Page 1

SSA-EB Series Emergency Stop Buttons

111880

Datasheet

• Push-to-stop, twist-to-release operation

• Rugged, modular design; easy assembly and

installation

• Kits available for easy selection

• Choice of metal or plastic button base with or without

enclosure; all kits include disc label with “Emergency

Stop” legend

• Choice of normally closed (safety) or combination

normally closed/normally open (non safety) contacts

• Latching design complies with ISO 13850; direct

Figure 1. SSA-EBM-xxE Series

with Enclosure

Figure 2. SSA-EBP-xxE Series

with Enclosure

(positive) opening operation per IEC 60947-5-1

Models

SSA-EBM-02L

SSA-EBM-11L

SSA-EBM-12L

SSA-EBP-02L

SSA-EBP-11L

SSA-EBP-12L

SSA-EBM-02E

SSA-EBM-11E

SSA-EBM-12E

SSA-EBP-02E

SSA-EBP-11E

SSA-EBP-12E

Button Base

Material

Metal

Plastic

Metal

Plastic

Contacts

2 normally closed

1 normally closed and 1

normally open

2 normally closed and 1

normally open

2 normally closed

1 normally closed and 1

normally open

2 normally closed and 1

normally open

2 normally closed

1 normally closed and 1

normally open

2 normally closed and 1

normally open

2 normally closed

1 normally closed and 1

normally open

2 normally closed and 1

normally open

Enclosure

Included

No

Yes

WARNING: Not a Safeguarding Device

An Emergency Stop Device is not considered a safeguarding device because it requires an

overt action by an individual to stop machine motion or hazards.

A safeguarding device limits or eliminates an individual's exposure to a hazard without action by the

individual or others. Because an individual must actuate the device for it to function, these devices do

not fit the definition of a safeguarding device and cannot be substituted for required safeguarding. Refer

to the relevant standards to determine those requirements.

Original Document

111880 Rev. A

12 February 2014

Page 2

SSA-EB Series Emergency Stop Buttons

Important -- Read This First!

The user is responsible for satisfying all local, state, and national laws, rules, codes, and regulations relating to

the use of this product and its application. Banner Engineering Corp. has made every effort to provide complete

application, installation, operation, and maintenance instructions. Please direct any questions regarding the use or

installation of this product to the factory applications department at the telephone numbers or address found at http://

www.bannerengineering.com.

The user is responsible for making sure that all machine operators, maintenance personnel, electricians, and

supervisors are thoroughly familiar with and understand all instructions regarding the installation, maintenance, and use of

this product, and with the machinery it controls. The user and any personnel involved with the installation and use of this

product must be thoroughly familiar with all applicable standards, some of which are listed within the specifications.

Banner Engineering Corp. makes no claim regarding a specific recommendation of any organization, the accuracy or

effectiveness of any information provided, or the appropriateness of the provided information for a specific application.

Applicable U.S. Standards Applicable International Standards

ANSI B11 Standards for Machine Tools Safety

Contact: Safety Director, AMT – The Association for Manufacturing

Technology, 7901 Westpark Drive, McLean, VA 22102, Tel.:

703-893-2900

ANSI NFPA 79 Electrical Standard for Industrial Machinery

Contact: National Fire Protection Association, 1 Batterymarch

Park, P.O. Box 9101, Quincy, MA 02269-9101, Tel.: 800-344-3555

ANSI/RIA R15.06 Safety Requirements for Industrial Robots and

Robot Systems

Contact: Robotic Industries Association, 900 Victors Way, P.O. Box

3724, Ann Arbor, MI 48106, Tel.: 734-994-6088

ISO 12100-1 & -2 (EN 292-1 & -2) Safety of Machinery – Basic

Concepts, General Principles for Design

IEC 60204-1 Electrical Equipment of Machines Part 1: General

Requirements

ISO 13849-1 (EN 954-1) Safety-Related Parts of Control Systems

ISO 13856-1 (EN1760-1), Safety of Machinery – Pressure-

Sensitive Protective Devices

Contact: Global Engineering Documents, 15 Inverness Way East,

Englewood, CO 80112-5704, Tel.: 800-854- 7179

Overview

Models SSA-EB series are metal or plastic “mushroom-style” mechanical emergency stop buttons, available with or without

a compact enclosure housing, to provide emergency stop actuation. When the button is armed, the switch’s normally

closed contacts are closed and its normally open contacts, if present, are open. When the button is pushed, the switch’s

normally closed contacts open and its normally open contacts close. The contacts remain in this condition until the push

button is manually rearmed. To manually rearm, twist the push button.

These emergency stop buttons are not safeguarding devices. They do not automatically protect personnel from injury.

Installation

Mechanical Installation

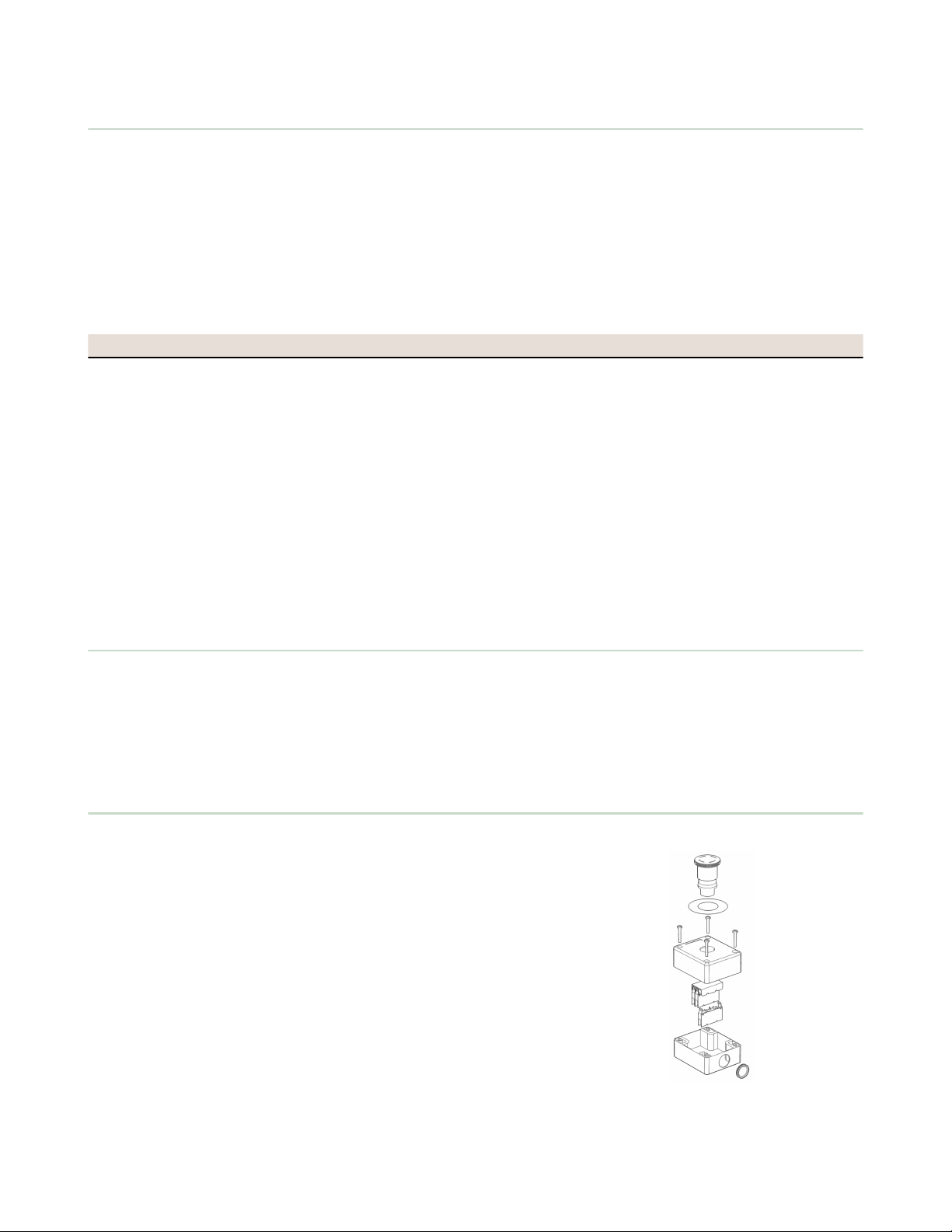

1. Metal models: Latch the push button onto the mounting adapter

by rotating it.

2. All Models: Attach the mounting adapter to the mounting surface

using the incorporated screws. (Tmax = 7.14 in-lb/0.8 Nm).

Snap the auxiliary contacts onto the mounting adapter. Use the

disc label with legend at every switch per appropriate standards

3. Mount the E-Stop button on a rigid surface that is easily

accessible and visible to operators and other personnel. Refer to

appropriate standards for recommendations on number and

placement.

Electrical Installation

To access the wiring chamber, remove four screws and the cover.

Conduit mounting via removable rubber plug or knockout.

Figure 3. Assembly

2 www.bannerengineering.com - tel: 763-544-3164 P/N 111880 Rev. A

Page 3

SSA-EB Series Emergency Stop Buttons

Maintenance

At machine set up, a Designated Person

1

should test each emergency stop push button for proper machine shutdown

response.

The Designated Person should check the emergency stop buttons for proper operation, physical damage, button looseness,

and excessive environmental contamination. This should take place on a periodic schedule determined by the user, based

on the severity of the operating environment and the frequency of switch actuations

Adjust, repair, or replace components as needed. If inspection reveals contamination on the switch, thoroughly clean the

switch and eliminate the cause of the contamination. Replace the switch and/or appropriate components when any parts or

assemblies are damaged, broken, deformed, or badly worn; or if the electrical/mechanical specifications (for the

environment and operating conditions) have been exceeded.

Always test the control system for proper functioning under machine control conditions after performing maintenance,

replacing the emergency stop device, or replacing any component of the device.

Replacement Parts

8-LP2T-B6644

• 22.5 mm plastic button (mounting

adapter sold separately)

• Twist to release, mechanical latching

ISO 13850 (EN 418) compliant

• Diameter 40 mm (without mounting

adapter)

8-LM2T-B6644

• 22.5 mm metal button (mounting

adapter sold separately)

• Twist to release, mechanical latching

ISO 13850 (EN 418) compliant

• Diameter 40 mm (without mounting

adapter).

8-LM2T-C01

• Normally closed (N.C.) positively

driven contact element

• Direct (positive) opening operation

per IEC/EN 60947-5-1

8-LM2T-C10

Normally open (N.O.) auxiliary contact

element

8-LM2T-AU115

• 60 mm diameter

8-LM2T-AU120

Metal mounting adapter for metal button

LPZP1A5

• Compact size - 70mm x 70mm x 56mm (2.7” x 2.7” x 2.2”)

• One 22mm hole (with key way) for installation of emergency stop palm/push button

• Maximum of three contact blocks

• Polycarbonate construction

• Wire entry via three sides (M16, M20 or M25) or the bottom (M16)

• Environmental rating: IP66, IP67 and IP69K (with proper installation and rated button)

• Mounting hole location (x4) - 45mm x 58mm

1

A Designated Person is identified in writing by the employer as being appropriately trained to perform a specified checkout procedure. A Qualified Person

possesses a recognized degree or certificate or has extensive knowledge, training, and experience to solve problems relating to the emergency stop

installation (reference ANSI B30.2).

P/N 111880 Rev. A www.bannerengineering.com - tel: 763-544-3164 3

• Non-adhesive plastic legend with

“Emergency Stop” inscription

Page 4

39.9 mm dia

[1.57”]

56 mm

[2.2”]

70 mm

[2.76”]

104.9 mm

[4.13”]

58 mm

[2.28”]

45 mm

[1.77”]

4.3 mm dia

[0.1693”]

70 mm

[2.76”]

40

[1.6"]

10

[0.4"]

50

[1.97"]

43

[1.7"]

23

[0.9"]

1-6 Max

[0.04 - 0.24"]

ADD-ON

Elements

SSA-EB Series Emergency Stop Buttons

Specifications

Mechanical Life

300,000 operations

Operating Force

0.8 kg

Environmental rating

IP65; NEMA 4, 13

Operating Temperature

–25 °C to 60 °C (–13 °F to 140 °F)

European Rating

Utilization categories: AC15 and DC13

Ui = 690 V ac

Ith = 10 A

UL designation = A 600 Q600

Mechanical Life

1,000,000 operations

Connections

(1 or 2) 12 AWG (2.5 mm²) maximum wire size

Construction

Polyamide and polycarbonate

Emergency Stop Push Button

Mounting Adapter

Plastic button: The adapter is fixed to the mounting surface using

incorporated screws (Tmax = 0.6 Nm)

Metal button: The adapter is fixed to the mounting surface using

incorporated screws (Tmax = 0.8 Nm)

Construction

Plastic parts: Polyamide and polycarbonate

Metal parts: Aluminum and zinc alloy

Certifications

Compliant with EN/IEC 60497-1; -5-1

Contacts

Environmental rating

IP20

Operating Temperature

IP20

Operating Temperature

–25 °C to 60 °C (–13 °F to 140 °F)

Certifications

Compliant with EN/IEC 60497-1; -5-1

Dimensions

Figure 4. SSA-EBM-xxE and EBP-xxE Series E-Stop Buttons

Figure 5. SSA-EBM-xxL and EBP-xxL Series E-Stop Buttons

4 www.bannerengineering.com - tel: 763-544-3164 P/N 111880 Rev. A

Page 5

SSA-EB Series Emergency Stop Buttons

Banner Engineering Corp Limited Warranty

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year following

the date of shipment. Banner Engineering Corp. will repair or replace, free of charge, any product of its manufacture

which, at the time it is returned to the factory, is found to have been defective during the warranty period. This warranty

does not cover damage or liability for misuse, abuse, or the improper application or installation of the Banner product.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR

IMPLIED (INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE), AND WHETHER ARISING UNDER COURSE OF PERFORMANCE, COURSE OF DEALING OR

TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion of Banner Engineering Corp., replacement. IN NO

EVENT SHALL BANNER ENGINEERING CORP. BE LIABLE TO BUYER OR ANY OTHER PERSON OR ENTITY FOR

ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL OR

SPECIAL DAMAGES RESULTING FROM ANY PRODUCT DEFECT OR FROM THE USE OR INABILITY TO USE THE

PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE, TORT, STRICT LIABILITY,

NEGLIGENCE, OR OTHERWISE.

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming any

obligations or liabilities relating to any product previously manufactured by Banner Engineering Corp.

www.bannerengineering.com - tel: 763-544-3164

Loading...

Loading...