Page 1

M-GAGE™ S18M

Vehicle Detection Sensor

Features

• 3-axis magnetoresistive-based technology; senses 3-dimensional changes to the

Earth’s magnetic field caused by the presence of ferrous objects

• Easy sensor installation (see page 4); above- or below-ground mounting options

• Compact, robust one-piece, self-contained sensor package replaces inductive-loop

sensing technology; no external controller needed

• Designed to minimize the effects of temperature swings and destabilizing magnetic

fields

• Sensor learns ambient background and stores settings in non-volatile memory

• Patented technologies

†

Caution . . .

For Factory-Approved

Applications Only

This sensor is to be used

only in factory-approved applications. See

warning on page 2, and list of approved

applications on page 3.

Models

Model Cable*

2 m (6.5')

S18MB

S18MBQ

* 9 m cables are available by adding suffix “W/30” to the model number of any cabled sensor

(e.g., S18MB W/30). A model with a QD connector requires a mating cable; see page 8.

** Consult factory for other output options.

5-conductor

cable

5-pin

Euro-style

QD fitting

Supply

Voltage

10 to 30V dc

Output

Type

Bipolar

NPN/PNP**

target being sensed.

Approved Applications

See page 3 for more details on factory-approved applications

Range

Range varies,

depending on

application and

See Figures 5

and 6.

Car Wash Entry/Exit

WARNING . . .

Never use this product as a sensing device for personnel protection. Doing so could lead to serious injury or death.

This product does NOT include the self-checking redundant circuitry necessary to allow its use in personnel safety applications.

A sensor failure or malfunction can cause either an energized or de-energized sensor output condition. Consult your current Banner Safety

Products catalog for safety products which meet OSHA, ANSI and IEC standards for personnel protection.

†

U.S. patent #6,546,344 B1

Drive-Up Kiosk Overhead Door

Not To Be Used for Personnel Protection

Loading Dock

Printed in USA 02/09 P/N 114430 rev. C

Page 2

M-GAGE™ S18M —

Vehicle Detection Sensor

Overview

The M-GAGE S18M sensor implements a passive sensing technology to detect large

ferrous objects. The sensor measures the change in the Earth’s natural magnetic field

(the ambient magnetic field) caused by the introduction of a ferromagnetic object.

This easy-to-use sensor is extremely robust and is unaffected by dirt and moisture,

making it ideal for demanding outdoor environments. Simple programming

procedures provide flexibility for a variety of applications (see page 5).

Theory of Operation

The sensor uses three mutually perpendicular magnetoresistive transducers. Each

transducer detects magnetic field changes along one axis. By incorporating three

sensing elements, maximum sensor sensitivity is achieved.

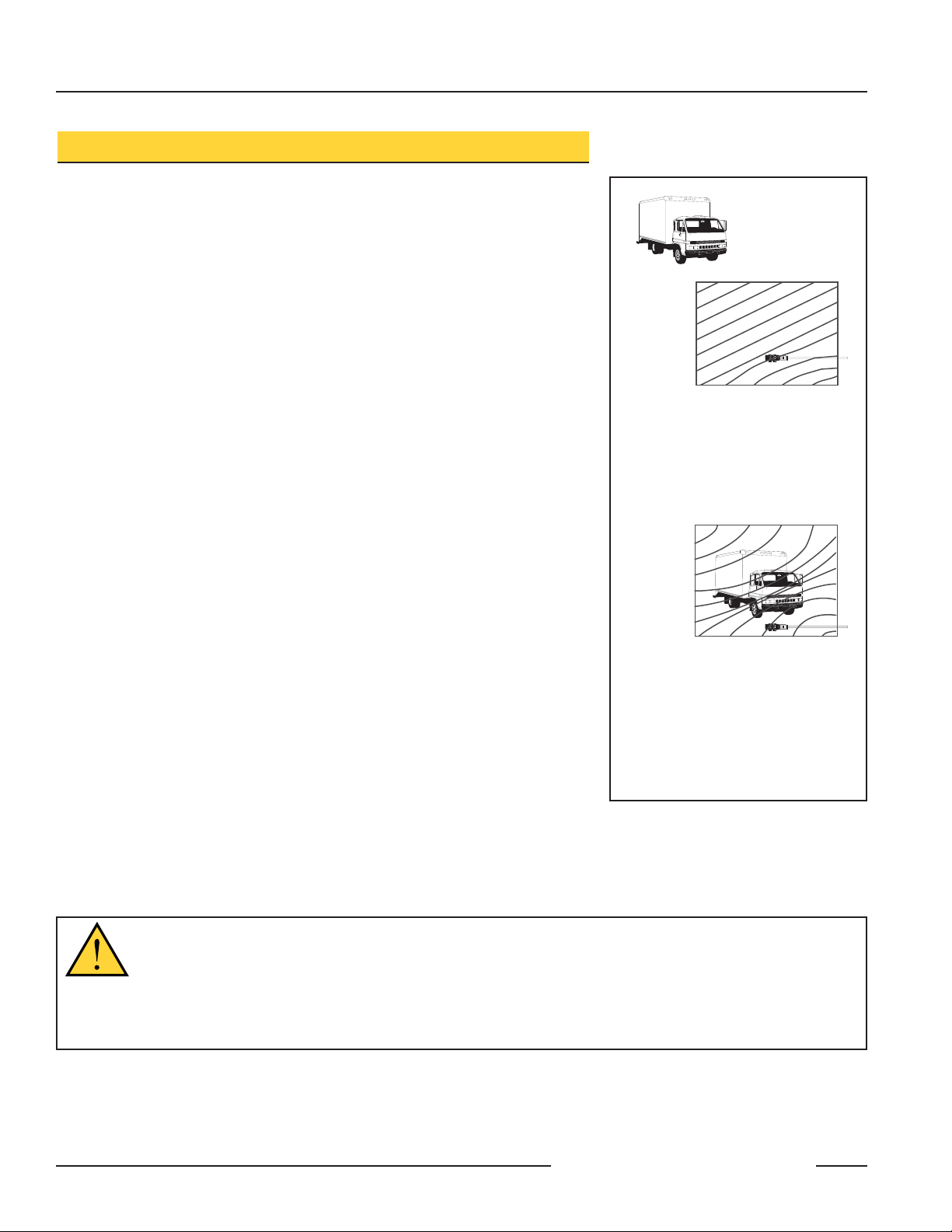

A ferrous object will alter the local (ambient) magnetic field surrounding the object, as

shown in Figure 1. The magnitude of this magnetic field change is dependent both on

the object (its size, shape, orientation, and composition) and on the ambient magnetic

field (its strength and orientation).

During a simple programming procedure, the S18M sensor measures the ambient

magnetic field. When a large ferrous object (for example, a truck, automobile, or

rail car) alters that magnetic field, the sensor detects the magnetic field changes

(anomalies). When the degree of magnetic field change reaches the sensor’s

threshold, the sensor’s discrete outputs switch.

A. Baseline magnetic field, with slight

disturbances caused by permanent

ferrous-metal objects within or near

the sensor, then . . .

Sensor Field of View and Range

The sensor range depends on three variables:

1. The local magnetic environment (including nearby ferrous material)

2. The magnetic properties of the object to be sensed

3. Sensor settings

The S18M can detect changes in the ambient magnetic field in all directions. As with

other sensors, the range will depend on the target. The strong disturbance of a large

ferrous object decreases as distance from the sensor increases, and the magnitude

and shape of the disturbance is dependent on the object’s shape and content.

The sensor can be programmed to react to magnetic field disturbances of greater or

lesser intensity, using two adjustments: background condition and sensitivity level.

Once background condition and sensitivity level are set, and both settings are stored

in non-volatile memory, the sensor is ready to detect the target object.

WARNING . . .

The mechanical opening, braking, and reversing systems of the door will not respond in sufficient time to prevent moving

trucks, cars, or material handling vehicles, even those traveling at low speeds, from coming in contact with the door. In

addition, the detection zone of the product may fluctuate due to changes in the local magnetic environment. All vehicles should

approach doors at speeds that allow the operator to ensure the door is operating properly and in an open position. Failure to follow these

procedures may result in serious injury or death.

Appropriate Use

B. After a large steel target object is

introduced.

The sensor detects the differential

(magnetic strength and orientation)

between fields A and B. If the

differential is greater than the

sensitivity threshold, the sensor’s

outputs conduct.

Figure 1. Magnetic detection overview

Banner Engineering Corp. • Minneapolis, MN U.S.A.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

www.bannerengineering.com • Tel: 763.544.3164

2 P/N 114430 rev. C

www.bannerengineering.com • Tel: 763.544.3164

Page 3

M-GAGE™ S18M —

Vehicle Detection Sensor

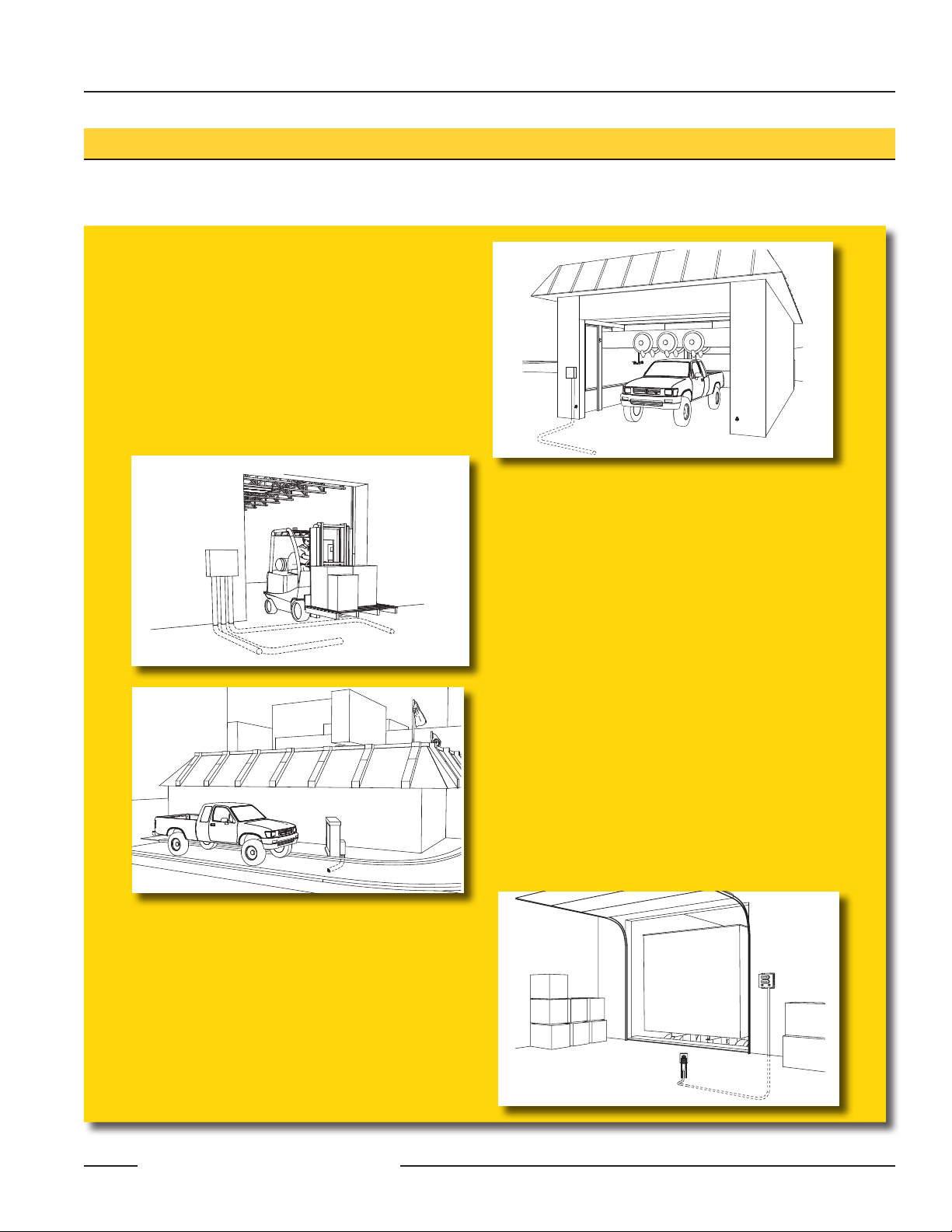

Approved Applications

The M-GAGE sensor provides a direct replacement for inductive-loop systems, and needs no external frequency controller box.

Unique mounting solutions allow an M-GAGE sensor to be replaced easily without disrupting or re-cutting the pavement.

Car Wash Entry/Exit

The Banner M-GAGE vehicle detection sensor will reliably

detect vehicles in and around car wash bays. It will

reliably detect the presence or absence of a vehicle to

provide collision avoidance at the exit of a conveyorized

tunnel, provide an entry or exit-door trigger, or trigger an

undercarriage wash.

Overhead Door

The Banner M-GAGE sensor can be used to trigger the

opening and closing of high-traffic internal overhead doors.

Mounted in the floor, it will reliably detect forklifts or trucks

as they approach the doors. Banner’s applications engineers

are available to help determine proper sensor placement for

specific door-trigger applications.

Drive-Up Kiosk

The Banner M-GAGE sensor reliably detects vehicles at

drive-through systems or other drive-up kiosks. It will

reliably detect a vehicle to trigger personnel that a vehicle

is present, and to initiate a timing system.

Loading Dock

The Banner M-GAGE sensor provides multiple advantages

for loading docks. It will reliably detect the presence of

a vehicle as it backs into a dock, triggering a light on the

interior of the building to notify the dock attendant that a

vehicle is in position for loading/unloading. The M-GAGE

can also be used to trigger dock/ramp leveling systems.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

P/N 114430 rev. C 3

www.bannerengineering.com • Tel: 763.544.3164

Page 4

M-GAGE™ S18M —

Vehicle Detection Sensor

Below-Grade Installation

Materials

• M-GAGE S18M Sensor

• SMP1 Conduit Plug

• 2" Schedule 80 rigid PVC conduit (1.5" may be used if there

is only one 90° bend); total length and number of elbows

depend on installation layout

• 2" (or 1.5") rigid PVC end cap (1 per installation)

• ¾" I.D. flexible, liquid-tight, non-metallic conduit (same

length as PVC conduit used for application)

• DPB1 Portable Programming Box

¾" Flex

1.

Conduit

SMP1 Flex

Conduit Plug

Figure 2. Below-grade installation

2.

2" PVC

Conduit

Procedure

1) Lay out 2" (or 1.5") PVC in the desired configuration. For

the best sensor performance, the sensing location (located

at the end of the conduit run) should be 6" below the final

surface. Provide an access point where the PVC comes

above grade (where the sensor and flex conduit can be fed

in or pulled out, as required).

3.

6" Below

Grade

Above-Grade Installation

Materials

• M-GAGE S18M Sensor

• SMP2 Conduit Plug

• ¾" Schedule 40 PVC electrical conduit; total length and

number of elbows depend on installation layout

• Electrician’s fishtape

• Silicone adhesive

• DPB1 Portable Programming Box

1.

Figure 3. Above-grade installation

¾" PVC Conduit

SMP2 Conduit Plug

Procedure

1) Mount the PVC electrical conduit from the sensing point

to the control panel. Plastic conduit should be used for at

least the first 6.1 m (20') from the sensing point; metal or

flexible conduit may be used the remainder of the distance.

2) Thread the S18M sensor into the threads of the SMP2

conduit plug.

3) Feed the fishtape into the conduit, from the control panel

towards the sensing point.

2.

2) Secure the end cap to the PVC, at the sensing location.

3) Measure the overall length of the PVC run, from the

sensing location to the control panel.

4) Cut a section of ¾" flex conduit to span the total distance

from the control panel to the sensing location.

5) Thread the sensor into the SMP1 conduit plug. Feed the

sensor cable into the flex conduit, until the sensor and plug

are snugly seated in the end of the flex conduit.

6) Feed the flex conduit by hand, sensor-end first, into the

4) Pull the sensor cable back through the conduit, until the

sensor almost reaches the end of the plastic conduit. Do

NOT pull sensor into conduit.

5) Apply a small amount of silicone adhesive to the outside of

the conduit at the sensing point end.

6) Press the conduit plug into the end of the conduit.

7) After the sensor is configured (see following section), wire

the sensor into the control device and power supply per the

wiring diagram on page 8.

PVC access point until the sensor reaches the PVC end cap.

7) Secure the remaining flex conduit from the access point to

the control cabinet.

8) After the sensor is configured (see following section), wire

the sensor into the control device and power supply per the

wiring diagram on page 8.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

4 P/N 114430 rev. C

www.bannerengineering.com • Tel: 763.544.3164

Page 5

PC

IR

Power ON LED

Configuration/

Output ON LED

Push Button

Brown Blue Gray White or Black

M-GAGE™ S18M —

Vehicle Detection Sensor

Sensor Configuration

For most applications, configure the M-GAGE sensor remotely, via the DPB1 Portable Programming

Box, which provides programming access to an underground or otherwise inaccessible sensor. For

optimum performance, the sensor must be fixtured so that it will not move either during or following

configuration.

Configuration using the sensor’s built-in push button is useful primarily for demonstration and

troubleshooting purposes.

Configuration via the DPB1 Portable Programming Box

Set Background Condition (No Vehicle Present)

Wire the M-GAGE sensor to the DPB1 as shown in Figure 4. Remove all vehicles and all other metal

objects temporarily in the sensing area, before setting the background condition.

Configuration Result

• “Click” the DPB1 TEACH push button once. • Sensor learns background.

Set

Background

Set Sensitivity Level (6 sensitivity levels; level 1 least sensitive, level 6 most sensitive)

Configuration Result

• “Double-click” the DPB1 TEACH push button. • Output LED flashes every 2 seconds;

Mode

Sensitivity

• To increase the sensitivity in increments, “click” the

push button again;

continue until desired

sensitivity level is reached.

Adjust

Sensitivity

• “Double-click” push button

to save setting.

• Drive a vehicle past/over sensor to trip the output;

verify Output LED comes ON as expected. Use a

small/light vehicle to ensure larger vehicles will be

Test

detected later.

Operation

• Adjust the sensitivity as needed.

• Disconnect DPB1 and hardwire sensor to

permanent power supply/output device (usersupplied). See page 8.

Operation

Prepare for

• Output indicator LED flashes

approximately 12 times, while background

is taught.

• Sensor returns to RUN mode.

sensor is at sensitivity level 1.

(When using the DPB1, the sensor always

reverts to sensitivity level 1.)

• Output LED will flash from 1 to 6 times

every 2 seconds to indicate sensor’s

sensitivity level (e.g., twice to indicate

level 2).

• Sensor returns to RUN mode

Set Push Button Enable/Disable

Configuration Result

• “Four-click” the DPB1 TEACH button to enable or

disable the push button.

Push Button

“Single-Click” to Set Background

Condition

“Double-Click” to Set Sensitivity

“Four-Click” to Enable/Disable

Push Button

Figure 4. Using the model DPB1 portable

programming box

Banner Engineering Corp. • Minneapolis, MN U.S.A.

P/N 114430 rev. C 5

www.bannerengineering.com • Tel: 763.544.3164

Enable/Disable

Configuration via the Sensor Push Button

Follow the instructions in the table above, with the following exceptions.

(For demonstration and troubleshooting only.)

Set Background Condition (No Vehicle Present):

• Press and hold the push button for 2 seconds, until the Output LED turns red.

• Release, and then “click” the push button once.

Set Sensitivity Level:

• Press and hold the push button for 2 seconds, until the Output LED turns red.

• Release, and then quickly “double-click” the push button. Increase the sensitivity by increments as

described above.

• When the sensor is set to desired sensitivity level, double-click push button to return sensor to RUN

mode.

• Sensor toggles between enable/disable

settings and returns to RUN mode

Page 6

M-GAGE™ S18M —

Distance

from vehicle

M-GAGE

M-GAGE

NOTE: Sensor orientation

is not a factor.

To p View

Side View

0

6 m (19') vehicle depicted

To p View

Side View

0.25 m

(0.8')

M-GAGE

M-GAGE

NOTE: Sensor orientation

is not a factor.

Distance from

the vehicle

1.2 m

(4')

-1.2 m

(-4')

2.4 m

(8')

-2.4 m

(-8')

3.7 m

(12')

4.9 m

(16')

6.1 m

(20')

7.3 m

(24')

Distance from Vehicle Front Bumper

Excess Gain (Sensitivity Level 5)

0.6 m

(2')

-0.6 m

(-2')

1.2 m

(4')

-1.2 m

(-4')

1.8 m

(6')

-1.8 m

(-6')

2.4 m

(8')

-2.4 m

(-8')

3.1 m

(10')

3.7 m

(12')

4.3 m

(14')

4.9 m

(16')

5.5 m

(18')

6.1 m

(20')

6.7 m

(22')

7.3 m

(24')

0 m

0

1

2

3

4

5

6

2.5 m

(8.0')

2.0 m

(6.4')

1.5 m

(4.8')

1.0 m

(3.2')

0.5 m

(1.6')

0

Distance from Vehicle Side

Excess Gain

(Sensitivity Level 5)

0

1

2

3

4

5

6

7

8

Vehicle Detection Sensor

Excess Gain

Typical Target Excess Gain Curves

Once the sensor has been securely mounted and is configured, it is ready to operate.

The following two example applications show typical responses for the M-GAGE

sensor.

Example 1 describes mounting the M-GAGE 1 meter above the ground to sense an

automobile; see Figure 5. The graph in Figure 5 shows the excess gain for a typical

car. Excess gain is a measure of the amount of “extra” signal detected by the sensor

over and above the level needed to detect the target. This example assumes a level

5 sensitivity threshold. The table at right compares the change in excess gain if the

sensitivity level changes.

If the sensitivity is at level 6, then the excess gain at a given distance would be

1.3 times larger than for a level 5 sensitivity. Conversely, if the sensitivity threshold is

level 1, then the excess gain would be one third as big as for level 5.

Example 2 (see Figure 6) illustrates a typical vehicle passing over a sensor mounted

underground. Note that excess gain is greatest when the bulk of the vehicle (the rear

axle) is positioned directly over the sensor.

Excess Gain vs Sensitivity Level

(Assumes Level 5)

Level Excess Gain Multiplier

1

2

3

4 0.66

5*

6

*Factory default setting

0.33

0.4

0.5

1.0

1.3

Figure 5. Application example 1: sensor mounted 1 meter (3.2') above ground

Figure 6. Application example 2: sensor mounted 0.25 meters (0.8') below ground

6 P/N 114430 rev. C

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 7

M-GAGE™ S18M —

39.8 mm

(1.57")

76.9 mm

(3.03")

18.0 mm

(0.71")

37.1 mm

(1.46")

6.0 mm

(0.24")

27 mm

(1.06")

66.8 mm

(2.63")

39.8 mm

(1.57")

Specifications

Vehicle Detection Sensor

Supply Voltage

Sensing Range

Sensing Technology

Supply Protection Circuitry

Output Configuration

Output Protection

Output Ratings

Output Response Time

Delay at Power-Up

Temperature Effect

Adjustments

Indicators Two indicators (see Figure 4 and instructions on page 5):

Remote TEACH Input

Construction Threaded Barrel: Thermoplastic polyester Push Button Housing: ABS/PC

Operating Conditions

Connections

Environmental rating

Vibration and Mechanical

Shock

Certifications

10 to 30V dc (10% max. ripple) at 43 mA, exclusive of load

Above +50°C, supply voltage is 10 to 24V dc (10% max. ripple)

See Figures 5 and 6.

Passive 3-axis magnetoresistive transducer

Protected against reverse polarity and transient voltages

Two SPST solid-state outputs conduct when object is sensed; one NPN (current sinking) and one PNP (current

sourcing)

Protected against short-circuit conditions

100 mA maximum (each output)

NPN saturation: < 200 mV @ 10 mA and < 600 mV @100 mA OFF-state leakage current: < 200 microamps

PNP saturation: < 1.2V @ 10 mA and < 1.6V @100 mA OFF-state leakage current: < 5 microamps

20 milliseconds

0.5 seconds

< 0.5 milligauss / °C

Configuration of Background Condition and Sensitivity Level may be set using the sensor’s push button or

remotely via the portable programming box (see page 5)

Power Indicator (Green)

Configuration/Output Indicator (Red/Yellow)

Impedance 12K ohms

Push Button: Santoprene Lightpipes: Acrylic

-40° to +70° C (-40° to +158° F); 100% max. rel. humidity

2 m or 9 m shielded 5-conductor (with drain) PVC jacketed attached cable or 5-pin Euro-style quick-disconnect

(see page 8 for quick-disconnect cable options)

Leak proof design is rated IEC IP67; NEMA 6P

All models meet Mil. Std. 202F requirements method 201A (vibration: 10 to 60Hz max., double amplitude 0.06",

maximum acceleration 10G). Also meets IEC 947-5-2: 30G 11 ms duration, half sine wave.

Dimensions

Cabled Model Quick-Disconnect Model

P/N 114430 rev. C 7

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 8

M-GAGE™ S18M —

bn

Remote Program

bu

wh

bk

gy

+

10 - 30V dc

–

Load

Load

100 mA max. load

Shield

bn

Shield

Remote Program

bu

wh

bk

gy

+

10 - 30V dc

–

Load

Load

100 mA max. load

White Wire

Blue Wire

Black Wire

Brown Wire

Gray Wire

Pin-out

PC

IR

O

U

T

P

U

T

R

E

M

O

T

E

PROGRAM

TEACH

PORTABLE

PROGRAMMING BOX

15-24 VDC

COMM.

ACTIVE

POWER

NPNPN

P

A B C D

+

SENSOR

VOLTAGE

-

24.1 mm

(0.95")

26.2 mm

(1.03")

Ø 33.0 mm

(1.30")

38.1 mm

(1.50")

M12 x 1

ø 15 mm

44 mm

max.

38 mm

max.

M12 x 1

ø 15 mm

38 mm

max.

Warranty: Banner Engineering Corporation warrants its products to be free from defects for a period

of one year. Banner Engineering Corporation will repair or replace, free of charge, any product of its

manufacture found to be defective at the time it is returned to the factory during the warranty period.

This warranty does not cover damage or liability for the improper application or installation of Banner

products. This warranty is in lieu of any other warranty either expressed or implied.

Vehicle Detection Sensor

Hookups

Cabled Model

Model Description

SMP1

SMP2

Conduit Plug for

used for below-grade installations

Conduit Plug for

for above-grade installations

¾" flexible conduit,

¾" rigid conduit, used

Quick-Disconnect Model

Accessories

Pin-Out

Handheld Portable Programming Box,

DPB1

used for configuring sensor when

push button is not accessible

Quick-Disconnect Cables

Style Model Length Connector Style Model Length Connector

5-Pin

Euro,

Straight

with

MQDEC2-506

MQDEC2-515

MQDEC2-530

2 m (6.5')

5 m (15')

9 m (30')

shield

P/N 114430 rev. C

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN USA 55441 • Phone: 763.544.3164 • www.bannerengineering.com • Email: sensors@bannerengineering.com

5-Pin

Euro,

Right-

angle

with

shield

MQDEC2-506RA

MQDEC2-515RA

MQDEC2-530RA

2 m (6.5')

5 m (15')

9 m (30')

Loading...

Loading...