Page 1

L-GAGE® LT7 Long-Range Time-of-Flight Laser Sensor

Self-contained retroreflective- and diffuse-mode laser distance sensors

Features

• Extremely long range: diffuse model up to 10 m with white target, up to 7 m with

gray target, up to 3 m with black target; up to 250 m for retroreflective models

• Visible pilot laser for easy alignment

• Multiple outputs in each model: discrete outputs can be used for precision

background suppression; and alarm outputs together with display provide easy

troubleshooting

• Diffuse models: Two discrete (PNP) plus 2 alarm outputs, and 4-20 mA analog

• Retroreflective models: Two discrete (PNP) plus 2 alarm outputs

• Fast, easy-to-use TEACH-mode programming via integrated push-buttons or serial

interface (no potentiometer adjustments)

• Ongoing LCD display of sensing distance (selectable in hundredths of an inch

or millimeters)

• RS422- or SSI-compatible serial connection options

Models

Sensing

Models

LT7PIDQ Diffuse

LT7PLVQ Retroreflective

Mode

Laser

Class Cable*

Class 2

Pilot Laser, Class

1 Sensing Laser

Integral

12-pin

M16 QD

connector

Sensing

Range**

0.5 to 10 m

(20" to 33')

0.5 to 250 m

(20" to 820')

Supply

Voltage

18 to

30V dc

* Requires a mating cable; see page 20.

** Diffuse-mode range specified using a 90% reflectance white card.

Retroreflective-mode range specified using the appropriate specified retro target; see page 22.

Discrete

Outputs

2 PNP

plus

2 Alarm

Analog

Output Serial

4-20 mA

RS422

or SSI

N/A

WARNING . . . Not To Be Used for Personnel Protection

Never use these products for personnel protection. Doing so could lead to serious injury or death.

These products do NOT include the self-checking redundant circuitry necessary to allow their use in personnel safety applications. A failure or malfunction can cause either an

energized or de-energized output condition. Consult your current Banner Safety Products catalog for safety products that meet OSHA, ANSI, and IEC standards for personnel

protection.

Printed in USA June 2013 P/N 120244 Rev. B

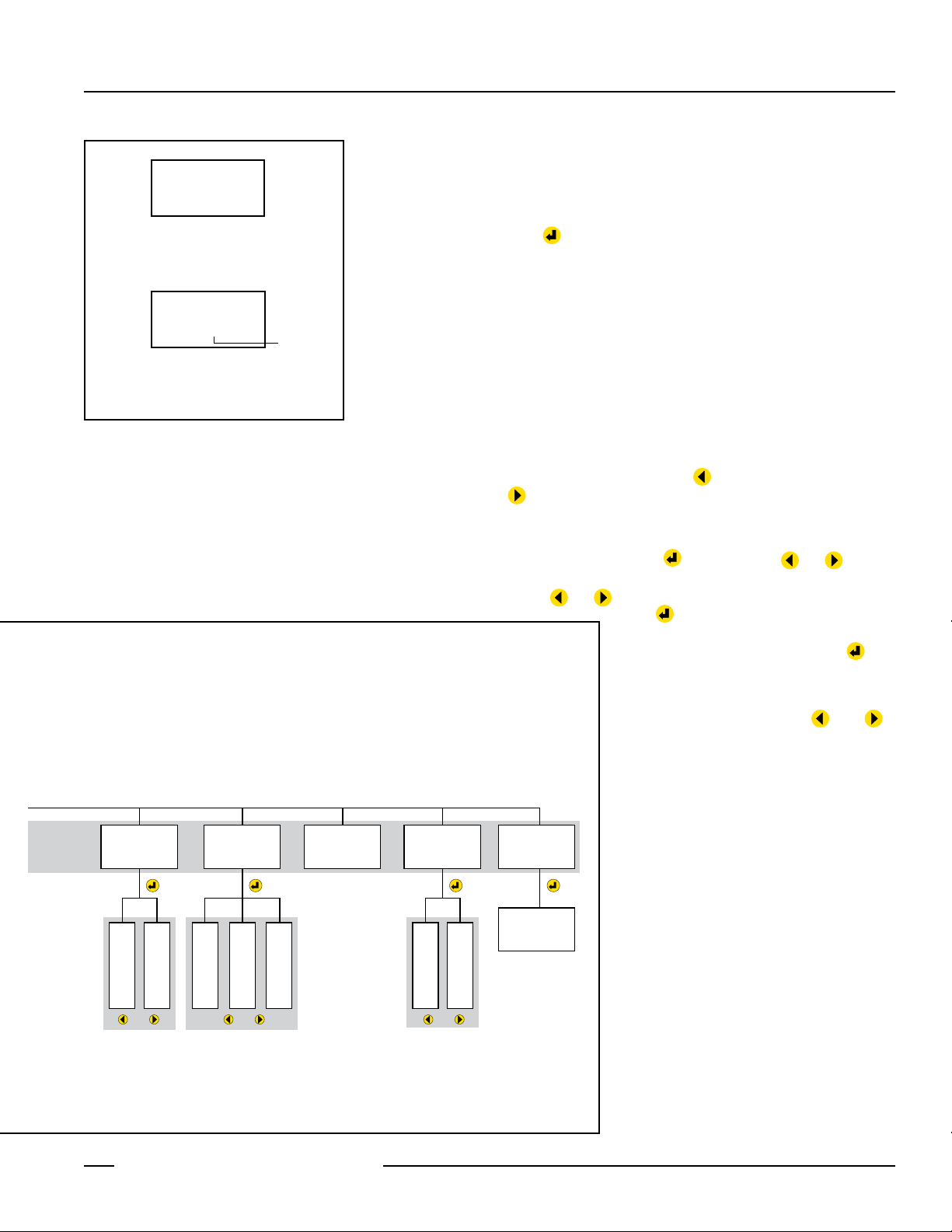

Page 2

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

ESC

Diffuse

Overview

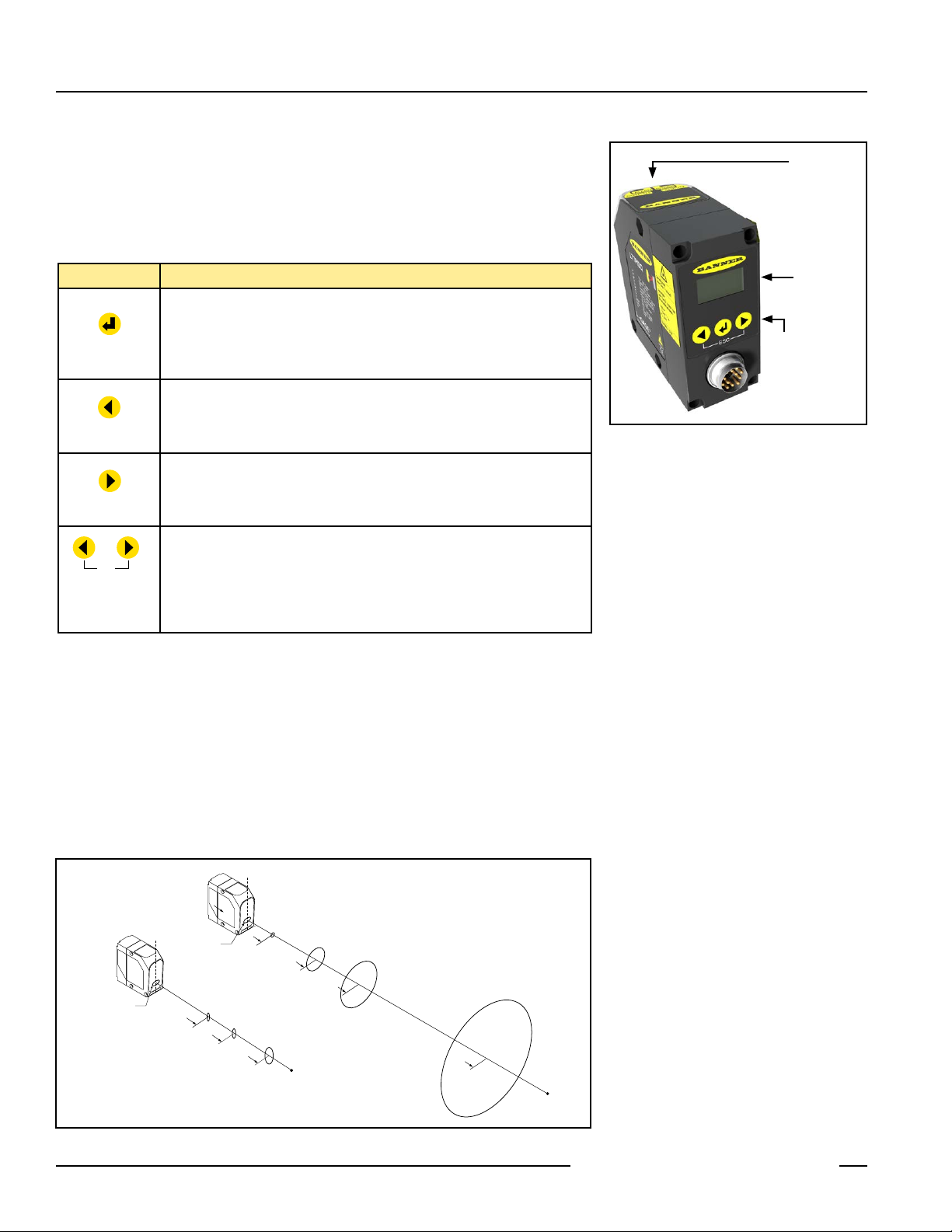

The sensor has an LCD display and 3 push buttons, which control all programming

functions. Serial interface programming can also be accomplished, via SSI or RS422.

Four status indicator LEDs on the sensor front/top provide ongoing status of power and

outputs.

Button Functions

• Run mode: Switches from Run mode to Programming mode

• Programming mode: Selects function and switches one menu level down

• Programming mode: Records value and switches one menu level up

Enter

Left Arrow

Right Arrow

Left and right

arrow buttons

simultaneously

• Manual adjust: Moves cursor one position to left or ends entry when cursor is

at the far left.

• Run mode: Press to light display

• Programming mode: Scrolls to the next menu position to the left (Figure 7)

• Manual adjust: Decreases current digit by 1

• QuickSet menu: Enables teach-in of Q1

• Run mode: Press to light display

• Programming mode: Scrolls to the next menu position to the right (Figure 7)

• Manual adjust: Increases current digit by 1

• QuickSet menu: Enables teach-in of Q2

• Escape: Cancels active function and switches to one menu level above (Figure

7) without saving new values

• Important: Both arrows must be pressed simultaneously. Previous value is

unchanged.

Status

Indicator

LEDs

2-line

Digital

Display

Programming

Push Buttons

Figure 1. Sensor features

The sensor has a 2-line LCD display and 4 LED indicators for ongoing indication of

sensing status: Power ON, Alarm, and Outputs 1 and 2.

In Run mode, the current measured value is displayed in the top line of the sensor’s

display, in millimeters or hundredths of an inch, as selected.

Sensing Options

Sensing Beam. The sensor uses an infrared Class 1 laser for sensing, and a visible red

Class 2 laser (or Pilot laser) for alignment. Both lasers are aimed at the identical target

spot. The laser beams are collimated to focus a compact spot, even at long sensing

distances (see Figure 2).

Retroreflective

10 m

4 x 12 mm

10 m

Ø 20 mm

50 m

10 x 20 mm

Ø 100 mm

100 m

Ø 200 mm

Ø 500 mm

250 m

10 x 5 mm

10 x 5 mm

3 x 10 mm

4 m

6 m

Figure 2. Light spot dimensions

2 P/N 120244 Rev. B

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

Page 3

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

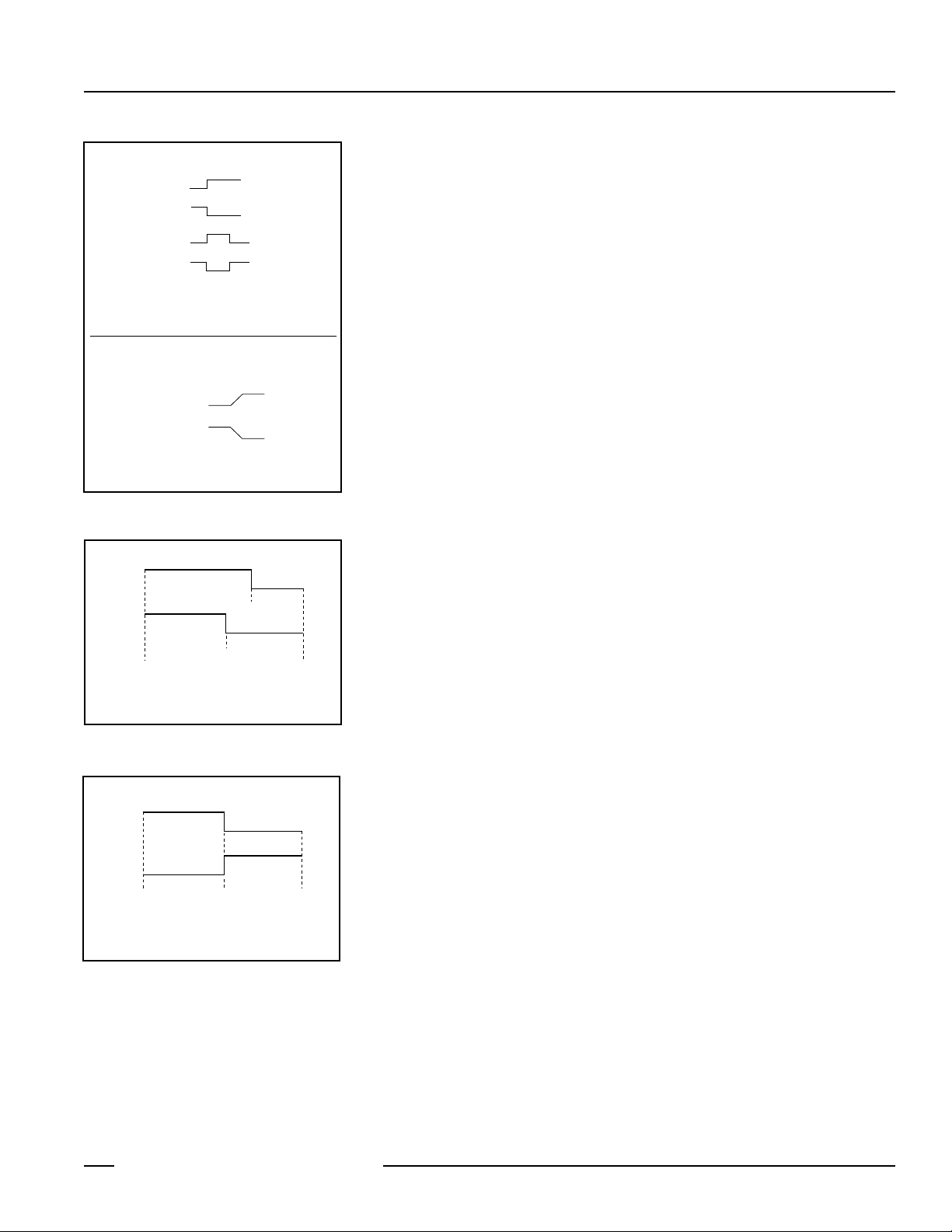

Discrete Outputs (Q1 and Q2) –

Single-point switching

Normally Closed

Normally Open

Two-point switching

Normally Closed

Normally Open

Hysteresis: Manually adjustable in ± 1 mm steps,

symmetrically around the switching point.

(If upper limit is reached, limit value of

measurement range becomes the upper limit.)

Analog Output (model LT7PIDQ only) –

NOTE: Analog A1 and A2 must be at least 300 mm apart.

A2

Mode 1 – Positive Slope

Mode 2 – Negative Slope

Two main TEACH methods:

• Individually teach A1 and A2 limits via manual input.

• Copy Discrete Output limits to Analog.

A1

A1

A2

Figure 3. Teach-mode options for each

output

Output 1

Output 2

Near

Sensing

Range

Figure 4. Each discrete output has its own limit for

background suppression

Output 1

Output 2

Near

Sensing

Range

Figure 5. The two discrete outputs share identical limits

for background suppression, but are

complementary

Point Q1.1

Teach

Point Q2.1

Teach

Point

(Q1.1 and

Q2.1 are

identical)

Teach

Far

Sensing

Range

Far

Sensing

Range

Password. A Password function is included to provide a measure of security for the

sensor settings. If Password is set to ON, the password must be entered before any

programming can take place. The password is always “1234”; it cannot be changed.

(The security results from the requirement to know the entry procedure and the timeout

function. If the password is not entered within approximately 10 seconds, the sensor will

return automatically to Run mode.) Measuring continues in the “background” while the

password is entered).

Select measurement in millimeters or inches (actually, hundredths of an inch. To “see”

whole inches on the display, imagine a decimal point on the display, two spaces in from

the right; see Figure 8).

Offset. An offset value can be entered or taught, which increases or reduces the measured

value, in order to compensate for a mounting position that does not correspond with the

zero point of the device. (For example, 3000 actual distance minus 1200 mm offset value

equals 1800 mm adjusted output value.) The offset value can be up to 100,000 mm (or

corresponding inch value); the plus or minus is also selectable. The offset value reverts to

0 if the factory preset function is used. The offset value applies equally to all outputs.

Factory Preset. Sensor easily reverts to factory preset conditions:

Teach-In –

Q1 and Q2 (Discrete) – single switchpoint (full sensing range), ± 5mm hysteresis

QA (Analog) – Mode 1, rising (positive slope, full sensing range)

Offset – 0

Unit – mm

Serial – RS422

Password – OFF

Multiple Outputs. The sensing distance can be taught using QuickSet, Teach-In, or by

manually entering the distance value(s). Either one or two sensing conditions may be

taught for each output (see Figures 4 and 5).

Discrete outputs: The two outputs may be configured identically or they may have

completely independent limits and configuration. One or two sensing conditions can be

taught for each. If one condition is taught, the output sets a switching threshold, around

which the selected hysteresis is applied. The two-point TEACH result differs, depending on

whether QuickSet or TEACH-IN is used to set the limits. In QuickSet, the sensor averages

the two taught values, then centers a 200 mm window around the averaged point (100

mm to each side). TEACH-IN window limits remain as taught; the window can be any

size. The selected hysteresis is applied to each threshold and window near limit and far

limit equally, no matter how they are taught.

Analog outputs: Analog limits 1 and 2 must be at least 300 mm apart. Individually teach

4 mA (A1) and 20 mA (A2) points or use the Copy function (selectable in the Analog

Output Mode menu) to copy the discrete limits (only the first limits of discrete 1 and 2) to

the analog output. (If copying Discrete limits to Analog, Discrete limits 1 and 2 must be

at least 300 mm apart, or sensor will not copy those limits.) The order in which they are

copied determines the analog output slope. For Mode 1 (positive slope) selected:

Q1, then Q2 – Limit Q1.1 becomes A1 (4 mA); Q2.1 becomes A2 (20 mA)

Q2, then Q1 – Limit Q1.1 becomes A2 (20 mA); Q2.1 becomes A1 (4 mA)

Manual Adjust: After Teach mode, Manual Adjust (or Edit) may be used to adjust the

value set for any output. It also can be used instead of Teach mode, to input a precise

limit value.

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

P/N 120244 Rev. B 3

Page 4

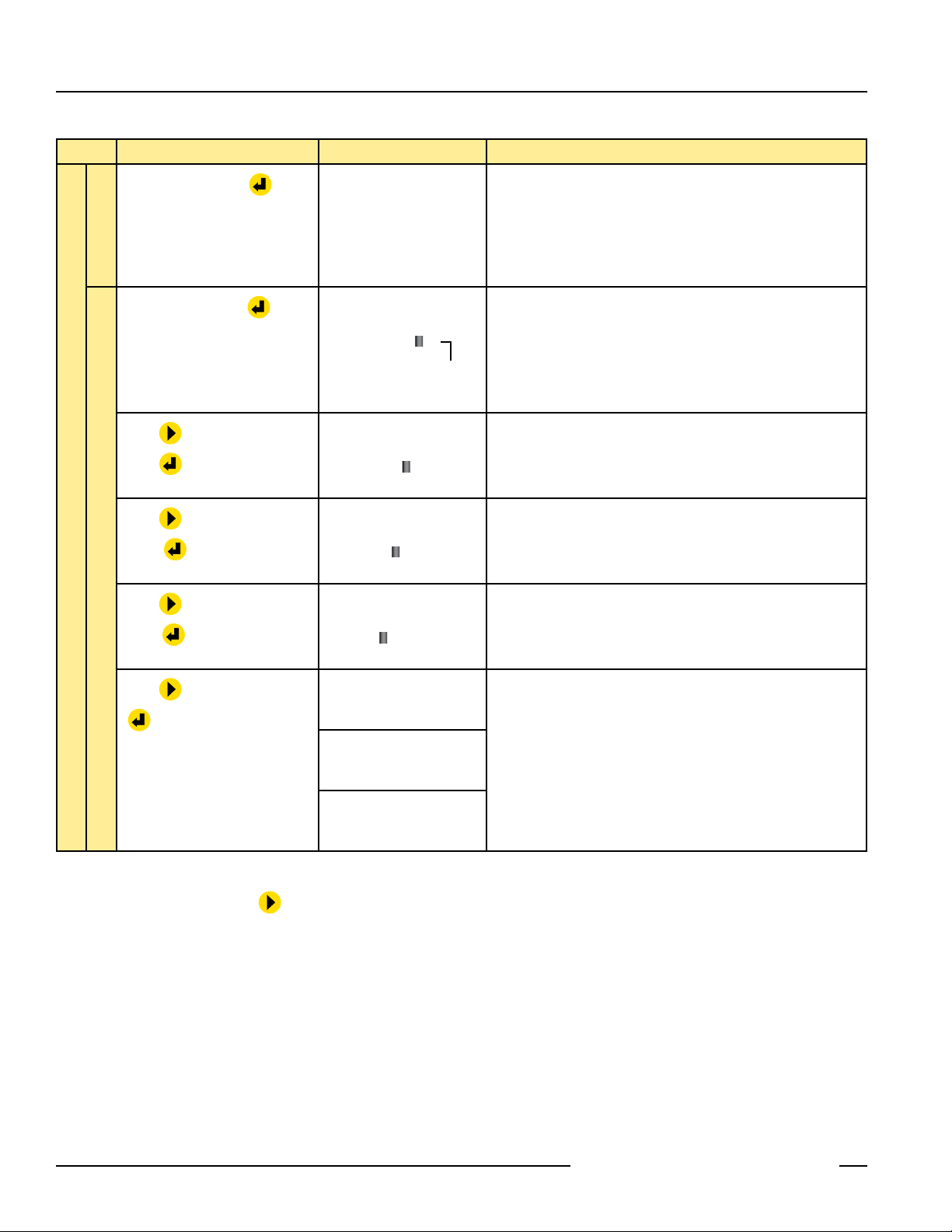

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

Mode Q1

Teach-In

(Set Q1)

Teach 1.1

Teach 1.2

Hyst 1

Teach-In

(Setup)

Mode Q2

Teach-In

(Set Q2)

Teach 2.1

Teach 2.2

Hyst 2

Mode Analog

Teach-In

Analog

Copy Q>A

Teach A1

Teach A2

Q1

Q2

QuickSet

(Enter)

4564 mm

Q1 |||| q2

Run Mode

Main Menu

Unit

(MM)

Unit > mm

Unit > inch

Serial > SSI

Password (Required only

if Password option is ON.

Factory preset is Password

OFF.

• Visible Pilot Laser OFF.

• Measuring Laser ON.

• Press or to

light display backlight

• Visible Pilot Laser ON.

• Measuring Laser ON.

• Display backlight ON.

Use or to scroll

between Main Menu

selections.

Use or to

scroll between

selections.

or

or or

or

or

Offset

(0)

Offset nnnn

Offset > clear?

or or or or

*Ext. Bus requires specialized sensor; not currently available.

Output 1

Menu

Output 2

Menu

Analog Output

Menu

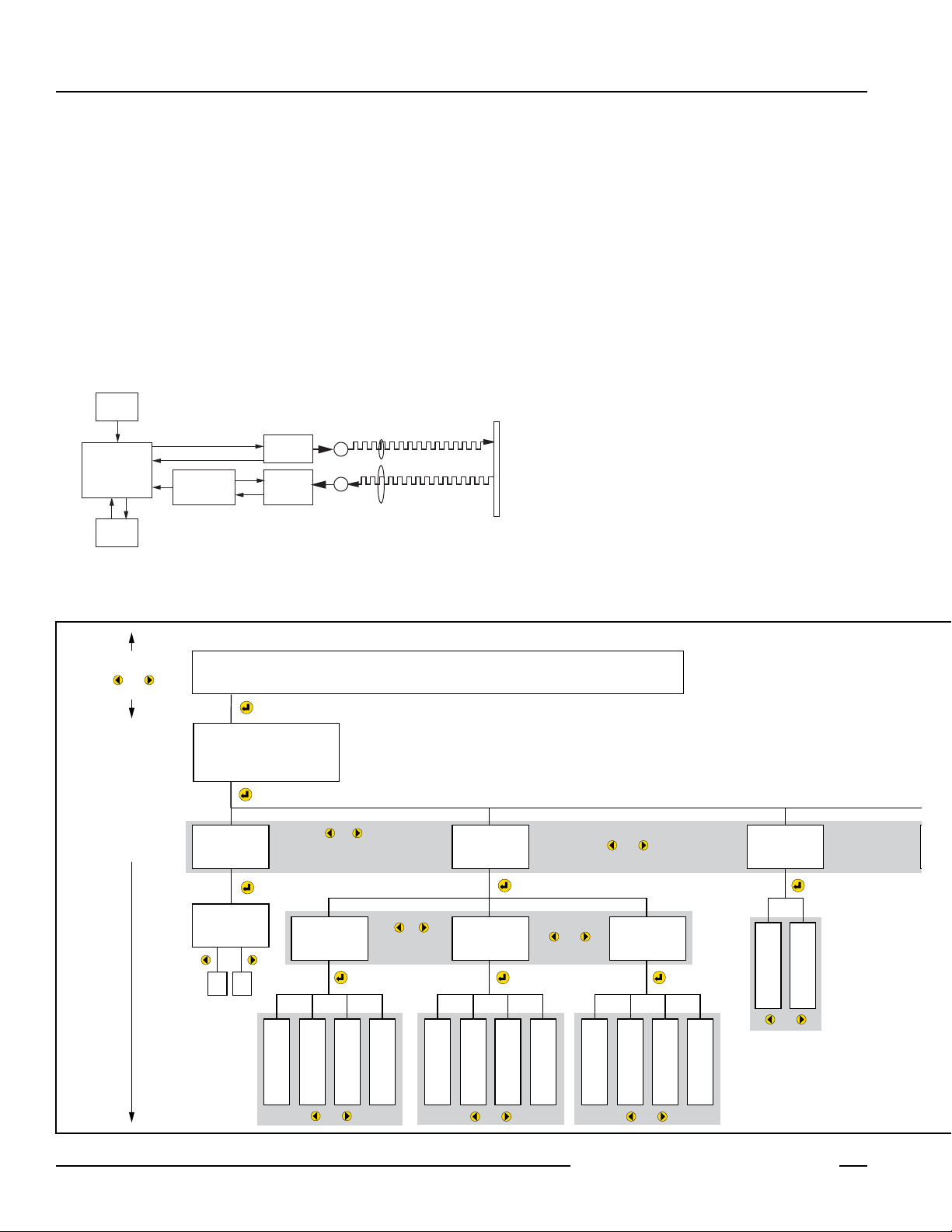

Theory of Operation

A short electrical pulse drives a semiconductor laser diode to emit a pulse of light. The

emitted light is collimated through a lens, which produces a very narrow laser beam.

The laser beam bounces off the target, scattering some of its light through the sensor’s

receiving lens to a photodiode, which creates an electrical pulse. The time interval

between the two electrical pulses (transmitting and receiving the beam) is used to

calculate the distance to the target, using the speed of light as a constant.

Multiple pulses are evaluated by the sensor’s microprocessor, which calculates the

appropriate position value. The outputs energize whenever the target is located between

the user-programmed window limits or when the preset switching threshold is crossed.

Outputs may be programmed for a variety of functions.

User

Interface

Microprocessor

Time-of-Flight

Engine

Output

Circuitry

Figure 6. Theory of operation

Emitter

Circuitry

Analog

Signal

Processing

Laser

Lenses Target

Emitter

E

R

Receiver

Element

Figure 7. Programming menu tree

4 P/N 120244 Rev. B

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

Page 5

DIST mm

1475

Sensor measures 1475 mm distance

to target.

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

Sensor Programming

The sensor may be programmed using either the on-board push buttons along with the

sensor’s LCD display, or via a serial interface. For serial interface instructions, see page

14. Sensor TEACH-mode instructions follow.

From Run mode, press Enter

OFF (factory setting), the sensor will proceed to the Main menu (see Figure 7). When the

sensor enters Programming mode, several things occur:

to access Programming mode. If Password is set to

DIST in

32512

Sensor measures 325.12" distance

to target.

Figure 8. Run mode display

Imaginary

decimal

point

• Sensor display lights up.

• Visible red Pilot laser turns ON.

• Measurement laser remains ON, alternating with the Pilot laser.

• Sensor proceeds to QuickSet on the Main menu (see Figure 7).

QuickSet: The received energy value is displayed in the form of a bar graph (the more

bars, the stronger the received signal). Outputs Q1 and Q2 are indicated as ON or OFF by

the LED indicators on the front of the sensor, and whether the “Q” is capitalized on the

display (Q1 = output 1 ON; q1 = output 1 OFF), press

to output Q1, and press

to teach the current condition to Q2. (Other Teach properties

to teach the current condition

are programmed in the Teach-In menu.) To quit the menu, use either the Enter button or

the Escape function.

Manual Adjust: After Teach-In and pressing Enter

to save, press

or

to

activate Manual Adjust (or Edit) mode for any output. The cursor flashes below the righthand digit of the display; press

or

to increase or decrease value by one unit.

Press

to save that digit and move cursor

to the next position left, and so on, until the

left-most digit is adjusted. Then press

to

adopt the manually adjusted value and switch

one menu level up.

Escape function: Press buttons

and

simultaneously to escape; sensor will go up

one menu level each time, and may not retain

new settings, depending on the programming

procedure.

Unit

(MM)

Unit > mm

Unit > inch

or or or

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

P/N 120244 Rev. B 5

Serial

(RS422)

Serial > SSI

Serial > Ext. Bus*

*Ext. Bus requires specialized sensor; not currently available.

RS422

(see page 13)

Serial > RS422

Password

(OFF)

Password (OFF)

Password (ON)

Factory

(Preset)

Factory > OK

Page 6

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

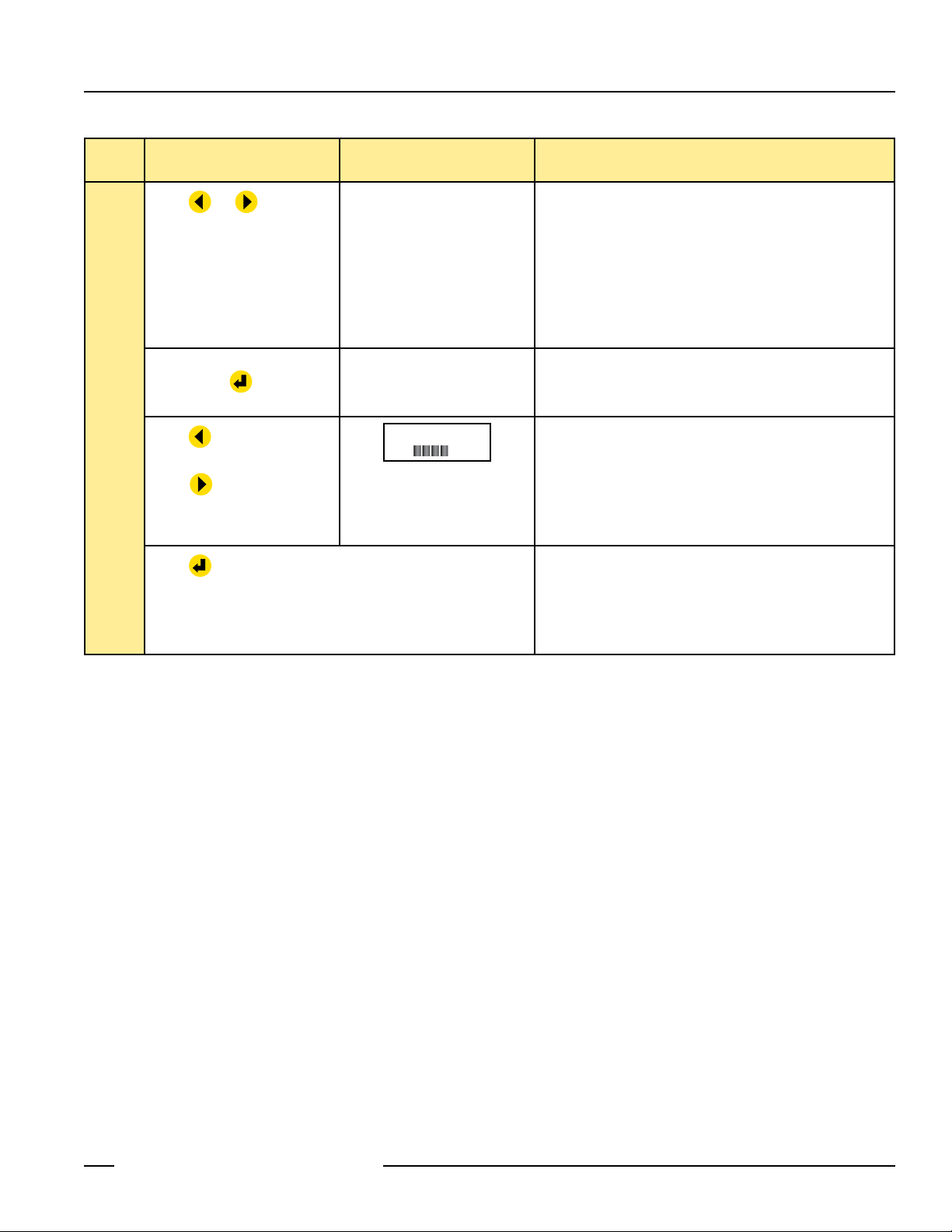

Procedure Example Displays Result

QuickSet

From Run mode, press

<ENTER>

No Password

If password is not required (factory preset condition), sensor proceeds

to QuickSet on the Main menu (Figure 7).

From Run mode, press

Press

press

Press

Programming Mode

press

Press

button 4 times,* then

button 3 times, then

button twice, then

Password Required

press

Press

button once, then press

PASSWORD

_ _ _ _

Blinking

Cursor

PASSWORD

_ _ _ 4

PASSWORD

_ _ 3 4

PASSWORD

_ 2 3 4

PASSWORD

1 2 3 4

PASSWORD

OK!

Sensor waits for valid password (1234); cursor blinks on right-hand

digit. If no password is begun within 10 seconds, sensor returns

automatically to Run mode.

Sensor inserts a 4 in the right-hand digit, then moves blinking cursor to

third position.

Sensor inserts a 3 in the third digit, then moves blinking cursor to

second position.

Sensor inserts a 2 in the second digit, then moves blinking cursor to

first position.

Sensor displays completed password and OK message, then proceeds

to QuickSet on the Main menu.

* Either arrow button may be pressed;

6 P/N 120244 Rev. B

QuickSet

ENTER

button will decrease number by one each time.

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

Page 7

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

q1 Q2

196

Main

Menu

QuickSet

Procedure Example Displays Result

QuickSet

Press

through Main menu options

With QuickSet visible on the

display, press

Press

<ENTER>

condition to Output 1.

Press

condition Output 2.

Press

– or –

Use Escape function*

or

to teach current

to teach current

to scroll

Bars indicate a strong signal

TEACH IN

OFFSET

UNIT

SERIAL

RS422

PASSWORD

FACTORY <PRESET>

QuickSet

<ENTER>

196 mm to target

Output 1 OFF

Output 2 ON

Sensor scrolls through Main menu options.

See following steps for procedures if other than QuickSet is

selected.

Sensor enters QuickSet program.

Current measured value is displayed on top line; received energy

value is indicated by bar graph (the more bars, the stronger the

received signal). Outputs Q1 and Q2 are indicated as ON or OFF by

the LED status indicators and by whether the “Q” is capitalized on

the display (Q1 = Output 1 ON; q1 = Output 1 OFF).

Sensor saves settings and returns to Main menu.

* Escape function available throughout Programming mode; returns sensor one step higher in menu.

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

P/N 120244 Rev. B 7

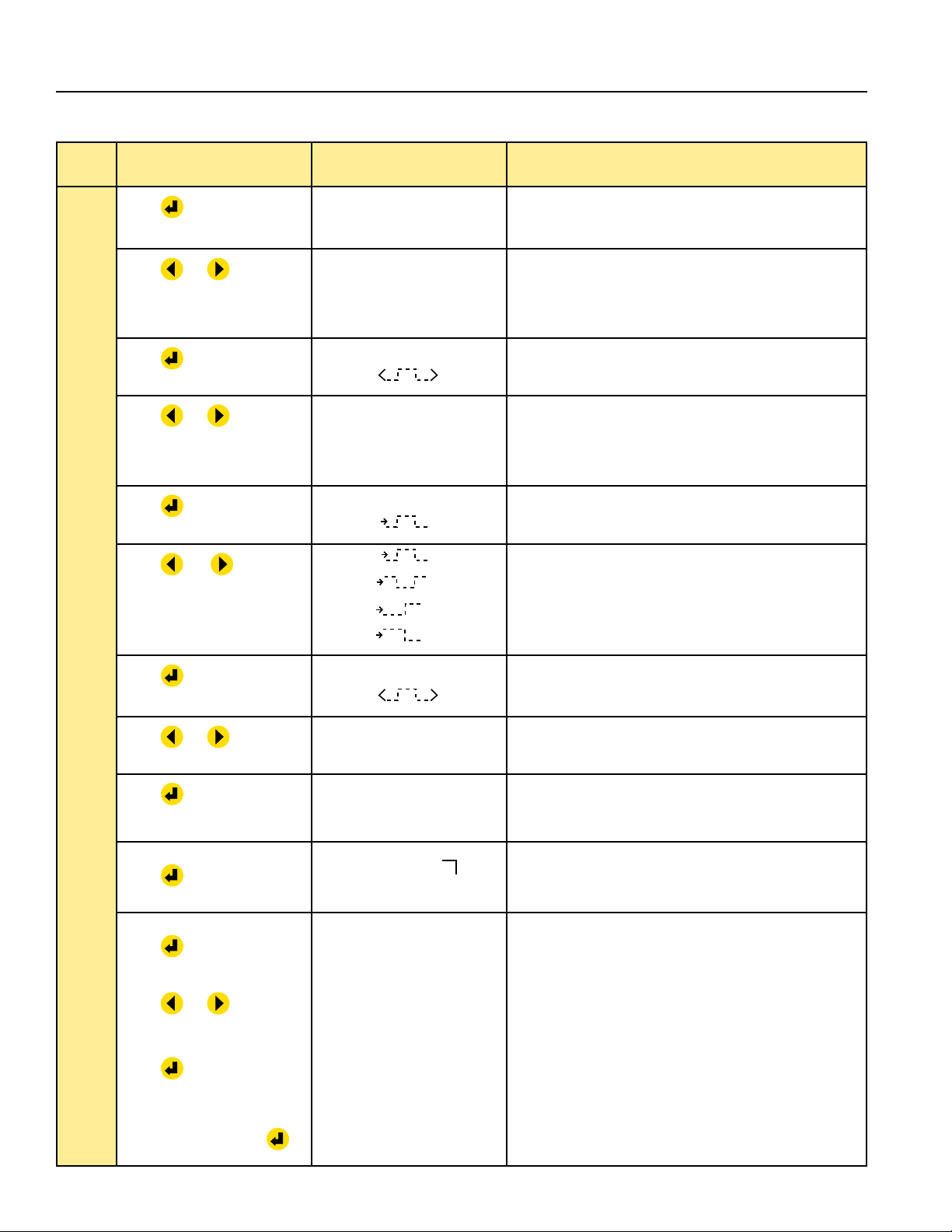

Page 8

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

Main

Menu

Procedure Example Displays Result

Press

menu.

Press

through output options.

Press

output.

Press

through options for Output 1.

Press

options.

Press

through options.

to enter TEACH-IN

or

to scroll

to select displayed

or

to scroll

to view output mode

or

to scroll

TEACH-IN

<SETQ1>

<SETQ1>

<SETQ2>

<ANALOG> (diffuse model only)

MODE Q1 Sensor displays current output and mode selections.

MODE Q1

TEACH1.1

TEACH1.2

HYST 1

MODE Q1 Sensor displays arrow to denote options can be viewed.

Sensor displays current output selected.

Sensor displays output options.

Sensor displays TEACH options for selected output.

See following steps for procedures if other than mode Q1.

Sensor displays output mode options.

TEACH-IN

Press

output mode.

to select displayed

(Setup) – Discrete

Press

through options for Output 1.

Press

option.

TEACH1.1

Press

condition.

Manual Adjust

Press

Adjust.

Press

or increase value of each digit.

Press

one digit left.

When cursor is at left-hand digit

or

to select displayed

to teach target

to access Manual

or

to select and move

to scroll

to decrease

MODE Q1 Sensor saves selected option.

TEACH 1.1

< 203>

TEACH 1.1

203

TEACH1.1

<241>

TEACH1.1

241

Limit 1 value

Sensor again displays TEACH options for selected output.

Sensor is ready to learn limit 1.

Proceed by teaching limit 1.1 target condition or via Manual Adjust

Sensor saves limit 1 setting and returns to Output 1 menu level.

Blinking cursor indicates active digit (beginning with right-hand

digit).

Sensor saves setting and returns to Output 1 menu level.

and value is correct, press

8 P/N 120244 Rev. B

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

Page 9

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

Main

Menu

Procedure Example Displays Result

TEACH 1.2

From Output 1 menu, press

teach 1.2 limit.

Repeat process on previous page

for limit 1.2.

Hysteresis

Press

function.

Press

increase value of each digit.

Press

TEACH-IN

digit left.

(Setup) – Discrete

When cursor is at left-hand digit

and value is correct, press

Use Escape function to go up one

menu level, or use

return to other Output 1 functions.

to

to select hysteresis

or

to decrease or

to select and move one

or

to

TEACH1.2

<12000>

HYST 1

< ±005>

HYST 1

±254

HYST 1

<±254> If value

is valid

– or –

HYST 1

LIMITED! If value is

outside

accepted limits

Sensor again displays TEACH options for selected output.

Blinking cursor indicates active digit (beginning with right-hand

digit).

Factory default setting is ± 005 (the minimum setting).

Maximum hysteresis setting is ± 254 mm or ± 9.99".

Sensor saves setting and returns to Hyst 1 menu level.

Repeat as desired for Output 2.

Teach processes for Outputs 1 and 2 are identical.

If value is outside accepted limits, sensor does not save new

setting.

TEACH Analog output individual limits using the same procedures as described above (except that the Analog output has no hysteresis

option). The Analog output has one unique function – copying the Discrete output limits (Q1.1 and Q2.1); for this procedure, see steps

below.

From TEACH-IN menu,

press

scroll to Analog Teach.

Select Analog mode, as for

discrete limits.

Press

TEACH-IN

Press

between options.

Press

option.

and

or

to copy Q to A

and

to select displayed

or

to scroll

to

(Setup) – Analog; Copy Discrete Limits

(If discrete limits are less than 300 mm apart)

TEACH-IN

<ANALOG>

COPY Q->A

<ENTER>

COPY Q->A

->Q1 & Q2

– or –

COPY Q->A

->Q2 & Q1

– or –

<300 mm

Sensor is ready to learn analog limits.

Procedure is identical to teaching discrete limits, except for copy/

paste function.

Sensor is ready to copy discrete limits to Analog output.

The option selected, in combination with the selected mode,

determines the analog output slope.

For Mode 1 (positive slope):

Q1 & Q2 – Limit Q1.1 becomes A1 (4 mA); Q2.1 becomes A2 (20

mA)

Q2 & Q1 – Limit Q1.1 becomes A2 (20 mA); Q2.1 becomes A1

(4 mA)

For Mode 2 (negative slope), the above is reversed.

If discrete limits are not at least 300 mm apart, display will show

< 300 mm and sensor will not perform the copy function.

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

P/N 120244 Rev. B 9

Page 10

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

Main

Menu

OFFSET

Procedure Example Displays Results

NOTE: Selected Offset value applies to all outputs equally.

Press

To Clear Offset, press

To Adjust Offset:

If no value was previously entered,

current sensing distance will be

displayed.

< 0 >

Press

distance.

-or-

Use

Offset Value adjustment.

to enter Offset menu.

to save current sensing

and

to activate

OFFSET

0

-then-

OFFSET

426

-or-

OFFSET

->CLEAR?

OFFSET

CLEARED!

OFFSET

0

-then-

OFFSET

426

• Used to zero sensor to predetermined setting.

• Expressed in either mm or hundredths of an inch, depending on

Unit selected (see below).

• Displayed Offset value is equal to the previously programmed

setting, followed by the current sensing distance.

• See following steps for procedure if other than Offset Value is

selected.

• If no value was previously entered, current sensing distance will

be displayed; see steps below.

• If a value is currently entered, the first option will be Offset

Clear?

Sensor clears Offset Value setting and returns to Main menu.

Cursor blinks on right-hand digit.

Press

decrease or increase value of each

digit;

hand digit between + and -.

Press

blinking cursor one position to left.

When cursor is at left-hand digit

and value is correct, press

Press

Press

between mm and inch options.

or

or

to save digit and move

or

UNIT

< MM >

When correct option is displayed,

press

.

10 P/N 120244 Rev. B

to

also toggles left-

to toggle

OFFSET

- 428

OFFSET

< -428>

UNIT

->MM

– or –

UNIT

->INCH

DIST mm

<5392>

Sensor saves each digit sequentially (including + or - sign).

Sensor saves setting and returns to Main menu.

Sensor is ready to accept new unit setting.

Select measurement in millimeters or inches (actually, hundredths

of an inch. To “see” whole inches on the display, imagine a

decimal point, two spaces in from the right.)

Sensor saves setting and returns to Main menu.

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

Page 11

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

Main

Menu

SERIAL

RS422

PASSWORD

Procedure Example Displays Results

See page 13.

RS422>

Dependent on serial connection selection; see page 13.

ENTER>

Press

• Press

< OFF >

• Press

• Press

or

between ON and OFF settings.

to save setting.

to enter Factory

Preset menu.

to toggle

PASSWORD

->OFF

PASSWORD

< OFF >

F-PRESET

->OK

Sensor is ready to accept new password setting.

If Password is set to ON, password must be entered each time

Programming mode is entered.

Sensor saves setting and returns to Main menu.

Returns sensor to factory preset conditions.

If activated, all previous settings are lost.

Use Escape function to exit without changing settings.

Factory settings are:

Teach-In – Limit value of measurement range; Q1 and Q2

single switching, normally open, analog mode 1, rising slope

Offset – 0

Unit – mm

Serial – RS422

Password – OFF

FACTORY

<PRESET>

Use Escape function to leave

settings as they are.

Press

Preset settings.

Use Escape function to return to

Run mode.

Run

Mode

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

P/N 120244 Rev. B 11

to revert to Factory

FACTORY

<PRESET>

F-PRESET

OK!

FACTORY

<PRESET>

DIST in

4839

Sensor returns to Main menu without changing settings.

Sensor returns to Main menu with factory preset condtions.

Sensor returns to Main menu with all saved settings.

Page 12

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

Alignment

Wherever the visible pilot laser spot is located, the sensing/measuring laser will be located

in the same position. For fine adjustment, use bracket model SMBLT7 with the fine-adjust

accessory kit SMBLT7F (see page 22) to provide up to ±3° angle in both X and Y axes.

Aligning the sensor manually (without the alignment aid accessory) – either model:

1. Mount the sensor.

2. Activate any Programming menu item (see Figure 7), so that the pilot laser is

ON.

3. Hold the retroreflector or target object at a short distance, for example less than

1 m (3'), and verify that the laser light spot is centered on it.

4. Move the reflector or target to its final position; verify that the laser spot is still

centered on it. Adjust as necessary.

5. Tighten the sensor mountings.

Using the alignment aid. For precise alignment of retroreflective models at long

distances, the alignment aid accessory (see Figure 9) is useful. It makes the visible pilot

laser spot easier to adjust, even when it is positioned off of the retroreflective target and at

a long distance – farther than 50 m (160').

1. Mount the sensor.

2. Mount the alignment aid on the front of the sensor, over the laser emitters as

shown in Figure 9.

3. Activate any menu item (see Figure 7), so that the pilot laser is ON.

4. Aim the sensor at the reflector.

5. Rotating the barrel as needed (depending on sensor mounting location), look into

the sight hole from about 2" (50 mm) away.

6. Turn the focus screw (opposite the sight hole) to focus the spot as sharply as

possible.

7. Adjust the sensor or target position until the laser spot is centered on the target.

8. Tighten the sensor mountings, recheck alignment; if ok, remove alignment aid.

NOTE: While alignment aid scope is in place, any measurements shown on the display will

be inaccurate. Also, the Pilot LED will be visible only through the alignment aid sight hole

(red laser light will not be visible to the naked eye on the target or another surface).

Sight

Hole

Focus

Screw

Figure 9. Alignment aid, mounted on sensor

Installation Notes

Some targets (those with a stepped plane facing the sensor, a boundary line, or rounded

targets) pose specific problems for sensing distances. For such applications, see Figure

10 for suggested mounting orientations.

12 P/N 120244 Rev. B

Recommended

Not Recommended

Figure 10. Sensor orientation for typical

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

targets

Page 13

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

Serial Communications

Factory delivery status settings are underlined below.

Serial Select (RS422/SSI)

With Serial Select it is possible to select the interface from RS422-compatible,

SSI1/10-compatible, or SSI1/8-compatible connections.

RS422-/ or SSI-Compatible

Depending on the setting made in Serial Select, the appropriate interface parameters are

displayed or altered. The following settings are possible:

• RS422

Baud rate: 4.8 or 9.6 or 19.2 or 38.4 or 57.6 kBaud

Data bit: 8 or 7

Stop bit: 1 or 2

REPEAT or SINGLE: REPEAT: the sensor continuously sends measured data via the

serial interface without waiting for a request.

SINGLE mode: a string of measured data is supplied only on request.

Parity: even (but not shown on LCD menu)

• SSI: 1/10 = LSB = 0.1 mm (10MIL) or 1/8 = LSB = 0.125 mm (8MIL)

6 possible codes:

BINARY24

BINARY24E

BINARY25

GRAY24

GRAY24E

GRAY25

Serial Response Speed

The distance measurement inside the sensor is recalculated every 12 ms. It is not a

moving average, but rather a new average is calculated for the previous 12 ms of data.

With the SSI output, the data can be read every 1.4 ms (likely the “same” reading for 8 or

9 readings, then a change). For most accurate target location prediction, sample at the 1.4

ms read rate of the SSI and see “when” the change happens. Worst case, that data will be

for the average target location over the previous 12 ms, plus 1.4 ms delay (i.e., the 12 ms

average was changed just after the previous read started).

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

P/N 120244 Rev. B 13

Page 14

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

RS422 Protocol

All commands via the RS422 serial interface have the following structure:

<STX><Command><[Data]><EOT>

The sensor answers all commands as follows:

<NAK> = the command was not recognized or the data is outside

the limit values.

or

<ACK> = the command was recognized and executed; the command

requires no return data.

or

<Data> = the command was recognized and the requested data has

been sent.

RS422 Cable

The RS422 interface is defined as a reliable, serial interface in full duplex mode, with

transfer rates up to 10 MBaud; max. cable length 1,000 m (4,000'). The shielded cable is

connected to the sensor connector and the ground terminal of the control cabinet.

RS422 User Commands and Their Meanings

Command Data to LT7* Data from LT7 Meaning

Get All Parameters

All parameters in text format:

LT7 $Revision x.xx$

Pilot laser status • Pilot laser status (ON/OFF/xx seconds ON)

Serial settings • Serial settings (see page 13)

Discrete Output Q1 settings • Discrete output condition

Discrete Output Q2 settings

GAP

Analog Output QA settings • Analog output condition (Diffuse sensors only)

Output status • Output unit of measure (mm or hundredth inch “10MIL”)

Offset status • Offset setting (in mm or hundredth inch)

Password setting • Password (enabled/disabled)

Error status

ECM — ACK

GDB — Energy value — 0 to -120dB

GNR — xxxxxxxxxx

All sensor parameters are displayed:

• Sensor software revision (number)

ON: Output high

OFF: Output low

Output mode (see IM1, IM2)

Limit 1 setting (see IL1, IL2)

Limit 2 setting (see IL4, IL5)

Hysteresis (see IH1, IH2)

Invert status (ON/OFF; see IN1, IN2)

Value (0 to 4095)

Limit 1 setting (see IL3)

Limit 2 setting (see IL6)

Invert status (ON/OFF; see INA)

• Error status (see GSI)

Execute Continuous Measurement

Set and triggered by the next request for measured values

Gain Level

Indicates the amount of receiving energy

Get Serial Number

Emitted as ASCII text (max. 24 characters)

Definitions:

STX: start transmission (hex 02 or CTRL B)

EOT: end of text (hex 04 or CTRL D)

NAK: no acknowledgement (hex 15 or CTRL U)

ACK: acknowledge (hex 06 or CTRL F)

Command: 3-digit command (ASCII text)

[Data]: whole numbers (ASCII text)

In ASCII text (command + data), spaces and

capitals/small letters are ignored.

14 P/N 120244 Rev. B

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

Page 15

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

Command Data to LT7* Data from LT7 Meaning

Get Error Status

0: No error

1: Error

Bit 7: Transmitter faulty

Bit 7

Bit 6

Bit 5

GSI —

X X X X X X X X

GTE — ±xxx

GVE — LT7 $Revision x.xx$

GCM — All available commands

ICM 0, 1 ACK

IDO Input desired value ACK

IVL 0, 1 ACK

ISB 0, 1 ACK

ESM — <meas. value>

EPW — ACK

Discrete Output Q1

000.. 254

IH1

IL1

IL4

IM1 0, 1, 2 ACK

IN1 0, 1 ACK

Input desired limit value (not

Input desired limit value (not

or

000.. 999

including Offset)

including Offset)

Bit 4

ACK

ACK

ACK

Bit 3

Bit 2

Bit 6: Receiver blinded or faulty

Bit 1

Bit 0

Bit 5: Temperature warning: T < -10°C or T > +70°C

Bit 4: Target out of range or transmitter faulty

Bit 3: Temperature error: T > +85°C

Bit 2: Supply voltage too low

Bit 1: PLL unlocked

Bit 0: Not used

Get Temperature

Internal temperature in °C

Get Version

Software version is displayed

Help Command/Get Commands

All available commands are displayed in text format

Input Continuous Measurement Mode

0: Continuous measurement output

1: Output of single measurement values

Input Offset Setting (All Outputs)

Up to 12,000 mm (plus or minus) or 480.00" (plus or minus)*

Enable Visible Laser

0: Pilot laser OFF

1: Pilot laser ON

Input Stand-by

0: Operation

1: Stand-by

Trigger/Execute Single Measurement

Request for measured value with single measurement output

Write Parameter Page/Execute Parameter Write

Parameters are stored

Set Discrete Q1 Hysteresis

0 - 254 mm or

0" - 9.99"

Input Discrete Q1 Limit 1

0 - 12,000 mm or 0" - 480.00"*

Selected Offset value will be applied to this limit

Input Discrete Q1 Limit 2

0 - 12,000 mm or 0" - 480.00"*

Selected Offset value will be applied to this limit

Discrete Output Q1 Mode

0: Inactive

1: 1 switching point

2: 2 switching points

Invert Discrete Output Q1

0: Q

1: Q inverted

*Decimal point and comma are “imaginary.” Do not input commas or periods in data (e.g., 12000 for mm or 48000 for inches).

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

P/N 120244 Rev. B 15

Page 16

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

Command Data to LT7 Data from LT7 Meaning

Discrete Output Q2

000.. 254

IH2

or

000.. 999

IL2

IL5

Input desired limit value (not

including Offset)

Input desired limit value (not

including Offset)

IM2 0, 1, 2 ACK

IN2 0, 1 ACK

Analog Output QA (Diffuse sensor models only)

IL3

IL6

Input desired limit value (not

including Offset)

Input desired limit value (not

including Offset)

INA 0, 1 ACK

ACK

ACK

ACK

ACK

ACK

Set Discrete Q2 Hysteresis

0 - 254 mm or

0" - 9.99"

Input Discrete Q2 Limit 1

0 - 12,000 mm or 0" - 480.00"*

Selected Offset value will be applied to this limit

Input Discrete Q2 Limit 2

0 - 12,000 mm or 0" - 480.00"*

Selected Offset value will be applied to this limit

Discrete Output Q2 Mode

0: Inactive

1: 1 switching point

2: 2 switching points

Invert Discrete Output Q2

0: Q

1: Q inverted

Input Analog QA Limit 1

0 - 12,000 mm or 0" - 480.00"*

Selected Offset value will be applied to this limit

Input Analog QA Limit 2

0 - 12,000 mm or 0" - 480.00"*

Selected Offset value will be applied to this limit

Invert Analog Output QA

0: Q

1: Q inverted

*Decimal point and comma are “imaginary.” Do not input commas or periods in data (e.g., 12000 for mm or 48000 for inches).

SSI-Compatible Interface

T = Duration of clock signal,

minimum 2 µSec = 500 kHz, max. 13 µSec = 77 kHz

Tv = Delay time max. 360 ns

T

Clock

Tv

SSI Data

Gn G1 G0Gn-1

Figure 11. SSI-compatible interface timing

Tm

Tm = Minimum time between last rising edge and reloading

of SSI approx. 24 µSec.

Gn = MSB (here Gray Code)

24 bit transmission: G1 = second LSB, G0 = LSB

24+E transmission: G1 = LSB, G0 = Error bit

25 bit transmission: G1 = second LSB, G0 = LSB

NOTE: With SSI-compatible transmission, data updates in synchronization with the readout

cycle. The data is as up-to-date as the time interval between two readouts. An

intermittent readout is therefore recommended. After a longer readout interval, the data

contents of the first readout can be “out-of-date” and should be ignored.

16 P/N 120244 Rev. B

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

Page 17

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

SSI Cable

The maximum baud rate for reliable data transfer depends on the cable length (see table).

The shielded connection cable is connected to the sensor connector and the ground

terminal of the control cabinet.

SSI Cable Length

Cable Length < 25 m < 50 m < 100 m < 200 m < 400 m

Baud Rate < 500 kHz < 400 kHz < 300 kHz < 200 kHz < 100 kHz

CAUTION . . . This sensor contains no

user-serviceable components.

Do not attempt to repair.

Incorrect component values may produce hazardous

laser radiation levels.

Troubleshooting; Error Codes

In the event of errors, corresponding error messages appear on the display and the error

outputs Qs and Qp (active low) are set according to the table below.

Multiple errors may simultaneously exist. The error status may be interrogated via the

RS422 “GSI” command. (For example, if a too-low supply voltage causes a counter error,

the GSI command would report “00000110”.)

LCD Error

Message

BLINDING Active 0 1 0 0 0 0 0 0 Internal error or ambient light too strong

LAS. ERR. Active Active 1 0 0 0 0 0 0 0

LOW VOLT Active Active 0 0 0 0 0 1 0 0

NO VALUE 0 0 0 0 0 0 0 0

PLL UNLOCKED Active Active 0 0 0 0 0 0 1 0 Counter error – repair or replace sensor

OVERTEMP

Dist (mm)

> Maximum

Out (Active Low) Bit

Qs Qp 7 6 5 4 3 2 1 0

Active 0 0 1 0 0 0 0 0

Active

(Laser

OFF)

Active

(Laser

OFF)

Active 0 0 0 1 0 0 0 0 No target in range or sensor badly aligned

0 0 1 0 1 0 0 0

Meaning

Measurement laser faulty – repair or replace

sensor

Voltage too low or error in measurement of

supply voltage

First measurement after switching ON –

sensor not yet ready. Message disappears

automatically when ready (after 300 ms).

Temperature out of acceptable range (below

-10°C or above +70°C)

Operating temperature too high (above +85°C

within housing); measurement laser switches

OFF. Switch sensor off; sensor may operate

after a cool-down period.

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

P/N 120244 Rev. B 17

Page 18

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

Specifications

LT7PLVQ LT7PIDQ

Sensing Range 0.5 to 250 m (using specified reflector) 6% Black card: 0.5 to 3 m

18% Gray card: 0.5 to 7 m

90% White card: 0.5 to 10 m

Supply Voltage 18 to 30V dc (10% maximum ripple)

Power Consumption < 4.5 W @ 25º C

Supply Protection Circuitry Protected against reverse polarity and transient over voltages

Measuring Laser Infrared, 900 nm, Class 1

Laser Control Measurement laser is ON when sensor is ON. Pilot (visible) laser enabled during Programming mode; alternates with

measurement laser.

Spot Size See Figure 2.

Pilot Laser Visible red, 650 nm, Class 2

Discrete & Analog Output

Protection

Discrete Outputs

Discrete Switch Points

Discrete Output Hysteresis

Alarm Outputs

Analog Output N/A 4-20 mA

Maximum Cable Length 100 m

Output Response Time 12 ms

Linearity ± 10 mm

Resolution/Repeatability ± 2 mm ± 4 mm

Color Sensitivity

(Diffuse Models)

Temperature Effect < ± 5 mm over the total sensing range

Minimum Analog

Window Size

Adjustments See pages 2-11. Push-button-directed password enable/disable, measurement unit select, offset value select, output

Serial Interface RS422 or SSI compatible

Serial Measurement Speed SSI: 1.4 ms (SSI cycle 80 µs); RS422: 2.9 ms @ 57.6 kBaud

Protected against continuous overload and short circuit

(2) 100 mA, PNP

Adjustable in 1 mm steps

Adjustable, 10 mm min.

50 mA, PNP (N.O.)

N/A Contact Factory.

N/A 300 mm

limits set, output mode select, analog output slope select (diffuse models only), and output limit manual adjust.

Indicators 4 LEDs: Green Power ON/OFF, Red Alarm (Error) LED, Orange Output 1 and Output 2 conducting LEDs,

2-line digital LCD display. See page 2 for more information.

Construction ABS shock-resistant housing; PMMA window; polycarbonate displays

Dimensions 93 x 93 x 42 mm; see page 19

Weight Approximately 230 g

Environmental Rating IEC IP67

Connections 12-pin M16 connector; 100 m (330’) max. cable length; use only cables listed on page 20

Operating Conditions Temperature: −10 to +50 °C (+14 to 132 °F) in continuous operation

Storage Temperature −30 to +75 °C (−22 to +167 °F)

Banner Engineering Corp. • Minneapolis, MN U.S.A

18 P/N 120244 Rev. B

www.bannerengineering.com • Tel: 763.544.3164

Page 19

Specifications, cont’d

10 mm x 5 mm

Vibration/Shock EN 60947-5-2

Application Notes

• All specifications are based on the specified surface at constant ambient conditions and

following a minimum operating time of 15 minutes.

• For best accuracy, allow a 15-minute warmup before programming or operating

• Crosstalk avoidance: Light spots must be separated by at least 200 mm.

• Also see page 12 for target orientation notes.

Certifications

Description of Laser Classes

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

Operating Mode

Laser Class 1

Setup Mode

Laser Class 2

Do not stare into beam

Dimensions

LT7PIDQ

wh TX + / SSI: Data +

bn Output 1 (PNP)

gn RX + / SSI: Clock +

ye Analog Output: 4 - 20mA

gy Alarm 1 Output (PNP)

pk Alarm 2 Output (PNP)

rd 18 - 30V dc

bk RX - / SSI: Clock -

vt N/C

gy/pk

rd/bu Output 2 (PNP)

bu Gnd

L - GAGE

bannerengineering.com

bannerengineering.com

TX - / SSI: Data -

TM

Class 1 (Infrared Sensing Laser)

Lasers that are safe under reasonably foreseeable

conditions of operation, including the use of optical

instruments for intrabeam viewing.

Reference 60825-1 Amend. 2 © IEC:2001(E),

section 8.2.

Class 2 (Visible Pilot Laser)

Lasers that emit visible radiation in the wavelength

range from 400 nm to 700 nm

where eye protection is normally afforded by

aversion responses, including the blink reflex. This

reaction may be expected to

provide adequate protection under reasonably

foreseeable conditions of operation, including the

use of optical instruments for intrabeam viewing.

Reference 60825-1 Amend. 2 © IEC:2001(E),

section 8.2.

OUTPUT1 OUTPUT2

ALARM POWER

42.0 mm

1.65"

95.0 mm

3.74"

3.21"

0.23"

Operating Mode

Laser Class 1

Setup Mode

Laser Class 2

Do not stare into beam

42.8 mm

(Infrared)

(Visible - Red)

1.68"

LT7PIDQ

wh TX + / SSI: Data +

bn Output 1 (PNP)

gn RX + / SSI: Clock +

ye Analog Output: 4 - 20mA

gy Alarm 1 Output (PNP)

pk Alarm 2 Output (PNP)

rd 18 - 30V dc

bk RX - / SSI: Clock -

vt N/C

gy/pk

TX - / SSI: Data rd/bu Output 2 (PNP)

bu Gnd

L - GAGE

bannerengineering.combannerengineering.com

TM

42.0 mm

1.65"

Class 1

Ø 5.7 mm

0.22"

M5 Threaded

27.5 mm

1.08"

Emitter

Operating Mode

(Infrared)

Laser Class 1

Setup Mode

Laser Class 2

(Visible - Red)

Do not stare into beam

Class 1

93.0 mm

ESC

3.66"

19.75 mm

0.78"

81.5 mm

5.75 mm

52.0 mm

2.05"

24.0 mm

0.94"

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

P/N 120244 Rev. B 19

Page 20

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

Hookups

*See pinout below.

red

bu

bn

red/bu

ye

gy

pk

wh

gn

gy/pk

bk

vt

load 1

+

18 - 30V dc

–

load 2

No Connection for Retro models

4-20 mA

Alarm Output 1 (Qs)

Alarm Output 2 (Qp)

RS422: Tx+ SSI: Data+

RS422: Rx+ SSI: Clock+

RS422: Tx– SSI: Data–

RS422: Rx– SSI: Clock–

No Connection

Pin* Name Cable Color Description

A TX+ White RS422: Transmitter data / SSI: Data +

B Q1 Brown Discrete Output 1

C RX+ Green RS422: Receiver data / SSI: Clock +

D analog Yellow Analog Output 4 to 20 mA

E Qs Gray Alarm Output 1

F Qp Pink Alarm Output 2

G V+ Red +18 to 30V dc

H RX- Black RS422: Receiver data / SS1: Clock –

J NC Violet

K TX- Gray/Pink RS422: Transmitter data / SS1: Data –

L Q2 Red/Blue Discrete Output 2

M GND Blue 0V (GND)

Accessories

Quick-Disconnect Cables

Style Model Length Pinout

12-pin Euro-style

right-angle

(Rating pending;

consult factory)

12-pin Euro-style

straight

(IP67)

MQDC-1210RA

MQDC-1230RA

MQDC-1210ST

MQDC-1230ST

3 m (10 ft)

10 m (30 ft)

3 m (10')

10 m (30')

F

G

E

D

H

M

L

J

C

A

K

B

Refer to hookups above for pin descriptions.

20 P/N 120244 Rev. B

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

Page 21

Accessory Mounting Brackets

0.71"

140.5 mm

20°

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

SMBLT7

(5.53")

90.5 mm

(3.56")

• Right-angle bracket

• 300 series stainless steel

• Fine-adjust accessory available (model SMBLT7F)

53.0 mm

(2.09")

11.0 mm

(0.43")

25.0 mm

(0.98")

49.5 mm

1.95"

14.0 mm

(0.55")

45.0 mm

(1.77")

Ø 3.1 mm

(0.12")

3.0 mm

(0.12")

SMBLT7F

• Fine-adjust accessory for model SMBLT7 bracket;

bracket sold separately

• 304 series stainless steel

• Mounting hardware included

14.0 mm

(0.55")

Opening for set screw

(included)

10.0 mm

(0.39")

Ø 3.0 mm

(0.12")

45°

18.0 mm

16.9 mm

0.67"

32.0 mm

(1.26")

Using the Bracket and Fine-Adjust Accessory

Bolt the two accessories to the base and/or angle of the bracket as shown in the photo above, aligning the small pins in the accessory

with the small holes in the bracket. Install the sensor on the bracket, and the bracket on the mounting surface, using the bracket’s curved

slots for rough alignment. Tighten these bolts finger-tight. Tighten or loosen the SMBLT7F set screws to fine-adjust the sensor alignment

in each axis; then tighten all bolts.

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

P/N 120244 Rev. B 21

Page 22

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

Retroreflectors

Model

BRT-250

BRT-540

BRT-700

BRT-TVHG-8X10P

LT7 Retro

Sensor Range

50 m (163')

200 m (655')

250 m (820')

For distances

up to

100 m (328')

Alignment Aid

Model Description

LAT-2

Clip-on attachment for sensor; allows laser spot to be seen

easily at long distances ≥ 50 m

Description

Reflector mounted to rigid

aluminum backing

250 x 250 mm (9.8" x 9.8")

540 x 540 mm (21.3" x 21.3")

700 x 700 mm (27.6" x 27.6")

Retroreflective Tape

203 x 254 mm (8" x 10")

NOTE: Retroreflective material has a pressure-sensitive adhesive.

For maximum adhesion, surfaces must be clean and dry before

applying. For best results, use full-size; target may be trimmed as

necessary.

22 P/N 120244 Rev. B

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

Page 23

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

Banner Engineering Corp. • Minneapolis, MN U.S.A

www.bannerengineering.com • Tel: 763.544.3164

P/N 120244 Rev. B 23

Page 24

L-GAGE® LT7 Long-Range Time-of-Flight Sensor

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year following the date of shipment. Banner Engineering Corp. will

repair or replace, free of charge, any product of its manufacture which, at the time it is returned to the factory, is found to have been defective during the warranty period. This

warranty does not cover damage or liability for misuse, abuse, or the improper application of the Banner product.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR IMPLIED (INCLUDING, WITHOUT LIMITATION, ANY WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE), AND WHETHER ARISING UNDER COURSE OF PERFORMANCE, COURSE OF DEALING OR TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion of Banner Engineering Corp., replacement. IN NO EVENT SHALL BANNER ENGINEERING CORP. BE LIABLE

TO BUYER OR ANY OTHER PERSON OR ENTITY FOR ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL

DAMAGES RESULTING FROM ANY PRODUCT DEFECT OR FROM THE USE OR INABILITY TO USE THE PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE,

TORT, STRICT LIABILITY, NEGLIGENCE, OR OTHERWISE.

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming any obligations or liabilities relating to any product previously

manufactured by Banner Engineering Corp.

P/N 120244

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN 55441 • Phone: 763.544.3164 • www.bannerengineering.com • Email: sensors@bannerengineering.com

Loading...

Loading...