Page 1

A-GAGE® EZ-ARRAY™ Instruction Manual

Two-piece sensing array with 2 analog and 2 discrete outputs, plus serial output

Features

A cost-effective, two-piece measuring light curtain designed for •

quick and simple installations with the sophistication to handle

the toughest sensing applications

Excels at high-speed, precise process monitoring and inspection, •

profiling, and web-guiding applications

A comprehensive combination of scanning options: •

– 14 measurement (“scan analysis”) modes

– 3 scanning methods

– Selectable beam blanking

– Selectable continuous or gated scan initiation

– Selectable threshold setting for semi-transparent applications

– 2 analog outputs, 2 discrete outputs, plus Modbus 485-RTU

serial output

Outstanding 4 meter range with 5 mm beam spacing•

Available in 12 lengths from 150 mm to 2400 mm•

Excellent 5 mm minimum object detection or 2.5 mm edge •

resolution, depending on scanning method

Receiver user interface for quick, intuitive setup of many common •

applications:

– 6-position DIP switch for setting scan mode, measurement

mode, analog slope, discrete output 2 option (complementary

measurement or alarm operation)

– 2 push buttons for gain method selection and alignment/

blanking

– 7 Zone LEDs for instant alignment and beam blockage

information

– 3-digit display for sensing information and diagnostics

Software PC interface available for advanced configuration setup•

Remote teach wire option for alignment, gain settings, inverted •

display, and DIP switch disable

WARNING . . .

Never use these products as sensing devices for personnel protection. Doing so could lead to serious injury or death.

These sensors do NOT include the self-checking redundant circuitry necessary to allow their use in personnel safety applications. A

sensor failure or malfunction can cause either an energized or de-energized sensor output condition. Consult your current Banner

Safety Products catalog for safety products which meet OSHA, ANSI and IEC standards for personnel protection.

Not To Be Used for Personnel Protection

Printed in USA 09/12 P/N 130426 Rev. C

Page 2

Table of Contents

1. Overview ........................................ 1

1.1 System Components ..............................1

1.2 Features ........................................2

1.3 Configuration via DIP Switch or PC Interface ...........2

1.4 Status Indicators..................................3

1.5 Receiver Gray (Remote Teach) Wire.................. 4

1.6 Scanning Method ................................. 5

1.7 Gain Configuration ................................ 7

1.8 Electronic Alignment Routine ........................8

1.9 Blanking ........................................8

1.10 Measurement Mode Selection . . . . . . . . . . . . . . . . . . . . . . 8

1.11 Analog Output Configuration .......................9

1.12 Discrete Output Configuration ......................9

1.13 Serial Communication ............................9

2. Components and Specifications .................... 10

2.1 Sensor Models .................................. 10

2.2 Cordsets and Connections......................... 11

2.3 Alignment Aids .................................. 11

2.4 Accessory Mounting Brackets and Stands............. 12

2.5 Replacement Parts ............................... 12

2.6 Specifications ...................................12

2.6 Specifications, continued ..........................13

2.7 Emitter and Receiver Dimensions ...................14

2.8 Standard Bracket Dimensions ......................15

3. Installation and Alignment ......................... 16

3.1 Mounting the Emitter and Receiver ..................16

3.2 Mechanical Alignment ............................17

3.3 Hookups .......................................18

3.4 Optical Alignment ...............................19

4. Using the Receiver User Interface................... 20

4.1 Configuration DIP Switch ..........................20

4.2 Alignment / Blanking Button (Electronic Alignment)....... 21

4.3 Gain (Sensitivity Adjust) Button ..................... 21

4.4 Inverting the 3-Digit Display ........................22

4.5 Troubleshooting and Error Codes ................... 22

5. Using the PC Interface (Banner Sensors GUI) ......... 23

5.1 Supplied Software ...............................23

5.2 Communications Connections ......................23

5.3 Accessing the GUI ...............................23

5.4 Factory Defaults .................................25

5.5 Alignment and Blanking ...........................25

5.6 Configuration Setup

5.7 System Config View ..............................27

5.8 Analog Output Config View ........................28

5.9 Discrete Output Config View ....................... 28

5.10 Comm Config View..............................29

5.11 Part Number and Version Info View .................29

5.12 System Diagnostics View.........................29

5.13 Communications Troubleshooting .................. 30

Appendix A. Modbus Reference ....................... 34

Glossary ....................................... 45

...............................26

A-GAGE EZ-ARRAY

Instruction Manual

Banner Engineering Corp. •Minneapolis, U.S.A.

www.bannerengineering.com•Tel:763.544.3164

Page 3

A-GAGE EZ-ARRAY

Instruction Manual

1. Overview

Overview

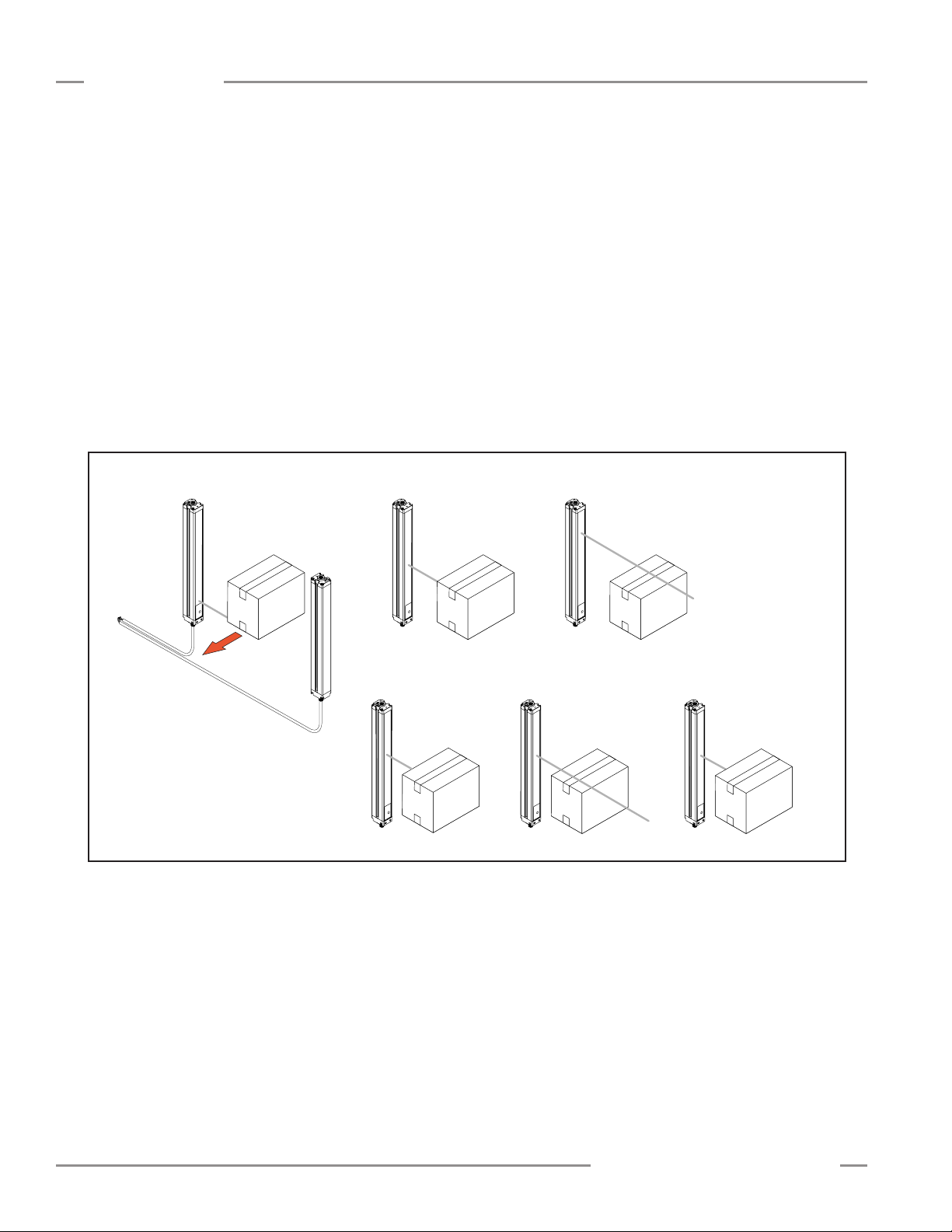

The A-GAGE™ EZ-ARRAY™ measuring light screen is ideal

for such applications as on-the-fly product sizing and profiling,

edge-guiding and center-guiding, loop tensioning control, hole

detection, parts counting, and similar uses (see Figure 1-1).

Emitters and receivers are available with arrays from 150 to

2400 mm (5.9" to 94.5") long. The emitter has a column of

infrared light emitting diodes (LEDs) spaced 5 mm apart; their

light is collimated and directed toward the receiver, positioned

opposite the emitter, which has photodiodes on the same

5 mm pitch. The light from each emitter LED is detected by the

corresponding receiver photodiode.

This sophisticated light curtain is capable of detecting opaque

cylindrical objects as small as 5 mm in diameter or measuring

part edges within 2.5 mm, depending on the scanning method

selected (see Section 1.6). The sensing range is 400 mm to 4 m

(16" to 13').

The EZ-ARRAY’s two-piece design makes it economical and

easy to use. Controller functionality is built into the receiver

housing. It can be configured for many straightforward

applications simply by configuring the six-position DIP switch on

the front of the receiver (the receiver user interface). For more

advanced control, easy-to-use PC interface software is available

on the included CD to configure the sensors using a PC.

Installation is easy, too. The emitter and receiver housings can

be side-mounted or end-cap-mounted using the included endcap brackets; longer models also include a center bracket (see

Section 3.1).

Beam synchronization is achieved via the 8-conductor sensor

cables. Individual LEDs and a 3-digit diagnostic display on the

receiver provide ongoing visual sensing status and diagnostic

information. Comprehensive data is available to a process

controller via a combination of five outputs: two analog, two

discrete, and one Modbus 485-RTU serial.

1.1 System Components

A typical A-GAGE EZ-ARRAY has four components: an emitter

and a receiver, each with an integral quick-disconnect (QD)

fitting, plus an 8-pin QD cordset for the emitter and for the

receiver (see Figure 1-2). For applications that use the Modbus

RTU-485 interface, an additional 5-wire cable is used to connect

the receiver with a PC or process controller, via the Modbus

485-RTU connection. (A PC used with software version 1.1

for configuration must run on Windows

version 1.2, when available, will be compatible with Vista

Emitter Receiver

®

XP or 2000; software

™

.)

Figure 1-1. A typical A-GAGE EZ-ARRAY application

Banner Engineering Corp. •Minneapolis, U.S.A.

www.bannerengineering.com•Tel:763.544.3164

8-Pin Euro

Sensor Cordset

Optional PC for PC interface

software configuration

5-Pin Euro Communications

Cable for use with PC;

USB adapter not shown

Figure 1-2. A-GAGE EZ-ARRAY system components

P/N 130426 Rev. C 1

Page 4

Overview

A-GAGE EZ-ARRAY

Instruction Manual

1.2 Features

Built-in features in the EZ-ARRAY contribute to its ease of

use. Many features are available using either the user-friendly

receiver interface or the more advanced PC interface.

Built-in diagnostic programming and easy-to-see indicators on

the receiver simplify physical alignment and troubleshooting

(Figure 1-3); more advanced diagnostics are available via the

PC interface.

The receiver has a bright LED that indicates overall sensing

status (OK, marginal alignment, and hardware error). Two

other LEDs indicate serial communication status. Seven Zone

indicators each communicate the blocked / aligned status of oneseventh of the total array. A 3-digit diagnostic display provides

further diagnostic information, including number of beams

blocked, whether blanking is configured, and troubleshooting

codes.

The emitter has a red LED that signals proper operation (ON

when power is applied). See Section 1.4 for more information

about indicators and Section 4.5 for display codes and

troubleshooting.

The Alignment routine (Section 4.2 or Section 5.6) automatically

equalizes the excess gain of each beam for reliable object

detection throughout the array. This routine need not be

performed again unless the sensing application changes, or if

the emitter and/or receiver is moved.

Configurable beam blanking accommodates machine

components and fixtures that must remain in or move through the

light screen. Blanking may be set using the receiver interface,

the teach wire, or the PC interface.

The EZ-ARRAY light screen provides a wide selection of sensing

and output options, including measurement (“scan analysis”)

modes and scanning methods that can determine a target

object’s location, overall size, total height, or total width, or the

number of objects. Scanning may be continuous or controlled by

a gate sensor. Up to 15 systems may be networked, via Modbus;

see Section 5 and Appendix A.

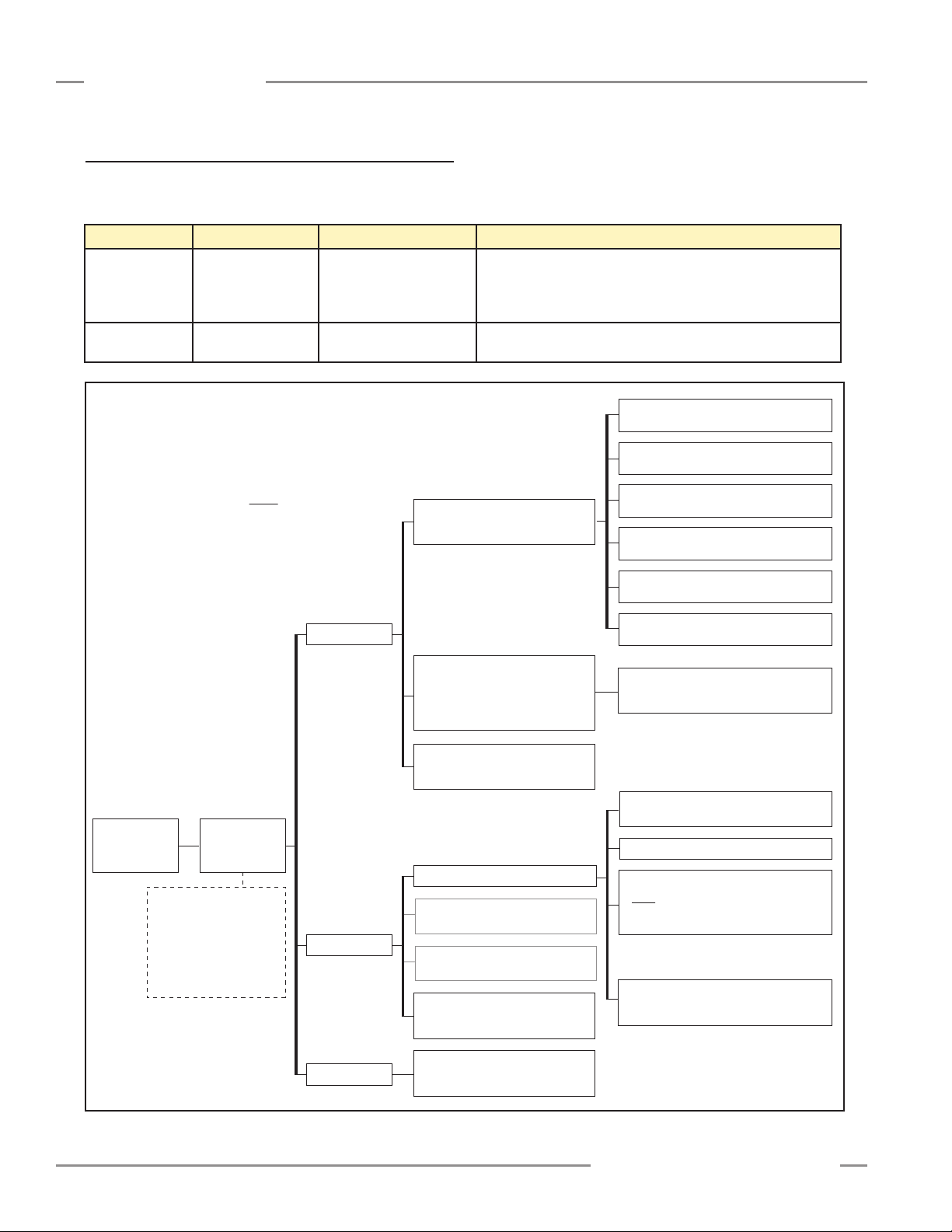

1.3 Configuration via DIP Switch or PC Interface

Commonly used configuration options can be set up easily via

a six-position DIP switch located behind a hinged clear access

panel on the front of the receiver.

Access to the DIP switch can be prevented by using the screwon security plate to hold the clear access panel closed or by

disabling them via the PC interface.

For more advanced, individualized applications, use the supplied

PC interface software program (the “Banner Sensors GUI”;

Section 5) to configure the receiver. The menu-driven program

easily accesses the many scanning and output options. After

the desired options are selected, the combination of selections

can be saved in an .xml file, stored in the system configuration

computer, and recalled as needed. Communication between the

Emitter Receiver

Power ON

LED

Figure 1-3. A-GAGE EZ-ARRAY features

2 P/N 130426 Rev. C

Connection to 5-pin

Communication Cable

Under Hinged Access Panel:

Zone Indicators

Beam #1

(Closest to

Display)

Screw-on Security Plate

limits access to DIP switch

and push buttons

6-Position

Configuration

DIP Switch

3-Digit Diagnostic

Display

Alignment/Blanking

Push Button

Gain (Sensitivity Adjust)

Push Button

Status, Communication Active, and

Communication Error LEDs

Banner Engineering Corp. •Minneapolis, U.S.A.

www.bannerengineering.com•Tel:763.544.3164

Page 5

A-GAGE EZ-ARRAY

Instruction Manual

Overview

sensors and a PC is accomplished via the serial output and

Modbus RTU-485 interface.

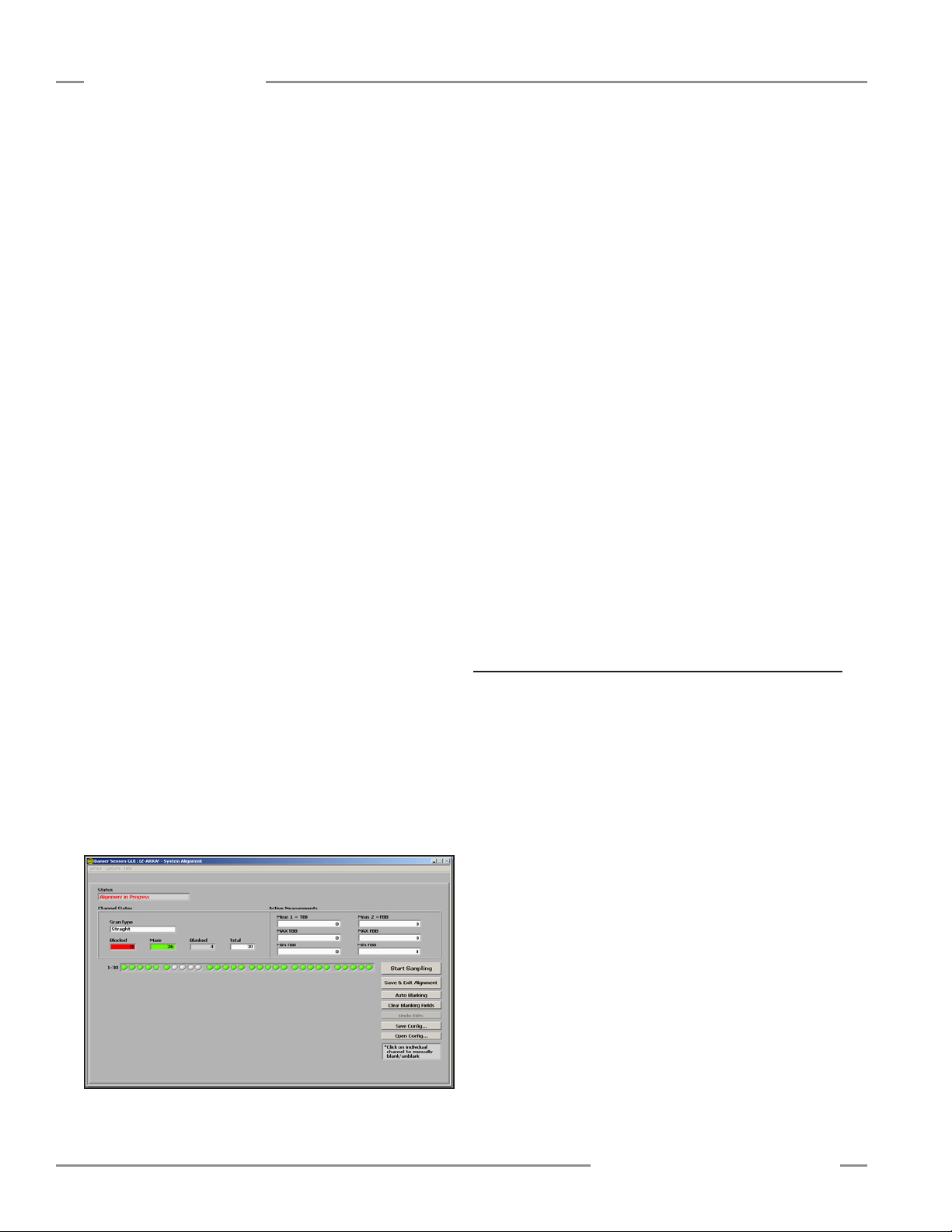

The software also provides alignment and diagnostics routines.

An Alignment screen displays the individual status of each beam

in the light screen, as well as the total number of beams, and

totals of beams blocked, made, and blanked. Built-in diagnostics

can be used to assess emitter and receiver status.

Outputs

In addition to the serial output (see above), all models have two

analog outputs and two discrete outputs.

The analog outputs are either 4–20 mA current or 0–10V

voltage, depending on model (see Section 2-1). They may be

configured (via DIP switch or PC interface) for either a positive

or negative slope.

Discrete output 1 is always used for measurement; discrete

output 2 may be used either for alarm or measurement

operation (selectable via DIP switch or PC interface). When

the receiver interface is used, discrete output 1 follows the

operation of analog output 1 (it conducts when the analog output

senses a target is present). When the PC interface is used for

configuration, both discrete outputs have full configurability,

including measurement mode, NPN or PNP polarity, and

normally open or normally closed operation.

Display Invert

For applications where the sensors must be mounted with the

display end at the top (so that the display is not right-reading),

the receiver’s diagnostic display can be inverted for easy

reading, either by use of the receiver’s remote wire (Section 1.5)

or the PC interface.

1.4 Status Indicators

Both the emitter and receiver provide ongoing visual indication

of operating and configuration status.

The emitter has a red LED that signals proper operation (ON

when power is applied).

into seven equal segments, each of which is represented by

one of the seven LEDs. The LED closest to DIP switch S6 (see

Figure 4-1) represents the group of optical channels closest to

the receiver display (the “bottom” group). The LED closest to DIP

switch 1 represents the far segment of channels.

These LEDs illuminate either green or red. When an LED is

green, no unblanked beams are obstructed in that segment.

When the LED is red, one or more beams in that segment is

obstructed.

Three-Digit Display

The 3-digit display has slightly different functions during normal

operation, alignment, and gain adjust modes. In normal operation

the display indicates current numerical value of the measurement

mode for analog output 1. The display also identifies the

following activated sensor functions: blanking and locked-out

user interface/electronic configuration, as shown in Figure 1-4.

(For directions for inverting the display, see Section 1.5 or 5.8.)

During blanking mode, the display reads “n”, followed by the

number of blocked beams in the array. During alignment mode, it

reads “A”, followed by the number of blocked, unblanked beams;

a period follows the A (“A.”) if blanking is configured.

During gain adjust mode, the display reads “

l” followed by “1” or

“2” to indicate the gain level. (A “1” represents high excess gain,

and a “2” represents low contrast.)

If a sensing error occurs, the display reads “c” followed by a

number that corresponds to the recommended corrective action

(see Section 4.5).

Blanking Indicator

The Blanking indicator will be visible (ON) when the blanking

feature is enabled. It appears as a period following the first digit

of the display.

Electronic Configuration Indicator

The Electronic Configuration indicator is ON when the sensor

configuration is defined by the PC interface, and not the DIP

switch and push buttons. When electronic configuration is

enabled, the DIP switch and push button settings are ignored.

The receiver has a bright Status LED that indicates overall

sensing status (OK, marginal alignment, and hardware error).

Two other LEDs indicate whether serial communication is active

or if there is a communication error. Seven Zone indicators

each communicate the blocked/aligned status of one-seventh

of the total array. A 3-digit diagnostic display provides further

diagnostic information: number of beams blocked, whether

blanking is configured, and troubleshooting codes. See Section

4.5 for display codes and troubleshooting.

Zone Indicators (Beams Blocked Segment)

Seven LEDs represent emitter/receiver alignment status. They

provide a visual aid for sensor alignment and monitoring objects

within the sensor’s field of view. The sensor array is partitioned

Banner Engineering Corp. •Minneapolis, U.S.A.

www.bannerengineering.com•Tel:763.544.3164

‘A’ in this

position indicates

Alignment mode

Figure 1-4. Indications provided by the receiver’s 3-digit display

Period ON

indicates

Blanking

Configured

Period ON indicates

Electronic Configuration

Enabled

P/N 130426 Rev. C 3

Page 6

Overview

TT T

1x

2x

3x

4x

T

T

T

T

T

T

T

T

T

T

T

T

T T

T

TT T

1x

TT T

1x

TT T

1x

TT T

1x

TT T

1x

2x

T

T

T

TT T

1x

2x

T

T

T

TT T

1x

2x

T

T

T

TT T

1x

2x

3x

T

T

T

T

T

T

T T

A-GAGE EZ-ARRAY

Instruction Manual

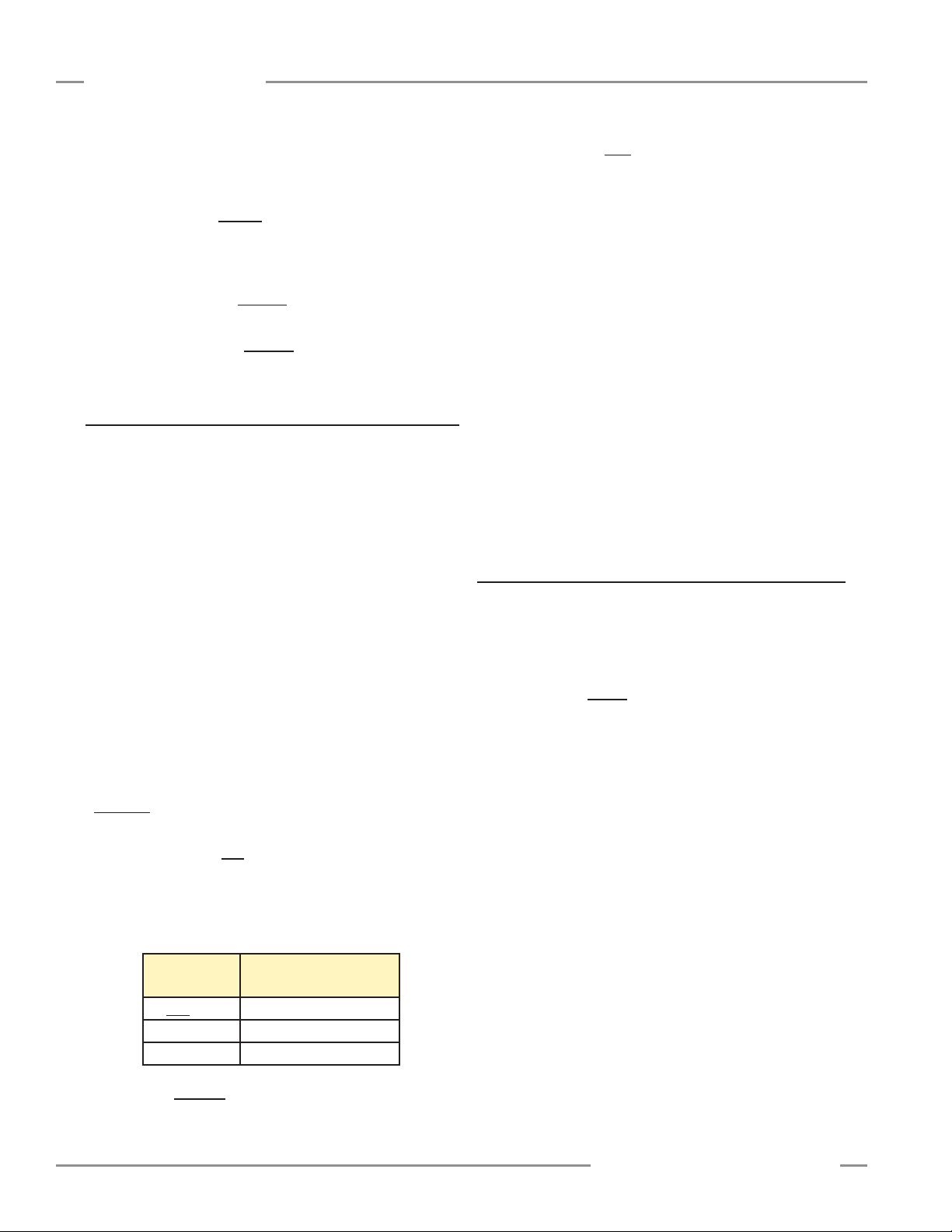

Receiver Interface Status Indicators

The receiver has three status indicators: green/red System

Status, yellow Modbus Activity, and red Modbus Error. The

following table lists the indicator states.

Receiver Interface Status Indicators

LED Indicator Color Explanation

System Status Green System is OK

Red Marginal Alignment or Hardware

Error; check 3-digit display*

Modbus

Activity

Modbus Error Red Communication Error: Check

* Display shows “c”: See Section 4.5.

Display shows only numbers: Low Gain/Marginal Alignment condition.

See Section 4.5.

Access Alignment Mode “A” appears on 3-digit display

Yellow ON

or Flashing

Process

Activity detected on the Modbus

communication channel

cabling or Modbus master

controller

Remote Wire Procedure

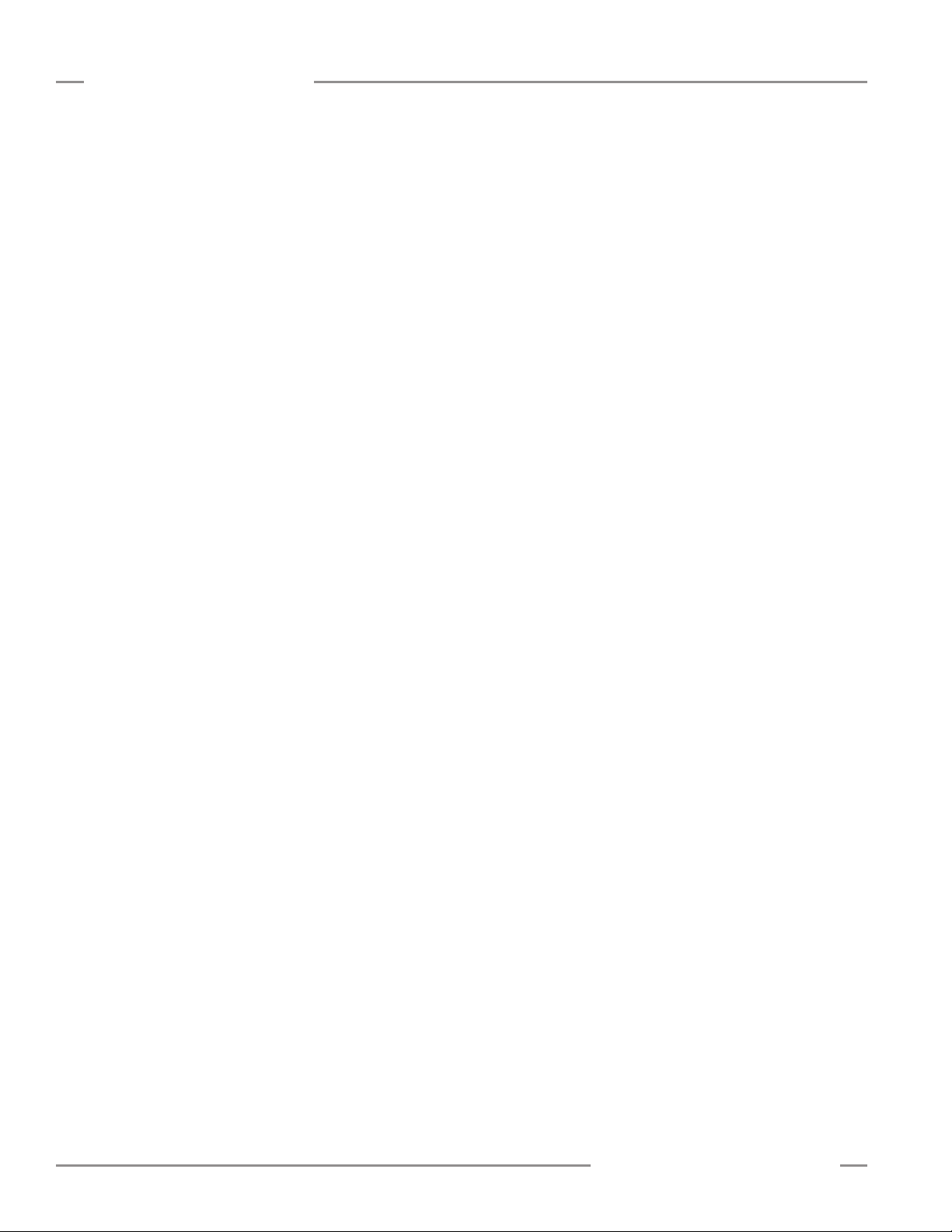

0.05 sec. ≤ T ≤ 0.8 sec.

1.5 Receiver Gray (Remote Teach) Wire

The receiver gray (remote teach) wire is used to electronically

emulate the receiver push button functions (see Section 4.5) via

a process controller, to disable the DIP switches for security, or

to provide a gate input to initiate sensor scanning. Connect a

normally open switch between the receiver’s gray wire and dc

common, or connect the gray wire to a digital input (PLC) and

pulse the wire as indicated in Figure 1-5.

NOTE: A low level is 0 to 2 volts and a high level is 10 to 30

volts or circuit open. Input impedance is 22kΩ.

Remote TEACH/Gate in the System Config view of the PC

interface Setup screen (Section 5.8) determines the functionality

of the receiver gray wire, as follows.

• Disabled: (selected via the PC interface only) the remote

wire has no function (regardless of whether it is low or high).

Result

Figure 1-5. Remote wire Teach procedures

4 P/N 130426 Rev. C

Access Blanking Mode

Exit Blanking Mode

Alignment/Blanking

Exit Alignment Mode Sensor returns to run mode

Access Gain Mode

Toggle Between Gain Settings Number changes from number “1” to “2”, back to “1”, etc.

Gain Method

Save Gain Level and Exit

Invert Display

Invert

Display

Receiver Interface

Enable/Disable

Enable/Disable

Receiver Interface

From Alignment Mode:

From Run Mode:

When correct level is displayed:

“n” appears on 3-digit display, along with number of

blocked beams

“A.” appears on 3-digit display (sensor returns to

alignment mode with blanking enabled)

“L” appears on 3-digit display, along with number “1” or

“2”, to designate gain level

Gain level is configured:

“1” = High-excess-gain setting

“2” = Low-contrast setting

Sensor returns to run mode

Display inverts from previous state; sensor continues in

run mode

The factory default is Receiver Interface enabled.

Four-pulsing the remote line saves the current settings

and disables the interface (the sensor continues to

operate using the saved settings; changes made to the

DIP switch will have no effect).

Repeating the process enables the Receiver Interface so

that settings can be changed.

Banner Engineering Corp. •Minneapolis, U.S.A.

www.bannerengineering.com•Tel:763.544.3164

Page 7

A-GAGE EZ-ARRAY

Instruction Manual

Overview

When the gray wire is disabled, the receiver is in continuous

scan mode; it begins a new scan immediately after updating

the outputs from the previous scan. (Continuous scan is used

in most analog output applications and whenever continuous

updating of the outputs is acceptable.) The gray wire is always

enabled when in DIP switch mode.

• Remote Teach — The gray wire provides the full Remote

Teach functionality shown in Figure 1.5.

• Alignment/Sensitivity — This mode is an abbreviated version

of Remote Teach. It can perform the alignment and sensitivity

adjustment functions, but not the display inversion or DIP

switch enable/disable functions.

Gate Mode options can be selected via the PC interface only.

The gray wire provides a gate input pulse, typically from a dc

device such as an NPN-output photoelectric sensor or a PLC

discrete output. Refer to Section 5 for more information.

• Gate – Active High — The receiver scans whenever the gate

is pulled high.

• Gate – Active Low — The receiver scans whenever the gate

is pulled low.

• Gate – Rising Edge — The receiver scans once for each lowto-high gate transition. (Multiple transitions cannot be faster

than the sensor’s response for them to be reliably detected.)

• Gate – Falling Edge — The receiver scans once for each

high-to-low gate transition. (Multiple transitions cannot be faster

than the sensor’s response for them to be reliably detected.)

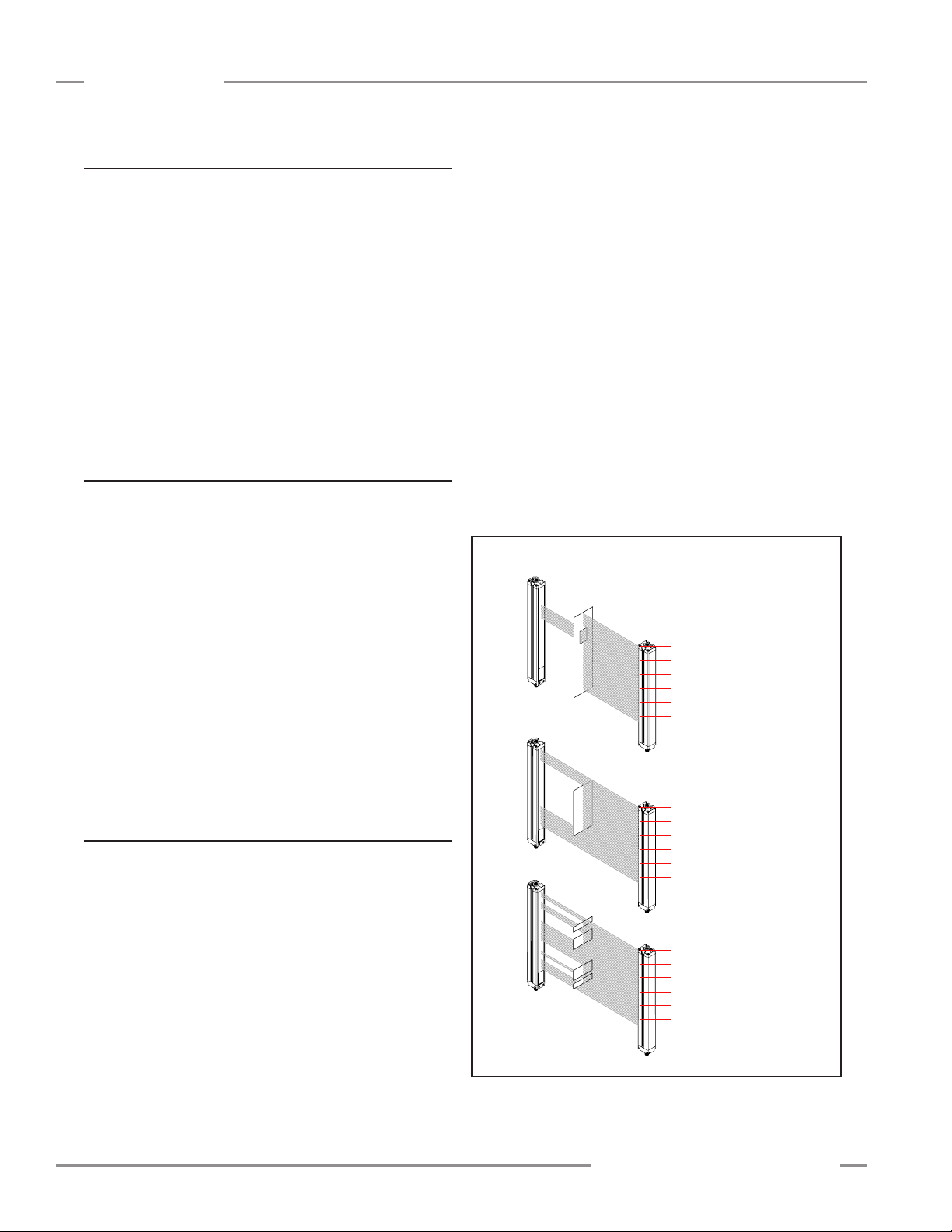

1.6 Scanning Method

One of three scanning methods may be configured:

• Straightscan

• Single-edgescan

• Double-edgescan(1,2,4,8,16,or32steps)

Straight Scan is the default mode, in which all beams are

scanned in sequence, from the display end to the far end

of the array. This scanning method provides the smallest

object detection size. Straight scan is used when low-contrast

sensitivity is selected or when single-edge and double-edge

scan cannot be used. The edge resolution is 5 mm (0.2"). When

low-contrast sensing is selected (used when measuring semitransparent objects), the minimum object detection size is 5 mm

(0.2") diameter. When high-excess-gain sensing is selected, the

minimum object detection size is 10 mm (0.4"). See Figure 1-5.

Single-Edge Scan is used to measure the height of a single

object. This scanning method is commonly used for box height

measurement. For single-edge scan, the receiver always

activates the first beam channel (or “bottom” beam, nearest the

display). When the first beam is blocked, the sensor performs a

binary search to hunt for the last beam blocked, as follows:

1. The receiver scans only the first beam until it is blocked (see

Figure 1-7).

2. When the first beam is blocked, the sensor looks to see

whether the middle beam is blocked or made (unblocked).

3. If the middle beam is made (unblocked), the sensor checks

the bottom quarter beam; if the middle beam is blocked, the

sensor checks the top quarter beam.

4. The routine continues to divide the number of beams in half

until the edge is found.

Single-edge scan can be used only for single, solid objects

that block the first beam (closest to the display). Because the

receiver checks only the first beam until it is blocked, single-edge

scan will not function when the item to be measured does not

block the first beam. Single-edge scan is also ineffective if the

object does not present a continuous blocked pattern.

Single-edge scan works only when the high-excess-gain setting

is enabled. When single-edge scan is selected, the sensor object

detection size is 10 mm and edge resolution is 2.5 mm.

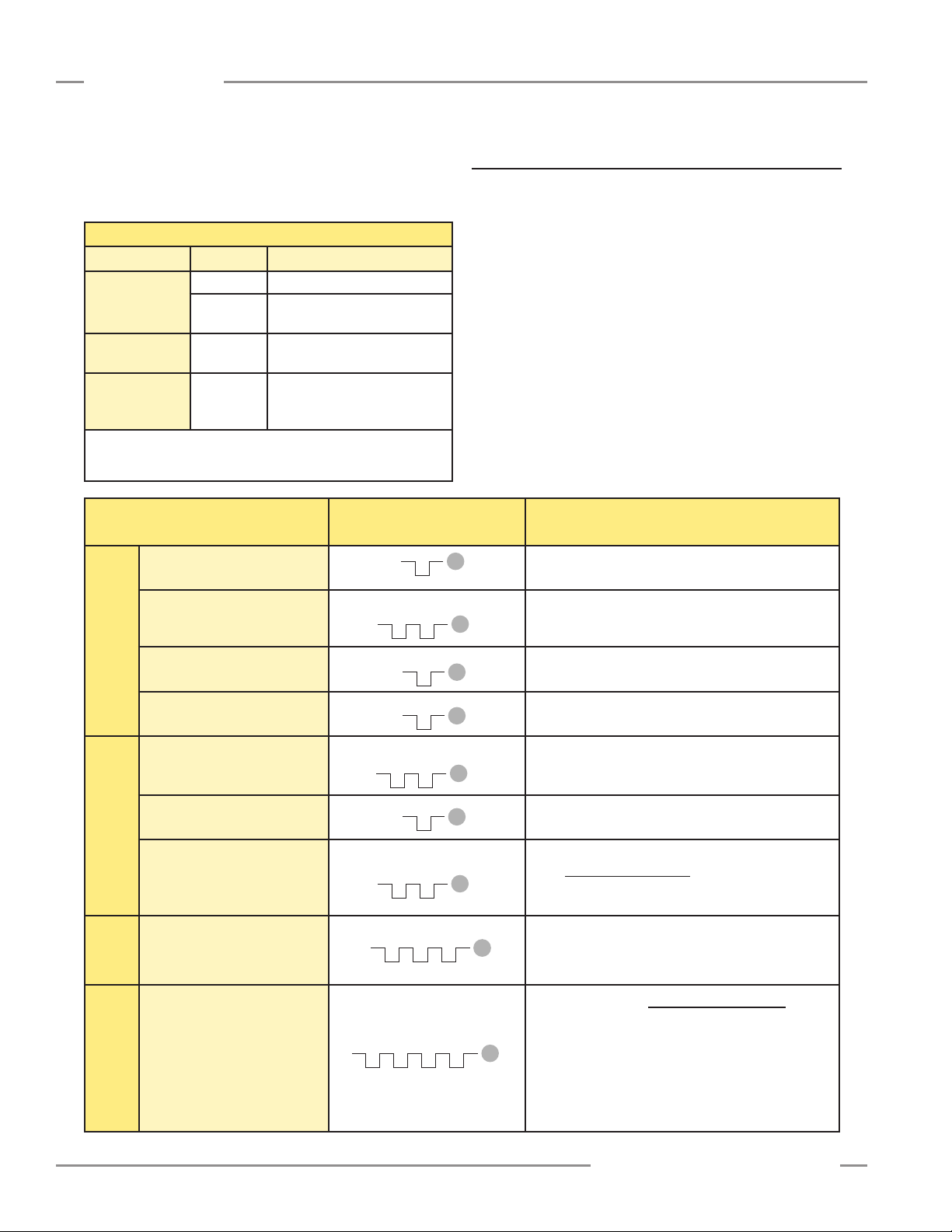

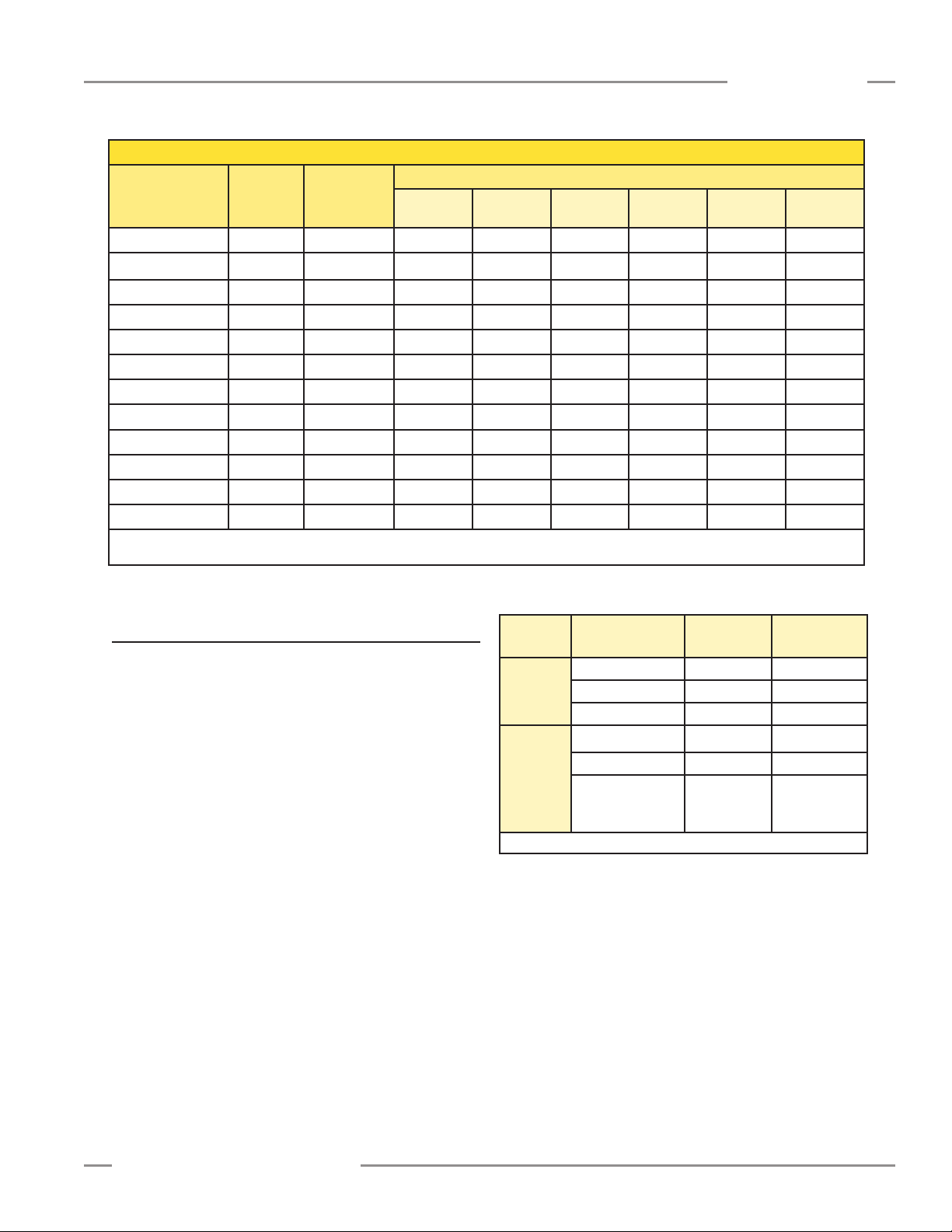

Sensor response time is a function of sensor length and

scanning method. Maximum scan times are shown in Figure 1-6.

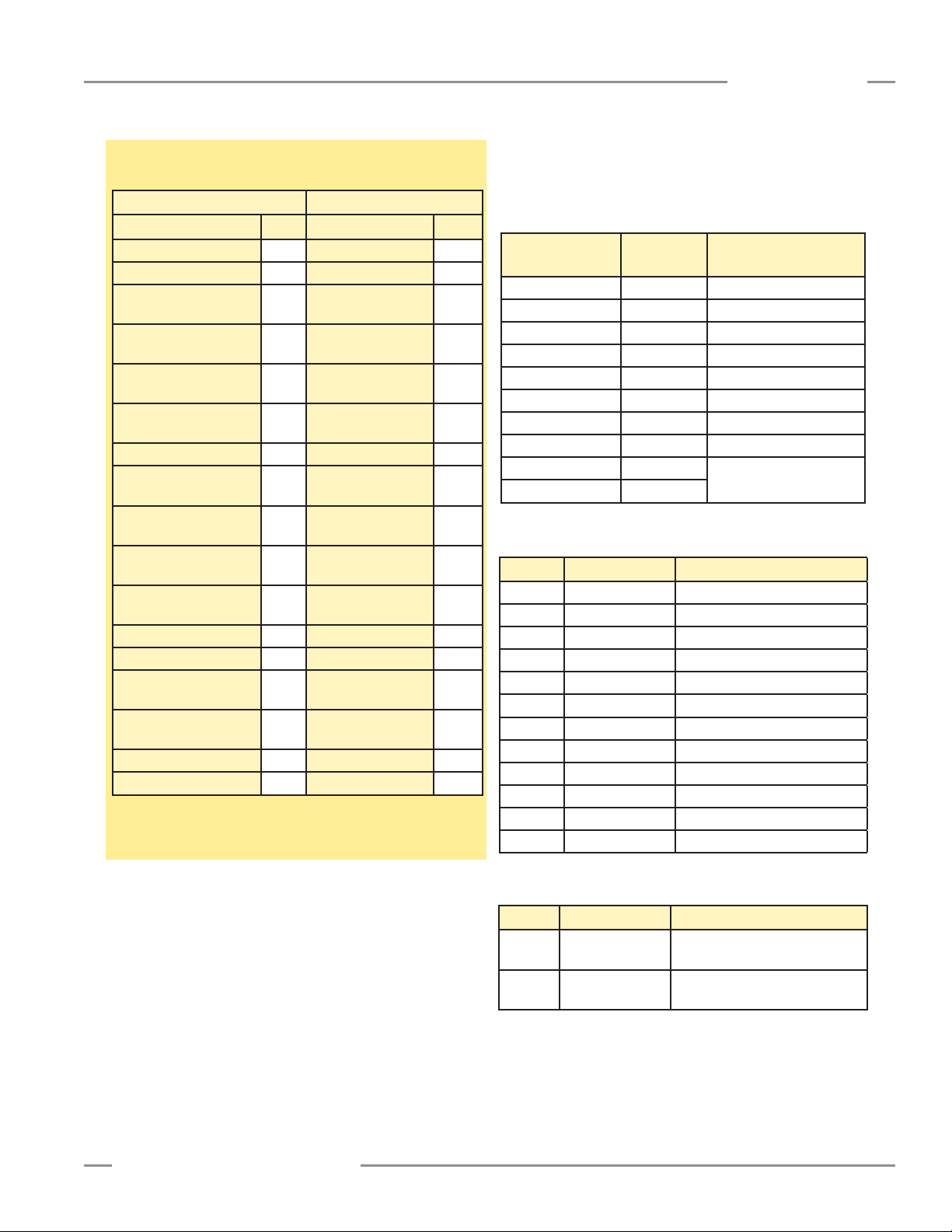

Straight Scan

Scanning Method

Minimum Object

Detection Size*

Edge Resolution

*MODS determined using a rod target object

Figure 1-6. The effect of scan mode and step size on minimum object detection size and edge resolution

Banner Engineering Corp. •Minneapolis, U.S.A.

www.bannerengineering.com•Tel:763.544.3164

Low-

Contrast

5 mm

(0.2")

5 mm

(0.2")

High-Excess-

Gain

10 mm

(0.4")

5 mm

(0.2")

Single-Edge

Scan

10 mm

(0.4")

2.5 mm

(0.1")

1 2 4 8 16 32

10 mm

(0.4")

2.5 mm

(0.1")

Double-Edge Scan (per Edge)

Step Size (Number of Beams)

20 mm

(0.8")

2.5 mm

(0.1")

30 mm

(1.2")

2.5 mm

(0.1")

50 mm

(2")

2.5 mm

(0.1")

90 mm

(3.6")

2.5 mm

(0.1")

P/N 130426 Rev. C 5

170 mm

(6.8")

2.5 mm

(0.1")

Page 8

Overview

A-GAGE EZ-ARRAY

Instruction Manual

Double-Edge Scan is used to detect two edges of a single

object, for example, to determine box width measurements.

Double-edge scan requires the selection of a step size: 1, 2,

4, 8, 16 or 32 beams. The sensor uses the steps to “skip” over

beams, as follows:

1. The sensor activates beam 1 (closest to the sensor display end).

2. The sensor activates the next beam, determined by the step

size. (For example, if the step size is 2, beam 3 is next; if the

step size is 8, beam 9 is next.)

3. As long as the activated beam is made (unblocked), the sensor

continues the stepping routine until a blocked beam is found.

4. When a blocked beam is found, a binary search is conducted

to find the object’s “bottom” edge.

Step #1 Step #2 Step #3

Beam #1 of 30

blocked

Beam #15

blocked

5. When the bottom edge is found, the sensor continues to step

through the array until it finds the next unblocked beam.

6. Another binary search is performed to find the second edge.

Similar to single-edge scan, double-edge scan has some

restrictions: the object should provide a solid obstruction; the size

of the object determines the maximum step size (Figure

1-6). Double-edge scan can be used to detect up to three

objects. Like single-edge scan, double-edge scan works only

when the high-excess-gain setting is selected. When doubleedge scan is selected, the sensor object detection size varies,

depending on the step size, but edge resolution is 2.5 mm.

Beam #23 clear

Emitter

Receiver

Step #4 Step #5

blocked

Figure 1-7. Finding an edge using a binary search (single-edge scan)

Step #6

Beam #19 clearBeam #17

Beam #18

blocked

6 P/N 130426 Rev. C

Banner Engineering Corp. •Minneapolis, U.S.A.

www.bannerengineering.com•Tel:763.544.3164

Page 9

A-GAGE EZ-ARRAY

Instruction Manual

Overview

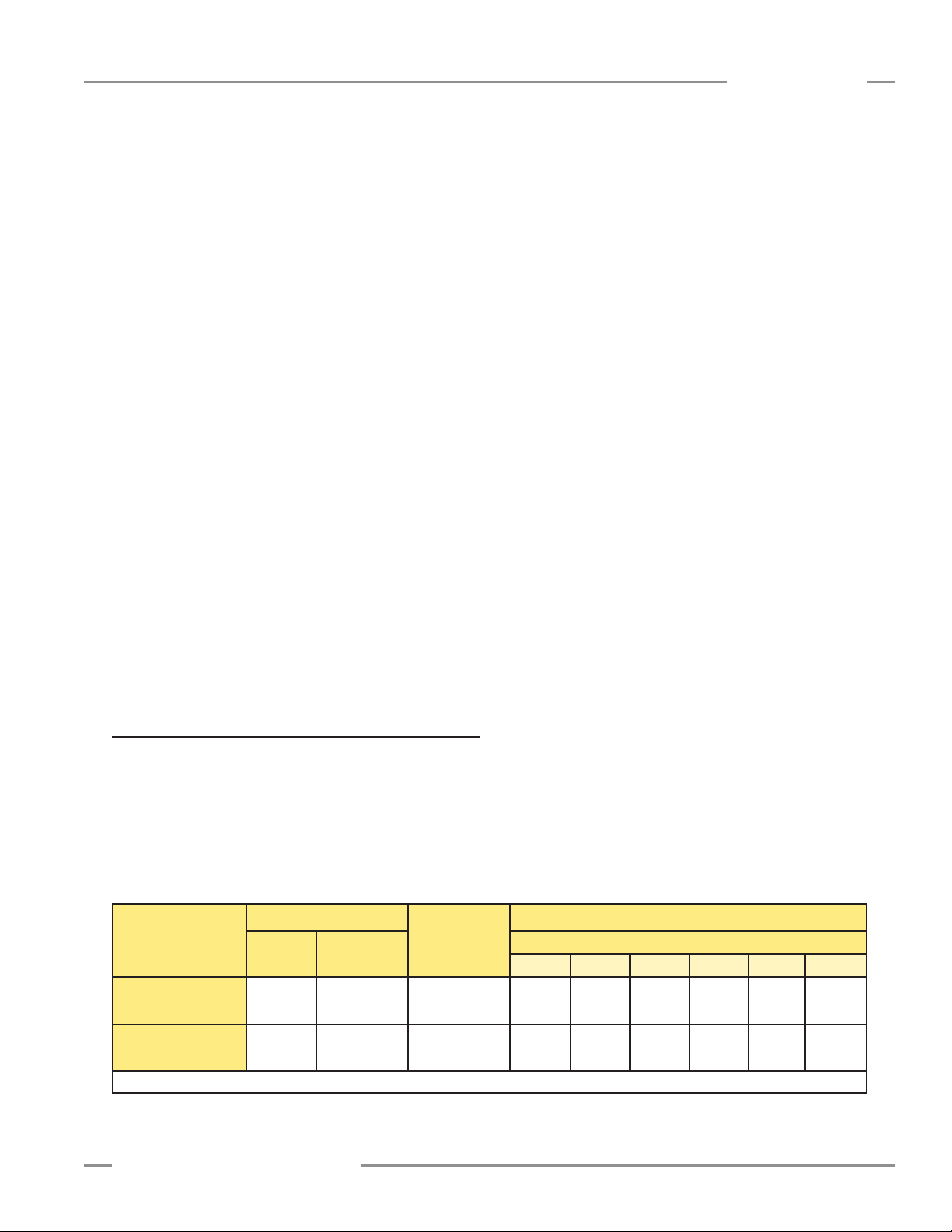

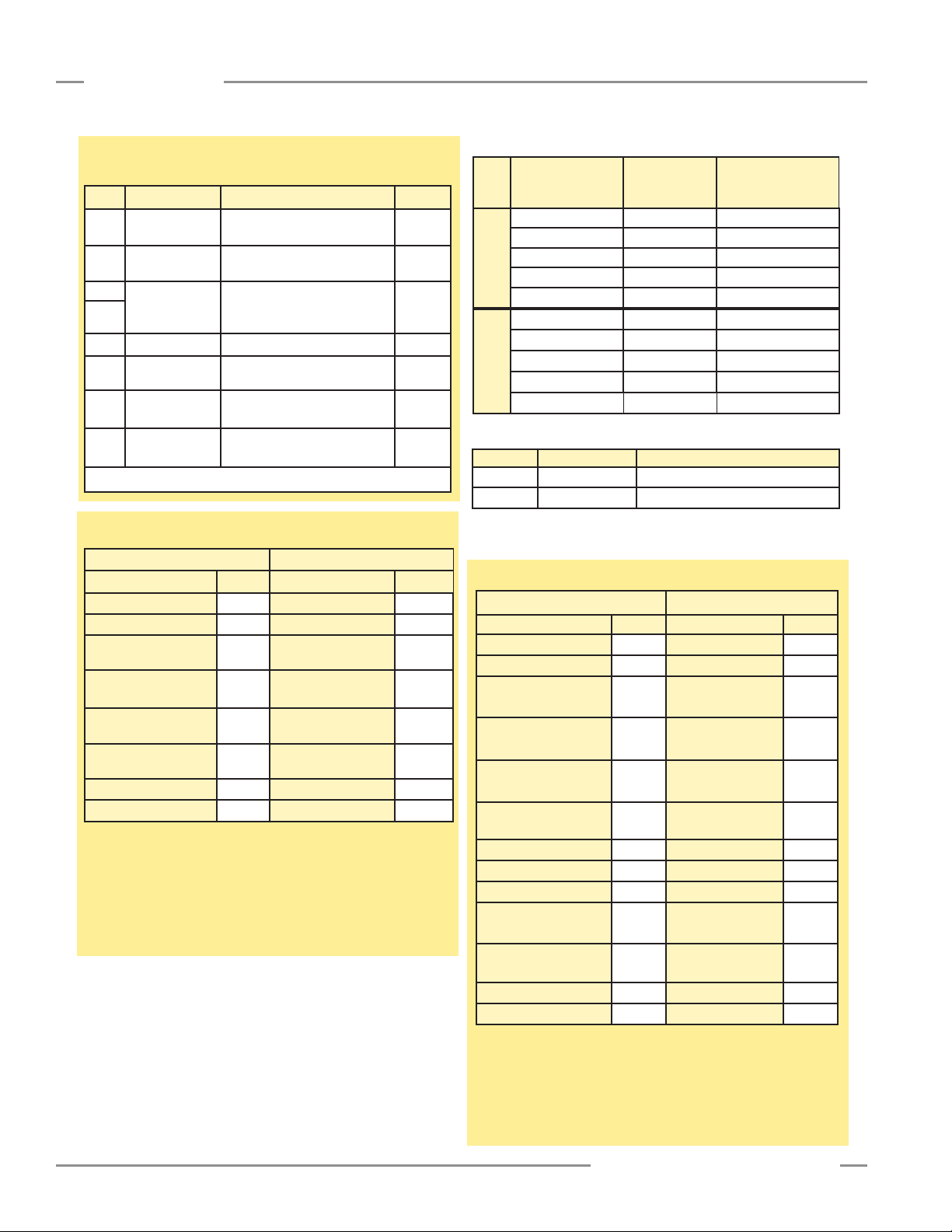

Maximum Scan Times (in milliseconds)

Array Length

150 mm (5.9") 2.8 1.5 3.4 2.8 2.5 2.4 1.9 N/A

300 mm (11.8") 5.0 1.5 5.9 4.1 3.2 2.8 2.3 2.1

450 mm (17.7") 7.1 1.6 8.5 5.5 4.2 4.0 3.2 2.5

600 mm (23.6") 9.3 1.6 11.0 6.8 4.9 4.2 4.0 2.8

750 mm (29.5") 11.4 1.7 13.5 8.1 5.7 4.6 4.5 4.5

900 mm (35.4") 13.6 1.7 16.0 9.5 6.1 4.7 4.6 4.6

1050 mm (41.3") 15.7 1.8 18.6 10.8 6.8 5.2 4.8 4.8

1200 mm (47.2") 17.9 1.8 21.1 12.2 7.4 5.5 4.9 4.9

1500 mm (59.1") 22.2 1.9 26.1 14.8 9.0 6.4 5.3 4.9

1800 mm (70.9") 26.5 2.0 31.2 17.5 10.5 7.3 6.0 5.6

2100 mm (82.7") 30.8 2.8 36.3 20.2 12.0 8.2 6.7 5.6

2400 mm (94.5") 35.1 2.8 41.4 22.9 13.5 9.1 7.4 5.9

NOTES: Scan times are exclusive of serial communication transmission times.

Scan times are also dependent on analog filter speed; see Section 5.8.

Figure 1-8. Maximum scan times for straight, single-edge and double-edge scanning

Straight

Scan

Single-Edge

Scan

Step

1 Beam

Step

2 Beams

Double-Edge Scan

Step

4 Beams

Step

8 Beams

Step

16 Beams

32 Beams

Step

1.7 Gain Configuration

The EZ-ARRAY provides two gain options for straight scan

applications: high excess gain and low contrast. The gain

method can be selected using the receiver push button, the

receiver remote teach wire, or the PC interface.

High (maximized) excess gain is suited for detecting opaque

objects and for reliable sensing in dirtier environments where

objects to be detected are 10 mm or larger. The high excess

gain method is always used in single- and double-edge scan.

The high excess gain option has a minimum blocked threshold

level, which provides reliable sensing at higher excess gain

levels.

The low-contrast setting is used for sensing semi-transparent

materials and for detecting objects as small as 5 mm (straight

scan only). In low-contrast operation, only a portion of a beam

must be blocked for detection to occur. In low-contrast operation,

the sensor sets an individual threshold for each optical channel

during the alignment process; this process equalizes the signal

strength to allow semi-transparent object detection.

When using the PC interface, low-contrast sensing provides

a fine-tune sensitivity setting of 15% to 50%. When using the

receiver interface, low-contrast sensitivity is always 30%.

Gain

Setting

Low

Contrast

High

Excess

Gain

* MODS: Minimum Object Detection Size

Figure 1-9. Effects of Gain selection on minimum object detection

Scan Method

Straight scan 5 mm 5 mm

Single-edge scan — —

Double-edge scan — —

Straight scan 10 mm 5 mm

Single-edge scan 10 mm 2.5 mm

Double-edge scan

size and sensing resolution

EZ-ARRAY

MODS*

Depends on

step size

EZ-ARRAY

Resolution

2.5 mm / edge

5 mm total

(both edges)

Banner Engineering Corp. •Minneapolis, U.S.A.

www.bannerengineering.com•Tel:763.544.3164

P/N 130426 Rev. C 7

Page 10

Overview

Last Beam Made (LBM)

First Beam Made (FBM)

Receiver

Emitter

Last Beam Blocked (LBB)

First Beam Blocked (FBB)

Receiver

Emitter

Total Beams Made (TBM)

Total Beams Blocked (TBB)

Receiver

Emitter

10

20

30

40

50

60

In Last Beam Blocked mode,

last beam is #55 of 60

In First Beam Blocked mode,

first beam is #20 of 60

In Last Beam Made mode,

last beam is #50 of 60

In First Beam Made mode,

first beam is #40 of 60

In Total Beams Made mode,

38 of 60 possible beams are

made

In Total Beams Blocked mode,

22 of 60 possible beams are

blocked

10

20

30

40

50

60

10

20

30

40

50

60

A-GAGE EZ-ARRAY

Instruction Manual

1.8 Electronic Alignment Routine

The objective of the optical alignment process is to adjust the

emitter light level to maximize sensor performance. Perform

the alignment procedure at installation and again whenever the

emitter and/or receiver is moved.

During the alignment procedure, the receiver polls each beam

channel to measure excess gain and performs a gain adjustment

for each beam. When the system exits the alignment procedure,

each channel’s signal strength is stored in non-volatile memory.

The procedure can be performed using the receiver remote wire,

the receiver interface or the PC interface (see Section 1.5, 4.2,

or 5.6). The receiver’s Alignment push button may be disabled,

using the PC interface.

1.9 Blanking

If a machine fixture or other equipment blocks one or more

sensing beams, the affected beam channels may be blanked.

The blanking option causes the receiver to ignore the status

of blanked beams for measurement mode calculations. For

example, if a machine fixture blocks one or more beams during

sensing, the output data will be incorrect; if the beams blocked

by the fixture are blanked, the output data will be correct.

Blanking may be configured using the receiver’s Alignment push

button, the receiver remote wire, or the PC interface.

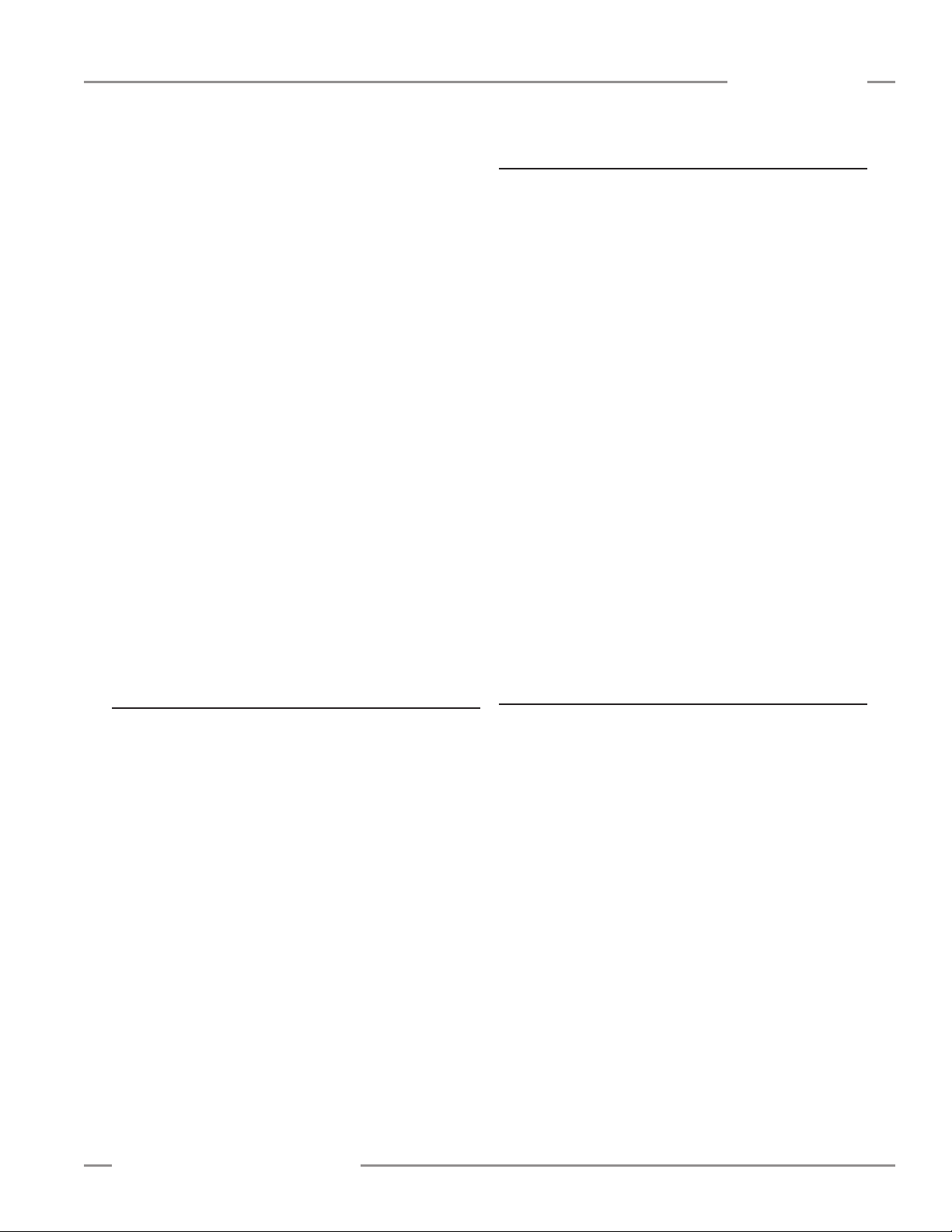

“Beam Location” Modes

• First Beam Blocked (FBB): The location of the first blocked

beam.

• First Beam Made (FBM): The location of the first made

(unblocked) beam.

• Last Beam Blocked (LBB): The location of the last blocked

beam.

• Last Beam Made (LBM): The location of the last made beam.

• Middle Beam Blocked (MBB): The location of the beam midway

between the first and last blocked beams.

“Beam Total” Modes

• Total Beams Blocked (TBB): The total number of blocked

beams.

• Total Beams Made (TBM): The number of beams made.

Contiguous Beams Blocked (CBB): The largest number of

•

consecutively blocked beams.

Contiguous Beams Made (CBM): The largest number of

•

consecutively made beams.

For total beam values (TBB and TBM analysis modes), selection

of blanked beams affects the proportional analog outputs.

Blanked beams are ignored both in the number of blocked or

made beams and in the total number of beams. For example, if a

30-beam array has 10 blanked beams and 10 of the remaining 20

beams are blocked, the analog output values will be at mid-range.

1.10 Measurement Mode Selection

The outputs may be configured for any of fourteen measurement

(scan analysis) modes, which refer to specific beam locations,

quantities of beams, or edge transitions. Note that not all

measurement mode options are available when the receiver

interface is used for configuration. Selected modes are individually

assigned to each output (see Section 4.1 or 5.9 and 5.10).

When using the PC interface for configuration, the discrete

outputs can have NPN or PNP polarity (regardless of model), be

normally open or normally closed, and be assigned to any of the

measurement modes. When using the receiver interface, limited

output configuration combinations may be selected (Section 4.1).

NOTE: Array beams are numbered in sequence (beam 1 located

8 P/N 130426 Rev. C

nearest the sensor display; see Figure 1-3). The “first

beam” referenced in the following descriptions is the beam

nearest the sensor display.

Figure 1-10. Measurement mode examples

Banner Engineering Corp. •Minneapolis, U.S.A.

www.bannerengineering.com•Tel:763.544.3164

Page 11

A-GAGE EZ-ARRAY

Instruction Manual

Overview

• Transitions (TRN): The number of changes from blocked to

clear status and from clear to blocked status. (If beams 6-34

are blocked, then there is a clear-to-blocked transition from

beam 5 to beam 6, and a blocked-to-clear transition from

beam 34 to beam 35.) Transition mode can be used to count

objects within the array.

• Outside Dimension (OD): The inclusive distance (measured

in beams) from the first blocked beam to the last blocked

beam.

• Inside Dimension (ID): The number of made beams, between

the first and last blocked beams.

• Contiguous First Beam Blocked (CFBB): The location of

the first blocked beam in the largest group of adjacent blocked

beams.

• Contiguous Last Beam Blocked (CLBB): The location of

the last blocked beam in the largest group of adjacent blocked

beams.

• Carpet Nap and Carpet Edge: These measurement modes

are used to measure the location of carpet backing and tuft,

and are selectable only via the PC interface, and only when

the Scan Type “Carpet Nap” is selected. The modes can be

measured from either end of the sensor, but at least 10 beams

(2") must be blocked from one edge.

• Special: This mode is reserved for specialized applications;

contact the factory for information.

1.12 Discrete Output Configuration

Discrete Output 1; Receiver Interface

When the receiver interface is used for configuration, the

measurement mode assigned to discrete output 1 is the same

as that assigned to analog output 1. When the analog output

detects a target present, discrete output 1 conducts (normally

open).

Discrete Output 2; Receiver Interface

Discrete output 2 (only) has two options: alarm and

complementary (measurement) operation.

Alarm: Output 2 energizes when the receiver detects a sensor

error (such as a disconnected cable) or whenever the excess

gain of one or more beams becomes marginal.

Complementary (Measurement): Discrete output 2 operation

is complementary to discrete output 1 (when output 1 is ON,

output 2 is OFF, and vice versa).

Discrete Output 1 and 2 Configuration; PC Interface

When the PC interface is used for configuration, the discrete

outputs have more options: either discrete output can be

assigned to any of the measurement modes, high and low set

points can be added, the outputs can be inverted, and hysteresis

values can be set, as well as a scan number to smooth output

performance. Discrete output 2 can be assigned to alarm mode

via the PC interface also. See Section 5.9 for more information.

1.11 Analog Output Configuration

Analog output configuration assigns analog outputs 1 and 2 to

one of the measurement modes described in Section 1.10. When

the selected measurement mode involves first or last beam

blocked or made (unblocked), the assigned output will vary in

proportion to the beam number identified during a scan. When the

measurement mode involves total beams blocked or made, that

assigned output will vary in proportion to the total beams counted

during a scan.

Analog outputs may have Null and Span values set in the PC

interface, in addition to a filter setting (to smooth the output) and

Zero Value (to specify the output value when the measurement

mode value is zero). See Section 5.8 for more information.

1.13 Serial Communication

When the PC interface is used, the receiver communicates

with a process controller via a Modbus RTU-485 interface. The

PC interface software has a Communications Settings menu

that includes the selected sensor communications port, options

(either leave this field set at DPB1, or change it to No Echo

Suppression), and a read-only window that provides current

communications status. Advanced settings are also accessible,

including baud rate, timeout (in milliseconds), message delay (in

milliseconds), sensor address, parity, retry and byte delay. See

Section 5.10 and the Appendix for more information.

Banner Engineering Corp. •Minneapolis, U.S.A.

www.bannerengineering.com•Tel:763.544.3164

P/N 130426 Rev. C 9

Page 12

Components and Specifications

2. Components and Specifications

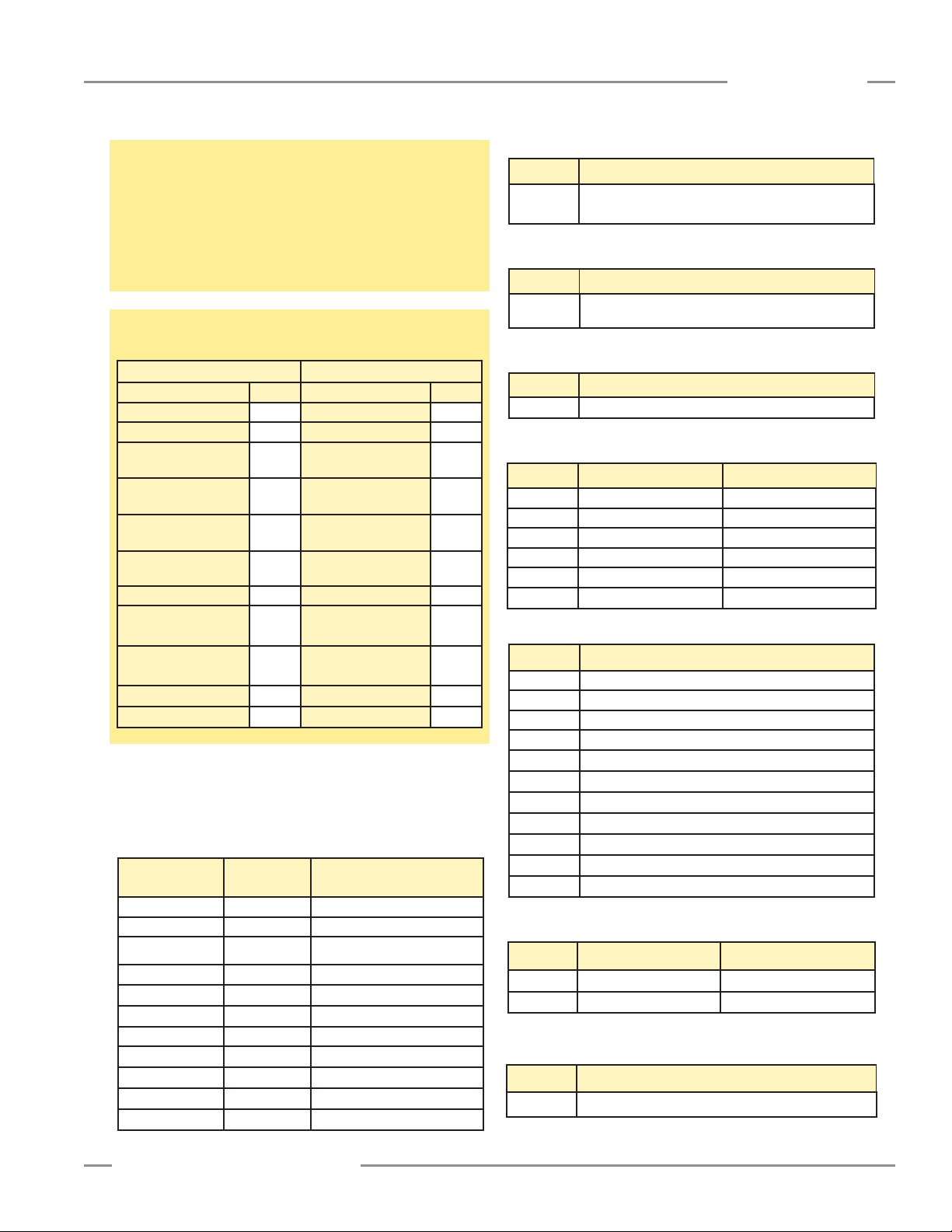

2.1 Sensor Models

A-GAGE EZ-ARRAY

Instruction Manual

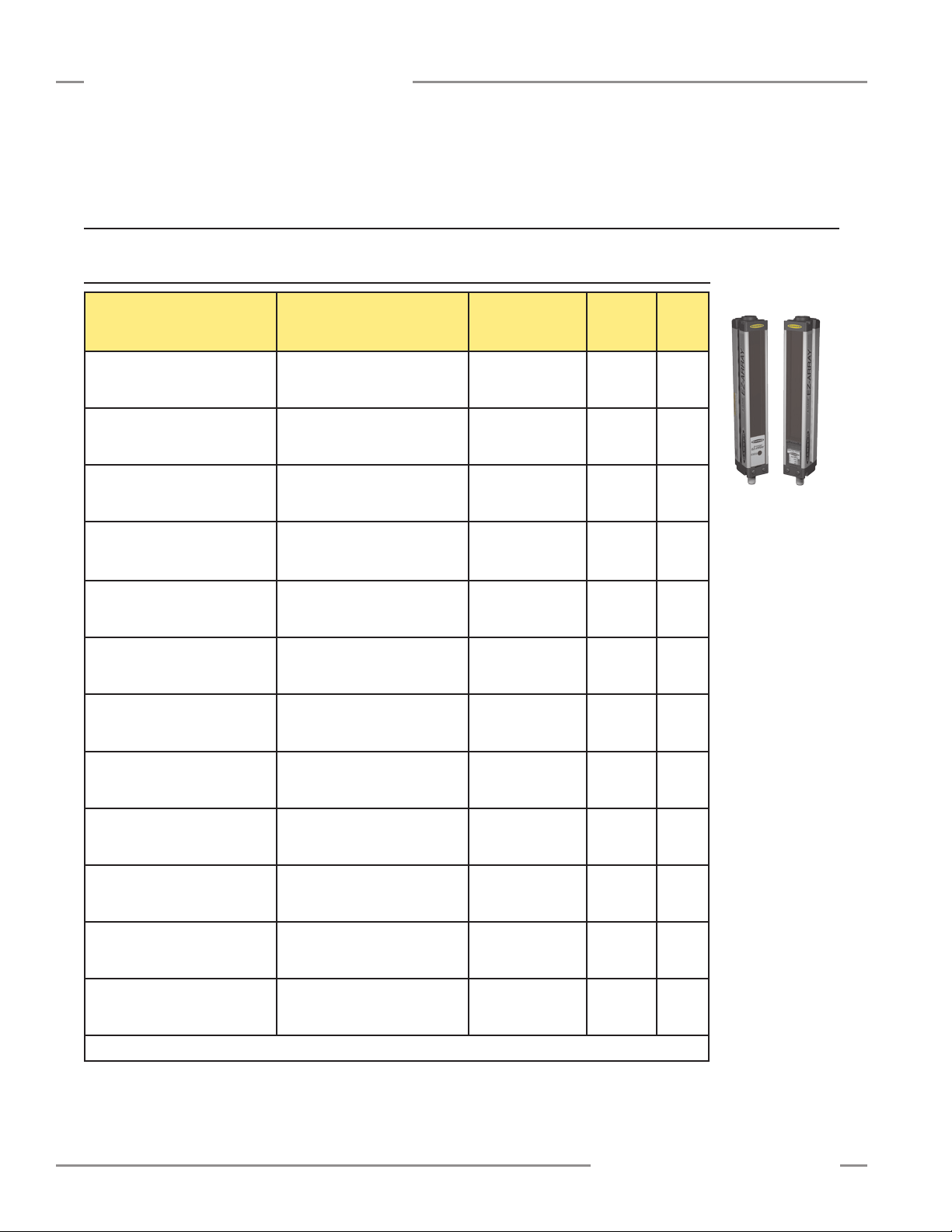

Emitter/Receiver Model

NPN Outputs

EA5E150Q Emitter

EA5R150NIXMODQ Receiver

EA5R150NUXMODQ Receiver

EA5E300Q Emitter

EA5R300NIXMODQ Receiver

EA5R300NUXMODQ Receiver

EA5E450Q Emitter

EA5R450NIXMODQ Receiver

EA5R450NUXMODQ Receiver

EA5E600Q Emitter

EA5R600NIXMODQ Receiver

EA5R600NUXMODQ Receiver

EA5E750Q Emitter

EA5R750NIXMODQ Receiver

EA5R750NUXMODQ Receiver

EA5E900Q Emitter

EA5R900NIXMODQ Receiver

EA5R900NUXMODQ Receiver

EA5E1050Q Emitter

EA5R1050NIXMODQ Receiver

EA5R1050NUXMODQ Receiver

EA5E1200Q Emitter

EA5R1200NIXMODQ Receiver

EA5R1200NUXMODQ Receiver

EA5E1500Q Emitter

EA5R1500NIXMODQ Receiver

EA5R1500NUXMODQ Receiver

EA5E1800Q Emitter

EA5R1800NIXMODQ Receiver

EA5R1800NUXMODQ Receiver

EA5E2100Q Emitter

EA5R2100NIXMODQ Receiver

EA5R2100NUXMODQ Receiver

EA5E2400Q Emitter

EA5R2400NIXMODQ Receiver

EA5R2400NUXMODQ Receiver

* Models with array lengths 1050 mm and longer ship with a center bracket as well as two end-cap brackets.

Emitter/Receiver Model

PNP Outputs

EA5E150Q Emitter

EA5R150PIXMODQ Receiver

EA5R150PUXMODQ Receiver

EA5E300Q Emitter

EA5R300PIXMODQ Receiver

EA5R300PUXMODQ Receiver

EA5E450Q Emitter

EA5R450PIXMODQ Receiver

EA5R450PUXMODQ Receiver

EA5E600Q Emitter

EA5R600PIXMODQ Receiver

EA5R600PUXMODQ Receiver

EA5E750Q Emitter

EA5R750PIXMODQ Receiver

EA5R750PUXMODQ Receiver

EA5E900Q Emitter

EA5R900PIXMODQ Receiver

EA5R900PUXMODQ Receiver

EA5E1050Q Emitter

EA5R1050PIXMODQ Receiver

EA5R1050PUXMODQ Receiver

EA5E1200Q Emitter

EA5R1200PIXMODQ Receiver

EA5R1200PUXMODQ Receiver

EA5E1500Q Emitter

EA5R1500PIXMODQ Receiver

EA5R1500PUXMODQ Receiver

EA5E1800Q Emitter

EA5R1800PIXMODQ Receiver

EA5R1800PUXMODQ Receiver

EA5E2100Q Emitter

EA5R2100PIXMODQ Receiver

EA5R2100PUXMODQ Receiver

EA5E2400Q Emitter

EA5R2400PIXMODQ Receiver

EA5R2400PUXMODQ Receiver

Analog Output

–

Current (4–20 mA)

Voltage (0–10V)

–

Current (4–20 mA)

Voltage (0–10V)

–

Current (4–20 mA)

Voltage (0–10V)

–

Current (4–20 mA)

Voltage (0–10V)

–

Current (4–20 mA)

Voltage (0–10V)

–

Current (4–20 mA)

Voltage (0–10V)

–

Current (4–20 mA)

Voltage (0–10V)

–

Current (4–20 mA)

Voltage (0–10V)

–

Current (4–20 mA)

Voltage (0–10V)

–

Current (4–20 mA)

Voltage (0–10V)

–

Current (4–20 mA)

Voltage (0–10V)

–

Current (4–20 mA)

Voltage (0–10V)

Array

Length

Y*

150 mm

(5.9")

300 mm

(11.8")

450 mm

(17.7")

600 mm

(23.6")

750 mm

(29.5")

900 mm

(35.4")

1050 mm

(41.3")*

1200 mm

(47.2")*

1500 mm

(59.1")*

1800 mm

(70.9")*

2100 mm

(82.7")*

2400 mm

(94.5")*

Total

Beams

30

60

90

120

150

180

210

240

300

360

420

480

Emitter

Receiver

10 P/N 130426 Rev. C

Banner Engineering Corp. •Minneapolis, U.S.A.

www.bannerengineering.com•Tel:763.544.3164

Page 13

A-GAGE EZ-ARRAY

22.5 mm

(0.88")

72.5 mm

(2.85 ")

70.0 mm

(2.75")

82.0 mm

(3.23")

77.5 mm

(3.05")

White

Brown

Blue

Gray

Black

Green

Yellow

Gray

Red

Brown

White

Blue

Pink

Ø15.0 mm

(0.59")

M12X1

48.5 mm

(1.91")

M12X1

Ø14.5 mm

(0.57")

40.0 mm

(1.57")

31.8 mm

(1.25")

31 mm

(1.22")

M12X1

Ø13.5 mm

(0.53")

Instruction Manual

2.2 Cordsets and Connections

Quick-Disconnect Sensor Cordsets

Model Description Pinout

MAQDC-815

Straight female

MAQDC-830

MAQDC-850

Communication Connections

Model Description Pinout

Communications Cables

MQDMC-506

MQDMC-515

MQDMC-530

connector,

8-pin Euro-style

Straight male

connector, 5-pin

Euro-style

5 m (15') long

9 m (30') long

15 m (50') long

2 m (6.5') long

5 m (15') long

9 m (30') long

Components and Specifications

Female Connector Shown

Male Connector Shown

MQDMC-506RA

MQDMC-515RA

Right-angle male

connector, 5-pin

2 m (6.5') long

5 m (15') long

Euro-style

MQDMC-530RA

9 m (30') long

USB Serial Adapter Dimensions

INTUSB485-1

For connection of 5-pin communications

cable to computer USB port

2.3 Alignment Aids

Model Description

LAT-1-SS

Self-contained visible-beam laser tool for aligning any EZ-ARRAY emitter/

receiver pair. Includes retroreflective target material and mounting clip.

EZA-LAT-SS Replacement adaptor (clip) hardware for EZ-ARRAY models

EZA-LAT-2 Clip-on retroreflective LAT target

BRT-THG-2-100 2" retroreflective tape, 100'

BT-1 Beam Tracker

Banner Engineering Corp. •Minneapolis, U.S.A.

www.bannerengineering.com•Tel:763.544.3164

LAT-1-SS

P/N 130426 Rev. C 11

Page 14

Components and Specifications

50.0 mm

(1.97")

58.2 mm

(2.29")

39.2 mm

(1.54")

4.2 mm

(0.17")

44.4 mm

(1.75")

20 mm

(0.79")

40 mm

(1.57")

C

L

(4) M10 Bolt

Pole

40 mm

(1.58") Square

Usable

Stand

Height

Base

6.4 mm (0.25")

120.6 mm (4.75")

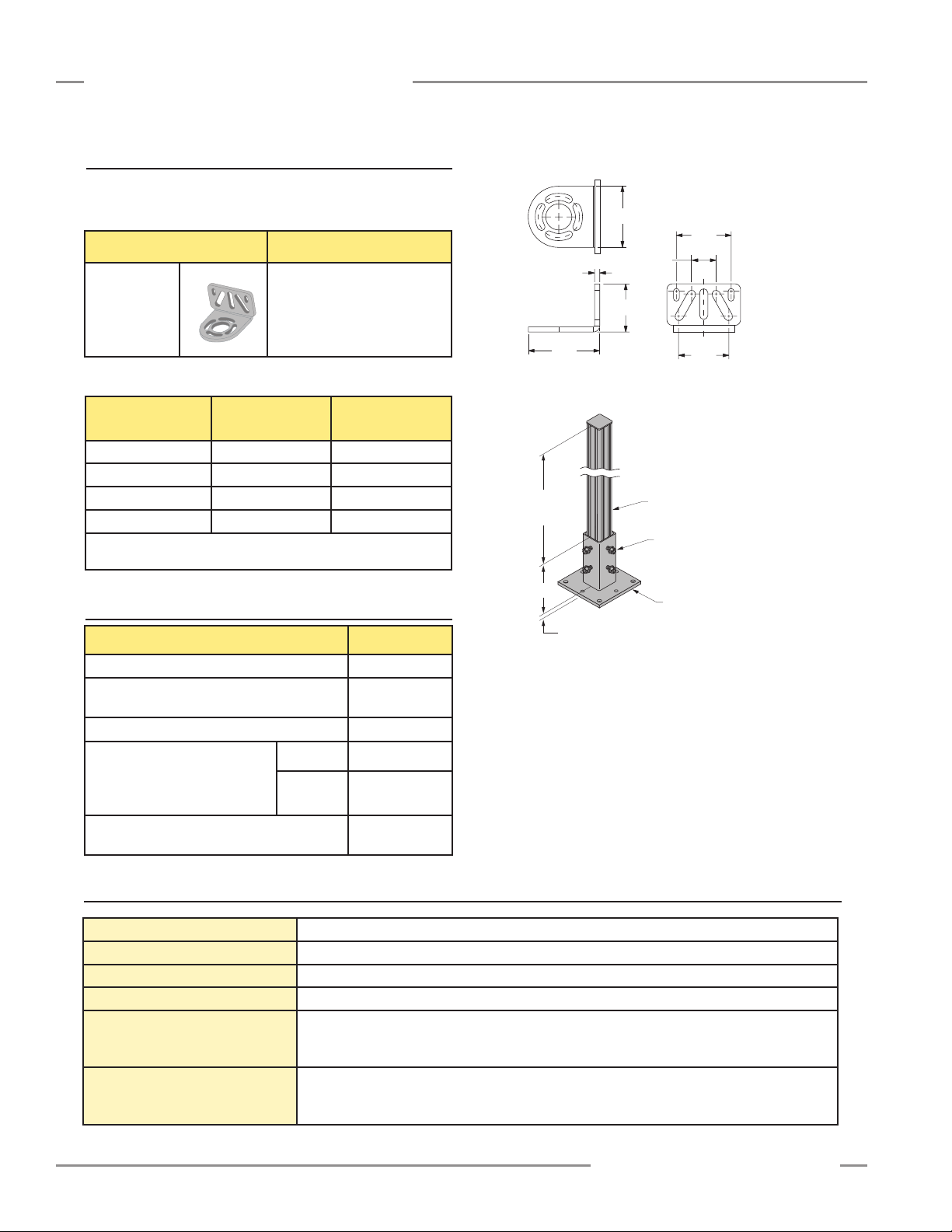

2.4 Accessory Mounting Brackets and Stands

See Section 2.5 for standard brackets. Order one EZA-MBK-20

bracket per sensor, two per pair.

Model Description

Universal adaptor bracket pair

EZA-MBK-20

for mounting to engineered /

slotted aluminum framing

™

(e.g., 80/20

, Unistrut™).

A-GAGE EZ-ARRAY

Instruction Manual

EZA-MBK-20

MSA Series Stands (Base Included)*

Stand

Model

MSA-S24-1

MSA-S42-1

MSA-S66-1

MSA-S84-1

* Available without a base by adding suffix “NB” to the model number, e.g.,

MSA-S24-1NB.

Useable Stand

Height

Overall Stand

Height

483 mm (19") 610 mm (24")

940 mm (37") 1067 mm (42")

1549 mm (61") 1676 mm (66")

2007 mm (79") 2134 mm (84")

2.5 Replacement Parts

Description Model

Access cover with label – receiver EA5-ADR-1

Access cover security plate (includes 2 screws,

wrench)

Wrench, security EZA-HK-1

Standard bracket kit with

Black EZA-MBK-11

hardware (includes 2 end

brackets and hardware to mount

to MSA Series stands)

Stainless

Steel

Center bracket kit (includes 1 bracket and

hardware to mount to MSA Series stands)

EZA-TP-1

EZA-MBK-11N

EZA-MBK-12

NOTE: Standard brackets shipped with sensors connect directly to

MSA series stands, using hardware included with the stands.

2.6 Specifications

Emitter/Receiver Range

Field of View

Beam Spacing

Light Source

Minimum Object Detection Size

Sensor Positional Resolution

12 P/N 130426 Rev. C

400 mm to 4 m (16" to 13')

Nominally ± 3°

5 mm (0.2")

Infrared LED

Straight Scan, Low-Contrast: 5 mm (0.2")

Straight Scan, High-Excess-Gain: 10 mm (0.4")

See Figure 1-5 for other scan mode values; size is tested using a rod.

Straight Scan: 5 mm (0.2")

Double-Edge Scan: 2.5 mm (0.1")

Single-Edge Scan: 2.5 mm (0.1")

Banner Engineering Corp. •Minneapolis, U.S.A.

www.bannerengineering.com•Tel:763.544.3164

Page 15

A-GAGE EZ-ARRAY

Instruction Manual

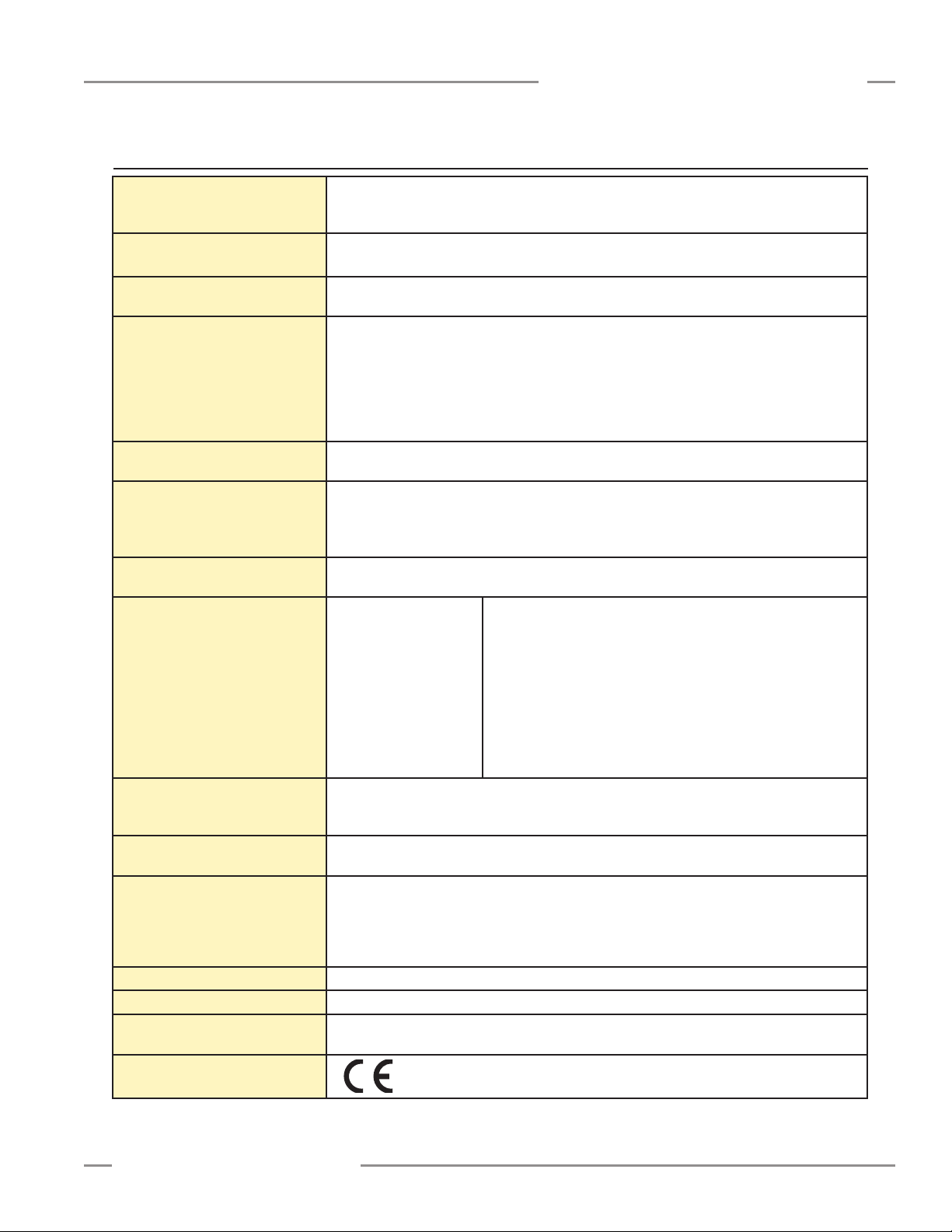

2.6 Specifications, continued

Components and Specifications

Supply Voltage (Limit Values)

Supply Power Requirements

Teach Input (Receiver Gray Wire)

Two Discrete Outputs

Two Analog Outputs

Serial Communication Interface

(also see Appendix A)

Scan Time

Status Indicators

(also see Section 1.4)

Emitter: 12 to 30V dc

Receiver Analog Current Models: 12 to 30V dc

Receiver Analog Voltage Models: 15 to 30V dc

Emitter/Receiver Pair (Exclusive of Discrete Load): Less than 9 watts

Power-up delay: 2 seconds

Low: 0 to 2 volts

High: 6 to 30 volts or open (input impedance 22 K ohms)

Solid-State NPN or PNP (current sinking or sourcing)

Rating: 100 mA maximum each output

OFF-State Leakage Current:

ON-State Saturation Voltage:

Protected against false pulse on power-up and continuous overload or short circuit.

Voltage Sourcing: 0 to 10V (maximum current load of 5 mA)

Current Sourcing: 4 to 20 mA (maximum resistance load = (V

EIA-485 Modbus RTU (up to 15 nodes per communication ring)

RTU binary format

Baud Rate: 9600, 19.2K or 38.4K

8 Data Bits, 1 Stop Bit, and Even, Odd, or 2 Stop Bits and No Parity

Scan times depend on scan mode and sensor length. Straight scan times range from 2.8 to 26.5 ms.

See Figure 1-8 for all combinations.

Emitter:

R ed Status LED

ON Red — Status OK

Flashing at 1 hz — Error

NPN: less than 200 uA @ 30V dc

PNP: less than 10 uA @ 30V dc

NPN: less than 1.6V @ 100 mA

PNP: less than 2.0V @ 100 mA

−3) / 0.020)

supply

Receiver:

7 Zone Indicators

Red — Blocked channels within zone

Green — All channels clear within zone

3- digit 7-segment measurement mode / diagnostic indicator

Se nsor Status Bi-Color Indicator LED

Red — Hardware Error or Marginal Alignment

Green — OK

Modbus Activity Indicator LED: Yellow

Modbus Error Indicator LED: Red

System Configuration

(Receiver Interface)

System Configuration

(PC interface)

Connections

Construction

Environmental Rating

Operating Conditions

Certifications

Banner Engineering Corp. •Minneapolis, U.S.A.

www.bannerengineering.com•Tel:763.544.3164

6-position DIP switch: Used to set scanning type, measurement modes, analog slope, and discrete

output 2 function (see Section 4.1).

Push Buttons: Two momentary push buttons for alignment and gain level selection.

Supplied software provides all configuration options of receiver interface, plus additional functionality;

see Sections 1 and 5.

Serial communication: The receiver uses a PVC-jacketed, 5-conductor 22-gauge quick-disconnect

cable, 5.4 mm diameter; see Sections 2.2 and 5.2.

Other Sensor connections: 8-conductor quick-disconnect cables (one each for emitter and receiver),

ordered separately; see Section 2.2 for available lengths (may not exceed 75 meters long), PVCjacketed cables measure 5.8 mm diameter, have shield wire; 22-gauge conductors.

Aluminum housing with clear-anodized finish; acrylic lens cover

IEC IP65

Temperature: −40° to +70° C (−40° to 158° F)

Maximum relative humidity: 95% at 50° C (non-condensing)

P/N 130426 Rev. C 13

Page 16

Components and Specifications

Y

L1

L2

L3

65 mm

(2.6")

R13 mm (0.5")

minimum bend

45.2 mm

(1.78")

56.0 mm

(2.20")

4.2 mm

(0.17")

36.0 mm

(1.42")

12 mm

(0.47")

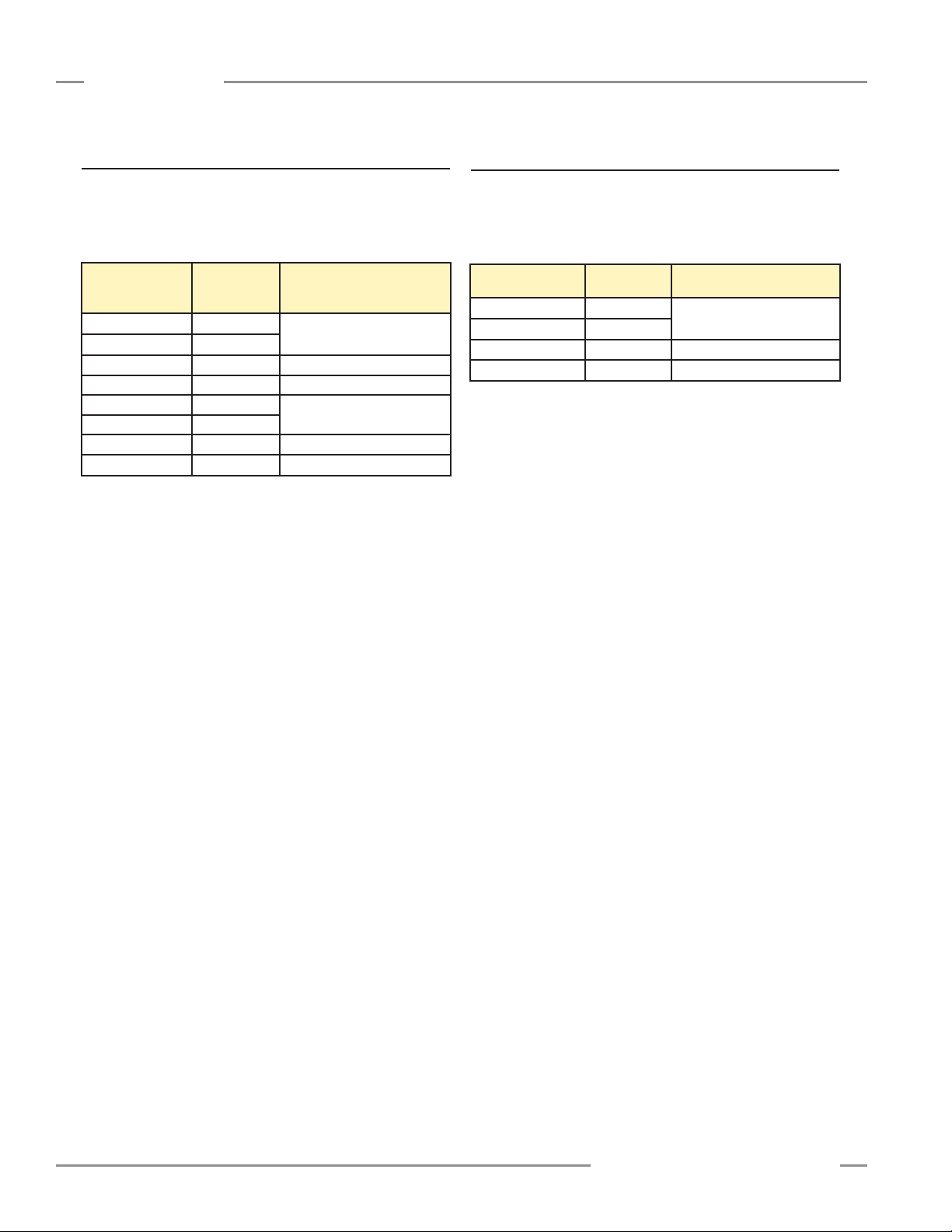

2.7 Emitter and Receiver Dimensions

A-GAGE EZ-ARRAY

Instruction Manual

With mounting bracket flanges “in”With mounting bracket flanges “out”

Emitter or Receiver

EA5..150..

EA5..300..

EA5..450..

EA5..600..

EA5..750..

EA5..900..

EA5..1050..

EA5..1200..

EA5..1500..

EA5..1800..

EA5..2100..

EA5..2400..

†

Nominal measurement

14 P/N 130426 Rev. C

Model

Housing Length

L1

227 mm (8.9") 260 mm (10.2") 199 mm (7.8") 150 mm (5.9")

379 mm (14.9") 412 mm (16.2") 351 mm (13.8") 300 mm (11.8")

529 mm (20.8") 562 mm (22.1") 501 mm (19.7") 450 mm (17.7")

678 mm (26.7") 704 mm (27.7") 650 mm (25.6") 600 mm (23.6")

828 mm (32.6") 861 mm (33.9") 800 mm (31.5") 750 mm (29.5")

978 mm (38.5") 1011 mm (39.8") 950 mm (37.4") 900 mm (35.4")

1128 mm (44.4") 1161 mm (45.7") 1100 mm (43.3") 1050 mm (41.3")

1278 mm (50.3") 1311 mm (51.6") 1250 mm (49.2") 1200 mm (47.2")

1578 mm (62.1") 1611 mm (63.4") 1550 mm (61.0") 1500 mm (59.1")

1878 mm (73.9") 1911 mm (75.2") 1850 mm (72.8") 1800 mm (70.9")

2178 mm (85.7") 2211 mm (87.0") 2150 mm (84.6") 2100 mm (82.7")

2478 mm (97.6") 2511 mm (98.9") 2450 mm (96.4") 2400 mm (94.5")

Distance Between Bracket Holes

L2 L3

Defined Area

Y

Banner Engineering Corp. •Minneapolis, U.S.A.

www.bannerengineering.com•Tel:763.544.3164

†

Page 17

A-GAGE EZ-ARRAY

50 mm

(1.96")

25 mm

(0.98")

4.2 mm

(0.17")

63.2 mm

(2.49")

Ø 21.5 mm

(0.85")

4 x 5.8 mm (0.23")

wide slots

4 x R 19.4 mm

(0.76")

38.2 mm

(1.50")

Ø 33 mm

(1.30")

4 x 45

20 mm

(0.79")

2 x R 5 mm

(0.20")

2 x 5 mm

(0.20")

2 x 15 mm

(0.59")

2 x 7 mm

(0.28")

20 mm

(0.79")

20 mm

(0.79")

Ø 60 mm

20 mm

(0.79")

17.5 mm

(0.69")

55 mm

(2.17")

50 mm

(1.97")

4.2 mm

(0.17")

55.6 mm

(2.19")

15 mm

(0.59")

20.0 mm

(0.79")

10 mm

(0.39")

9.5 mm

(0.37")

36 mm

(1.42")

Ø 8.3 mm

(0.33")

Ø 7 mm

(0.28")

Instruction Manual

2.8 Standard Bracket Dimensions

Components and Specifications

End Cap Brackets

(model EZA-MBK-11*)

* Dimensions are identical for model EZA-MBK-11N

stainless steel brackets.

Center Bracket

(model EZA-MBK-12**)

** Supplied with emitters

and receivers over 1050 mm.

Banner Engineering Corp. •Minneapolis, U.S.A.

www.bannerengineering.com•Tel:763.544.3164

P/N 130426 Rev. C 15

Page 18

Installation

3. Installation and Alignment

A-GAGE EZ-ARRAY

Instruction Manual

3.1 Mounting the Emitter and Receiver

Compact EZ-ARRAY emitters and receivers are easy to handle

during mounting. When mounted to the sensor end caps, the

supplied mounting brackets allow ±30° rotation. An emitter may

be separated from 400 mm to 4 m (16" to 13') from its receiver.

From a common point of reference, make measurements to

locate the emitter and receiver in the same plane, with their

midpoints and display ends directly opposite each other. (If

sensors are mounted with their display ends at the top, see

Section 1.5 or 5.8 for directions on inverting the 3-digit display.)

Mount the brackets to the emitter and receiver housings using

the supplied M6 bolts and Keps nuts, or user-supplied hardware;

see Figure 3-1.

EZ-ARRAY End-Cap Brackets

(supplied with each emitter and receiver)

End-Mounted

Side-Mounted

(two center brackets may

be substituted)

Center mounting brackets must be used with longer sensors,

if they are subject to shock or vibration. In such situations,

the sensors are designed to be mounted with up to 900 mm

unsupported distance (between brackets). Sensors 1050 mm and

longer are supplied with a center bracket to be used as needed

with the standard end-cap brackets.

1. Attach the center bracket to the mounting surface when

mounting the end-cap brackets.

2 Attach the clamp to both slots of the housing, using the

included M5 screws and T-nuts.

3. After the sensor is mounted to the end-cap brackets, attach

the clamp to the center bracket using the supplied M5 screw.

Swivel Center Bracket

(supplied with emitters and receivers 1050 mm and longer)

Sensors are designed to be

mounted with up to 900 mm

unsupported distance between

brackets.

Bracket

Clamp

NOTE: Sensor brackets are designed to mount directly to accessory MSA series stands (Section 2.3), using hardware supplied with

the stands.

Figure 3-1. A-GAGE EZ-ARRAY emitter and receiver mounting hardware

Banner Engineering Corp. •Minneapolis, U.S.A.

16 P/N 130426 Rev. C

www.bannerengineering.com•Tel:763.544.3164

Page 19

A-GAGE EZ-ARRAY

Level Surface

Level Surface

XX

AB

Emitter Receiver

level level

level

level

Y Y

Z

Z

XX

Instruction Manual

3.2 Mechanical Alignment

Mount the emitter and receiver in their brackets and position the

windows of the two units directly facing each other. Measure

from one or more reference planes (e.g., the building floor) to

the same point(s) on the emitter and receiver to verify their

mechanical alignment. Use a carpenter’s level, a plumb bob,

or the optional LAT-1-SS Laser Alignment Tool, or check the

diagonal distances between the sensors, to achieve mechanical

alignment.

When alignment is difficult, a LAT-1-SS tool is useful to assist

or confirm alignment by providing a visible red dot along the

sensor’s optical axis (see Figure 3-3). Snap the LAT-1 clip onto

the sensor housing, turn on its laser emitter, and use a strip of

retroreflective tape at the opposite sensor to see the dot.

Installation

Also check “by eye” for line-of-sight alignment. Make any

necessary final mechanical adjustments, and hand-tighten the

bracket hardware. See Sections 3.4 and 4.2 for further alignment

information.

Verify that:

•Theemitterandreceiveraredirectlyoppositeeachother,and

nothing is interrupting the beams.

•Thesensingareaisthesamedistancefromacommon

reference plane for each sensor.

•Theemitterandreceiverareinthesameplaneandare

level/plumb and square to each other (vertical, horizontal,

or inclined at the same angle, and not tilted front-to-back or

side-to-side).

Figure 3-3. Optical alignment using the LAT-1-SS

Angled or Horizontal Installations – verify that:

•DistanceXattheemitterandreceiverareequal.

•DistanceYattheemitterandreceiverareequal.

•DistanceZattheemitterandreceiverareequalfromparallel

surfaces.

•Verticalface(i.e.,thelens)islevel/plumb.

•Sensingareaissquare.Checkdiagonalmeasurementsifpossible;

see Vertical Installations, at right.

Figure 3-2. Sensor mounting, mechanical alignment

Banner Engineering Corp. •Minneapolis, U.S.A.

www.bannerengineering.com•Tel:763.544.3164

Vertical Installations – verify that:

•DistanceXattheemitterandreceiverareequal.

•Bothsensorsarelevel/plumb(checkboththe

side and face).

•Sensingareaissquare.Verifydiagonalmeasurementsif

possible (Diagonal A = Diagonal B).

P/N 130426 Rev. C 17

Page 20

Installation

wh wh

ye

ye

gn

gn

rd

rd

gy

0-2V dc

gy

bare bare

pk

bu

bn

pk

bu

bn

Sync

Power Supply V+

10-30V dc

Power

Power Supply V-

Sync

Power Supply V+

Power Supply V-

V Out 1

V Out 2

Out 1

Out 2

Teach

Shield Shield

Receiver Emitter

Load

Load

+–

+

–

+

–

Receiver Emitter

wh wh

ye

ye

gn

gn

rd

rd

gy

0-2V dc

gy

bare bare

pk

bu

bn

pk

bu

bn

Sync

Power Supply V+

Power Supply V-

Sync

Power Supply V+

Power Supply V-

V Out 1

V Out 2

Out 1

Out 2

Teach

Shield Shield

Load

Load

+

–

+

–

10-30V dc

Power

+–

Modbus

white

black

blue

D1/B/+

D0/A/–

common

brown

gray

White

Brown

Blue

Gray

Black

3.3 Hookups

Refer to Figures 3-4, 3-5, and 3-6 for the appropriate hookup

information.

Serial Connection

This connection is used only when the PC interface is also used.

The receiver has a Modbus RTU-485 serial interface. A separate

5-pin Euro-style connection is provided at the end opposite from

the power cable connection to electrically connect the serial

communication cable to an external PC or PLC. Refer to Figure

3-4; the white wire is connected to the Modbus D1/B/ + terminal

and the black wire is connected to the D0/A/ − terminal.

A-GAGE EZ-ARRAY

Instruction Manual

Male Connector Pinout

White: D1 / B / +

Black: D0 / A / –

Blue: Common

Inputs

Refer to Figures 3-5 and 3-6 for standard hookup information.

Receiver gray wire: The receiver has an input that can be used

as a gate input or for remote teach. To initiate remote teach,

alignment, and gating functions, tie the wire through a switch to

sensor common. See Sections 1.7 and 5.7 for more information.

Outputs

Refer to Figures 3-5 and 3-6 for standard hookup information

and Section 2.6 Sensor Specifications for further electrical

requirements.

Analog white and yellow wires: The receiver has two analog

outputs. Depending on receiver model, both outputs are either

voltage or current. The white wire is referenced as analog output

1; the yellow wire is referenced as analog output 2. Both analog

current and voltage will source current through an external load

to sensor common.

Discrete Outputs: The receiver has two discrete outputs;

the green wire is referenced as discrete #1, and the red wire,

discrete #2. Depending on model, both outputs are either NPN

or PNP, unless the polarity is altered via the PC interface. Refer

to Section 2.6 Specifications for further electrical requirements.

Sync (Pink) Wire

The emitter and receiver are electrically synchronized via the

pink wire. The emitter and receiver pink wires must only be

electrically connected together.

Figure 3-4. Serial communication hookup

Figure 3-5. NPN hookup

18 P/N 130426 Rev. C

Figure 3-6. PNP hookup

Banner Engineering Corp. •Minneapolis, U.S.A.

www.bannerengineering.com•Tel:763.544.3164

Page 21

A-GAGE EZ-ARRAY

Straightedge

Straightedge

a)

b)

c)

d)

Instruction Manual

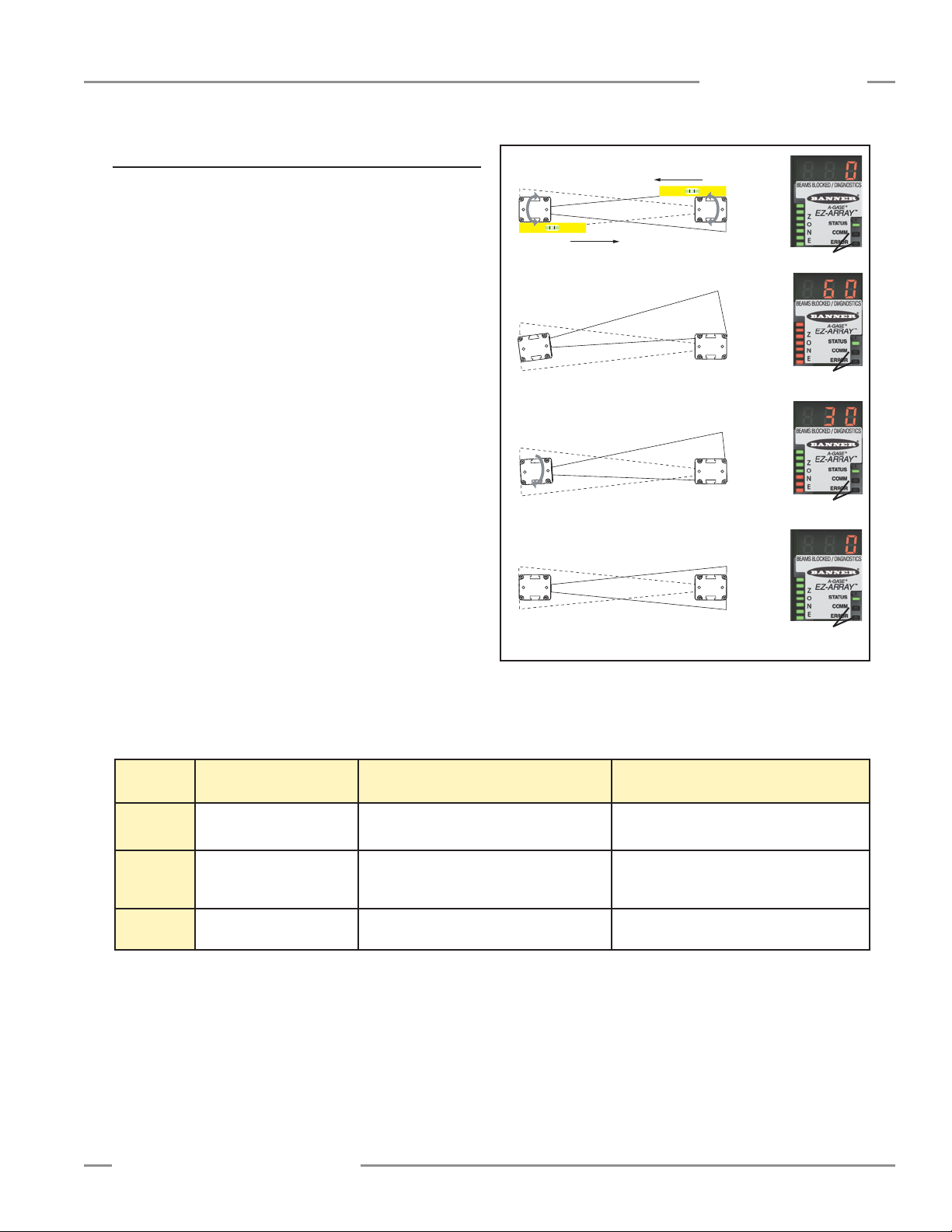

3.4 Optical Alignment

After the electrical connections are made, power up the emitter

and receiver. Verify that input power is present to both emitter

and receiver; the emitter Status indicator and the receiver Status

LED should be ON green. If the receiver Status LED is on red

(and a “c” appears on the 3-digit display), refer to Section 4.5.

NOTE: At power-up, all Zone indicators are tested (flash

red), then the number of blocked beams is displayed.

Observe the receiver indicators (see table below).

0 beams blocked; all Zone indicators ON Green

Installation

OFF

Optimize Alignment and Maximize Excess Gain

Verify that the emitter and receiver are pointed squarely at

60 beams blocked; all Zone indicators ON Red

OFF

each other. A straightedge (e.g., a level) can help determine the

direction the sensor is facing (see Figure 3-7).

Slightly loosen the sensor mounting screws and rotate one

sensor to the left and right, noting the positions where the

receiver Zone indicators turn from green to red; repeat with the

other sensor. Center each sensor between the noted positions

30 beams blocked; 4 Zone indicators ON Green, 3 ON Red

OFF

and tighten the end cap mounting screws, making sure to

maintain the positioning. The sensor windows should directly

face each other.

Once optimum optical alignment is verified, proceed to

configuration, via the remote teach wire, the receiver interface,

or the PC interface (Section 1.5, 4.2, or 5.3) and complete the

0 beams blocked; all Zone indicators ON Green

OFF

electronic alignment. This further alignment step adjusts the

emitted light level of each beam for the application, to maximize

Figure 3-7. Optimizing optical alignment; 300 mm model shown

sensing performance.

Possible Indicator Combinations

Zone

Indicators

Either Clear or Blanked

All ON Green Some ON Red (zones with blocked beams)

Some ON Green (zones with all clear beams)

All Beams

Some Beams

Blocked or Mis-Aligned

Out of Alignment

All ON Red

(Some beams blocked in each zone)

Receiver

ON Green ON Green ON Green

Status

Indicator

3-Digit

Display

Banner Engineering Corp. •Minneapolis, U.S.A.

www.bannerengineering.com•Tel:763.544.3164

0

(Number of blocked beams)

Number of blocked beams Total number of beams in the array

P/N 130426 Rev. C 19

Page 22

Receiver Interface

4. Using the Receiver User Interface

A-GAGE EZ-ARRAY

Instruction Manual

The receiver user interface comprises the six-position DIP

switch, two push buttons, 3-digit display, and other indicators

present on the receiver (see Section 1.4 for more complete

status indicator information). The receiver interface enables

configuration of standardized combinations of the EZ-ARRAY

sensing options (output configuration, scanning methods and

modes); for more advanced setup, refer to Section 5 for PC

interface configuration instructions.

4.1 Configuration DIP Switch

The DIP switch can be used to configure the sensor. Access the

switch by removing the screw-on security plate and lifting the

clear hinged access cover. The access cover may be removed

entirely (pull straight out to remove, press back in to replace) for

easier access during configuration.

Some of the switches are assigned their own functions, others

work together in combination (see table). Switches S1 and S2

in combination select one of four scanning modes. Switches S3

and S4 in combination select one of four measurement mode

pairs (one for each analog output). Switch S5 defines the analog

slope setting for both analog outputs and S6 defines whether

discrete output 2 is complementary to discrete 1, or functions as

an alarm (when configuration is accomplished via DIP switch,

discrete output 1 conducts when analog output 1 senses the

presence of a target).

EZ-ARRAY Receiver User Interface DIP Switch Settings

Switch Settings* Result

S1 S2 Scan Mode

ON ON Straight Scan

ON OFF Double-Edge, Step 1

OFF ON Double-Edge, Step 4

OFF OFF Single-Edge

S3 S4

ON ON TBB FBB

ON OFF LBB MBB

OFF ON OD ID

OFF OFF CBB CFBB

S5 ON

S5 OFF

S6 ON

S6 OFF

*Underlined settings are factory defaults

Analog 1

(Value reads on 3-digit display)

Positive Analog Slope

Negative Analog Slope

Discrete 2 Complementary

Discrete 2 Alarm

Analog 2

Scanning Modes (S1 and S2)

Straight Scan (S1 ON, S2 ON) is the most versatile scanning

mode and can be used without the exceptions noted in the

other scanning modes. Use this scanning mode when using

the low-contrast sensitivity setting to measure semi-transparent

materials.

To open access

cover, insert a

small flat-blade

screwdriver, press

up, and pull

Figure 4-1. Receiver user interface. NOTE: All DIP switch positions

are shown in the ON condition.

20 P/N 130426 Rev. C

Double-Edge Step 1 (S1 ON, S2 OFF) can be used when

three or fewer opaque objects are presented to the light curtain

at one time. The advantage of this mode is improved sensor

edge resolution (2.5 mm). The minimum object detection size is

10 mm.

Double-Edge Step 4 (S1 OFF, S2 ON) can be used when three

or fewer opaque objects are presented to the light curtain and

the minimum size object to be detected is 30 mm. This scanning

mode ignores objects smaller than 30 mm. Like Double-Edge

Step 1, the sensor edge resolution is 2.5 mm. See Figure 1-8 for

sensor scan times.

Single-Edge Scan (S1 OFF, S2 OFF) can be used when a

single opaque object is presented to the light curtain at one time.

The object must block the “bottom” channel (the channel closest

to the receiver display). Like the double-edge scans, the sensor

edge resolution is 2.5 mm. The minimum object detection size is

10 mm. See Figure 1-8 for sensor scan times.

Banner Engineering Corp. •Minneapolis, U.S.A.

www.bannerengineering.com•Tel:763.544.3164

Page 23

A-GAGE EZ-ARRAY

Instruction Manual

Receiver Interface

Because single-edge scan is capable only of measuring the

height of an opaque object that blocks the bottom channel

and all channels up to the height of the object, the pertinent

measurement modes are LBB (last beam blocked) or TBB

(total beams blocked). When single-edge scan is selected, the

selected measurement mode will be applied to both analog

outputs. Selection of OD/ID with single-edge scan will result in

an error code.

Measurement Modes (S3 and S4)

The measurement modes, determined by switches S3 and S4

in combination, define what information is calculated by the

sensor and sent via the analog outputs. See Section 1.10 for

measurement mode definitions. Discrete output 1 will conduct

when analog output 1 detects a target. (If single-edge scan is

selected, select measurement mode LBB or TBB.)

During normal operation, the 3-digit diagnostic display reads out

the numerical value of the specified measuring mode for analog

output 1.

Analog Slope (S5)

Switch S5 defines the analog output slope. As the measurement

mode values increase, the analog output voltage can either

increase (positive slope, S5 ON) or decrease (negative slope, S5

OFF). Switch S5 applies the same slope to both analog outputs.

Complementary / Alarm (S6)

Switch S6 defines the operation of discrete output 2. When the

receiver user interface is used, discrete output 1 is active when

an object is detected by the sensor (normally open operation).

In complementary mode (S6 ON), output 2 will always be in the

opposite state of output 1. In alarm mode (S6 OFF), discrete

output 2 will be active when the sensor detects a system fault.

System faults include a failed emitter, mis-wiring of the emitter/

receiver communication wire (the pink wire), and low excess gain

(if the sensor is configured for high-contrast sensitivity).

4.2 Alignment / Blanking Button (Electronic Alignment)

The Alignment/Blanking push button is used both to maximize

the alignment and to access the blanking feature. The electronic

alignment routine adjusts the emitted light level to maximize

sensor performance. Perform the procedure at installation

and again when the emitter and/or receiver is moved. For PC

interface software alignment instructions, see Section 5.5.

Blanking is used to maintain sensing accuracy in applications

where a fixed object (for instance a permanently mounted

bracket) will block one or more beams. The sensor will ignore

the blanked channels when calculating outputs from the selected

measurement modes.

Electronic Alignment and Blanking — Receiver Interface

To initiate the electronic alignment procedure, use a small

screwdriver to press the Alignment/Blanking button for two or

more seconds. The left-hand digit of the 3-digit display will read

“A” (representing alignment); the right two digits will show the

number of beams blocked. The receiver is learning the clear

condition. Rotate the sensors as required (but do not change

the distance between them). When the receiver’s 3-digit display

shows 0 beams blocked, the sensors are adequately aligned.

Tighten the sensor mounts, then press the Alignment/Blanking

button again for two seconds to exit alignment mode. If all

sensor light channels are clear, the EZ-ARRAY stores each

channel’s signal strength in non-volatile memory and reads

“ - - - ” on the 3-digit display. Re-alignment is not required again,

unless the emitter or receiver is moved.

If any beams are blocked by objects other than the sensing

target to be measured during run mode, those beams can be

blanked in alignment mode for more accurate measurement.

The blocked beams must be either blanked or cleared during

alignment mode for alignment to proceed (see below). While

the “A” is visible on the receiver display, momentarily (about 0.5

seconds max.) press the Alignment/Blanking button again. The

“A” will change to “n” to indicate the sensor is ready to “learn”

the blanking pattern; momentarily press the button again to exit

the blanking routine. The sensor blanks the blocked beams and

the display changes to “A.”; the period following the lefthand digit

signifies blanking is active. Press the Alignment/Blanking button

for two seconds to exit alignment mode. The EZ-ARRAY stores

each channel’s signal strength in non-volatile memory and reads

“

-. - - ” on the 3-digit display to denote blanking is in use.

Flashing “000” on the 3-Digit Display

When returning to run mode, the receiver determines whether

any unblanked beam channels are obstructed. If any channels

are obstructed, the new alignment settings are not saved; the

receiver flashes zeroes on the display three times and sensing

will continue, using the previously set alignment settings. If this

occurs, either clear the blocked beams and repeat the alignment

routine or repeat the alignment routine and blank the blocked

beams.

4.3 Gain (Sensitivity Adjust) Button

To change the sensitivity (Gain setting), press and hold the

button for two seconds. The left-hand digit of the 3-digit display

will read “

or “2” (low-contrast. The sensitivity level can then be toggled

between the values 1 and 2. When the desired sensitivity level

is displayed, hold the Gain push button for 2 seconds and the

sensor will return to run mode.

l”; the right-hand digit will read “1” (high excess-gain)

Banner Engineering Corp. •Minneapolis, U.S.A.

www.bannerengineering.com•Tel:763.544.3164

P/N 130426 Rev. C 21

Page 24

Receiver Interface

A-GAGE EZ-ARRAY

Instruction Manual

4.4 Inverting the 3-Digit Display

For instances where the sensors must be mounted in an

inverted position, the 3-digit display can be can be inverted

for readability. See the remote teach procedure (Section 1.5).

The 3-digit display can then be switched back to “normal” by

repeating the procedure.

NOTE: The periods on the three seven-segment indicators do

not move when the display is inverted.

Error

Code

1 Receiver EEPROM Hard Failure

Receiver Alignment/Blanking

2