Page 1

MULTI-BEAM®LS10 Light Screen System

For Sensing Small Parts at High Speeds

Printed in USA 05/08 P/N 03557 rev. F

*Emitters come with a 3-pin Mini-style connector; receivers come with a 4-pin connector. All require a mating cable; see page 5.

LS10 Light Screen System

• Emitter and receiver pair produce a strobed array of modulated light

beams to produce a light screen

• Simple, economical and highly reliable means of sensing small parts

which pass anywhere through the light screen

• Light screen area measures 90 mm (3.5") high, and as wide as the

distance between the emitter and receiver

• Fast, 1 millisecond response; output includes a 5-millisecond pulse

stretcher for interfacing reliability

• Tight beam spacing for sensing small parts as small as 5.6 mm (0.22")

diameter

• Totally self-contained; very rugged with totally encapsulated circuitry

• Bipolar design offers the choice of NPN (current sinking) or PNP

(current sourcing) outputs from the same receiver; both outputs may

be used simultaneously

LS10E

100 to 1220 mm

(4" to 48")

4-Pin Mini-style QD

7.6 mm (0.30")

LS10RSR

3-Pin Mini-style QD

Models Range Cable*

Supply

Voltage

Output

Type

Minimum Resolution

4-Pin Mini-style QD

LS10ESR

100 to 200 mm

(4" to 8")

3-Pin Mini-style QD

12-30V DC

Bipolar

NPN/PNP

DO

5.6 mm (0.22")

LS10R

Infrared, 880 nm

LS10 Series Opposed Mode Emitter (E) and Receiver (R)

WARNING . . .

Not To Be Used for Personnel Protection

Never use these products as sensing devices for personnel protection. Doing so could lead to serious injury or death.

These sensors do NOT include the self-checking redundant circuitry necessary to allow their use in personnel safety

applications. A sensor failure or malfunction can cause either an energized or de-energized sensor output condition. Consult your current

Banner Safety Products catalog for safety products which meet OSHA, ANSI and IEC standards for personnel protection.

!

Page 2

MULTI-BEAM®LS10 Light Screen System

2

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

LS10 System Overview

LS10 Light Screen Systems consist of two self-contained units: an emitter and a

receiver. Multiple infrared LEDs in the emitter are aligned in a row and strobed (turned

ON one at a time) in a specific sequence and at a high frequency. Receivers contain a

matching array of phototransistors. The length (height) of the array is 90 mm (3.5"),

and produces a curtain of light as wide as the distance between the emitter and

receiver. The receiver may be placed 4" to 48" opposed from the emitter

(LS10E/LS10R) or 4" to 8" away (LS10ESR/LS10RSR). The LS10E/LS10R system can

detect objects as small as 7.6 mm (0.30") in diameter; minimum detectable object

profile for the LS10ESR/LS10RSR system is 5.6 mm (0.22").

NOTE: Sensing should not take place within 1/2" of any LS10 system sensor face.

The light from the emitter is modulated to minimize sensitivity to ambient light. An

indicator LED on the emitter lights whenever power is applied. The receiver has an

Alignment LED which lights whenever the beam is broken.

The receiver output interfaces directly with dc loads or circuits up to 30V dc, and

offers both sinking (NPN) and sourcing (PNP) output transistors. The sinking (NPN)

output may be connected directly to any Banner MAXI-AMP or MICRO-AMP logic

module for additional system control. Outputs are energized continuously while the

beam is broken. A 5 millisecond pulse stretcher (OFF delay) is included to improve

interfacing reliability.

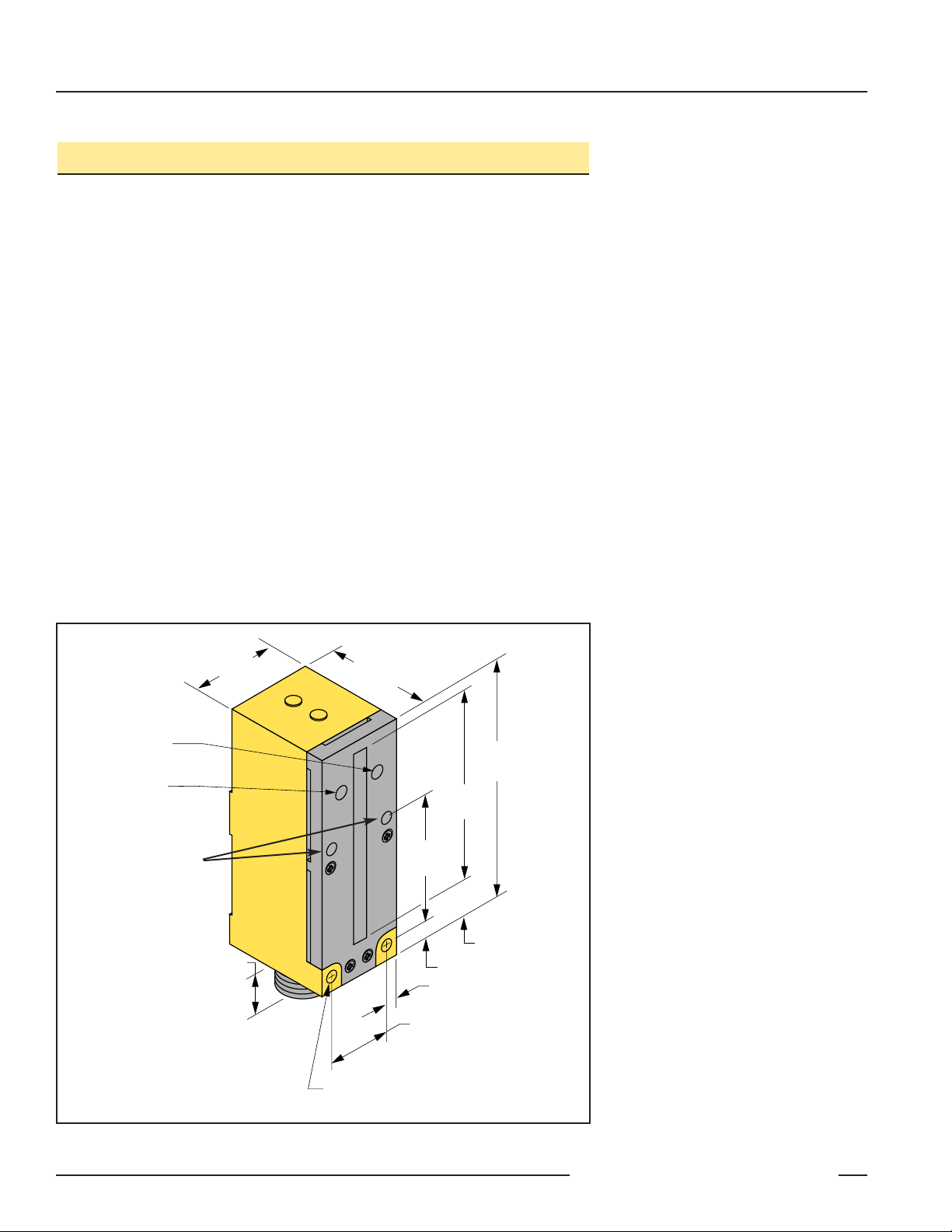

Figure 1. LS10 features

Max. Torque

2.28 Nm (20 in/lbs)

For Mounting Hardware

Receiver:

Alignment LED

Emitter:

Power ON LED

40.1 mm

(1.58")

13.2 mm

(0.52")

49.0 mm

(1.93")

116.0 mm

(4.55")

89.0 mm

(3.5")

60.0 mm

(2.36")

18.0 mm (0.71")

7.6 mm (0.30")

5.1 mm (0.20") (2)

30.0 mm (1.18") (2)

5 mm (0.2") (#10)

Screw Clearance (4)

Page 3

MULTI-BEAM®LS10 Light Screen System

3

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Installation and Alignment

The reliable performance of light screen systems requires careful alignment and

secure mounting. The 2-part, 3-axis mounting brackets on page 5 are highly

recommended. Mounting locations should be as free from vibration as possible. If

vibration is unavoidable, mount the emitter and receiver to vibrate together; no highamplitude differential vibration is allowed.

Mount the emitter and receiver at their operating locations with their front panels

exactly parallel and opposite each other. (The row of transmitter LEDs should be

exactly parallel with and opposite to the row of receiver phototransistors.) This

constitutes optimal mechanical alignment.

Optimal mechanical alignment does not always result in perfect optical alignment, and

perfect optical alignment is absolutely necessary. When optical alignment is

satisfactory, and emitter/receiver vibration is at moderate or lower levels, the receiver

Alignment status indicator (see Figure 1) will be OFF and remain OFF whenever the

light screen is unobstructed.

Adjusting Optical Alignment

Beginning with perfect mechanical alignment, adjust optical alignment as described in

steps #1 through #5. The procedure assumes use of the SMBLS mounting bracket

shown in Figure 2. Only the position of the emitter will be adjusted.

1) Loosen the two bolts holding the two parts of the bracket together just enough to

allow the upper (“carriage”) bracket, along with the emitter, to be rotated. Also,

slightly loosen the mounting bolts in the curved slots of the “base” bracket, which

will allow the bracket to be tipped from side to side.

2) With power applied to both the emitter and receiver, “tip” the entire bracket

(including the emitter) slightly from side to side. Find the extremes of movement

between which the receiver’s red Alignment LED remains OFF. Secure the base

bracket at the point midway between the extremes.

3) Rotate the carriage bracket (to which the emitter is attached) slightly in both

directions, as shown in Figure 2. Find the extremes of rotation between which the

receiver’s red Alignment indicator LED remains OFF. Secure the emitter midway

between the extremes by tightening the two bolts that lock the two parts of the

bracket together.

4) Loosen the two mounting bolts that hold the emitter to the carriage bracket. Slide

the emitter up and down vertically in the bracket, noting the extremes between

which the receiver’s Alignment LED indicator remains OFF. Tighten the bolts to

secure the emitter midway between the extremes. (NOTE: If the initial mechanical

alignment was inadequate, it may be necessary to repeatedly alternate tipping,

rotating, and sliding movements to attain perfect optical alignment.)

5) Check for proper alignment by moving a pencil (or a similar object) along the 3.5"

dimension of the sensing window. The receiver Alignment indicator LED and

outputs should come ON while the pencil is anywhere within the sensing window.

When this is true, tighten all mounting hardware securely in position.

Carriage

Figure 2. Achieving perfect optical

alignment with the LS10; bracket

SMBLS shown.

Bracket

Rotation

Sliding

Tipping

Base

Bracket

Page 4

MULTI-BEAM®LS10 Light Screen System

4

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

LS10 Series Specifications

Certifications

Supply Voltage and Current 12 to 30V dc (10% maximum ripple) at less than 70 mA (emitter) or 45 mA (receiver – exclusive of load)

Supply Protection Circuitry Protected against reverse polarity

Output Configuration Bipolar: One current sourcing (PNP) and one current sinking (NPN) open-collector transistor

Output Rating 125 mA maximum each output

Off-state leakage current: less than 1 microamp

Output saturation voltage (PNP output): < 1 volt at 10 mA and < 2 volts at 150 mA

Output saturation voltage (NPN output): < 200 millivolts at 10 mA and < 1 volt at 150 mA

Output Protection Circuitry Protected against false pulse on power-up and continuous overload or short circuit of outputs

Output Response Time Receiver will respond to a “dark” signal of 1 millisecond or longer duration; a 5-millisecond pulse stretcher

(OFF Delay) is included to improve interfacing reliability; successive parts must have at least 10 millisecond

separation

Repeatability 30 microseconds (light-to-dark)

Resolution 5.6 mm (0.22") or 7.6 mm (0.30"), depending on model

Indicators Power (emitter only): lights whenever power is applied

Alignment (receiver only): lights whenever light screen is interrupted

Construction Reinforced thermoplastic polyester housing, acrylic lenses, and stainless steel hardware

Environmental Rating Meets NEMA standards 1, 2, 3, 12, and 13; IEC IP54

Connections See product selection tables

Operating Conditions Temperature: 0° to +50°C (+32° to 122°F)

Maximum relative humidity: 90% at 50°C (non-condensing)

Application Notes i) The best sensing resolution occurs near the center of the sensing area, midway between the emitter

and receiver.

ii) Outputs are energized continuously while the light screen is interrupted.

LS10 Emitters with Quick-Disconnect

(3-Pin Mini-Style)

LS10 Receivers with Quick-Disconnect

(4-Pin Mini-Style)

bn

bk

bu

+

–

12-30V dc

bn

wh

bu

+

–

bk

12-30V dc

Load

Load

LS10 Series Hookups

Black Wire

Blue Wire

Brown Wire

White Wire

Brown Wire

Black Wire

Blue Wire

Page 5

MULTI-BEAM®LS10 Light Screen System

5

Banner Engineering Corp. • Minneapolis, U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Accessories

Replacement Lens Assemblies

LS Series lens assemblies are field-replaceable.

Model Description

UC-LS10

UC-LS10SR

Replacement lens for LS10E and LS10R

Replacement lens for LS10ESR and LS10RSR

Quick-Disconnect (QD) Cables

4-Pin Mini

MBCC-406

MBCC-412

MBCC-430

2 m (6.5')

4 m (12')

9 m (30')

Style Model Length Connector

3-Pin Mini

MBCC-306

MBCC-312

MBCC-330

2 m (6.5')

4 m (12')

9 m (30')

Straight

Straight

Used with:

LS10 Series Emitters

LS10 Series Receivers

Mounting Brackets

SMBLS

• Two 11-gauge zinc plated steel, right angle brackets

fasten together to they can rotate relative to each other

• Assembly hardware and cable gland are included

SMB30UR

• 2-piece universal swivel bracket for limit-switch

style sensors

• 300 series stainless steel

• Includes stainless steel swivel locking hardware

64.0 mm

(2.52")

30.0 mm

(1.18")

4 x 6.0 mm

(0.24")

60.0 mm

(2.36")

4 x 16.0 mm

(0.64")

8X #10-32 Tap

172.0 mm

(6.77")

99.8 mm

(3.93")

57.2 mm

(2.25")

9.7 mm

(0.38")

50.8 mm

(2.00")

69.9 mm

(2.75")

57.2 mm

(2.25")

#10 Hardware

(included)

7.1 mm

(0.28") x 90°

(2 slots)

1/4"-28 x 1/2"

Screw

2X

66.0 mm

(2.60")

50.8 mm

(2.00")

70.0 mm

(2.76")

5 x 7 mm (1/4")

Clearance

Page 6

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN 55441 • Phone: 763.544.3164 • www.bannerengineering.com

MULTI-BEAM®LS10 Light Screen System

WARRANTY: Banner Engineering Corp. warrants its products to be free from defects for one year. Banner Engineering Corp. will repair or

replace, free of charge, any product of its manufacture found to be defective at the time it is returned to the factory during the warranty

period. This warranty does not cover damage or liability for the improper application of Banner products. This warranty is in lieu of any

other warranty either expressed or implied.

Loading...

Loading...