Page 1

L-GAGE® LT3 Long-Range Time-of-Flight Laser Sensor

!

!

Self-contained laser distance sensor, two discrete outputs

Features

• Extremely long range: 5 m with white targets, or 3 m with gray targets for diffuse

mode sensors, up to 50 m for retroreflective models

• Two discrete (switched) outputs in each sensor, with independent window limits

• Discrete outputs can be used for precision background suppression

• Output select wire is used to choose either NPN or PNP outputs (see hookups)

• Fast, easy-to-use integrated push-button TEACH-mode programming; no

potentiometer adjustments

• Remote TEACH function for security and convenience

• Output response is programmable for three speeds

• High-grade retroreflective target included with each retroreflective-mode sensor

• Choose 2 m or 9 m unterminated cable, or 8-pin Euro-style swivel QD connector

• Rugged construction withstands demanding sensing environments; rated IEC

IP67, NEMA 6

†

. . .

This

WARNING . . .

Not To Be Used for

Personnel Protection

Never use these products as sensing

devices for personnel protection. Doing

so could lead to serious injury or death.

These sensors do NOT include the

self-checking redundant circuitry

necessary to allow their use in personnel

safety applications. A sensor failure

or malfunction can cause either an

energized or de-energized sensor output

condition. Consult your current Banner

Safety Products catalog for safety

products which meet OSHA, ANSI and

IEC standards for personnel protection.

CAUTION

sensor contains no userserviceable components.

Do not attempt to repair.

ncorrect component values may produce

I

hazardous laser radiation levels.

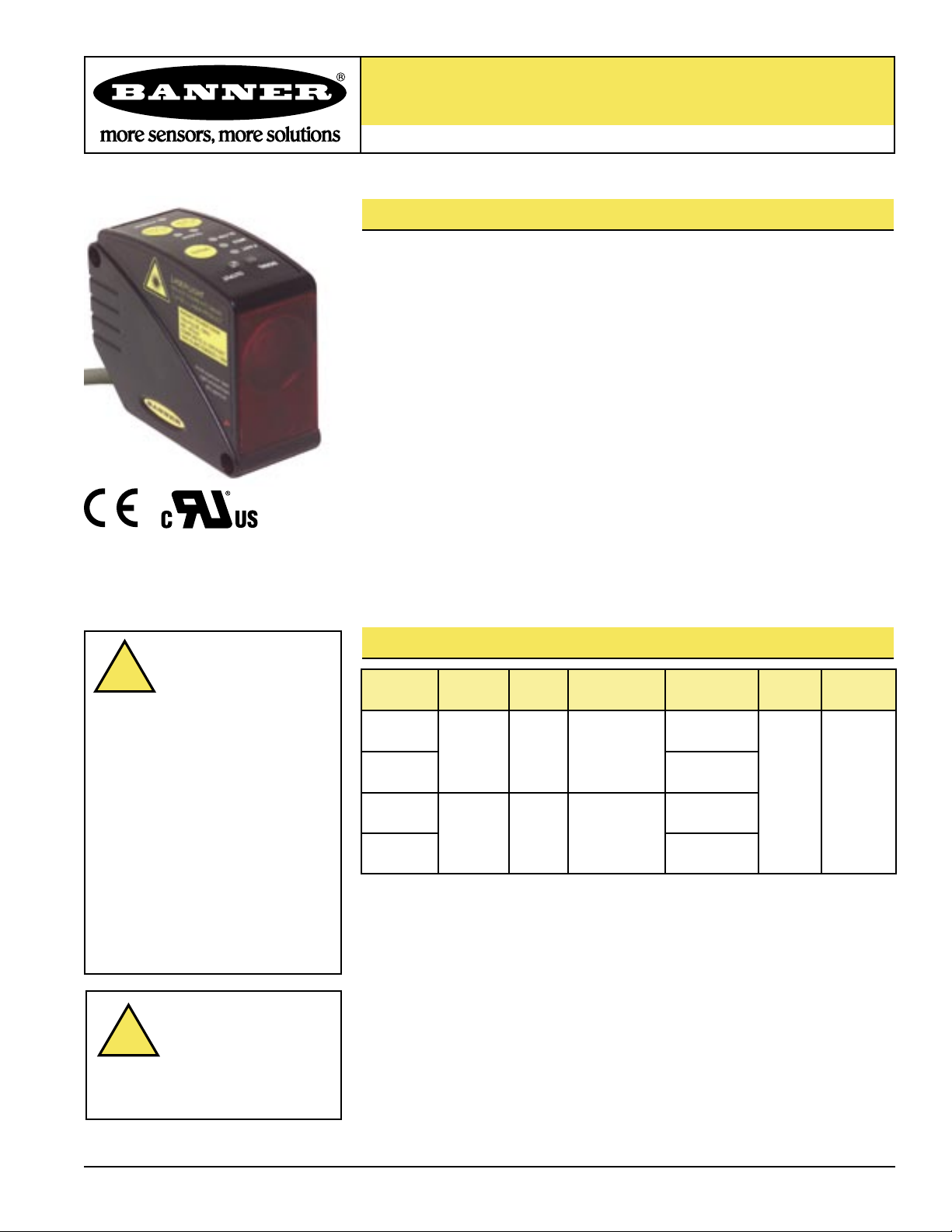

Models

Models

LT3BD

LT3BDQ

LT3BDLV

LT3BDLVQ

* 9 m cables are available by adding suffix “W/30” to the model number of any cabled

sensor (e.g., LT3BD W/30). A model with a QD connector requires a mating cable;

see page 11.

** Retroreflective range specified using included model BRT-TVHG-8X10P

high-grade target.

†

NOTE: See Banner website for information on analog/discrete models at:

Sensing

Mode

Diffuse Class 2

Retroreflective

bannerengineering.com

Laser

Class

Class 1

Sensing

Distance

0.3 to 5 m

(11.8" to 16.4')

0.5 to 50 m**

(20" to 164')

Cable*

2 m (6.5')

8-wire

8-pin

Euro-style QD

2 m (6.5')

8-wire

8-pin

Euro-style QD

Supply

Voltage

12 to

24V dc

Discrete

Output

NPN or

PNP

Selectable

Printed in USA 02/05 P/N 68503 rev. C

Page 2

L-GAGE® LT3 Long-Range Time-of-Flight Sensor –

Microprocessor

User

Interface

Emitter

Circuitry

Analog

Signal

Processing

Time-of-Flight

Engine

Output

Circuitry

Laser

Emitter

Lenses Target

Receiver

Element

E

R

SIGNAL OUTPUT

FAST

MED

SLOW

TEACH

POWER

SPEED

Signal LED

Output LED

Response Speed

Indicators

Discrete Output

1

Teach LED

Discrete Output 2

Teach LED

Discrete Output 1

Programming

Push Button

Discrete Output 2

Programming

Push Button

Power ON/OFF LED

Response Speed

Push Button

D

D

Theory of Operation

A short electrical pulse drives a semiconductor laser diode to emit a pulse of light. The

emitted light is collimated through a lens, which produces a very narrow laser beam.

The laser beam bounces off the target, scattering some of its light through the sensor’s

receiving lens to a photodiode, which creates an electrical pulse. The time interval

between the two electrical pulses (transmitting and receiving the beam) is used to

calculate the distance to the target, using the speed of light as a constant.

Multiple pulses are evaluated by the sensor’s microprocessor, which calculates the

appropriate position value. The discrete (switched) output energizes whenever the

target is located between the user-programmed discrete window limits. Window

limits for both discrete outputs may be the same, or they may be programmed

independently.

Two Discrete Outputs

Figure 1. Theory of operation

Response Speed

Prior to setting window limits, use the sensor’s Speed push button to toggle between

the three response speed settings. The selected speed will be indicated by one of the

three Response Speed indicator LEDs (see Figure 2). See Specifications for further

information.

Sensor Setup

Allow 30 minutes after power-up to allow the sensor’s internal temperature to stabilize,

before operating or attempting to program the sensor. If the sensor will be used in

applications where the temperature is several degrees higher or lower than ambient,

allow the sensor to stabilize in that condition before programming the window limits.

(Range will decrease as the sensor warms up.)

The laser enable feature allows the sensor to be continually powered, and enabled only

when being used. This eliminates the need for the extended warm-up period between

uses.

The sensor’s red Signal LED indicates the condition of the received signal from the

object being measured. When programming window limits, this LED must be ON solid

(not flashing) for the sensor to accept the setting. On diffuse-mode models, to ensure

that the received signal will not be marginal during operation, move the target object

300 mm beyond the furthest desired set point during setup, and verify that the signal

LED is still ON solid.

Window Limits

Window limits may be taught to the sensor in several ways. The following methods

(beginning on page 4) describe the programming procedures using the push buttons on

the top of the sensor or via remote programming (remote TEACH).

2 P/N 68503 rev. C

Programming

Figure 2. Sensor features

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 3

L-GAGE® LT3 Long-Range Time-of-Flight Sensor –

RADIANT POWER 0.5 mW

650 - 670 n

m

COMPLIES WITH 21 CFR PART

1040.10 AND EN60825-1:199

4

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

LASER LIGHT

Avoid exposure laser light emitted

from this aperture

Output 1

Near

Sensing

Range

Teach

Point 2

Output 2

Far

Sensing

Range

Teach

Point 1

Output 1

Near

Sensing

Range

Output 2

Far

Sensing

Range

Teach

Point

Two Discrete Outputs

Class 2 Safety Notes

Low-power lasers are by definition

incapable of causing eye injury within

the duration of the blink, or aversion

response, of 0.25 seconds. They must

also emit only visible wavelengths (400700 nm). Therefore, an eye hazard can

exist only if an individual overcomes

the natural aversion to bright light and

stares directly into the laser beam.

These lasers are required to have a

“hazard” label and to have an indicator

light to indicate that laser emission is

occurring.

When operating a class 2 laser:

• Do not permit a person to stare

directly into the beam

• Do not point the laser at a person’s

eye at close range

Beam Paths:

The beam emitted by a class 2 laser

product should be terminated at the

end of its useful path. Open laser beam

paths should be located above or below

eye level, where practical.

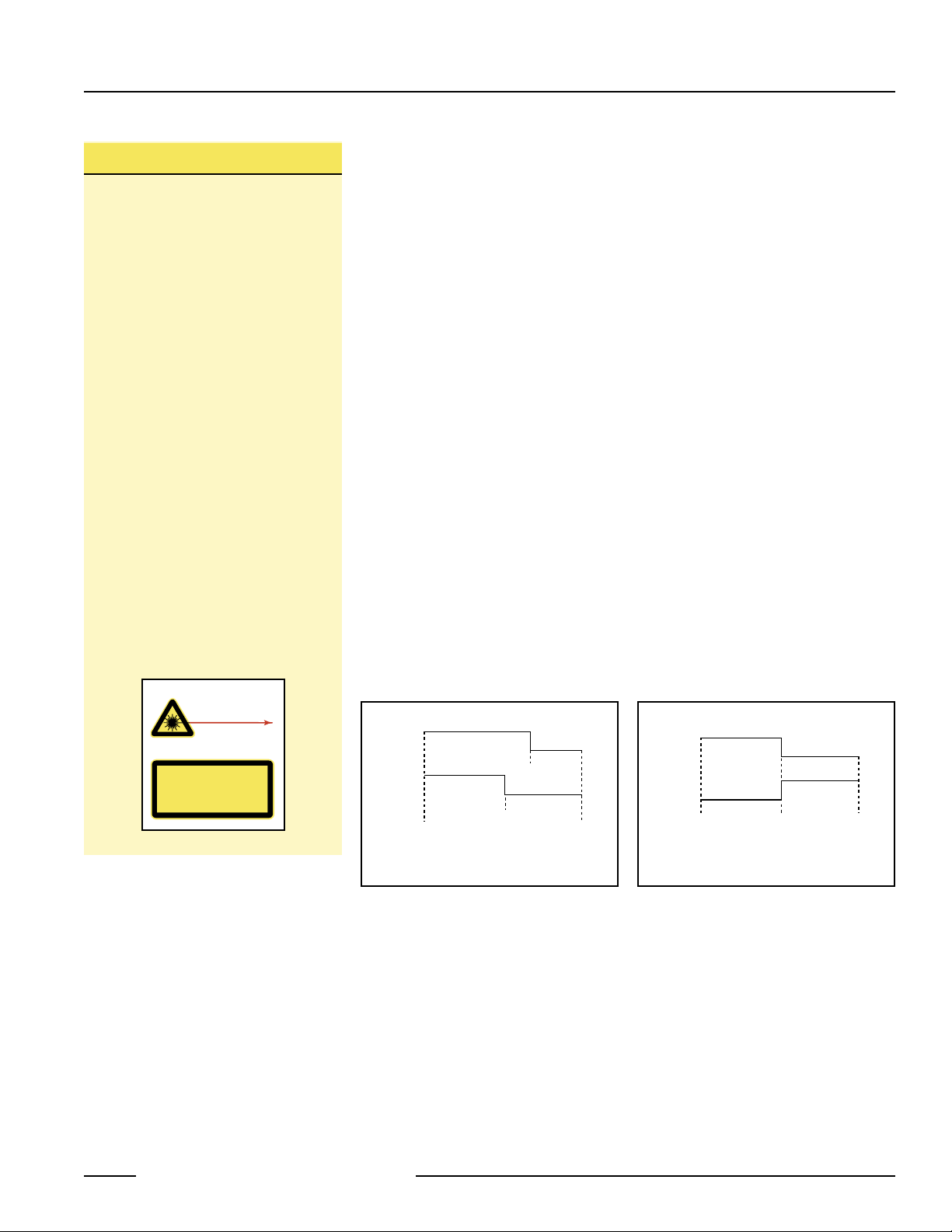

Push-Button Programming

Both outputs may be taught simultaneously, when complementary operation is required

(while one output is conducting, the other is not). When taught separately, each output

may be taught different limits (one output may be taught a window, and the other may

be programmed for background suppression, for example).

Remote Programming

To program the sensor remotely or to disable the keypad, the Remote Programming

function may be used. Disabling the keypad prevents accidental or unauthorized

adjustment of any programming settings. Connect the yellow wire of the sensor to +5

to 24V dc, with a remote programming switch connected between them.

NOTE: The impedance of the remote teach input is 55 kΩ.

Programming is accomplished by following a sequence of input pulses (see pages 4

and 5). The duration of each pulse (corresponding to a push button “click”), and the

period between multiple pulses, are defined as “T”: 0.04 seconds < T < 0.8 seconds.

Teaching Discrete Limits for Background Suppresson

For some applications, ignoring objects beyond a certain distance may be required. To

suppress the background, place a target object at the selected distance, and teach the

position twice. The sensor’s discrete output will activate when an object is detected

between the sensor’s minimum sensing distance and the taught position.

NOTE: The sensor allows for some forgiveness in this procedure. If the two limits are

not exactly the same (but less than 20 mm apart), the sensor will put the set

point at the “average” of the two limits.

Output 1 and Output 2 may be taught independent limits for background suppression

(see Figure 3).

To set both outputs at exactly the same limits, set them simultaneously. This will result

in complementary outputs (while one output is conducting, the other is not; see

Figure 4). Hysteresis will be controlled by Output 1 and Output 2 will follow.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Figure 3. Each output has its own limit for

background suppression

Figure 4. The two outputs share identical

limits for background suppression,

but are complementary

P/N 68503 rev. C 3

Page 4

L-GAGE® LT3 Long-Range Time-of-Flight Sensor –

or

D

D

D

or

D

D

D

T TT T T

T TT T

T

T TT T T

T TT T

T

D

or

D

D

D

Output 1

Near

Limit 2

Far

Limit 2

Output 2

Near

Limit 1

Far

Limit 1

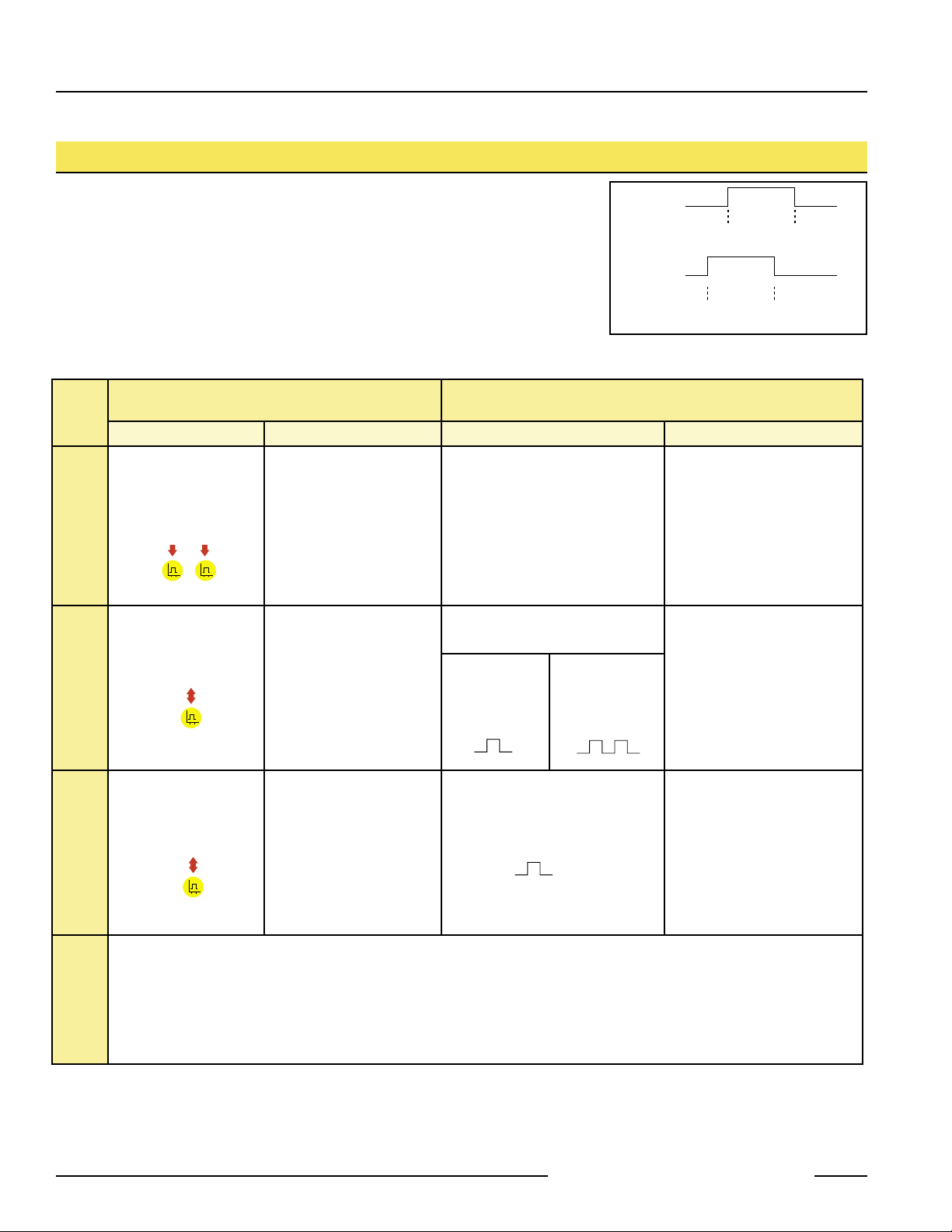

Teaching Independent Limits for Either Output

Either output may be programmed first.

Figure 5. Each output has its own near and

Two Discrete Outputs

far limits

Procedure Result Procedure Result

• Push and hold

push button for

desired output

> 2 seconds*

Mode

Programming

• Position the target for

the first limit**

• “Click” the same push

button

Teach

First Limit

• Position the target for

the second limit

• “Click” the same push

button

Teach

Second Limit

Push Button

0.04 sec. ≤ “click” ≤ 0.8 sec.

• Appropriate TEACH LED

turns ON

• Sensor is waiting for first

limit

• TEACH LED flashes

• Sensor learns first limit

and waits for second limit

• TEACH LED goes OFF

• Sensor learns second

limit and returns

automatically to RUN

mode

Remote Wire

0.04 sec. ≤ T ≤ 0.8 sec.

No action required

• Position the target for the first

limit**

Output 1

• Single-pulse

the remote

line

• Position the target for the second

limit

• Single-pulse the remote line

Output 2

• Double-pulse

the remote line

• Appropriate TEACH LED turns

ON, then flashes at 2 Hz

• Sensor learns first limit and

waits for second limit

• Appropriate TEACH LED

goes OFF

• Sensor learns second limit

and returns automatically to

RUN mode

Repeat for other output, if a second output is desired.

Output

Program Second

* Sensor will return to RUN mode if first TEACH condition is not registered within 120 seconds.

** Press and hold the same push button (or hold the remote line high) > 2 seconds (before teaching the second limit) to exit PROGRAM mode

without saving any changes. The sensor will revert to the last saved program.

4 P/N 68503 rev. C

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 5

L-GAGE® LT3 Long-Range Time-of-Flight Sensor –

or

D

D

D

or

D

D

D

D

or

or

D

D

D

D

D

D

or

or

D

D

D

D

D

T TT T

T

T TT T T

T TT T

T

Output 1

Near

Limit

Far

Limit

Output 2

Teaching Identical Limits for Both Outputs Simultaneously

To set both outputs at exactly the same limits, they may be set simultaneously. This

will result in complementary outputs (while one output is conducting, the other is not).

Hysteresis will be controlled by Output 1 and Output 2 will follow.

Figure 6. Both outputs have identical limits,

Two Discrete Outputs

but are complementary

Procedure Result Procedure Result

• Push and hold either

push button for

> 2 seconds*

• Briefly “click” the

Mode

Programming

other button

• Position the target for

the first limit**

• “Click” either push

button

Teach

First Limit

• Position the target for

the second limit

• “Click” either push

button

Teach

Second Limit

Push Button

0.04 ≤ “click” ≤ 0.8 sec.

• Corresponding TEACH

LED turns ON

• Corresponding TEACH

LED turns ON

• Sensor is waiting for first

limit

• Both TEACH LEDs flash at

2 Hz, alternating Red and

Green

• Sensor learns first limit

and waits for second limit

• Both TEACH LEDs go OFF

• Sensor learns second

limit and returns

automatically to RUN

mode

Remote Wire

0.04 sec. ≤ T ≤ 0.8 sec.

No action required

• Position the target for the first

limit**

• Triple-pulse the remote line

• Position the target for the second

limit

• Single-pulse the remote line

• Both TEACH LEDs turn ON

• Sensor learns first limit and

waits for second limit

• Both TEACH LEDs flash at

2 Hz, alternating Red and

Green

• Both TEACH LEDs go OFF

• Sensor learns second limit

and returns automatically to

RUN mode

* Sensor will return to RUN mode if first TEACH condition is not registered within 120 seconds.

** Press and hold the same push button (or hold the remote line high) > 2 seconds (before teaching the second limit) to exit PROGRAM mode

without saving any changes. The sensor will revert to the last saved program.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 68503 rev. C 5

Page 6

L-GAGE® LT3 Long-Range Time-of-Flight Sensor –

T T T T T T

T

T

Sensor Setup

Response Speed

Use the Speed push button to toggle between the three response speed settings. The

selected speed is indicated by one of three Response Speed indicator LEDs (see

Figure 2).

Discrete Output Response Speed

Slow

Medium

Fast

Push Button Lockout

Enables or disables the keypad to prevent accidental or unauthorized adjustment of the

programming settings.

Procedure

Push Button

• Not available

via push button

Remote Wire

0.04 sec. ≤ T ≤ 0.8 sec.

• Four-pulse the

remote line

100 ms ON and OFF

10 ms ON and OFF

1 ms ON and OFF

Result

• Push buttons are either enabled

or disabled, depending on

previous condition

Two Discrete Outputs

Push Buttons

Enable/Disable

6 P/N 68503 rev. C

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 7

L-GAGE® LT3 Long-Range Time-of-Flight Sensor –

Indicators

Two Discrete Outputs

Selected

Response Speed

Slow

Medium

Fast

Laser

Enable Time

150 ms

60 ms

51 ms

Power Up/Laser Enable Indicators

When powering up the sensor, the following should occur:

• All LEDs turn ON for 1 second

• Allow 0.6 second delay for Laser Enable at power up. If sensor is already powered up,

see table at left for Laser Enable time. Laser Disable time for all speeds is

50 ms.

Signal LED

Signal LED

ON

OFF

Flashing

Output LED

window limits.

Power ON/OFF LED

Power ON/OFF LED

OFF

Flashing @ 2Hz

Flashing @ 1Hz

ON Solid

(red) – indicates the strength and condition of the sensor’s incoming signal.

Status

Good signal

No signal is received, or the target is beyond the range limitations of the

sensor (with some tolerance beyond the recommended minimum and

maximum sensing distance)

Marginal signal strength (can not teach limits)

(yellow) – lights when a target is sensed within the programmed discrete

(green) – indicates the operating status of the sensor.

Status

Power is OFF

Discrete output is overloaded (RUN mode)

Power ON, Laser is disabled

Sensor is operating normally (power ON, Laser enabled)

Indicates

Indicates

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 68503 rev. C 7

Page 8

L-GAGE® LT3 Long-Range Time-of-Flight Sensor –

Specifications

Two Discrete Outputs

Sensing Range Diffuse Mode

90% White card: 18% Gray card: 6% Black card:

0.3 to 5 m 0.3 to 3 m 0.3 to 2 m

Supply Voltage and Current

Supply Protection Circuitry

Delay at Power-up

Sensing Beam

Output Protection

Output Configuration

Output Rating

Output Response Time

Repeatability

Color Sensitivity

(Diffuse Models)

Discrete Output Hysteresis

Temperature Drift

Minimum Window Size

Remote Teach Input

Remote TEACH

Adjustments

Laser Control

Indicators

12 to 24V dc (10% maximum ripple); 108 mA max. @ 24V dc or [2600/V dc] mA

Protected against reverse polarity and transient voltages

1 second; outputs do not conduct during this time

Typical beam dia: 6 mm @ 3 m

Typical laser lifetime: 75,000 hours

Diffuse: 658 nm visible red IEC and CDRH Class 2 laser; 0.5 mW max. radiant output power.

Retroreflective Mode: 658 nm visible red IEC and CDRH Class 1 laser; 0.15 mW max. radiant output power.

Protected against short circuit conditions

SPST solid-state switch; selectable NPN (current sinking) or PNP (current sourcing)

100 mA maximum

Off-state leakage current: < 5 µA

Output saturation NPN: < 200 mV @ 10 mA and < 600 mV @100 mA

Output saturation PNP: < 1.2V @ 10 mA and < 1.6V @ 100 mA

Fast: 1 ms ON and OFF

Medium: 10 ms ON and OFF

Slow: 100 ms ON and OFF

See Figures 7 and 9.

90% white to 18% gray: <10 mm; 90% white to 6% black: < 20 mm. See Figure 8.

Diffuse Mode

Fast: 10 mm

Medium: 5 mm

Slow: 3 mm

Diffuse Mode: < 2 mm / °C Retroreflective Mode: < 3 mm/°C

Diffuse Mode: 20 mm Retroreflective mode: 40 mm

18 kΩ minimum (65 kΩ at 5V dc)

To teach: Connect yellow wire to +5 to 24V dc

To disable: Connect yellow wire to 0 to +2V dc (or open connection)

See Remote Programming on pages 3 - 5.

Response speed: Push button toggles between 3 response speeds

Window limits: TEACH-mode programming of near and far window limits (see programming procedure).

Limits may also be taught remotely via TEACH input (see page 4).

NPN/PNP Select: See hookups, page 10

Factory defaults: 150 ms response speed

Window limits 0.3 m - 5 m using a 90% reflectivity white card

Push buttons enabled

To enable laser beam: Connect red wire to +5 to 24V dc. See page 7 for delay times on enable.

To disable: Connect to 0 to +1.8V dc (or open connection)

Green Power ON LED: Indicates when power is ON, overloaded output and laser status

Yellow Output LED: Indicates when discrete load output is conducting

Red Signal LED: Indicates target is within sensing range and the condition of the received light signal

Yellow Speed LED: Indicates the response speed setting

Yellow TEACH LEDs: In programming mode, indicate active output(s)

NOTE: See page 7 for more information on indicator behavior.

Retroreflective Mode

0.5 to 50 m (using

supplied target)

Retroreflective Mode

Fast: 20 mm

Medium: 10 mm

Slow: 6 mm

8 P/N 68503 rev. C

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 9

L-GAGE® LT3 Long-Range Time-of-Flight Sensor –

1

0

10 2 3

Distance (m)

Resolution/Repeatability vs. Distance

4 5

2

Resolution (mm)

3

4

5

6% Black

18% Gray

90% White

Fast

Medium

Slow

-30

-20

-10

0

10

20

-40

10 2 3

Distance (m)

Typical Color Sensitivity

4 5

Color Sensitivity (mm)

90% White to 18% Gray

90% White to 6% Black

2

4

0

100 20 30

Distance (m)

Repeatability vs. Distance

40 50

6

Repeatability (mm)

8

10

12

14

16

18

20

Fast

Medium

Slow

Specifications, cont’d

Two Discrete Outputs

Construction

Environmental Rating

Connections

Operating Conditions

Application Notes

Certifications

Housing: ABS

Window: Acrylic

Quick-disconnect: ABS/polycarbonate blend

IP67, NEMA 6

2 m (6.5') or 9 m (30') shielded 7-conductor (with drain) PVC-jacketed attached cable or 8-pin Euro-style

quick-disconnect

Temperature: 0° to +50°C (+32° to +122°F)

Maximum Relative Humidity: 90% at 50°C (non-condensing)

• Allow 30-minute warm-up before programming or operating (see Sensor Setup, page 2).

• Retroreflective performance specifications are based on use with BRT-TVHG-8X10P high-grade target.

Results may vary with other retroreflective target materials.

Figure 7. LT3 repeatability (diffuse mode)

Figure 9. LT3 repeatability (retroreflective mode)

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Figure 8. LT3 color sensitivity (typical; diffuse mode)

P/N 68503 rev. C 9

Page 10

L-GAGE® LT3 Long-Range Time-of-Flight Sensor –

RADIANT POWER 0.5mW

10ns PULSE, 1MHz

650 - 670

nm

COMPLIES TO 21 CFR PART

1040.10 AND

EN60825-1:1994

LASER LIGHT

DO NOT STARE INTO BEAM

CL

ASS 2 LASER PRODUCT

Avoid exposure- laser

light emitted from

this aperture

RADIANT POWER 0.15mW

10ns PULSE, 1MHz

650 - 67

0

nm

Complies with IEC 60825-1:2001

and 21 CFR 1040.10 & 1040.11

except for deviations pursuant to

Laser Notice No. 50, dated

July 26, 2001

LASER LIGHT

CLASS 1 LASER PRODUCT

Laser light

emitted from

this aperture

bn

+

12-24V dc

+5-24V dc

0-1.8V dc

+5-24V dc

Shield

Teach

Laser ON

–

bu

gy

wh

rd

gn

ye

Load 2

Load 1

Output Select

bn

+

12-24V dc

+5-24V dc

+5-24V dc

+5-24V dc

Shield

Teach

Laser ON

–

bu

gy

wh

rd

gn

ye

Load 2

Load 1

Output Select

1. Press and hold appropriate Teach button untill Teach

light turns ON

.

2. Adjust target to 1st limit point. Press Teach

button. (Teach flashes.)

3. Adjust target to 2nd limit point.

Press Teach button.

(Teach turns OFF.)

Avoid exposure–laser

light emitted from

this aperture

RADIANT POWER 0.5mW

10ns PULSE, 1MHz

650 - 670nm

COMPLIES TO 21 CFR PART

1040.10 AND EN60825-1:1994

SIGNAL OUTPUT

FAST

MED

SLOW

TEACH

POWE

R

SPEED

DD

86.9 mm

(3.42")

102.7 mm

(4.04")

35.3 mm

(1.38")

5.2 mm

(0.20")

48.8 mm

(1.92")

5.9 mm

(0.23")

75.6 mm

(2.98")

15.0 mm

(0.59")

68.5 mm

(2.70")

19.5 mm

(0.76")

40.6 mm

(1.59")

2x ø4.5 mm (0.18")

C'sink ø7.3 mm (0.29"), 5.3 mm (0.21") deep

87.0 mm

(3.43")

Dimensions

Mounting Hardware:

M4 x 0.7 x 40 socket-head cap screw

M4 x 0.7 hex nut with captured toothed lock washer

M3 short arm hex key

Two Discrete Outputs

Class 1 Label

(Retroreflective-Mode Models)

Class 1

Lasers that are safe under

reasonably foreseeable conditions

of operation, including the use of

optical instruments for intrabeam viewing.

Reference 60825-1 Amend. 2 © IEC:2001(E),

section 8.2.

Description of Laser Classes

Class 2

Lasers that emit visible

radiation in the wavelength range

from 400 nm to 700 nm where eye

protection is normally afforded by aversion

responses, including the blink reflex. This reaction

may be expected to provide adequate protection under

reasonably foreseeable conditions of operation, including

the use of optical instruments for intrabeam viewing.

Reference 60825-1 Amend. 2 © IEC:2001(E), section 8.2.

Hookups

Class 2 Label

(Diffuse-Mode Models)

PNP HookupNPN Hookup

10 P/N 68503 rev. C

NOTE: Hookups for QD models are functionally identical.

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

Page 11

L-GAGE® LT3 Long-Range Time-of-Flight Sensor –

M12 X 1

14.2 mm

(0.56")

42.0 mm

(1.65")

Gray

Yellow

Green

Brown

Shield

White

Blue

Red or Pink

85.5 mm

5.0 mm

(0.20")

65.0 mm

(2.56")

13.0 mm

(0.51")

68.0 mm

(2.67")

14.0 mm

(0.55")

R172 mm (6.77")

2x R2.5 (0.10")

32.0 mm

(1.26")

R89.6 mm

(3.53")

2x R2.5

(0.10")

ø5.0 mm

(0.20")

31.5°

33.5°

13.0 mm

(0.51")

8.0 mm

(0.31")

20.5 mm

(0.81")

24.1 mm

(0.94")

10.0

°

5.0°

R47.5 mm

(1.87")

ø5.0 mm

(0.20")

2x ø4.0 mm

(0.16")

65.0 mm

(2.56")

16.0 mm

(0.63")

28.0 mm

(1.10")

22.0 mm

(0.87")

2x ø5.0 mm (0.20")

70.0 mm

(2.75")

5.0 mm

(0.20")

6.0 mm (0.24")

90.0 mm

(3.53")

ø28.0 mm

(1.10")

19.0 mm

(0.74")

20.89 mm

(0.822")

19.2 mm

(0.76")

R5.5 mm

(0.22")

12.3 mm

(0.48")

R 89.6 mm (3.52")

32°

33°

17.0 mm

(0.67")

16x R2.5 mm

(0.09")

4x R5.0 mm (0.20")

45.2 mm

(1.79")

C

L

C

L

5°

72.0 mm

(2.83")

35.0 mm

(1.38")

355.2°

Two Discrete Outputs

Accessories

Euro-Style Quick-Disconnect Cables

Cable: PVC jacket, polyurethane connector body, chrome-plated brass coupling nut

Conductors: 24 AWG high-flex stranded, PVC insulation, gold-plated contacts

Temperature: -40° to +105°C (-40° to +221°F)

Voltage Rating: 30V ac/36V dc

Style Model Length Connector Pin-Out (Female View)

8-Pin Euro

Straight

MQDC-806

MQDC-815

MQDC-830

2 m (6.5')

5 m (15')

9 m (30')

Retroreflective Tape

Model Size

BRT-TVHG-8X10P

NOTE: Retroreflective material has a pressure-sensitive adhesive. For maximum adhesion, surfaces must be clean and dry before applying. For

best results, use full-size; target may be trimmed as necessary.

203 x 254 mm (8" x 10")

Accessory Mounting Brackets

• Full bracket

• 304 series stainless steel

• Mounting hardware included

SMBLT31

• Right-angle bracket

• 300 series stainless steel

SMBLT32

Banner Engineering Corp. • Minneapolis, MN U.S.A.

www.bannerengineering.com • Tel: 763.544.3164

P/N 68503 rev. C 11

Page 12

L-GAGE® LT3 Long-Range Time-of-Flight Sensor –

89.6 mm

(3.53")

12.7 mm

(0.50")

41.4 mm

(1.63")

Ø 4.5 mm

(0.18")

20°

10°

56°

54.1 mm

(2.13")

20°

14.5 mm

(0.57")

82.5 mm

(3.25")

4 X R 3.3 mm

(0.13")

31.2 mm

(1.23")

42.9 mm

(1.69")

2.7 mm

(0.10")

130.5 mm

(5.11")

115.0 mm

(4.50")

2 X 29.7 mm

(1.18")

2 X 55.9 mm

(2.20")

107.9 mm

(4.25")

Accessory Mounting Brackets, continued

• Replaceable windows for welding environments

SMBLT3IP

• Stainless steel construction

• Includes 2 weld-resistant windows

Two Discrete Outputs

WARRANTY: Banner Engineering Corp. warrants its products to be free from defects

P/N 68503 rev. C

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN 55441 • Phone: 763.544.3164 • www.bannerengineering.com • Email: sensors@bannerengineering.com

for one year. Banner Engineering Corp. will repair or replace, free of charge, any product

of its manufacture found to be defective at the time it is returned to the factory during

the warranty period. This warranty does not cover damage or liability for the improper

application of Banner products. This warranty is in lieu of any other warranty either

expressed or implied.

Loading...

Loading...