Page 1

™

™

L-GAGE

L-GAGE

Laser Gauging Sensors

Laser Gauging Sensors

Page 2

L-GAGE

L-GAGE™: A new paradigm for precision laser measurement.

™

: A new paradigm for precision laser measurement.

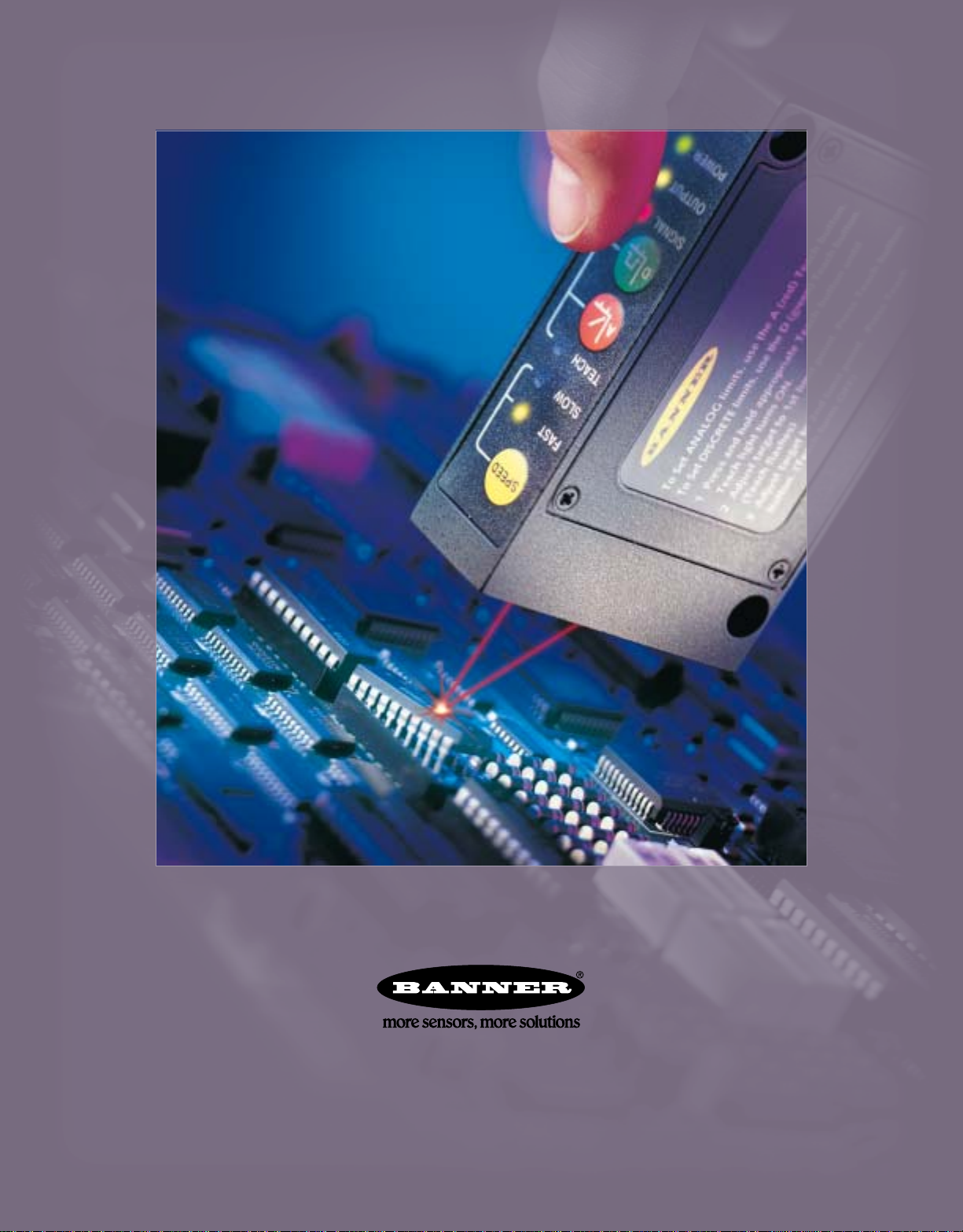

Unique,*self-contained design replaces large, cumbersome systems.

Laser gauging sensors are typically large, two-piece systems, and are difficult to

use. The new Banner L-GAGE has changed all that with a completely self-contained,

12 to 30V dc patent-pending design measuring only 55 mm X 82 mm X 20 mm

82 mm

(3.2")

55mm

(2.2")

(2.2" X 3.2" X 0.8"). By eliminating the need for a separate controller, the

one-piece L-GAGE is easier to wire, decreases setup time and conserves valuable

production space, with the added bonus of superior performance.

*Patent pending

Ultra-precise & accurate, with both analog & discrete outputs.

Advanced digital signal processing algorithms make the L-GAGE Class 2 modulated

visible laser gauging sensor a powerhouse of performance for a wide range of

measurement applications. It features an outstanding maximum resolution of

3 µm (0.0001"). It’s ultra-narrow effective beam resolves precision distance, height

or thickness measurement and gauging applications, including robot arm

calibration, wafer profiling, diameter or thickness measurement, and assembly

dimension inspection, to name only a few.

A price point as sharp as its laser emitter.

Now you can upgrade to laser technology for the same cost as

a contacting sensor. L-GAGE sensors are the first in their category

to break the $1,000 price barrier, providing an economical and

highly accurate solution at a much lower cost. Previously

cost-prohibitive applications can now be solved with ease. And

because L-GAGE sensors do not contact the parts they measure,

they can be used with moving processes, hot parts and sticky

parts. They also include measuring features that are unavailable

on contacting probes, giving the L-GAGE sensors a distinct

advantage in performance as well as price.

Infinitely more flexible.

L-GAGE sensors are vastly more flexible and

easier to program than currently-available

gauging sensors. Why buy an inflexible fixedrange laser sensor when the more-advanced

L-GAGE lets you pick the exact range you need

with the push of a button? And you get both

discrete (switched) and analog outputs in the

same unit, each independently programmable.

It’s a better solution for all your applications. For

additional flexibility, analog units are available

with either 4 to 20 mA or 0 to10V outputs.

2

Page 3

L-GAGE

L-GAGE™: The world’s first teachable laser sensor.

(2.9" to 4.9")

™

: The world’s first teachable laser sensor.

Define your own custom sensing window

by simply pushing a button.

Unlike older, inflexible, fixed-range technology, Banner’s

unique TEACH-mode programming allows you to set your own

75 mm to 125 mm

custom-sized sensing windows, and place them anywhere within

either a 45 mm to 60 mm (1.8" to 2.4") or 75 mm to 125 mm

(2.9" to 4.9") range using a single push button. One

L-GAGE sensor can be easily programmed to provide

an analog output, discrete output, or both

simultaneously with independently controlled

sensing window limits.

45 mm to 60 mm

(1.8" to 2.4")

Automatic gain control.

L-GAGE sensors feature Automatic

Gain Control (AGC) to automatically

compensate for varying colors,

helping to minimize linearity errors

and false triggering associated with

conventional laser sensors.

Remote programming.

For maximum convenience and easier access

for programming hard-to-reach sensors,

TEACH-mode programming can also be

accomplished from a remote location using

an external switch, computer or controller.

The integral key pad may be locked remotely,

providing added security by eliminating

possible tampering with sensor adjustments.

Easy as 1, 2, 3!

Simple programming instructions

(three short sentences) are printed

on the side of the L-GAGE for

permanent, easy access.

3

Page 4

L-GAGE

L-GAGE™: Advanced features help you solve more applications.

™

: Advanced features help you solve more applications.

Exclusive scalable analog output.

Unlike conventional gauging sensors, and available only from

Banner,

L-GAGE sensors allow you to automatically scale the

analog output over your desired sensing window. This unique

feature speeds setup and allows for maximum resolution in electricallynoisy environments. Unique Auto-Zero feature allows you to easily set a

sensing distance set point centered within a 10 mm wide window.

Fast LED:

1.0 ms response

Programmable response times.

Output response is programmable to three speeds,

one, 10, and 100 milliseconds, by simply pushing a button.

You instantly get the response time that works with your

Both LEDs:

10 ms response

Slow LED:

100 ms response

machine cycle speeds.

Advanced diagnostics.

L-GAGE sensors keep you

constantly informed of

operating status throughout

programming and operation.

Sensors also include an alarm

output for signal saturation;

discrete output can be

programmed to detect a

missing target.

Yellow fast/slow LEDs indicate

response time.

Tri-color (red, green, yellow)

TEACH LED indicates sensor is

ready for programming each

limit (analog, discrete, or both

analog and discrete).

Analog Teach button.

Ambient light immunity.

With its modulated laser beam and narrow

optical band-pass filter, the L-GAGE is

highly immune to ambient light,

including high-energy factory lighting.

Protected circuitry.

Integral circuitry protects L-GAGE sensors

from reverse polarity, over voltage, and

transient voltage.

Durable construction.

Rugged L-GAGE sensors have a die-cast

zinc alloy housing, with an aluminum

top cover and an acrylic lens cover.

They are rated IP67 and NEMA 6, and

have an operating temperature range

of -10° to +50°C (+14° to +122°F).

Discrete Teach button.

Red LED indicates target is in the

sensing window and the condition

of the received light signal.

Yellow LED indicates when the

discrete load output is conducting.

Green LED indicates Power ON

and flashes to indicate Output

Overloaded and disabled laser.

Pre-wired or quick-disconnect, 10 to 30V dc.

L-GAGE sensors are available with a 2 m (6.5') or 9 m

(30') attached, 8-conductor PVC potted-in cable, or an 8-pin

Euro-style quick disconnect pigtail connector that allows easy sensor

installation and removal. Keyed connectors prevent wiring errors.

4

Page 5

L-GAGE

RADIANT POWER 0.15 mW

8KHz 8-16% DUTY CYCLE

660 - 680 nm

COMPLIES WITH 21 CFR

1040.10 AND EN60825-1:1994

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

LASER LIGHT

Avoid exposure -

laser light emitted

from his aperture

T

E

A

C

H

S

L

O

W

F

A

S

T

P

O

W

E

R

O

U

T

P

U

T

S

I

G

N

A

L

S

P

E

E

D

A

D

RADIANT POWER 0.15 mW

8KHz 8-16% DUTY CYCLE

660 - 680 nm

COMPLIES WITH 21 CFR

1040.10 AND EN60825-1:1994

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

LASER LIGHT

Avoid exposure -

laser light emitted

from his aperture

T

E

A

C

H

S

L

O

W

F

A

S

T

P

O

W

E

R

O

U

T

P

U

T

S

I

G

N

A

L

S

PE

E

D

A

D

RADIANT POWER 0.15 mW

8KHz 8-16% DUTY CYCLE

660 - 680 nm

COMPLIES WITH 21 CFR

1040.10 AND EN60825-1:1994

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

LASER LIGHT

Avoid exposure -

laser light emitted

from his aperture

T

EA

C

H

S

L

O

W

F

A

S

T

P

O

W

E

R

O

U

T

P

U

T

S

IG

N

A

L

S

P

E

E

D

A

D

T

o

S

e

t

A

N

A

L

O

G

l

i

m

i

t

s

,

u

s

e

t

h

e

A

(

r

e

d

)

T

e

a

c

h

b

u

t

t

o

n

.

T

o

S

e

t

D

I

S

C

R

E

T

E

l

i

m

i

t

s

,

u

s

e

t

h

e

D

(

g

r

e

e

n

)

T

e

a

c

h

b

u

t

t

o

n

.

1

P

r

e

s

s

a

n

d

h

o

l

d

a

p

p

r

o

p

r

i

a

t

e

T

e

a

c

h

b

u

t

t

o

n

u

n

t

i

l

T

e

a

c

h

l

i

g

h

t

t

u

r

n

s

O

N

.

2

A

d

j

u

s

t

t

a

r

g

e

t

t

o

1

s

t

l

i

m

i

t

p

o

i

n

t

.

P

r

e

s

s

T

e

a

c

h

b

u

t

t

o

n

.

(

T

e

a

c

h

f

l

a

s

h

e

s

)

3

A

d

j

u

s

t

t

a

r

g

e

t

t

o

2

n

d

l

i

m

i

t

p

o

i

n

t

.

P

r

e

s

s

T

e

a

c

h

b

u

t

t

o

n

.

(

T

e

a

c

h

t

u

r

n

s

O

F

F

)

TEACH

SLOW

FA

ST

P

O

W

E

R

OUTPUT

S

I

G

N

A

L

SPEED

A

D

T

o

S

e

t

A

N

A

L

O

G

l

i

m

i

t

s

,

u

s

e

t

h

e

A

(

r

e

d

)

T

e

a

c

h

b

u

t

t

o

n

.

T

o

S

e

t

D

I

S

C

R

E

T

E

l

i

m

i

t

s

,

u

s

e

t

h

e

D

(

g

r

e

e

n

)

T

e

a

c

h

b

u

t

t

o

n

.

1

P

r

e

s

s

a

n

d

h

o

l

d

a

p

p

r

o

p

r

i

a

t

e

T

e

a

c

h

b

u

t

t

o

n

u

n

t

i

l

T

e

a

c

h

l

i

g

h

t

t

u

r

n

s

O

N

.

2

A

d

j

u

s

t

t

a

r

g

e

t

t

o

1

s

t

l

i

m

i

t

p

o

i

n

t

.

P

r

e

s

s

T

e

a

c

h

b

u

t

t

o

n

.

(

T

e

a

c

h

f

l

a

s

h

e

s

)

3

A

d

j

u

s

t

t

a

r

g

e

t

t

o

2

n

d

l

i

m

i

t

p

o

i

n

t

.

P

r

e

s

s

T

e

a

c

h

b

u

t

t

o

n

.

(

T

e

a

c

h

t

u

r

n

s

O

F

F

)

TEACH

SLOW

FA

ST

P

O

W

E

R

OUTPU

T

S

I

G

N

A

L

SPEED

A

D

T

o

S

e

t

A

N

A

L

O

G

li

m

i

t

s

,

u

s

e

t

h

e

A

(

r

e

d

)

T

e

a

c

h

b

u

t

t

o

n

.

T

o

S

e

t

D

I

S

C

R

E

T

E

l

i

m

i

t

s

,

u

s

e

t

h

e

D

(

g

r

e

e

n

)

T

e

a

c

h

b

u

t

t

o

n

.

1

P

r

e

s

s

a

n

d

h

o

l

d

a

p

p

r

o

p

r

ia

t

e

T

e

a

c

h

b

u

t

t

o

n

u

n

t

i

l

T

e

a

c

h

l

i

g

h

t

t

u

r

n

s

O

N

.

2

A

d

j

u

s

t

t

a

r

g

e

t

t

o

1

s

t

l

i

m

i

t

p

o

i

n

t

.

P

r

e

s

s

T

e

a

c

h

b

u

t

t

o

n

.

(

T

e

a

c

h

f

l

a

s

h

e

s

)

3

A

d

j

u

s

t

t

a

r

g

e

t

t

o

2

n

d

l

i

m

i

t

p

o

i

n

t

.

P

r

e

s

s

T

e

a

c

h

b

u

t

t

o

n

.

(

T

e

a

c

h

t

u

r

n

s

O

F

F

)

TEACH

SLOW

FAS

T

P

O

W

E

R

OUTPUT

S

I

G

N

A

L

SPEED

A

D

RADIANT POWER 0.15 mW

8KHz 8-16% DUTY CYCLE

660 - 680 nm

COMPLIES WITH 21 CFR

1040.10 AND EN60825-1:1994

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

LASER LIGHT

Avoid exposure -

laser light emitted

from his aperture

T

E

A

C

H

S

L

O

W

F

A

S

T

P

O

W

E

R

O

U

T

P

U

T

S

I

G

N

A

L

S

P

E

E

D

A

D

P

U

T

4 mm

20 mm

12 mm

28 mm

T

E

A

C

H

S

L

O

W

F

A

S

T

P

O

W

E

R

O

U

T

P

U

T

S

I

G

N

A

L

S

P

E

E

D

A

D

T

o S

e

t A

N

A

L

O

G

lim

i

t

s,

u

s

e th

e

A

(re

d

) T

e

a

ch

b

u

tto

n.

To

S

et

D

I

S

C

R

E

T

E

li

m

its

, us

e

t

he

D

(g

re

e

n)

T

eac

h

b

u

t

to

n

.

1P

re

s

s

a

n

d h

o

ld

a

pp

ro

p

r

ia

te

T

ea

ch

b

ut

to

n

u

nt

il

T

e

a

c

h

lig

ht

tur

n

s

O

N

.

2A

d

ju

st

ta

rg

et to

1

st

li

m

i

t p

oi

nt

. P

re

s

s T

ea

c

h

b

u

tto

n.

(T

e

ac

h

flas

h

e

s

)

3A

d

ju

st ta

rg

e

t to

2

n

d

lim

it

po

i

nt.

P

re

ss

Te

a

c

h

b

u

tto

n

. (T

e

a

ch

t

ur

ns

O

F

F

)

T

E

A

C

H

S

L

O

W

F

A

S

T

P

O

W

E

R

O

U

T

P

U

T

S

I

G

N

A

L

S

P

E

E

D

A

D

T

o

S

e

t

A

N

A

L

O

G

l

im

its

, u

se

t

he

A

(re

d)

Te

a

c

h

b

utt

on

.

To

S

e

t D

IS

C

R

E

TE

l

im

it

s, u

s

e

t

h

e

D

(gr

ee

n

) T

e

a

ch

bu

t

t

on

.

1P

res

s an

d

h

old

a

p

pr

op

ria

t

e

T

e

a

ch

b

u

tto

n

u

n

t

il

T

ea

c

h

li

gh

t t

u

rns

O

N

.

2A

d

ju

st t

a

rg

e

t to

1

s

t l

im

it

p

oi

n

t.

Pre

s

s

T

e

a

c

h

b

u

tto

n

. (T

e

a

c

h

fla

s

h

e

s)

3A

dj

u

st

tar

ge

t

to

2n

d

li

m

i

t po

i

nt.

P

r

e

ss

Te

a

c

h

b

ut

t

on

. (

T

ea

ch

tu

rn

s O

FF

)

T

E

A

C

H

S

L

O

W

F

A

S

T

P

O

W

E

R

O

U

T

P

U

T

S

I

G

N

A

L

S

P

E

E

D

A

D

T

o

S

e

t

A

N

A

L

O

G

l

im

its

,

us

e

th

e

A

(re

d

) T

e

ac

h

b

ut

ton

.

T

o

Se

t

D

IS

C

RE

T

E lim

it

s

, u

se

th

e

D

(

g

re

en

)

T

ea

c

h

b

ut

ton

.

1P

re

ss

a

nd

h

o

ld

ap

p

ro

p

ria

te

T

e

a

ch

b

u

tto

n

u

nt

i

l

T

e

ach

l

ig

ht t

ur

n

s

O

N

.

2A

dj

us

t

tar

ge

t t

o

1

st

lim

it

po

in

t.

Pr

es

s

T

e

a

ch

b

u

tt

on

.

(T

ea

c

h

fla

sh

es

)

3A

dj

us

t ta

rg

e

t

to

2

nd

lim

it p

o

in

t

. P

re

s

s T

e

a

c

h

b

utto

n

. (T

e

ach

tu

rn

s O

F

F)

RADIANT POWER 0.15 mW

8KHz 8-16% DUTY CYCLE

660 - 680 nm

COMPLIES WITH 21 CFR

1040.10 AND EN60825-1:1994

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

LASER LIGHT

Avoid exposure -

laser light emitted

from his aperture

T

E

A

C

H

S

L

O

W

F

A

S

T

P

O

W

E

R

O

U

T

P

U

T

S

I

G

N

A

L

S

P

E

E

D

A

D

RADIANT POWER 0.15 mW

8KHz 8-16% DUTY CYCLE

660 - 680 nm

COMPLIES WITH 21 CFR

1040.10 AND EN60825-1:1994

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

LASER LIGHT

Avoid exposure -

laser light emitted

from his aperture

T

E

A

C

H

S

L

O

W

F

A

S

T

P

O

W

E

R

O

U

T

P

U

T

S

I

G

N

A

L

S

P

E

E

D

A

D

RADIANT POWER 0.15 mW

8KHz 8-16% DUTY CYCLE

660 - 680 nm

COMPLIES WITH 21 CFR

1040.10 AND EN60825-1:1994

DO NOT STARE INTO BEAM

CLASS 2 LASER PRODUCT

LASER LIGHT

Avoid exposure -

laser light emitted

from his aperture

T

E

A

C

H

S

L

O

W

F

A

S

T

P

O

W

E

R

O

U

T

P

U

T

S

I

G

N

A

L

S

P

E

E

D

A

D

A

F

F - (A+B) = Thickness

B

L-GAGE™Laser Sensor Applications

™

Laser Sensor Applications

WOOD PROFILING

Objective: Profile wood moldings; inspect milled dimensions.

Sensor: L-GAGE model LG10A65NU

Operation: The L-GAGE, with a 100 mm standoff distance and

a 50 mm measuring window, can accurately profile

a wide variety of wooden moldings in milling

applications. Not only is the L-GAGE fast and

accurate, it is also very tolerant of changing wood

colors. For example, changing from dark walnut to

light ash requires no change in sensor configuration.

RUN-OUT INSPECTION OF WHEEL CASTING

Objective: Prior to machining, inspect a wheel casting to ensure

that six critical dimensions are within tolerance.

Sensor: L-GAGE model LG5A65PU

Operation: Wheel castings slide into a rotating fixture beneath six

stationary L-GAGE sensors. Each L-GAGE is positioned

so that a nominal casting is at the center of the sensor’s

measuring window. The 0 to 10V dc outputs of all six

sensors are fed into a PLC, which records maximum runout.

The LG5A, with its wide beam diameter, was selected for

best output stability on a rough casting surface. The L-GAGE

non-contact sensor eliminates frequent sensor replacement

and recalibration.

S

I

G

N

A

L

D

1040.10 AND EN60825-1:1994

COMPLIES WITH 21 CFR

660 - 680 nm

8KHz 8-16% DUTY CYCLE

RADIANT POWER 0.15 mW

A

T

E

A

C

H

from his aperture

CLASS 2 LASER PRODUCT

laser light emitted

DO NOT STARE INTO BEAM

Avoid exposure -

S

LO

LASER LIGHT

W

F

A

S

T

S

P

E

E

D

THICKNESS MEASUREMENT OF PLYWOOD

Objective: Measure thickness at three points across the width

of a sheet of plywood

Sensor: L-GAGE model LG10A65NU

Operation: Three pairs of L-GAGE sensors are set up across a sheet

of laminate. Thickness at each location is determined

by subtracting the distance from each sensor to the

plywood from the distance between the pair of sensors:

t = F - (A+ B), where A is the top distance, B is the

bottom distance, and F is the fixed distance between the

sensors in each pair.

5

Page 6

L-GAGE

L-GAGE™Laser Sensors Model Selection & Accessories

™

Laser Sensors Model Selection & Accessories

4-20 mA current analog output

■

Model Number Part Number Range Focal Point Resolution* Cables Analog Output Discrete Output

LG5A65NI

LG5A65NIQ

LG5A65PI

LG5A65PIQ

LG5A65NU

LG5A65NUQ

LG5A65PU

LG5A65PUQ

LG5B65NI

LG5B65NIQ

LG5B65PI

LG5B65PIQ

LG5B65NU

LG5B65NUQ

LG5B65PU

LG5B65PUQ

LG10A65NI

LG10A65NIQ

LG10A65PI

LG10A65PIQ

LG10A65NU

LG10A65NUQ

LG10A65PU

LG10A65PUQ

* Best resolution for analog and discrete outputs determined with a white ceramic test surface at the specified distance, with the sensor response speed set for slow (100 milliseconds).

** For 9 m (30') cable assembly, add w/30 to model number.

54086

54087

54089

54090

57571

57572

57565

57566

55964

55968

55966

55969

57574

57575

57568

57569

54092

54093

54095

54096

57577

57578

57580

57581

45-60 mm (1.8"-2.4")

75-125 mm (3.0"-4.9")

70 mm (2.8")

53 mm (2.1")

For small

object detection

180 mm (7.1")

<3 µm (0.0001")

<10 µm (0.0004")

@ 100 mm

0-10V dc voltage analog output

■

6" (15.2 cm) 8-pin Euro QD

6" (15.2 cm) 8-pin Euro QD

6" (15.2 cm) 8-pin Euro QD

@ 50 mm

6" (15.2 cm) 8-pin Euro QD

6" (15.2 cm) 8-pin Euro QD

6" (15.2 cm) 8-pin Euro QD

6" (15.2 cm) 8-pin Euro QD

6" (15.2 cm) 8-pin Euro QD

6" (15.2 cm) 8-pin Euro QD

6" (15.2 cm) 8-pin Euro QD

6" (15.2 cm) 8-pin Euro QD

6" (15.2 cm) 8-pin Euro QD

2m (6.5') 8-wire**

2m (6.5') 8-wire**

2m (6.5') 8-wire**

2m (6.5') 8-wire**

2m (6.5') 8-wire**

2m (6.5') 8-wire**

2m (6.5') 8-wire**

2m (6.5') 8-wire**

2m (6.5') 8-wire**

2m (6.5') 8-wire**

2m (6.5') 8-wire**

2m (6.5') 8-wire**

NPN (sinking)

4-20ma Sourcing

PNP (sourcing)

NPN (sinking)

0-10V dc Sourcing

PNP (sourcing)

NPN (sinking)

4-20ma Sourcing

PNP (sourcing)

NPN (sinking)

0-10V dc Sourcing

PNP (sourcing)

NPN (sinking)

4-20ma Sourcing

PNP (sourcing)

NPN (sinking)

0-10V dc Sourcing

PNP (sourcing)

L-GAGE Mounting Bracket Model SMBLG (Part Number 55815)

Type 304 stainless steel mounting bracket is corrosion resistant and provides up to 42° of vertical adjustment

and up to 40° of horizontal adjustment. This attractively designed unit enhances the appearance of your

equipment and saves you time and money through reduced installation time and lower total installed cost.

Custom brackets can be designed for your unique applications.

L-GAGE Mounting Bracket Model SMBLGA (Part Number 55906)

Similar to Model SMBLG above but also provides spring-loaded precision adjustment screws enabling the

installer to make extremely accurate adjustments for small targets or long range applications. Type 304

stainless steel. Request the Banner Sensor Catalog (P/N 99000) or CD ROM (P/N 99100) for other available

models. Custom brackets can be designed for your unique applications.

Euro-style Quick Disconnect Cable Model MQDC-830 (Part Number 57595)

Straight 8-pin cable, 9 m (30') length. Electrically shielded design with PUR jacket and polyurethane

connector body with nickel plated brass coupling nut.

6

Page 7

L-GAGE

L-GAGE™Laser Sensor Specifications & Dimensions

™

Laser Sensor Specifications & Dimensions

Supply Specifications:

Supply Voltage:12 to 30V dc, (10% maximum ripple); 50mA max at 24Vdc

(exclusive of load).

Sensing Supply Protection Circuitry: Protected against reverse polarity,

over voltage, and transient voltages.

Delay at Power-up:1.25 second.

Sensing Characteristics:

Sensing Beam: 670 nm visible red IEC and CDRH Class 2 laser; 0.20 mW

maximum radiant output power.

Range: LG5: 45.0 to 60.0 mm (1.77" to 2.36"); LG10: 75.0 to 125.0 mm (2.95" to 4.92").

Minimum Window Size (Analog or Discrete): LG5: 1.5 mm (0.06");

LG10: 5 mm (0.2").

Analog Resolution and Repeatability of Discrete Trip Point:

LG5 System response speed set at fast: <40 µm (0.0016") @ 50 mm (2").

System response speed set at medium: <12 µm (0.0005") @ 50 mm (2").

System response speed set at slow: <3 µm (0.0001") @ 50 mm (2").

LG10 System response speed set at fast: <150 µm (0.006") @ 100 mm (2").

System response speed set at medium: <50 µm (0.0016") @ 100 mm (2").

System response speed set at slow: <10 µm (0.0016") @ 100 mm (2").

Analog Linearity:

LG5 ±60 µm (±0.002") over 45 to 60 mm (1.77" to 2.36") sensing window.

±10 µm (±0.0004") over 49 to 51 mm (1.93" to 2.00") sensing window.

LG10 ±200 µm (±0.008") over 75 to 125 mm (2.95" to 4.92") sensing window.

±20 µm (±0.0008") over 95 to 100 mm (3.74" to 3.93") sensing window.

55.3 mm

(2.18")

4.6 mm

(0.18")

45.5 mm

(1.79")

20.2 mm (0.80")

ER

T

82.3 mm

(3.24")

POW

O

U

T

P

U

SIGNAL

RADIA

8KH

660 - 680 nm

C

1040.10 AN

68.3 mm

(2.69")

D

O

MP

D

C

NT P

z 8-16%

LIES W

A

C

H

L

A

S

E

O

N

R

O

T

L

S

A

S

T

S

A

2

R

L

A

S

E

Avoid exposure laser light em

from

his aperture

OW

ER 0.15 m

D

UTY CYCLE

ITH 21 CFR

D EN60825-1:1994

POWER

OUTPUT

SIGNAL

D

A

T

E

A

C

S

H

L

O

W

S

T

L

A

S

D

E

O

N

R

C

O

L

T

L

A

S

S

I

T

S

G

A

2

R

H

E

L

A

IN

T

S

T

E

O

R

B

A

P

v

E

R

o

A

O

id

M

D

la

e

U

C

s

x

e

T

p

r lig

o

s

fro

u

h

R

re

m

t e

A

-

D

h

m

is

IA

8

it

a

K

N

te

H

p

T

d

z

e

P

6

8

r

6

tu

O

-1

0

r

W

- 6

e

6

C

%

E

O

8

R

D

0

M

0

nm

U

1

P

.1

T

0

L

5

4

Y

I

E

m

0

C

.1

S

W

Y

W

0

C

A

IT

L

N

E

H

D

2

E

1

N

C

6

F

0

8

R

25

-1

:1

9

9

4

T

E

A

SLO

W

F

A

ST

SPEED

L

IG

H

E

IN

T

T

O

R

B

P

E

R

A

O

M

D

U

C

T

itted

W

F

A

S

P

E

E

D

23.9 mm

(0.94")

Beam Dimensions

Y

X

Emitted Light

Received Light

19.1 mm

(0.75")

9.3 mm

(0.37")

Hysteresis (Discrete Output): LG5: < 0.2 mm (0.008"); LG10 <1 mm (0.04").

Color Sensitivity: LG5: <75 µm (0.003") (typical) for white or dark gray ceramic target;

LG10: < 100 µm (0.01") (typical) for white or dark gray ceramic target.

Temperature Drift: LG5: ±7 µm /°C; LG10: ±25 µm /°C.

Output Specifications:

Output Configurations: Discrete (switched) output: SPST solid-state switch

(choose NPN or PNP models).

Analog output: Current models: 4 to 20 milliamp current

sourcing; Voltage models: 0 to10V dc current sourcing.

Alarm output: SPST Solid-state switch (NPN or PNP

depending on discrete output model).

Output Ratings: Discrete (switched): 100 mA maximum.

Analog output: Current models: 1KΩ max @ 24V dc;

Voltage models: 2.5KΩ minimum load impedance.

Alarm output: 100 mA maximum.

Output Protection: Discrete outputs are protected against continuous overload

and short circuit.

Output Response Time: Discrete output: system response speed set at fast:

2.0 milliseconds ON and OFF; system response speed set

at medium: 10 milliseconds ON and OFF; system

response speed set at slow: 100 milliseconds ON and OFF.

Analog output (-3 dB): fast: 450 Hz (1 millisecond);

medium: 45 Hz (10 millisecond); slow: 4.5 Hz

(100 millisecond).

L-GAGE Beam Dimensions (typical)

Focal

Point* Width (X) Height (Y)

Distances

45 mm 0.3 mm 0.5 mm

53 mm

(2.1")

53 mm 0.1 mm 0.1 mm

60 mm 0.3 mm 0.5 mm

45 mm 0.6 mm 0.9 mm

70 mm

(2.8")

53 mm 0.4 mm 0.6 mm

60 mm 0.3 mm 0.4 mm

75 mm 1.1 mm 1.5 mm

180 mm

(7.1")

100 mm 0.8 mm 1.1 mm

125 mm 0.6 mm 0.8 mm

* The Focal Point is the distance measured from the lens (front of sensor) at which

the diameter of the laser image is smallest.

Beam Beam

7

Page 8

Banner: Industry’s number one supplier of sensors & machine safety products.

Banner: Industry’s number one supplier of sensors & machine safety products.

When you buy your sensors and machine

safety products from Banner, you gain the

confidence of dealing with the industry’s

largest, most knowledgeable and experienced

photoelectric company. We have the broadest

line of products and the most advanced

manufacturing capabilities in the industry.

We can handle any size order, large or

small, utilizing the most advanced

manufacturing capabilities.

We can deliver any of more than 15,000

different products in just three days–most

can ship within hours!

Just as important, we have the largest

photoelectric sales and support network

in the industry, backed by the world’s finest

application engineers. With our global sales

support network, we’re close by wherever

you’re located, and we’re ready to help you

with your applications, plus give you

excellent service support. When you add it up,

you’ll find the best value in Banner products.

Visit Banner On-Line at

www

.baneng.com

• Complete product information for:

–

Photoelectric sensors

–

Measurement and

inspection sensors

–

Machine safety products

• Up-to-date “What’s New” page.

• Complete descriptions for each product,

with links to product data sheets and

dimension drawings.

• Product catalogs, specifier’s guides,

and product brochures available for

immediate download or email request.

•

Documents available in multiple languages.

For more information or

applications assistance:

Call 1.888.3.SENSOR

(1.888.373.6767)

The Banner Photoelectric

Sensors Catalog & CD ROM.

The industry’s most complete catalog;

more than 700 pages of detailed

product and technical information

on more than 12,000 photoelectric

sensors. Simple selection charts

make specifying the

correct sensor easier

than ever. Call, write,

or email for your

copy today, P/N

99000; CD ROM,

P/N 99100.

Worldwide Representation.

• Australia

• Argentina

• Austria

• Belgium

• Brazil

• Canada

• Chile

• China

• Colombia

• Costa Rica

• Czech Republic

• Denmark

• Egypt

• Estonia

• Finland

• France

• Germany

• Greece

• Hong Kong

• Hungary

• Iceland

• India

• Indonesia

• Ireland

• Israel

• Italy

• Japan

• Korea

• Latvia

• Lithuania

• Luxembourg

• Malaysia

• Mexico

The Banner Machine Safety

Products Catalog & CD ROM.

A complete catalog of Machine Safety

Products including Banner’s extensive

line of safety light screen controllers,

emitters and receivers. Also included

are Banner’s two-hand anti-tiedown

controls and full line of safety interlock

switches and E-stop

safety modules.

Call, write, or

email for your

copy today, P/N

99500; CD ROM,

P/N 99100.

• Netherlands

• New Zealand

• Norway

• Pakistan

• Peru

• Philippines

• Poland

• Portugal

• South Africa

• Russia/CIS

• Singapore

• Slovakia

• Spain

• Sweden

• Switzerland

• Taiwan

• Thailand

• Turkey

• United

Kingdom

• Uruguay

• Venezuela

Banner Engineering Corporation, P.O. Box 9414, Minneapolis, MN 55440 U.S.A.

Phone 612.544 .3164 Fax 612.544 .3213 www.baneng.com Email: sensors@baneng.com

PRINTED IN U.S.A. Copyright, 1999 Banner Engineering Corporation P/N 59987

Loading...

Loading...