Page 1

Gain

Adjustment

Blue (2)

Brown (1)

No

Connection

No

Connection

LED

Indicator

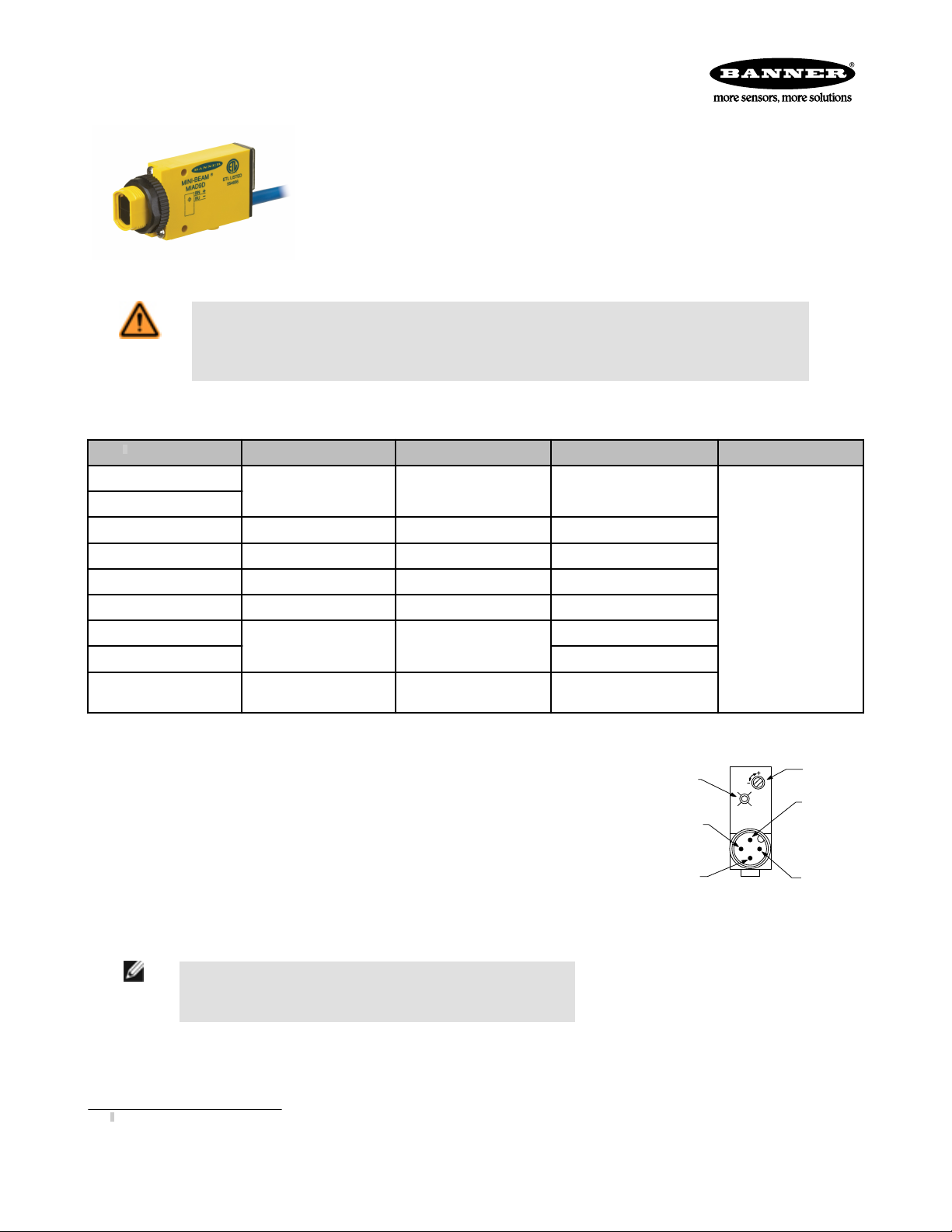

MINI-BEAM® MIAD9 Series

NAMUR Intrinsically Safe DC Sensors

• Intrinsically safe sensors with MINI-BEAM performance and small size

• For use with approved switching amplifiers with intrinsically safe input circuits

• Output 1 mA or less in the dark and 2 mA or more in the light

• Models with integral cable or quick-disconnect

WARNING: Not To Be Used for Personnel Protection

Never use this device as a sensing device for personnel protection. Doing so could lead to serious injury or death. This

device does not include the self-checking redundant circuitry necessary to allow its use in personnel safety applications. A sensor

failure or malfunction can cause either an energized or de-energized sensor output condition.

Models

1

Model

MI9E Emitter

MIAD9R Receiver

MIAD9LVAG Polarized Retroreflective Visible red, 650 nm 50 mm to 2 m (2 in to 7 ft)

MIAD9LV Retroreflective Visible red, 650 nm 5 m (16.4 ft)

MIAD9D Diffuse Infrared, 880 nm 380 mm (15 in)

MIAD9W Divergent Diffuse Infrared, 880 nm 75 mm (3 in)

MIAD9CV

MIAD9CV2 43 mm (1.7 in)

Fiber Optic (Glass) MIAD9F Infrared, 880 nm Range varies by sensing mode

Sensing Mode Sensing Beam Sensing Range Output Type

Opposed Infrared, 880 nm Range: 6 m (20 ft)

Constant Current

≤ 1.2 mA dark

≥ 2.1 mA light

16 mm (0.6 in)

Convergent Visible red, 650 nm

and fiber optics used

Overview

MIAD9 Series NAMUR Sensors are small, rugged, self-contained two-wire sensors designed for use with approved

switching amplifiers with intrinsically safe input circuits. MIAD9 Series sensors are designed in accordance with DIN 19

234.

These sensors vary the impedance across the sensor output, which passes 1 mA or less in the “dark” condition and 2

mA or more in the “light”condition. A red LED on the rear of the sensor lights whenever the sensor sees the “light”

condition. A rugged, clutched, 15-turn slotted brass screw Gain control potentiometer enables precise adjustment of

system sensitivity.

Models are available with either a 2 m (6.5 ft) or 10 m (30 ft) long attached PVC-covered cable, or a 4-pin Euro-style

quick disconnect (QD) connector. Quick disconnect models (with “Q” in the model number suffix) use MQD9-4.. mating

cable (either straight or right angle connector; see Quick-Disconnect (QD) Cables on page 7). Contact Banner Engineering for availability of sensor models with 10 m (30 ft) long attached cable.

NOTE: If sensors with output characteristics according to DIN 19 234 are used in

hazardous areas, they must be used with approved switching amplifiers with intrinsically safe input circuits.

Special Conditions for Safe Use

Parts of the enclosure are non-conducting and may generate an ignition-capable level of ESD. Cleaning of the equipment shall be done only with a damp cloth.

1

Only standard 2 m (6.5' ft cable models are listed. For 4-pin Euro-style Integral QD models: add suffix “Q” to the model number (for example, MIAD9RQ); accessory mating cable required, see Quick-Disconnect (QD) Cables on page 7.

Figure 1. Features (rear of sensor, quick-

disconnect model shown)

P/N 39616_web Rev. I 6/7/2013

Page 2

MINI-BEAM® MIAD9 Series

Hazardous Area Application

Associated apparatus may include amplifiers and barriers to monitor apparatus supply current, which is the apparatus output signal. Associated apparatus must limit both

supply voltage and supply current in the event of failures.

Installation Notes

Hazardous Area Application

Entity Parameters: Associated Apparatus may include amplifiers and barriers to monitor apparatus supply current, which is the apparatus output signal. Associated apparatus must limit both supply voltage and supply current in the event of failures.

CAUTION: Special Conditions for Safe Use: Parts of the Enclosure are non-conducting and may generate an ignition- capable level

of ESD. Cleaning of the equipment shall be done only with a damp cloth.

Associated Apparatus Sensor Apparatus

Voc ≤ 15V dc

Isc ≤ 60 mA

Ca ≥ C(cable) + Ci

Cable Parameters (if unknown)

C(cable) = 60 pF/ft.

L(cable) = 0.2 μH/ft.

Vmax = 15V dc

Imax = 60 mA

Ci = 0.3 μF

Li = 0

Pi = 225 mW

La ≥ L(cable) + Li

FM Installation

1. Associated Apparatus (barrier) entity parameters must meet the following requirements:

Voc ≤ Vmax

Isc ≤ Imax

Ca ≥ Ci + Ccable

La ≥ Li + Lcable

2. The Associated Apparatus shall not be connected to any device that uses or generates in excess of 250 Volts rms or dc.

3. Intrinsic safety ground, if required for the Associated Apparatus, shall be less than 1 ohm.

4. Installation shall be in accordance with the National Electrical Code (ANSI/NFPA70), local codes, Associated Apparatus manufacturer’s installation requirements and

ANSI/ISA RP12.6 for hazardous (classified) location installation.

5. Associated Apparatus is not required for installation of the devices within a Division 2 hazardous (classified) location. The maximum voltage for Division 2 installation

is 15V dc.

6. Maximum connector torque: 6 ft-lbs.

CSA Installation

1. Associated Apparatus (barrier) entity parameters must meet the following requirements:

Voc ≤ Vmax

Isc ≤ Imax

Ca ≥ Ci + Ccable

La ≥ Li + Lcable

2. The Associated Apparatus shall not be connected to any device that uses or generates in excess of 250 Volts rms or dc.

3. Intrinsic safety ground, if required for the Associated Apparatus, shall be less than 1 ohm.

4. Installation shall be in accordance with the Canadian Electrical Code, Part 1.

5. Associated Apparatus (barrier) shall be installed in accordance with the manufacturer’s instructions.

6. Associated Apparatus is not required for installation of the devices within a Division 2 hazardous (classified) location when installed in, or through the wall of a

suitable enclosure with provision for connection of rigid metal conduit per the Canadian Electrical Code, as acceptable to the local inspection authority having juris-

diction. The maximum rating for Division 2 installation is 15V dc, 60 mA.

7. In Division 2 installations, observe the following warning.

2 www.bannerengineering.com - tel: 763-544-3164 P/N 39616_web Rev. I

Page 3

MINI-BEAM

® MIAD9 Series

Specifications

WARNING: Explosion Hazard

Do not disconnect equipment unless power has been switched Off or the area is known to be non-hazardous.

Supply Voltage and Current

5 to 15V dc (provided by the amplifier to which the sensor is connected)

Output

Constant current output: ≤ 1.2 mA in the “dark” condition and ≥ 2.1 mA

in the “light” condition

Output Response Time

Opposed mode: 2 ms ON/400 μs OFF

All other modes: 5 ms ON/OFF (does not include amplifier response)

Adjustments

15-turn slotted brass screw GAIN (sensitivity) adjustment potentiometer

(clutched at both ends of travel); located on rear panel and protected by

a clear gasketed acrylic cover

Indicators

Red LED Alignment Indicator Device (AID) located on rear panel lights

when the sensor sees a “light” condition; pulse rate is proportional to

signal strength (the stronger the signal, the faster the pulse rate).

Construction

Reinforced thermoplastic polyester housing, totally encapsulated, o-ring

sealing, acrylic lenses, and stainless steel screws

Environmental Rating

Banner tested to NEMA standards 1, 2, 3, 3S, 4, 4X, 6, 12 and 13

IEC IP67

Connections

PVC-jacketed 2-conductor 2 m or 9 m cables, or special 4-pin Eurostyle quick-disconnect (QD) fitting are available; QD cables are ordered

separately.

Operating Conditions

Temperature: −40 °C to +70 °C (−40 °F to +158 °F)

Design Standards

ATEX (European)

EN 60079-0, EN 60079-11, and EN 60079-26

Canadian

CAN/CSA C22.2, No. 142-M1987, No.157-92, No. 1010.1, E60079-0,

and E60079-11

United States

FM Class 3600, 3610, and 3810, ANSI/ISA 61010-1 (82.02.01),

ANSI/ISA 60079-0, 60079-11, and 60079-26

Approvals

ATEX (European)

II 1 G Ex ia IIC T5 Ga Ta = –40 °C to 70 °C - 39616; Entity;

FM12ATEX0094X

Entity Parameters:

V

= 15 V dc, I

Max

= 60 mA, Ci = 0.3 μF, Li = 0 mH.

Max

Canada

Intrinsically safe for Class I, II and III, Division 1, Groups A, B, C, D, E, F

and G T5 Ta = –40 °C to 70 °C - 39616; Entity

Non-incendive for Class I, Division 2, Groups A, B, C and D, T5 Ta = –40

°C to 70 °C

Intrinsically safe for Class I, Zone 0 Ex ia Group IIC T5 Ta = -40°C to

70°C - 39616; Entity

Entity Parameters:

V

= 15 V dc, I

Max

= 60 mA, Ci = 0.3 μF, Li = 0 mH.

Max

a = Sensing mode D, W, F, LV, LVAG, CV, CV2 or R.

b = Connection method Q or blank.

United States

Intrinsically safe for Class I, II and III, Division 1, Groups A, B, C, D, E, F

and G T5 Ta = –40 °C to 70 °C - 39616; Entity

Non-incendive for Class I, Division 2, Groups A, B, C and D, T5 Ta = –40

°C to 70 °C

Suitable for Class II and III, Division 2 (Class II and III, Division 2 applies

only to model numbers ending in suffix "Q"), Groups F and G*, T5 Ta = –

40 °C to 70 °C

Intrinsically safe for Class I, Zone 0 AEx ia Group IIC T5 Ga Ta = –40 °C

to 70 °C; Entity

Entity Parameters:

V

= 15 V dc, I

Max

= 60 mA, Ci = 0.3 μF, Li = 0 mH.

Max

a = Sensing mode D, W, F, LV, LVAG, CV, CV2 or R.

b = Connection method Q or blank.

Certifications

P/N 39616_web Rev. I www.bannerengineering.com - tel: 763-544-3164 3

Page 4

1

10

100

0.10 m

(0.33')

1.0 m

(3.3')

10 m

(33')

0.01 m

(0.033')

E

X

C

E

S

S

G

A

I

N

DISTANCE

1000

MI9E & MIAD9R

Opposed Mode

1

10

100

0.10 m

(0.33')

1.0 m

(3.3')

10 m

(33')

0.01 m

(0.033')

E

X

C

E

S

S

G

A

I

N

DISTANCE

1000

MIAD9LVAG

Retroreflective Mode

With BRT-3 Reflector

5 m

(15')

4 m

(12')

3 m

(9')

2 m

(6')

1 m

(3')

0

0

25 mm

50 mm

75 mm

25 mm

50 mm

75 mm

0

1.0"

2.0"

3.0"

1.0"

2.0"

3.0"

DISTANCE

MIAD9LVAG

Retroreflective Mode

With BRT-3 Reflector

1

10

100

0.10 m

(0.33')

1.0 m

(3.3')

10 m

(33')

0.01 m

(0.033')

E

X

C

E

S

S

G

A

I

N

DISTANCE

1000

MIAD9LV

Retroreflective Mode

With BRT-3 Reflector

5 m

(15')

4 m

(12')

3 m

(9')

2 m

(6')

1 m

(3')

0

0

25 mm

50 mm

75 mm

25 mm

50 mm

75 mm

0

1.0"

2.0"

3.0"

1.0"

2.0"

3.0"

DISTANCE

MIAD9LV

Retroreflective Mode

With BRT-3 Reflector

1

10

100

10 mm

(0.4")

100 mm

(4")

1000 mm

(40")

1 mm

(0.04")

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

MIAD9D

Diffuse Mode

375 mm

(15")

300 mm

(12")

225 mm

(9")

150 mm

(6")

75 mm

(3")

0

0

5 mm

10mm

15 mm

5 mm

10 mm

15 mm

0

0.2"

0.4"

0.6"

0.2"

0.4"

0.6"

DISTANCE

MIAD9D

Diffuse Mode

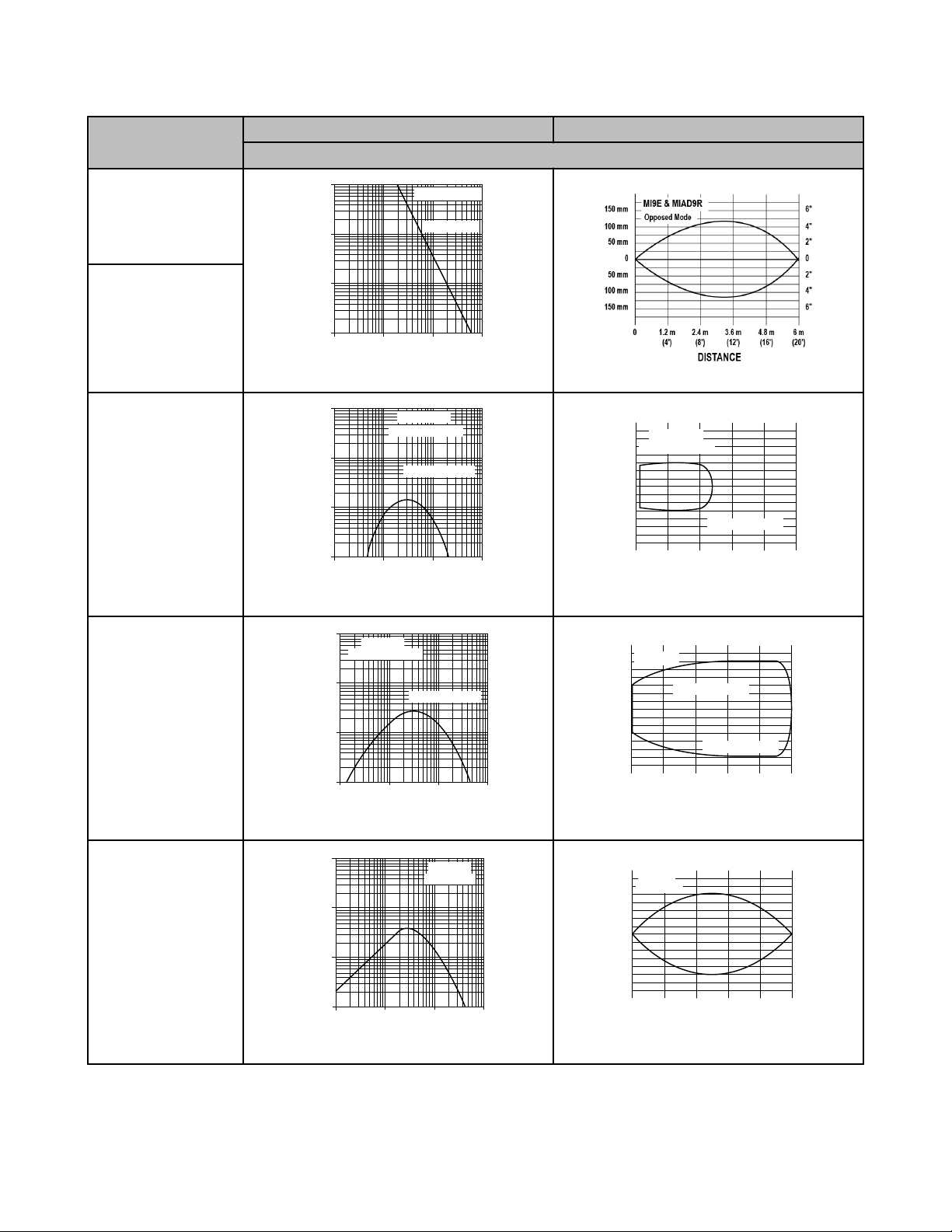

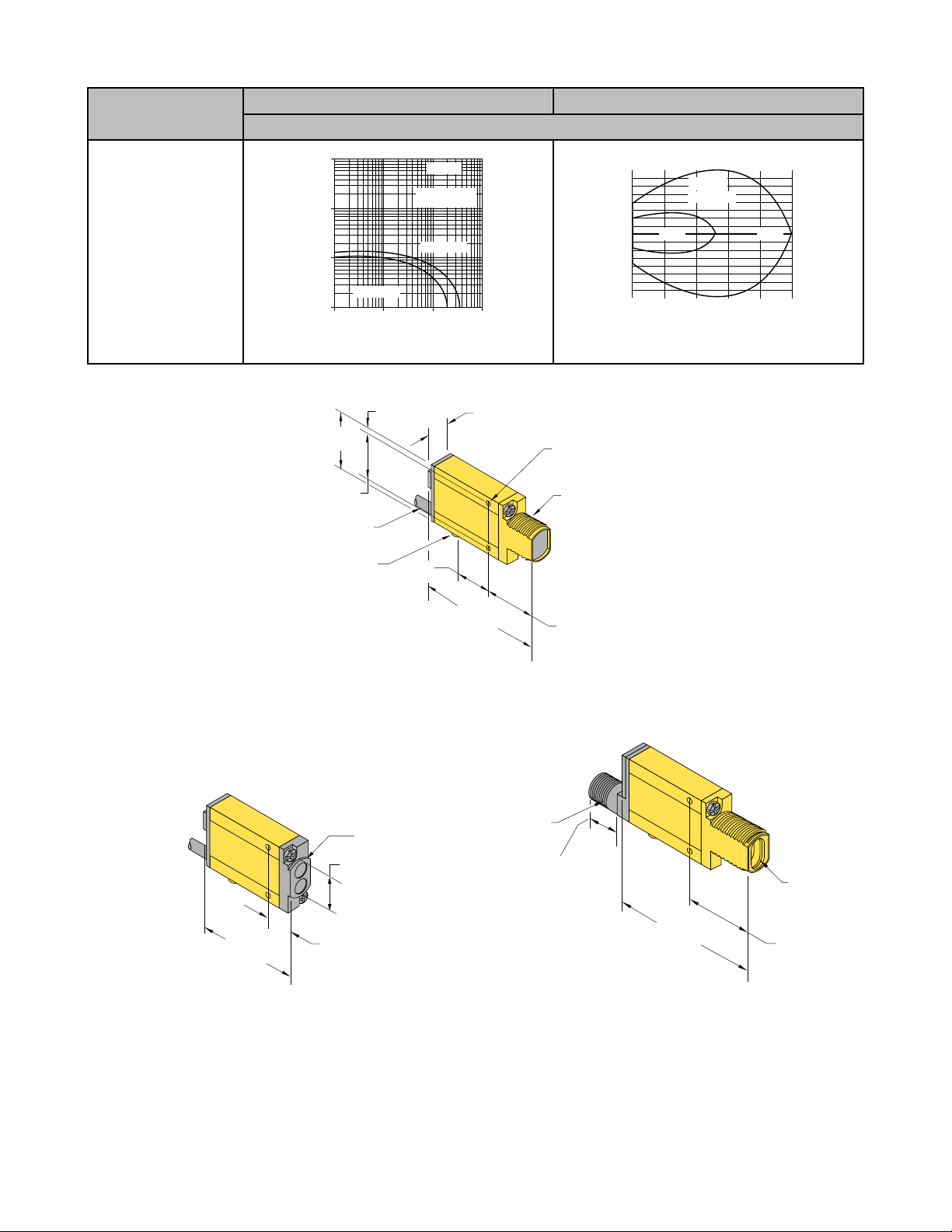

Performance Curves

Model Excess Gain Beam Pattern

Diffuse mode performance based on 90% reflectance white test card

MI9E Emitter

MIAD9R Receiver

MINI-BEAM® MIAD9 Series

MIAD9LVAG

MIAD9LV

MIAD9D

4 www.bannerengineering.com - tel: 763-544-3164 P/N 39616_web Rev. I

Page 5

1

10

100

1 mm

(0.04")

10 mm

(0.4")

100 mm

(4")

0.01 mm

(0.004")

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

MIAD9W

Divergent

Diffuse Mode

125 mm

(5")

100 mm

(4")

75 mm

(3")

50 mm

(2")

25 mm

(1")

0

0

5 mm

10mm

15 mm

5 mm

10 mm

15 mm

0

0.2"

0.4"

0.6"

0.2"

0.4"

0.6"

DISTANCE

MIAD9W

Divergent Mode

1

10

100

1 mm

(0.04")

10 mm

(0.4")

100 mm

(4")

0.1 mm

(0.004")

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

MIAD9CV

Convergent Mode

1

10

100

1 mm

(0.04")

10 mm

(0.4")

100 mm

(4")

0.1 mm

(0.004")

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

MIAD9CV

Convergent Mode

1

10

100

10 mm

(0.4")

100 mm

(4")

1000 mm

(40")

1 mm

(0.04")

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

MIAD9CV2

Convergent Mode

125 mm

(5")

100 mm

(4")

75 mm

(3")

50 mm

(2")

25 mm

(1")

0

0

1 mm

2 mm

3 mm

1 mm

2 mm

3 mm

0

0.04"

0.08"

1.2"

0.04"

0.08"

1.2"

DISTANCE

MIAD9CV2

Convergent Mode

1

10

100

10 mm

(0.40")

100 mm

(4.0")

1000 mm

(40")

1 mm

(0.04")

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

MIAD9F

Opposed Mode

Glass Fibers

IT13S Fiber

IT23S Fiber

500 mm

(20")

400 mm

(16")

300 mm

(12")

200 mm

(8")

100 mm

(4")

0

0

25 mm

50 mm

75 mm

25 mm

50 mm

75 mm

0

1"

2"

3"

1"

2"

3"

DISTANCE

MIAD9F

Opposed Mode

IT13S IT23S

MINI-BEAM® MIAD9 Series

Model Excess Gain Beam Pattern

Diffuse mode performance based on 90% reflectance white test card

MIAD9W

MIAD9CV

MIAD9CV2

MIAD9F—Opposed Mode

P/N 39616_web Rev. I www.bannerengineering.com - tel: 763-544-3164 5

Page 6

1

10

100

1 mm

(0.04")

10 mm

(0.40")

100 mm

(4")

0.1 mm

(0.004")

1000

E

X

C

E

S

S

G

A

I

N

DISTANCE

MIAD9F

Diffuse Mode

Glass Fibers

BT23S Fiber

BT13S Fiber

37.5 mm

(1.5")

30 mm

(1.2")

22.5 mm

(0.9")

15 mm

(0.6")

7.5 mm

(0.3")

0

0

.06 mm

1.2 mm

1.8 mm

.06 mm

1.2 mm

1.8 mm

0

.025"

.050"

.075"

.025"

.050"

.075"

DISTANCE

MIAD9F

Diffuse Mode

BT13S BT23S

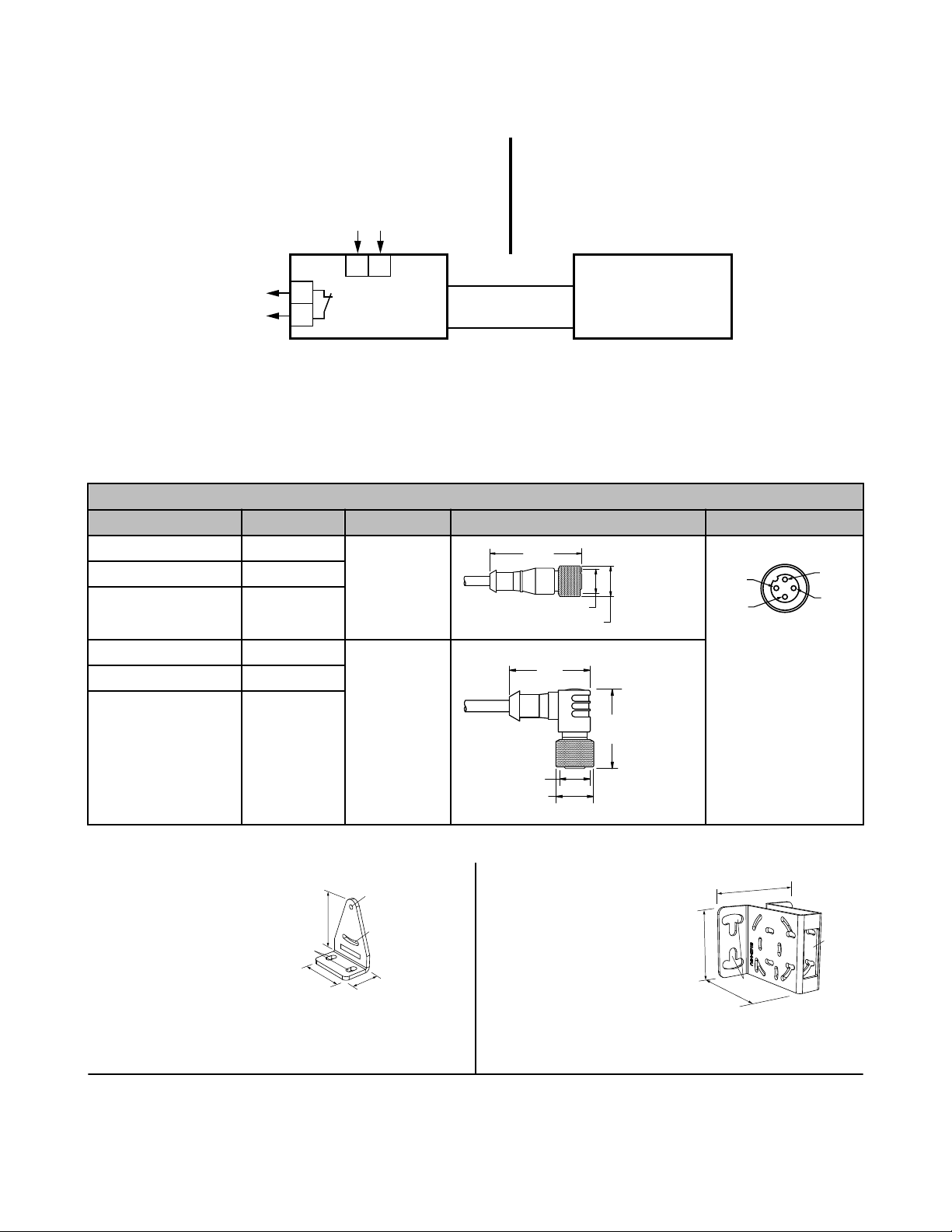

66.0 mm

(2.60")

12.2 mm (0.48")

Mounting Peg

(ø 6.3 mm x 2.5 mm)

ø 3 mm Clearance (2)

M18 x 1 x 15 mm Thread

(Mounting Nut Supplied)

3.2 mm

(0.13")

27.4 mm (1.08")

30.7 mm

(1.21")

24.1 mm

(0.95")

19.1 mm

(0.75")

2 m (6.5') Cable

51.8 mm

(2.04")

13.2 mm

(0.52")

18.0 mm

(0.71")

Bezel

Fiber Optic Fitting

69.9 mm

(2.75")

M12 x 1 Thread

Quick-disconnect

31.2 mm (1.23")

18.5 mm

(0.73")

Model Excess Gain Beam Pattern

Diffuse mode performance based on 90% reflectance white test card

MIAD9F—Diffuse Mode

Dimensions

MINI-BEAM® MIAD9 Series

Figure 2. Opposed, Retro, Diffuse, Convergent Models (Suffix E, R, LV, D, and CV)

6 www.bannerengineering.com - tel: 763-544-3164 P/N 39616_web Rev. I

Figure 3. Diffuse Models (suffix W)

Figure 4. Glass Fiber Models (suffix F)

Page 7

MIAD9 Series

NAMUR Sensor

DIN 19234

Brown

Non-Hazard Area Hazard Area

Blue

+

+

Switching Amplifier

(sensor power source

and monitor)

Switched

Output

Factory Mutual Approved

Associated Apparatus

Apparatus

–

–

V dc Supply

44 Typ.

ø 14.5

M12 x 1

2

3

4

1

32 Typ.

[1.26"]

30 Typ.

[1.18"]

ø 14.5 [0.57"]

M12 x 1

46

B

C

A

32

20

70

54

65

16

A

B

MINI-BEAM® MIAD9 Series

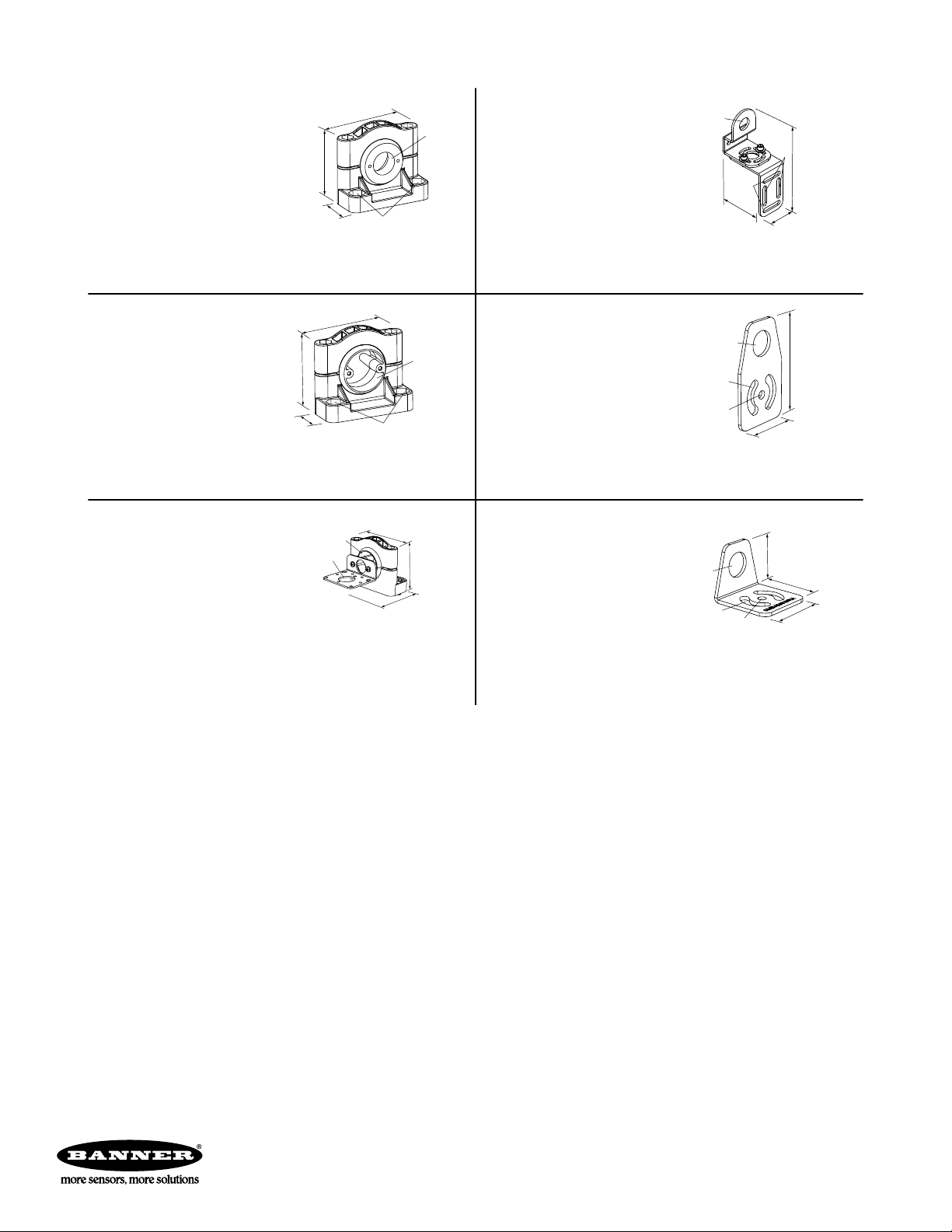

Hookups

Accessories

Quick-Disconnect (QD) Cables

4-Pin Threaded M12/Euro-Style Cordsets (for use with NAMUR sensors)

Model Length Style Dimensions Pinout

MQD9-406 1.83 m (6 ft) Straight

MQD9-415 4.57 m (15 ft)

MQD9-430 9.14 m (30 ft)

MQD9-406RA 1.83 m (6 ft) Right-Angle

MQD9-415RA 4.57 m (15 ft)

MQD9-430RA 9.14 m (30 ft)

1 = Brown

2 = Blue

Brackets

SMB312S

• Stainless steel 2-axis, side-mount

bracket

SMB46U

• Right-angle

• U bracket for sensor protection

• 14-ga. 316 stainless steel

A = 4.3 x 7.5, B = diam. 3, C = 3 x

15.3

P/N 39616_web Rev. I www.bannerengineering.com - tel: 763-544-3164 7

Hole center spacing: A = 16.0

Hole size: A = 16.5 x 18.7, B = 34.0 x 13.0

Page 8

51

24

23

B

C

A

30

41

46

A

B

C

46

41

B

C

A

32

66

69

A

B

65

54

27

A

41

46

A

B

30

C

54

43

65

16

A

B

B

A

51

42

25

MINI-BEAM® MIAD9 Series

SMB312B

• Stainless steel 2-axis, bottommount bracket

• Includes mounting foot

A = diam. 6.9, B = 4.3 x 10.5, C = 3.1

x 15.2

SMB312PD

• Right-angle mounting bracket with

a curved slot for versatile orientation

• 12-ga. stainless steel

• 18 mm sensor mounting hole

• Clearance for M4 (#8) hardware

Hole center spacing: A to B = 24.2

Hole size: A = ø 4.6, B = 17 × 4.6, C = ø 18.5

NOTE: Not for use with plastic fiber optic

sensors

SMB18A

• Right-angle mounting bracket with

a curved slot for versatile orientation

• 12-ga. stainless steel

• 18 mm sensor mounting hole

• Clearance for M4 (#8) hardware

Hole center spacing: A to B = 24.2

Hole size: A = ø 4.6, B = 17.0 × 4.6, C = ø 18.5

SMB18FA..

• Swivel bracket with tilt and pan movement for precision adjustment

• Easy sensor mounting to extruded rail

T-slots

• Metric and inch size bolts available

• 18 mm sensor mounting hole

Hole size: B=ø 18.1

Model Bolt Thread (A)

SMB18FA 3/8 - 16 × 2 in

SMB18FAM10 M10 - 1.5 × 50

SMB46L

• Right-angle

• L bracket

• 14-ga. 316 stainless steel

Hole center spacing: A = 16.0

Hole size: A = 16.5 x 18.7

SMB46S

• Right-angle

• S bracket

• 14-ga. 316 stainless steel

Hole center spacing: A = 16.0

Hole size: A = 16.5 x 18.7, B = 34.0 x 10.0

SMB18Q

• Right-angle flanged bracket

• 18 mm sensor mounting hole

• 12-ga. stainless steel

Hole center spacing: A to B = 24.2

Hole size: A = ø 4.6, B = 17.0 × 4.6, C = ø 19.0

SMB18SF

• 18 mm swivel bracket with M18 × 1

internal thread

• Black thermoplastic polyester

• Stainless steel swivel locking hardware included

Hole center spacing: A = 36.0

Hole size: A = ø 5.3, B = ø 18.0

8 www.bannerengineering.com - tel: 763-544-3164 P/N 39616_web Rev. I

Page 9

B

A

67

59

29

137

64

42

B

A

C

A

67

58

29

B

45

78

A

B

C

68

57

78

A

B

48

45

40

A

B

C

MINI-BEAM® MIAD9 Series

SMB3018SC

• 18 mm swivel side or barrelmount bracket

• Black reinforced thermoplastic

polyester

• Stainless steel swivel locking

hardware included

Hole center spacing: A = 50.8

Hole size: A = ø 7.0, B = ø 18.0

SMB30SUS

• Side-mount swivel with extended

range of motion

• Black reinforced thermoplastic

polyester

• Stainless steel swivel locking

hardware included

Hole center spacing: A = 50.8, B = 24.1

Hole size: A = ø 7, B = ø 7.6

SMB30SK

• Flat-mount swivel bracket with extended range of motion

• Black reinforced thermoplastic

polyester and 316 stainless steel

• Stainless steel swivel locking

hardware included

Hole center spacing: A = 50.8

Hole size: A = ø 7, B = ø 18

SMB18UR

• 2-piece universal swivel bracket

• 300 series stainless steel

• Stainless steel swivel locking

hardware included

• Mounting hole for 18 mm sensor

Hole center spacing: A = 25.4, B = 46.7

Hole size: B = 6.9 × 32.0, C = ø 18.3

SMBAMS18P

• Flat SMBAMS series bracket with

18 mm hole for mounting sensors

• Articulation slots for 90+° rotation

• 12-ga. (2.6 mm) cold-rolled steel

Hole center spacing: A = 26.0, A to B = 13.0

Hole size: A = 26.8 × 7.0, B = ø 6.5, C = ø 19.0

SMBAMS18RA

• Right-angle SMBAMS series

bracket with 18 mm hole for

mounting sensors

• Articulation slots for 90+° rotation

• 12-ga. (2.6 mm) cold-rolled steel

Hole center spacing: A = 26.0, A to B = 13.0

Hole size: A = 26.8 × 7.0, B = ø 6.5, C = ø 19.0

Banner Engineering Corp Limited Warranty

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year following the date of shipment. Banner Engineering Corp.

will repair or replace, free of charge, any product of its manufacture which, at the time it is returned to the factory, is found to have been defective during the warranty

period. This warranty does not cover damage or liability for misuse, abuse, or the improper application or installation of the Banner product.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR IMPLIED (INCLUDING, WITHOUT LIMITATION,

ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE), AND WHETHER ARISING UNDER COURSE OF PERFORMANCE,

COURSE OF DEALING OR TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion of Banner Engineering Corp., replacement. IN NO EVENT SHALL BANNER ENGINEERING CORP. BE

LIABLE TO BUYER OR ANY OTHER PERSON OR ENTITY FOR ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES RESULTING FROM ANY PRODUCT DEFECT OR FROM THE USE OR INABILITY TO USE THE PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE, TORT, STRICT LIABILITY, NEGLIGENCE, OR OTHERWISE.

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming any obligations or liabilities relating to any product

previously manufactured by Banner Engineering Corp.

www.bannerengineering.com - tel: 763-544-3164

Loading...

Loading...