Page 1

L-GAGE Laser Gauging Sensor Models

L-GAGE™Laser Gauging Sensor – 45 to 60 mm Range

Class 2 visible laser displacement sensor with both analog and discrete (switched) outputs

Printed in USA P/N 55801

L-GAGE Laser Gauging Sensor Features

• Self-contained Class 2 modulated visible laser gauging sensor needs no separate controller

• Narrow effective beam is excellent for precision distance, height or thickness

measurement or gauging applications

• Resolution to better than 10 microns

• Sensing window may be sized as needed, and placed anywhere within the

45.0 to 60.0 millimeter (1.77" to 2.36") sensing distance; 1.5 mm (0.06") minimum

window size

• Banner’s unique scalable analog output (patent pending) automatically distributes

the output signal over the width of the programmed sensing window

• Analog and discrete (switched) outputs

• Window limits for analog and discrete outputs may be set independently

• Analog output slope is either positive or negative, depending upon which window

limit is programmed first

• Fast, easy-to-use integrated push-button TEACH-mode programming; no

potentiometer adjustments

• Remote TEACH function for security and convenience

• Unique feature holds analog output value for 2 seconds upon loss of signal

• Modulated laser beam and narrow optical band-pass filter provide a high level of

ambient light immunity, including immunity from high-energy factory lighting

• Alarm output for signal saturation

• Output response is programmable for three speeds

• 12 to 30V dc operation

• Enclosure rated IECIP67; NEMA 4X

LG5B65PI

Models Sensing Distance Cable*

Supply

Voltage

LG5B65NI

45.0 to 60.0 mm

(1.77 to 2.36")

2 m (6.5')

8-wire

12 to 30V dc

* NOTE: 9 m (30') cables are available by adding suffix “W/30” to the model number of any cabled sensor (e.g., LG5A65NI W/30)

†

See Figure 2 on page 4 for more information. NOTE: In general, 70 mm focal point models are recommended for most distance measurement

applications, because small surface irregularities will be averaged out due to the larger beam size.

TEACH

SLOW

FAST

P

O

W

E

R

O

U

T

P

U

T

S

IG

N

A

L

SPEED

A

D

PNP (sourcing)

Discrete Output

NPN (sinking)

Analog Output

Analog current output

(4 to 20 mA)

PNP (sourcing)

LG5A65PI

NPN (sinking)

LG5A65NI

Focal Point

†

53 mm (2.1")

Beam size at 53 mm:

ø0.1 mm (ø0.004")

70 mm (2.8")

Beam size at 53 mm:

0.4 x 0.6 mm

(0.016 x 0.024")

Page 2

L-GAGE™ Laser Gauging Sensor

page

2

L-GAGE Laser Gauging Sensor Overview

Banner’s Class 2 visible laser displacement sensor brings a sophisticated, yet costeffective solution to precision measurement applications. L-GAGE Series sensors

feature all-in-one design and require no separate controller.

Near and far sensing window limits are set quickly using simple push-button or

remote signal TEACH-mode programming. One sensor can simultaneously provide

both analog and discrete (switched) outputs. Sensing window limits for each output

may be independently programmed, if desired. The analog signal features Banner’s

unique scalable output (patent pending), which automatically distributes the 4 to 20

milliamp output signal over the width of the programmed sensing window. If an

analog voltage output is required, this can be accomplished by using an alternate

hookup. (See Hookups, page 5.)

The L-GAGE Laser Gauging Sensor boasts many additional features, including

selectable response speed, self-diagnostics with alarm output, comprehensive status

indicator system, and unique output “hold” function for momentary signal loss in

profiling applications.

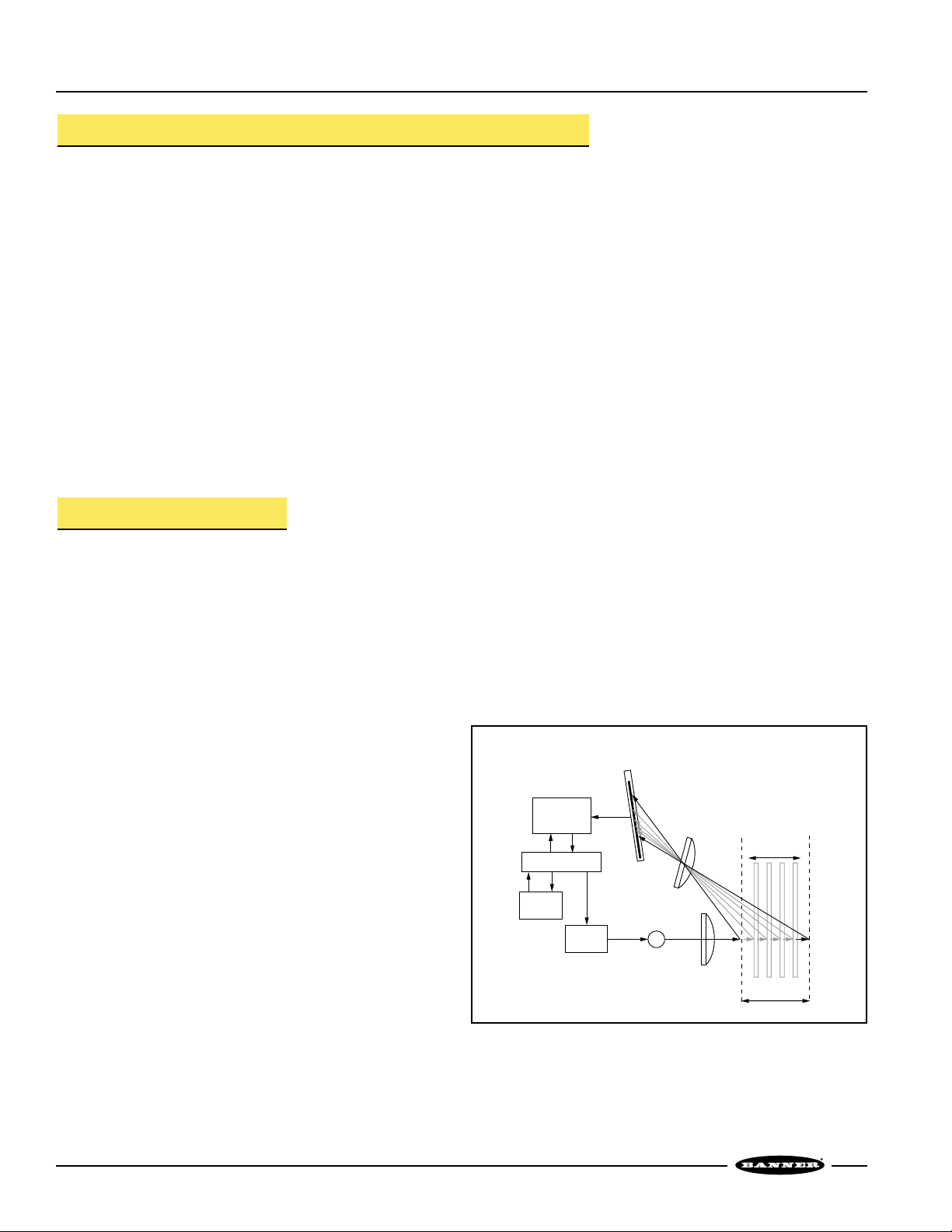

Optical Triangulation

The design of the L-GAGE Laser Gauging Sensor is based on optical triangulation (see

figure 1). An emitter transmits visible laser light through a lens, toward a target. The

laser light beam from the emitter bounces off the target, scattering some of its light

through another lens to the sensor’s PSD (position-sensitive device) receiver element.

The target’s distance from the receiver determines the angle the light travels to the

receiver element; this angle in turn determines where the received light will fall along

the PSD receiver element.

The position of the light on the PSD receiver element is processed through analog

and digital electronics and analyzed by the microprocessor,

which calculates the appropriate output value. The analog

output provides a variable 4 to 20 milliamp current that is

proportional to the target’s position within the user-programmed

analog window limits (see page 8). The discrete (switched)

output energizes whenever the target is located between the

user-programmed discrete window limits. Analog and discrete

window limits may be the same, or programmed independently.

Figure 1. Optical triangulation sensing system overview

Signal

Conditioning

Circuitry

Microprocessor

Output

Circuitry

Emitter

Circuitry

PSD

Receiver

Element

R

E

Laser

Emitter

Lenses

Near

Limit

Target Movement

Programmed

Sensing Window

Far

Limit

Page 3

L-GAGE™ Laser Gauging Sensor

page

3

L-GAGE Laser Gauging Sensor Specifications

Sensing Range

Supply Voltage 12 to 30V dc, (10% maximum ripple); 50 mA max at 24V dc (exclusive of load)

Supply Protection Circuitry Protected against reverse polarity, over voltage, and transient voltages

Delay at Power-up 1.25 second

Sensing Beam 670 nm visible red IEC and CDRH Class 2 laser; 0.15 mW radiant output power

Output Configurations Discrete (switched) output: SPST solid-state switch; choose NPN (current sinking) or PNP (current

sourcing) models

Analog output: 4 to 20 milliamp current sourcing

Alarm output: SPST solid-state switch; NPN (current sinking) or PNP (current sourcing), depending on

discrete output model

Output Ratings Discrete (switched) and Alarm output: 100 mA maximum

Off-state leakage current: less than 5 microamps

Output saturation voltage (PNP output): less than 1.2 volts at 10 mA and less then 1.6 volts at 100 mA

Output saturation voltage (NPN output): less than 200 millivolts at 10 mA

and less then 600 millivolts at 100 mA

Analog output: 1 kΩ max @ 24V dc; max load resistance = Vcc – 3.3

[

0.02

Ω

]

Output Response Time Discrete Output:

Fast: 3.6 milliseconds ON and OFF

Medium: 10 milliseconds ON and OFF

Slow: 40 milliseconds ON and OFF

Analog Output (-3 dB):

Fast: 250 Hz (1.6 milliseconds average with 1.6 millisecond update rate)

Medium: 40 Hz (10 milliseconds average with 1.6 millisecond update rate)

Slow: 10 Hz (40 milliseconds average with 2.1 millisecond update rate)

Analog Resolution and

Repeatability of Discrete

Trip Point*

Fast: 0.06% of sensing distance (<30 microns @50 mm)

Medium: 0.03% of sensing distance (<15 microns @50 mm)

Slow: 0.02% of sensing distance (<10 microns @50 mm)

Analog Linearity* ± 60 microns (±0.002")

Hyste r esis (Discrete Output) <0.35% of sensing distance

Laser Control Connect green wire to +5 to 30V dc to enable laser beam; connect to 0 to +1.8V dc (or open connection)

to disable; 250 millisecond delay upon enable.

45.0 to 60.0 mm (1.77" to 2.36")

Adjustments Response speed: push button toggles between 1.6, 10, and 40 milliseconds

Window limits (analog or discrete): TEACH-mode programming of near and far window limits (see

programming procedure). Limits may also be taught remotely via TEACH input (see page 7).

Analog output slope: the first limit taught is assigned to minimum output current (4mA).

Output Protection Outputs are protected against continuous overload and short circuit

Color Sensitivity* <75 microns (0.003") (typical) for white to dark gray ceramic target

Temperature Drift ±7 microns/°C

*Using white ceramic test surface (see Application Notes).

Resolution and linearity specified at 24V dc, 22°C.

Minimum Window Size

(Analog or Discrete)

1.5 mm (0.06")

Remote Teach and Laser

Control Input Impedance

55 kΩ

Page 4

G

N

L-GAGE Laser Gauging Sensor Specifications (continued)

L-GAGE™ Laser Gauging Sensor

page

4

Indicators

Construction Housing: Zinc alloy die-cast, plated and painted finish

Cover plate: aluminum with painted finish

Lens: acrylic

Green Power ON LED: Indicates when power is ON, overloaded output and laser status.

Yellow Output LED: Indicates when discrete load output is conducting.

Red Signal LED: Indicates when target is within sensing range and the condition of the received light

signal.

Tri-color Red/Green/Yellow TEACH LED: Indicates sensor is ready for programming each limit (indicates

red for analog output, green for discrete, and yellow for simultaneous analog and discrete.)

Yellow Fast/Slow LEDs: Combination of 2 lights ON or OFF indicates one of 3 response speeds.

NOTE: See page 5 for more information on indicator behavior.

Environmental Rating IP67, NEMA 4X

Vibration and

Mechanical Shock

Vibration: 60 Hz, 30 minutes, 3 axes

Shock: 30G for 11 milliseconds, half sine wave, 3 axes

Operating Conditions Temperature: -10° to +50° C (+14° to 122° F)

Maximum relative humidity: 90% at 50° C, non-condensing

Application Notes For comparison, white ceramic test surface has approximately 91% of the reflectivity of a white Kodak test

card with a matte finish. A dark gray ceramic test surface has approximately 11% of the reflectivity of a white

Kodak test card with a matte finish.

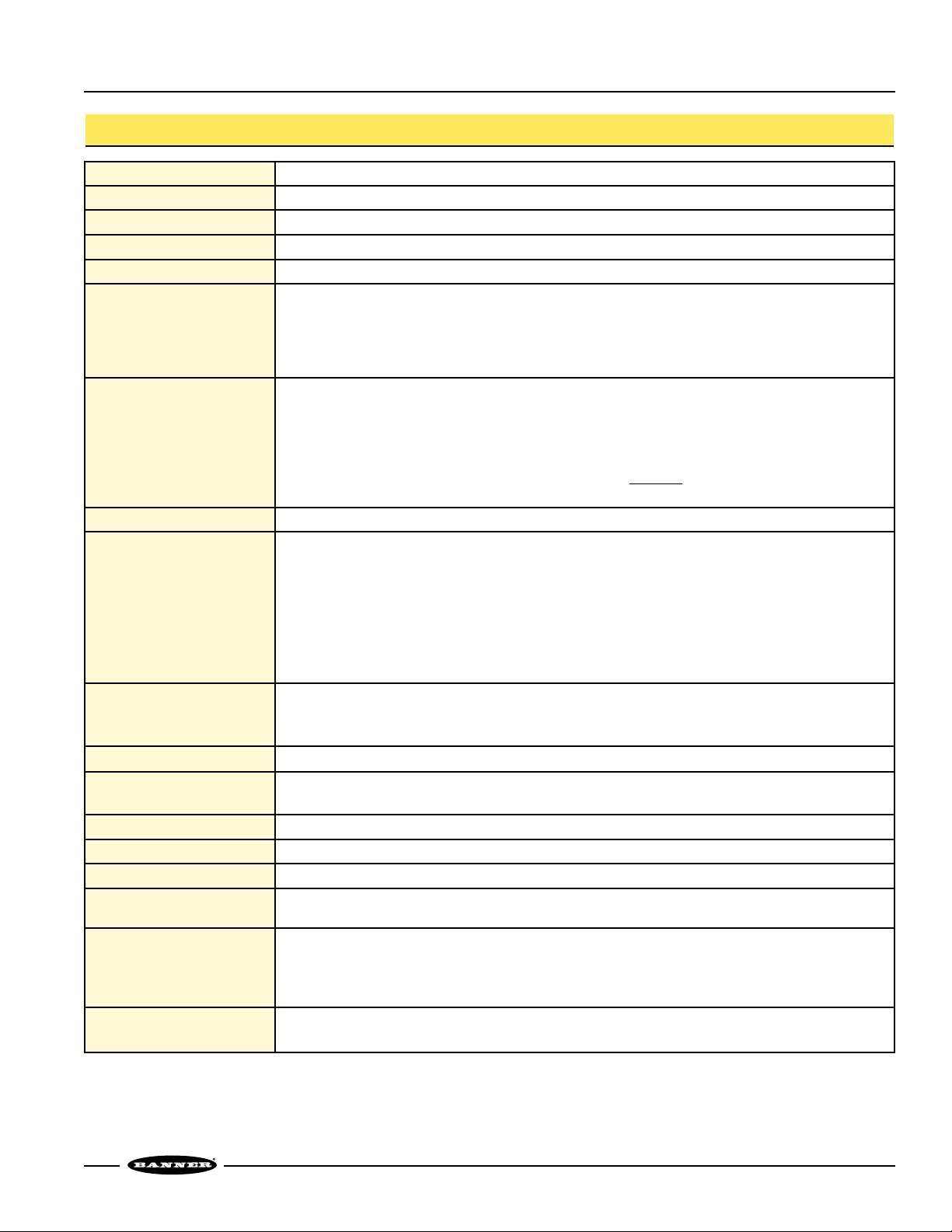

Figure 2. L-GAGE Laser Gauging Sensor and beam dimensions

Connections 2 m (6.5') or 9 m (30') 7-conductor shielded PVC-jacketed attached cable.

L-GAGE Beam Dimensions (typical)

Focal

Point

†

Distance

Beam

Width (X)

Beam

Height (Y)

53 mm

(2.1")

45 mm 0.3 mm 0.5 mm

60 mm

53 mm

0.3 mm

0.1 mm

0.5 mm

0.1 mm

70 mm

(2.8")

45 mm 0.6 mm 0.9 mm

53 mm 0.4 mm 0.6 mm

60 mm 0.3 mm 0.4 mm

† The Focal Point is the distance measured from

the lens (front of sensor) at which the diameter

of the laser image is smallest.

A

L

D

A

55.3 mm

(2.18")

4.6 mm

(0.18")

45.5 mm

(1.79")

20.2 mm (0.80")

POWER

68.3 mm

OUTPUT

SIGNAL

(2.69")

D

R

A

D

IA

8

K

N

H

z

6

8

6

-1

0

- 6

C

8

O

M

P

1

0

L

4

IE

0

.1

0

A

LASER LIGHT

D

O

N

O

C

T

L

A

S

S

T

S

A

R

2

E

L

A

I

N

S

E

R

Avoid exposure -

P

laser light emitted

from his aperture

T

P

O

W

6

E

%

R

D

0

0

U

n

.1

T

m

5

Y

m

C

S

Y

W

C

A

L

IT

N

H

D

2

E

1

C

N

6

F

0

R

8

2

5

-1

TEACH

T

O

R

O

W

E

:1

9

B

E

A

M

D

U

C

T

9

4

LASER LIGHT

D

O

N

C

O

L

T

A

S

S

A

v

l

a

s

f

r

o

RADIANT POWER 0.15 mW

8KHz 8-16% DUTY CYCLE

660 - 680 nm

COMPLIES WITH 21 CFR

1040.10 AND EN60825-1:1994

SLOW

FAST

S

T

A

2

L

A

S

o

i

d

e

e

r

l

i

m

h

SPEED

TEACH

SLOW

FAST

R

E

I

N

T

E

O

R

B

P

E

R

A

O

M

D

U

C

x

p

T

o

s

g

u

h

r

e

t

e

-

m

i

s

i

t

a

t

e

p

d

e

r

t

u

r

e

SPEED

23.9 mm

19.1 mm

Beam Dimensions

X

Emitted Light

(0.94")

Received Light

(0.75")

Y

82.3 mm

(3.24")

9.3 mm

(0.37")

Page 5

L-GAGE™ Laser Gauging Sensor

page

5

L-GAGE Laser Gauging Sensor Hookups

NPN Hookup

PNP Hookup

Conversion from Current to

Voltage Output

*NOTE: The bare shield wire should be connected as follows:

1) If the sensor housing is mounted so that it is in continuity with both the machine

frame and earth ground, connect the bare wire (also) to earth ground.

2) If the sensor housing is mounted so that it is insulated from the machine frame,

connect the bare wire to -V dc (together with the blue wire).

3) If the sensor is mounted so that it is in continuity with the machine frame, but

not with earth ground, do not connect the bare wire (i.e. cut off the bare wire).

**NOTE:

For best results, install a small

amount of capacitance (e.g., 0.1µF)

in parallel with the load resistor

Typical Voltage Response

Value

of R

Output Voltage

250Ω

500Ω

1 to 5V

2 to 10V

Modes

The L-GAGE Laser Gauging Sensor operates in two modes: TEACH (or programming)

and RUN.

TEACH-Mode Programming

Response Speed

Use the Speed push button to toggle between the three response speed settings. The

combination of indicator lights (Fast and Slow) will tell you which of the three is

selected:

Using the L-GAGE Laser Gauging Sensor

Slow Fast

Analog Output

Frequency Response (-3dB)

ON OFF 10 Hz

ON ON 40 Hz

OFF ON 250 Hz

Discrete Output

Response Speed

40 milliseconds

10 milliseconds

3.6 milliseconds

bn

bu

4-20 mA

wh

Load

Discrete

gy

Load

Alarm

rd

Load

ye

Remote Teach

Laser Control

gn

bare wire*

+

12-30V dc

–

+5-30V dc

+5-30V dc

0V dc

ON

OFF

bn

bu

4-20 mA

wh

Load

Discrete

gy

Load

Alarm

rd

Load

ye

Remote Teach

Laser Control

gn

bare wire*

12-30V dc

+

–

+5-30V dc

+5-30V dc

0V dc

ON

OFF

bn

bu

**

wh

RV

+

12-30V dc

–

Page 6

L-GAGE™ Laser Gauging Sensor

page

6

Window Limits

Window limits may be taught to the sensor in several ways. The following methods

describe the TEACH procedures for programming using the sensor push buttons;

remote programming (remote TEACH) procedures are described on page 7.

Teaching Limits for Either Analog or Discrete Output

1. Choose the output for the first set of window limits (analog or discrete) and push

and hold the corresponding button until the tri-color TEACH LED turns ON

(solid). This indicates the sensor is waiting for the first limit: red for analog

output, or green for discrete output.

2. Position the target for the first limit and briefly “click” the same button. This will

teach the sensor the first limit. The TEACH LED will flash at 2Hz to acknowledge

receiving the first window limit; it is now waiting for the second limit.

3. Position the target for the second limit and “click” the button again. This will

teach the sensor the second limit. The TEACH LED will turn OFF to indicate that

the sensor will now function in normal RUN mode.

4. Repeat for the opposite output (analog or discrete) if a second output is desired.

Teaching Analog Limits Using the Auto-Zero Feature (Analog Output)

For some analog applications, a sensing distance set point centered within a sensing

window may be required. The TEACH procedure is simple: teaching the same limit

twice causes the sensor to program a 10 mm wide window centered on the position

taught (position ±5 mm).

Teaching Fixed-Field Sensing Mode (Discrete Output)

Teaching the same limit twice creates a sensing window with the far limit at the teach

distance and the near limit at the minimum operating range of the sensor

(approximately 44 mm).

Teaching Limits for Both Analog and Discrete Outputs Simultaneously

If you want both your discrete and analog outputs to be set at exactly the same limits,

you may set both simultaneously.

1. Push and hold either the Analog or the Discrete programming push button until

the tri-color TEACH LED turns ON. “Click” the other button (Analog or Discrete).

The TEACH LED turns Yellow. The sensor is waiting for the first limit.

2. Position the target for the first limit and “click” either TEACH button. The TEACH

LED will flash at 2Hz, alternating red and green, to acknowledge receiving the

first window limit; it is now waiting for the second limit.

3. Position the target for the second limit and “click” the buttons again to teach the

sensor the second limit. The TEACH LED will turn OFF to indicate that the sensor

will now function in normal RUN mode.

Figure 3. L-GAGE™Laser Gauging Sensor

programming push buttons and

indicators

Response Speed

Push Button

Response Speed

Indicators

Teach LED

Analog Output

Programming Push Button

Discrete (Switched) Output

Programming Push Button

Signal LED

Output LED

Power ON/OFF LED

SPEED

FAST

SLOW

TEACH

A

D

SIGNAL

OUTPUT

POWER

Page 7

Figure 4. Timing programs for remote TEACH programming

L-GAGE™ Laser Gauging Sensor

page

7

Remote Programming

To program the sensor remotely or to disable the keypad, the Remote Programming

function may be used. Disabling the keypad prevents anyone on the production floor

from adjusting any of the programming settings. Connect the yellow wire of the

L-GAGE Laser Gauging Sensor to +5 to 30V dc, with a remote programming switch

connected between them. NOTE: The impedance of the remote teach imput is 55 kΩ.

Programming is accomplished by following the sequence of input pulses, following

the button-pushes and “clicks” for programming on the sensor buttons. The duration

of each pulse (corresponding to a push button “click”), and the period between

multiple pulses, are defined as: 0.04 seconds < T < 0.8 seconds.

To access each of the programming modes, pulse the remote switch a prescribed

number of times:

• 1 pulse: Discrete TEACH Mode

• 2 pulses: Analog TEACH Mode

• 3 pulses: Dual Discrete/Analog TEACH Mode

• 4 pulses: Disables (locks out) or enables the keypad for security

> 0.8 sec

Teach Second

Discrete Limit

T T

Teach First

Analog Limit

Teach First Limits Teach Second Limits

> 0.8 sec

T

Teach Second

Analog Limit

> 0.8 sec

TTT

Discrete

Limits Only

Analog

Limits Only

Analog & Digital

Together

T

Teach First

Discrete Limit

TT

TTTT

T TTT

T

T

Push Button

Lockout

0.04 sec < T < 0.8 sec

Push Button Lockout

Page 8

L-GAGE™ Laser Gauging Sensor

page

8

RUN Mode

Signal LED

The Signal LED indicates the strength and condition of the sensor’s incoming signal.

Signal LED Status Indicates

OFF

No signal is received, or the target is beyond the range limitations

of the sensor (with some tolerance beyond the recommended

minimum and maximum sensing distance)

Flashing @ 2Hz Received signal is adequate for processing

Flashing @ 10Hz

Received signal is in saturation (i.e., signal is too strong); alarm

output energizes

ON Solid Received signal is within the nominal conditions for the sensor

Output LED

The Output LED lights when the discrete output is conducting.

Power ON/OFF LED

The Power ON/OFF LED indicates the operating status of the sensor.

Power ON/OFF LED Indicates

OFF Power is OFF

Flashing @ 2Hz Discrete or alarm output is overloaded

Flashing @ 1Hz Power ON, Laser is disabled

ON Solid Sensor is operating normally (power is ON, Laser enabled)

Power Up/Laser Enable

When powering up the sensor, the following should occur:

• All LEDs turn ON for 1 second

• Allow 1.25 second delay for Laser Enable at power up. (If sensor is already powered

up, allow 0.25 second for Laser Enable.)

Analog Output

The L-GAGE Laser Gauge may be programmed for either a positive or a negative output

slope, depending on which condition is taught first (see Figure 5). If the near limit is

taught first, the slope will be positive; if the far limit is taught first, the slope will be

negative. Banner’s unique scalable analog output (patent pending) automatically

distributes the output signal over the width of the programmed sensing window. Factory

analog output is 4 to 20 mA; if a voltage output (e.g. 1 to 5V dc) is required, this can be

accomplished by using an alternate hookup (see Hookups, page 5).

The L-GAGE also features a 2-second hold upon loss of the analog signal, which is useful

for profiling and similar applications. In the event of analog signal loss for longer than 2

seconds, the analog output goes to 3.6 mA, which may be used to trigger an alarm.

Figure 5. Output current as a function of

target position

NOTE: The linear analog output tracks

slightly past each window limit

(from 3.8 to 20.5 mA).

20

Analog Output (mA)

4

Near

Window

Positive

Slope

Target Position

Far

Window

Page 9

L-GAGE™ Laser Gauging Sensor

page

9

Installation Notes

Some targets (those with a stepped plane facing the sensor, a boundary line, or

rounded targets) pose specific problems for sensing distances. For such applications,

see figure 6. for suggested mounting orientations.

Figure 6. Sensor orientations for typical targets

Class 2 Safety Notes

Low-power lasers are by definition

incapable of causing eye injury within

the duration of the blink, or aversion

response of 0.25 seconds. They must

also emit only visible wavelengths

(400-700 nm). Therefore, an ocular

hazard can only exist if an individual

overcomes their natural aversion to

bright light and stares directly into the

laser beam. The product requirements

for these lasers are to have a [hazard]

label and to have an indicator light to

indicate laser emission.

The two operational safety rules are:

• Do not permit a person to stare at the

laser from within the beam

• Do not point the laser at a person’s

eye at close range

Beam Paths:

The beam emitted by a class 2 laser

product should be terminated at the

end of its useful path. Open laser beam

paths should be located above or

below eye level where practical.

Recommended

NOT Recommended

CAUTION . . .

This sensor contains no user-servicable components. Do not attempt to

repair. Incorrect component values may produce hazardous laser

radiation levels.

P

O

W

E

1040.10 AND EN60825-1:1994

COMPLIES WITH 21 CFR

660 - 680 nm

8KHz 8-16% DUTY CYCLE

RADIANT POWER 0.15 mW

R

O

U

T

P

U

T

S

IG

N

P

O

W

E

R

O

U

T

P

U

T

SIG

N

A

L

D

A

T

E

A

C

H

from his aperture

CLASS 2 LASER PRODUCT

laser light emitted

DO NOT STARE INTO BEAM

Avoid exposure -

S

L

O

LASER LIGHT

W

F

A

S

T

S

P

E

E

D

1040.10 AND EN60825-1:1994

COMPLIES WITH 21 CFR

660 - 680 nm

8KHz 8-16% DUTY CYCLE

RADIANT POWER 0.15 mW

A

L

D

A

T

E

A

C

H

from his aperture

CLASS 2 LASER PRODUCT

laser light emitted

DO NOT STARE INTO BEAM

Avoid exposure -

S

L

O

LASER LIGHT

W

F

A

S

T

S

P

E

E

D

1040.10 AND EN60825-1:1994

COMPLIES WITH 21 CFR

660 - 680 nm

8KHz 8-16% DUTY CYCLE

RADIANT POWER 0.15 mW

P

O

W

E

R

O

U

T

P

U

T

SIG

N

A

L

D

A

T

E

A

C

H

from his aperture

CLASS 2 LASER PRODUCT

laser light emitted

DO NOT STARE INTO BEAM

Avoid exposure -

S

L

O

LASER LIGHT

W

F

A

S

T

S

P

E

E

D

LASER LIGHT

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

Avoid exposure laser light emitted

from this aperture

RADIANT POWER 0.15 mW

8KHz 8-16% DUTY CYCLE

660 - 680 nm

COMPLIES WITH 21 CFR

1040.10 AND EN60825-1:1994

R

E

W

O

P

T

U

P

T

U

O

L

A

N

IG

S

D

Teach light turns ON.

button. (Teach turns OFF)

(Teach flashes)

3Adjust target to 2nd limit point. Press Teach

A

2Adjust target to 1st limit point. Press Teach button.

H

C

1Press and hold appropriate Teach button until

A

E

T

To Set DISCRETE limits, use the D (green) Teach button.

To Set ANALOG limits, use the A (red) Teach button.

W

O

L

S

T

S

A

F

D

E

E

P

S

R

E

T

U

L

A

H

W

D

E

E

!

R

E

W

O

P

T

U

P

T

U

O

W

O

P

P

T

U

O

N

IG

S

D

Teach light turns ON.

button. (Teach turns OFF)

(Teach flashes)

3Adjust target to 2nd limit point. Press Teach

A

2Adjust target to 1st limit point. Press Teach button.

C

1Press and hold appropriate Teach button until

A

E

T

To Set DISCRETE limits, use the D (green) Teach button.

To Set ANALOG limits, use the A (red) Teach button.

O

L

S

T

S

A

F

P

S

L

A

N

G

SI

D

Teach light turns ON.

button. (Teach turns OFF)

(Teach flashes)

3Adjust target to 2nd limit point. Press Teach

A

2Adjust target to 1st limit point. Press Teach button.

H

C

1Press and hold appropriate Teach button until

A

E

T

To Set DISCRETE limits, use the D (green) Teach button.

To Set ANALOG limits, use the A (red) Teach button.

W

O

L

S

T

S

A

F

D

E

E

P

S

Page 10

L-GAGE™ Laser Gauging Sensor

page

10

Accessories

Brackets

Model Description

SMBLG

L-GAGE Sensing

Mounting Bracket

• 304 Stainless Steel

Dimensions

53.0 mm

(2.09")

37.6 mm

(1.48")

13.0 mm

(0.51")

2x 6.5 mm

(0.26")

5.9 mm

(0.23")

31.0 mm

(1.22")

31.0 mm

(1.22")

2.2 mm

(0.09")

ø56.0 mm (2.21")

ø43.0 mm (1.69")

ø6.3 mm (0.25")

47.0 mm

(1.85")

38.5 mm

(1.52")

55.0 mm

(2.17")

95.0 mm

(3.74")

77.0 mm

(3.03")

2x

20.0 mm

(0.79")

3x M3 x 0.5

ø75.5 mm

(2.97")

ø88.5 mm

(3.49")

4x 17.0°

4x 25.0°

8x Full Radius

2x 15°

2x 30°

2x 8.0 mm

(0.32")

72.8 mm

(2.87")

61.0 mm

(2.40")

30.5 mm

(1.20")

2x 20°

2x 40°

27.0 mm

(1.06")

ø6.3 mm (0.25")

ø44.5 mm (1.75")

ø31.5 mm (1.24")

2x 14.0 mm

(0.55")

2x 9.0 mm

(0.35")

8x Full Radius

Page 11

L-GAGE™ Laser Gauging Sensor

page

11

Brackets

Model Description

SMBLGA

L-GAGE Adjustable

Bracket Assembly

• 304 Stainless Steel

Dimensions

ø6.3 mm (0.25")

ø44.5 mm (1.75")

ø31.5 mm (1.24")

2x 14.0 mm

2x 9.0 mm

(0.35")

(0.55")

2.2 mm

(0.09")

2x 40°

27.0 mm

(1.06")

40 mm Typ.

(1.5")

2x 20°

30.5 mm

(1.20")

8x Full Radius

61.0 mm

(2.40")

53.0 mm

72.8 mm

(2.87")

(2.09")

37.6 mm

(1.48")

5.9 mm

(0.23")

31.0 mm

(1.22")

31.0 mm

(1.22")

2.2 mm

(0.09")

47.0 mm

(1.85")

38.5 mm

(1.52")

55.0 mm

(2.17")

95.0 mm

(3.74")

77.0 mm

(3.03")

3x M3 x 0.5

ø75.5 mm

(2.97")

ø88.5 mm

(3.49")

4x 17.0°

4x 25.0°

8x Full

Radius

40 mm Typ.

(1.5")

13.0 mm

(0.51")

2x 6.5 mm

(0.26")

ø56.0 mm (2.21")

ø43.0 mm (1.69")

ø6.3 mm (0.25")

2x

20.0 mm

(0.79")

2x 15°

2x 8.0 mm

(0.32")

2x 30°

Page 12

Banner Engineering Corp., 9714 Tenth Ave. No., Minneapolis, MN 55441 • Phone: 612.544.3164 • Fax: 612.544.3573 • E-mail: sensors@baneng.com

L-GAGE™ Laser Gauging Sensor

WARRANTY: Banner Engineering Corporation warrants its products to be free from defects for one year. Banner Engineering Corporation

will repair or replace, free of charge, any product of its manufacture found to be defective at the time it is returned to the factory during the

warranty period. This warranty does not cover damage or liability for the improper application of Banner products. This warranty is in lieu

of any other warranty either expressed or implied.

WARNING . . .

Not To Be Used for Personnel Protection

Never use these products as sensing devices for personnel protection. Doing so could lead to serious injury or death.

These sensors do NOT include the self-checking redundant circuitry necessary to allow their use in personnel safety

applications. A sensor failure or malfunction can cause either an energized or de-energized sensor output condition. Consult your current

Banner Safety Products catalog for safety products which meet OSHA, ANSI and IEC standards for personnel protection.

!

Loading...

Loading...