Page 1

BeoSound 3000

Type 2671, 2672, 2673, 2674, 2675, 2676, 2677, 2680

Service Manual

English, German, French, Italian, Spanish

illustration

Page 2

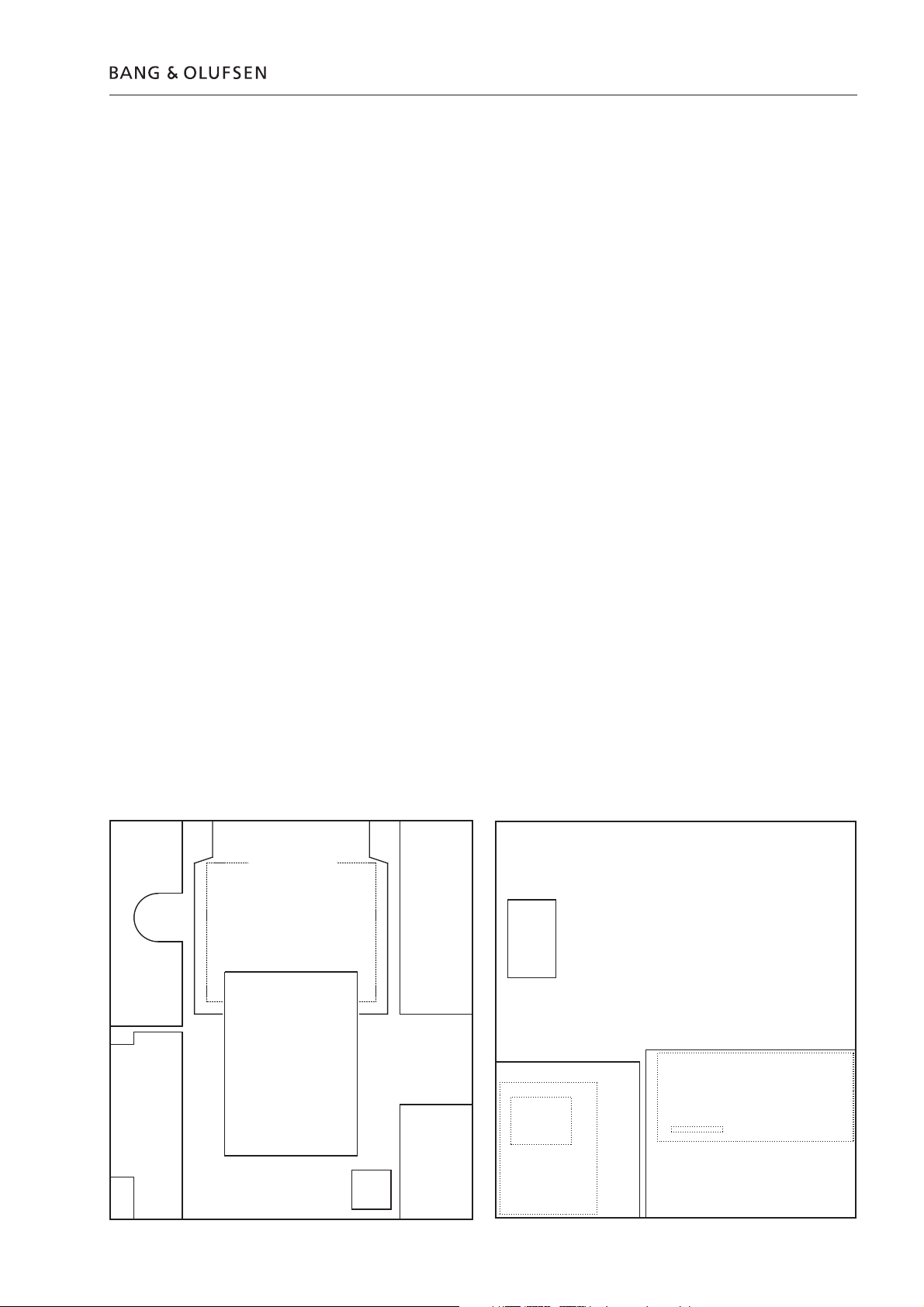

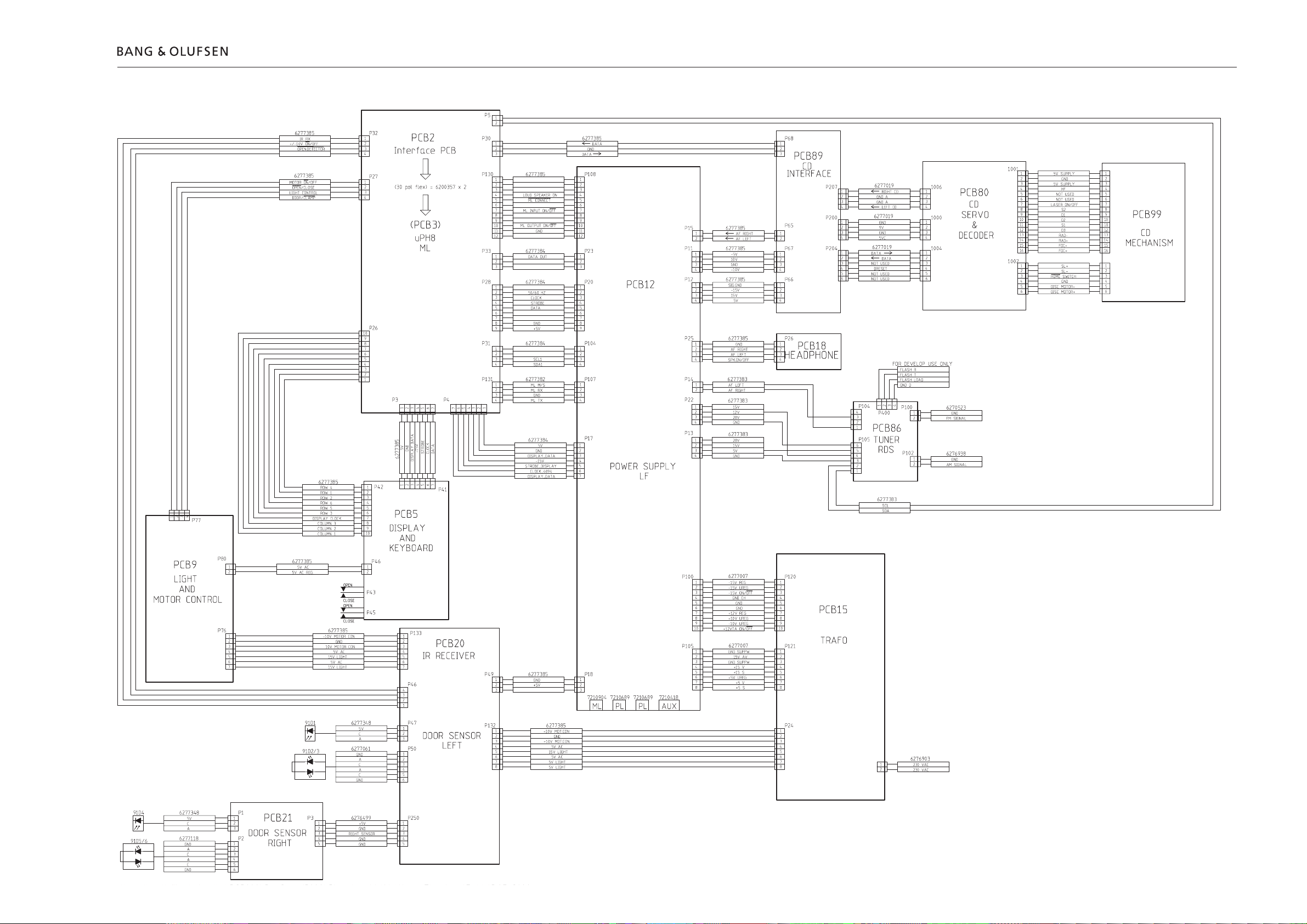

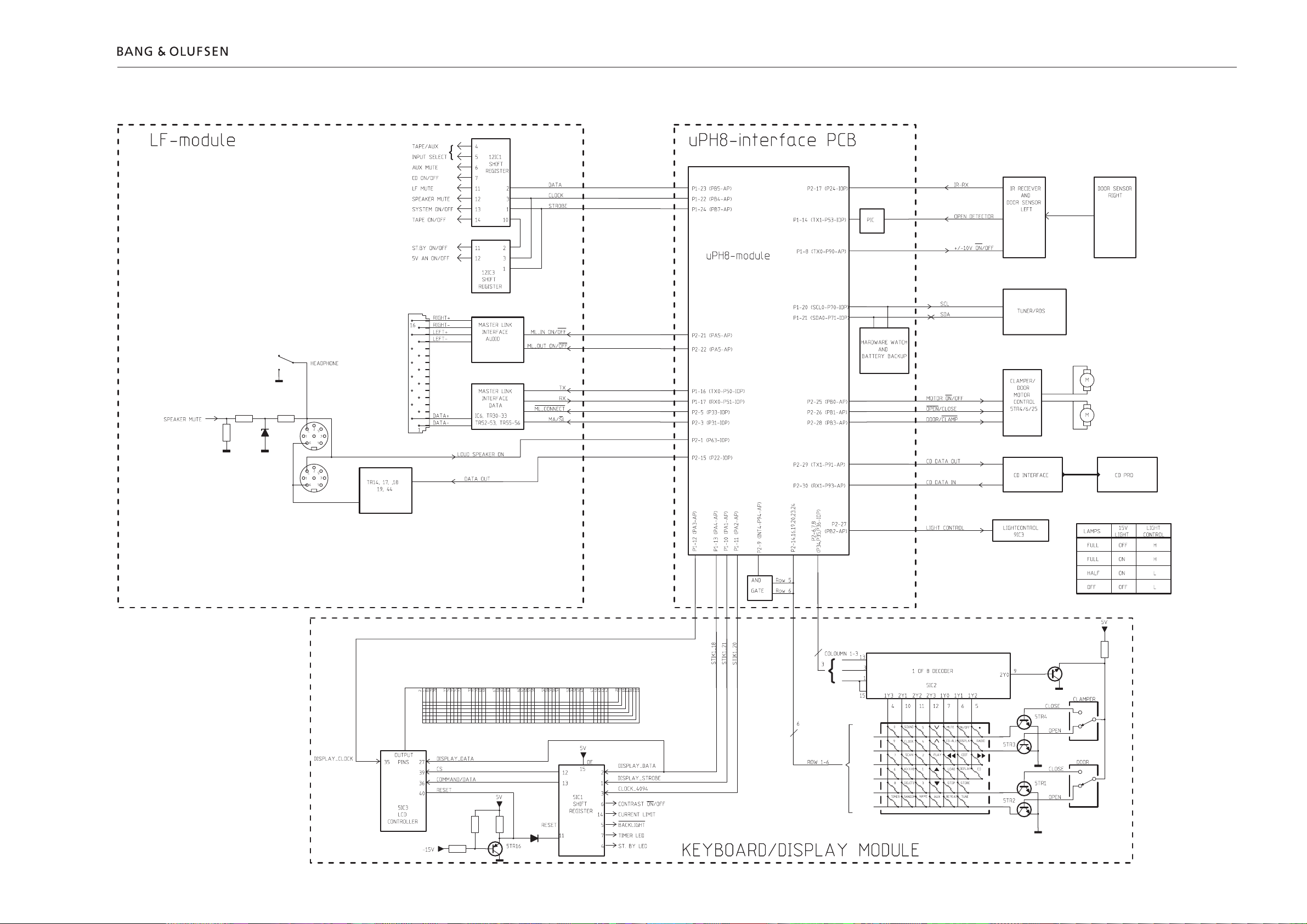

1.1Survey of modules

2 Interface f/µPH8 .................................................. diagram E

page 2.14

3 µPH8 Microcomputer ......................................... diagram E

page 2.14

5 Display ............................................................ diagram F, M

page 2.15, 2.25

9 Light and motor control .................................... diagram F

page 2.15

12 Power Supply, Input select & Pre-amp. .....diagram G, H, I

page 2.17, 2.18, 2.19

14 Master Link Audio interface ............................. diagram H

page 2.18

15 Transformer ..........................................................diagram I

page 2.19

18 Headphone ........................................................ diagram G

page 2.17

20 IR receiver and left door sensor ...................... diagram F, J

page 2.15, 2.21

21 Door sensor right .................................................diagram J

page 2.21

28 Light supply ........................................................ diagram F

page 2.15

86 Tuner-FM/AM-RDS-Stereo decoder ...... diagram A, B, C, D

page 2.9, 2.10, 2.11, 2.12

89 Interface f/CD PRO MKI ......................................diagram K

page 2.23

99 CD PRO MKI ........................................................ diagram L

page 2.24

9

20

90*/99

5

87*/

89

21

18

* for CD PRO MKII

28

3

2

15

86

14

12

Page 3

1.2

SPECIFICATION GUIDELINES FOR SERVICE USE BeoSound 3000

With FM, AM and RDS Type 2671 EU (230V)

Type 2672 GB (240V)

Type 2673 USA-CDN (120V)

Type 2674 J (100V)

Type 2675 AUS (240V)

Type 2676 TWN (120V)

Type 2677 KOR (220V)

Type 2680 LAT (230V)

Preamplifi er section

Total harmonic distortion + Noise R,L < 0.1%/1 kHz

Response vs. frequency:

AUX in 20-20,000Hz ±1dB

Input sensitivity/impedance

AUX 200 mV

Input impedance, AUX >22 kΩ

Max. input signal, AUX 2.0 V

Signal-to-noise ratio:

AUX, A-weighted >80 dB

Channel separation 10kHz, AUX >60 dB

Channel unballance ±1.5 dB

Bass control at 100Hz ±9 dB

Treble control at 10kHz ±9 dB

Output:

Source seperation >65 dB

Tone regulation Bass, 100 Hz 9.0 dB ± 2 dB

Tone regulation Treble 10 kHz 9.0 dB ± 2 dB

Headphones 3.5 V / 235 Ω

Specifi cation guidelines

Tuner, FM section

FM range (50 kHz grid) 87.5-108 MHz

FM range for type 2674 - Japan 76-90 MHz

FM aerial impedance 75 Ω

Usable sensitivity mono 14 dBf - 1.4 µV

Usable sensitivity stereo 19 dBf - 2.5 µV

50 dB quieting sensitivity mono 21 dBf - 2.5 µV

50 dB quieting sensitivity stereo 40 dBf - 28 µV

Signal-to-noise ratio mono 68 dB

Signal-to-noise ratio stereo 62 dB

Frequency response stereo 30 - 15,000 Hz +1/-3 dB

THD + noise mono 0.63 %

THD + noise stereo 0.6 %

Intermodulation distortion stereo 50 dB

Stereo channel separation 35 dB

Subcarrier product rejection 50 dB, stereo

Tuner, AM section

AM range EU (9 kHz grid) LW 153 - 279 kHz

MW 522 - 1611 kHz

GB (9 kHz grid) LW 153 - 279 kHz

MW 522 - 1611 kHz

USA MW (10 kHz grid) 520 kHz - 1710 kHz

Japan MW (9 kHz grid) 522 kHz - 1629 kHz

AUS MW (9 kHz grid) 522 kHz - 1611 kHz

Taiwan MW (9 kHz grid) 522 kHz - 1611 kHz

Korea MW (9 kHz grid) 522 kHz - 1611 kHz

LW sensitivity 20 dB S/N ratio 80 - 72 dBµV/m (10 - 4 mV/m) TYP 4mV/meter

MW sensitivity 20 dB S/N ratio 68 - 60 dBµV/m (2.5 - 1mV/m) TYP 2mV/meter

Number of programmes 60

IR Operation Beo4

Page 4

Specifi cation guidelines

CD player

CD, disc types 12 cm (5”), 8 cm (3”)

Frequency response 20 - 20,000 Hz ±1 dB

SNR (digital zero) >96 dB / 101 dB A-weighted

Dynamic range >98 dB

Channel difference ±0.3 dB

D/A converter Bitstream + Analog fi lter

Dimensions

W x H x D / Weight 32 x 36 x 16 cm / 7 kg

Cabinet fi nish Black / aluminium

Power consumption Typical 23 watts / stand-by 3 watts

Accessories

Type 2051 Stand, silver, black, blue, green, red

Type 2052 Center wall bracket, black

Type 2087 System wall bracket, black

V-antenna with coax cable 8720039

AM loop antenna 8720043

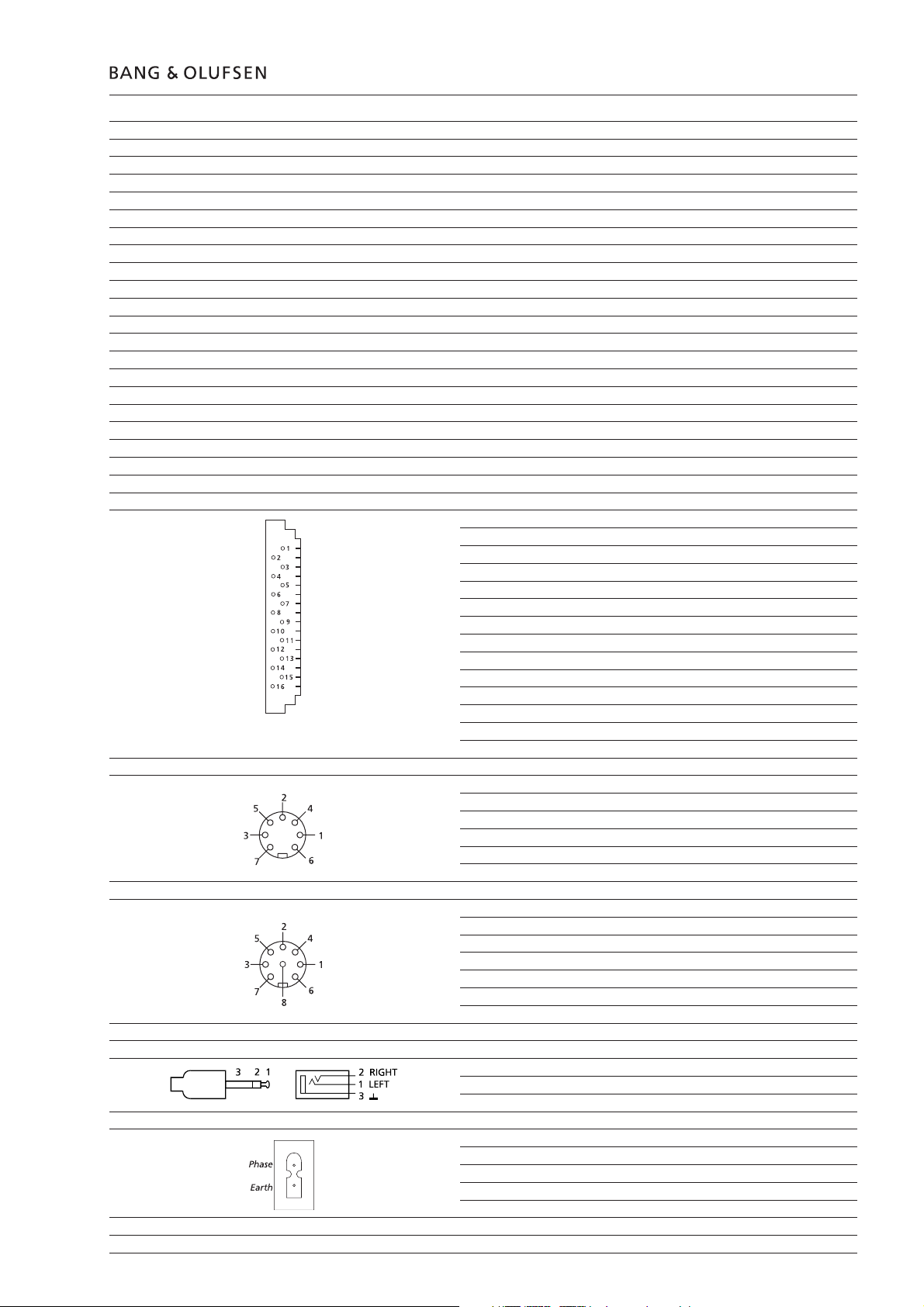

Connections

Master Link Pin 1 Data- -0.25V

Pin 2 Data+ +0.25V

Pin 3 ML sence 0-5V

Pin 4-10 N.C.

Pin 11 Supply voltage -7V > -15V, stand-by -3V > -15V

Pin 12 Supply voltage 7V > 15V, stand-by 3V > 15V

Pin 13 Audio L 1V bal., R

Pin 14 Audio L+

1V bal., Rin 2.2MΩ, Rout 75Ω

Pin 15 Audio R 1V bal., Rin 2.2MΩ, Rout 75Ω

Pin 16 Audio R+

1V bal., Rin 2.2MΩ, Rout 75Ω

in 2.2MΩ, Rout 75Ω

1.3

Audio Aux Link Pin 1 Audio L out 1V RMS, Rout 1KΩ

Pin 2 GND

Pin 3 Audio L in 0.25V RMS to 2V RMS, Rin 47KΩ

Pin 4 Audio R out 1V RMS, Rout 1KΩ

Pin 5 Audio R in 0.25V RMS to 2V RMS, Rin 47KΩ

Pin 6-7 Not used

Power Link Power up (ON = >2.7V -1mA)

Pin 2 Signal GND

Pin 3 Audio L out 0V to 2V RMS

Pin 4 Speaker ON (ON = >2.7V -1mA)

Pin 5 Audio R out 0V to 2V RMS

Pin 6 Datalink out (High = >4V, Low = <0.2V)

Pin 7 Data GND

Pin 8 PL+ ON

Headphones 4.1V / 235Ω

Mains Cable included,

100V AC, J type 2674

120V AC, USA-CDN type 2673-2676

220V AC, KOR type 2677

230V AC, EU-LAT type 2671-2680

240V AC, GB-AUS type 2672-2675

Subject to change without notice

Page 5

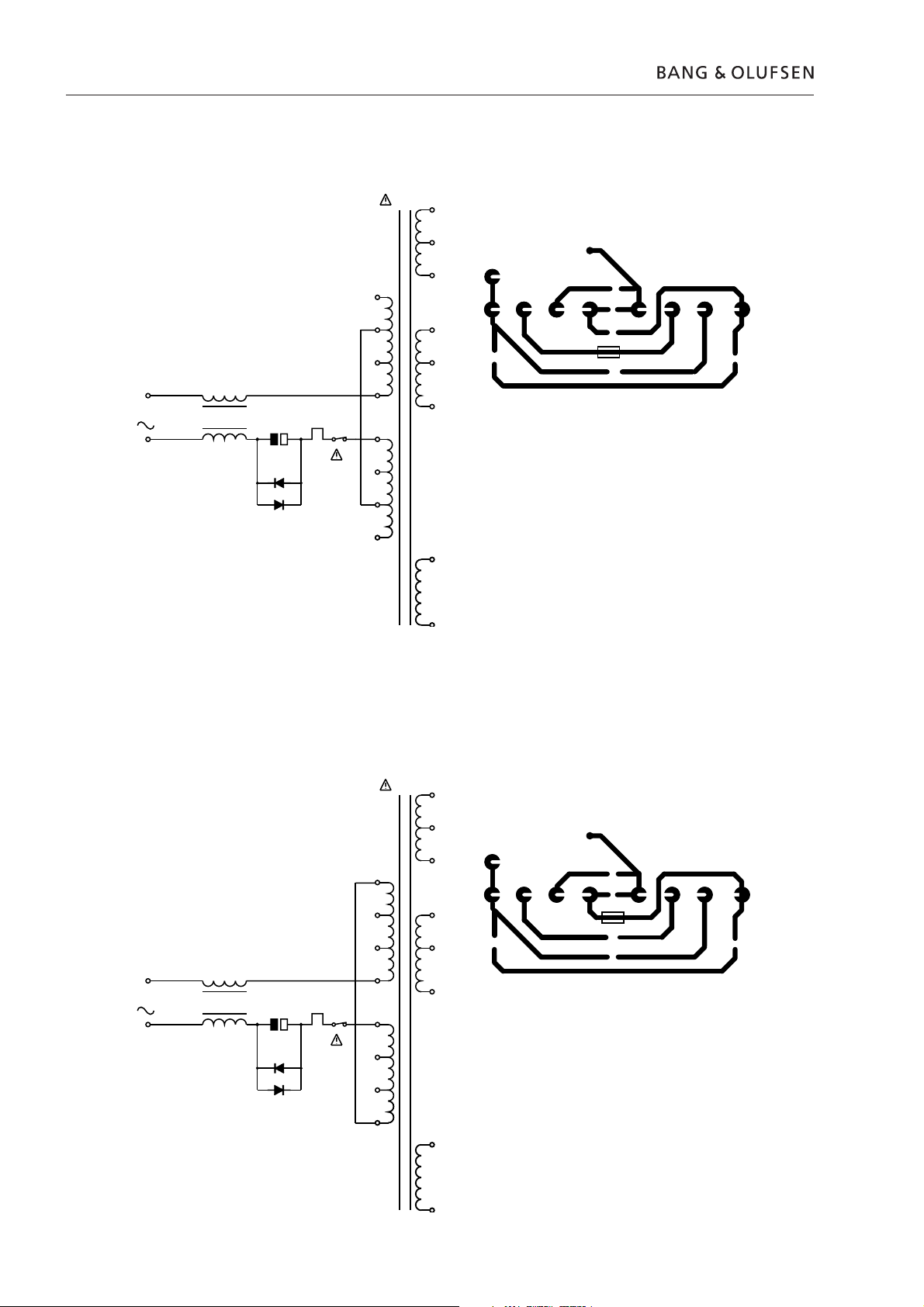

1.4

2

2

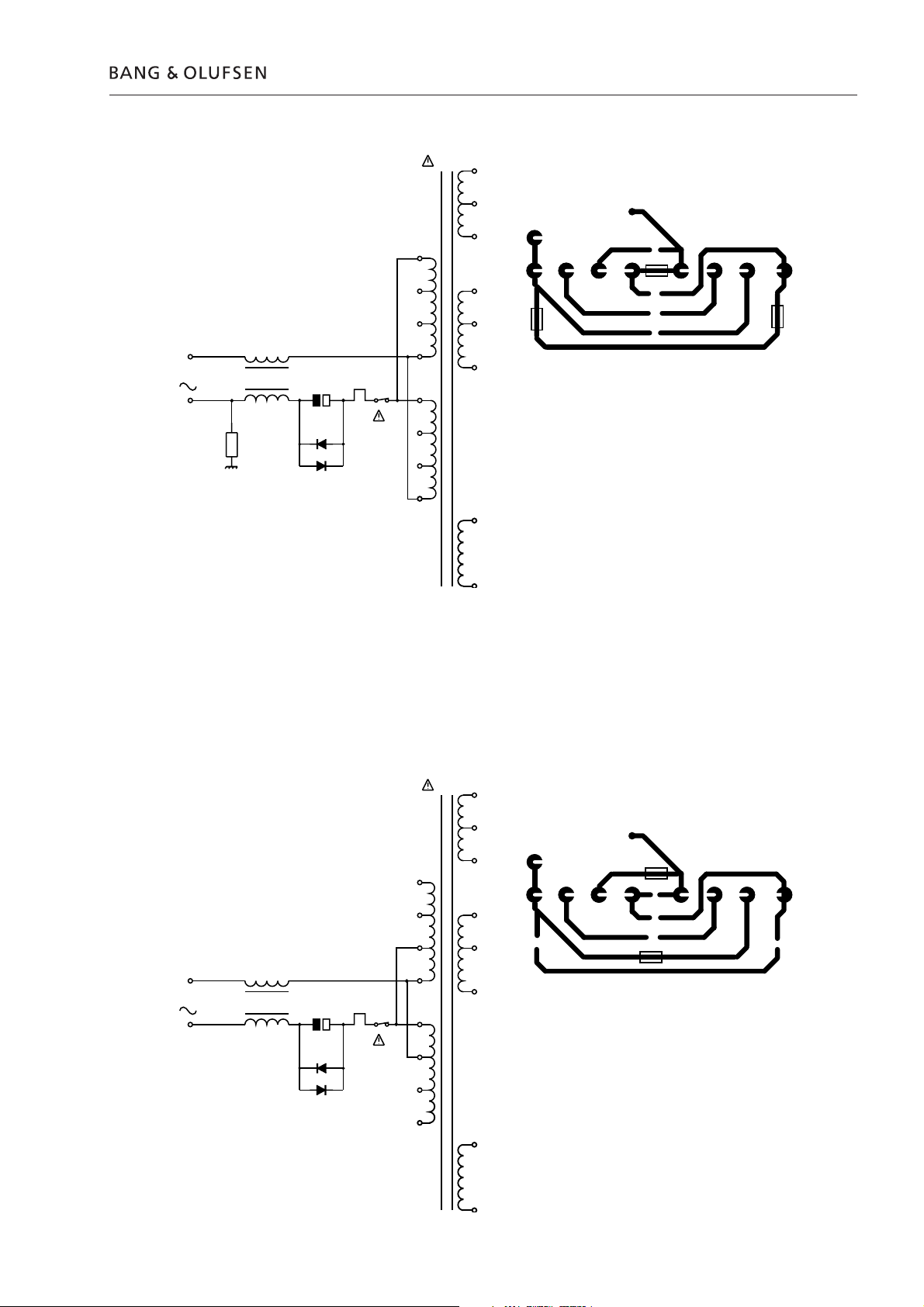

Wiring of transformer

Wiring of transformer, PCB15

Type 2671, 2677, 2680

EU, LAT 230V~

KOR 220V~

T1p

1B

16

15

30V

L1p

0.4mH

12

1

3

2

1C

C13p

D9

D10

TF1

1C

1C

1C

1000µ

4

8

6

7

5

14

11

10

13

9

120V

100V

230V

100V

120V

240V

120V

Type 2672, 2675

GB, AUS 240V~

L1p

0.4mH

1C

40V

C13p

1000µ

D10

D9

TF1

1C

1C

1C

T1p

1B

1

3

2

4

8

6

7

5

16

15

12

14

11

10

13

120V

100V

230V

100V

120V

240V

120V

9

Page 6

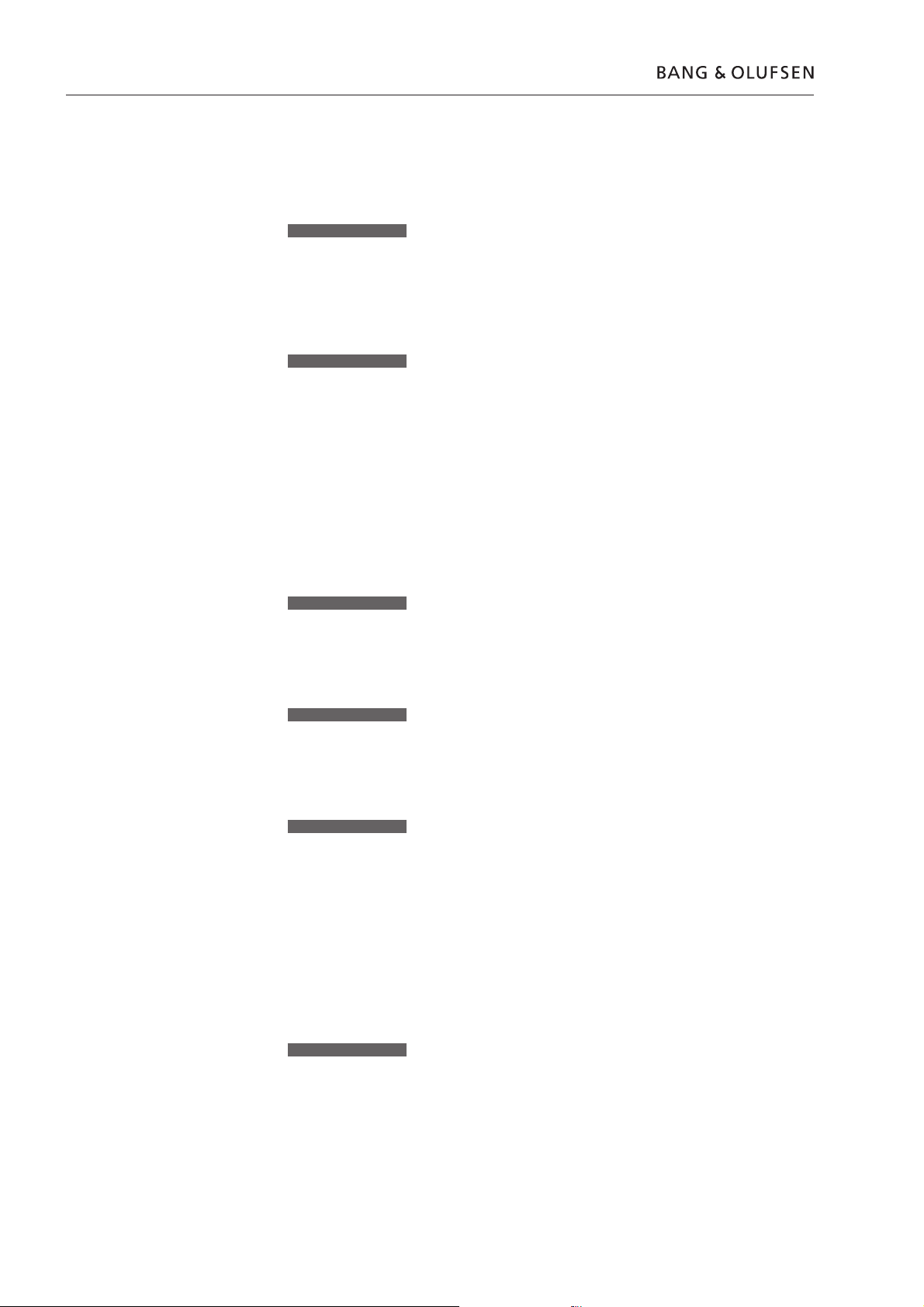

Type 2673, 2676

USA-CDN, TWN 120V~

Wiring of transformer

T1p

1B

16

15

1.5

120V

R1p

1B

3M3

L1p

0.4mH

12

1

3

2

1C

C13p

D9

D10

TF1

1C

1C

1C

1000µ

4

8

6

7

5

14

11

10

13

9

120V

100V

230V

100V

120V

240V

120V

Type 2674

JPN 100V~

100V

L1p

0.4mH

T1p

1B

1

3

2

1C

C13p

D9

D10

TF1

1C

1C

1C

1000µ

4

8

6

7

5

16

15

12

14

11

10

13

120V

100V

230V

100V

120V

240V

120V

9

Page 7

1.6 Brief operation guide

Brief operation guide

For more detailed operation see

User’s guide

Tune in radio stations

RADIO

TUNE

FM ?

m

p

PLAY

FM 88.9

m

p

0 – 9

Press RADIO to switch

on the radio

Press TUNE to access the

tuning function. FM ?

appears

Switches from FM to

AM, or vice versa

Press PLAY to select AM

or FM. FM or AM and

the current frequency

appears

Press to search for a

radio station – up or

down the frequency

band

Or, key in the exact

frequency

Switch on the radio

RADIO

0 – 9

m

p

•

r

u

MUTE

Note: Pressing 0 will swap between present and

previous radio station

Press RADIO to switch

on the radio

Use the number keys to

select a stored station

Step through all stored

stations

Switch to standby

Adjust the volume up or

down

Silences the speakers

immediately. Press again

to recall the sound

PLAY

FINE 0

m

p

PLAY

STEREO ?

m

p

PLAY

P 15 ?

m

p

0 – 9

PLAY

STORED

Press PLAY to accept*.

FINE 0 appears

Press to fi ne tune, if

necessary

Press PLAY to accept.

STEREO ? appears

Switches from STEREO

to MONO

Press PLAY to accept –

the fi rst available

program number

appears

Press to switch to a

different program

number

Or, key in the program

number you want

Press PLAY to store the

station on the displayed

program number.

STORED appears,

indicating that the

station is stored

Play a CD

CD

0 – 9

m

p

STOP

PLAY

n

l

Plays the CD in the

compartment

Plays specifi c track

numbers

Plays the next track

Plays the previous track

Pauses playing

Resumes playing

Searches forwards on

the CD

Searches backwards on

the CD

Keep the button pressed

down until you have

reached the point you

want

*Note: When the requested station is found, you

can skip the fi ne tune and stereo/mono selection

by pressing STORE instead of PLAY. Now just enter

a program number and press PLAY or STORE to

store the station.

Page 8

Brief operation guide

1.7

Set the built-in clock

CLOCK

14 : 45

m

p

0 – 9

PLAY

23 AUG

m

p

PLAY

2000

m

p

PLAY

STORE ?

STORE

STORED

Press CLOCK to access

the clock function. The

time appears

Press to change to the

exact time, if necessary

Alternatively key in the

exact time

Press PLAY to accept.

The date appears

Press to change the date,

if necessary

Press PLAY to accept.

The year appears

Press to change the year,

if necessary

Press PLAY to accept.

STORE ? appears

Press STORE to store the

new setting.

STORED appears

Using the Beo4

RADIO

CD

m

or

p

n

or

l

STOP

GO

r

u

•

Turns on the radio

Starts the CD player

Press to step through

your radio programs or

tracks on a CD

Alternatively, key in the

exact number, using the

number keys

Searches through a CD

Searches backwards

through a CD

Pauses playback any time

Press to resume

playback

Raises the volume

Lowers the volume

Switches off

Option programming

For the Beo4 terminal the key sequence is the following:

•

then

LIST

GO

LIST

then

1

Press and hold

Press to access the setup function. The Beo4 display reads [OPTION?] - let go of

both buttons

Press to access Option-programming

Press to display [V.OPT] CTV, or

[A.OPT] audio, or

[L.OPT] link room products

Key in the number of the approiate Option, e.g. 1

The digit sequence to be used depends on the setup.

Option 0 = No IR reception

Option 1 = Two IR-eyes in the same main room

Option 2 = One IR-eye in the main room

Page 9

2.1

Explanation of diagram

Explanation of diagram

Component print and coordinate system

Control circuit

Wiring connections

Type numbers of transistors and ICs are indicated on the diagrams. If the position

is followed by an asterisk the spare part number must always be used because the

component in question has been specially selected, e.g. TR102*.

The largest PCBs have component prints and a coordinate system on both the print

and the component side.

On the diagrams every component has a coordinate number. This indicates in which

coordinate on the PCB the component is situated. The coordinate numbers are

written in smaller print types than the position numbers.

In certain control circuits the active mode is indicated by a function term or by an

abbreviation. This may be e.g. ST.BY. = low in the stand-by mode or ST.BY. = high

in the stand-by mode.

The wiring connections on the diagrams are assembled in ‘bundles’. The individual

wires are provided with one of the following codes:

INTERNAL CONNECTION ON ONE DIAGRAM PAGE

12

Internal connections on a diagram page are indicated by a number.

The bend of the wire indicates in wich direction the other end of the wire is found.

CONNECTION TO ANOTHER DIAGRAM PAGE

DIAGRAM A

C3

C32 A32

A connection to another diagram page is indicated by a number as well as by a

letter of the diagram to which the connection leads.

Supply Voltages

All supply voltages in the diagrams are indicated by an arrow and a voltage indication.

Ground symbols

Three different ground symbols are used in the set.

= RF - OSC - SH - IF1 - IF2 - A

= Chassis

20

DIAGRAM C

1220

A3

Symbol of safety components

= D

When replacing components with this symbol, components with identical part

numbers must be used. The new component must be mounted in the same way

as the one replaced.

Page 10

Measuring conditions

Caution

Explanation of diagram

All DC voltages have been measured in relation to ground with a voltmeter with

an input impedance of 10 Mohms.

The DC voltages are stated in volts (V), e.g. 0.7V.

All oscillograms and AC voltages have been measured in relation to ground with

an oscilloscope or a voltmeter with an input resistance of 1Mohm.

AC voltages are stated in millivolts (mV), e.g. 660mV.

The use of any controls, adjustments or procedures other than those specifi ed

herein may result in hazardous radiation exposure.

2.2

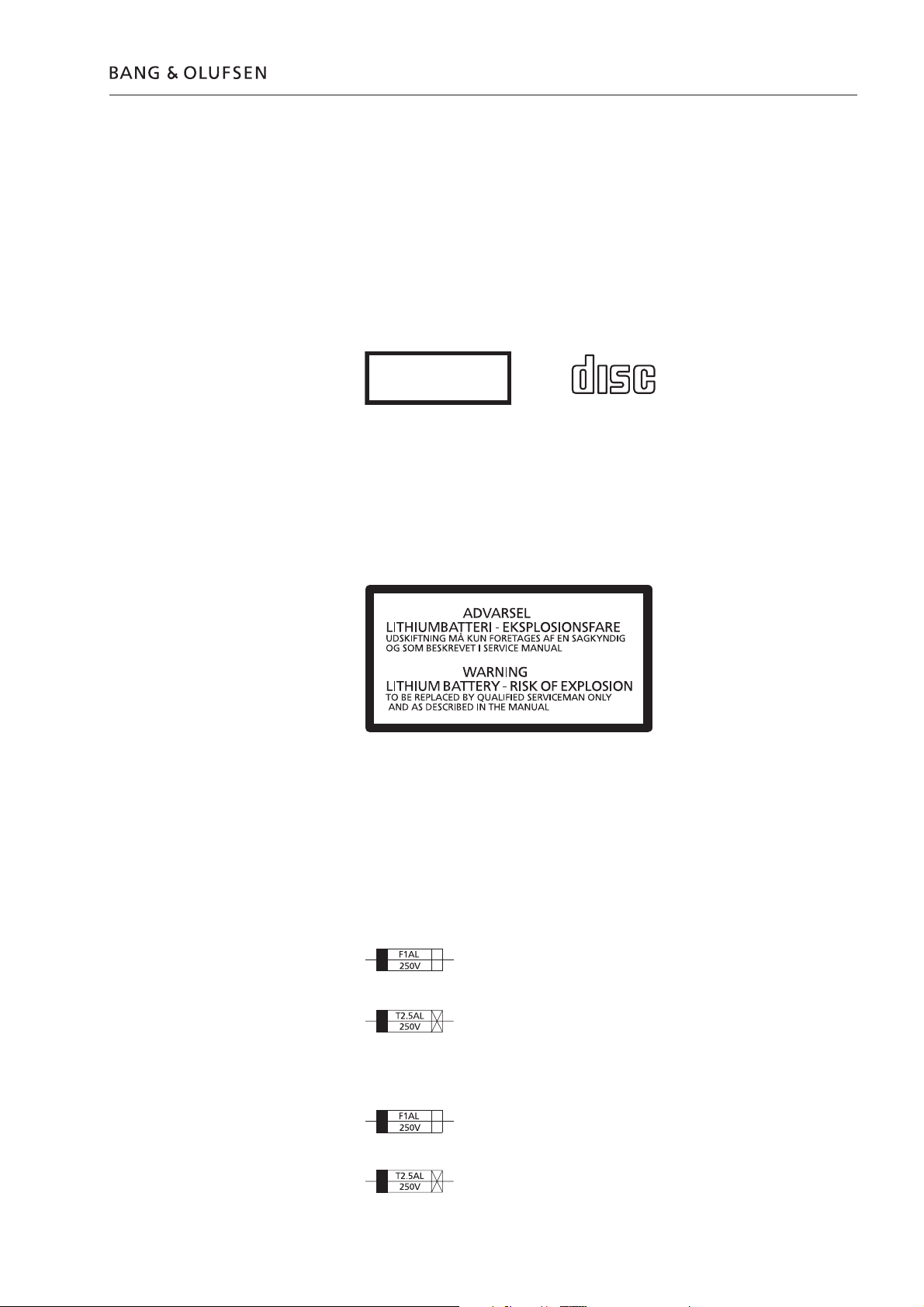

CD laserdiode

Lithium battery

CLASS 1

COMPACT

LASER PRODUCT

DIGITAL AUDIO

The black and yellow label on the compact disc player serves as a warning that the

apparatus contains a laser system and is classifi ed as a class 1 laser product. The

apparatus must be opend by qualifi ed servicemen only.

Wavelenght 780 nm ±20 nm, 30ºC

Effect 2 mW ±0.1 mW, 30ºC

WARNING

Short-circuit and overcharging of some types of lithium batteries may result in a

violent explosion.

When replacing the lithium battery in this set, note the following:

Use only batteries at the same make and type as mentioned in this service manual

(see page 3.1).

Place the battery exactly like the old one.

Explanation of the fuse symboles used in the set

Replace with the same type 1 ampere 250 volts quick acting fuse.

Replace with the same type 2.5 ampere 250 volts slow acting fuse.

Explanation des symboles de fusible utilisés dans l’appareil

Remplacer par un fusible rapide de même type et de 1 ampères 250 volts.

Remplacer par un fusible retardè de même type et de 2.5 ampères 250 volts.

Page 11

Wiring diagram

2.4 Wiring diagramWiring diagram 2.4

2.4

Page 12

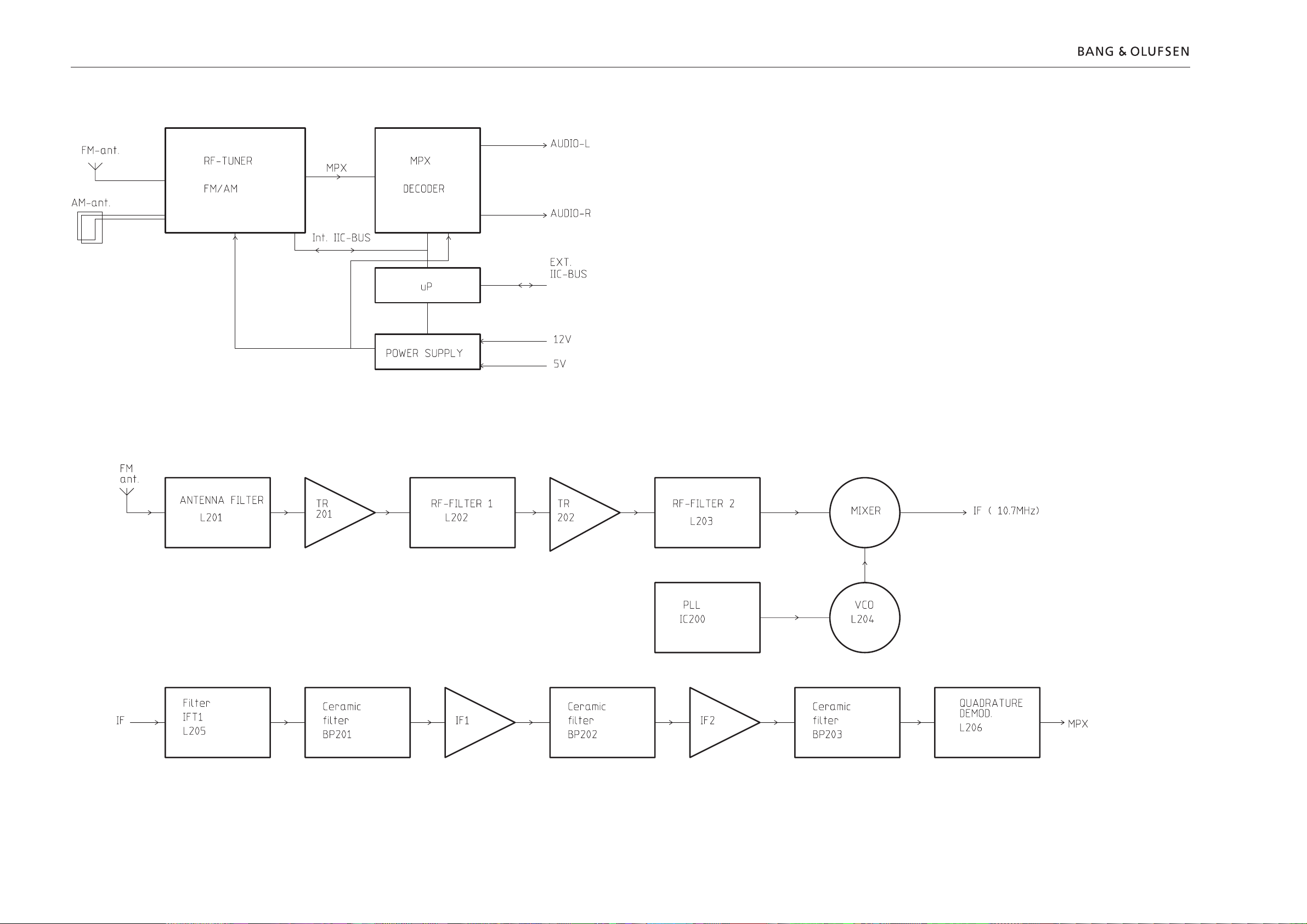

2.5

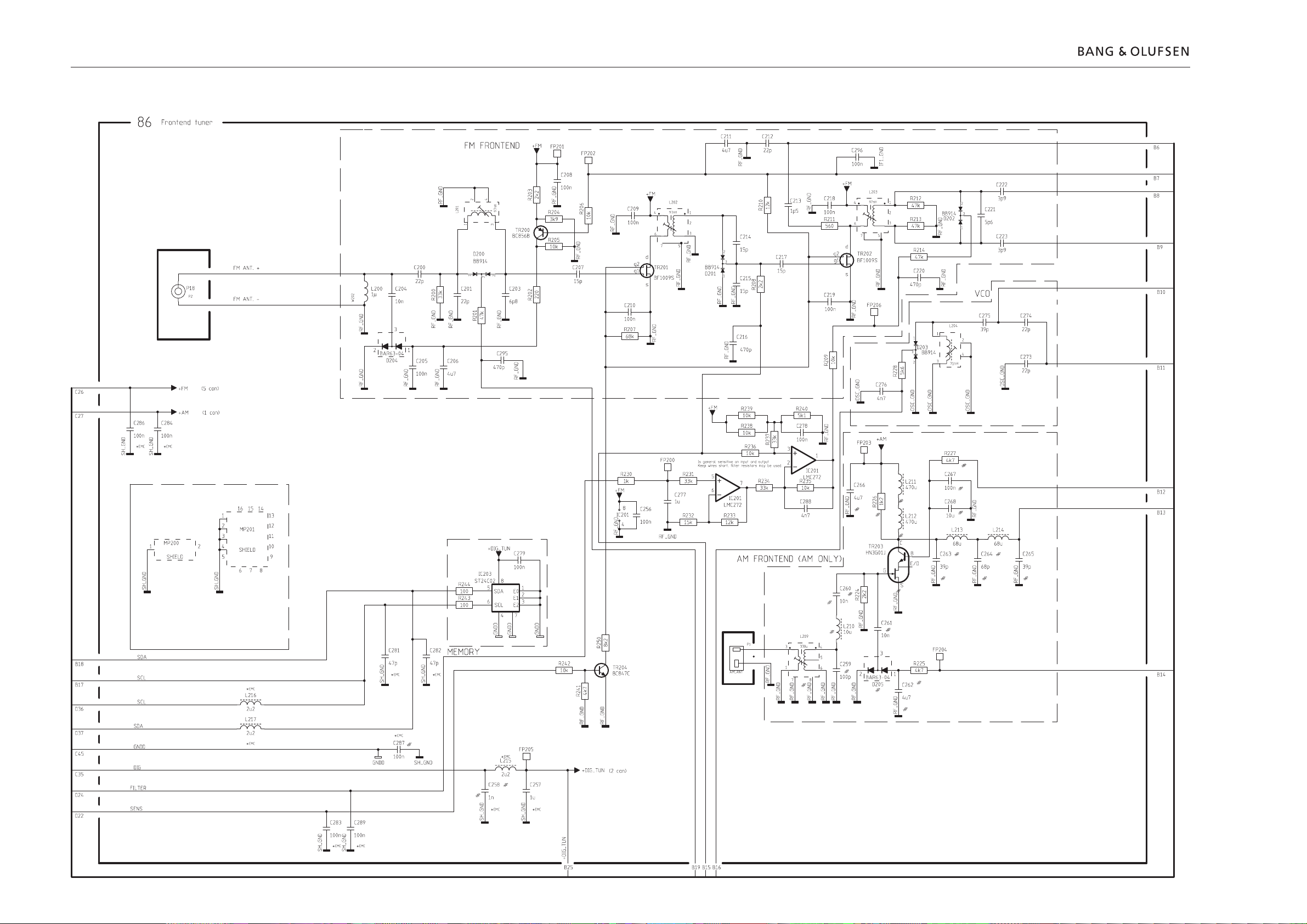

Block diagram for frontend tuner

2.5 Block diagramBlock diagram 2.5

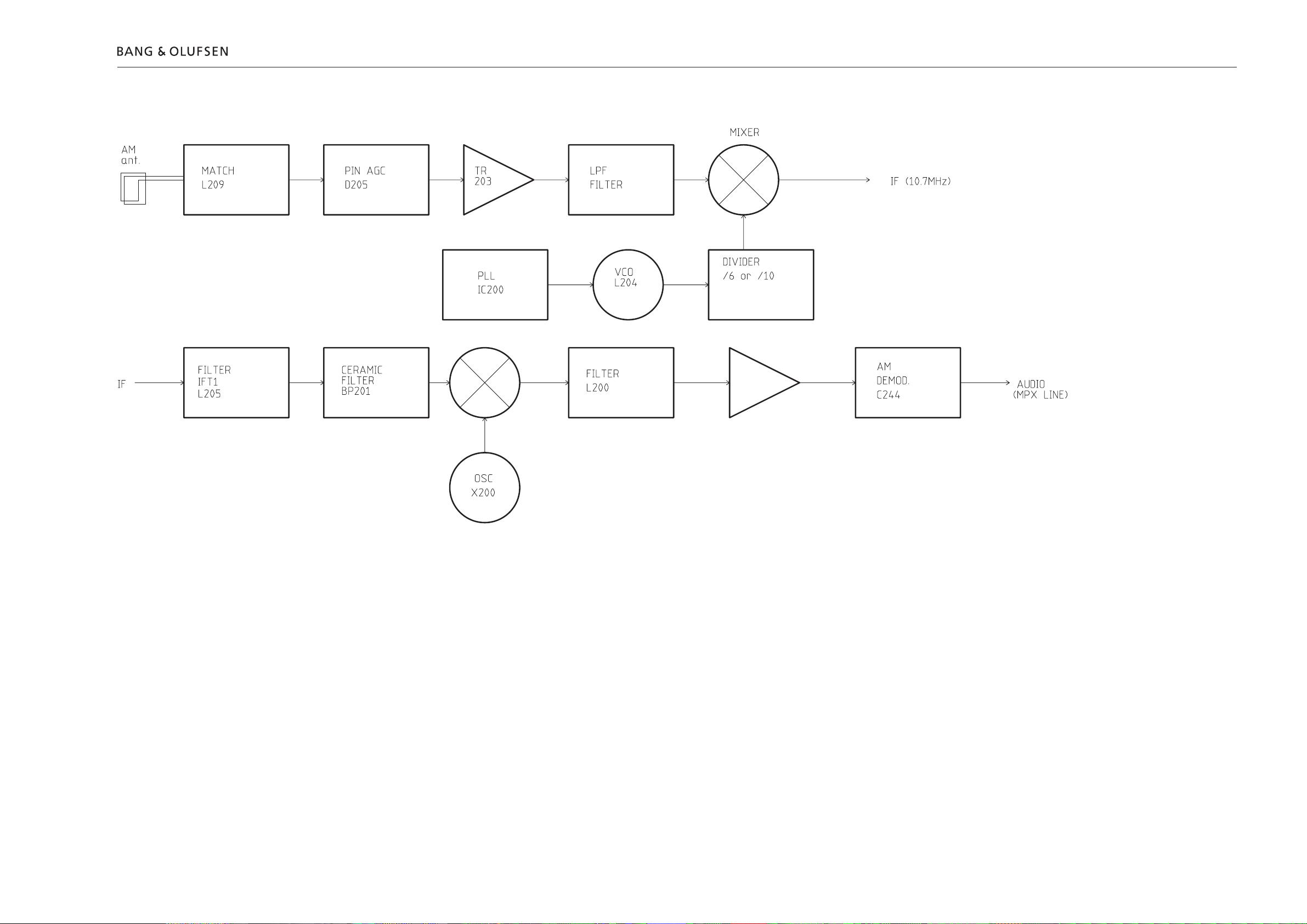

Page 13

AM block diagram

2.6 Block diagramBlock diagram 2.6

2.6

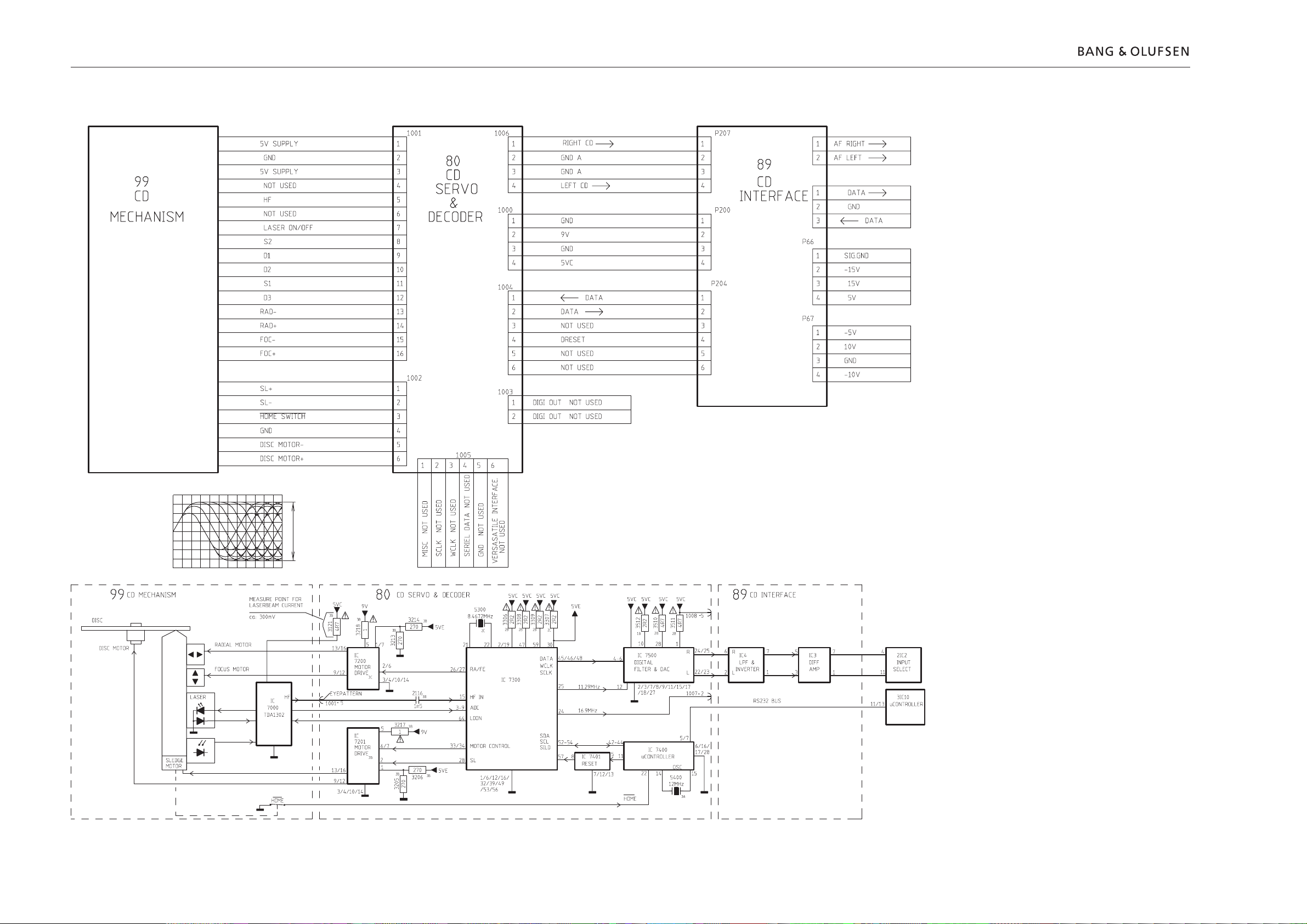

Page 14

2.7

Block diagram for CD PRO

2.7 Block diagramBlock diagram 2.7

EYEPATTERN

2.5V

0.5µs/DIV

1.3V

Page 15

Block diagram for system key controle

2.8 Block diagramBlock diagram 2.8 2.8

Page 16

2.9

Diagram A – Frontend tuner PCB drawing for PCB86 see page 2.13

2.9 Diagram ADiagram A 2.9

Page 17

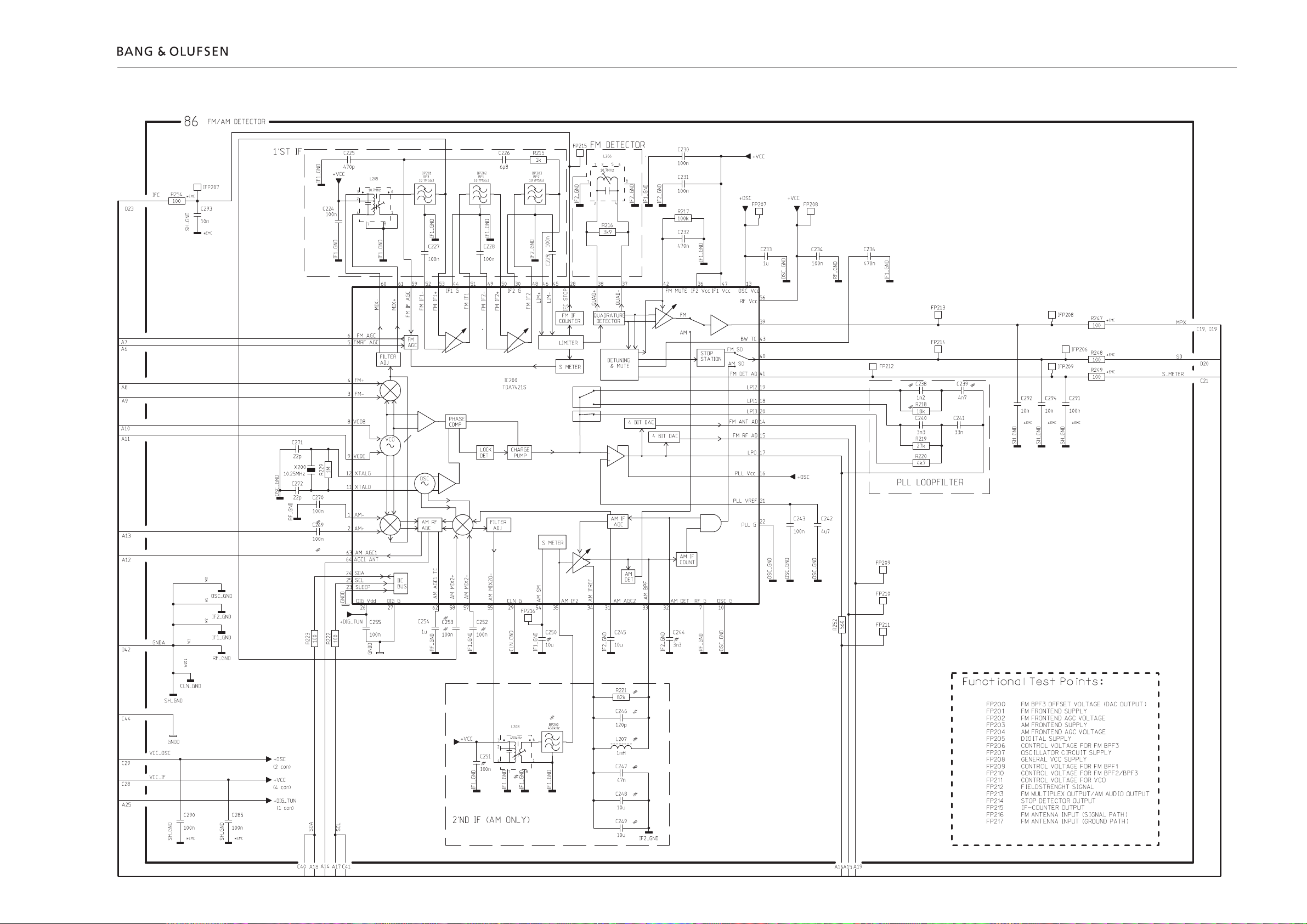

Diagram B – FM/AM Detector PCB drawing for PCB86 see page 2.13

2.10 Diagram BDiagram B 2.10

2.10

Page 18

2.11

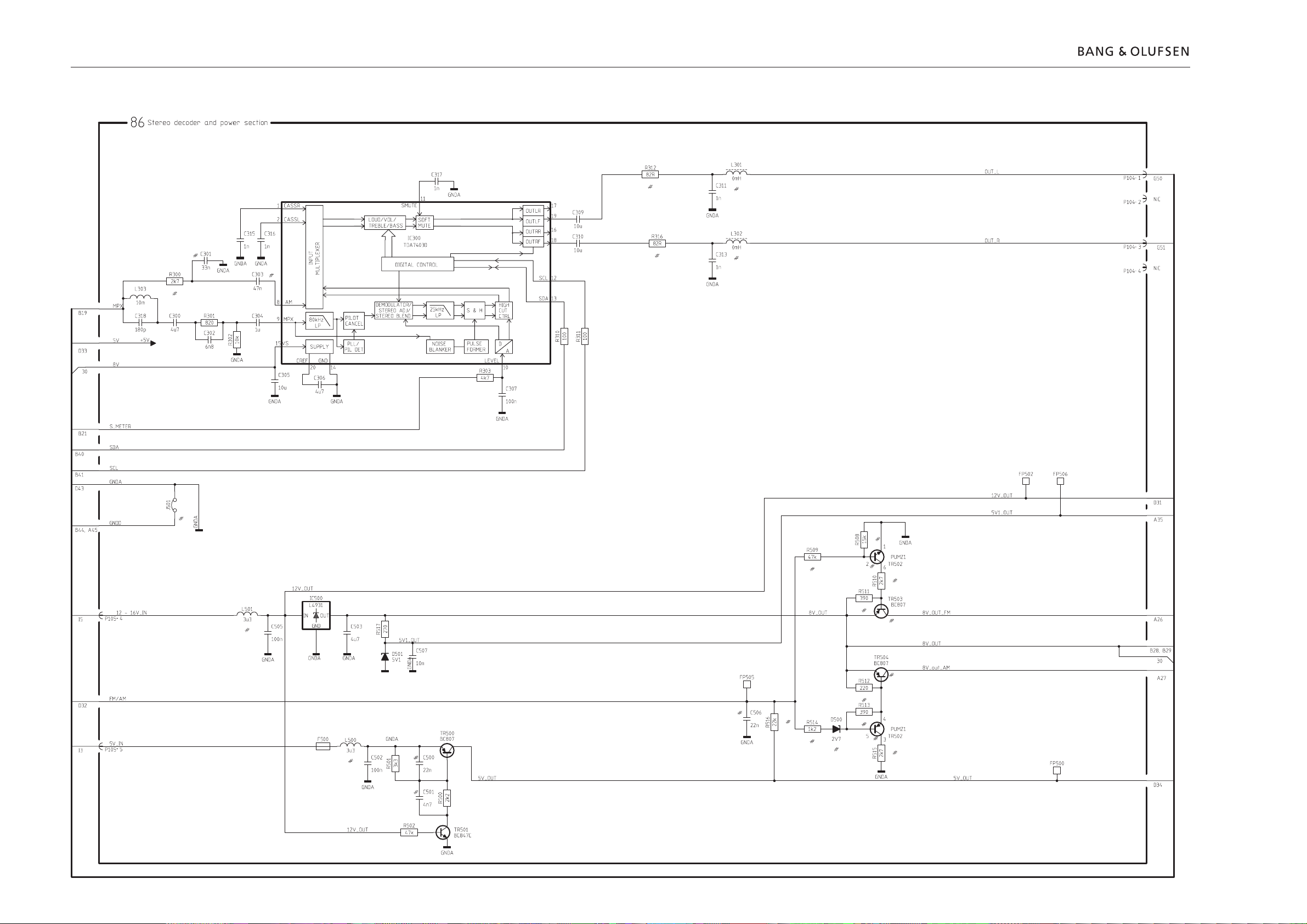

Diagram C – Stereo decoder and power section PCB drawing for PCB86 see page 2.13

2.11 Diagram CDiagram C 2.11

Page 19

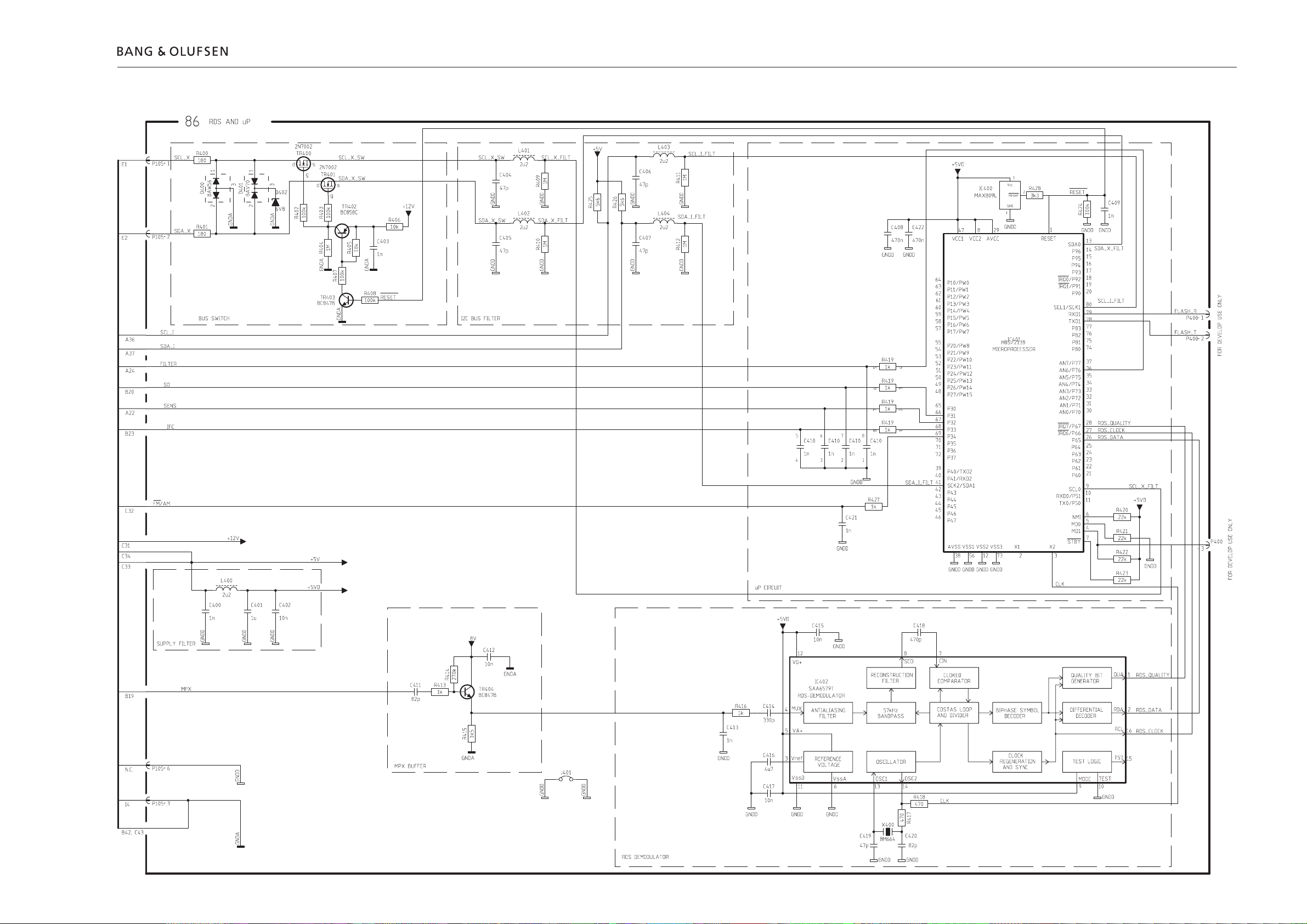

Diagram D – RDS, µP & IIC bus fi lter PCB drawing for PCB86 see page 2.13

2.12 Diagram DDiagram D 2.12

2.12

Page 20

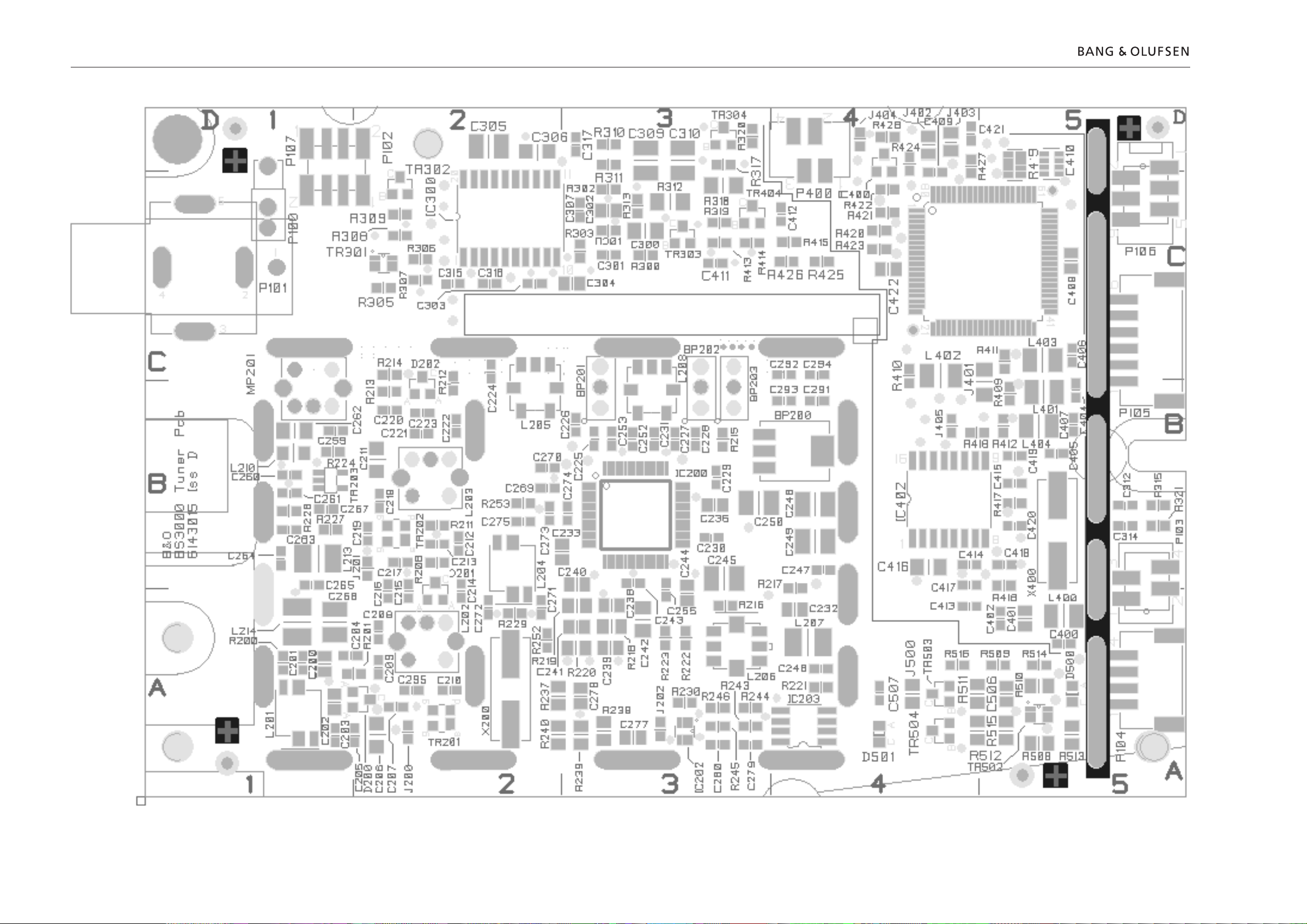

PCB86, Tuner-FM/AM-RDS-Stereo decoder

2.13 PCB drawingPCB drawing 2.132.13

Page 21

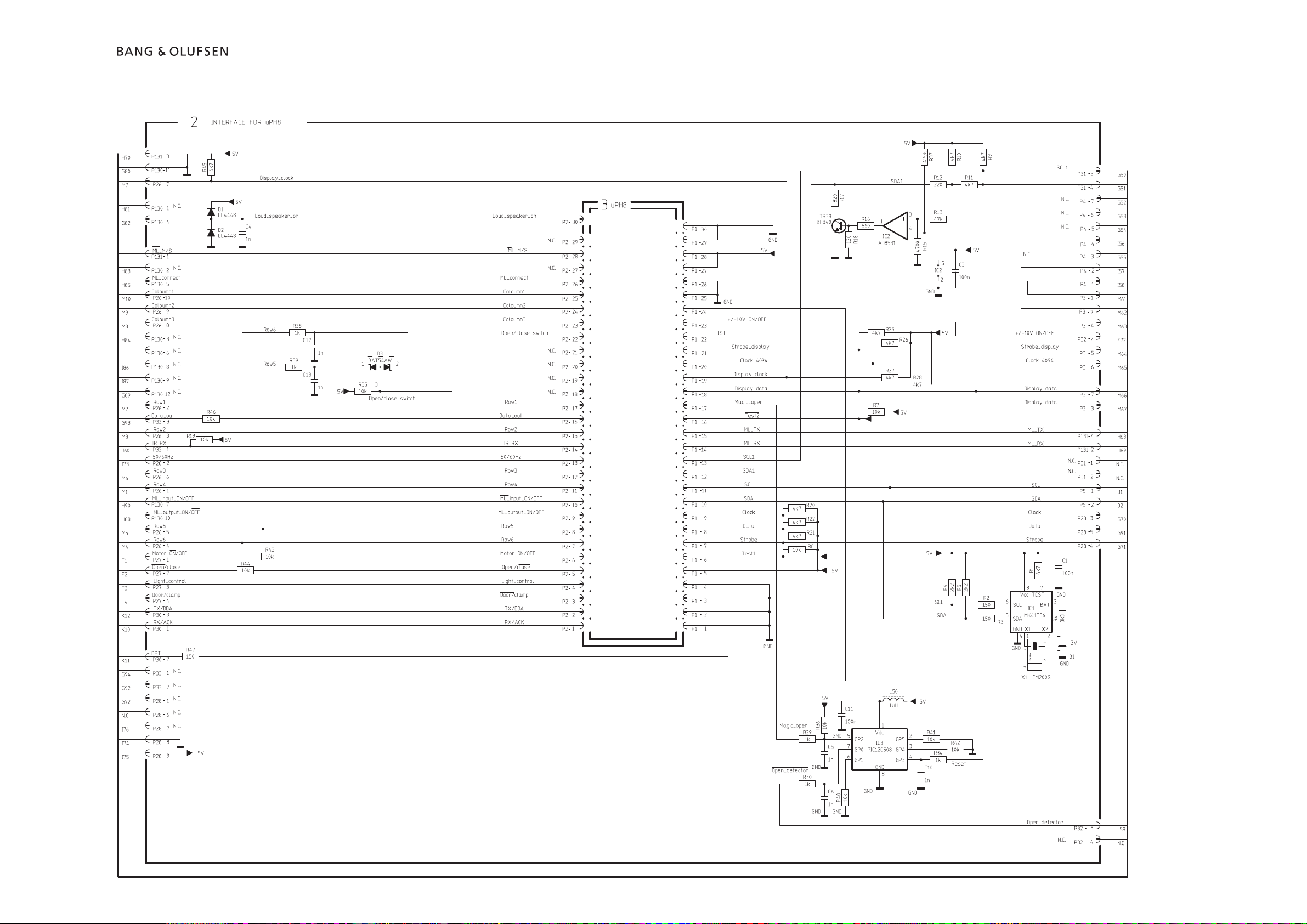

Diagram E – Interface for µP & µPH8 PCB drawing for PCB2 see page 2.16

2.14 Diagram EDiagram E 2.14

2.14

Page 22

2.15

Diagram F – Light and Motor control, Light supply & IR PCB drawing for PCB9 see page 2.16

2.15 Diagram FDiagram F 2.15

Page 23

PCB9, Light and motor control

PCB2, Interface f/µPH8

2.16 PCB drawingPCB drawing 2.16 2.16

Page 24

2.17

Diagram G – Input select PCB drawings for PCB12 see page 2.20

2.17 Diagram GDiagram G 2.17

Page 25

Diagram H – Master Link Interface PCB drawings for PCB12 see page 2.20

2.18 Diagram HDiagram H 2.18

2.18

Page 26

2.19

Diagram I – Power Supply & Transformer PCB drawings for PCB12 see page 2.20 PCB drawing for PCB15 see page 2.22

2.19 Diagram IDiagram I 2.19

Page 27

PCB12, Power Supply, Input select & Pre-amplifi er

2.20 PCB drawingsPCB drawings 2.20 2.20

Page 28

2.21

Diagram J – Door sensor PCB drawings for PCB20 & PCB21 see page 2.22

2.21 Diagram JDiagram J 2.21

Page 29

PCB20, IR receiver and left door sensor

2.22 PCB drawingsPCB drawings 2.22 2.22

PCB21, Door sensor right MKII

PCB15, Transformer

Page 30

2.23

2.23 Diagram KDiagram K 2.23

Diagram K – CD Interface

PCB5, Display

Page 31

Diagram L – CD Servo & Decoder

EYEPATTERN

2.24 Diagram LDiagram L 2.24

2.24

2.5V

0.5µs/DIV

1.3V

Page 32

2.25

Diagram M – Display & Keyboard PCB drawing for PCB5 see page 2.23

2.25 Diagram MDiagram M 2.25

Page 33

List of electrical parts

List of electrical parts 3.1

Resistors not referred to are standard, see page 3-9

PCB2, 8006796 Interface f/µPH8

PCB3, 8006797 µPH8 Microcomputer

IC1∆ 8342397 149 Memory/clock

M141T56M6

TR38* 8320740 51 BF 840

D1- 8300606 250 LL 4448

D2

D3 8301120 69 BAT 54AW

C1 4011135 100nF -20+80% 16V

C3 4010274 100nF -20+80% 25V

C4- 4010237 1nF 10% 50V

C6

L50 8021301 Coil 1µH 20%

X1 8090230 Crystal 32.768KHz

B1 8700027 Battery lithium 3V

P1- 7221357 Socket 30 pole

P2

P3- 7221378 Socket 7 pole

P4

P5 7221272 Plug 2 pole

P26 7221359 Plug 10 pole

P27 7221329 Plug 4 pole

IC2∆ 8343699 169 AD 8531

IC3∆ 8343682 151 PIC 12C508

C10 4010237 1nF 10% 50V

C11 4010316 100nF 10% 25V

C12- 4010237 1nF 10% 50V

C13

P28 7221356 Plug 9 pole

P30 7221330 Plug 3 pole

P31- 7221329 Plug 4 pole

P32

P33 7221330 Plug 3 pole

P130 7221361 Plug 12 pole

P131 7221329 Plug 4 pole

PCB5, 8001362 Display

∆ indicates that static electricity may destroy

the component

* specially selected or adapted sample

IC1∆ 8341025 150 4094B

IC2∆ 8343771 147 SN74ALS156

IC3∆ 8341079 151 µPD 7228

TR1- 8320755 51 BC 847B

TR6

TR8 8320755 51 BC 847B

TR13- 8320753 51 BC 856B

TR16

D1- 8300482 250 LL 4148

D2

DP1 8330259 Display, lower

DP2 8330468 Display, upper

R14- 5011912 1.2KΩ 1% 1/8W

R15

R18- 5011912 1.2KΩ 1% 1/8W

R19

R29 5011914 5.1KΩ 1% 1/8W

IC4∆ 8341226 150 4001B gate 4x2

input

TR17- 8320936 51 BC 847C

TR20

TR24 8320811 51 BC 857B

TR25 8320955 57 PMBF 4393

TR26 8320811 51 BC 857B

D3 8300577 250 Z3.9V 2% 0.5W

D4 8300661 250 Z4.3V 2% 0.5W

R39 5210006 LDR 3.3KΩ 33%

R40 5011912 1.2KΩ 1% 1/8W

R49 5012069 2KΩ 1% 1/8W

R56 5370435 1KΩ

R78 5370400 10KΩ

Page 34

3.2 List of electrical parts

Resistors not referred to are standard, see page 3-9

PCB9, 8001550 Light and motor control

C1- 4010166 100nF -20+80% 50V

C2

C4- 4010166 100nF -20+80% 50V

C5

C6 4000241 100pF 5% 50V

C8 4000241 100pF 5% 50V

X1 8030221 Crystal 455KHz

P41 7220714 Plug 7 pole

P42 7220717 Plug 10 pole

P43 7220710 Plug 3 pole

IC1∆- 8341420 136 TCA0372

IC2∆

TR1- 8320755 51 BC 847B

TR2

TR3- 8320811 51 BC 857B

TR7

TR8- 8320755 51 BC 847B

TR11

TR13 8320755 51 BC 847B

D1- 8300482 250 LL 4148

D2

D4 8300774 250 Z5.1V 5% 0.5W

D5- 8300482 250 LL 4148

D8

D9 8300723 250 Z8.2V 2% 0.5W

C9- 4010170 2.2nF 10% 50V

C12

C13- 4000241 100pF 5% 50V

C19

C20 4010157 10nF 10% 50V

C21 4200517 2.2µF 20% 50V

P44 7210853 Socket 13 pole

P45 7220710 Plug 3 pole

P46 7220724 Plug 2 pole

IC3∆ 8341041 138 LM 324

TR14 8320425 32 BD 436

TR21 8320507 18 BC 337-25

TR22 8320497 18 BC 547B

TR23 8320811 51 BC 857B

TR24 8320755 51 BC 847B

TR25 8320811 51 BC 857B

TR30 8320811 51 BC 857B

D10 8300577 250 Z3.9V 2% 0.5W

D14 8300772 250 Z24V 5% 0.4W

D16- 8300482 250 LL 4148

D19

D24 8300482 250 LL 4148

∆ indicates that static electricity may destroy

the component

R27 5010064 2.2KΩ 5% 1/4W

R28 5010069 3.9KΩ 5% 1/4W

R29 5010700 3.9KΩ 5% 1/2W

R31 5011378 0.82Ω 5% 1/4W

R32 5011845 8.2Ω1% 1/4W

R33 5011834 845Ω 1% 1/8W

R35 5011845 8.2Ω 1% 1/4W

R37 5011834 845Ω 1% 1/8W

R38 5011527 12KΩ 1% 1/8W

R39 5011752 12.7KΩ 1% 1/8W

R40 5011527 12KΩ 1% 1/8W

R41 5011752 12.7KΩ 1% 1/8W

R42 5021151 1.5Ω 1% 1/4W

R43 5011834 845Ω 1% 1/8W

R45 5021151 1.5Ω 1% 1/4W

C1 4010220 100nF 10% 50V

C3 4010220 100nF 10% 50V

C4 4200524 10µF 20% 25V

C5- 4000287 220nF -20+80% 25V

C6

C7 4200515 4.7µF 20% 25V

C11 4010157 10nF 10%

R47 5011854 2.1KΩ 1% 1/4W

R48 5011598 24.9KΩ 1% 1/8W

R49 5011838 18KΩ 1% 1/8W

R50 5011760 23.7KΩ 1% 1/8W

R67 5011601 200KΩ 1% 1/8W

R68 5011600 100KΩ 1% 1/8W

R69- 5011601 200KΩ 1% 1/8W

R71

R74- 5011595 26.7KΩ 1% 1/8W

R75

R78 5011600 100KΩ 1% 1/8W

R82- 5011598 24.9KΩ 1% 1/8W

R83

R101 5011600 100KΩ 1% 1/8W

C12 4010166 100nF -20+80% 50V

C13 4200524 10µF 20% 25V

C14- 4010157 10nF 10%

C16

Page 35

List of electrical parts 3.3

PCB12, 8001833 Power Supply, Input

select & Pre-amplifi er

P76 7220714 Plug 7 pole

P77 7220711 Plug 4 pole

P78- 7220709 Plug 2 pole

P80

IC1∆ 8341025 151 4094B

IC2∆ 8341059 151 4052

IC3∆ 8341025 151 4094B

IC4∆ 8342238 151 TDA 7318D

IC5∆ 8341225 151 LM 3578

TR1 8320427 32 BD 437

TR2- 8320428 32 BD 438

TR4

TR5 8320443 32 BD 442

TR6- 8320755 51 BC 847B

TR7

TR8- 8320512 18 BC 337-25

TR9

TR10- 8320523 17 BC 327-25

TR12

TR13 8320753 51 BC 856

TR14 8320755 51 BC 847B

TR15- 8320811 51 BC 857B

TR16

TR17- 8320755 51 BC 847B

TR19

TR20- 8320816 51 BC 846B

TR21

TR22 8320811 51 BC 857B

TR23 8320755 51 BC 847B

TR24 8320753 51 BC 856B

TR25- 8320755 51 BC 847B

TR33

P81 7220710 Plug 3 pole

IC6∆ 8341231 151 LF 347

IC7∆ 8341022 151 4558

IC8∆ 8340205 151 LF 347-TL074

IC10∆ 8341022 151 4558

IC11∆ 8341747 151 TL 7705BCD

TR34 8320936 51 BC 847C

TR35- 8320755 51 BC 847B

TR41

TR42- 8320811 51 BC 857B

TR45

TR46- 8320755 51 BC 847B

TR47

TR48- 8320759 51 BC 817-25B

TR49

TR50- 8320811 51 BC 857B

TR53

TR54- 8320856 54 2N7002

TR55

TR56 8320899 54 BSS 84P-50V

TR57- 8320811 51 BC 857B

TR59

TR60- 8321080 51 FMMT 491ATA

TR63

TR64 8320811 51 BC 857B

TR65 8320941 51 2SC 4213

TR66 8320753 51 BC 856B

TR67 8320755 51 BC 847B

TR68 8320941 51 2SC 4213

D1- 8300907 250 GF 1B

D2

D3- 8300520 250 Z6.8V 5% 0.5W

D6

D7- 8300562 250 Z5.6V 2% 0.5W

D8

D9- 8300605 250 Z10.0V 5% 0.5W

D10

D11- 8300606 250 LL 4448

D23

D24 8300562 250 Z5.6V 2% 0.5W

D25- 8300606 250 LL 4448

D34

D35 8301045 250 BAS 216

D36 8300607 250 Z3.3V 5% 0.4W

D37- 8300606 250 LL 4448

D40

R4 5011557 10KΩ 1% 1/8W

R8 5011332 10MΩ 10% 1/8W

R9 5011557 10KΩ 1% 1/8W

R10 5011792 4.75KΩ 1% 1/8W

R11- 5011599 49.9KΩ 1% 1/8W

R12

R13- 5011632 1.5KΩ 1% 1/4W

R16

R17- 5011912 1.2KΩ 1% 1/8W

R18

R19- 5011914 5.1KΩ 1% 1/8W

R21

D41 8300914 250 SS 14

D42- 8300644 250 Z6.2V 2% 0.5W

D43

D44 8300645 250 Z3.3V 2% 0.5W

D45 8300677 250 Z4.7V 5% 0.5W

D46- 8300723 250 Z8.2V 2% 0.5W

D47

D48- 8300726 250 Z7.5V 2% 0.5W

D49

D50 8300762 250 Z9.1V 2% 0.5W

D51 8300914 250 SS 14

D52 8300482 250 LL 4148

D55- 8300606 250 LL 4448

D56

R74 5011903 180Ω 1% 1/4W

R263 5011982 698Ω 1% 1/8W

R264 5011871 365Ω 1% 1/8W

R265 5011984 5.62KΩ 1% 1/8W

R266 5011987 28.7KΩ 1% 1/8W

R267 5011988 22KΩ 1% 1/8W

R268 5012057 6.8KΩ 1% 1/8W

R269 5012317 46.4KΩ 1% 1/10W

R271- 5012331 10KΩ 1% 1/10W

R272

R273 5012350 27.4KΩ 1% 1/10W

R274 5021542 0.22Ω 5% 1/4W

∆ indicates that static electricity may destroy

the component

C1- 4000233 220pF 5% 50V

C4

C5 4000277 22pF 5% 50V

C6 4000351 1.5nF 5% 50V

C7 4000412 100pF 5% 50V

C8 4000381 820pF 5% 50V

C9- 4000408 47pF 5% 50V

C14

C15- 4000412 100pF 5% 50V

C16

Page 36

3.4 List of electrical parts

Resistors not referred to are standard, see page 3-9

C17 4000418 330pF 5% 50V

C18- 4000416 220pF 5% 50V

C24

C25 4000418 330pF 5% 50V

C26 4000420 470pF 5% 50V

C27- 4000457 1.5nF 5% 50V

C28

C29 4000420 470pF 5% 50V

C30- 4000461 1nF 5% 50V

C33

C34 4010132 1nF 10% 50V

C35 4010209 47nF 10% 50V

C36 4000461 1nF 5% 50V

C37 4010132 1nF 10% 50V

C38 4010176 10nF -20+80% 50V

C39 4010237 1nF 10% 50V

C40- 4010262 1.8nF 10% 50V

C41

C42- 4010269 6.8nF 10% 50V

C43

C44- 4010271 10nF 10% 50V

C45

C48- 4010237 1nF 10% 50V

C50

C51 4010263 2.2nF 10% 50V

C52- 4010271 10nF 10% 50V

C56

C59- 4010271 10nF 10% 50V

C65

C66- 4010274 100nF -20+80% 25V

C67

C68 4010334 220nF 10% 16V

C69 4010271 10nF 10% 50V

C70- 4010316 100nF 10% 25V

C71

C72 4010316 100nF 10% 25V

C73- 4130307 150nF 10% 63V

C76

C77 4201256 470µF 20% 25V

C78 4010271 10nF 10% 50V

C79 4200824 22µF 20% 50V

C80- 4010271 10nF 10% 50V

C81

C82- 4010272 22nF -20+80% 50V

C84

C85 4010274 100nF -20+80% 25V

C86 4010314 220nF -20+80% 25V

C87- 4201174 2.2µF 20% 50V

C88

C89 4201301 220µF -20+50% 16V

C90 4200824 22µF 20% 50V

C91- 4201173 10µF 20% 50V

C95

C96 4200824 22µF 20% 50V

C97 4201537 1000µF 20% 35V

C98- 4201173 10µF 20% 50V

C99

C100- 4201173 10µF 20% 50V

C106

C107 4201474 330µF 20% 63V

C108- 4201171 1µF 20% 50V

C109

C110 4201173 10µF 20% 50V

C111- 4201170 0.47µF 20% 50V

C112

C113- 4201173 10µF 20% 50V

C121

C122- 4201174 2.2µF 20% 50V

C123

C124 4000287 220nF -20+80% 25V

C125 4010272 22nF -20+80% 50V

C126- 4010274 100nF -20+80% 25V

C127

C128 4200961 220µF 20% 10V

C129- 4010237 1nF 10% 50V

C133

C134 4000290 22nF 10% 50V

L1 8021274 Coil 330µH 10%

L2- 8020821 Coil 2.2µH 5%

L3

F1 6604038 Fuse 1AF 250V

P1 7210418 Socket 7 pole DIN

P2- 7210689 Socket 8 pole DIN

P3

P4 7210904 Socket 16 pole

ML-socket

P11- 7220711 Plug 4 pole

P13

P14- 7220709 Plug 2 pole

P15

P16 7220712 Plug 5 pole

P17 7220714 Plug 7 pole

P18 7220710 Plug 3 pole

L4- 8021003 Coil 100µH 5%

L7

P19 7220712 Plug 5 pole

P20 7220716 Plug 9 pole

P21 7220709 Plug 2 pole

P22 7220711 Plug 4 pole

P23 7220710 Plug 3 pole

P25 7220711 Plug 4 pole

P100 7211195 Socket 10 pole

P103- 7220711 Plug 4 pole

P104

P105 7211186 Socket 8 pole

P107 7220711 Plug 4 pole

P108 7220719 Plug 12 pole

Page 37

List of electrical parts 3.5

PCB14, 8001771 Master Link Audio interface

PCB15, 8001834 Transformer EU

IC1∆- 8341022 138 4558

IC7∆

TR3 8320811 51 BC 857B

TR4- 8320755 51 BC 847B

TR5

R2 5011841 11.8KΩ 1% 1/8W

R4 5011841 11.8KΩ 1% 1/8W

R5- 5011531 5.9KΩ 1% 1/8W

R6

R8 5011841 11.8KΩ 1% 1/8W

R10 5011841 11.8KΩ 1% 1/8W

R11- 5011531 5.9KΩ 1% 1/8W

R12

C1- 4000277 22pF 5% 50V

C2

C3- 4000241 100pF 5% 50V

C4

C6- 4000241 100pF 5% 50V

C7

TR1 8320427 32 BD 437

TR2- 8320428 32 BD 438

TR4

D1- 8300023 209 1N 4002

D4

IC8- 8341024 150 4066

IC10

TR6 8320811 51 BC 857B

R14- 5011557 10KΩ 1% 1/8W

R15

R19- 5011557 10KΩ 1% 1/8W

R20

R23- 5011571 75Ω 1% 1/8W

R26

C11- 4010166 100nF -20+80% 50V

C14

C100- 4000345 1nF 5% 50V

C101

D5- 8300907 250 DO-214BA

D14

PCB15, 8006798 Transformer US

R10 5020625 2.7Ω 5% 0.3W

C1- 4010166 100nF -20+80% 50V

C6

C7- 4010216 22nF 10% 100V

C9

C10 4201111 6800µF 20% 16V

C11 4201426 3300µF 20% 16V

L1 8022295 Coil 2 x 0.4mH

T1 8013501 Mains transformer 100V-120V-230V-240V

F1- 6600155 Fuse 1.6 AT 250V

F4

F5 6600067 Fuse 2.5 AT 250V

P24 7220715 Plug 8 pole

7219087 Mains socket

R1 5000194 3.3Mohm 10% 1/2W

F1- 6600162 Fuse 1.6 AT 125V

F4

F5 6600081 Fuse 2.5 AT 125V

All other electrical parts see PCB15, Transformer EU

C12 4201425 6800µF 20% 16V

C13 4200821 1000µF -20+50% 6.3V

C14- 4201098 4700µF 20% 35V

C15

C16- 4010166 100nF -20+80% 50V

C19

PCB18, 8001817 Headphone

∆ indicates that static electricity may destroy

the component

Page 38

3.6 List of electrical parts

Resistors not referred to are standard, see page 3-9

PCB20, 8005738 IR receiver and left door sensor

IC1∆ 8341041 138 LM 324

TR1- 8320740 51 BF 840

TR2

TR3- 8320755 51 BC 847B

TR7

TR12- 8320755 51 BC 847B

TR16

D1 8300482 250 LL 4148

D3- 8300482 250 LL 4148

D6

R20 5011985 13.3KΩ 1% 1/8W

R28- 5012258 215KΩ 1% 1/8W

R30

R31 5012331 10KΩ 1% 1/10W

R53- 5012164 1MΩ 1% 1/8W

R56

R57 5012240 100KΩ 1% 1/10W

C1 4010257 15nF 10% 50V

C2- 4000408 47pF 5% 50V

C5

C6- 4000414 150pF 5% 50V

C13

C14- 4000420 470pF 5% 50V

C19

C20- 4010263 2.2nF 10% 50V

C21

C22- 4010271 10nF 10% 50V

C23

L1 8020562 Coil 455KHz

TR17 8320769 51 BC 849C

TR18- 8320811 51 BC 857B

TR21

TR22 8321072 19 ZTX 690B

TR23 8321073 19 ZTX 790A

D7- 8330145 244 Ir detector

D8

R66 5012467 13.3Ω 1% 1/10W

R67 5012466 22.1Ω 1% 1/10W

R68- 5020981 1.8Ω 10% 0.35W

R69

R70 5021047 10Ω 5% 0.14W

R71- 5012365 11KΩ 1% 1/10W

R73

C24 4010314 220nF -20+80% 25V

C25 4010195 2.7nF 5% 50V

C26- 4010316 100nF 10% 25V

C29

C30 4130313 470nF 20% 63V

C32 4200510 10µF 20% 16V

C33 4010316 100nF 10% 25V

C34 4200510 10µF 20% 16V

C35 4010316 100nF 10% 25V

C217 4200510 10µF 20% 16V

C219 4200961 220µF 20% 10V

PCB21, 8006799 Door sensor right

symbol of safety components, see page 2.1

∆ indicates that static electricity may destroy

the component

BP1 8030056 Cer. fi lter 455KHz

P46 7220726 Plug 4 pole

P47 7220725 Plug 3 pole

P49 7220725 Plug 3 pole

P50 7220728 Plug 6 pole

IC1∆ 8341041 138 LM 324

TR3 8320755 51 BC 847B

TR7 8320755 51 BC 847B

TR32 8320755 51 BC 847B

R2 5011632 1.5KΩ 1% 1/4W

R5 5012240 100KΩ 1% 1/10W

R6 5012331 10KΩ 1% 1/10W

R10 5012164 1MΩ 1% 1/8W

R12 5012258 215KΩ 1% 1/8W

R15 5012164 1MΩ 1% 1/8W

R17 5012258 215KΩ 1% 1/8W

R20 5012164 1MΩ 1% 1/8W

P83 7220693 Contact pin 2 pole

P132 7220730 Plug 8 pole

P133 7220729 Plug 7 pole

P250 7220727 Plug 5 pole

TR36- 8320755 51 BC 847B

TR37

TR47 8320811 51 BC 847B

R22 5012258 215KΩ 1% 1/8W

R25 5012164 1MΩ 1% 1/8W

R38 5012466 22.1Ω 1% 1/10W

R39 5012467 13.3Ω 1% 1/10W

R53 5021047 10Ω 5% 0.14W

R65- 5012365 11KΩ 1% 1/10W

R67

Page 39

List of electrical parts 3.7

PCB28, 3358279 Light supply

PCB86, 8006800 Tuner-FM/AM-RDSStereo decoder EU/US

C2 4010316 100nF 10% 25V

C4 4010263 2.2nF 10% 50V

C8- 4000414 150pF 5% 50V

C9

C13- 4000414 150pF 5% 50V

C14

C18 4000414 150pF 5% 50V

C19 4000229 150pF 5% 50V

C23- 4000414 150pF 5% 50V

C24

P1 7220710 Plug 3 pole

P2 7220728 Plug 6 pole

P3 7220727 Plug 5 pole

TR1 8320425 32 BD 436

D1- 8300557 250 BYM10

D4

C1- 4000345 1nF 5% 50V

C3

IC200∆ 8343626 147 TDA 7421S

IC201∆ 8343652 151 LMC 272

IC203∆ 8342519 151 EEPROM

M24C02-MN6T

Advanced adjustments procedure when

replacing this component. Replacement of

PCB86 is recommended 8006800.

C27 4010157 10nF 10% 50V

C30 4010271 10nF 10% 50V

C33 4200826 10µF 20% 16V

C49 4010195 2.7nF 5% 50V

C52 4200961 220µF 20% 10V

C57- 4010316 100nF 10% 25V

C58

C59 4200510 10µF 20% 16V

C60 4010316 100nF 10% 25V

IC300∆ 8343681 136 TDA 7403

IC400∆ 8343809 170 MAX 809L

IC401∆ 8343673 147 µP H8S/2138

IC402∆ 8342568 136 SAA 6579T

IC500∆ 8343733 168 L 4931

TR200 8320753 51 BC 856B

TR201- 8321276 53 Mosfet 9V 1GHz

TR202

TR203 8321277 169 HN 3G01J

TR204 8320936 51 BC 847C

TR301 8321198 136 PUM X1

TR302 8320778 51 BC 857

TR303- 8321080 51 FMMT 491ATA

TR304

TR400- 8320856 68 2N 7002

TR401

D200- 8301140 252 BB 914

D203

D204- 8301143 267 BAR 63-04

D205

D400 8300894 69 BAW 56

R208 5013156 2.2KΩ 1% 1/16W

R209 5012331 10KΩ 1% 1/10W

R216 5013244 3.9KΩ 1% 1/16W

R226 5013152 1.2KΩ 5% 1/16W

R231 5012238 33KΩ 1% 1/10W

R234 5012238 33KΩ 1% 1/10W

R235- 5012331 10KΩ 1% 1/10W

R236

R237 5012238 33KΩ 1% 1/10W

R238- 5012331 10KΩ 1% 1/10W

R239

R240 5012559 5.1KΩ 1% 1/10W

TR402 8320778 51 BC 857

TR403- 8320755 51 BC 847B

TR404

TR500 8320971 51 BC 807-40

TR501 8320936 51 BC 847C

TR502 8321196 136 PUM Z1

TR503- 8320971 51 BC 807-40

TR504

D401 8300895 252 BAV 70

D402 8300520 250 Z6.8V 5% 0.5W

D500 8301056 250 Z2.7V 2% 0.4W

D501 8301064 250 Z5.1V 2% 0.4W

R300 5013242 2.7KΩ 1% 1/16W

R301 5013236 820Ω 1% 1/16W

R400- 5011903 180Ω 1% 1/4W

R401

R415 5013239 1.5KΩ 1% 1/16W

R419 5030051 4 x 1KΩ 5% 1/16W

R425- 5013246 5.6KΩ 1% 1/16W

R426

R428 5013243 3.3KΩ 1% 1/16W

R514 5013238 1.2KΩ 1% 1/16W

R517 5021532 270Ω 1% 1/4W

∆ indicates that static electricity may destroy

the component

C200 4000404 22pF 5% 50V

C201 4001127 22pF 5% 50V

C203 4001121 6.8pF 50V

C204 4011122 10nF 10% 50V

C205 4011134 100nF 10% 16V

C206 4010419 4.7µF 10% 10V

C207 4001125 15pF 5% 50V

C208 4011134 100nF 10% 16V

C209- 4011135 100nF -20+80% 16V

C210

C211 4010434 4.7µF

C212 4000404 22pF 5% 50V

C213 4001118 3.9pF 5% 50V

C214- 4001125 15pF 5% 50V

C215

C216 4001143 470pF 5% 50V

Page 40

3.8 List of electrical parts

Resistors not referred to are standard, see page 3-9

C217 4001125 15pF 5% 50V

C218- 4011135 100nF -20+80% 16V

C219

C220 4001143 470pF 5% 50V

C221 4001120 5.6pF 5% 50V

C222- 4001118 3.9pF 5% 50V

C223

C224 4011135 100nF -20+80% 16V

C225 4001143 470pF 5% 50V

C226 4001121 6.8pF 50V

C227- 4011134 100nF 10% 16V

C231

C232 4010387 470nF 10% 16V

C233 4010323 1µF -20+80% 16V

C234 4010274 100nF -20+80% 25V

C236 4010387 470nF 10% 16V

C238 4000493 1.2nF 10% 50V

C239 4000494 4.7nF 10% 50V

C240 4000495 3.3nF 10% 50V

C241 4000496 33nF 10% 50V

C242 4010419 4.7µF 10% 10V

C243 4011134 100nF 10% 16V

C244 4000495 3.3nF 10% 50V

C245 4010420 10µF 10% 10V

C246 4001136 120pF 5% 50V

C247 4011130 47nF 10% 16V

C248- 4010420 10µF 10% 10V

C250

C251 4010316 100nF 10% 25V

C252- 4011134 100nF 10% 16V

C253

C254 4010421 1µF 10% 16V

C255 4011134 100nF 10% 16V

C256 4010316 100nF 10% 25V

C257 4010323 1µF -20+80% 16V

C258 4010237 1nF 10% 50V

C259 4001135 100pF 5% 50V

C260- 4011122 10nF 10% 50V

C261

C262 4010419 4.7µF 10% 10V

C263 4001130 39pF 5% 50V

C264 4001133 68pF 5% 50V

C265 4001130 39pF 5% 50V

C266 4010322 4.7µF -20+80% 16V

C267 4011134 100nF 10% 16V

C268 4010420 10µF 10% 10V

C269- 4011134 100nF 10% 16V

C270

C271- 4001127 22pF 5% 50V

C274

C275 4001130 39pF 5% 50V

C276 4000494 4.7nF 10% 50V

C277 4010421 1µF 10% 16V

C278 4010316 100nF 10% 25V

C279 4011134 100nF 10% 16V

C281- 4000408 47pF 5% 50V

C282

C283- 4010274 100nF -20+80% 25V

C287

C288 4000494 4.7nF 10% 50V

C289- 4010274 100nF -20+80% 25V

C290

C291 4011134 100nF 10% 16V

C292- 4011122 10nF 10% 50V

C294

C295 4001143 470pF 5% 50V

C296 4011135 100nF -20+80% 16V

C300 4010419 4.7µF 10% 10V

C301 4011128 33nF 10% 25V

C302 4011120 6.8nF 10% 50V

C303 4011130 47nF 10% 16V

C304 4010421 1µF 10% 16V

C305 4010435 10µF -20+80% 25V

C306 4010419 4.7µF 10% 10V

C307 4011134 100nF 10% 16V

C309- 4010420 10µF 10% 10V

C310

C311 4010237 1nF 10% 16V

C313 4010237 1nF 10% 16V

C315- 4011110 1nF 10% 50V

C317

C318 4001138 180pF 5% 50V

C400 4011110 1nF 10% 50V

C401 4010321 470nF -20+80% 16V

C402 4011122 10nF 10% 50V

C403 4010237 1nF 10% 16V

C404- 4001131 47pF 5% 50V

C407

C408 4010321 470nF -20+80% 16V

C409 4011110 1nF 10% 50V

C410 4011056 4 x 1nF 10% 50V

C411 4001134 82pF 5% 50V

C412 4011122 10nF 10% 50V

C413 4011110 1nF 10% 50V

C414 4001141 330pF 5% 50V

C415 4011122 10nF 10% 50V

C416 4010419 4.7µF 10% 10V

C417 4011122 10nF 10% 50V

C418 4001143 470pF 5% 50V

C419 4001131 47pF 5% 50V

C420 4001134 82pF 5% 50V

C421 4011110 1nF 10% 50V

C422 4010321 470nF -20+80% 16V

C500 4010315 22nF 10% 25V

C501 4010267 4.7nF 10% 50V

C502 4010316 100nF 10% 25V

C503 4010434 4.7µF

C505 4010316 100nF 10% 25V

C506 4010315 22nF 10% 25V

C507 4011122 10nF 10% 50V

L200 8021078 Coil 1µH 10%

L201 8021319 Coil 97nH

L202- 8021320 Transformer 97nH

L203

L204 8021318 Coil 71nH

L205 8021322 Transformer 10.7MHz

L206 8021321 Coil 10.7MHz

L207 8021325 Coil 1mH

L208 8021323 Transformer 450KHz

L209 8020909 Coil 330µH 10% 796KHz

L210 8021324 Coil 10µH

Page 41

3.9 List of electrical partsList of electrical parts 3.9 3.9

PCB86, 8006801 Tuner-FM/AM-RDSStereo decoder JAP

PCB89, 8001867 Interface f/CD PRO MKI

L211- 8020626 Coil 470µH 5%

L212

L213- 8020714 Coil 68µH 10%

L214

L215- 8020821 Coil 2.2µH 5%

L217

L301- 6000064 Jumper

L302

BP200 8030391 Cer. fi lter 450KHz ±KHz

BP201- 8030400 Cer. fi lter 10.7MHz

BP203

X200 8090274 Crystal 10.25MHz X400 8090206 Crystal 8.664MHz

F500 6604039 Fuse 200mA

P100 7210612 Socket antenna mini-jack

P101 7221373 Male connector

P102 7221082 Plug 2 pole

P103 7211221 Socket 4 pole

P104 7221131 Plug 4 pole

MP100 3302584 Shield f/FM-tuner

MP200 3320430 Shield radio

IC203∆ 8342519 151 EEPROM M24C02-MN6T

Advanced adjustments procedure when replacing this component.

Replacement of PCB86 is recommended 8006801.

C248- 4010420 10µF 10% 10V

C250

All other electrical parts see PCB86, Tuner EU/US

IC1 8340796 105 7805 2% 5V

IC2∆ 8341041 138 LM 324

TR2 8320755 51 BC 847B

TR3 8321050 19 ZTX 788-STZ

D3 8300201 250 Z6.2V 5% 0.4W

L303 8021345 Coil 10mH

L400- 8020821 Coil 2.2µH 5%

L404

L500- 8020822 Coil 3.3µH 5%

L501

P105 7221157 Plug 6/6 pole

P106 7211222 Socket 6 pole

P107 7221082 Plug 2 pole

P400 7211221 Socket 4 pole

MP201 3320431 Shield

IC3- 8341022 138 4558

IC4

TR4 8320755 51 BC 847B

TR5 8320811 51 BC 857B

Standard resistors

Resistors SMD 2% 1/8 W

SMD 5% 1/8 W

Glue dots, approx. 200, part no. 3181932

0.55mm

3.2mm

1.6mm

Resistors SMD 5% 1/10 W

Glue dots, approx. 200, part no. 3181932

0.55mm

2.0mm

1.25mm

5% 2% 2% 2% 2% 2% 5% 2%

x1 x10 x100 x1K x10K x100K x1M x10M

1.0 5011623 5011647 5011218 5011227 5011241 5011256 5011267 5011730

1.1 5011624 5011648 5011669 5011681 5011689 5011694 5011707

1.2 5011625 5011649 5011219 5011682 5011490 5011257 5011708

1.3 5011626 5011650 5011670 5011683 5011242 5011258 5011709

1.5 5011627 5011651 5011220 5011228 5011243 5011259 5011710

1.6 5011628 5011652 5011671 5011684 5011690 5011695 5011711

1.8 5011629 5011653 5011672 5011229 5011244 5011260 5011712

2.0 5011630 5011654 5011673 5011685 5011691 5011696 5011713

2.2 5011216 5011655 5011674 5011230 5011245 5011261 5011714

2.4 5011634 5011656 5011675 5011686 5011246 5011697 5011715

2.7 5011635 5011657 5011497 5011231 5011247 5011262 5011716

3.0 5011731 5011658 5011499 5011500 5011692 5011698 5011717

3.3 5011217 5011659 5011676 5011232 5011248 5011263 5011718

3.6 5011636 5011660 5011677 5011687 5011249 5011264 5011719

3.9 5011637 5011661 5011221 5011233 5011491 5011699 5011720

4.3 5011638 5011662 5011498 5011688 5011492 5011700 5011721

4.7 5011639 5011269 5011222 5011234 5011250 5011265 5011722

5.1 5011640 5011663 5011678 5011235 5011493 5011701 5011723

5.6 5011641 5011664 5011223 5011236 5011251 5011702 5011724

6.2 5011642 5011665 5011224 5011237 5011693 5011703 5011725

6.8 5011643 5011666 5011225 5011238 5011252 5011704 5011726

7.5 5011644 5011667 5011679 5011239 5011253 5011705 5011727

8.2 5011645 5011270 5011226 5011240 5011254 5011266 5011728

9.1 5011646 5011668 5011680 5011489 5011255 5011706 5011729

x1 x10 x100 x1K x10K x100K x1M x10M

0.0 6000072

1.0 5011920 5011932 5011944 5011956 5011968 5011980 5012275

1.2 5012326 5011921 5011933 5011945 5011957 5011969 5012267

1.5 5012379 5011922 5011934 5011946 5011958 5011970 5012268

1.8 5012380 5011923 5011935 5011947 5011959 5011971 5011989

2.2 5011924 5011936 5011948 5011960 5011972 5012220

2.7 5011925 5011937 5011949 5011961 5011973 5012269

3.3 5011926 5011938 5011950 5011962 5011974 5012261

3.9 5011927 5011939 5011951 5011963 5011975 5012270

4.7 5012472 5011928 5011940 5011952 5011964 5011976 5012271

5.6 5011929 5011941 5011953 5011965 5011977 5012272

6.8 5011930 5011942 5011954 5011966 5011978 5012273

8.2 5011931 5011943 5011955 5011967 5011979 5012274

∆ indicates that static electricity may destroy

the component

R27- 5011986 15.4KΩ 1% 1/8W

R28

R29- 5012290 4.87KΩ 1% 1/10W

R30

R31- 5012297 5.62KΩ 1% 1/10W

R32

C1- 4000351 1.5nF 5% 50V

C2

C3- 4000414 150pF 5% 50V

C4

C5- 4000416 220pF 5% 50V

C6

C11- 4010314 220nF -20+80% 25V

C13

C14- 4010272 22nF -20+80% 50V

C16

C17- 4010274 100nF -20+80% 25V

C19

P65 7220709 Plug 2 pole

P66- 7220711 Plug 4 pole

P67

P68 7220710 Plug 3 pole

R34- 5012331 10KΩ 1% 1/10W

R35

R36- 5011557 10KΩ 1% 1/8W

R39

R40- 5012331 10KΩ 1% 1/10W

R41

C20- 4201173 10µF 20% 50V

C21

C23- 4201174 2.2µF 20% 50V

C24

C25 4200524 10µF 20% 25V

C26 4010274 100nF -20+80% 25V

C30 4010272 22nF -20+80% 50V

C31 4010166 100nF -20+80% 50V

C37 4010314 220nF -20+80% 25V

C38 4010274 100nF -20+80% 25V

C39 4010271 10nF 10% 50V

P200 7220711 Plug 4 pole

P204 7220713 Plug 6 pole

P207 7220711 Plug 4 pole

Resistors SMD 5% 1/16 W

0.45mm

1.6mm

0.8mm

x1 x10 x100 x1K x10K x100K x1M x10M

1.0 5013201 5013213 5013225 5013237 5013249 5013261 5013273 5013285

1.2 5013202 5013214 5013226 5013262 5013274

1.5 5013203 5013215 5013227 5013263

1.8 5013204 5013216 5013228 5013240 5013276

2.2 5013205 5013217 5013229 5013241 5013253 5013265 5013277

2.7 5013206 5013218 5013254 5013266 5013278

3.3 5013207 5013231 5013040 5013255 5013267 5013279

3.9 5013208 5013220 5013268 5013280

4.7 5013209 5013221 5013233 5013245 5013257 5013269 5013281

5.6 5013210 5013222 5013234 5013258 5013270 5013282

6.8 5013211 5013223 5013235 5013259 5013271 5013283

8.2 5013212 5013224 5013135 5013260 5013272 5013284

Page 42

List of mechanical parts

Front

9001

9002

4.1 List of mechanical partsList of mechanical parts 4.14.1

9021

6

9022

9023

9024

6

9025

1

1

1

1

9

1

9008

9009

9003

9004

9005

9006

9007

9026

9027

2

2

2

2

9005

7

7

7

9011

0501

9012

9013

0502

0503

05DP2

0504

5

4

90/99

6

6

9024

9025

9024

9025

9027

4

5

9010

3

9014

0505

0501

9012

3

9013

0502

0503

05DP1

0504

3

9014

0506

9015

3

9016

3

9017

3

3

9018

87/89

9019

3

9028

9020

9029

Page 43

4.2 List of mechanical partsList of mechanical parts 4.2 4.2

Front

9001 3162622 Cover, left

9002 3162830 Glass, left

9003 2802056 Ring f/clamper with magnet strips

9004 3017028 Wheel

9005 2830111 Cylinder pin

9006 3162652 Clamper

9007 3152726 Cover f/clamper

9008 2819251 Spring

9009 3164877 Cover

9010 3904124 Alu foil w/tape

9011 3162461 Cover f/CD

9012 8230100 PCB w/lamp

9013 3131356 Light cabinet

9014 3322145 Window

9015 3322137 Window

9016 2572045 Spacer

9017 7500270 Contact spring

9018 2816257 Ground spring

9019 2776665 Set of buttons

9020 3451632 Front piece, complete

9021 2917025 Ball

9022 2816235 Spring

9023 2311045 Magnet top

9024 3333017 Rubber damping

9025 2812132 Compression spring

9026 3112418 Chassis

9027 2810254 Tension spring

9028 3162623 Cover, right

9029 3162831 Glass, right

Screws

05Module 8001362 Display

0501 8330286 LED backlight module

0502 7500272 Contact rubber

0503 2574079 Rubber pad

0504 3370148 Foil

0505 3151285 Holder, upper

0506 3151292 Holder, lower

05DP1 8330259 Display, lower

05DP2 8330468 Display, upper

09module 8001550 Light and motor control

87Module 8001823 Interface f/CD PRO MKII introduced from serial no. _________________

89Module 8001867 Interface f/CD PRO MKI

90Module 8420240 CD PRO MKII incl. pos. no. 9021, 9022 and 9023 introduced from

serial no. _________________

99Module 8420218 CD PRO MKI incl. pos. no. 9021, 9022 and 9023

1 2013144 Screw 3 x 8mm

2 2036036 Screw 2.5 x 4mm

3 2013118 Screw 3 x 8mm

4 2013172 Screw 3 x 6mm

5 2036085 Screw 2.5 x 6mm

6 2038118 Screw 3 x 6mm

7 2038133 Screw 3 x 11mm

Page 44

4.3 List of mechanical partsList of mechanical parts 4.34.3

9

Chassis

3

8

9

9101

1M1

9102

9102

9103

9104

9105

10

101111

11

10

12

13

13

13

12

9106

9108

3

9109

9110

9111

9112

9126

9120

91M2

10

9121

12

9

10

3

10

13

13

13

11

11

3

11

3

9122

9122

9123

9124

9125

9127

9107

9128

16

12

9129

2001

2002

003

004

114

115

115

17

18

17

17

17

1

17

1

20

9130

9130

1

9131

3

19

9132

20

3

9133

8

3

28

3

86

20

1

1

1

3

9116

9116

9116

1

9134

18

9148

9149

9148

9148

1201

9150

9151

9152

9137

9138

9139

14

12

29

22

29

1

23

23

24

25

25

1

24

26

27

32

27

9162

27

9153

27

9154

27

9155

28

15

28

28

9156

9157

30

2

9158

31

1

21

31

1

30

3

30

9159

160

161

9117

9118

9119

21

9119

9119

22

9119

22

8

22

9115

9117

9117

9118

9119

9135

9136

9142

9143

9144

9145

9146

9147

23

23

24

24

25

25

26

26

26

24

25

24

25

26

24

25

24

25

23

23

26

9140

9141

9137

23

23

9138

9139

9142

9143

9145

9144

Page 45

4.4 List of mechanical partsList of mechanical parts 4.4 4.4

Chassis

9101 2722055 Belt pulley

9102 2831070 Shaft

9103 3151277 Holder

9104 2732076 Belt

9105 2722054 Belt pulley

9106 2700152 Gear wheel, complete

9107 2819295 Spring

9108 6276391 Wire w/switch

9109 3035062 Slide shoe

9110 2819254 Spring

9111 2700092 Gear wheel

9112 2854153 Arm

9114 3114455 Chassis incl. pos. no. 9117, 9118, 9119, 9133 and 9152

9115 3947546 Copper tape - 1.6m

9116 3152747 Wire holder

9117 3103303 Foot

9118 2642030 Clamp

9119 2311029 Clip

9120 3151276 Holder

9121 2722055 Pulley

9122 2831071 Shaft

9123 2732092 Belt

9124 6276391 Wire w/switch

9125 2722053 Belt pulley

9126 2700093 Gear wheel

9127 2724087 Cord pulley

9128 2815029 Ground spring

9129 2815032 Leaf spring

9130 2311030 Clip

9131 2548254 Bracket

9132 3010033 Stop f/transport screw

9133 3031587 Bracket

9134 2810133 Tension spring

9135 2810155 Spring

9136 3955042 Cord

9137 2391086 Locking piece

9138 3152727 Holder

9139 2391087 Locking piece

9140 2548247 Bracket

9141 3013088 Guide rail incl. pos. no. 9137, 9138 and 9139

9142 2391086 Locking piece

9143 3152727 Holder

9144 2391087 Locking piece

9145 3035060 Slide shoe

9146 3013089 Guide rail incl. pos. no. 9142, 9143, 9144 and 9145

9147 2548247 Bracket

9148 3030116 Hinge

9149 3358275 Heat sink

9150 3358274 Heat sink

9151 3152730 Holder

9152 3124121 Mounting plate

9153 3430605 Rear cover

9154 3164900 Cable cover

9155 3151321 Strap

9156 3300120 Screen

9157 3031682 Frame

9158 6100273 Mains cable, type 2671 (EU)

6100329 Mains cable, type 2672 (GB)

6100307 Mains cable, type 2673-2676 (USA-CDN-TWN)

6100331 Mains cable, type 2674 (JPN)

6100332 Mains cable, type 2675 (AUS)

9159 3031689 Holder f/PCB3

9160 2560279 Rail

9161 3124129 Counterweight

9162 3152757 Holder f/antenna

Screws, washers etc.

02Module 8006796 Interface f/µPH8

03Module 8006797 µPH8 Microcomputer

12Module 8001833 Power supply, Input select & Pre-amplifi er

1201 3152799 Holder

Sockets, see wiring diagram

14Module 8001771 Master Link Audio interface

15Module 8001834 Transformer EU

Sockets, see wiring diagram

15Module 8006798 Transformer US

Sockets, see wiring diagram

18Module 8001817 Headphone

20Module 8005738 IR receiver and left door sensor

2001 3300124 Screen, inner

2002 3300123 Screen, outer

2003 3304135 Shielded box

2004 3300129 Screen

91D1 6277348 Wire - Plug with reception diode

91D2 6277061 Wire - Plug with transmitter diode, left

91D3 6277061 Wire - Plug with transmitter diode, left

21Module 8006799 Door sensor right

91D4 6277348 Wire - Plug with reception diode

91D5 6277118 Wire - Plug with transmitter diode, right

91D6 6277118 Wire - Plug with transmitter diode, right

1 2013144 Screw 3 x 8mm

3 2013118 Screw 3 x 8mm

8 7530119 Solder tag

9 2011310 Screw 2.2 x 4.5mm

10 2938237 Bushing

11 2930074 Spacer

12 2390001 Lock washer

13 2036061 Screw 2.6 x 6.5mm

16 2013190 Screw 3 x 8mm

17 2038149 Screw 3 x 8mm

18 2013218 Screw

19 2625002 Washer

20 2389064 Nut

21 2380145 Nut

22 2058017 Screw 3 x 8mm

23 2036066 Screw 2.5 x 2.7mm

24 2724078 Cord pulley

25 2364019 Rivet

26 2011050 Screw 3 x 8mm

27 2038094 Screw 3 x 10mm

28 2039064 Screw 3 x 12mm

29 2039062 Screw 3 x 5mm

30 2039035 Screw 3 x 8mm

31 2622052 Washer

32 2038116 Screw 3 x 20mm

91M1 8400190 Motor

91M2 8400189 Motor

Page 46

4.5 List of mechanical partsList of mechanical parts 4.54.5

Wire bundles

Accessories

Packing

User’s Guide

See wiring diagram page 2.4

The part no. is printed on the diagram above the wire bundle, as shown.

See specifi cation guidelines page 1.3

3392405 Outer carton

3397824 Foam packing

3946038 Foil

3508252 Danish

3508253 Swedish

3508254 Finnish

3508255 English

3508256 German

3508257 Dutch

3508258 French

3508259 Italian

3508260 Spanish

3508261 Japanese

3508262 Taiwanese

3508263 Korean

3508264 Greek

3508265 Hebrew

3508266 Brazilian

Stand, type 2051

1205111, silver

1205194, green

1205196, black

1205198, blue

1205199, red

Reference book

3505687 Danish

3505688 Swedish

3505689 Finnish

3505690 English

3505691 German

3505692 Dutch

3505693 French

3505694 Italian

3505695 Spanish

3505696 Japanese

3505697 Taiwanese

3505698 Korean

3505699 Greek

3505700 Hebrew

3505701 Brazilian

9501 3451589 Cover plate, silver

3451591 Cover plate, green

3451592 Cover plate, black

3451593 Cover plate, blue

3451594 Cover plate, red

9502 3458890 Cover plate, bottom

9503 2752043 Bottom

9504 3013094 Guide rail, right

9505 3013094 Guide rail, left

a 3103313 Foot, spike

b 3103322 Foot, soft

c 2046040 Screw 6 x 63mm

c 2046041 Screw 6 x 66mm

3502921 Setting-up guide

3397953 Foam packing

3392423 Outer carton

Page 47

Center wall bracket, black, type 2052

1205266

List of mechanical parts 4.6

9510 2777052 Handle, right

2777053 Handle, left

9511 1205266 Wall bracket

9512 2038130 Screw 3 x 25mm

9513 2043016 Screw 4 x 10mm

2930126 Bush

3390432 Wire holder

3502922 Setting-up guide

Page 48

4.7 List of mechanical parts

System wall bracket, black, type 2087

1208766

9520

9521

9522

9523

9524

9525

9520 3152790 Holder f/antenna

9521 2038116 Screw 3 x 20mm

9522 2777052 Holder, right

2777053 Holder, left

9523 2038130 Screw 3 x 25mm

9524 3031319 Wall plate

9525 1208726 System wall bracket, complete

3390341 Screw assortment

3390342 Wire holder assortment

3502996 Setting-up guide

3392185 Outer carton

3397774 Foam packing

Page 49

TM (test mode) names/function for adjustments and service

Tuner test modes

TM 01: Automatic offset-adjustment for FM

TM 02: Manual offset-adjustment for FM

TM 03: Status for offset-adjustment

TM 04: Variant status

TM 06: Check RDS name

TM 07: Setting up of tuner variant

Master test modes

TM 20: Test of display functions

TM 21: Open ML-out

TM 22: Test of keyboard functions

TM 23: Software version

TM 24: Service operation counter

TM 25: Open ML-in

TM 27: Service of error detection

TM 28: Validity test for ROM/RAM/EEPROM

TM 32: Read-out of product ID

TM 34: Read-out of options

TM 35: Power down ON

TM 36: Power down OFF

Testmodes, English 5.1

CD test modes

Test mode activating

Deactivating

TM 61: Focus on

TM 62: Focus off

TM 63: Starts turntable motor

TM 64: Stops turntable motor

TM 65: Light pen to outermost position

TM 66: Light pen to the innermost position

TM 67: Starts CD

TM 68: Stops CD

Wait 20 - 30 sec. after connecting to mains.

By means of keyboard from St.by mode: Press SOUND 0 2 5 8 with no more than

2 sec. between the individual enterings.

By means of remote control from St.by (can only be done if the product is not in

option 0) :

Press SHIFT 9 0 2 5 8 with only 2 sec. between.

The remote control has to be in RADIO or CD option.

In TM the tuner is fully functional and may overwrite the display but the TM will

continue.

Press

• and the display shows “TM OFF” or disconnect from mains.

Page 50

5.2 Testmodes, English

Glass doors lock

TM01

When the glass doors are locked it is not possible to open them by magic open.

The glass doors can only be locked if the product is in St. by, the glass doors are

closed and only by remote control.

Press SHIFT 9 0 3 6 9 with no more than 2 sec. between the individual entering.

The display shows “LOCKED”.

To unlock the glass doors press SHIFT 9 0 3 6 9 with no more than 2 sec. between

the individual entering.

The display shows “UNLOCKED”.

The function will be remembered in NVRAM after disconnecting from mains.

From TM01 to TM09.

- Wait 20 - 30 sec. after connecting to mains.

- By keyboard from St.by mode: Press SOUND 0 2 5 8 RADIO with no more than

2 sec. between the individual entering. Then key in the TM no.

- By remote control from St.by (can only be done if the product is not in option 0):

- Press SHIFT 9 0 2 5 8 with no more than 2 sec. between the individual entering.

Then key in TM no.

Automatic offset-adjustment for FM is done by letting the tuner search for the

frequency 100 MHz (84 MHz for Japan) and when the signal is found the offset

will be calculated and stored in NVRAM. The display shows “A OFFSET”.

If failure the display shows “TM ERROR”.

TM02

TM03

TM04

TM06

Manual offset-adjustment for FM is done by key-in a frequency. The tuner search

tunes for this frequency and the offset will be calculated and stored in NVRAM.

The display shows “M OFFSET”.

If failure the display shows “TM ERROR”.

Read-out offset status.

If the offset-adjustment is needed the display shows “TM ERROR”.

If the result of the offset-adjustment is positive the display shows “OFFSET n”.

If the result of the offset-adjustment is negative the display shows “OFFSET -n”.

The fi gure n is in steps of 12.5 kHz.

Read-out variant status: EUROPA (EU) FM, EUROPA (EU) FM/AM, USA (US) and

JAPAN (JP). The display shows e.g. “EU FM/AM”.

If failure the display shows “TM ERROR”.

Checking that the RDS name of the radio programme in question is RDS-PS.

The display shows “TM OK”.

If wrong RDS name or if name is missing the display shows “TM ERROR”.

Page 51

TM07

Testmodes, English 5.3

Tuner variant setup:

If from EU or AUS to US:

Key in the 3 digits indicating the choice.

No. 0: 003 = variant US

No. 1: 001 = RDS on, or 000 = RDS off

No. 2: 175 = FM starts in 500 kHz

No. 3: 216 = FM stops in 500 kHz

No. 4: 075 = Deemphas in µs

No. 5: 000 = LW starts in kHz dividing with AM raster. 0 if no LW

No. 6: 000 = LW stops in kHz dividing with AM raster. 0 if no LW

No. 7: 053 = MW starts in kHz dividing with AM raster. 0 if no MW

No. 8: 171 = MW stops in kHz dividing with AM raster. 0 if no MW

No. 9: 010 = AM raster. Steps in kHz. 0 if no AM

If from US or AUS to EU.

No. 0: 001 = variant EU FM. (002 if EU FM/AM)

No. 1: 001 = RDS on, or 000 = RDS off

No. 2: 175 = FM starts in 500 kHz

No. 3: 216 = FM stops in 500 kHz

No. 4: 050 = Deemphas in µs

No. 5: 017 = LW starts in kHz dividing with AM raster. 0 if no LW

No. 6: 031 = LW stops in kHz dividing with AM raster. 0 if no LW

No. 7: 058 = MW starts in kHz dividing with AM raster. 0 if no MW

No. 8: 179 = MW stops in kHz dividing with AM raster. 0 if no MW

No. 9: 009 = AM raster. Steps in kHz. 0 if no AM

If from EU or US to AUS

No. 0: 005 = variant AUS

No. 1: 001 = RDS on, or 000 = RDS off

No. 2: 175 = FM starts in 500 kHz

No. 3: 216 = FM stops in 500 kHz

No. 4: 050 = Deemphas in µs

No. 5: 000 = LW starts in kHz dividing with AM raster. 0 if no LW

No. 6: 000 = LW stops in kHz dividing with AM raster. 0 if no LW

No. 7: 058 = MW starts in kHz dividing with AM raster. 0 if no MW

No. 8: 179 = MW stops in kHz dividing with AM raster. 0 if no MW

No. 9: 009 = AM raster. Steps in kHz. 0 if no AM

Page 52

5.4 Testmodes, English

TM20

TM21

TM22

TM23

Checking the display by showing 3 types of letters in 3 rounds until all pixels are

used/tested.

Press PLAY to shift between icons in the display.

Opens the signal from AUX-plug to the ML-output.

The display shows “AUX 2 ML”.

Test of key-board functions.

By pressing a key for instance CD the display will show “CD”.

The testmode can only be ended by IR-remote control command “STOP”.

This testmode can only be activated by IR-remote control command.

Read out of Software version. Press PLAY to continue.

AP xx.xxx = Application processor. (Main CPU)

OS xx.xxx = APOS

IO xx.xxx = I/O processor

TU xx.xxx = Tuner processor. (Tuner-FEP)

CD xx.xxx = CD processor. (CD-FEP)

TM24

TM25

Service running counter.

First the Stand-by time will appear.

Press PLAY to toggle between the different counters.

- St. by time

- Radio-mode time

- CD-mode time

- AUX-mode time

- ML active time

- Theft protection active time

Number of times the theft protection has been unlocked.

Number of times the product has been switched on/off.

All numbers are stated in interval of 10. (e.g. 3 = 30.)

When all counters have been shown the display will ask for a new test mode.

Opens ML-in.

A source must be selected to have a correct measurement.

Signal coming from the ML-in, exit on the PL and AUX as by normal selection.

Page 53

TM27

Testmodes, English 5.5

Service Error detection.

The last registred errors regarding EEPROM, ML, IIC-bus, RS232 driver, CD and lids

can be read-out. This test mode is also used for deleting all error-registrations.

To toggle between error indications press PLAY. When all errors are read press

PLAY to reset all errors registered or press STOP to keep error register.

By pressing

YY.MM.DD

hh.mm.ss.

MEM: last EEPROM error.

- 2: EEPROM writes error

- 3: EEPROM reads error

- 4: EEPROM reads error only FF

- 11: EEPROM writes owerfl ow

- 12: EEPROM controls init fail

- 13: EEPROM controls calloc fail

- 99: EEPROM content error

ML: Last error regarding to ML.

- 8: Link tied down

- 16: Link tied up

- 32: Confi guration impossible

m or p the time for errors will be shown.

IIC: Component which gave the last error regarding IIC-bus.

- 102: Tuner FEP

- 136: Sound Processor

- 208: Clock

SER: The last error from the RS232 driver.

- 02: CDA queue not attached

- 03: CDA error timeout

- 04: CDA error unknown buf addr

- 05: CDA error data expected

- 06: CDA error unknown CMD

- 07: CDA error checksum

- 08: CDA error RX timeout

- 09: CDA error out of buffers

- 10: CDA error uart overrun

- 11: CDA error uart framing

- 12: CDA error uart parity

CD: CD error.

- 2: Focus error

The CD could not focus within the time limit.

- 3: Radial error

Set when the CD did not get on track after several retries.

- 4: Turntable motor error

Set when the disc did not spin up or down within the limit.

- 5: PLL lock error

Set when PLL is out of lock during tracking mode.

- 6: Jump error

Set when a seek could not be performed or an error occured during a binary search.

- 7: Subcode error

Set when a subcode could not be read within the time limit.

Page 54

5.6 Testmodes, English

- 8: TOC read error

Set when the TOC could not be read, no access possible to lead-in.

- 20: Serial communication overrun error

Expected command byte, but received a data byte.

- 22: Serial communication noise error

Check did not match.

- 23: Serial communication software error

Queue full.

- 37: Selection error

OS: Error in the operation system.

- 07: IL TLG from FEP to APOS

- 08: IL TLG from APOS to FEP

- 09: IL RX TX BUF limit

- 13: FEP does not exist

IO: Last error in the I/O driver.

- 01: IIC1 2 error

- 05: Cannot confi gure FEP

- 06: FEP communication error

- 07: IL TGL from FEP to APOS

- 08: IL TGL from APOS to FEP

- 09: Interlink RX TX BUF limit

- 14: FEP does not exist

- 21: MLSL timeout error

- 22: MLSL TX BUF full TLG does not send

- 23: ML key lost key repaired

- 24: External communication not allowed in preproject

- 25: LSL format error

- 26: LS IR format error

- 27: LSL TX imposs

- 28: LSL link tied up

- 29: LSL link tied down

- 30: Generic ICB error

- 31: ICB L7 timeout

- 32: ICB L7 illegal timeout

- 33: ICB L7 out of repositories

- 34: ICB L7 illegal L7 ack

- 35: ICB L7 Acknowledge unexpected

- 36: ICB L7 read response unexpected

- 37: ICB L7 illegal resource type

- 38: ICB L7 resource still running

- 39: ICB L7 resource already free

- 40: ICB L7 illegal IOP service

- 41: ICB L7 illegal IOP object

- 42: ICB L7 telegram fl ushed

- 43: ICB L7 resource disabled

- 44: ICB L7 HW clock illegal command

- 45: ICB L7 HW clock illegal event

- 46: ICB L2 retrans limit reached

- 47: IIC component disabled

- 48: Power down of IOP impossible

- 49: CDS bus disabled

Page 55

E7: Last error in the main micro-processor.

- 16: Illegal timer ID

- 17: Timer not free

- 21: Illegal date value

- 22: Illegal time value

- 23: Illegal timer parameters

- 32: Illegal simple message ID

- 33: Out of message buffers

- 34: Message buffer virtual limit reached

- 64: Non ISR func. called from ISR

- 65: Physical stack limit reached

- 66: Stack virtual limit reached

- 67: Out of IAS objects

- 68: IAS signal lost

- 69: Overfl ow in IAS FIFO

- 70: IR queue not attached

- 71: LSL queue not attached

- 72: Scan queue not attached

- 73: Active keyscan queue not attached

- 74: Uart 0 queue not attached

- 75: TIIC queue not attached

- 76: RIIC queue not attached

- 77: Out of power down callback OBJ

- 78: Power down entered with timer running

- 79: Watchdog reset

Testmodes, English 5.7

IOP: Last error in the I/O microprocessor.

- 01: Watchdog reset

- 02: ICB layer 2 timeout

- 03: ICB layer 7 illegal service

- 04 ICB layer 7 illegal object

- 05: Reg mem data frame not valid

- 06: Data frame not valid

- 07: Illegal port ID

- 08: LSL TX impossible

- 09: LSL tied up

- 10: LSL tied down

- 11: IIC slave buffer full

- 12: IIC slave transmit timeout

- 13: IIC illegal switch port

- 14: IIC2 slave addressed

- 15: IIC conditional polling timeout

- 16: IOP IIC error

- 17: PD entered while service waitning

- 18: TP ICBL7 illegal command

- 19: TP module HW error APOS

- 21: TP clock error APOS

Page 56

5.8 Testmodes, English

TM28

TM31

This TM checks the function of ROM, RAM, EEPROM. (O, A, P).

To readout TM, O and A have to be (+).

E.g. MEM ++- indicates error in the EEPROM.

Default settings for sale purpose.

Option: 1

Volume: 32

Balance: 0

Bass: 0

Treble: 0

Loudness: OFF

Radio programs erased.

CD settings erased.

Timer settings erased.

After default settings the display shows DEFAULT TM ERROR.

If error occurs in TM the display will show TM ERROR.

Item-number, serial-number, type-number, master pin-code, running counter and

all offset adjustments will not be erased.

TM32

TM34

TM35

TM36

ID-readout of the product.

Press PLAY to toggle between the ID-numbers.

Item = 7 fi gures.

Type = 4 fi gures.

Serial = 8 fi gures.

MA PIN = OK or ERR.

If error in the readout all fi gures = 0.

Option readout.

Power down ON.

When power down mode is possible the display = TM OK.

Power down OFF.

When power down mode is not possible the display = TM OK.

Page 57

Testmodes, English 5.9

To use CD test modes it is necessary to select CD, in the TM the HF-signal will not be used

TM61

Focus ON.

The CD-pen will try to focus.

This TM can only be turned off by using TM62.

TM62

Focus OFF.

The CD-pen will be turned OFF.

TM63

Starts turntable motor.

This TM can only be turned off by using TM64.

TM64

Turns off the turntable motor.

TM65

Light pen to outermost position.

The optical pickup unit goes to the outermost position and stays there.

This TM can only be turned off by TM66. Do not give other commands in the

meantime.

TM66

TM67

TM68

Light pen to the innermost position.

The optical pickup unit goes to the innermost position and stays there.

The CD starts playing.

The CD stops playing.

When error in CD-TM the Error-number refers to TM27 CD-errors.

Page 58

5.10 Repair tips, English

Replacement of CD-mechanism

- Open the glass doors.

- Disconnect the main voltage.

- Dismount the glass doors by pulling forward at the bottom fi rst and then at the top.

Take care that the glass door does not scratch the display.

- Remove the seven screws A in the back cover. Pull out the back cover by wrenching

the corners C of the back cover to the side.

- Dismount the two side front covers by pulling them carefully outwards at the top

and bottom until a loud click is heard.

- Click off the CD-front cover.

- Remove the front panel by unscrewing the eight screws E.

- The complete CD-mechanism with CD-servo/decoder PCB can now be lifted out

forwards by removing the four screws.

- Dismount the plugs connecting CD-servo/decoder PCB to the CD-interface-PCB

and the CD-mechanism with CD-servo/decoder PCB can now be replaced.

E

E

E

E

Page 59

Removal of gearbox for CD-clamp

Repair tips, English 5.11

The product must not be connected to the mains when dismantling.

- The clamp must be electrically sealed.

- Lift up the clamp manually.

- Dismount the spring R at its bottom most point.

- Dismount the lead to the motor, plug 9P78.

- Loosen the screw S and take out the gearbox.

Make sure that the two parts of the fi tting at the top of the arm Q are pressed

completely together when reassembling; then tighten the fi tting.

Q

P78

9

S

R

Page 60

5.12 Repair tips, English

Mounting of wire for glass doors

Readjustment of wire

- Turn the wire pulley G clockwise until it stops. (Closed door position).

- Turn the wheel H in click position.

- Mount the wire in the wire pulley H (the end with the heavy spring).

- Run the wire in the second innermost groove of the wire pulley H (underneath the

pulley), up around the uppermost pulleys (I, J, K and L) and down around the

lowermost pulleys (M, N, and O).

- Turn the pulley G anticlockwise.

- Fasten the wire in the pulley H.

- Mount the wire on pulley P and turn pulley G to check that everything is OK.

- Turn the pulley G such that the centre of the pulleys G and H is fl ush with the

upper edge of the tower X.

- Push the wire clamping clip towards the centre and tighten (not too tight).

L

I

X

H

G

P

M

K

J

O

N

Page 61

Adjustment of the glass doors

Repair tips, English 5.13

- Open the glass doors, press • and wait for the glass doors to close and disconnect

main voltage.

- Remove the seven screws A in the back cover. Pull out the back cover by wrenching

the corners C of the back cover to the side.

- Remove the fi ve screws B, and lift PCB12/15 out of the cabinet.

- Loosen the top and bottom screws holding the maladjusted glass door on the wire

(only one door at the time).

- The maladjusted glass door can now be pushed to the middle-stop and the screws

at the top and at the bottom of the glass door have to be tighten fi rmly.

- Connect the main voltage. Open the glass doors, press

doors to close and disconnect main voltage.

- If necessary adjust the other glass door in the same way.

Note, be careful not to loosen both glass doors at the same time.

• and wait for the glass

Page 62

5.14 Repair tips, English

Test of Master Link DATA receiver/transmitter