MICRO-AMP® System

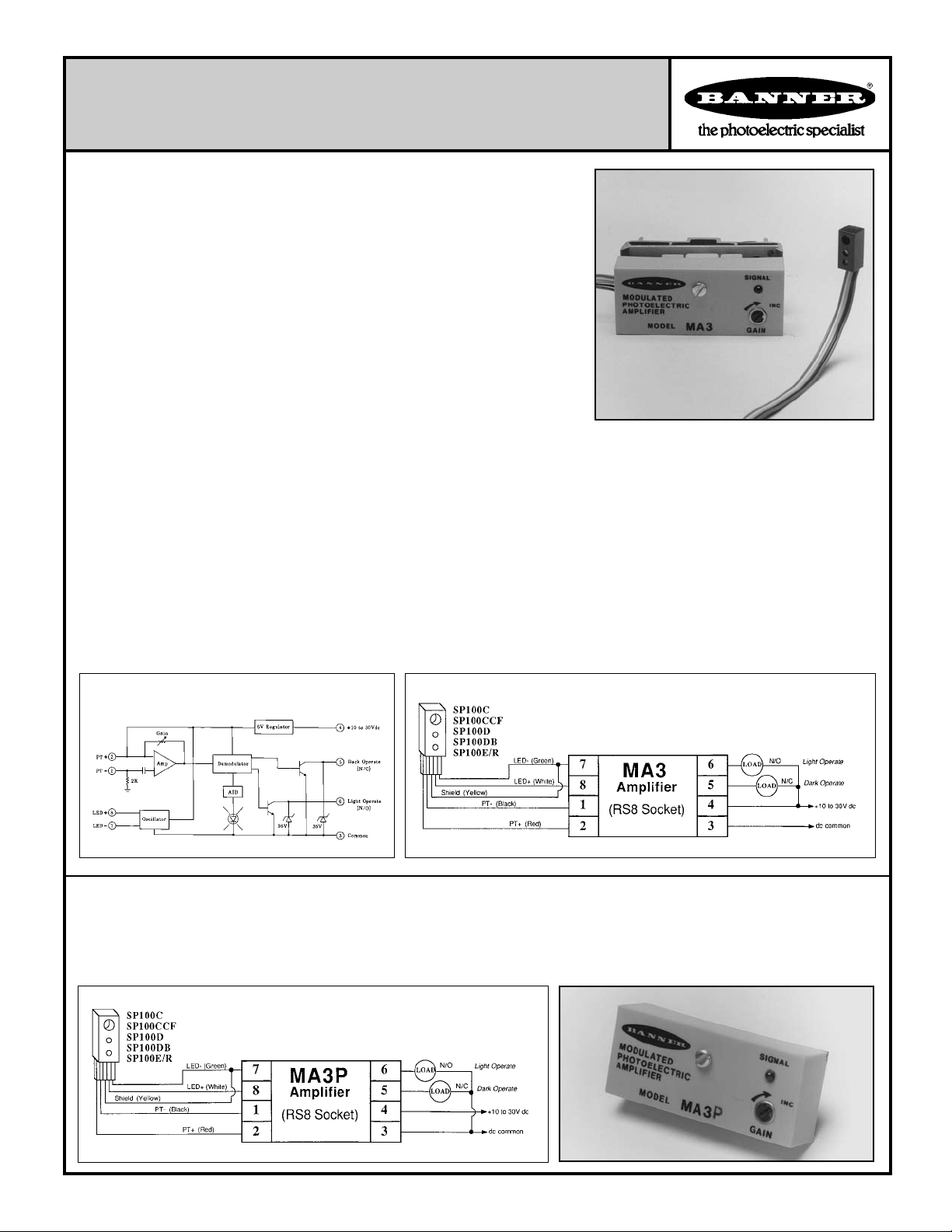

MA3 and MA3P Modulated Ampliers

Banner MICRO-AMP® modules MA3 and MA3P are modulated ampliers designed

for use with the miniature SP100 Series remote sensors. Miniature photoelectric

sensors, such as the SP100s, have traditionally been used as non-modulated devices with

very limited response. These specially-engineered ampliers bring about a dramatic

improvement in the optical performance of miniature remote sensors.

MICRO-AMP modules are powered by 10 to 30 volts dc, and feature the patented

Banner Alignment Indicator Device (AID™) signal strength LED. Sensor sensitivity

is adjustable via a top-mounted GAIN potentiometer. Model MA3 has complementary current sinking (NPN) outputs; model MA3P has complementary current sourcing (PNP) outputs. Circuitry is epoxy-encapsulated and enclosed in a tough molded

VALOX® housing. Connections may be made to the MICRO-AMP via the optional

RS8 socket/wiring base, or the module may be mounted directly to a printed circuit

board (see page 3).

The small size and the slim ribbon-style connecting cable of SP100 Series sensors

make it possible to use photoelectrics in many situations previously thought to be

impractical or even impossible.

MICRO-AMP® Model MA3 Specications

SUPPLY VOLTAGE: 10 to 30V dc at less than 20 milliamps (ex-

clusive of load); 10% maximum ripple.

OUTPUT CONFIGURATION: two open-collector NPN (current

sinking) transistor (solid-state) switches; one normally open (light

operate) and one normally closed (dark operate); 150 milliamps maximum, each output. Saturation voltage less than 0.5V dc at 10 milliamp

load. Off-state leakage current less than 1 microamp.

RESPONSE SPEED: 1 millisecond ON and OFF.

REPEATABILITY: 0.3 millisecond.

SENSOR LEAD LENGTH: 15 feet (4,5 m) maximum.

ADJUSTMENT: GAIN adjustment (single-turn potentiometer;

adjust with small at-blade screwdriver).

INDICATOR: exclusive Banner Alignment Indicator Device

(AID™) system lights a red LED indicator whenever the sensor "sees"

its own modulated light source, and pulses at a rate proportional to the

strength of the received light signal.

CONSTRUCTION*: totally encapsulated plug-in package with

molded VALOX® housing. Gold-ashed connection pins.

OPERATING TEMPERATURE:

0 to +70 degrees C (32 to +158 degrees F).

*A Dimension Drawing appears on page 3.

Functional Schematic, MA3 Amplier

Hookup Diagram, MA3 Amplier

Model MA3P: PNP (current sourcing) output

Model MA3P has the same specications and performance as the MA3 amplier, except that the MA3P has complementary PNP outputs in

place of the MA3's NPN conguration.

OUTPUT: two PNP transistors, complementary outputs; one normally open (light operate) and one normally closed (dark operate). 150 milliamps maximum, each output. Saturation voltage is less than 1V dc at 10 milliamps. Off-state leakage current is less than 1 microamp.

Hookup Diagram, MA3P Amplier

Printed in USA

03340F3G

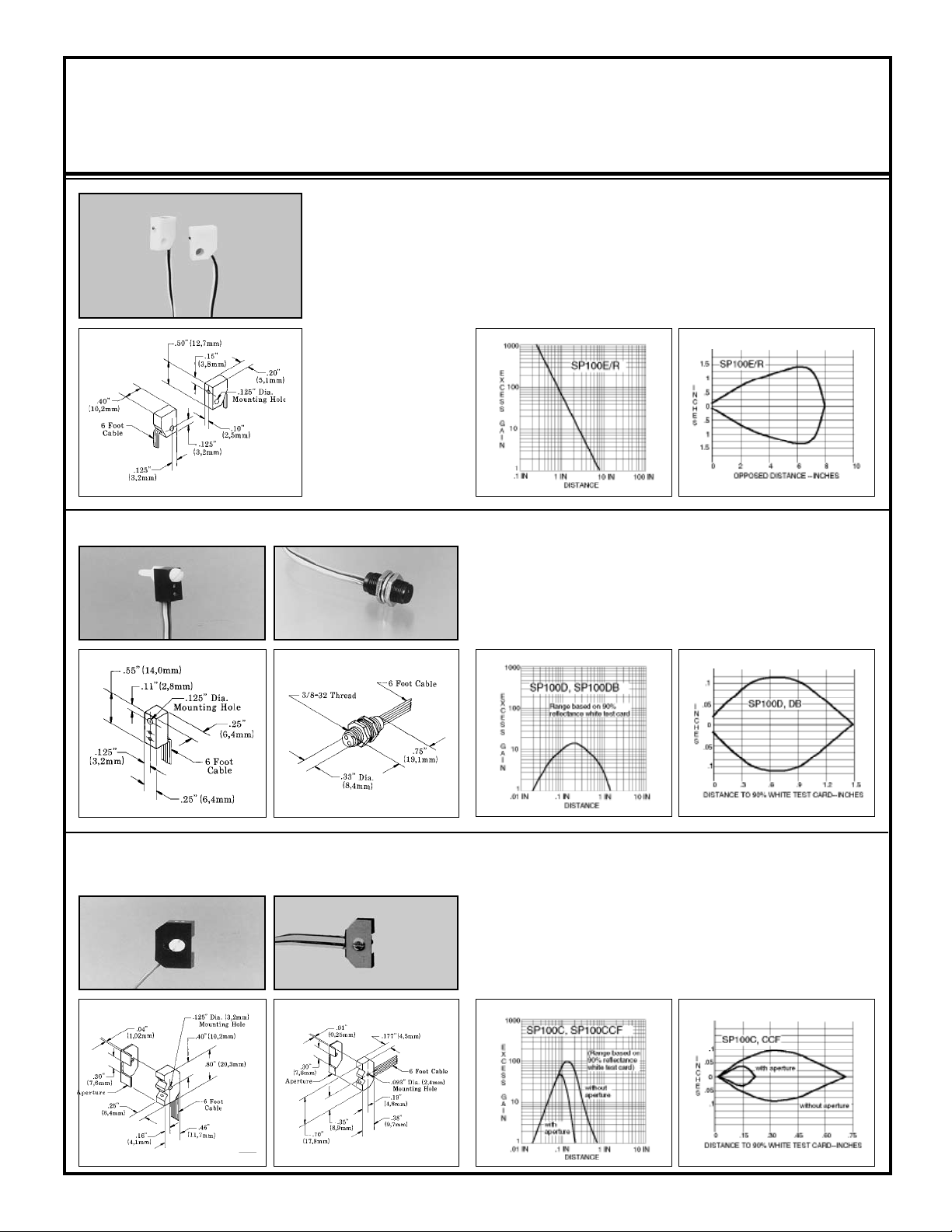

Sensors for use with MA3 and MA3P Modulated Ampliers

Temperature range for all miniature modulated remote sensors is 0 to 70 degrees C (+32 to 158 degrees F).

Sensors are epoxy-encapsulated and optics are hermetically sealed.

Models/Dimensions Excess Gain Beam Pattern

SP100D

SP100E &

SP100R

Range: 8 inches (20cm)

Beam: infrared, 880nm

Effective beam: .05 inch

(1,3mm diameter)

Cable (all 6-foot lengths):

SP100E: 2-wire ribbon cable

(white, green).

SP100R: 3-wire ribbon cable

(red, black, yellow).

SP100D, DB, C, CCF: 5-wire

ribbon cable (white, green, red,

black, yellow). See hookup

drawing.

SP100DB

OPPOSED Mode Sensors

SP100E and SP100R miniature opposed sensors have a slim right-angle design

which allows them to be mounted in very tight locations. The thin, exible ribbon cable which exits from one corner may be run in any direction away from

the sensing point. The SP100E and R have a wide beam angle for forgiving

line-of-sight alignment. Alignment is easily made exact (and monitored) using

the AID™ LED on the MICRO-AMP module.

DIFFUSE Mode Sensors

Models SP100D and SP100DB are general-purpose miniature diffuse sensors

which detect the reection of their own light from the surface of an object. The

SP100D is a right-angle design which is generally held in place using a #4 (3mm)

screw. The SP100DB ("B" = Barrel) is an in-line threaded barrel which typically

mounts through a 3/8" (10mm) diameter hole using the lock nuts which are supplied. The optical response characteristics of these two sensors are identical.

CONVERGENT Mode Sensors

SP100C SP100CCF

Models SP100C and CCF are ideally suited to applications where depth of eld

is critical. The emitter and receiver are both directed at a point 0.1 inch (2,5mm)

ahead of the front surface. An aperture is included which, when attached, nar-

rows the depth of eld (see curves, below). This is particularly useful when it

is necessary to detect an object while ignoring another object or a surface just a

fraction of an inch farther away. The high excess gain at the focus allows detec-

tion of objects of low reectivity. The SP100C and CCF differ only in housing

style. Model SP100C is for general application. Model SP100CCF is used where

a narrow prole is important for mounting.

2

MICRO-AMP® System Accessories

RS8 Socket

The RS8 socket is the most frequently used means of mounting and wiring a MICRO-AMP

module. It consists of a socket

with two four-terminal connection strips, all wired together

onto a PC board. The PC board

assembly slides into a 1 inch

(25mm) long PVC track which

is used to mount the entire as-

sembly. A hold-down screw

keys the correct polarity of the

module.

RS8K Socket

The RS8K is a kit of parts that

comprise the socket portion of

the RS8 assembly. It is used to

provide a socket for MICROAMP modules that are installed

onto printed circuit boards. The

RS8K consists of a molded

socket block and 8 individual

socket pins. A nylon screw is

included to afx the socket block

to the PC board. The drill size for

the pins is #50 (.070"; 1,8mm).

Drill pattern dimensions are

included.

Dimensions, MA3 and MA3P, shown with RS8

Wiring Socket

MICRO-AMP

module

pin conguration.

®

Mounting Track

Track Model

TR100-1

TR100-4

TR100-6

TR100-12

"A" Dimension

1" (25mm)

4" (10cm)

6" (15cm)

12" (30cm)

TR100-1 1 inch (25mm) long (supplied with RS8 socket)

TR100-4 4 inch (100mm) long (supplied with MPS-15 series power supply)

TR100-6 6 inch (150mm) long

TR100-12 12 inch (300mm) long

PVC mounting track for MICRO-AMP components is available in 6 and 12 inch

lengths for systems which use multiple components. For example, a 6-inch length

will accomodate one MPS-15 power supply plus two additional RS8 sockets with

modules.

Longer lengths of mounting track may be supplied on a quote basis.

Dimensions, TR-100 Mounting Track

Minimum

number of slots

1

2

3

8

3

MPS-15 and MPS-15-230 Power Supplies

The MPS-15 Series power supplies are designed specically to supply power for the

Banner MICRO-AMP series ampliers and logic modules. They are constructed on small

PC boards that are track-mountable for compatibility with other track-mounted MICROAMP components. The MPS-15 includes a socket for a MICRO-AMP amplier or logic

module having current sinking (NPN) output*. The combination of an MPS-15 series

power supply and a MICRO-AMP module makes a complete and compact sensing and/or

control system.

A built-in 5-amp rated SPDT output relay is supplied for easy interfacing to an external

load or circuit. Its action is controlled by the outputs of a MICRO-AMP module which is

plugged into the on-board module socket*. A switch on the PC board selects which module

output (normally open or normally closed) will activate the relay.

Two models are available. Model MPS-15 is for 120V ac operation. Model MPS-15-230

is for 220/240V ac power. Up to three MICRO-AMP modules may be powered by one

MPS -15 or MPS-15-230 power supply. A 4-inch (10cm) long mounting track is included

with each supply. Optional 6-inch (15cm) track model TR100-6 neatly accomodates the

MPS-15 Series PC board plus the PC boards of two additional RS8 sockets to form a

complete three-module MICRO-AMP sensing/logic system. (See Mounting Track information, page 3.)

*Do not plug MICRO-AMP modules with PNP (current sourcing) outputs ("P" sufx) into the socket on the MPS-15 or MPS 15-230 power supply.

Other MICRO-AMP® Modules

Module

Model

MA3A

MA3-4 and MA3-4P

MA4-2

MA4G

MA4L

MA5

MPC3

(for printed circuit

board mounting)

WARNING MICRO-AMP

personnel safety applications. A sensor or amplier failure or malfunction can result in either an energized or a de-energized output

condition.

Never use this product as a sensing device for personnel protection. Its use as a safety device may create an unsafe condition which

could lead to serious injury or death.

Only MACHINE-GUARD and PERIMETER-GUARD Systems, and other systems so designated, are designed to meet OSHA and

ANSI machine safety standards for point-of-operation guarding devices. No other Banner sensors or controls are designed to meet these standards, and

they must NOT be used as sensing devices for personnel protection.

Modulated

Amplier

YES

YES

MICRO-AMP logic

modules are designed to

accept the output signal

from a MICRO-AMP

amplier and process

that signal for a required

logic function. MICROAMP logic modules

themselves contain no

amplier.

YES

Logic Functions Used with (Input) Full Description

NONE (ON/OFF)

NONE (ON/OFF)

ONE-SHOT

4-input logic gate:

AND, NOR, X-NOR

Latch or alternate-action

ip-op

ON-delay or OFF-delay

NONE (ON/OFF)

®

Systems do NOT include the self-checking redundant circuitry necessary to allow their use in

Ban ne r SP100FF modu-

lated xed-eld sensor

Banner high-performance

remote sensors

Switches, contacts, or

NPN (current sinking)

output of dc sensors or

ampliers, including:

Banner MULTI-BEAM,

MAXI-BEAM, VALUBEAM, MINI-BEAM,

and ECONO-BEAM

sensors; plus MAXIAMP and MICRO-AMP

modules.

Banner SP100 Series miniature modulated remote

sensors

Banner catalog or

data sheet 03523

Banner catalog or

data sheet 03341

Banner catalog or

data sheet 03350

Banner catalog or

data sheet 03351

Banner catalog or

data sheet 03352

Banner catalog or

data sheet 03353

Banner catalog or

data sheet 03336

WARRANTY: Banner Engineering Corporation warrants its products to be free from defects for one year. Banner Engineering Corporation will repair or replace,

free of charge, any product of its manufacture found to be defective at the time it is returned to the factory during the warranty period. This warranty does not

cover damage or liability for the improper application of Banner products. This warranty is in lieu of any other warranty either expressed or implied.

Banner Engineering Corp. 9714 10th Ave. No., Minneapolis, MN 55441 Telephone: (763) 544-3164 FAX (applications): (763) 544-3573

Loading...

Loading...