Page 1

MAXI-AMP® System

Stand-alone sensor contr ol modules

Product

Line

Specifications

Versatile, cost-effective sensor control modules: models

•

available for use with most Banner photoelectric sensors

Power supply, photoelectric amplifier (CD and CM

•

Series), programmable timing logic (CD5, CM5, and CL5

models), and output relay in a single, compact plug-in

module

•

CD5, CL5, and CM5 models include 12 selectable delay,

pulse, and latch timing logic functions

(single or dual functions)

•

All models have 5-amp SPDT electromechanical relay

output (solid-state switch optional); some models offer

additional solid-state dc switch (see table, page 2)

Printed in USA P/N 32882

Page 2

™

MAXI-AMP System

Stand-alone Sensor Control Modules

Banner MAXI-AMPs are the most versatile and cost-effective

sensor control modules available anywhere. MAXI-AMP system

modules combine power supply, photoelectric amplifier (CD and

CM series), programmable timing logic (CD5, CM5, and CL5

models), and output relay in a single, compact plug-in module. This

integrated stand-alone design saves both the expense of a separate

control chassis and a substantial amount of control panel space.

MAXI-AMP modules are powered directly by AC line voltage.

Models are available for either 120V ac or 220/240V ac operation.

CD Series MAXI-AMP modules accept input signals from SP12

Series preamplified remote sensors. The preamplified design of

this system produces exceptionally high noise immunity.

CM Series MAXI-AMPs are designed to work with the popular line

of Banner high-performance modulated remote sensors. The CR

Series is a low-gain version of the CM Series, and is designed for

use with the SP100 Series miniature remote sensors.

CL Series MAXI-AMP modules accept input signals from any

MODULE

MODEL

CD3RA

CD3RB

CD5RA

CD5RB

CM3RA

CM3RB

CM5RA

CM5RB

CL3RA

CL3RB

CL5RA

CL5RB

CI3RC

CP12RC

CP12C

SUPPLY

VOLTAGE

105 to 130V ac, or

12 to 28V dc

210 to 250V ac, or

12 to 28V dc

105 to 130V ac, or

12 to 28V dc

210 to 250V ac, or

12 to 28V dc

105 to 130V ac, or

12 to 28V dc

210 to 250V ac, or

12 to 28V dc

105 to 130V ac, or

12 to 28V dc

210 to 250V ac, or

12 to 28V dc

105 to 130V ac, or

12 to 28V dc

210 to 250V ac, or

12 to 28V dc

105 to 130V ac, or

12 to 28V dc

210 to 250V ac, or

12 to 28V dc

105 to 130V ac

or

210 to 250V ac

USED WITH

(INPUT)

CD Series MAXI-AMP

modules contain a

modulated photoelectric

amplifier for use with

SP12 Series preamplified

remote sensors

(pp. 7-9).

CM Series MAXI-AMP

modules contain a

modulated photoelectric

amplifier for use with the

full complement of

Banner high performance modulated remote

sensors (pp. 13-17).

CL Series modules

accept signals from any

Banner DC sensor or

module with NPN

(current sinking) output.

SMI912 series intrinsically

safe sensors.

Supplies 400mA to power

MAXI-AMP modules

and/or other 10-30V dc

sensing devices.

Banner dc module and most dc self-contained sensors.

CI Series MAXI-AMPs provide the power supply, current ampli-

fier, and output device for an SMI912 Series intrinsically safe

sensor. CI Series modules are covered in data sheet P/N 03461.

CD5, CM5, and CL5 models include a multi-function timing logic

circuit, which is easily programmed for twelve of the most popular

and useful delay, pulse, and latch functions. MAXI-AMPs offer the

choice of either single or dual timing functions in the same module.

MAXI-AMPs offer a 5-amp SPDT electromechanical relay output.

Solid-state switches are available as an option. CD3, CM3 and CL3

models offer an additional solid state dc switch.

®

MAXI-AMPs are contained in a tough NORYL

housing which

measures a compact 1.6 x 2.3 x 4". Electrical connections are made

via any standard 11-pole round-pin relay socket (model RS-11).

All MAXI-AMP system modules (except model CI3RC) are CSA

certified and UL recognized.

OUTPUT

CONFIGURATION

SPDT electromechanical relay, plus NPN

transistor solid-state

switch

SPDT

electromechanical relay

SPDT electromechanical relay, plus NPN

transistor solid-state

switch

SPDT

electromechanical relay

SPDT electromechanical relay, plus NPN

transistor solid-state

switch

SPDT

electromechanical relay

SPDT E/M relay, isolated solid state DC switch

SPDT electromechanical relay

No output device

(power supply only)

LOGIC

FUNCTION(S)

ON/OFF

(output follows input)

Selection of 12 programmable functions

including delay, pulse,

limit, cycle, and latch

ON/OFF

(output follows input)

Selection of 12 programmable functions

including delay, pulse,

limit, cycle, and latch

ON/OFF

(output follows input)

Selection of 12 programmable functions

including delay, pulse,

limit, cycle, and latch

ON/OFF

(output follows input)

No logic function

(power supply only)

REFER TO

PAGES ...

See pages

3-9

See pages

10-17

See pages

18-21

See data sheet 03461

See page 22

2

Page 3

™

MAXI-AMP CD Series

Programmable Modulated Amplifier and Control Modules

for use with SP12 Series Preamplified Remote Photoelectric Barrel Sensors

Modulated photoelectric amplifier, power supply,

•

output relay, and versatile timing logic (CD5 models)

in one compact, stand-alone package

120 or 240V ac or 12-28V dc operation; requires only

•

the addition of a Banner SP12 preamplified opposed

mode sensor pair to create a powerful sensing system

CD5 models are easily programmed for any of twelve

•

delay, one-shot, and latch functions (either single or

dual timing); interrogation schemes are possible

using auxiliary input

Exceptionally high immunity to ambient light and

•

electrical noise; no false pulse on power-up

Rugged, 15-turn potentiometers for precise timing

•

and sensitivity adjustment; tough Noryl

Includes Banner's exclusive AID™ alignment system

•

CD Series MAXI-AMP modules combine power supply, modulated

photoelectric amplifier, timing logic (in CD5 models) and output

switch in a single compact, cost-saving module. CD Series modules

work together with Banner SP12 Series preamplified remote sensors.

These sensors offer small size and high power, and are built to operate

in highly demanding sensing environments. Their preamplified design

gives them exceptionally high immunity to electrical noise (see page 7

for further information). MAXI-AMP modules themselves are also

ruggedly built for dependable industrial duty.

CD Series MAXI-AMP modules contain a state-of-the-art Banner

CMOS modulator/demodulator/amplifier circuit that offers high immunity to both ambient light and electrical interference plus reliable

sensor performance. All models have Banner's exclusive, patented

Alignment Indicating Device (AID™) system, which lights an LED

indicator whenever the receiver sees a "light" condition, and pulses the

LED at a rate proportional to the received light signal strength. MAXIAMP modules operate from a variety of voltages (see tables at right).

All CD Series modules are programmable for LIGHT or DARK operate. Module input response time may be set at either 1.5 or 15 milliseconds. The 15-millisecond response mode offers maximum sensing

power (excess gain) with SP12 Series sensors. CD Series modules also

feature selectable sensor modulation frequencies ("A" and "B"). This

makes it possible to operate two high-powered SP12 Series sensor pairs

using different modulation frequencies (at the same response time

setting) in close proximity to each other without optical crosstalk.

CD5 models include a versatile multi-function timing logic circuit that

is programmable for 12 popular and useful delay, one-shot, and latch

functions. Each timing function has a choice of three time ranges.

Timing and sensitivity adjustments use rugged 15-turn potentiometers

for very accurate settings. CD Series module circuit design prevents

false outputs on system power-up.

The output circuit for CD3A, 3B, 5A, and 5B modules consists of two

SPST solid-state switches: one for ac loads of up to 250V ac (3/4 amp),

and a second for dc loads of up to 30V dc (50 mA). Models CD5RA

and CD5RB have a 5-amp SPDT electromechanical relay. CD3RA and

CD3RB modules have a 5-amp SPDT electromechanical relay plus an

NPN transistor solid-state switch. For more information on output

circuit load capability, refer to the tables (right) and the Specifications

section on the next page.

®

housing

MAXI-AMP™ CD Series amplifier and control modules are

designed to operate with SP12 Series

sensors (foreground, see page 7).

MODEL

CD3RA

CD3RB

CD5RA

CD5RB

MODEL

CD3A

CD3B

CD5A

CD5B

SUPPLY

VOLTAGE

105 to 130V ac, or

12 to 28V dc

210 to 250V ac, or

12 to 28V dc

105 to 130V ac, or

12 to 28V dc

210 to 250V ac, or

12 to 28V dc

SUPPLY

VOLTAGE

105 to 130V ac, or

12 to 28V dc

210 to 250V ac, or

12 to 28V dc

105 to 130V ac, or

12 to 28V dc

210 to 250V ac, or

12 to 28V dc

Generalized Hookup: models with solid-state output

Isolated

solid-state

contacts:

DC load

AC load

Load common

AC

Supply

4

5

6

7

8

CD3A

CD3B

CD5A

CD5B

SPDT electromechanical

relay, plus

NPN transistor

solid-state

switch

SPDT electromechanical

relay (5 amp

contact rating)

SPST solidstate contact

for switching

AC loads up

to 250V ac

and 3/4 amp,

plus solidstate contact

for switching

DC loads up

to 30V dc and

up to 50mA.

3

2

1

11

10

9

LOGICOUTPUT

ON/OFF

12

timing

functions

LOGICOUTPUT

ON/OFF

12

timing

functions

LED +

LED -

Common

PT PT +

Auxiliary

(see table)

3

Page 4

MAXI-AMP™ CD Series Modules Specifications

SUPPLY VOLTAGE: Models CD3(R)A, CD5(R)A: 105 to 130V ac,

50/60Hz (4 VA), or 12 to 28V dc* at 70mA. Models CD3(R)B,

CD5(R)B: 210 to 250V ac, 50/60Hz (4 VA), or 12 to 28V dc* at 70mA.

*NOTE: do not connect ac power when using external dc power.

OUTPUT CONFIGURATION:

CD3A, CD3B, CD5A, CD5B: Two solid-state SPST switches, one for

ac loads of up to 250V ac and up to 3/4 amp, the other for dc loads of up

to 30V dc and up to 50mA. CD3A and CD3B also have a logic level

current sinking NPN transistor switch at pin #9, maximum load 20mA

at 12V dc max.

CD3RA and CD3RB: SPDT electromechanical relay (see specifications, below) plus an NPN transistor solid-state logic-level dc switch (at

pin #9, maximum load 20mA at 12V dc max.).

CD5RA and CD5RB: SPDT electromechanical relay (specs below).

SPDT Electromechanical Relay Specifications:

CONTACT RATING: 250V ac max, 24V dc max, 5 amps max.

(resistive load), 1/10 H.P. at 240V ac. Install a transient suppressor

(MOV) across contacts that switch inductive loads.

CLOSURE TIME: 10 milliseconds max.

RELEASE TIME: 10 milliseconds max.

MAXIMUM SWITCHING SPEED: 20 operations/second

MECHANICAL LIFE: 20,000,000 operations

AMPLIFIER:

RESPONSE SPEED: Programmable for 1.5 or 15 milliseconds. NOTE:

use 15 millisecond setting for maximum sensor excess gain.

MODULATION FREQUENCY: selectable, "A" or "B".

SENSOR LEAD LENGTH: 100 feet (30 m) maximum, each sensor.

When splicing, use separate cable for emitter and receiver, or order

sensors with extended cable length.

SENSOR HOOKUP: One SP12 Series opposed mode sensor pair per

amplifier module. Additionally, one self-contained sensor may be

connected at pin #9 (CD5 models) to provide a RESET or INHIBIT

signal. +15V dc power for this one additional sensor is available at

module pin #3 (40mA maximum load).

TIMERS (CD5 models only):

Timing ranges: LOW range - 10 to 150 milliseconds

MIDDLE range - 0.1 to 1.5 seconds

HIGH range - 1 to 15 seconds

Repeatability: +/-2% of set time over all extremes of

supply voltage and temperature

ADJUSTMENTS: Miniature switches are provided for programming

of LIGHT/DARK operate, amplifier response time, modulation frequency, normally open or normally closed output and timing function

(CD5 models). 15-turn clutched potentiometer for gain (sensitivity) and

time settings (CD5 models).

OPERATING TEMPERATURE: 0 to 50°C (+32 to 122°F).

INDICATOR LEDs: Two LEDs. A red indicator LED is "ON" when

the module output is energized. Exclusive Banner Alignment Indicating

Device (AID™) system lights another red LED indicator whenever the

receiver "sees" its own modulated light source, and pulses it at a rate

proportional to the strength of the received light signal.

®

CONSTRUCTION: Rugged Noryl

polyphenylene oxide (PPO®)

housing, 1.6" x 2.3" x 4". Standard round-pin 11-pole plug base.

Noryl® is a registered trademark of General Electric Co.

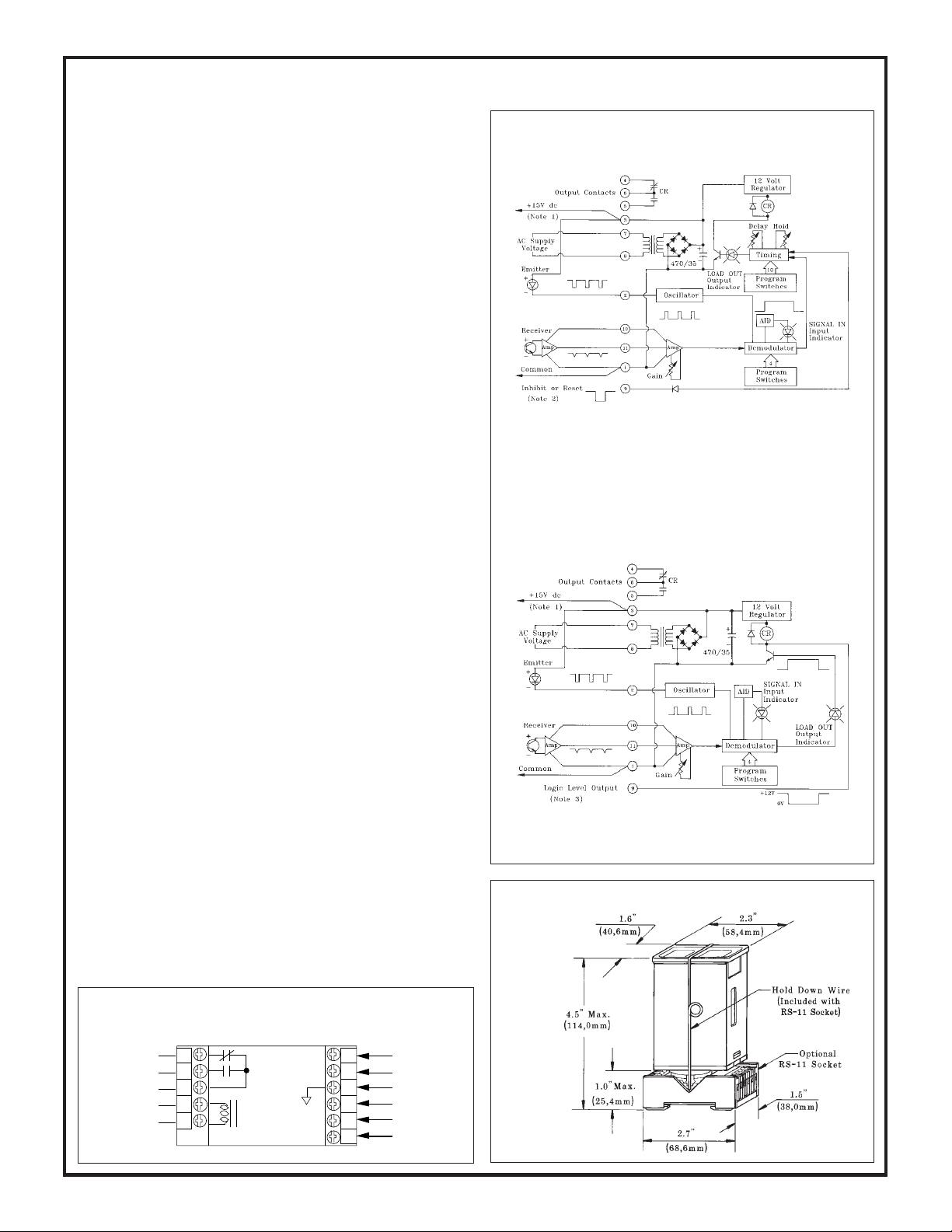

Functional Schematics

Models CD5RA, CD5RB

NOTE #1: power is available at pins #3 (+) and #1 (-) for an external 10 to 30V dc

device (see hookup example, page 9). Current available is 40 mA at 120V ac (240V

ac) line level; 30mA at 105V ac (210V ac) line level. Alternately, the module may be

powered by 12 to 28V dc at pins #3 (+) and #1 (-). Do not connect ac voltage when

using external dc power.

NOTE #2: pulling pin #9 low (to common) will inhibit the timing, or reset the latch

of CD5 models (see "Description of Logic Functions", page 6).

Models CD3RA, CD3RB

NOTE #3: pin #9 of CD3 models may be connected directly as the input to Banner CL

Series MAXI-AMPs or to Banner MICRO-AMP™ or Plug Logic modules (see

hookup example, page 9).

Dimension Drawing

Generalized Hookup:

models with electromechanical relay output

SPDT 5A

Relay

Output

CD3RA

AC

Supply

87654

CD3RB

CD5RA

CD5RB

4

LED +

LED -

Common

PT PT +

Auxiliary

9 10 11 1 2 3

(see table)

Page 5

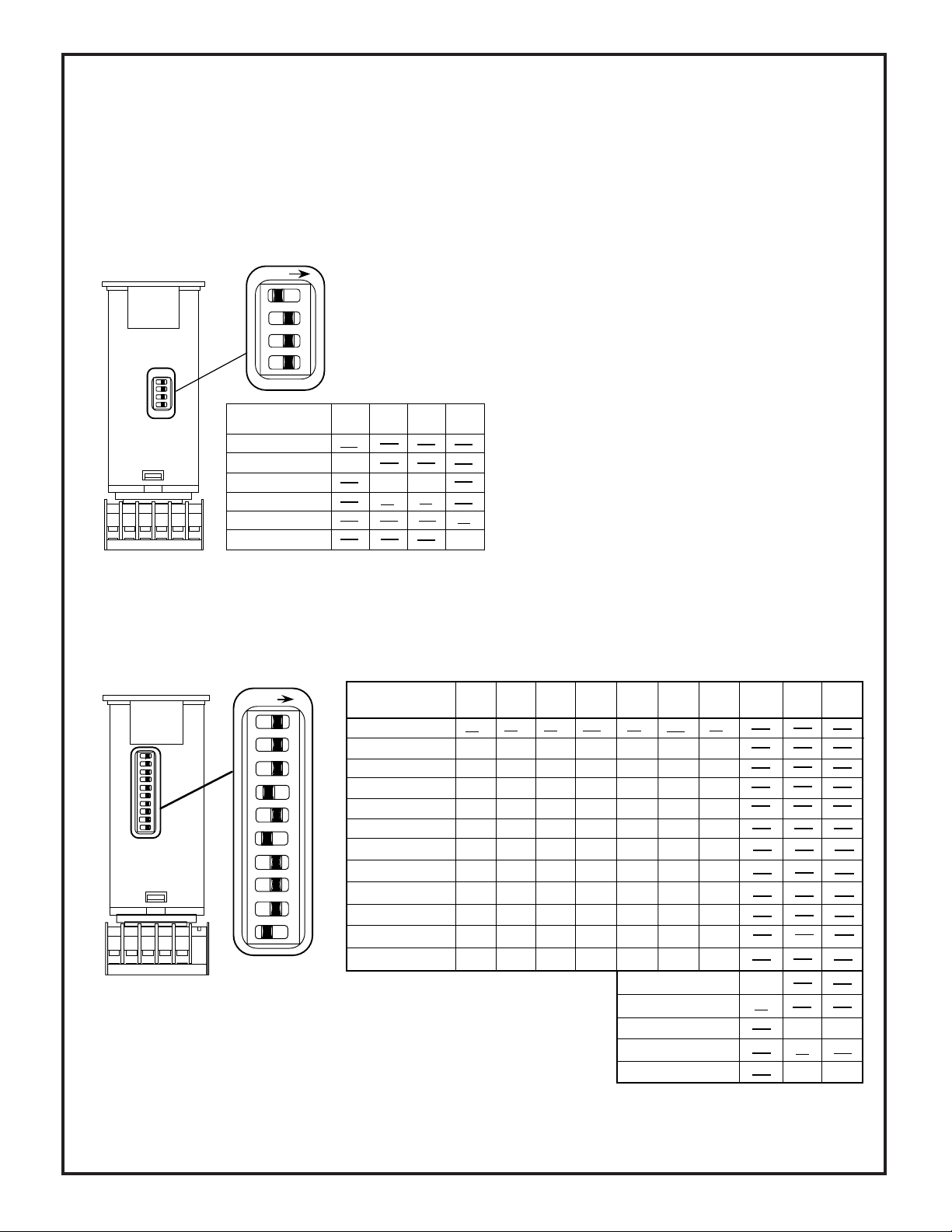

Amplifier Programming (all CD Series modules)

f

Amplifier response conditions may be programmed via the group of four

switches located on one of the narrow sides of the MAXI-AMP™

module.

Switch #1 selects the modulation frequency of the amplifier and the

emitter light source. When two pairs of SP12 Series sensors are being

used in close proximity to each other, the modulation frequency switch

of their respective CD Series modules should be set to different modula-

ON

O

1

F

F

2

3

4

AMPLIFIER

PROGRAMMING

Modulation freq. "A"

Modulation freq. "B"

1.5 millisecond response

15 millisecond response

Light operate

Dark operate

Factory settings are

shown at left. The

"underlined" settings in

table below are factory

settings.

SWITCH SWITCH SWITCH SWITCH

#1 #2 #3 #4

OFF

ON

OFF

OFF

ON

ON

ON

OFF

tion frequencies. This makes it possible to use the two sensor pairs

in close proximity without optical crosstalk. Both amplifiers must

be set for the same response time (either 1.5 or 15 milliseconds) to

ensure freedom from crosstalk.

Switches #2 and #3 are used to program the amplifier response

time. The 15 millisecond setting allows SP12 Series sensors to

operate at their maximum excess gain.

Switch #4 is used to select LIGHT OPERATE or DARK OPER-

ATE. In the LIGHT OPERATE mode, the output will energize (in

ON/OFF or LATCH operation) or the timing function will initiate (in

DELAY, ONE-SHOT, or LIMIT operation) when the receiver

"sees" sufficient light (excess gain greater than 1X). In DARK

OPERATE, the output will energize or timing will begin when the

receiver is sufficiently dark (excess gain less than 1X).

The diagram at the left shows the location of switches 1-4,

and the table summarizes the settings required for each

response condition.

NOTE: An adhesive-backed mylar label is supplied. It may

be marked to indicate switch programming and then applied to the MAXI-AMP housing as a switch cover.

Timing Logic Programming (CD5 models)

Settings illustrated below are factory settings. Factory settings are "underlined" in the table.

ON

O

1

F

F

2

3

4

5

6

7

8

9

10

TIMING LOGIC

PROGRAMMING

On/Of

On Delay

Off Delay

On and Off Delay

One-shot

Delayed One-shot

Limit

Repeat Cycle

AC Latch

DC Latch

Delay and Latch

Limit and Latch

A group of ten switches, located on the side of the module opposite the amplifier program

switches, is used to select the timing logic for the CD5 models.

Switches #1 through #7 are used to select the logic function. Switch #8 programs the output for

either NORMALLY OPEN or NORMALLY CLOSED operation. Switches #9 and #10

program the time range(s). There are three ranges: 10 to 150 milliseconds, 0.1 to 1.5 seconds,

and 1 to 15 seconds. The programmed range will be the same for both functions of a dual timing

mode (ON & OFF DELAY, DELAYED ONE-SHOT, and REPEAT CYCLE). However,

DELAY and HOLD times are independently adjustable within the selected range.

SWITCH SWITCH SWITCH SWITCH

#1 #2 #3 #4 #5 #6 #7 #8 #9 #10

ON ON OFF ON

ON

ON ON OFF ON OFF ON

ON OFF ON OFF ON OFF

OFF OFFOFF OFF OFF

ON ON ONOFFOFF OFFOFF

ON

OFF ON ON OFF

ON

ON ON OFF OFF ONONON

ON ON OFF OFF OFF ONON

OFF

OFF OFFOFF OFF ON

ONOFFOFF OFF ON OFF ON

OFF

OFF

OFF ON ON OFF ON

ONON OFF ONONON

SWITCH SWITCH SWITCH SWITCH SWITCH SWITCH

ON

OFF

ON

ONON

ON

ONONON

N/C Output

N/O Output

.15 Sec. Max. Time

1.5 Sec. Max. Time

15 Sec. Max. Time

OFF

ON

OFF OFF

OFF

ON

ON

OFF

The diagram shows switch locations, and the

table summarizes the program switch positions.

5

Page 6

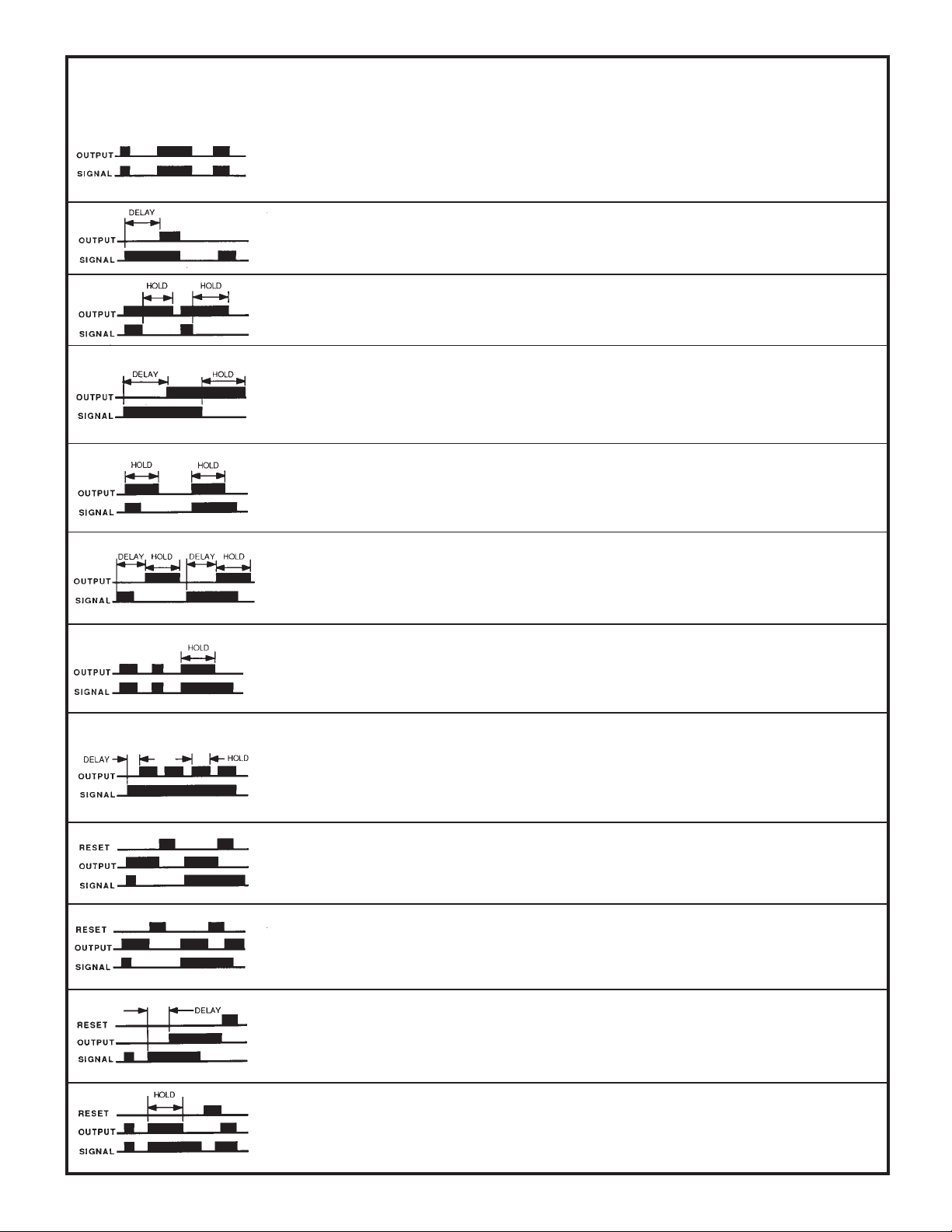

Description of Logic Functions for CD5, CL5, CM5, and CR5 models

ON/OFF: ON/OFF operation does not involve timing. The output simply follows the action of the input signal.

Grounding pin #9 (AUXILIARY) turns the output "off", regardless of the state of the input signal. This may be accomplished

by closing a switch or relay contact between pins #9 and #1 (common), or by connecting an open collector NPN (current sinking)

output of any external dc device directly to pin #9. NOTE: connect the COMMON of any external dc device to pin #1 of the

MAXI-AMP to establish a voltage reference between the dc supply for the external device and the internal dc supply of the

MAXI-AMP.

ON DELAY: The ON DELAY timer keeps the output "off" until the selected LIGHT or DARK signal has been present

for the preset "DELAY" time. If the input signal is interrupted, the timing is reset and starts over with the next signal. Grounding

pin #9 immediately cancels an output in progress and resets the delay timer. The delay timer is restarted when the inhibit signal

is removed, if an input signal is present.

OFF DELAY: The output energizes immediately when the input signal occurs, but does not de-energize until the signal

has been removed for the preset OFF-DELAY ("HOLD") time. Grounding pin #9 prevents an output from occuring. If an

inhibit input occurs during an output, the output remains "on" for the remainder of the OFF-DELAY time.

ON & OFF DELAY: ON and OFF DELAY logic combines both timing functions into a single mode. The ON-

DELAY ("DELAY") time and the OFF-DELAY ("HOLD") time are independently adjustable within the selected time range.

Momentary grounding of pin #9 during the ON-DELAY period resets the DELAY timer. An inhibit signal which occurs during

an output will allow the output to stay energized for the remainder of the OFF-DELAY time. ON and OFF DELAY logic is

often used in jam and void control, high/low level control, and edge-guiding applications.

ONE-SHOT: The output of a ONE-SHOT function is a pulse of adjustable "HOLD" duration which is independent

of the duration of the input signal. With the MAXI-AMP programmed for LIGHT operate, the pulse occurs when the input

signal changes from dark to light. In DARK operate, the pulse occurs with a light to dark input transition. Grounding pin #9

prevents the one-shot from triggering, but does not affect a pulse already under way.

DELAYED ONE-SHOT: A DELAYED ONE-SHOT is initiated by either a momentary or maintained input

signal. This input starts the adjustable "DELAY" period, after which the output pulses for an adjustable pulse ("HOLD") time.

No further action occurs unless the input is removed and reapplied, beginning a new sequence. Grounding pin #9 during the

delay period will cancel the sequence, and no output occurs. This feature is often used for inspection/rejection control logic.

An inhibit signal will not affect a pulse under way.

LIMIT: The output of the LIMIT function follows the action of the input, as it does with the ON/OFF function. However,

an input signal which is longer than the adjustable LIMIT ("HOLD") time will turn the output "off". Removing the input signal

resets the timer. This function is sometimes called "TIME LIMITED ON/OFF", and is useful for energy conservation.

Grounding pin #9 cancels the output. Lifting the inhibit restarts the LIMIT timer, if an input signal is present.

REPEAT CYCLE: The REPEAT CYCLE function provides an oscillating output when an input signal is present.

Presence of an input signal triggers an adjustable "DELAY" timer. After the delay, the output energizes for an adjustable

"HOLD" period. If the input remains, the output continues to cycle "on" and "off" at this rate indefinitely. When the signal

is removed, any output in progress completes and then remains "off" until the next signal and DELAY period. Grounding pin

#9 cancels the sequence, but will allow the completion of a "HOLD" period in progress. Lifting the inhibit signal begins the

DELAY period, if an input signal is present.

AC LATCH: An AC LATCH is the combination of a ONE-SHOT and a LATCH. A momentary or sustained input

will latch the output "on". Grounding pin #9 will reset the latch, even if the input signal remains. The output will not re-latch

until the input signal is removed and then reapplied.

DC LATCH: The output will latch "on" whenever the selected LIGHT or DARK input condition occurs. Grounding

pin #9 of a dc latch will turn the output "off" regardless of the state of the input signal. If the signal is present when the reset

is removed, the output will immediately latch "on" again.

DELAY AND LATCH: The DELAY + LATCH is a combination of the ON-DELAY and DC LATCH functions.

An input must be present for at least the adjustable "DELAY" time for the output to latch "on". If the input signal is removed

during the timing cycle, the timing is reset. Momentary grounding of pin #9 resets the latch and/or the DELAY timing cycle.

Sustained grounding of pin #9 inhibits any output.

LIMIT AND LATCH: The LIMIT + LATCH operates exactly like the LIMIT function, except that the LIMIT

("HOLD") timer can be reset only by the auxiliary input. An output remains latched "off" until reset by momentarily grounding

pin #9. In addition to resetting the timer, grounding pin #9 will hold the output "off", regardless of the state of the input signal.

6

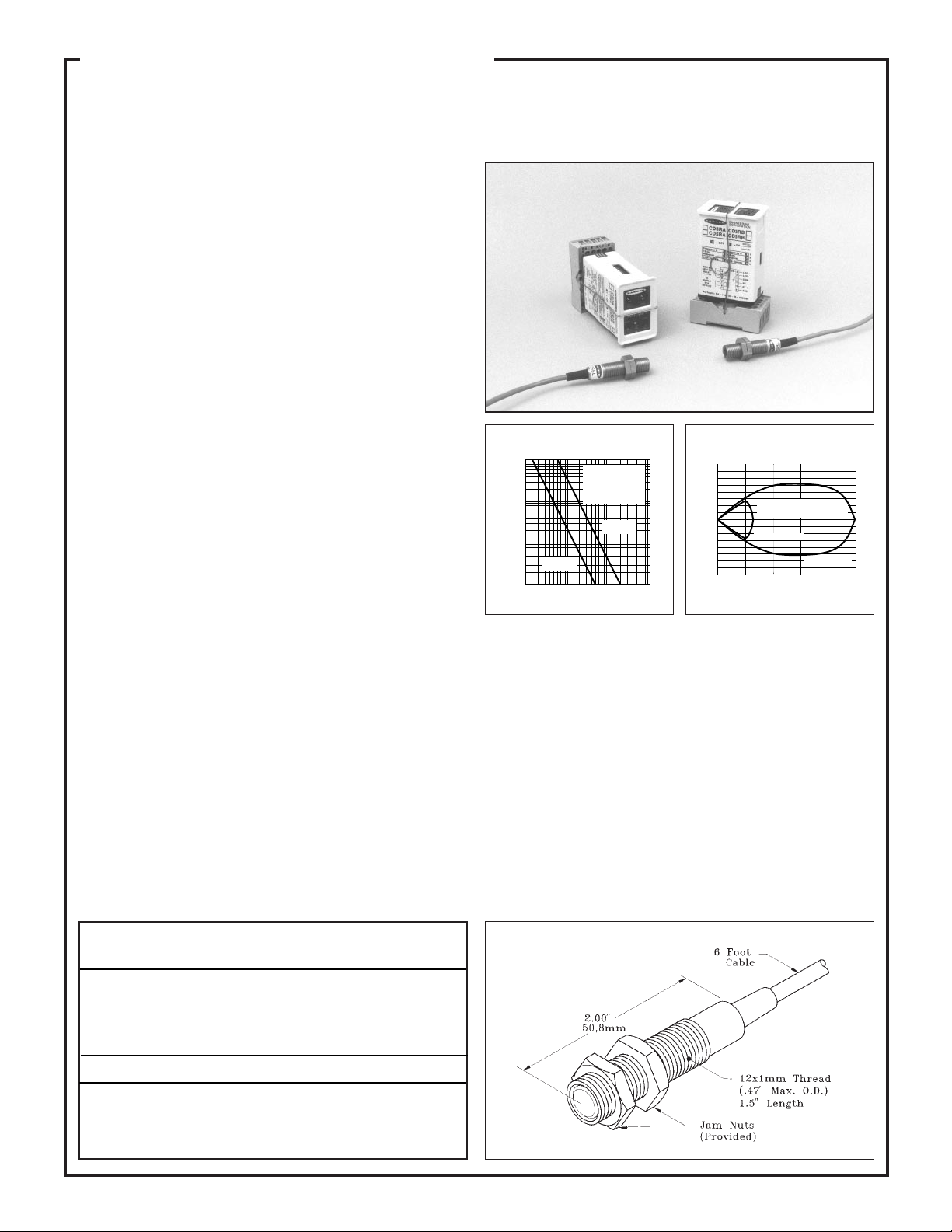

Page 7

0

MAXI-AMP

System

SP12 Series Opposed Mode Remote Modulated Barrel Sensors

for use with MAXI-AMP CD Series Modules

Leakproof NEMA 6P threaded-barrel opposed mode

™

•

remote sensor pairs; VALOX® or stainless steel housing

Compact and powerful: 1/2" (12mm) in diameter by 2"

•

long; 200-foot sensing range. Apertures are available.

Special preamplified circuit design for noise immunity

•

equal to that of self-contained sensors

Banner SP12 Series sensors are a family of powerful, modulated,

totally-encapsulated opposed mode remote sensor pairs in compact,

threaded-barrel type housings. They are the ideal choice for applications that require high excess gain together with small size in difficult

sensing environments. SP12 Series sensors are especially effective at

penetrating heavy contaminants when used at close range.

The preamplified design of these sensors results in exceptional noise

immunity. Signals carried along remote receiver cables are often

subject to interference (from electrical noise sources) that can be as

strong as (or stronger than) the desired light signal. The severity of this

problem often worsens with increasing sensor cable length. SP12

Series receivers contain a preamplifier that immediately boosts the

received light signal to a high level before sending it down the cable to

the rest of the sensing system.

SP12 Series sensors are designed for use with the Banner CD Series

MAXI-AMP™ modules. CD Series modules provide sensor power,

additional amplification, a choice of several programmable timing

logic functions (CD5 models), and output circuitry for interfacing to

a load. They also allow two different programmable sensor modulation

frequencies, making it possible to use multiple high-powered sensor

pairs in close proximity to each other without optical crosstalk. CD

Series modules are available for a wide range of supply voltages. Each

CD module powers one SP12 emitter/receiver pair. See page 3 for more

information.

SP12 sensors are rated NEMA 6P (IEC IP67) for use in wet locations.

There is a choice of either VALOX

table, below). Positive sealing at both ends of the sensors, with no

exposed epoxy interfaces, eliminates all leak paths (including capillary

leakage). Electronics are fully encapsulated for maximum resistance to

mechanical shock and vibration. Lenses are acrylic, and quad-ring

sealed. These sensors may be used with watertight, thread-on apertures to create very narrow, very powerful effective beams (see next

page).

A 1/2" clearance hole is required for mounting. Alternatively, the

Banner model SMB12MM mounting bracket may be used (see next

page). SP12 Series sensors are supplied with 6-1/2 feet of PVCcovered attached cable, or QD connectors (page 8). Options for models

with attached cable are summarized below. The maximum recommended emitter or receiver cable length is 100 feet (each).

®

or stainless steel housing style (see

SP12 Series sensors (foreground) shown with MAXI-AMP™

CD Series amplifier and logic

modules (see pages 3-6).

Models are also available with QD connectors (page 8).

Beam PatternExcess Gain Curve

100

E

X

C

100

E

S

S

G

10

A

I

I

N

0

1 FT

SP12 Series

opposed mode

emitters and

receivers

15ms

response

1.5ms

response

10 FT 100 FT 1000FT

DISTANCE

60

40

I

20

N

C

0

H

E

20

S

40

60

SP12 Series emitters

and receivers

1.5ms response

15ms response

80 120 160 200

400

OPPOSED DISTANCE--FEET

Specifications, SP12 Sensors

SUPPLY VOLTAGE: sensors are powered from a Banner CD Series

MAXI-AMP™ module (see page 3).

RANGE: up to 200 feet in opposed mode (see gain curve, above).

RESPONSE SPEED: selectable for 1.5 or 15 milliseconds; a function

of the MAXI-AMP CD Series module.

LIGHT BEAM: infrared LED, 880nm. Effective beam diameter: 3/8".

CONSTRUCTION: NEMA 6P.

12mm diameter tubular threaded VALOX

positive sealing at both ends, quad-ring sealed acrylic lens. Electronics

fully epoxy-encapsulated. Two jam nuts are provided: VALOX® for

VALOX

®

units; stainless steel for stainless steel units. Mounting

requires 1/2" diameter clearance hole.

OPERATING TEMPERATURE: -40 to +70°C (-40 to +158°F).

CABLE: sensors are supplied with 6-1/2 feet of PVC-covered 2- or 3-

conductor cable. Models with QD connectors are available (page 8).

VALOX® is a registered trademark of General Electric Co.

®

or stainless steel housing;

SP12 Series Barrel Sensors

Model Type Housing Material

SP12SEL

SP12PEL

SP12SRL

SP12PRL

NOTE: Models with 30-foot attached cable are available (contact factory

for information). 2- and 3-conductor 50- and 100-foot extension cables

(without connectors) are also available. For 2-conductor (emitter) cable:

order model EC12E-50 (50') or model EC12E-100 (100'). For 3-conductor

(receiver) cable: order model EC12R-50 (50') or model EC12R-100 (100').

Emitter

Emitter

Receiver

Receiver

Stainless steel

VALOX

®

Stainless steel

VALOX

®

Dimension Drawing

7

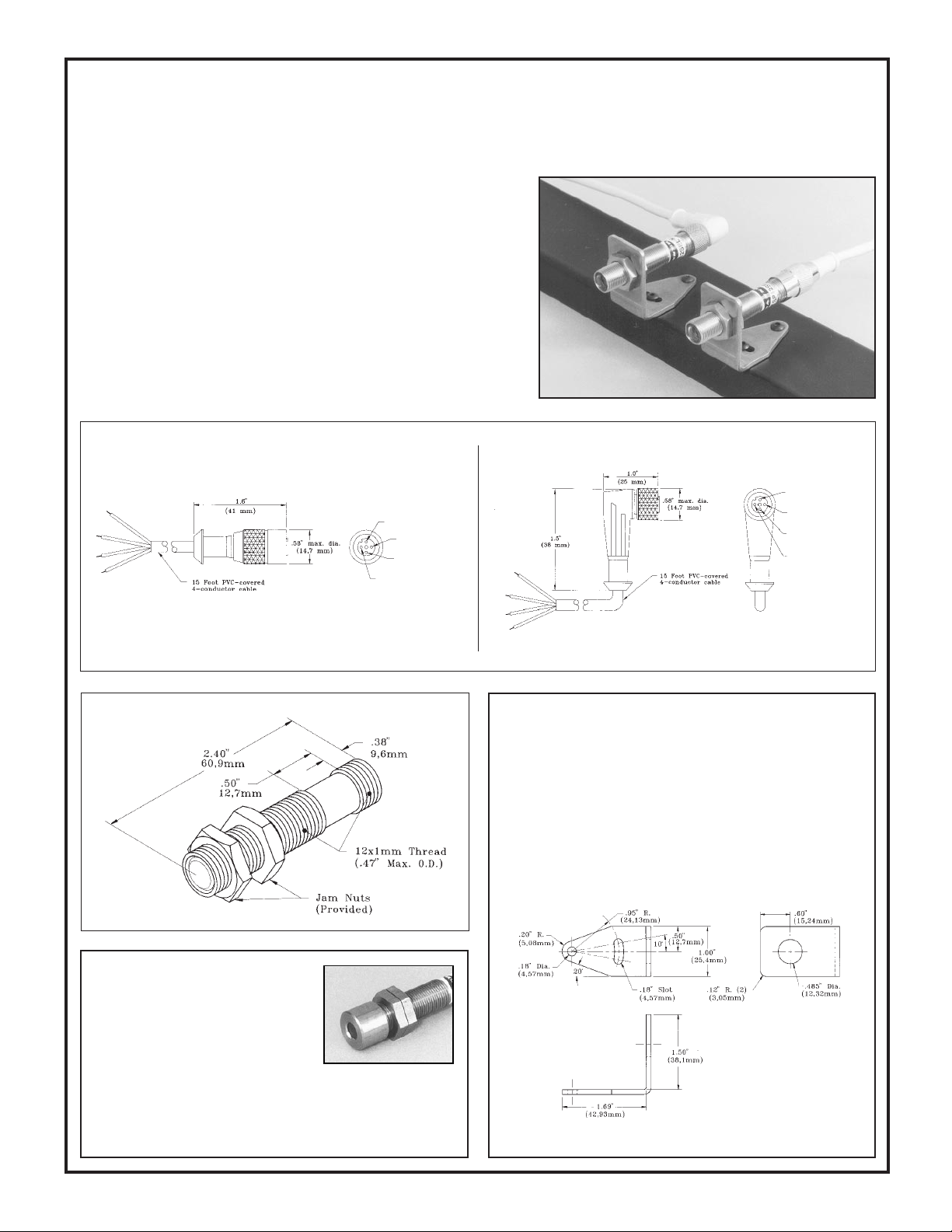

Page 8

SP12 Series Opposed Mode Remote Modulated Barrel Sensors

with Quick Disconnect (QD) Cable Option

The stainless steel models of SP12 Series modulated remote barrel sensors

may be ordered with a built-in connector designed to mate with eurofast™

quick-disconnect (QD) cables. The resultant sensor model numbers are:

SP12SELQD (emitter), and

SP12SRLQD (receiver).

he mating cables are ordered separately. Cables are available in 15 foot

T

lengths with either of two styles of mating connector. Cable model MQDC415 has a straight connector, and model MQDC-415RA has a right-angled

connector (see drawings below). In both models, the plug body is molded

to the PVC cable for waterproof integrity. Plug contacts are gold-plated.

Dimensional Information for MQDC-415 Cable

White wire

Blue wire

Black wire

Brown wire

Dimension Drawing

Dimensional Information for MQDC-415RA Cable

White wire

Blue wire

Black wire

Brown wire

Model SMB12MM Mounting Bracket

Model SMB12MM is a stainless steel mounting bracket for SP12

Series sensors. The sensor mounts to the bracket using the two jam

nuts supplied with the sensor. This rugged, slotted bracket allows

±10 degrees of lateral movement. Bracket is 12-gauge stainless

steel. The bracket mounting holes accommodate #8 hardware.

SMB12MM bracket:

Apertures

Rectangular and circular thread-on watertight apertures are available for SP12

sensors. Apertures are used to shape and

size the sensor's effective beam and to

protect the sensor's lens. Use of apertures

with these high-gain sensors makes it

possible to create very narrow, concentrated sensing beams for

demanding applications. Aperture Kit AP12SC includes three

round apertures with openings of .02", .04". and .10" diameter.

Aperture kit AP12SR has three rectangular apertures .02", .04",

and .10" wide. Both include lens, o-rings, and thread-on housing.

8

Page 9

r

r

r

r

SP12 Sensor Hookup to CD Series MAXI-AMP™ Modules

1) Hookup of SP12 Series Sensors (all models)

SP12 Series sensors are especially designed for use with CD Series modules. The basic hookup is given here (QD sensor models shown). Each MAXI-AMP™

CD Series module supports use of one pair of SP12 Series sensors. CD5 Series module models also support use of a GATE or INHIBIT sensor at pin #9 (below,

this page).

Models with isolated solid-state contacts

DC Load

AC Load

Load Common

AC

SUPPLY*

CD3A

87654

CD3B

CD5A

CD5B

LED + (white)

LED - (green)

2 3

COMMON (black)

1

PT - (blue)

PT + (brown)

9 10 11

Emitter

AUX

Receiver

Models with electromechanical relay contacts

SPDT 5A

Relay

Output

AC

SUPPLY*

LED + (white)

LED - (green)

CD3RA

87654

CD3RB

CD5RA

CD5RB

COMMON (black)

PT - (blue)

PT + (brown)

9 10 11 1 2 3

AUX

Emitter

Receiver

*105 to 130V ac or 210 to 250V ac, 50/60Hz, depending on model. To power the MAXI-AMP™ module from a dc supply, connect

+12 to 28V dc at ≥70mA to terminal #3 and dc common to terminal #1. Make no connection to terminal #7 or #8.

2) Logic Level NPN Output (CD3 models)

The AUXILIARY terminal (#9) of models CD3A, CD3B, CD3RA and

CD3RB modules offers a logic-level NPN (current sinking) output which may

be used as a fast-response solid-state inhibit signal to the AUXILIARY input

of MAXI-AMP CD5, CL5, CM5, or CR5 Series modules. This output may

also serve as an input to any MICRO-AMP™, Plug Logic, or CL

AC

Supply

54

6

CM5

7

models

8

1 2 3

10 11

9

Series logic module. In addition,

this output may interface to other dc

devices or circuits like counters,

rate meters, or programmable logic

controllers. Switching capacity is

20mA maximum at 12V dc max.

AC

Supply

4

5

CD3

models

876

2 3

1

11

10

9

The example here shows the use of

SP12 Series sensors and a CD3 module to provide inspection information, with the SP300D functioning

as a product (GATE) sensor.

SP300D

(Inspection)

SP12 Series Emitte

white

green

black

red

Inhibit

white

green

black

blue

brown

Gate

(Interrogate)

See Hookup Diagram #1 (above) for load and power connection information.

Typically, the CM5 module would

be programmed for the ONE-SHOT

or DELAYED ONE-SHOT logic

function. If the SP12 pair "sees" an

acceptable condition when the

SP300D senses the leading (or trailing) edge of a product, the CD3 will

inhibit a reject pulse from occuring.

Data

SP12 Series Receive

3) Power for External Devices (all models)

External 10 to 30V dc devices such as

self-contained sensors may be connected

between terminals #3 (+) and #1 (-) of

any CD series MAXI-AMP module.

Terminal #3 offers 40mA maximum.

This is sufficient to power most Banner

self-contained dc sensors.

As the example at the right illustrates,

the current sinking output of a self-

contained sensor powered by the MAXIAMP may be used as the input to the

AUXILIARY terminal of a CD5 module.

AC

Supply

87654

+15V dc @40mA

CD5

models

NOTE: Black wire from

SE612

is not used

Inhibit

GATE

white

green

black

1 2 3

blue

brown

9 1011

White

Brown

+15V dc

(#3)

SP12 Series Emitte

DATA

(Inspection)SE612

Blue

(#1)

(Interrogate)

SP12 Series Receive

9

Page 10

MAXI-AMP™ CM Series

Modulated Amplifier Modules

CM Series MAXI-AMPs combine power supply, modulated photoelectric amplifier, timing logic (in CM5 models) and output relay in a

single compact, cost-saving module. CM-series modules work together with the popular family of Banner high-performance modulated

remote sensors (pages 13-17). These sensors offer small size and

excellent optical performance, and are built to operate in highly

demanding sensing environments. MAXI-AMP modules themselves

are also ruggedly built for dependable industrial duty.

CM Series MAXI-AMP modules contain the state-of-the-art Banner

custom-designed CMOS modulator/demodulator/amplifier circuit, offering high immunity to both ambient light and electrical interference

plus reliable sensor performance. All models have Banner's exclusive,

patented Alignment Indicating Device ("AID™") system, which lights

an LED indicator whenever the sensor sees a "light" condition, and

pulses the LED at a rate proportional to the received light signal

strength.

All CM Series modules are programmable for LIGHT or DARK

operate and either high or low hysteresis. Input response time may be

set at 0.3, 2, or 10 milliseconds. The 10-millisecond response mode

offers enhanced immunity to electrical interference ("noise"), and also

Recognized Certified

MODEL

CM3RA

CM3RB

CM5RA

CM5RB

minimizes optical "crosstalk" between adjacent sensors. Unlike other

amplifier designs, input response time settings of the CM Series

modules do not affect sensor range.

CM5 models include a versatile multi-function timing logic circuit

which is programmable for 12 of the most popular and useful delay,

one-shot, and latch functions (see page 6). Each timing function has a

choice of three time ranges. Timing and sensitivity adjustments are

accomplish-ed via rugged 15-turn potentiometers for very accurate

settings. CM Series circuitry is designed to prevent false outputs on

system power-up.

An auxiliary input is available on CM5 models for interrogation or reset

of the selected logic function (see example, page 17). Page 6 describes

the function of the auxiliary input for each logic mode. A dc power

supply is included for powering an additional self-contained dc sensor.

The output circuit for all CM Series modules is an SPDT 5-amp electromechanical relay. Additionally, CM3 models have an NPN transistor

solid-state switch. The output may be programmed for either normally

open or normally closed operation. A solid-state relay is offered as an

option to the electromechanical relay (see information below).

SUPPLY

VOLTAGE

105 to 130V ac, or

12 to 28V dc

210 to 250V ac, or

12 to 28V dc

105 to 130V ac, or

12 to 28V dc

210 to 250V ac, or

12 to 28V dc

OUTPUT

SPDT electromechanical

relay, plus NPN

transistor solidstate DC switch

SPDT electromechanical relay

(5 amp contact

rating)

LOGIC

ON/OFF

12

timing

functions

Solid-state Output Option

CM Series modules are available with a solid-state relay which replaces the

electromechanical relay. This is actually two SPST solid-state contacts. One

contact will switch ac loads. The contact is rated at 250V ac maximum and

3/4 amps maximum at 25 degrees C (derated to 1/2 amp at 50 degrees C). The

other solid-state contact will switch dc loads of up to 30V dc and up to 50

milliamps. Both contacts are isolated from the MAXI-AMP power supply.

MODEL

CM3A

CM3B

CM5A

CM5B

SUPPLY

VOLTAGE

105 to 130V ac, or

12 to 28V dc

210 to 250V ac, or

12 to 28V dc

105 to 130V ac, or

12 to 28V dc

210 to 250V ac, or

12 to 28V dc

OUTPUT

SPST solid-state

contact for

switching AC

loads up to 250

V ac and up to

3/4 amp, plus

solid-state contact for switching DC loads up

to 30V dc and up

to 50mA.

MAXI-AMP CR Series Modulated Modules for SP100 Series Miniature Remote Sensors

The amount of amplification available from CM Series MAXI-AMP

modules is too high to operate with the Banner SP100 Series of

miniature modulated remote sensors. CR Series modules correct this

incompatibility with a modified modulated amplifier design. CR Series

specifications are exactly the same as for the standard CM Series

models (listed above) except for the difference in amplifier gain.

Available models are listed in the table at the right.

SP100 Series sensors are ideal for OEM machinery and for tight spaces

where the use of photoelectric sensors was previously considered

impossible. The SP100 Series is described in the Banner catalog.

CR Series modules are also available with the solid-state output option

(see above).

MODEL

CR3RA

CR3RB

CR5RA

CR5RB

SUPPLY

VOLTAGE

105 to 130V ac, or

12 to 28V dc

210 to 250V ac, or

12 to 28V dc

105 to 130V ac, or

12 to 28V dc

210 to 250V ac, or

12 to 28V dc

OUTPUT

SPDT electromechanical

relay, plus NPN

transistor solidstate DC switch

SPDT electromechanical relay

(5 amp contact

rating)

LOGIC

ON/OFF

12

timing

functions

LOGIC

ON/OFF

12

timing

functions

10

Page 11

MAXI-AMP CM and CR Series Specifications

SUPPLY VOLTAGE: Models CM3(R)A, CM5(R)A, CR3(R)A, and

CR5(R)A: 105 to 130V ac, 50/60Hz (4 VA), or 12 to 28V dc* at 70mA.

Models CM3(R)B, CM5(R)B, CR3(R)B, and CR5(R)B: 210 to 250V ac, 50/

60Hz (4 VA), or 12 to 28V dc* at 70mA.

*NOTE: do not connect ac power if using external dc power.

OUTPUT CONFIGURATION:

Models CM3A, CM3B, CM5A, CM5B, CR3A, CR3B, CR5A, CR5B have

SPST solid-state relay for switching ac or dc (see page 10).

Models CM3RA, CM3RB, CM5RA, CM5RB, CR3RA, CR3RB, CR5RA,

CR5RB have SPDT electromechanical (e/m) relay with the following ratings:

CONTACT RATING: 250V ac max, 24V dc max, 5 amps max. (resistive load),

1/10 H.P. at 240V ac. Install transient suppressor (MOV) across contacts which

switch inductive loads.

CONTACT RESPONSE: 10 milliseconds max. open/close;

20 operations/second max.

MECHANICAL LIFE: 20,000,000 operations

CM3 and CR3 models also have a logic level current sinking NPN transistor

switch at pin #9. See schematic (right) and hookup info.

AMPLIFIER:

RESPONSE SPEED: programmable for 10, 2, or 0.3 milliseconds. NOTE: use

10 millisecond setting whenever possible for enhanced noise rejection.

HYSTERESIS: if programmed "HIGH", approximately 20%; if programmed

"LOW", approximately 5%. NOTE: see cautions for "LOW" setting, page 12.

MODULATION FREQUENCY: approximately 10kHz.

SENSOR LEAD LENGTH: 50 feet (15 m) maximum. Use separate

shielded cable for emitter and receiver, or order sensors with extended cable

length. NOTE: see splicing precautions, page 17.

MULTIPLE SENSOR HOOKUP: Up to three sensors may be wired

together to one CM-series amplifier for "OR" operation (in LIGHT operate) or

"NAND" operation (in DARK operate). Emitters are connected in series, and

receivers are connected in parallel. When wiring two sensors to one MAXIAMP, multiply excess gain data for each sensor by 1/2 (obtain data from

applicable excess gain curve). When wiring three sensors to one MAXI-AMP,

multiply excess gain by 1/3.

TIMERS (CM5 models only):

TIMING RANGES: LOW range - 10 to 150 milliseconds

REPEATABILITY: +/-2% of set time over all extremes of supply

MIDDLE range - 0.1 to 1.5 seconds

HIGH range - 1 to 15 seconds

voltage and temperature

ADJUSTMENTS: Miniature switches for programming of LIGHT/ DARK

operate, amplifier response time, amplifier hysteresis, normally open or normally closed output, and timing function (CM5 & CR5 models). 15-turn

clutched potentiometer for gain and time setting(s) (CM5 and CR5 models).

OPERATING TEMPERATURE: 0 to 50°C (32 to 122°F).

INDICATOR LEDs: Red indicator LED is "ON" when the module output

is energized. Exclusive Banner Alignment Indicating Device (AID™) system

lights a red LED indicator whenever the receiver "sees" its own modulated light

source, and pulses it at a rate which is proportional to the strength of the received

light signal.

CONSTRUCTION: Rugged NORYL

ing, 1.6" x 2.3" x 4". Standard round-pin 11-pole plug base.

®

polyphenylene oxide (PPO®) hous-

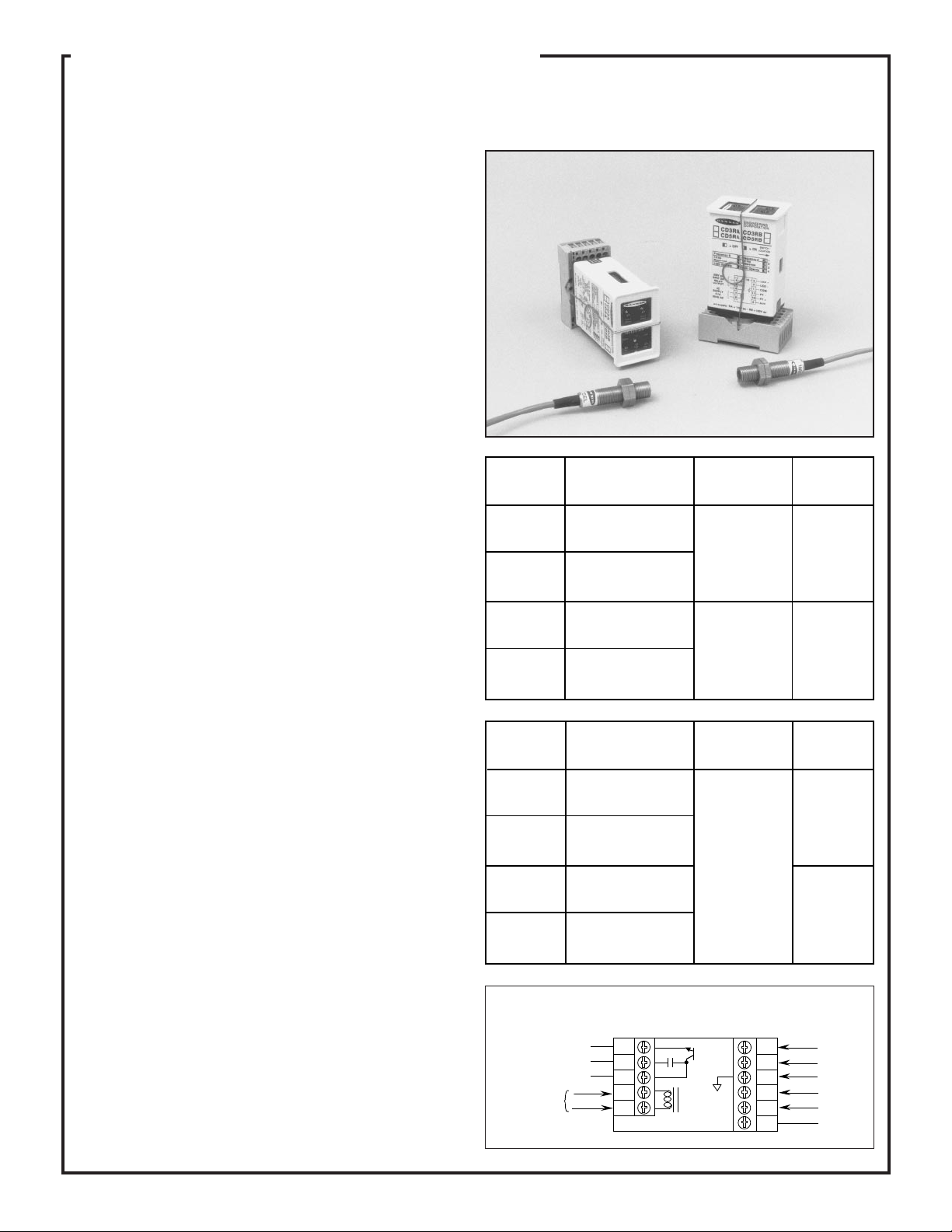

Functional Schematics

CM5 & CR5 Models

NOTE #1: power is available at pins #3 (+) and #1 (-) for an external 10 to 30V dc

device (see hookup example, page 17). Current available is 40 mA at 120V ac (240V

ac) line level; 30mA at 105V ac (210V ac) line level. Alternately, the module may

be powered by 12 to 28V dc at pins #3 (+) and #1 (-). Do not connect ac voltage if using

external dc power.

NOTE #2: pulling pin #9 low (to common) will inhibit the timing, or reset the latch

of CM5 or CR5 models (see "Description of Logic Functions", page 6).

CM3 & CR3 Models

NOTE #3: pin #9 of CM3 or CR3 models may be connected directly to the

AUXILIARY input of a MAXI-AMP or Banner M Series module. It may also serve

as the input to Banner CL series MAXI-AMPs or to Banner Plug Logic modules (see

hookup example, page 17).

Dimension Drawing

Generalized Hookup

models with electromechanical relay output

NOTE: If MAXI-AMP is powered by a dc power supply, connect +12 to 28V dc

@ ≥70mA to terminal #3 and dc common to terminal #1.

Make no connections to terminal #7 or #8.

11

Page 12

Amplifier Programming (all models)

Amplifier response conditions may be programmed via the group of four

switches located on one of the narrow sides of the MAXI-AMP module.

Switch #1 selects the amount of amplifier hysteresis. Hysteresis is the

amount of signal change beyond the switching threshold which is

required to cause the amplifier output to change state, and is expressed

as a percent of amplifier gain. The NORMAL setting of 20% should

always be used, except for low contrast situations such as many color

registration applications.

ON

1

O

F

F

2

3

4

AMPLIFIER

PROGRAMMING

Normal hysteresis (20%)

Low hysteresis (5%)

10 millisecond response

2 millisecond response

0.3 millisecond response

Light operate

Dark operate

Factory settings shown at

left. "Underlined" settings

in table below are factory

settings.

SWITCH SWITCH SWITCH SWITCH

#1 #2 #3 #4

ON

OFF

OFF

ON

ONON

ON

OFF

ON

OFF

NOTE: the LOW hysteresis setting should be used only when all

sensing conditions remain stable. "Buzzing" of the output (in ON/

OFF and LIMIT operation) or false outputs (in DELAY, ONESHOT, or LATCH operation) may occur if sensing variables (e.g.-

web flutter) result in optical contrast approaching unity.

Switches #2 and #3 are used to program the amplifier response time.

The 10 millisecond setting should be used whenever possible for the

greatest immunity to electrical interference ("noise"). The 2 millisecond setting has more interference rejection than the 0.3 millisecond

mode. Sensor performance (excess gain) is identical in all three

response settings.

Switch #4 is used to select LIGHT OPERATE or DARK

OPERATE. In the LIGHT OPERATE mode, the output will

energize (in ON/OFF or LATCH operation) or the timing

function will initiate (in DELAY, ONE-SHOT, or LIMIT

operation) when the receiver "sees" sufficient light (excess

gain greater than 1X). In DARK OPERATE, the output will

energize or timing will begin when the receiver is suffi-

ciently dark (excess gain less than 1X).

The diagram at the left shows the location of switches 1-4,

and the table summarizes the settings required for each

response condition.

NOTE: an adhesive-backed mylar label is supplied, which

may be marked to indicate switch programming and then

applied to the MAXI-AMP housing as a switch cover.

Timing Logic Programming (CM5 and CR5 models)

Settings illustrated below are factory settings. Factory settings are "underlined" in the table.

ON

1

O

F

F

2

3

4

5

6

7

8

9

10

TIMING LOGIC

PROGRAMMING

On/Off

On Delay

Off Delay

On and Off Delay

One-shot

Delayed One-shot

Limit

Repeat Cycle

AC Latch

DC Latch

Delay and Latch

Limit and Latch

A group of ten switches, located on the side of the module opposite the amplifier program

switches, is used to select the timing logic for the CM5 and CR5 models.

Switches #1 through #7 are used to select the logic function. Switch #8 programs the output

for either NORMALLY OPEN or NORMALLY CLOSED operation. Switches #9 and #10

program the time range(s). There are three ranges: 10 to 150 milliseconds, 0.1 to 1.5 seconds,

and 1 to 15 seconds. The programmed range will be the same for both functions of a dual

timing mode (ON & OFF DELAY, DELAYED ONE-SHOT, and REPEAT CYCLE).

However, DELAY and HOLD times are independently adjustable within the selected range.

SWITCH SWITCH SWITCH SWITCH

#1 #2 #3 #4 #5 #6 #7 #8 #9 #10

ON ON OFF ON

ON

ON ON OFF ON OFF ON

ON OFF ON OFF ON OFF

OFF OFFOFF OFF OFF

ON ON ONOFFOFF OFFOFF

ON

OFF ON ON OFF

ON

ON ON OFF OFF ONONON

ON ON OFF OFF OFF ONON

OFF

OFF OFFOFF OFF ON

ONOFFOFF OFF ON OFF ON

OFF

OFF ON ON OFF ON

ONON OFF ONONON

SWITCH SWITCH SWITCH SWITCH SWITCH SWITCH

OFF

ONON

ON

OFF

N/C Output

N/O Output

.15 Sec. Max. Time

1.5 Sec. Max. Time

15 Sec. Max. Time

The diagram shows switch locations, and the

table summarizes the program switch

positions.

ON

ON

ONONON

OFF

ON

OFF OFF

OFF

ON

ON

OFF

12

Page 13

MAXI-AMP System

Sensors for use with CM Series Modulated Amplifiers

Sensors are epoxy-encapsulated and optics are hermetically sealed. Cables are 6 feet (2m) long. 30-foot (9m) cables available by special order.

Sensor accessories are shown on page 24.

OPPOSED Mode

ALL MODELS:

Range: 8 feet (2,4m)

Beam: infrared, 880nm

Effective Beam:

.14 inch (3,6mm) dia.

LR models are emitters

PT models are receivers

LR200 & PT200

Temp. range: -40 to +100 degrees C

Housing material: black Delrin

LR250 & PT250 LR300 & PT300 LR400 & PT400

Temp. range: -40 to +100 degrees C

®

Housing material: black Delrin

Excess GainModels/Dimensions

1000

E

X

C

100

E

S

S

G

10

A

I

I

N

1

.1 FT 1 FT 10 FT 100 FT

Temp. range: -40 to +80 degrees C

®

Housing material: black VALOX

LR/PT200, 250,

300, & 400

DISTANCE

Beam Pattern

12

8

I

4

N

C

0

H

E

4

S

8

12

Temp. range: -40 to +100 degrees C

®

Housing material: anodized alum.

LR/PT200, 250,

300, 400

20

4 6 8 10

OPPOSED DISTANCE--FEET

LR/PT200, 250, 300, and 400 opposed mode remote sensors are

identical electronically and optically, and differ only in their housings.

All are totally epoxy-encapsulated and use hermetically sealed glass

lenses to eliminate condensation inside the optical chamber. These

sensors may be washed down without damage. Operating temperature

is determined by the type of cable used (see specifications above).

These sensor pairs feature wide beam angle for forgiving line-of-sight

alignment. At the same time, the effective beam of each pair is only

1/8 inch, allowing small-profile resolution and reliable response to fastmoving objects. LR models are emitters; PT models are receivers.

LR200 & PT200: this is a right-angle design which mounts through a

7/16 inch (12mm) diameter hole, using the steel jam nut which is

included. This pair is used most commonly on small conveyors when

it is desireable to run the cable directly down to a wireway.

LR250 & PT250: these sensors feature a 1/4 inch (6,4mm) diameter

smooth barrel design, and are usually held in place in a clearance hole

with a small set-screw. Optional mounting blocks (shown below) are

available. Model SMB250 holds the sensor in place with two setscrews. The block is then mounted to a bracket (like model SMB300,

page 15), or directly to a machine frame with two #6 screws. Block

model SMB250C holds an LR & PT250 together to converge at

approximately 1/2 inch ahead of the block.

SMB250 SMB250C

LR & PT300: this is a miniature right-angle design which is mounted

in place using two #4 screws. This pair uses a very flexible, low-profile

2-wire cable. Despite their small size, the optical performance of the

LR/PT300 is equal to the other remote sensor pairs.

LR400 & PT400: the 3/8 inch (9,5mm) diameter threaded barrel

design makes the LR/PT400 the most versatile and most popular remote

opposed sensor pair. They are easily mounted through clearance holes

using the jam nuts which are supplied. They may be used with optional

L4 or L16 lenses for extended range and/or higher excess gain. The

addition of an L4 lens on both the LR and PT400 will increase their

range from 8 feet to 40 feet and increase the excess gain at any distance

by a factor of 25X. A pair of L16 lenses will increase available excess

gain by a factor of 250X.

L4 lens

The LR/PT400 pair is often used at close range with optional AP400 aperture

assemblies to create a very small and well-defined effective beam for resolving

small profiles, increasing sensing repeatability, or easing response time requirements.

AP400 apertures

L16 lens

Aperture model

AP400-010

AP400-015

AP400-040

AP400-030R

Aperture size

.010" dia.

.015" dia.

.040" dia.

.030" x .125"

13

Page 14

MAXI-AMP System

Sensors for use with CM Series Modulated Amplifiers

Sensors are epoxy-encapsulated. Cables are 6 feet (2m) long. 30-foot (9m) cables available by special order.

Sensor accessories are shown on page 24.

Models/Dimensions Excess Gain

SP300EL &

SP300RL

Emitter-receiver pair SP300EL/RL are extremely rugged and are totally encapsulated in anodized aluminum housings. The threaded hub at the cable exit

allows for the use of flexible armored cable or protective PVC tubing with the

addition of compression gland model CF7-16 (page 24). This pair uses

SP300L

Range: 50 feet (15m)

Effective Beam: .5 inch (13mm) dia.

Temp. range: -40 to +100 degrees C

Housing material: anodized aluminum

Range: 15 feet (4,5m) with BRT-3

retroreflector

Temp. range: -40 to +80 degrees C

Housing material: blue anodized

aluminum

Beam Pattern

Long Range

OPPOSED Mode

1000

SP300EL/RL

E

X

C

100

E

S

S

SP300EL/RL

G

10

A

I

I

N

1

.1 FT 1 FT 10 FT 100 FT

DISTANCE

18

12

I

6

N

C

0

H

E

6

S

12

18

20

100

OPPOSED DISTANCE --FEET

30 40 50

collimating lenses to increase range. These sensors should also be used at short

ranges for their high excess gain or to avoid optical "crosstalk" in situations which

require several pairs to be mounted adjacent to one another.

RETROREFLECTIVE

Mode

NOTE: for complete information on retroreflective materials, see Banner catalog.

1000

E

X

100

C

E

S

S

G

10

A

I

I

N

SP300L

with

BRT-T tape

with

BRT-3 target

with

BRT-1 target

1

.1 FT 1 FT 10 FT 100 FT

DISTANCE

6

4

I

2

N

C

0

H

E

2

S

4

6

SP300L

with BRT-3 reflector

40

8 12 15 18

DISTANCE TO REFLECTOR--FEET

Model SP300L is a remote retroreflective sensor with the same rugged design

as the SP300EL/RL, described above. Its useable range is from 6 inches to 15

feet (0,2 to 4,5m) using the model BRT-3 retroreflector.

LP400WB

Range: 3 inches (76mm)

DIVERGENT

Mode

Temp. range:

-40 to +80 degrees C

Housing material: blue anodized

aluminum

"WB" in this model number designates "wide beam". The LP400WB is an

infrared divergent mode (wide angle diffuse mode) sensor which is particularly

14

If the object that is to break the beam has a shiny surface, then the SP300L and its

retroreflector should be mounted so that the beam is at an angle of 10 degrees or

more to that surface in order to eliminate false signals which are caused by proxing.

1000

LP400WB

E

X

100

C

E

S

S

G

10

A

I

I

N

1

.1 IN 1 IN 10 IN 100 IN

Range based on

90% reflectance

white test card

DISTANCE

1.5

1.0

I

.5

N

C

0

H

E

.5

S

1.0

1.5

DISTANCE TO 90% WHITE TEST CARD--INCHES

LP400WB

10

2 3 4 5

forgiving for reflectively sensing transparent or translucent materials or for

sensing objects with irregular surfaces (e.g.- webs with "flutter"). The optics are

such that even small threads or wires .005" (0,1mm) or greater in diameter may be

detected when they pass within .25" (6mm) of the sensor's plastic lens. Due to its

wide response pattern, the LP400WB should not be used for precise positioning

control, nor should it be mounted with its lens recessed into a hole.

Page 15

MAXI-AMP System

Sensors for use with CM Series Modulated amplifiers

Sensors are epoxy-encapsulated. Cables are 6 feet (2m) long. 30-foot (9m) cables available by special order.

Sensor accessories are shown on page 24.

Models/Dimensions

SP300D

Range: 12 inches (30cm)

Temp. range: -40 to +80 degrees C

Housing material: green anodized

aluminum

SP320D

Range: 12 inches (30cm)

Temp. range: -40 to +80 degrees C

Housing material: black VALOX

Excess Gain

Beam Pattern

DIFFUSE

Mode

®

1000

SP300D, SP320D

E

X

100

C

E

S

S

G

10

A

I

I

N

1

.1 IN 1 IN 10 IN 100 IN

DISTANCE

.6

.4

I

.2

N

C

0

H

E

.2

S

.4

.6

DISTANCE TO 90% WHITE TEST CARD--INCHES

SP300D: the SP300D is the diffuse mode version of the SP300L with the

same rugged aluminum housing and totally encapsulated construction. The

glass lenses are hermetically sealed, which eliminates any possibility of

condensation inside the lenses and allows operation in adverse environments like steam washdown and high vibration. The SP300D may be

mounted by its through-holes or with the SMB300 bracket, as shown below.

SP320D: model SP320D is identical to the SP300D, except for its housing.

The 320 is a miniature plastic package, designed to fit into very tight

locations. It mounts using two #4 (3mm) screws. The SP320D and the

SP300D are excellent for nearly any presence sensing application.

SP300D, 320D

30

6 9 12 15

SMB300

UNIVERSAL MOUNTING

BRACKET for

SP300 Sensors

SP1000V

Range: focus at 3.8 inches (96mm)

Temp. range: -40 to +80 degrees C

Housing material: black anodized

aluminum

CONVERGENT Mode

Accessory bracket model SMB300 is designed for 2-axis universal mounting of sensor models SP300EL, SP300RL, SP300L, and SP300D. These

sensors are affixed to the SMB300 with two #6 (3,5mm) screws. The

bracket, in turn, mounts with two #10 (5mm) screws.

In addition, as indicated by the dimension drawing, the SMB300 has a

clearance slot for mounting LR400, PT400, and LP400WB barrel sensors.

LR & PT200 sensors may be mounted with the SMB300, using its 7/16-20

threaded hole and steel jam nut, which is supplied with the sensors. LR250

and PT250 sensors may be used with the SMB300 when the SMB250 block

is used (see page 13). Also, two SMB250 blocks may be attached to the

SMB300 bracket and angled to mechanically converge an LR & PT250

sensor pair.

The SP1000V is a convergent mode sensor that produces a very small 0.1

inch (2,5mm) diameter sensing image at a point exactly 3.8 inches (96mm)

from its glass lenses. As the excess gain curve illustrates, the SP1000V has

a very sharp drop-off of gain beyond the focus point. This feature makes it

an excellent choice for detecting a small part which is only a fraction of an

inch in front of another surface, such as parts on a conveyor (viewed from

above). It is also ideal for fill level detection and for precise positioning

control, in lieu of opposed sensing.

1000

E

SP1000V

X

100

C

E

S

S

G

10

A

I

I

N

1

.1 IN 1 IN 10 IN 100 IN

DISTANCE

.090

.060

I

.030

N

C

0

H

E

.030

S

.060

.090

10

DISTANCE TO 90% WHITE TEST CARD--INCHES

SP1000V

2 3 5 4

15

Page 16

MAXI-AMP System

Sensors for use with CM Series Modulated Amplifiers

Sensors are epoxy-encapsulated and optics are hermetically sealed. Cables are 6 feet (2m) long. 30-foot (9m) cables available by special order.

Sensor accessories are shown on page 24.

Models/Dimensions

FIBER OPTIC Mode

glass fiber optics

FOF-400 Fiber optic Fitting

For complete information on glass

fiber optic assemblies and accessories, see Banner product catalog.

LR400 & PT400

with FOF-400 fittings and

fiber optics

Range: see excess gain curves

Temp. range: -40 to +100 degrees C

The threaded barrel design of the

LR400 and PT400 (see page 14) permit the connection of any Banner

glass fiber optic assembly by using

two model FOF-400 fittings. The

sensors are typically mounted

through 3/8 inch (10mm) diameter

clearance holes, with the FOF-400

fittings threaded onto them after

mounting. Setscrews in the fittings

lock the fibers in place, but allow

rapid replacement without disturbing any electrical wiring.

As the excess gain curves show, the

LR/PT400 combination produces a

high-performance fiber optic sensing system. With the amplifier's 1

millisecond response time, this system can be used for almost any fiberoptic requirement.

Fiber optic information:

IT13S: individual assembly

.06 in. (1,5mm) dia. bundle

IT23S: individual assembly

.12 in. (3mm) dia. bundle

BT13S:bifurcated assembly

.06 in. (1,5mm) dia. bundle

BT23S:bifurcated assembly

.12 in. (3mm) dia. bundle

L9: .5 in. (12mm) dia. lens

L16F: 1.0 in. (25mm) dia.

lens

1000

LR/PT400

E

X

100

C

E

S

S

with IT13S

G

fibers

10

A

I

I

N

1

.1 IN 1 IN 10 IN 100 IN

1000

E

X

C

100

E

S

S

G

10

A

Opposed mode,

I

I

with IT23S

N

fibers

1

.1 FT

1000

Retroreflective mode, with

BT13S fibers

E

with L16F

X

100

lens

C

and BRT-3

E

reflector

S

S

G

10

A

I

I

N

1

.1 FT 1 FT 10 FT 100 FT

1000

Diffuse mode -- range based on

90% reflectance white

test card

E

X

C

100

E

S

S

G

10

A

I

I

N

with

BP13S

fibers

1

.1 IN 1 IN 10 IN 100 IN

Opposed mode,

no lenses

with IT23S

fibers

DISTANCE

LR/PT400

with

L9

lenses

1 FT 10 FT 100 FT

DISTANCE

LR/PT400

with L9 lens

and BRT-3

reflector

DISTANCE

LR/PT400

with

BT23S

fibers

DISTANCE

with

L16F

lenses

Beam PatternExcess Gain

3

LR/PT400

2

I

1

N

C

0

H

E

1

S

2

3

OPPOSED DISTANCE--INCHES

LR/PT400

24

Opposed mode

16

I

8

N

C

0

H

E

8

S

16

24

9

LR/PT400

6

I

3

N

C

0

H

E

3

S

6

9

DISTANCE TO REFLECTOR--FEET

0.6

LR/PT400

0.4

I

0.2

N

C

0

H

E

0.2

S

0.4

0.6

DISTANCE TO 90% WHITE TEST CARD--INCHES

Opposed mode

w/IT23S fibers

w/IT13S fibers

12

60

IT23S fibers and

L9 lenses

150

OPPOSED DISTANCE--FEET

50

10

18

IT23S fibers and

L16F lenses

30 45 75

Retroreflective mode,

with BRT-3 reflector and

BT13S fiber

w/L9 lens

10

w/BT13S fibers

2

60

w/L16F lens

15

Diffuse mode

w/BT23S fibers

3

24

20

30

25

5 4

Hookup to CM Series MAXI-AMP Modules

The hookup diagrams on this page and the

next include all of the remote sensors for use

with CM Series modulated amplifier modules. It is important to note how the shield wire

of a remote sensor is wired. The shield wire is the

uninsulated wire in each sensor cable. Failure to

connect the shield as shown may result in false

operation of the amplifier. When wiring emitters, it is good practice to connect the positive

(white) wire first. LEDs are sensitive to application of the wrong voltage, and can easily be

destroyed.

NOTE: up to three sensors may be connected to

each amplifier (see specifications).

16

Hookup of LR/PT200, 250, 300, and 400

Page 17

Sensor Hookup Diagrams for CM Series MAXI-AMP Modules

Hookup of LR300 and PT300

Hookup of SP320D

Hookup of SP300D, SP300L, LP400WB,

and SP1000V

NOTE REGARDING CABLE SPLICING:

When splicing additional cable length to modulated remote sensors,

it is important to use a separate shielded cable for emitter and

receiver wires. Combining emitter and receiver wires together in

the same cable (even if the cable is shielded) will result in direct

coupling of the emitter signal to the receiver leads. This is called

"cable crosstalk", and will not allow full amplifier sensitivity setting

without an amplifier "lock on" situation, which appears as a continuous LIGHT condition. Banner offers extension cable for remote

sensors which, if used for cable splicing, will minimize the chances

for cable crosstalk (see page 24).

Logic Level NPN Output (CM3 models)

The AUXILIARY terminal (#9) of CM3 models offers a

logic-level NPN (current sinking) output which may be used

as a fast-response solid-state inhibit signal to the AUXILIARY input of MAXI-AMP CM5 modules. This output may

also serve as an input to any B Series, Plug Logic, or CL

Series module. In addition, this output may interface to

other dc devices or circuits like counters, rate meters, or

programmable logic controllers. Switching capacity is

20mA at 12V dc.

The example here shows the use of LR & PT400 sensors and

a CM3 module to provide inspection information, with the

SP300D functioning as a product sensor. Typically, the

CM5 module would be programmed for the ONE-SHOT or

DELAYED ONE-SHOT logic function. If the LR & PT400

"sees" an acceptable condition when the SP300D senses the

leading (or trailing) edge of a product, the CM3 will inhibit

a reject pulse from occuring.

Power for External Devices

External 10 to 30V dc devices such as self-contained sensors

may be connected between terminals #3 (+) and #1 (-) of any

CM series MAXI-AMP module. Terminal #3 offers 40mA

maximum. This is sufficient to power most Banner selfcontained dc sensors.

As the example at the right illustrates, the current sinking

output of a self-contained sensor powered by the MAXIAMP may be used as the input to the AUXILIARY terminal

of a CM5 module.

CM5

Model

CM3

Model

CM5

Model

17

Page 18

MAXI-AMP

™

CL Series

Logic-level Input Modules

Banner CL Series MAXI-AMP™ modules are the perfect solution for

many sensing/control applications where economy, versatility, dependability, and ruggedness are important. CL Series MAXI-AMPs

combine power supply, timing logic (in CL5 models) and output relay

in a single compact, cost-saving module. The integrated, stand-alone

design saves both the expense of a separate control chassis and a

substantial amount of panel space. Several models are available, for

either 120V ac or 240V ac operation, and either with or without timing

logic (models are listed in table at above right). Alternatively, any

model may be powered by 12 to 28V dc.

The well-defined electrical characteristics of CL Series MAXI-AMP

modules provide a wealth of application possibilities. The input

circuit accepts signals from any Banner dc sensor with an NPN

(current sinking) output; as well as from MAXI-AMP, MICRO-AMP,

and Plug Logic modules. The input is compatible with almost any

sensor or circuit which has an NPN transistor (current sinking) output.

Additionally, inputs may be generated by limit switches, contact

closures, and optical couplers. A 50mA power supply is included for

powering 10 to 30V dc devices.

CL5 models offer a versatile multi-function timing logic circuit which

is programmable for twelve of the most popular and useful delay, oneshot, and latch functions (see page 6). The MAXI-AMP offers the

choice of either single or dual timing functions in the same module.

Logic and timing may be easily reprogrammed as control requirements change.

Recognized Certified

MODEL

CL3RA

CL3RB

CL5RA

CL5RB

In order to allow accurate timing adjustments, each CL5 model has

three time ranges to choose from. Timing adjustments are made via

rugged 15-turn potentiometers. Circuitry is included to prevent any

possibility of false output on power-up.

An auxiliary input is available on CL5 models for interrogation or

reset of the selected logic function by using an additional sensor or

input signal (see example, page 20). Page 6 describes the function of

the auxiliary input for each logic mode.

The output circuit for all CL Series modules is an SPDT 5-amp electromechanical relay. A solid-state relay is offered as an option to the

electromechanical relay (see information below).

Additionally, CL3 models have an NPN transistor solid-state switch.

This solid-state output may be used to take advantage of the amplifier's

fast 1-millisecond response. This output may be connected directly to

the primary or auxiliary input of other Banner logic modules, including CL5 modules, MICRO-AMP logic modules, and Plug Logic

modules. In addition, this output can interface to other dc devices or

circuits such as counters, rate meters, or programmable controllers.

Switching capacity is 20mA at 12V dc. The output may be programmed for either normally open or normally closed operation.

Like all MAXI-AMPs, the CL Series modules are designed both

electrically and mechanically for solid dependability in industrial

environments.

SUPPLY

VOLTAGE

105 to 130V ac, or

12 to 28V dc

210 to 250V ac, or

12 to 28V dc

105 to 130V ac, or

12 to 28V dc

210 to 250V ac, or

12 to 28V dc

OUTPUT

SPDT electromechanical

relay, plus NPN

transistor solidstate switch

SPDT electromechanical relay

(5 amp contact

rating)

LOGIC

ON/OFF

12

timing

functions

Solid-state Output Option

CL Series modules are available with a solid-state relay which replaces

the electromechanical relay. This is actually two SPST solid-state

contacts. One contact will switch ac loads, and is rated at 250V ac

maximum and 3/4 amps maximum at 25 degrees C (derated to 1/2 amp

at 50 degrees C). A solid-state contact is particularly helpful when

switching inductive ac loads which can cause electrical "noise" and

contact damage when switched with a "hard" relay contact.

The other solid-state contact will switch dc loads of up to 30V dc and

up to 50 milliamps. Both solid-state outputs are electrically isolated

from the MAXI-AMP power supply. Both outputs switch within the 1

millisecond response time of the CL module circuitry. NOTE: ac loads

may take up to 1/2 cycle (8.3 milliseconds) to turn "off".

Both outputs are normally open, but may be programmed for normally

closed operation.

Except for the output configuration, the specifications for the models

listed in the table at the right are exactly the same as for the standard CL

Series models.

18

MODEL

CL3A

CL3B

CL5A

CL5B

SUPPLY

VOLTAGE

105 to 130V ac, or

12 to 28V dc

210 to 250V ac, or

12 to 28V dc

105 to 130V ac, or

12 to 28V dc

210 to 250V ac, or

12 to 28V dc

OUTPUT

SPST solid-state

contact for

switching AC

loads up to 250V

ac and up to 3/4

amp, plus solidstate contact for

switching dc

loads up to 30V

dc and up to

50mA.

LOGIC

ON/OFF

12

timing

functions

Page 19

MAXI-AMP CL Series Specifications

SUPPLY VOLTAGE: Models CL3RA, CL5RA: 105 to 130V ac,

50/60Hz (4 VA), or 12 to 28V dc* at 60mA. Models CL3RB, CL5RB:

210 to 250V ac, 50/60Hz (4 VA), or 12 to 28V dc at 60mA. *Do not

connect ac voltage if using external dc power.

OUTPUT CONFIGURATION: all models have SPDT electro-

mechanical relay:

CONTACT RATING: 250V ac max, 24V dc max, 5 amps max.

(resistive load), 1/10 H.P. at 240V ac. Install transient suppressor

(MOV) across contacts which switch inductive loads.

CLOSURE TIME: 10 milliseconds max.

RELEASE TIME: 10 milliseconds max.

MAXIMUM SWITCHING SPEED: 20 operations/second

MECHANICAL LIFE: 20,000,000 operations

CL3 models also have a logic level current sinking NPN transistor

switch at pin #9. See schematic below and hookup info.

AMPLIFIER:

RESPONSE SPEED: 1 millisecond