong,

lightweight extruded aluminum, and have a dual-channel design that allows easy and

accurate height adjustment using the supplied “T” nuts.

Each stand includes two major parts:

1. A welded steel base, and

2. An aluminum pole; 24", 42", 66", or 84" in length.

Hardware is included for attaching either a MICRO-SCREEN® or MINI-SCREEN®

sensor, an SFP.. Safety Point, or a corner mirror to the pole. (EZ-SCREEN™ or

MACHINE-GUARD™ sensors, and SSM-Series mirrors require an adapter bracket; refer

to the appropriate data sheet.) A post level also is included with each stand for accurate

installation.

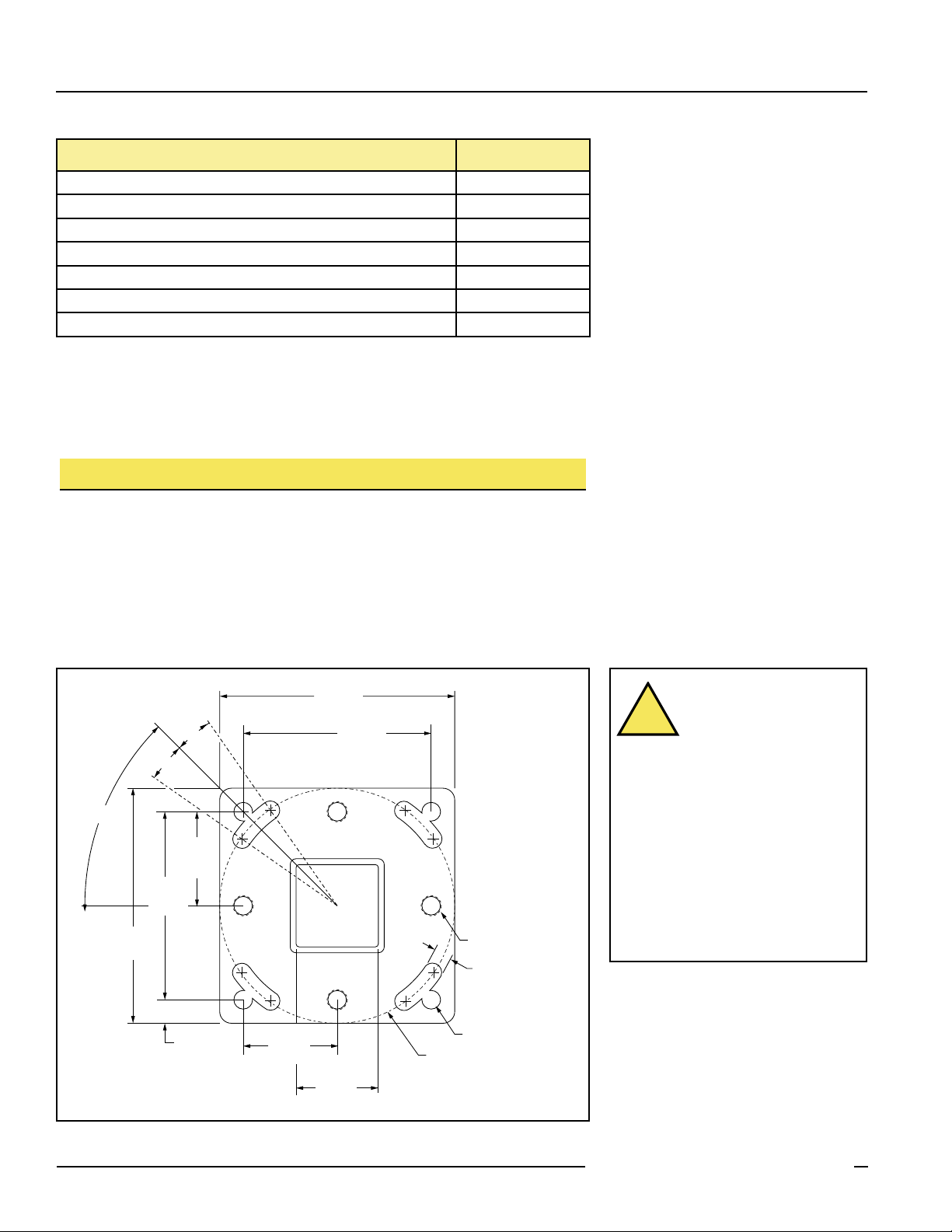

The pole is held securely in its base by four bolts (included). The base bolts to a flat

surface with user-supplied 5/16" or M8 hardware. The base plate has four threaded

holes for leveling bolts (also included, see Figure 2).

Figures 3, 4 and 5 detail how a sensor or mirror attaches to the post using the supplied

hardware. This mounting design allows the sensor or mirror to easily slide up or down

the pole and then lock into position by tightening four screws.

Printed in USA 10/04 P/N 43687 rev. C

Page 2

MSA Series Stands

127 mm

(5.0")

127 mm

(5.0")

102 mm

(4.0")

51 mm

(2.0")

44.5 mm

(1.75")

Square

51 mm

(2.0")

10º

10º

45º

13 mm

(0.5")

ø127 mm (5.0")

102 mm

(4.0")

4x 0.397"

4x 0.397"

4x M10 x 1.0

!

Included with Each MSA Series Stand Quantity

Clear anodized extruded aluminum pole 1

Black epoxy-painted welded steel base assembly 1

Post level 1

Black zinc-plated steel adapter plate 2

M10 x 1 x 18 mm-long slotted/Phillips hex head bolt 4

M4 x 0.7 x 10 mm-long slotted hex head screw 12*

M4 “T” nut 8*

* Extra screws and T-nuts are included to accommodate mounting of center bracket used

with longer MICRO-SCREEN® Sensors.

NOTE: Adapter bracket EZA-MBK-2 is required for mounting EZ-SCREEN™ or MACHINE-

GUARD™ sensors, or SSM-Series mirrors. Refer to the data sheets for those products

for more information.

Installation of Base and Pole

1) Refer to Figure 2. The base is secured to the floor or other flat surface using

5/16" or M8 hardware, supplied by the installer. Place the base on its mounting

hardware, but do not tighten. Install an M10 leveling bolt (supplied) into each of

the four threaded holes for leveling purposes.

2) Using the post level (supplied), adjust the leveling bolts for true vertical level.

Continue to check the vertical level of each pole while tightening the base

mounting hardware.

WARNING . . .

Maintain Required

Separation Distance

The light screen produced

by the optical safety system sensors

must be placed at a minimum safe

distance from the dangerous motion

of the machine being guarded. This

necessary minimum distance is called the

separation distance, and is discussed in

Section 3 of the appropriate instruction

manuals. Failure to calculate this

distance correctly and to maintain

minimum separation distance can result

in serious injury or death.

Figure 2. Stand base mounting hole pattern

2 P/N 43687 rev. C

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 3

Stand Pole

Bracket

(2 supplied with sensor)

2x M3 Screw

(supplied with sensor)

M4 Screw and "T" Nut

(8 supplied with stand; use as needed)

MICRO-SCREEN

(emitter/receiver)

Figure 3. Sensor-to-stand mounting for MICRO-SCREEN sensor

MSA Series Stands

Mounting Sensor or Mirror to Pole

1) Verify that all poles used for the light screen installation are

exactly parallel to each other before mounting sensors and/

or mirrors.

2) Refer to Figures 3, 4, 5, 6, and 7. Assemble the brackets and

hardware as shown in the appropriate figure.

3) Loosely mount the bracket assemblies (see step 2, above) to

the pole using the M4 screws and “T” nuts supplied with the

stand†.

Note that Figures 3, 4 and 5 show the bracket assembly

pointed “outward” (away from the sensor or mirror). One

or both of the bracket assemblies may be reversed to point

“inward,” if necessary. However, access to the mounting

screws becomes less convenient and mirror rotation is

limited when a bracket assembly is pointed inward.

Figure 4. Sensor-to-stand mounting for MINI-SCREEN sensor

Figure 5. Mirror-to-stand mounting for MSM Series mirror

Figure 6. Adapter bracket-to-stand mounting, shown ready for

mounting of EZ-SCREEN or MACHINE-GUARD sensor or

SSM-Series mirror

4) Mount the sensor or mirror to its brackets using the screws

supplied with the sensor or mirror. Temporarily tighten those

screws. (NOTE: MICRO-SCREEN sensors from 40" to 48"

long also include one center bracket, and MICRO-SCREEN

sensors from 52" to 72" long include two center brackets.

M4 and “T” nuts are provided with the stands for these

situations. See the MICRO-SCREEN installation manual for

further details.)

5) Slide the sensor or mirror into position along the length of

the pole and tighten the M4 screws into their “T” nuts to lock

the sensor or mirror into position.

IMPORTANT: Step 5 requires accuracy. If no mirrors are

involved in the sensing path, then any feature of the emitter

can be matched in vertical position with the same feature on

the receiver. However, if one or more mirrors is used, the

center of each mirror must match the vertical position of

the center of the defined area of the sensors. The upper and

lower limits of the defined area are dimensioned in the light

screen instruction manual.

6) Loosen the bracket screws (tightened in Step 4) to allow the

sensor or mirror to rotate for alignment. See the light screen

instruction manual for alignment information.

Figure 7. Swivel bracket-to-stand mounting for SFP12 or

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 43687 rev. C 3

SFP30 Point

Page 4

MSA Series Stands

WARRANTY: Banner Engineering Corp. warrants its products to be free from defects for one year. Banner Engineering Corp. will repair

or replace, free of charge, any product of its manufacture found to be defective at the time it is returned to the factory during the warranty

period. This warranty does not cover damage or liability for the improper application of Banner products. This warranty is in lieu of any

other warranty either expressed or implied.

P/N 43687 rev. C

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN USA 55441 • Phone: 763.544.3164 • www.bannerengineering.com • Email: sensors@bannerengineering.com

Loading...

Loading...