Baldor SD23H2A04-E, SD23H2A10-E, SD23H2A15-E, SD23H2A22-E, SD23H2A45-ER Installation & Operating Manual

...Page 1

$25.00

SERIES 23H

AC Servo Control

INSTALLATION & OPERATING MANUAL

10/95 MN723

MN723H-10/95 11/28/95 1:04 AM Page 1 (Black plate)

Page 2

Table of Contents

Section 1

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Safety Notice . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

Section 2

Installation

Location and Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Altitude Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Temperature Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Main Circuit Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

AC Line Impedance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

AC Power Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4

Wiring and Protective Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5

Operating 460 VAC Control on 380-400 VAC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Operating Control with Single Phase Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-11

Single Phase Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Motor Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-12

Dynamic Braking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-14

Resolver Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-19

Incremental Position Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-21

Remote Keypad Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-22

Logic and Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-24

Analog Inputs and Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-25

External Trip Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-27

Opto-isolated Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-28

Opto-isolated Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-30

Operating Mode Connection Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

Keypad Only Operating Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-32

Standard Run 3 Wire Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-33

15 Speed, Two Wire Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-34

Bipolar Speed or Torque Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-36

Process Control Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-37

Pre-Operation Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-41

Minimum Parameter and Control Setup Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-42

TABLE OF CONTENTS

MN723H-10/95 11/28/95 1:04 AM Page 3 (Black plate)

Page 3

Section 3

Keypad Programming and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Using the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-3

Display Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Adjusting Display Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-5

Program Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Control Software Parameter Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-6

Accessing Parameter Blocks for Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Programming or Changing Parameters when Security Code Not Used . . . . . . . . . . . . . . . .3-20

System Security . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-21

Program or Change Security System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-22

Program or Change Security System Access Timeout Parameter . . . . . . . . . . . . . . . .3-23

Program or Change Parameter with Security Code in Use . . . . . . . . . . . . . . . . . . . . . . . . .3-24

Operating the Control from the Keypad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

Accessing Jog Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-25

Keypad Entered Speed Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-26

Arrow Key Speed Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-27

Reset Control to Factory Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-28

Display Key Functions and Screens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

Section 4

Diagnostic Info and Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

How to Access Diagnostic Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

No Keypad Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-3

How to Access The Fault Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-4

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-7

Fault Symptoms and Possible Causes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-8

Improper Motor Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

Manually Tuning the Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-13

Appendix A Baldor District Offices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-1

Appendix B Control Watts Loss for Enclosure Sizing . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-2

Appendix C Terminal Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-3

Appendix D Recommended Wire Sizes and Protective Devices . . . . . . . . . . . . . . . . . . .5-4

Appendix E Short Circuit Current Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-8

Appendix F Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Appendix G Parameter List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-18

TABLE OF CONTENTS

MN723H-10/95 11/28/95 1:04 AM Page 4 (Black plate)

Page 4

Section 1

General Information

Intr

oduction

The Baldor Series 23H PWM control uses flux vector technology. Flux vector technology is a closed

loop control scheme using an algorithm to adjust the phase of voltage and current applied to a three

phase permanent magnet synchronous motor. The servo control separates the current into it's flux

and torque producing components. They are independently adjusted and vectorially added to

maintain a 90 degree relationship between them. This produces maximum torque from base speed

down to and including zero speed. Above base speed, the flux component is reduced for constant

horsepower operation.

The control should be sized to the motor using the rated output current of the control.

The Baldor Series 23H control may be used in many different applications. It may be programmed

by the user to operate in four different operating zones; 2.5 KHz PWM or 8.0 KHz PWM constant

torque or variable torque. It can also be configured to function in a number of modes depending

upon what the application requires and user preference.

It is the responsibility of the user to determine the optimum operating zone and mode to interface

the control to the application. These choices can be made through the keypad on the face of the

controller as explained in Section 3 of this manual.

Warranty

BALDOR warrants that the products sold will be free from defects in material and workmanship and

perform to BALDOR's applicable published specifications for a period of two (2) years from the date

of shipment from BALDOR's plant. BALDOR extends this limited warranty to each buyer of the

control for the purpose of resale and to the original purchaser for use. (Use shall be defined as

installation and application of power.) The liability of BALDOR hereunder shall be limited to replacing

or repairing, at its option, any defective units or parts thereof which are returned F.O.B. BALDOR's

plant. In no event shall BALDOR be liable for any consequential or incidental damages.

Equipment or parts which have been subjected to abuse, misuse, accident, alteration, neglect,

unauthorized repair or installation are not covered by warranty. BALDOR shall make the final

determination as to the existence and cause of any alleged defect. No liability is assumed for

expendable items such as fuses. No warranty is made with respect to custom equipment or

products produced to Buyers specifications except as specially stated in writing by BALDOR in the

contract for such custom equipment.

This warranty is the only warranty made by BALDOR with respect to the goods delivered hereunder,

and may be modified or amended only by a written agreement signed by a duly authorized officer of

BALDOR and accepted by Buyer.

Warranty of any product purchased by BALDOR from others is limited in time and scope to any

warranty given BALDOR by such suppliers.

Except as hereinabove provided. BALDOR MAKES NO WARRANTIES, EXPRESS OR IMPLIED,

INCLUDING ANY WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE.

1-1GENERAL INFORMATION

MN723H-10/95 11/28/95 1:04 AM Page 5 (Black plate)

Page 5

Safety Notice

THIS EQUIPMENT CONTAINS VOLTAGES WHICH MAY BE AS HIGH AS 1000 VOLTS AND

ROTATING PARTS ON MOTORS AND DRIVEN MACHINES. HIGH VOLTAGE AND

MOVING PARTS CAN CAUSE SERIOUS OR FATAL INJURY. ONLY QUALIFIED

PERSONNEL FAMILIAR WITH THIS MANUAL AND ANY DRIVEN MACHINERY SHOULD

ATTEMPT TO START-UP OR TROUBLESHOOT THIS EQUIPMENT.

OBSERVE THESE PRECAUTIONS:

USE EXTREME CAUTION, DO NOT TOUCH ANY CIRCUIT BOARD, POWER DEVICE OR

ELECTRICAL CONNECTION WITHOUT INSURING THAT HIGH VOLTAGE IS NOT

PRESENT.

THE UNIT MUST BE PROPERLY GROUNDED. DO NOT APPLY AC POWER BEFORE

FOLLOWING GROUNDING INSTRUCTIONS.

DO NOT OPEN COVER FOR 5 MINUTES AFTER REMOVING AC POWER, TO ALLOW

CAPACITORS TO DISCHARGE.

IMPROPER CONTROL OPERATION MAY CAUSE VIOLENT MOTION OF MOTOR SHAFT

AND DRIVEN EQUIPMENT. BE CERTAIN THAT UNEXPECTED MOTOR SHAFT

MOVEMENT WILL NOT CAUSE INJURY TO PERSONNEL OR DAMAGE TO EQUIPMENT.

PEAK TORQUES OF SEVERAL TIMES RATED MOTOR TORQUE CAN OCCUR DURING A

CONTROL FAILURE.

MOTOR CIRCUIT MAY HAVE HIGH VOLTAGE PRESENT WHENEVER AC POWER IS

APPLIED, EVEN WHEN MOTOR IS NOT ROTATING.

SUITABLE FOR USE ON A CIRCUIT CAPABLE OF DELIVERING NOT MORE THAN THE

MAXIMUM LINE SHORT CIRCUIT CURRENT AMPERES LISTED IN APPENDIX E,

230 VAC OR 460 VAC MAXIMUM PER CONTROLLER RATING.

1-2 GENERAL INFORMATION

MN723H-10/95 11/28/95 1:04 AM Page 6 (Black plate)

Page 6

Specifications

Power .75 - 37.2 KW (1 - 50 HP) @ 230 VAC

.75 - 186.5 KW (1 - 250 HP) @ 460 VAC

Input Frequency 50 / 60 HZ

Output Voltage 0 to max input VAC

Output Current See Control Rating Table

Service Factor 1.0

Duty Continuous

Overload Capacity Constant Torque: 200% for 3 secs

150% for 60 secs

Variable Torque: 115% for 60 secs

Operating Conditions:

Rated Input Voltages and Frequencies:

(Jumper Selectable)

230 VAC Models 180 - 264 VAC @ 60 Hz

180 - 230 VAC @ 50 Hz

460 VAC Models 340 - 457 VAC @ 50 Hz

400 - 528 VAC @ 60 Hz

Input Line Impedance 3% Minimum Required

Ambient Temperature Operating: 0 to +40 deg C

Storage: -30 to +65 deg C

Humidity 10 to 90 % non-condensing

Altitude Sea level to 3300 feet without derating

Keypad Display:

Display Backlit LCD alpha-numeric, 2 lines

x 16 characters each line

Keys 12 key membrane with tactile feel

1-3GENERAL INFORMATION

MN723H-10/95 11/28/95 1:04 AM Page 7 (Black plate)

Page 7

Functions Output status monitoring

Digital speed control

Parameter setting and display

Fault log display

Motor run and jog

Local / Remote toggle

LED Indicators Forward run command

Reverse run command

Stop command

Jog active

Remote Mount 100 feet max from control

Control Specifications:

Control Method PWM

Velocity Loop Bandwidth Adjustable to 60 Hz

Current Loop Bandwidth Adjustable to 400 Hz

Maximum Output Frequency 500 Hz

8.0 KHz PWM Frequency Full rating 1-8 KHz PWM frequency, adjustable to

16 KHz with derating- See note preceding Ratings

Tables

Selectable Operating Modes Keypad

Standard 3 Wire Control

Two Wire Control w / 15 Preset Speeds

Bipolar Speed / Torque Control

Serial

Process

Dif

ferential Analog Input:

Common Mode Rejection 40 db

Full Scale Range +/-5VDC, +/-10VDC, 4-20 mA

Auto-selectable Resolutions 12 bits + sign below 1VDC command

9 bits + sign above 1VDC command

Update rate 2.0 msec in speed mode

1.0 msec in torque mode

1-4 GENERAL INFORMATION

MN723H-10/95 11/28/95 1:04 AM Page 8 (Black plate)

Page 8

Other Analog Input:

Full Scale Range 0 - 10 VDC

Resolution 9 bits + sign

Update Rate 2.0 msec

Analog Outputs: 2 Assignable

Full Scale Range 0 - 5 VDC

Resolution 8 bits

Update Rate 2.0 msec

Digital Inputs:

Opto-isolated Logic Inputs 9 Assignable

Rated Voltage 10 - 30 VDC (closed contacts std)

Input Impedance 6.8 K Ohms

Update Rate 8 msec

Digital Outputs:

Opto-isolated Logic Outputs 4 Assignable

ON Current Sink 60 mA Max

ON Voltage Drop 2 VDC Max

Update Rate 8 msec

1-5GENERAL INFORMATION

MN723H-10/95 11/28/95 1:04 AM Page 9 (Black plate)

Page 9

Diagnostic Indications:

Current Sense Fault Regeneration (DB) Overload

Ground Fault Soft Start Fault

Instantaneous Overcurrent Undervoltage

Invalid Power Base ID Ready

Line Power Loss Parameter Loss

Microprocessor Failure Overload

Overtemperature (Motor or Control) Overvoltage

Overspeed

Following Error

NOTE: ALL SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

Control Ratings

Ratings Tables follow

NOTE: DERATE THE CONTINUOUS AND PEAK CURRENT OUTPUT RATINGS BY

30% 16 KHz PWM FREQUENCY. DERATE PROPORTIONALLY BETWEEN

8.0 KHz AND 16 KHz.

1-6 GENERAL INFORMATION

MN723H-10/95 11/28/95 1:05 AM Page 10 (Black plate)

Page 10

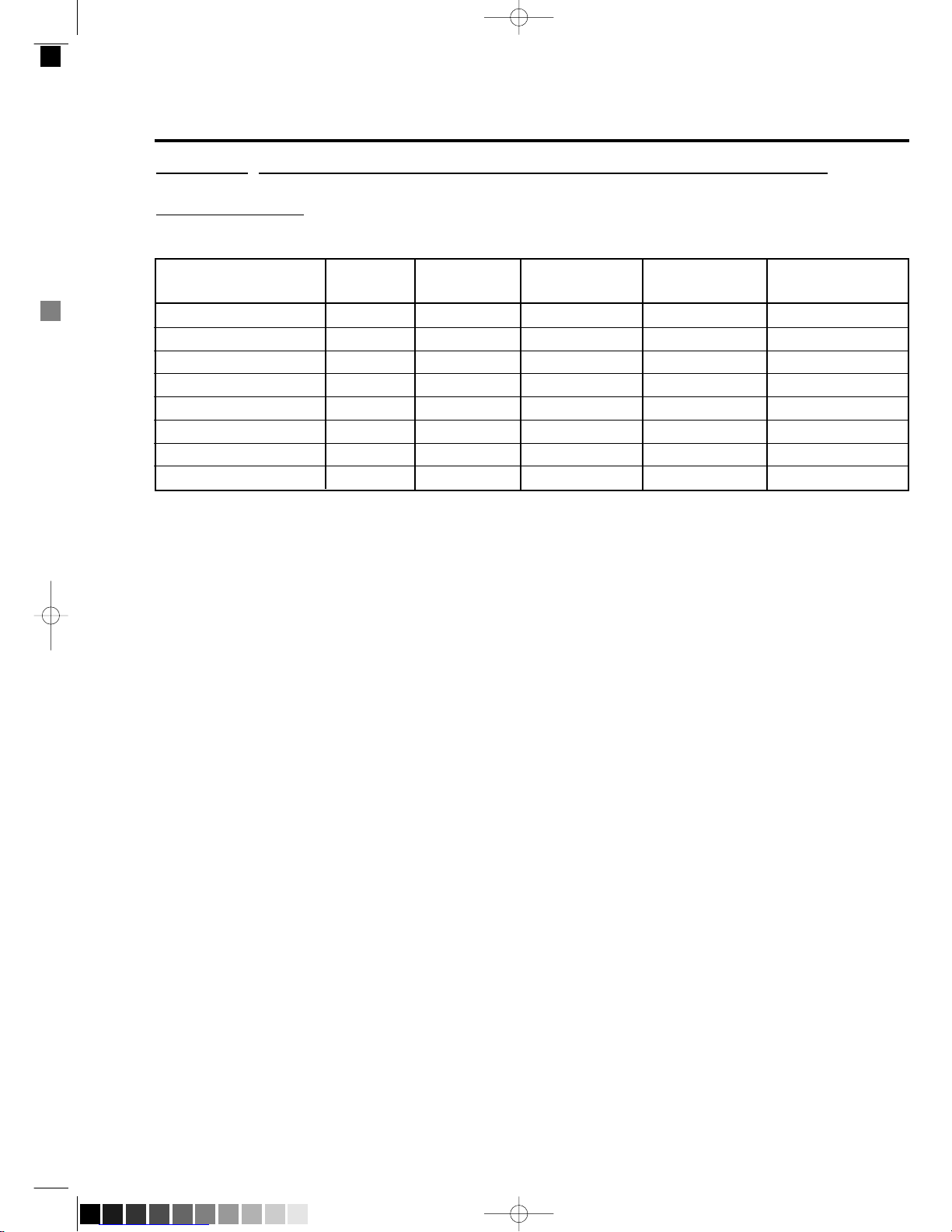

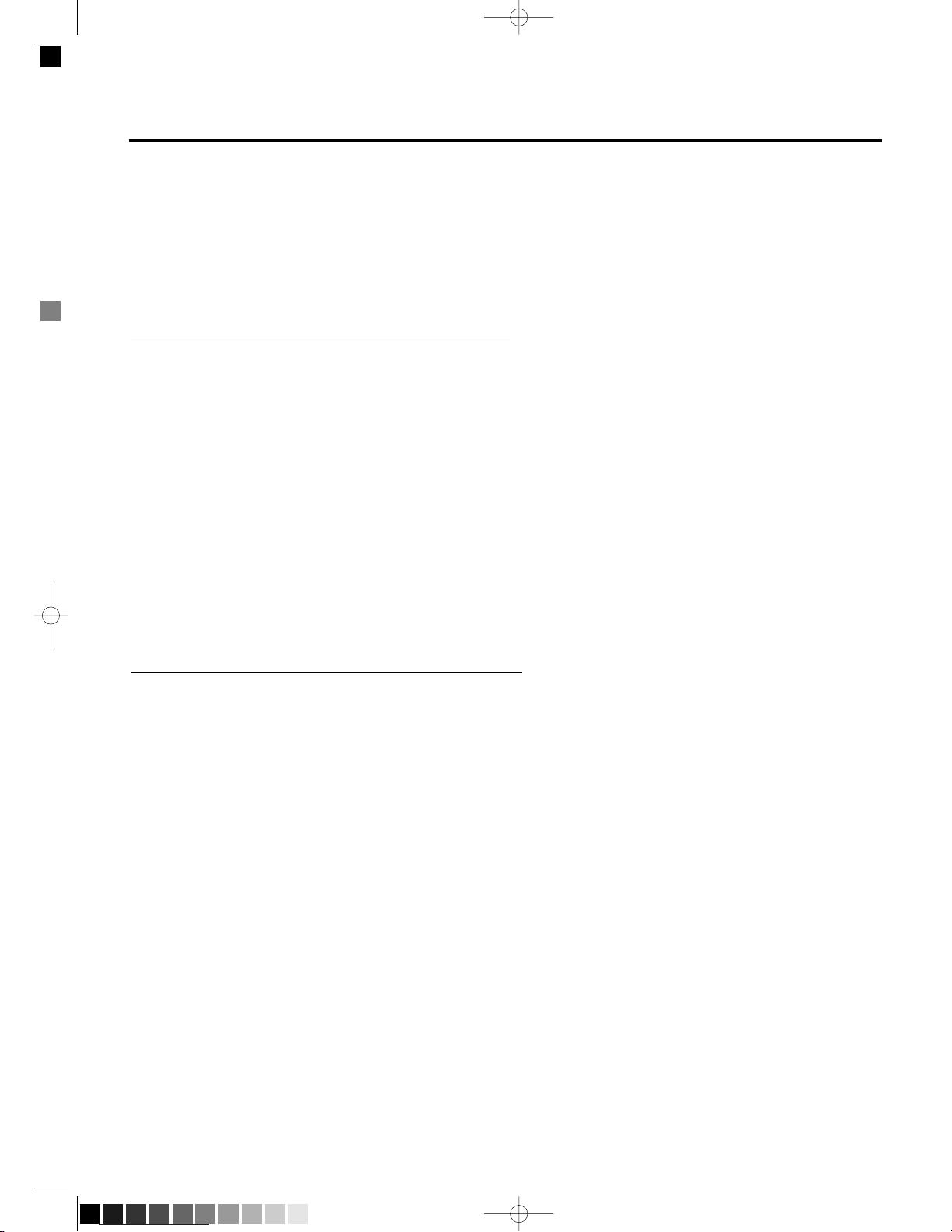

Ratings Series 23H Stock Products

1-7GENERAL INFORMATION

QUIET 8.0 kHz PWM STANDARD 2.5 kHz PWM

CATALOG INPUT CONSTANT TORQUE VARIABLE TORQUE CONSTANT TORQUE VARIABLE TORQUE

NO. VOLT SIZE IC IP KW HP IC IP KW HP IC IP KW HP IC IP KW HP

SD23H2A03-E 230 A 3 6 .56 .75 3.6 4.2 .75 1 4 8 .75 1 6.8 7.8 1.5 2

SD23H2A04-E 230 A 4 8 .75 1 6.8 7.8 1.5 2 7 14 1.5 2 9.6 11 2.2 3

SD23H2A07-E 230 A 7 14 1.5 2 9.6 11 2.2 3 10 20 2.2 3 15.2 17.5 3.7 5

SD23H2A10-E 230 A 10 20 2.2 3 15.2 17.5 3.7 5 15 30 3.7 5 15.2 17.5 3.7 5

SD23H2A15-E 230 B 15 30 3.7 5 22 25 5.5 7.5 22 44 5.5 7.5 28 32 7.4 10

SD23H2A22-E 230 B 22 44 5.5 7.5 28 32 7.4 10 28 56 7.4 10 28 32 7.4 10

SD23H2A30-ER 230 C 30 60 7.4 10 42 48 11.1 15 42 72 11.1 15 54 62 14.9 20

SD23H2A45-ER 230 C 45 90 11.1 15 54 62 14.9 20 55 100 14.9 20 68 78 18.6 25

SD23H2A55-ER 230 C 55 122 14.9 20 54 62 14.9 20 55 130 14.9 20 54 62 14.9 20

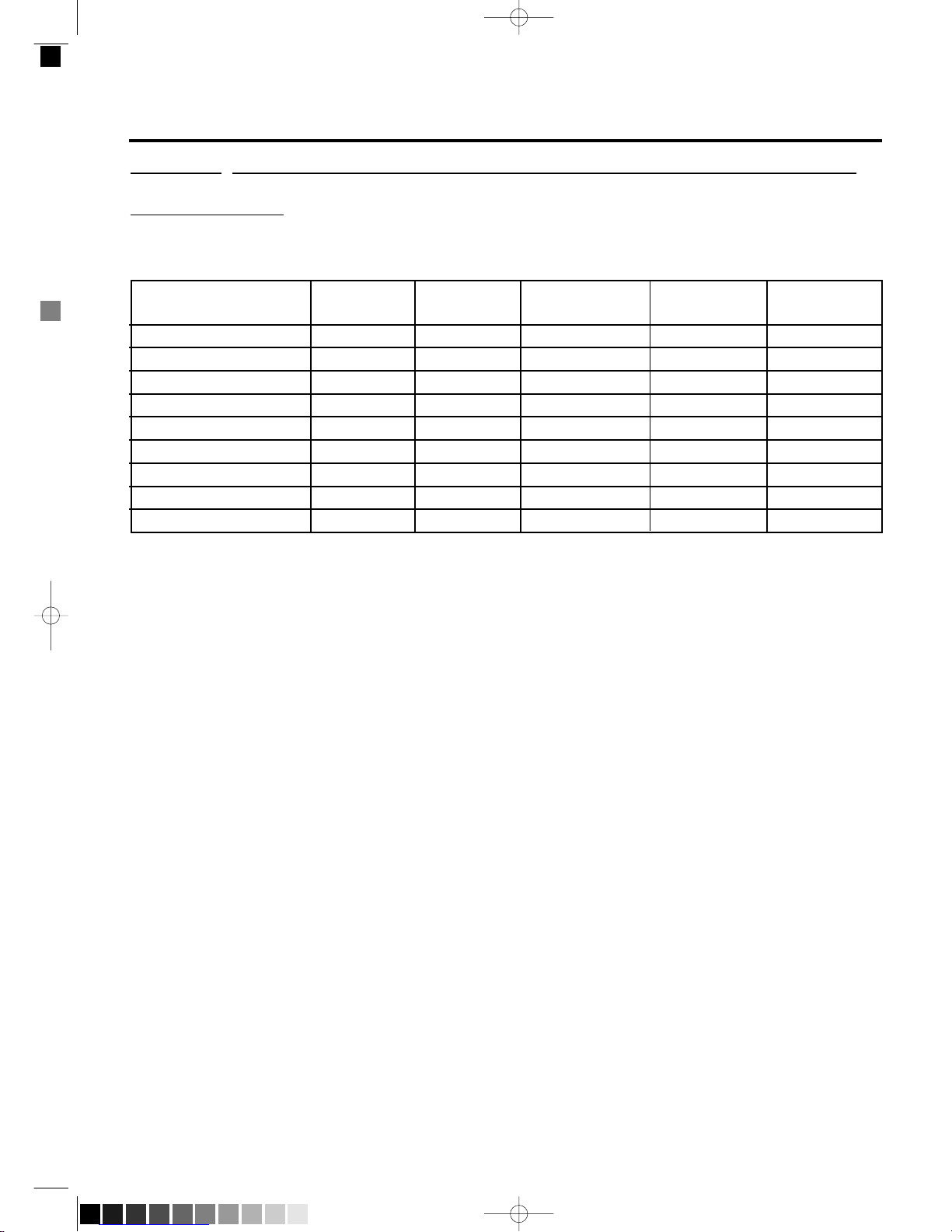

Ratings 23H Custom Products

QUIET 8.0 kHz PWM STANDARD 2.5 kHz PWM

CATALOG INPUT CONSTANT TORQUE VARIABLE TORQUE CONSTANT TORQUE VARIABLE TORQUE

NO. VOLT SIZE IC IP KW HP IC IP KW HP IC IP KW HP IC IP KW HP

SD23H4A02-E 460 A 2 4 .75 1 3.4 3.9 1.5 2 3.5 7 1.5 2 4.8 5.5 2.2 3

SD23H4A04-E 460 A 4 8 1.5 2 4.8 5.5 2.2 3 5 10 2.2 3 7.6 8.7 3.7 5

SD23H4A05-E 460 A 5 10 2.2 3 7.6 8.7 3.7 5 7 15 3.7 5 7.6 8.7 3.7 5

SD23H4A08-E 460 B 8 16 3.7 5 11 12.7 5.5 7.5 11 22 5.5 7.5 14 16.1 7.4 10

SD23H4A11-E 460 B 11 22 5.5 7.5 14 16.1 7.4 10 14 28 7.4 10 14 16.1 7.4 10

SD23H4A15-E 460 C 15 30 7.4 10 21 24 11.1 15 21 36 11.1 15 27 31 14.9 20

SD23H4A22-ER 460 C 22 44 11.1 15 27 31 14.9 20 27 54 14.9 20 34 39 18.6 25

SD23H4A30-ER 460 C 30 60 14.9 20 27 31 14.9 20 30 70 14.9 20 34 39 18.6 25

MN723H-10/95 11/28/95 1:07 AM Page 11 (Black plate)

Page 11

1-8 GENERAL INFORMATION

MN723H-10/95 11/28/95 1:07 AM Page 12 (Black plate)

Page 12

Section 2

Installation

This section covers all instructions for proper mounting and wiring of the Baldor Series 23H servo

control. All tools required for normal installation should be available from any electrical service

technician. If problems arise after installation, please refer to Section 4 Diagnostics and

Troubleshooting.

Location and Mounting

Select a mounting surface for the control that will allow the control to be mounted in a vertical

position using the mounting holes provided. The area selected should allow for free air circulating

around the control. Provide for at least two inches of clearance on all sides for maximum cooling

efficiency.

CAUTION: AVOID LOCATING CONTROL IMMEDIATELY ABOVE OR BESIDE HEAT

GENERATING EQUIPMENT, OR DIRECTLY BELOW WATER OR STEAM

PIPES.

The control is designed for panel mounting. Mount in a clean dry enclosure with an ambient

temperature less than +40 deg C. DO NOT mount control above transformer or other sources of

heat. DO provide 2" minimum clear area above and below the control to allow free flow of air over

heatsink on the back of the enclosure.

Provide access to the front of the enclosure to adjust parameters and to observe the keypad. Allow

room to remove the front cover to gain access to the power components. Mounting dimensions are

provided in Section 5.

ALTITUDE DERATING: Control ratings apply to 3300 feet (1000 meters) altitude without

derating required. For installations at higher altitudes derate the

continuous and peak output currents of the control by 2% for

each 1000 feet above 3300 feet.

TEMPERATURE DERATING: Control ratings apply to 40°C ambient. Derate output by 2%/°C

above 40°C, up to a maximum of 60°C.

Main Cir

cuit Wiring

Inter-connection wiring is required between the vector control, AC power source, host controller and

any optional control stations. Use UL Listed closed loop connectors sized for the wire gage involved.

Connectors are to be installed using the crimp tool specified by the connector manufacturer.

CAUTION: SERIES 23H CONTROLS FEATURE UL APPROVED ADJUSTABLE MOTOR

OVERLOAD PROTECTION SUITABLE FOR MOTORS NO LESS THAN 50%

OF THE OUTPUT RATING OF THE CONTROL. OTHER GOVERNING ENCIES

SUCH AS NEC MAY REQUIRE SEPARATE OVER-CURRENT PROTECTION.

THE INSTALLER OF THIS EQUIPMENT IS RESPONSIBLE FOR COMPLYING

WITH THE NATIONAL ELECTRIC CODE AND ANY APPLICABLE LOCAL

2-1INSTALLATION

MN723H-10/95 11/28/95 1:07 AM Page 13 (Black plate)

Page 13

CODES WHICH GOVERN SUCH PRACTICES AS WIRING PROTECTION,

GROUNDING, DISCONNECTS AND OTHER CURRENT PROTECTION.

SEE APPENDIX E FOR MAXIMUM AC LINE SHORT CIRCUIT CAPACITIES

FOR ALL CONTROL CATALOG LISTINGS.

AC Line Impedance

The Baldor Series 23H servo control requires a minimum line impedance of 3%. If the incoming

power line does not have a minimum of 3% impedance, the addition of a line reactor will provide the

needed impedance in most cases. Use the formula below to calculate the size of the line reactor you

must provide. Line reactors are available from Baldor. Note: Continuous input currents for Series 23H

controls provided in Table 2.0 which follows.

L = (V L-L x .03) / (I x 1.732 x 377)

Where: L = minimum line inductance in henrys

V

L-L = input voltage measured from line to line

.03 = desired percentage of impedance

I = the continuous input current rating of the control

1.732 = square root of three

377 = constant used if the input frequency is 60 Hz. Use 314 if the Input

frequency is 50 Hz.

The controller is self protected from normal AC line transients and surges provided input impedance

from the AC line is at least 3% (voltage drop at the input is 3%minimum when the control draws

rated input current). Additional external protection may be required if high energy surges are present

on the incoming power source. These surges could be caused by sharing a power source with arc

welding equipment, large motors being started across the line, or other industrial equipment

requiring large surge currents. To prevent control damage due to power source disturbances the

following should be considered:

a. Connect the control on a feeder line with a line impedance of 3% minimum.

b. Supply power to the control through a 3% minimum impedance line reactor or

transformer.

Line reactors serve several purposes:

1) minimize voltage spikes from the power line that may cause the control to trip on overvoltage spikes.

2) minimize voltage harmonics from the control to the power line.

3) provide additional short circuit capability at the control.

CAUTION: DO NOT USE POWER FACTOR CORRECTION CAPACITORS ON THE INPUT

POWER LINES TO THE CONTROL OR DAMAGE TO THE CONTROL MAY

RESULT.

2-2 INSTALLATION

MN723H-10/95 11/28/95 1:07 AM Page 14 (Black plate)

Page 14

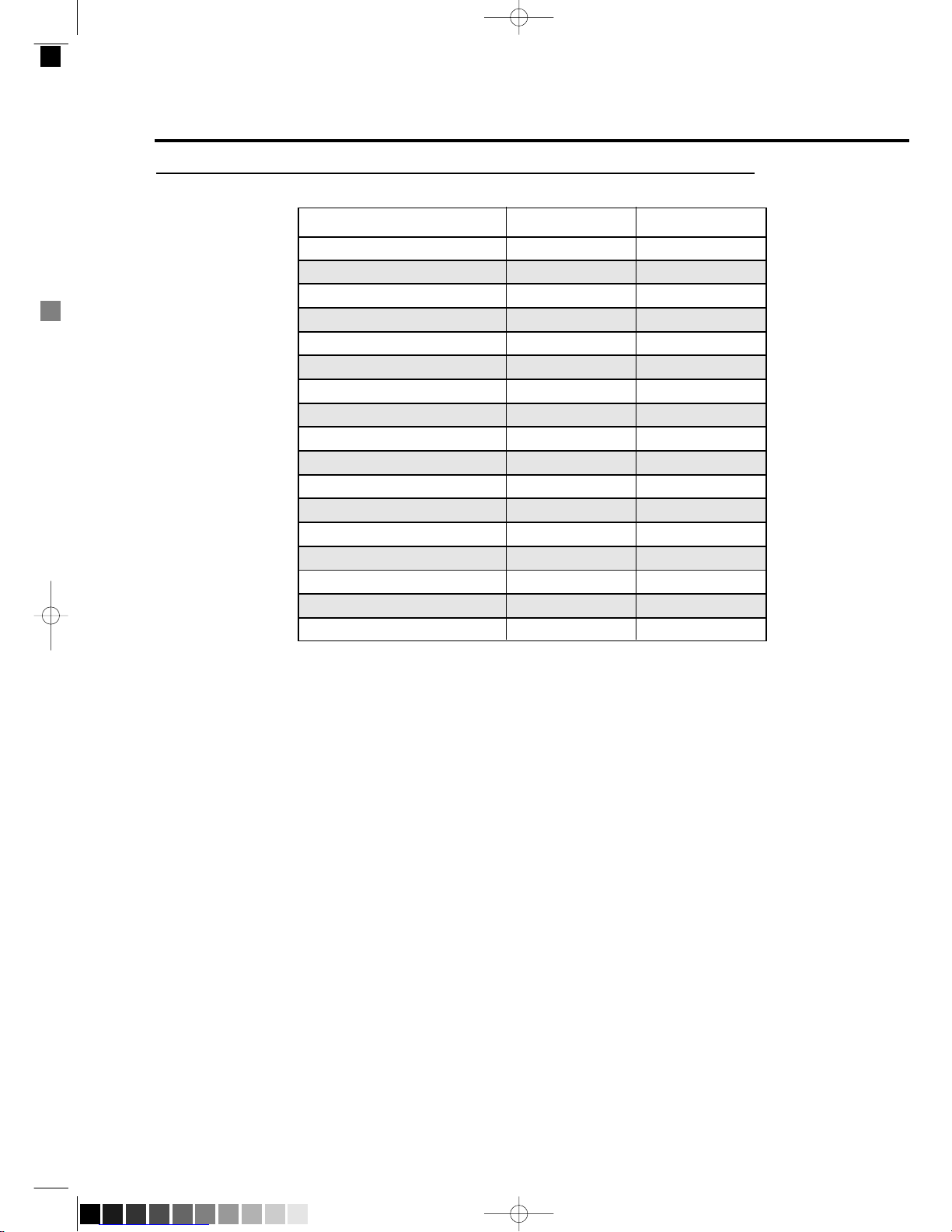

Table 2.0A Input Current Requirements - Series 23H Stock Products

2-3INSTALLATION

Catalog Number Line Voltage Input Current

SD23H2A03-E 230 6.8

SD23H2A04-E 230 9.6

SD23H2A07-E 230 15.2

SD23H2A10-E 230 15.2

SD23H2A15-E 230 28

SD23H2A22-E 230 28

SD23H2A30-ER 230 54

SD23H2A45-ER 230 68

SD23H2A55-ER 230 54

SD23H4A02-E 460 4.8

SD23H4A04-E 460 7.6

SD23H4A05-E 460 7.6

SD23H4A08-E 460 14

SD23H4A11-E 460 14

SD23H4A15-ER 460 27

SD23H4A22-ER 460 34

SD23H4A30-ER 460 34

MN723H-10/95 11/28/95 1:07 AM Page 15 (Black plate)

Page 15

AC Power Connections

The control requires input power protection in the form of either a circuit breaker or fuses. Circuit

breakers are recommended. See Table 2.1 for fuse and breaker sizing. Connect the fused three

phase AC power lines to the input power terminals L1, L2, and L3. The phase rotation of the

incoming power source is unimportant as the control is not phase sensitive.

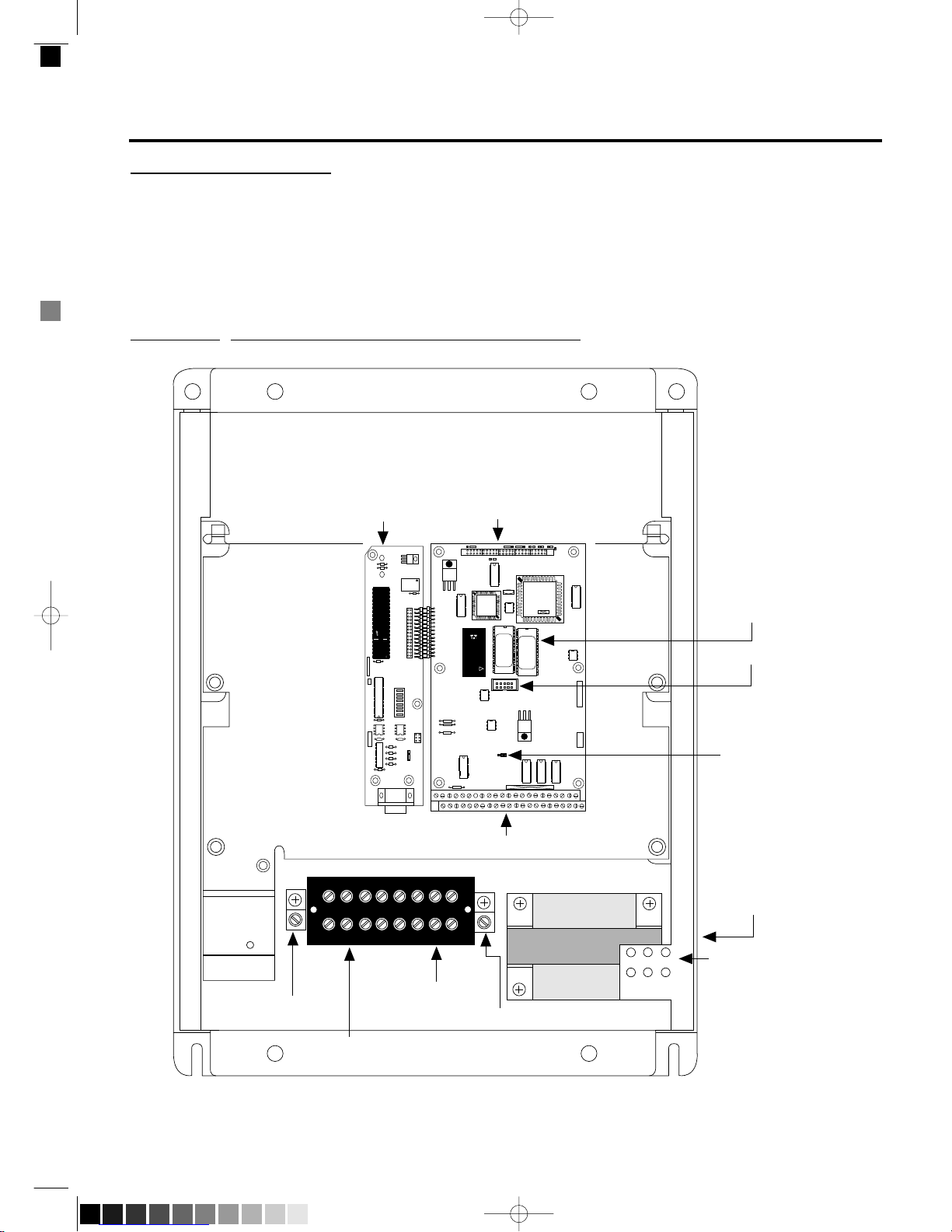

Figure 2-1 Series 23H Control with Cover Removed

2-4 INSTALLATION

DS1225Y-200

NONVOLATILE SRAM

9232D1 025313

DALLAS

59312

PC 16880CN

NE18550 FN

PATENTED

AG

X0-54B

3.6864 MHz

Dale

93-40

C7

04

C8

U6

C14

C10

C11

C12

C13

OTHER

RS232

JP3

2 WIRE

4 WIRE

C9

05

S1

SERIAL NO.

1 2 3 4 5 6 7 8

C6

C2

C3

C1

C4

+

+

U1

C5

VR1

U8

1

9

J4

19

29

VR1

J2

X1

RXD16

BALDOR SWEO DRIVE

SERIAL NO.

U10

ASSY NO 00839

JP1

U10

U9

Optional

Expansion Board

Control Board

J1 Control Connections

L1 L2 L3 T1 T2 T3 B+/R1 R2

(Labeled B+ and B- for

the “EO” controls

Main Circuit Connections

Control

Transformer T1

Keypad Connector

Software EPROMS

(Example shown is the “C” size controller. Other enclosure sizes vary

slightly in terminal sizes, transformer location, etc.

Power Ground

Motor Ground

JP1 Jumper

for 4-20mA

D1

D2

GND

Braking Logic

connections for

size C,D,E,F

“EO” Controls

(Not present on

Size A and B, “E”

Controls)

MN723H-10/95 11/28/95 1:07 AM Page 16 (Black plate)

Page 16

Wiring and Protective Devices

This control must be provided with a suitable input power protection device. Use the recommended

fuses or circuit breaker listed in Tables which follow. Input and output wire size is based on the use of

75 degree C rated copper conductor wire. The table is specified for NEMA B motors.

Circuit Breaker 3 phase, thermal magnetic. Equal to GE type THQ or

TEB for 230 VAC or GE type TED for 460 VAC.

Fast Action Fuses Buss KTN on 230 VAC, Buss KTS on 460 VAC or equivalent.

Time Delay Fuses Buss FRN on 230 VAC or Buss FRS on 460 VAC or equivalent.

2-5INSTALLATION

MN723H-10/95 11/28/95 1:07 AM Page 17 (Black plate)

Page 17

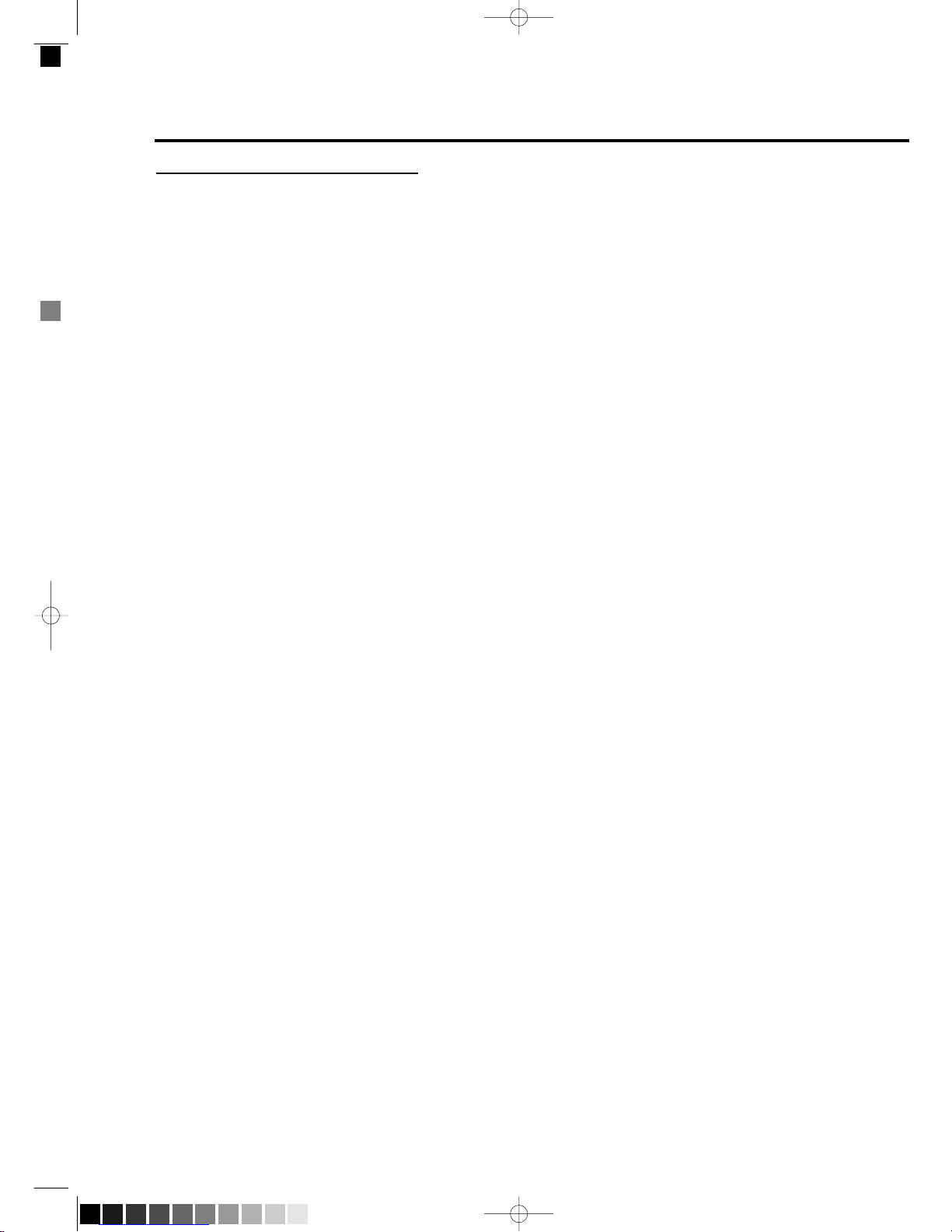

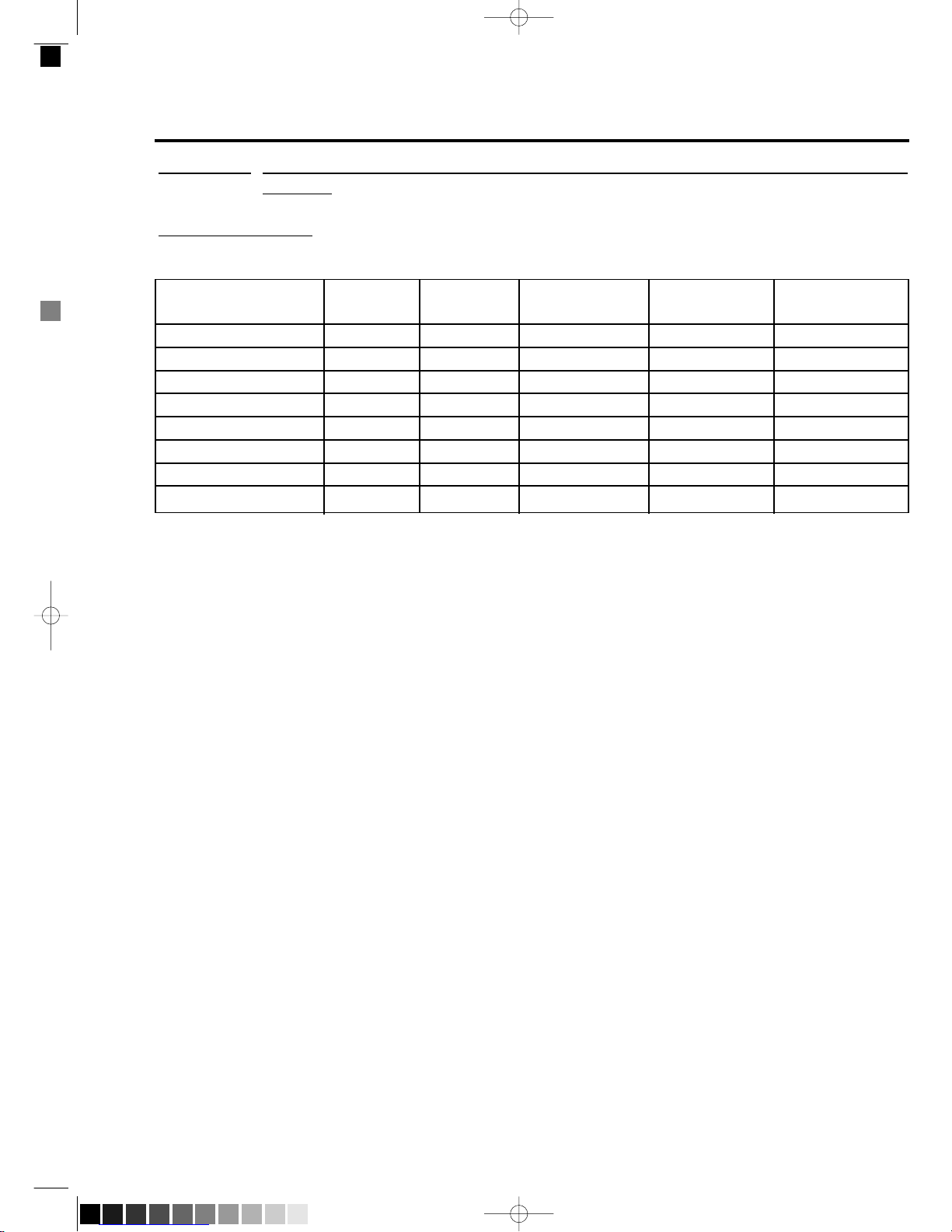

Table 2.1A Series 23H Stock Product Wire Size and Protection Devices

230VAC Controls

Catalog No. Max CT Input Input Fuse Input Fuse Wire Gauge

HP Breaker Fast Acting Time Delay AWG

SD23H2A03-E 1 15A 15A 15A 14

SD23H2A04-E 2 20A 20A 15A 14

SD23H2A07-E 3 30A 30A 15A 14

SD23H2A10-E 5 40A 40A 20A 12

SD23H2A15-E 7.5 60A 60A 30A 10

SD23H2A22-E 10 80A 80A 40A 8

SD23H2A30-ER 15 60A 60A 60A 4

SD23H2A45-ER 20 75A 75A 75A 3

SD23H2A55-ER 25 100A 100A 100A 2

NOTE: ALL WIRE SIZES BASED ON 75° C COPPER WIRE, 40°C AMBIENT, 3% LINE

IMPEDANCE. HIGHER TEMPERATURE SMALLER GAUGE WIRE MAY BE USED

PER NEC AND LOCAL CODES.

2-6 INSTALLATION

MN723H-10/95 11/28/95 1:08 AM Page 18 (Black plate)

Page 18

Table 2.1B Series 23H Product Wire Size and Protection Devices (Continued)

460VAC Controls

Catalog No. Max CT Input Input Fuse Input Fuse Wire Gauge

HP Breaker Fast Acting Time Delay AWG

SD23H4A02-E 2 10A 10A 10A 14

SD23H4A04-E 3 15A 15A 15A 14

SD23H4A05-E 5 20A 20A 15A 14

SD23H4A08-E 7.5 30A 30A 15A 14

SD23H4A11-E 10 40A 20A 20A 12

SD23H4A15-ER 15 30A 30A 30A 8

SD23H4A22-ER 20 40A 40A 40A 8

SD23H4A30-ER 25 50A 50A 50A 6

NOTE: ALL WIRE SIZES BASED ON 75° C COPPER WIRE, 40°C AMBIENT, 3% LINE

IMPEDANCE. HIGHER TEMPERATURE SMALLER GAUGE WIRE MAY BE USED

PER NEC AND LOCAL CODES.

2-7INSTALLATION

MN723H-10/95 11/28/95 1:08 AM Page 19 (Black plate)

Page 19

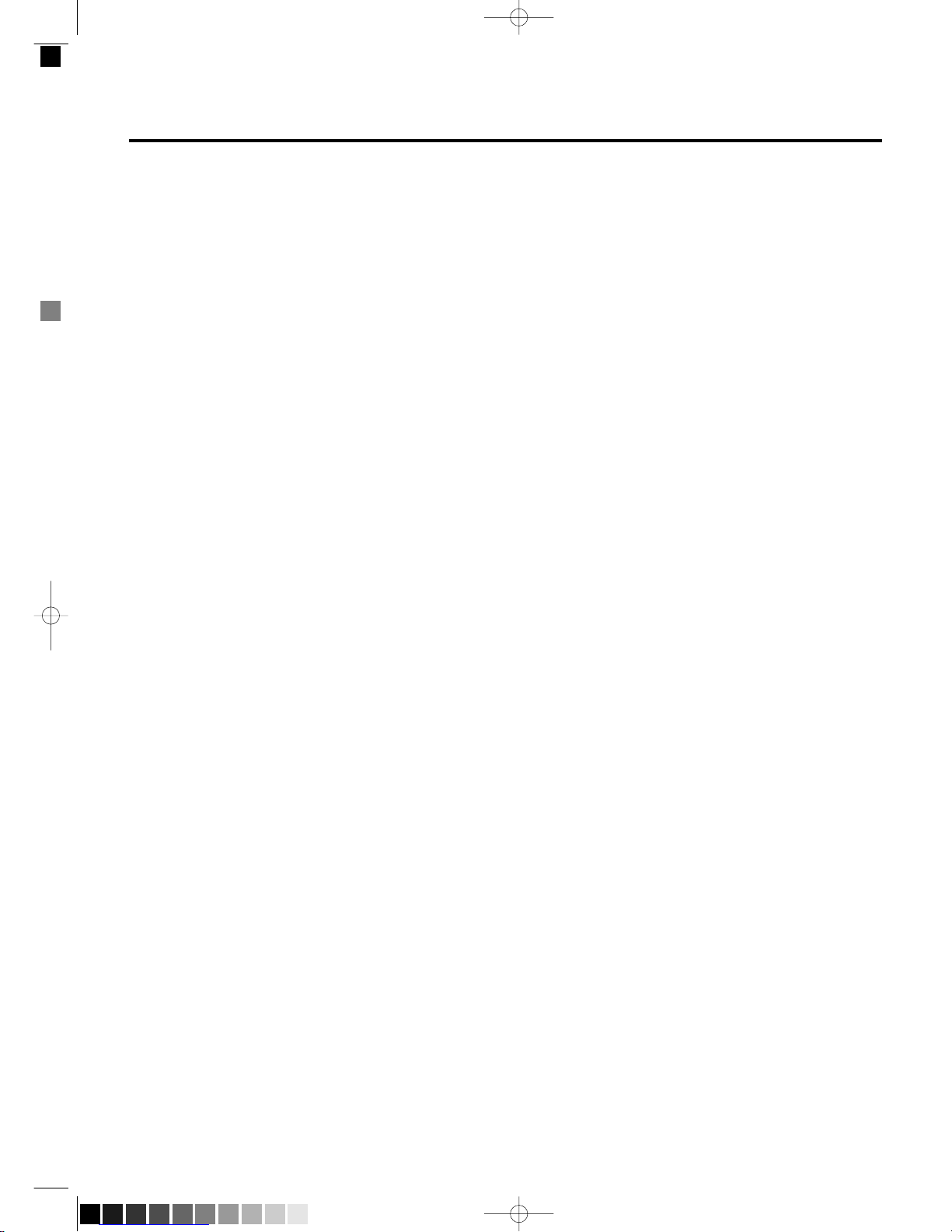

Table 2.2A Series 23H Stock Single Phase Rating Wire Size and Protection Devices

230 VAC Controls

Catalog No. Max CT Input Input Fuse Input Fuse Wire Gauge

HP Breaker Fast Acting Time Delay AWG

SD23H2A03-E 1 15A 15A 15A 14

SD23H2A04-E 2 15A 15A 15A 14

SD23H2A07-E 3 15A 15A 15A 14

SD23H2A10-E 5 15A 15A 15A 14

SD23H2A15-E 7.5 20A 20A 20A 12

SD23H2A22-E 10 30A 30A 30A 10

SD23H2A30-ER 15 40A 40A 40A 8

SD23H2A45-ER 20 60A 60A 60A 4

SD23H2A55-ER 25 75A 75A 75A 4

NOTE: ALL WIRE SIZES BASED ON 75° C COPPER WIRE, 40°C AMBIENT, 3% LINE

IMPEDANCE. HIGHER TEMPERATURE SMALLER GAUGE WIRE MAY BE USED

PER NEC AND LOCAL CODES.

2-8 INSTALLATION

MN723H-10/95 11/28/95 1:08 AM Page 20 (Black plate)

Page 20

Table 2.2B Series 23H Custom Single Phase Rating Product Wire Size and Protection

Devices

460 VAC Controls

Catalog No. Max CT Input Input Fuse Input Fuse Wire Gauge

HP Breaker Fast Acting Time Delay AWG

SD23H4A02-E 2 15A 15A 15A 14

SD23H4A04-E 3 15A 15A 15A 14

SD23H4A05-E 5 15A 15A 15A 14

SD23H4A08-E 7.5 15A 15A 15A 14

SD23H4A11-E 10 15A 15A 15A 14

SD23H4A15-ER 15 25A 25A 25A 10

SD23H4A22-ER 20 30A 30A 30A 8

SD23H4A30-ER 25 40A 40A 40A 8

NOTE: ALL WIRE SIZES BASED ON 75° C COPPER WIRE, 40°C AMBIENT, 3% LINE

IMPEDANCE. HIGHER TEMPERATURE SMALLER GAUGE WIRE MAY BE USED

PER NEC AND LOCAL CODES.

2-9INSTALLATION

MN723H-10/95 11/28/95 1:08 AM Page 21 (Black plate)

Page 21

Connect an earth ground to the control according to applicable local electrical codes. The earth

ground should be connected to the control chassis ground lug. Also connect motor ground to

control ground lug.

The use of a power disconnect is recommended between the input power and the control to provide

a fail safe method to disconnect the control from the input power. The control will remain in a

powered-up condition until all input power is removed from the control and the internal bus voltage is

depleted.

CAUTION: DO NOT ATTEMPT TO SERVICE THIS EQUIPMENT WHILE BUS VOLTAGE IS

PRESENT WITHIN THE CONTROL. REMOVE INPUT POWER AND WAIT AT

LEAST 5 MINUTES FOR THE RESIDUAL VOLTAGE IN THE BUS

CAPACITORS TO DISSIPATE.

CAUTION: THIS UNIT HAS AN AUTOMATIC RESTART FEATURE THAT WILL START

THE CONTROL WHENEVER INPUT POWER IS APPLIED AND A

MAINTAINED EXTERNAL RUN (FWD OR REV) COMMAND IS GIVEN TO THE

CONTROL. IF AN AUTOMATIC RESTART OF THE CONTROL COULD CAUSE

PERSONAL INJURY OR HARM, THE AUTO RESTART FEATURE OF THE

CONTROL SHOULD BE DISABLED BY EXTERNAL CONTROL WIRING

BREAKING THE ENABLE OR RUN SWITCH INPUTS.

2-10 INSTALLATION

MN723H-10/95 11/28/95 1:08 AM Page 22 (Black plate)

Page 22

Operating a 460 VAC Control on 380-400 VAC

Size A and B controls may be used directly with a 380-400 VAC power source, no reconfiguration of

the control is necessary.

Control sizes C, D, E, and F all must be reconfigured for operation on the reduced line voltage.

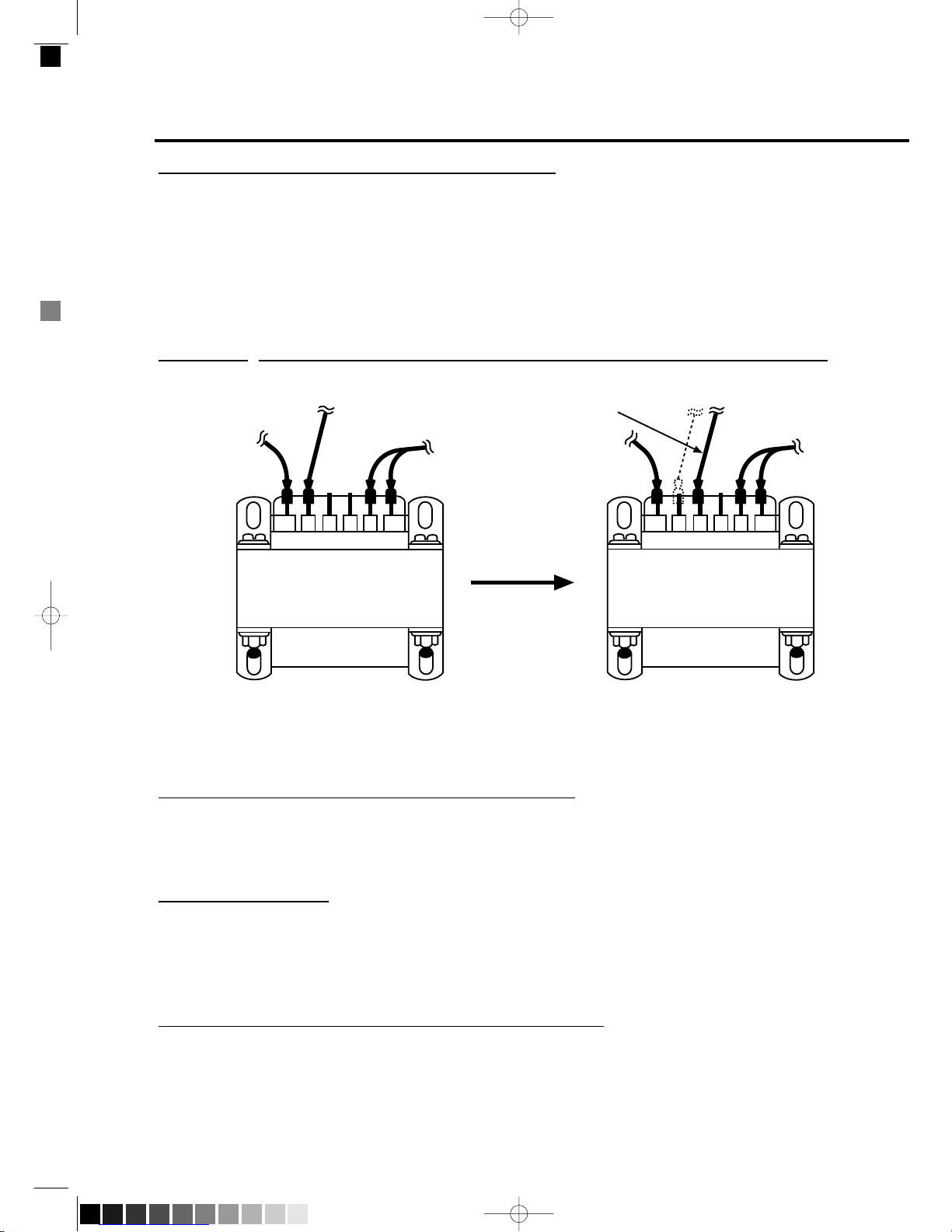

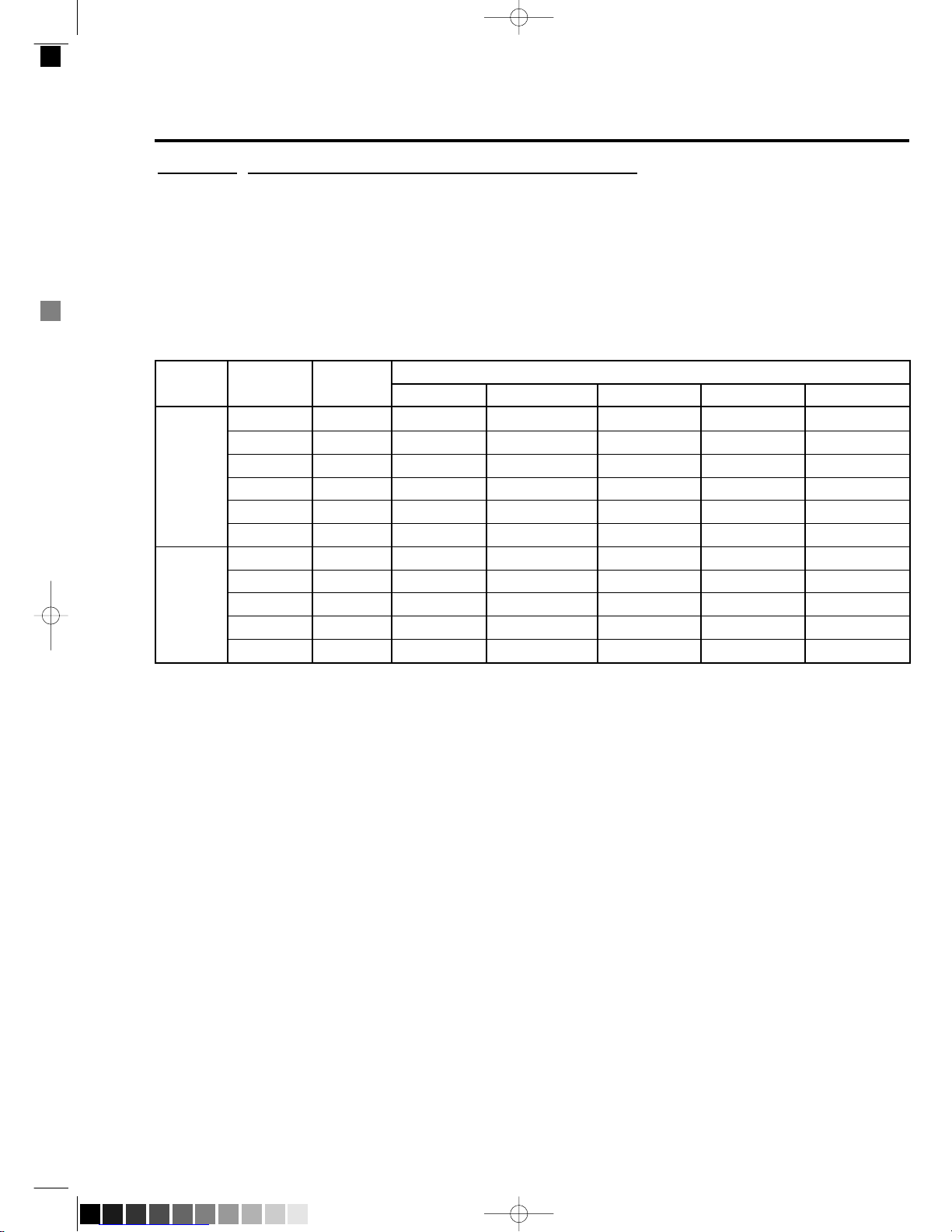

Specifically, the control transformer (see Figure 2-2) must have the wire on terminal 5 moved to

terminal 4 as shown below. Remove the front cover to gain access to the control transformer.

Figure 2-2 Configuring the Control Transformer for 380 - 400 VAC Operation

Operating the Control with a Single Phase Input

Single phase AC input power can be provided to the control instead of three (3) phase input to the

controls when the changes listed below have been made.

Power Connections

Connect the incoming power to input terminals L1 and L2. Place a jumper between control input

terminals L2 and L3. Size this jumper wire the same as the incoming line to L1. Change circuit board

jumpers as instructed below.

Hardware Jumpers Changes for Single Phase Input

1-50 HP 230 VAC controls: No hardware jumper changes to control necessary.

1-10 HP 460 VAC controls: No hardware jumper changes to control necessary.

2-11INSTALLATION

1 2 3 4 5 6

460V

1 2 3 4 5 6

380V/400V

NOTE: WIRES 3 & 6

MAY NOT BE PRESENT

ON ALL MODELS

MOVE WIRE FROM

POSITION 5 TO 4

MN723H-10/95 11/28/95 1:08 AM Page 23 (Black plate)

Page 23

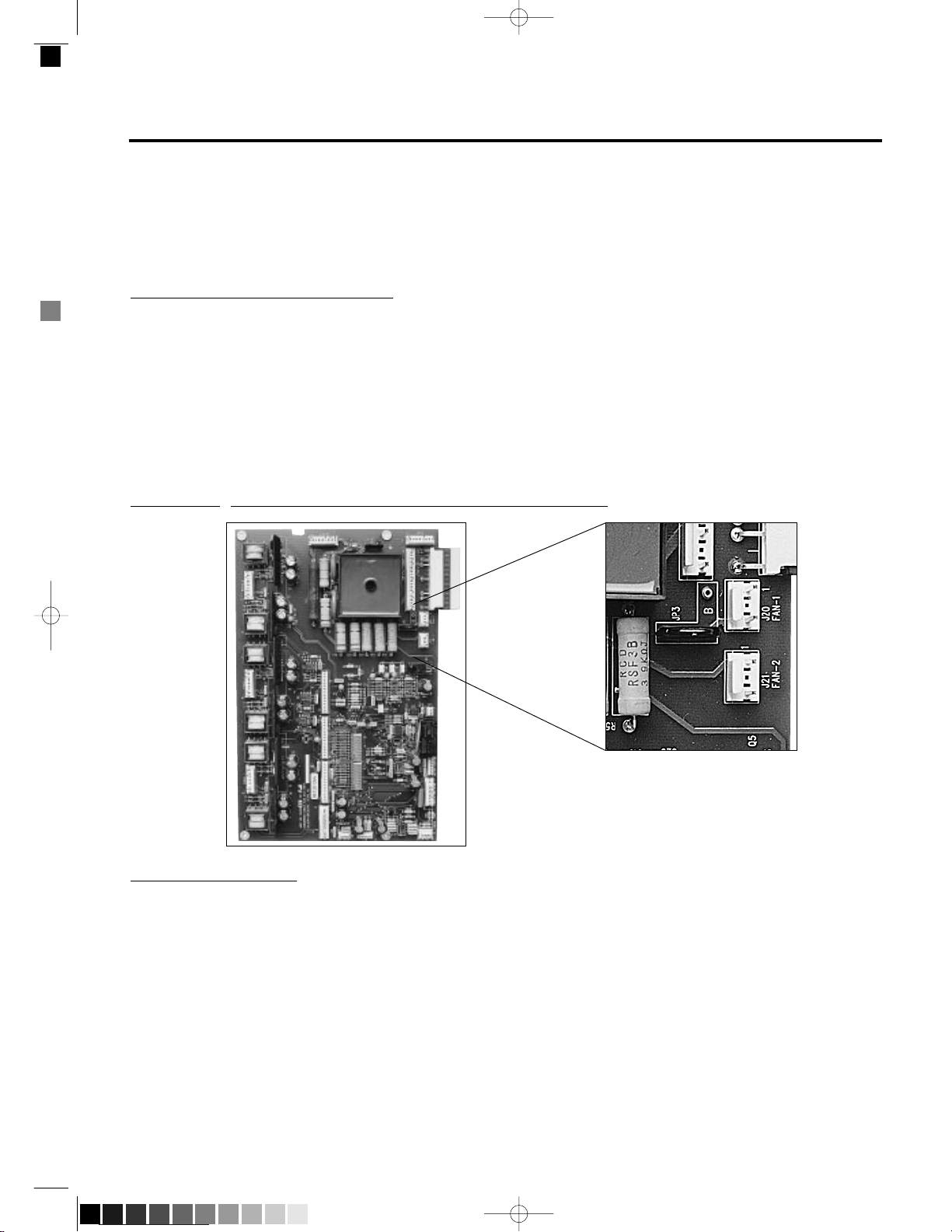

15-60 HP 460 VAC controls: Jumper JP3 on the gate drive circuit board (Figure 2-3) must be moved

from position "A" to position "B". The gate drive circuit board is under the main control board. For

controls equipped with gate drive board No. 083051 only, no jumper changes required.

75-250 HP 460 VAC controls: No hardware jumper change required for these controls.

Single Phase Control Derating

No derating is required for 1 and 2 HP controls.

3-10 HP controls must be derated by 40% of their nameplated rating for single phase operation.

15 HP and larger controls must be derated by 50% of their nameplated rating for single phase

operation.

Figure 2-3 Gate Driver Circuit Board with JP3 Jumper.

Motor Connections

Connect the three phase power leads of the AC permanent magnet motor to terminals T1, T2, and

T3 of the control power terminal strip. Motor power connections are not phase sensitive. The motor

ground lead or case ground should be connected to the control chassis ground screw. Connection

of motor temperature sensor switch to the external trip input, J1-16 located on the J1 terminal strip

is optional. The motor thermostat must be a dry contact (N.C.) type requiring no external power to

operate.

CAUTION: VOLTAGE MAY BE PRESENT AT THE MOTOR WHENEVER THE CONTROL

IS RECEIVING INPUT POWER. REMOVE ALL POWER FROM THE CONTROL

BEFORE ATTEMPTING ANY SERVICE OF THE MOTOR.

2-12 INSTALLATION

MN723H-10/95 11/28/95 1:09 AM Page 24 (Black plate)

Page 24

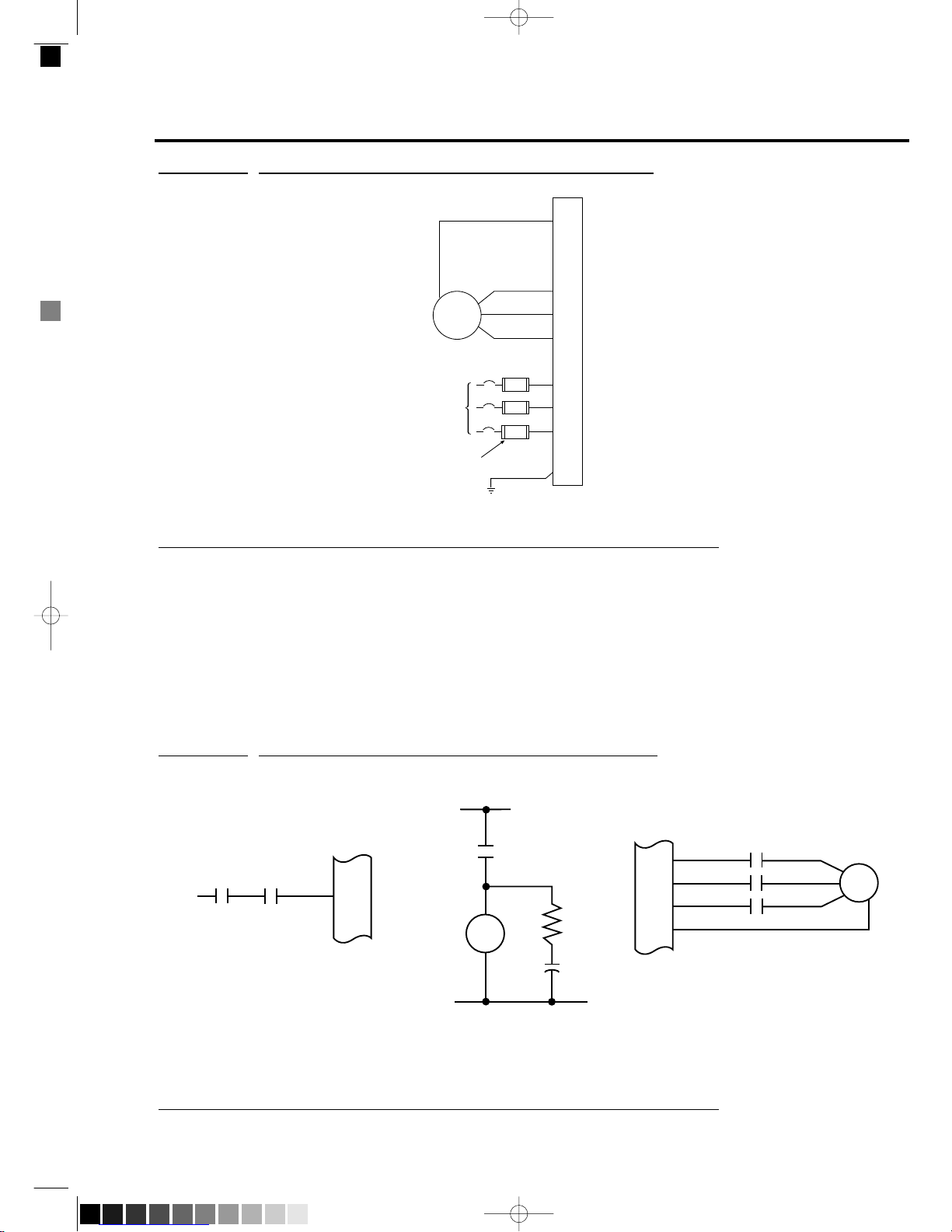

Figure 2-4 Motor Connections without Output Contactor

See Appendix C For Recommended Terminal Tightening Torques

A motor circuit contactor is recommended to provide a positive disconnection to prevent motor

rotation which could pose a safety hazard to personnel or equipment. Open the Enable input to J1

terminal strip at least 20 msec before main M-contacts open to prevent arcing at contacts. This

greatly increases contactor life and allows use of IEC rated contactors. See Figure 2-5 for motor

connection with M-contactor.

Figure 2-5 Typical Connection using Output M-Contactor

See Appendix C For Recommended Terminal Tightening Torques

2-13INSTALLATION

50/60 HZ

3 Phase

Power

MOTOR

GND

T3

T2

T1

Breaker or Fuse Protection -

Customer Option, Subject

to Local Codes

GND

R2

B+\R1

T3

T2

T1

L3

L2

L1

GND

ENABLE

7

8

9

J1-8 CONNECTION

M

J1

ENABLE

M

T1

T2

T3

GND

M

MN723H-10/95 11/28/95 1:09 AM Page 25 (Black plate)

Page 25

Dynamic Braking (DB) Selection

General Procedure

Use the following steps for proper selection of dynamic braking hardware:

1. Calculate the watts to be dissipated per the formulas to follow.

2. Identify the middle number of the controller and determine which dynamic brake hardware is

required based on the model number suffix (-E, -ER).

3 Select the required hardware from the Baldor Electric Company 501 catalog or from the

hardware listings that follow.

Sizing Procedure

For either general machinery or hoisting applications, the same sizing procedure (with different

formulas) is used:

1. Determine TDEC (Deceleration Torque or weight to be lowered)

2. Determine D r(Dynamic Braking Duty Cycle)

3. Determine W r(Regenerated Watts)

4. Use External Dynamic Brake Resistor Assemblies Table to select the part number for braking

hardware.

General Machinery

To determine deceleration torque, use the formula:

Where:

T

DEC = deceleration torque in lb-ft

∆RPM = change in speed

WK

2

= inertia in lb-ft

2

t = seconds

Hoisting Applications:

To determine hoist braking duty cycle use the formula:

Where:

Dr = duty cycle

LT = lowering time

TCT = total cycle time

2-14 INSTALLATION

∆RPM x WK

2

308 x t

T

DEC

=

LT

TCT

Dr=

MN723H-10/95 11/28/95 1:09 AM Page 26 (Black plate)

Page 26

2-15INSTALLATION

To determine average regenerated watts caused by lowering a load, use the formula:

where:

lbs = weight to be lowered

FPM = speed in ft/minute

EFF = mechanical efficiency as a decimal

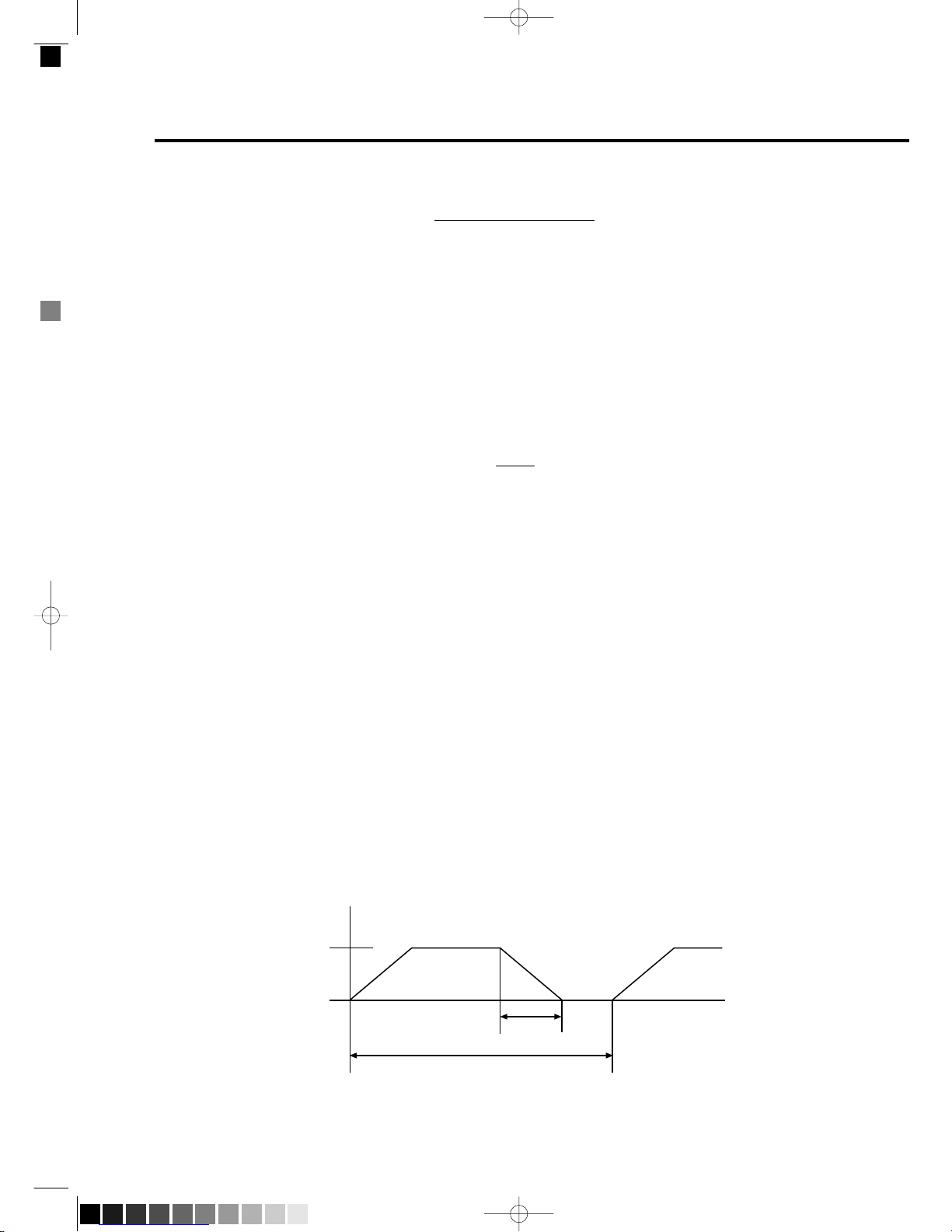

To determine dynamic braking duty cycle, use the formula:

where:

Dr = duty cycle

BT = braking time required to decelerate

TCT = total cycle time

To determine the watts to be dissipated, use the formula:

where:

Sr = maximum speed regenerating (RPM)

Sm = minimum speed regenerating (RPM)

NOTE: TO PROVIDE MAXIMUM LIFE AND ALLOW FOR UNANTICIPATED LOADS,

MULTIPLY THE REGENERATED WATTS (Wr) RATING BY 1.25.

Drx lbs x FPM x EFF

44

Wr=

wr= T

DEC

x (Sr+ Sm) x Drx (0.0712)

Braking Time (BT)

Total Cycle Time (TCT)

Sr

Sm

BT

TCT

Dr=

MN723H-10/95 11/28/95 1:09 AM Page 27 (Black plate)

Page 27

If the application requires dynamic braking to dissipate motor generated energy, an optional external

braking assembly or kit will be required. The type of dynamic braking assembly or kit depends on the

specific control model and user preference. The available assemblies and kits that will fit a given

control depend on the control catalog number suffix.

CAUTION: DB SHOULD NOT BE USED IN APPLICATIONS REQUIRING CONTINUOUS

BRAKING (REGENERATION).

Control Catalog Numbers with an "E" Suffix

These controls come equipped with both the dynamic braking transistor and braking resistor factory

installed. This configuration is capable of providing 100% braking torque for 6 seconds of a 20%

braking duty cycle. Should additional braking capacity be required an optional externally mounted

braking resistor hardware is required.

This hardware is available in two configurations:

1) RG Kit-includes braking resistors mounted on brackets and the resistors are wired

together for the correct equivalent resistance required by the braking transistor.

2) RGA Assemblies-includes braking resistors on brackets, wired together for correct

resistance and mounted in a NEMA 1 screened enclosure.

A listing of RGA assemblies available follows in Table 2.3.

Control Catalog Numbers with an "ER" Suffix

These controls have the dynamic braking transistor installed at the factory but no dynamic braking

resistors. Should you need dynamic braking capacity optional separately mounted external braking

resistor kits or assemblies are available from Baldor.

One hardware configuration is the RG kit which comes with resistors mounted on brackets and the

resistors wired together for the correct resistance required by the control's DB transistor. These

resistors must be mounted in an enclosure by the customer.

The other DB hardware configuration available is the RGA Assembly. It includes the resistors on

brackets and the resistors wired together all mounted in a NEMA 1 screened enclosure.

A listing of available RGA assemblies follows in Table 2.3.

2-16 INSTALLATION

MN723H-10/95 11/28/95 1:09 AM Page 28 (Black plate)

Page 28

Table 2.3 Dynamic Braking Resistor Assemblies (RGA)

RGA Assemblies include braking resistors completely assembled and mounted in a NEMA 1

enclosure. For 1-10 HP (E) controls select braking resistor that has the correct ohm value for the

control and adequate continuous watts capacity. For 15 HP and above (EO, ER, and MO controls)

select braking resistor from table with matching ohms for the RTA selected and adequate continuous

watts capacity. Note: Can use RBA assembly instead of separate RTA and RGA assemblies. See

Figure 2-6 for RGA connection diagram.

Input

HP

Total Continuous Rated Watts

Volts OHMs 600 1200 2400 4800 6400

230 1-3 20 RGA620 RGA1220 RGA2420 RGA4820

5 14 RGA614 RGA1214 RGA2414 RGA4814

7.5-20 6 RGA606 RGA1206 RGA2406 RGA4806

25-30 4 RGA604 RGA1204 RGA2404 RGA4804

40 3 RGA1203 RGA2403 RGA4803

50 2 RGA1202 RGA2402 RGA4802 RGA6402

460 1-5 56 RGA656 RGA1256 RGA2456 RGA4856

7.5-10 24 RGA624 RGA1224 RGA2424 RGA4824

15-25 20 RGA620 RGA1220 RGA2420 RGA4820

30-60 10 RGA610 RGA1210 RGA2410 RGA4810

75-250 4 RGA2404 RGA4804 RGA6404

2-17INSTALLATION

MN723H-10/95 11/28/95 1:09 AM Page 29 (Black plate)

Page 29

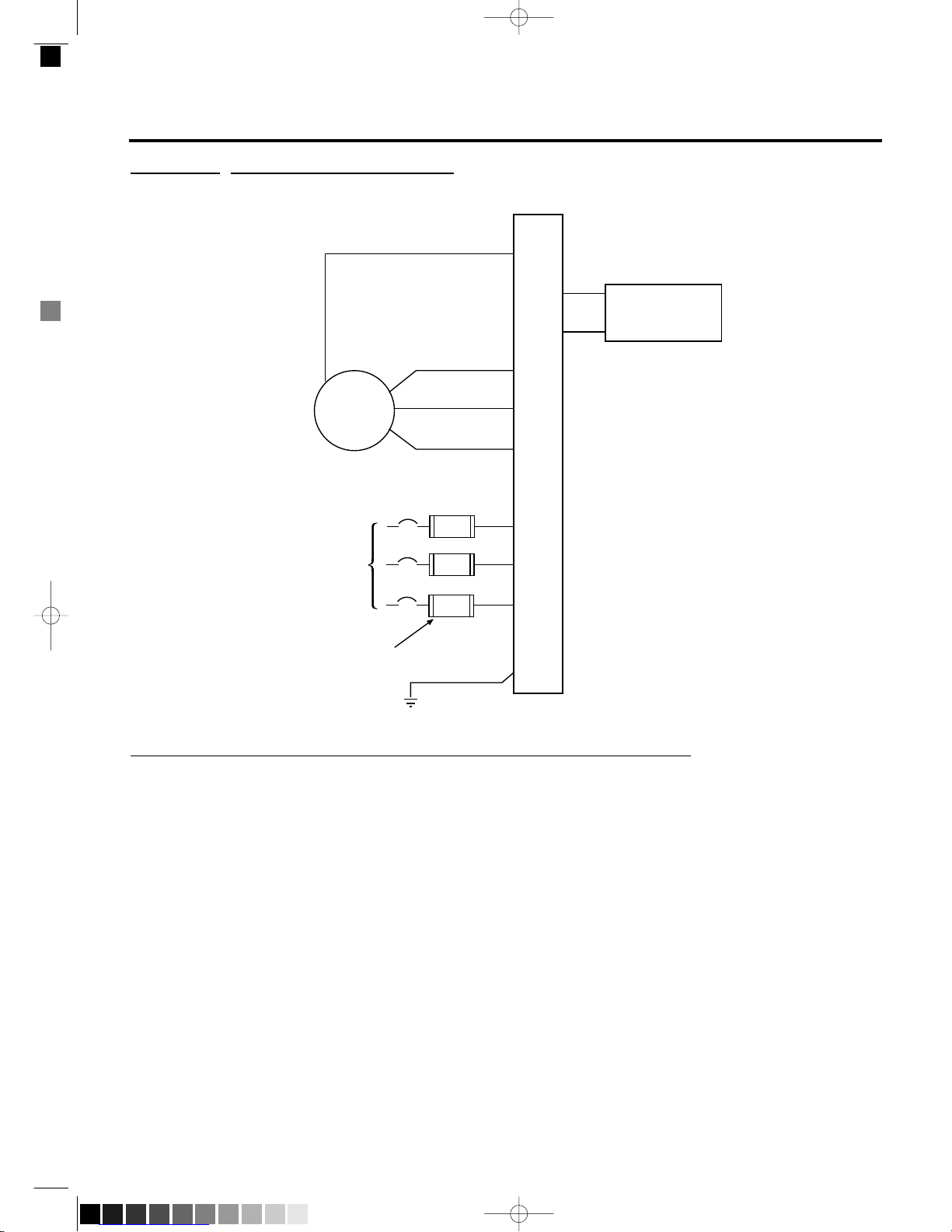

Figure 2-6 Wiring for RGA Assembly

See Appendix C For Recommended Terminal Tightening Torques

2-18 INSTALLATION

50/60 HZ

3 Phase

Power

MOTOR

GND

T3

T2

T1

Breaker or Fuse Protection Customer Option

Optional

Dynamic Brake

(RGA)

GND

R2

B+\R1

T3

T2

T1

L3

L2

L1

GND

MN723H-10/95 11/28/95 1:09 AM Page 30 (Black plate)

Page 30

Resolver Wiring

The 23H control requires the use of resolver feedback from the motor shaft. The resolver power and

signal connections are made to the control's J1 terminal strip.

Resolver wiring must be twisted shielded pairs, #22 AWG minimum size, 150' maximum, with an

insulated overall shield. Connect all shields to J1-29. Maximum wire-to-wire or wire-to-shield

capacity shall not exceed 7500 picofarads per pair (50 pf/foot at 150' length).

2-19INSTALLATION

MN723H-10/95 11/28/95 1:09 AM Page 31 (Black plate)

Page 31

Connecting the Resolver

CAUTION: DO NOT CONNECT ANY SHIELDS TO THE MOTOR FRAME. THE

RESOLVER POWER SUPPLY OUTPUT PROVIDED BY THE CONTROL AT J127 IS REFERENCED TO CIRCUIT BOARD COMMON. DO NOT CONNECT

THIS OUTPUT TO GROUND OR ANOTHER POWER SUPPLY OR DAMAGE

TO THE CONTROL MAY RESULT.

Resolver wiring must be separated from power wiring. Separate parallel runs of resolver cable by at

least 3" from power wires. Cross power wires at right angles only. Insulate or tape off ungrounded

end of shields to prevent contact with other conductors or ground.

Figure 2-10 Resolver Connections

See Appendix C For Recommended Terminal Tightening Torques

2-20 INSTALLATION

RESOLVER

R2

R1

S3

S4

S2

S1

P

P

P

J1

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

SINE + 2V RMS

SINE COS + 2V RMS

COS EXCITATION + 4V RMS, 10 KHz

EXCITATION – (COMMON)

SHIELD

NOT USED

A OUT

A OUT

B OUT

B OUT

INDEX OUT (C)

INDEX OUT (C)

NOT USED

COMMON

CONTROL BOARD

P

= TWISTED PAIR

INCREMENTAL POSITION OUTPUT

MN723H-10/95 11/28/95 1:09 AM Page 32 (Black plate)

Page 32

Incremental Position Output

The control provides a simulated encoder output of the motor mounted resolver on terminal strip J1

pins 31-38 as shown in Figure 2-10. This output simulates a 1024 line encoder with quadrature

outputs. Counting in quadrature will provide 4096 pulses per revolution of the motor shaft when

using a standard single speed resolver. This output may be used by external hardware to monitor the

motor position. Splitting this output is not recommended.

This output also provides one (1) index marker (“C” channel marker) per resolver speed. For

example, a single speed resolver will have one pulse generated per one shaft revolution. A two

speed resolver will have two pulses generated per one revolution of the shaft with 180˚ mechanical

separation.

Figure 2-11 Optional Resolver Filter for High Noise Environment

See Appendix C For Recommended Terminal Tightening Torques

2-21INSTALLATION

RESOLVER

R2

R1

S3

S4

S2

S1

P

P

P

J1

23

24

25

26

27

28

SINE + 2V RMS

SINE COS + 2V RMS

COS EXCITATION + 4V RMS, 10KHz

COMMON

CONTROL BOARD

RESOLVER FILTER P/N 0088801

SINE +

SINE COS +

COS -

EXC +

COM.

MN723H-10/95 11/28/95 1:09 AM Page 33 (Black plate)

Page 33

Remote Keypad Mounting

Instructions for Remote Keypad Mounting Using Optional Baldor Keypad Extension

Cable

The keypad assembly (DC00005A-00) comes complete with the screws and gasket required to

mount it to an enclosure. When the keypad is properly mounted to a NEMA Type 4 enclosure, it

retains the Type 4 rating.

Tools Required:

Drill, center punch, tap handle, screwdrivers: Phillips and straight, crescent wrench.

8-32 tap and #29 drill (if threading mounting surface).

1-1/4 standard knockout punch (1-11/16" nominal diameter).

RTV sealant.

(4) 8-32 nuts and lock washers.

Extended 8-32 screws (socket ,phillister) will be required if the mounting surface is thicker than

12 gage and is not tapped (through hole approach).

Remote keypad mounting template. (See next page for template)

Mounting Instructions: For tapped mounting holes

1. Locate a flat 4" wide x 5.5" minimum high mounting surface. Material should be sufficient

gage (14 minimum).

2. Place the template provided on the mounting surface or mark the holes as shown on the

template.

3. Accurately center punch the 4 mounting holes (marked A) and the large knockout (marked B).

4. Drill the four mounting holes (A) with a #29 bit. Tap an 8-32 thread.

5. Locate the 1-1/4" knockout center(B) and punch using the manufacturers instructions.

6. Debur knockout and mounting holes making sure the panel stays clean and flat.

7. Apply RTV to the 4 holes marked (A).

8. Assemble the keypad to the panel.

9. From the inside of the panel, apply RTV over each of the four mounting screws. Cover a 3/4"

area around each screw.

Mounting Instructions: For Clearance mounting holes replace numbered steps above

with the following:

4. Drill four # 19 clearance holes (A).

8. Hold the keypad in place on the panel and tighten the (4) 8-32 nuts over a locking washer.

9. From the inside of the panel, apply RTV over each of the four mounting screws and nuts.

Cover a 3/4" area around each screw while making sure to completely encapsulate the nut

and washer.

2-22 INSTALLATION

MN723H-10/95 11/28/95 1:09 AM Page 34 (Black plate)

Page 34

Figure 2-12 Remote Keypad Mounting Template

2-23INSTALLATION

4.000

2.500

FOUR PLACES

8-32 TAP USE DRILL #29

8-32 CLEARANCE USE #19 OR 0.166"

1-11/16" DIAMETER HOLE

USE 1.25" CONDUIT KNOCKOUT

(A)

(A)

(A)

(A)

(B)

1.250

1.340

4.810

5.500

SCALE NOT TO BE ALTERED

DIMENSIONS CAN BE DISTORTED DUE TO REPRODUCTION

MN723H-10/95 11/28/95 1:09 AM Page 35 (Black plate)

Page 35

Logic and Control Wiring

All logic and control connections are made at the 44 pin terminal strip J1. The terminal strip is divided

into a lower and an upper row. The lower row carries pins numbered 1-22 with the upper row being

23-44.

Wire with Class 1 wiring. All external control wiring to the control should be run in a conduit,

separated from all other wiring. The use of shielded wire is recommended for all control wiring. The

shield of the control wiring should be connected to the J1 analog ground of the control only. The

other end of the shield should be taped to the wire jacket to prevent electrical shorts and ground

loops.

Figure 2-13 23H Control Terminal Strip J-1

See Appendix C For Recommended Terminal Tightening Torques

2-24 INSTALLATION

ANALOG GND

ANALOG INPUT 1

POT REFERENCE

ANALOG INPUT + 2

ANALOG INPUT - 2

ANALOG OUT 1

ANALOG OUT 2

ENABLE

OPTO INPUT

OPTO INPUT

OPTO INPUT

OPTO INPUT

OPTO INPUT

OPTO INPUT

OPTO INPUT

EXTERNAL TRIP

INPUT COMMON

USER COMMON

OPTO OUT #1

OPTO OUT #2

OPTO OUT #3

OPTO OUT #4

+ 24V

OPTO IN POWER

OPTO OUT RETURN #1

OPTO OUT RETURN #2

OPTO OUT RETURN #3

OPTO OUT RETURN #4

A

A

B

B

INDEX

INDEX

NOT USED

COMMON

SINE +

SINE –

COSINE +

COSINE –

EXCITATION +

COMMON

SHIELD

NOT USED

123

224

325

426

527

628

729

830

931

10 32

11 33

12 34

13 35

14 36

15 37

16 38

17 39

18 40

19 41

20 42

21 43

22 44

INCREMENTAL

POSITION

OUTPUT

RESOLVER

INPUT

J1

MN723H-10/95 11/28/95 1:10 AM Page 36 (Black plate)

Page 36

Analog Inputs and Outputs

Figure 2-14 Analog Inputs and Outputs

See Appendix C For Recommended Terminal Tightening Torques

Analog Inputs

Two analog inputs are available on J1; analog input #1 or pot input(J1-J3) and analog input #2 (J14-J1-5). (If using a 4-20mA command signal, jumper JP1 located above the J1 terminal strip on the

main control board MUST be moved from the middle and right pins to the left and middle pins.)

Analog input #1 is used when the controller is set to Standard Three Wire Control, Process, or

Bipolar Control. In this mode the reference comes from an external 5KOhm potentiometer

connected so that the full resistance is connected from J1-1 to J1-3. The wiper of the pot should be

connected at terminal J1-2 as shown in Figure 2-14. The command will be recognized at terminals

J1-1 and J1-2. When using a potentiometer as the speed command, process feedback or setpoint

source, the ANA CMD select parameter must be programmed for "POT". An absolute 0-10VDC

speed command signal may also be connected on J1-1 and J1-2.

Analog input #2 accepts a differential command +/-5VDC, +/-10VDC or 4-20 mA as selected by the

user in the ANA CMD Select programming block. This input is buffered to provide 40 db common

mode isolation with up to +/- 15 volts common mode relative to common. Analog input #2 is used

with Bipolar control.

Either analog input may be grounded provided the common mode range is not exceeded.

NOTE: NO ANALOG INPUTS ARE USED FOR THE 15 SPEED TWO WIRE CONTROL

OR THE SERIAL CONTROL MODES.

2-25INSTALLATION

1 ANALOG GND

2 ANALOG INPUT 1

3 POT REFERENCE

4 ANALOG INPUT + 2

5 ANALOG INPUT - 2

6 ANALOG OUT 1

7 ANALOG OUT 2

COMMAND POT 5K OHM

or 0-10 VDC ON PINS 1 & 2

PROGRAMMABLE 0-5V (FACTORY PRESET: SPEED)

DIFFERENTIAL ± 5V, ±10V

or 4-20 mA INPUT

PROGRAMMABLE 0-5V (FACTORY PRESET : CURRENT)

J1

MN723H-10/95 11/28/95 1:10 AM Page 37 (Black plate)

Page 37

Analog Outputs

Two programmable analog outputs are provided on J1-6 and J1-7. These outputs are scaled 0 - 5

VDC (1ma Max output current) and can be used to provide real-time status of various control

conditions. The return for theses outputs is J1-1 Analog ground. An explanation of the different

conditions follows. The state of these outputs is programmed in the Level 1, Output Block.

Name Description of Programmable Analog Outputs

ABS SPEED Absolute value of speed with +5 VDC = MAX RPM. Useful as a speed meter

output.

ABS TORQUE Absolute value of torque with +5 VDC = torque at CURRENT LIMIT.

SPEED COMMAND Absolute value of the commanded speed with +5 VDC = MAX RPM.

PWM VOLTAGE Amplitude of PWM voltage. 0 - Max AC voltage.

FLUX CURRENT Flux current feedback. Useful with CMD FLUX CUR.

CMD FLUX CUR Commanded flux current.

MOTOR CURRENT Amplitude of control continuous current including motor excitation current.

2.5V = rated current.

LOAD COMPONENT Amplitude of load current not including the motor excitation current. 2.5V =

rated current.

QUAD VOLTAGE Load controller output. Useful in diagnosing control problems.

DIRECT VOLTAGE Flux controller output.

AC VOLTAGE PWM control voltage which is oproportional to AC line to line motor terminal

voltage. 2.5V centered.

BUS VOLTAGE 5V = 1000VDC.

TORQUE Bipolar torque output. 2.5V centered, 5V = max positive torque, 0V = max

negative torque.

POWER Bipolar power output. +2.5V = zero power, 0V = negative rated peak power,

+5V = positive rated peak power.

VELOCITY Motor speed scaled +2.5V = zero speed, 0V = negative maximum RPM,

+5V = positive maximum RPM.

2-26 INSTALLATION

MN723H-10/95 11/28/95 1:10 AM Page 38 (Black plate)

Page 38

OVERLOAD Accumulated current 2X time, OVERLOAD occurs at +5V.

PH 2 CURRENT Sampled AC phase 2 motor current, 2.5V = zero current, 0V = negative

rated peak current, +5V = positive rated peak current.

PH 3 CURRENT Sampled AC phase 2 motor current, 2.5V = zero current, 0V = negative

rated peak current, +5V = positive rated peak current.

POSITION Position within a single revolution. 5V = 1 complete revolution. (The counter

will reset to 0 once every revolution.)

External Trip Input

Terminal J1-16 is available for connection to a normally closed thermostat in all operating modes.

This connection is available for connection to a motor thermostat or overload relay. The thermostat

or overload relay should be a dry contact type with no power available from the contact. If the motor

thermostat or overload relay should ever open the circuit indicating an over-temperature condition,

the control will automatically shut down and give an External Trip fault. In order for the External Trip

to be activated, the External Trip parameter in the programming Protection Block must be set to

"ON".

2-27INSTALLATION

MN723H-10/95 11/28/95 1:10 AM Page 39 (Black plate)

Page 39

Opto-isolated Outputs

Four programmable Opto-isolated outputs are available at terminals J1-19 through J1-22. These

outputs can be used to monitor various control conditions.

Powering the Opto-isolated Outputs

The Opto-isolated outputs may be configured as sinking or sourcing. All must be configured the

same. The Opto-isolated outputs will sink up to 60 mA or current each. The maximum voltage from

opto output to common when active is 1.0 VDC (TTL compatible). The Opto-isolated outputs may be

connected in different ways as shown in Figure 2-15.

Figure 2-15 Opto-isolated Output Connection Configurations

See Appendix C For Recommended Terminal Tightening Torques

2-28 INSTALLATION

SHOWS TYPICAL FLYBACK DIODE RATED AT 1 AMP - 100V (1N4002) MINIMUM ACROSS

RELAY (IF RELAY DOESN'T HAVE ONE BUILT-IN). USE FLYBACK DIODE ON EACH RELAY.

USING EXTERNAL SUPPLY

(SINKING THE RELAY)

USING EXTERNAL SUPPLY

(SOURCING THE RELAY)

EXTERNAL USER SUPPLY

RETURN (-)

EXTERNAL USER SUPPLY

RETURN (-)

TYPICAL

EXTERNAL USER

SUPPLY + 10-30 VDC

39

40

41

42

43

44

17

18

19

20

21

22

EXTERNAL USER

SUPPLY + 10-30 VDC

39

40

41

42

43

44

17

18

19

20

21

22

TYPICAL

USING INTERNAL SUPPLY

(SOURCING THE RELAY)

TYPICAL

39

40

41

42

43

44

17

18

19

20

21

22

+ 24 VDC

(INTERNAL)

USING INTERNAL SUPPLY

(SINKING THE RELAY)

+ 24 VDC

(INTERNAL)

39

40

41

42

43

44

17

18

19

20

21

22

TYPICAL

Customer

Supplied

Relays

Customer

Supplied

Relays

Customer

Supplied

Relays

Customer

Supplied

Relays

MN723H-10/95 11/28/95 1:10 AM Page 40 (Black plate)

Page 40

Opto-Isolated Output Selection

Four independent programmable opto-isolated outputs are available on the J1 connector for

external monitoring of drive conditions. These outputs are available on terminals J1-19 thru J1-22.

These outputs require 5-30 VDC to operate. Each will sink up to 60mA maximum. The voltage drop

across the output may be as high as 1VDC (TTL compatible). These outputs may be configured as

shown in Figure 2-15. The output state for each of these outputs is programmed in the Output

(programming) Block. If the opto outputs are used to directly drive a relay, a flyback diode rated at

1A, 100 V minimum should be connected across the relay coil.

Name Description of Opto-isolated Output

AT SETPOINT Closed when motor speed equals setpoint command.

READY Open if a fault exists or AC power is not applied.

ZERO SPEED Closed when the motor speed is less than the user specified speed

threshold, otherwise open.

AT SPEED Closed whenever the motor speed is within the user specified tolerance

band of the commanded speed, open outside tolerance band.

OVERLOAD Closed when an RMS current overload has not occurred, open upon

overload.

KEYPAD CONTROL Closed when the control is under LOCAL keypad control.

AT SET SPEED Closed whenever the motor speed is above the user specified "set

speed", open below set speed.

FAULT Closes when a FAULT is present.

FOLLOWING ERROR Closed when the motor speed is outside the user specified tolerance

band of the Acc-Dec and S-Curve conditioned commanded speed.

Open when the motor speed is within tolerance band of conditioned

speed command.

DRIVE ON Closed when the motor current has reached excitation level and capable

of producing torque.

CMD DIRECTION Closed when reverse input direction command is received, open for

forward.

AT POSITION Closed during a positioning command when the control is within the

tolerance band.

2-29INSTALLATION

MN723H-10/95 11/28/95 1:10 AM Page 41 (Black plate)

Page 41

OVER-TEMP WARN Closed when the control heat sink detector senses the control is within

3 Deg C of tripping on INT OVER-TEMP.

MOTOR DIRECTION Closed when reverse input direction command is received, open for

forward.

Opto-isolated Inputs

Nine Opto-isolated inputs are available at terminals J1-8 through J1-16 to command various output

conditions. The available command input may change depending on the operating mode selected.

Opto-isolated Input Power

The opto-isolated inputs (J1 connector pins 8-16) are normally operated by closing contacts or

switches between them and pin J1-17, input common. The voltage rating of the opto inputs is 10-30

VDC. The opto inputs may be configured as sinking or sourcing provided all of the inputs are

configured the same.

See Figure 2-16 below for opto-input power configuration options.

NOTE: IF THE CONTROL'S INTERNAL 24VDC SUPPLY IS TO BE USED TO POWER

THE OPTO INPUTS, CONNECTOR PIN J1-39 MUST BE JUMPERED TO

J1-40 AND ALL RETURNS TERMINATED AT J1-17.

2-30 INSTALLATION

MN723H-10/95 11/28/95 1:10 AM Page 42 (Black plate)

Page 42

Figure 2-16 Opto Input Power Configurations

See Appendix C For Recommended Terminal Tightening Torques

2-31INSTALLATION

USER +10-30VDC

RETURN

N/C

OPTO IN POWER

8

9

10

11

12

13

14

15

16

17

J1

39

40

ENABLE

FORWARD

REVERSE

INPUT #1

INPUT #2

INPUT #3

INPUT #4

INPUT #5

INPUT #6

INPUT COMMON

USER +10-30VDC

OPTO INPUTS CLOSING TO GROUND

OPTO IN POWER

8

9

10

11

12

13

14

15

16

17

J1

39

40

ENABLE

FORWARD

REVERSE

INPUT #1

INPUT #2

INPUT #3

INPUT #4

INPUT #5

INPUT #6

INPUT COMMON

OPTO INPUTS USING INTERNAL POWER SUPPLY

USER +10-30VDC

RETURN

N/C

OPTO IN POWER

8

9

10

11

12

13

14

15

16

17

J1

39

40

ENABLE

FORWARD

REVERSE

INPUT #1

INPUT #2

INPUT #3

INPUT #4

INPUT #5

INPUT #6

INPUT COMMON

USER +10-30VDC

OPTO INPUTS CLOSING TO +VDC

+24V

+24V

+24V

MN723H-10/95 11/28/95 1:10 AM Page 43 (Black plate)

Page 43

Operating Mode Connection Diagrams

Six different operating modes are available in the Series 23H servo control. These operating modes

define the basic motor control setup and the operation of the input and output terminals. These

operating modes are selected by programming the Operating Mode parameter in the Input

programming Block. Available operating modes include:

Keypad Only Operation

Standard Run, 3 Wire Control

15 Speed, 2 Wire Control

Bipolar Speed or Torque

Process Control

Serial

NOTE: THE SERIAL OPERATING MODE REQUIRES THE OPTIONAL RS-232 OR

THE OPTIONAL RS422/485 SERIAL EXPANSION BOARD. ITS OPERATION

IS NOT COVERED IN THIS MANUAL. CONNECTION OF AND

INSTRUCTIONS FOR SERIAL EXPANSION BOARDS IS PROVIDED IN

SERIAL COMMUNICATIONS EXPANSION BOARD MANUAL NO. MN1310.

THIS MANUAL IS SHIPPED WITH ALL SERIAL EXPANSION BOARDS.

Connection diagrams for each operating mode follow.

Keypad Only Operating Mode

For Keypad Only operation, program the Operating Mode parameter in the Input programming block.

Then set the keypad itself to LOCAL pressing the LOCAL key with the motor stopped (LOCAL key

toggles between the LOCAL and REMOTE mode of operation). The word "LOCAL" should appear in

the keypad display.

When in the Keypad Only operating mode the only opto-input that is active is the External Trip input

on J1-16. The analog inputs and opto-outputs remain active.

Figure 2-17 Keypad Only Operation Connection Diagram

If the External Trip parameter is programmed “on”, wire as shown.

See Appendix C For Recommended Terminal Tightening Torques

J1-16...OPEN causes an External Trip to be received by the control. The control will

disable and display external trip when it is programmed “on”. Factory preset is “off”.

2-32 INSTALLATION

OPTO INPUT

16

17

18

19

J1

COMMON

+24V

38

39

40

41

INPUT COMMON

MN723H-10/95 11/28/95 1:10 AM Page 44 (Black plate)

Page 44

Standard Run 3 Wire Control Mode

Figure 2-18 Standard Run 3-Wire Connection Diagram

See Appendix C For Recommended Terminal Tightening Torques

NOTE: FOR 4-20MA INPUT MOVE JUMPER JP1 ON THE MAIN CONTROL BOARD

TO THE LEFT TWO PINS.

J1-8 OPEN disables the control and motor coasts to a stop. CLOSED allows current to

flow in the motor and produce torque.

J1-9 MOMENTARY CLOSED starts motor operation in the Forward direction. In JOG mode

(J1-12 CLOSED), continuous CLOSED jogs motor in the Forward direction.

J1-10 MOMENTARY CLOSED starts motor operation in the Reverse direction. In JOG

mode(J1-12 CLOSED), CONTINUOUS closed JOGS motor in the Reverse direction.

J1-11 When OPEN control removes power from motor and disables. Coasts or brakes to

stop depending on Keypad Stop Mode parameter setting.

J1-12 CLOSED places control in JOG mode, Forward and Reverse run are used to jog the

motor.

J1-13 OPEN selects ACC / DEC / S-CURVE group 1. CLOSED selects group 2.

J1-14 CLOSED selects preset speed #1, (J1-12, will override this), OPEN allows speed

command from Analog input #1 or #2.

J1-15 OPEN to run, CLOSED to reset fault condition.

J1-16 OPEN causes an external trip to be received by control. The control will disable and

display external trip when programmed "on". Factory preset is "off".

2-33INSTALLATION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

SINE +

SINE –

COSINE +

COSINE –

EXCITATION +

COMMON

SHIELD

NOT USED

A

A

B

B

INDEX

INDEX

NOT USED

COMMON

+24V

OPTO IN POWER

OPTO OUT RETURN #1

OPTO OUT RETURN #2

OPTO OUT RETURN #3

OPTO OUT RETURN #4

ENABLE

FORWARD RUN

REVERSE RUN

STOP

CLOSED = JOG SPEED

ACCEL/DECEL/SELECT

PRESET SPEED #1

FAULT RESET

EXTERNAL TRIP

INPUT COMMON

PROGRAMMABLE 0-5V OUTPUT (FACTORY PRESET: SPEED)

PROGRAMMABLE 0-5V OUTPUT (FACTORY PRESET: CURRENT)

J1

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

0-5VDC OR

0-10VDC OR

4-20 mA

ANALOG GND

ANALOG INPUT 1

POT REFERENCE

ANALOG INPUT +2

ANALOG INPUT -2

ANALOG OUT 1

ANALOG OUT 2

USER COMMON

OPTO OUT #1

OPTO OUT #2

OPTO OUT #3

OPTO OUT #4

5kOhm COMMAND POT

REFER TO POWERING THE

OPTO-ISOLATED OUTPUTS

BOTH CLOSED =

FORWARD

RESOLVER

INPUT

INCREMENTAL

POSITION

OUTPUT

MN723H-10/95 11/28/95 1:10 AM Page 45 (Black plate)

Page 45

15 Speed 2-Wire Control Mode

Figure 2-19 15 Speed 2-Wire Control Connection Diagram

See Appendix C For Recommended Terminal Tightening Torques

J1-8 OPEN disables the control & motor coasts to a stop. CLOSED allows current to flow

in the motor and produce torque.

J1-9 CLOSED operates the motor in the Forward direction (with J1-10 open). OPEN coasts

or brakes to stop depending on Keypad Stop motor parameter setting.

J1-10 CLOSED operate motor in the Reverse direction (with J1-9 open). OPEN coasts or

brakes to stop depending on Keypad Stop mode parameter setting.

J1-11-14 Selects programmed preset speeds per table below.

J1-15 Selects ACC/DEC group. OPEN selects group 1. CLOSED selects group 2.

J1-16 OPEN causes External Trip to be received by the control. Control will disable and

display external trip when programmed to be"on". Factory preset is "off".

See Switch T

ruth Table on next page.

2-34 INSTALLATION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

SINE +

SINE –

COSINE +

COSINE –

EXCITATION +

COMMON

SHIELD

NOT USED

A

A

B

B

INDEX

INDEX

NOT USED

COMMON

+24V

OPTO IN POWER

OPTO OUT RETURN #1

OPTO OUT RETURN #2

OPTO OUT RETURN #3

OPTO OUT RETURN #4

ENABLE

CLOSED = FORWARD

CLOSED = REVERSE

SWITCH 1

SWITCH 2

SWITCH 3

SWITCH 4

ACC/DEC/“S” SELECT 1

EXTERNAL TRIP

INPUT COMMON

PROGRAMMABLE 0-5V OUTPUT (FACTORY PRESET: SPEED)

PROGRAMMABLE 0-5V OUTPUT (FACTORY PRESET: CURRENT)

J1

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

ANALOG OUT 1

ANALOG OUT 2

USER COMMON

OPTO OUT #1

OPTO OUT #2

OPTO OUT #3

OPTO OUT #4

RESOLVER

INPUT

INCREMENTAL

POSITION

OUTPUT

REFER TO POWERING THE

OPTO-ISOLATED OUTPUTS

BOTH CLOSED = FORWARD

BOTH OPEN = STOP

NO CONNECTIONS

ALL CLOSED =

FAULT RESET

MN723H-10/95 11/28/95 1:10 AM Page 46 (Black plate)

Page 46

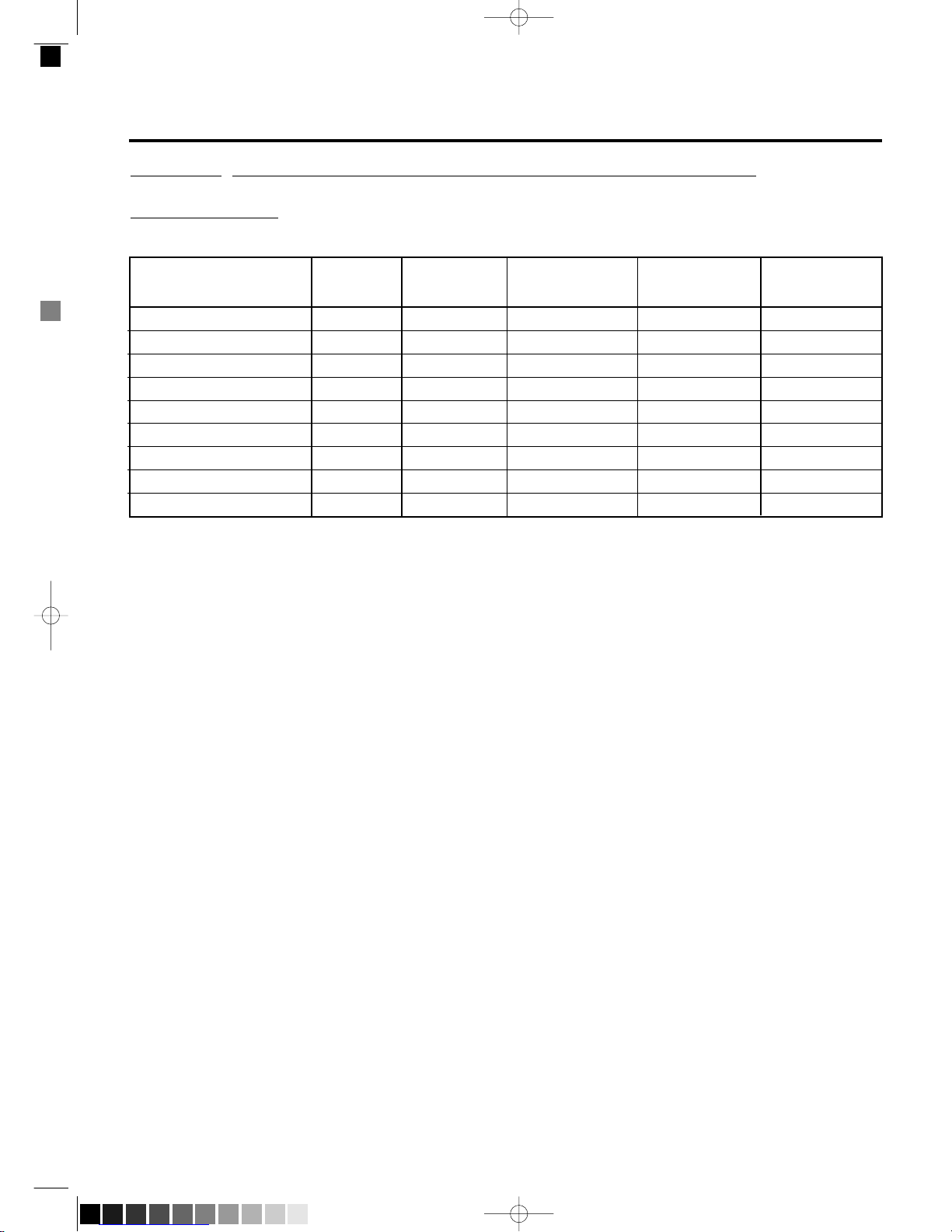

Switch Truth Table for 15 Speed, 2 Wire Control Mode

FUNCTION J1-11 J1-12 J1-13 J1-14

Preset 1 Open Open Open Open

Preset 2 Closed Open Open Open

Preset 3 Open Closed Open Open

Preset 4 Closed Closed Open Open

Preset 5 Open Open Closed Open

Preset 6 Closed Open Closed Open

Preset 7 Open Closed Closed Open

Preset 8 Closed Closed Closed Open

Preset 9 Open Open Open Closed

Preset 10 Closed Open Open Closed

Preset 11 Open Closed Open Closed

Preset 12 Closed Closed Open Closed

Preset 13 Open Open Closed Closed

Preset 14 Closed Open Closed Closed

Preset 15 Open Closed Closed Closed

Fault Reset Closed Closed Closed Closed

2-35INSTALLATION

MN723H-10/95 11/28/95 1:10 AM Page 47 (Black plate)

Page 47

Bipolar Speed or Torque Control Mode

In addition to individual motor bipolar speed or torque control, this mode of operation allows the user

to store up to four (4) different complete sets of motor parameters. Why multiple parameter sets?

An example might be to run a motor connected Wye and then to run it at another time connected

Delta; or to run each of (up to) 4 different motors at different times. To program multiple parameter

sets:

1. Access a parameter table using switches J1-13 and J1-14 per Table 2.3.

2. Program, auto-tune and adjust parameters for one configuration.

3. Access second parameter set using J1-13 and J1-14 switches per Table 2.3.

4. Program, auto-tune and adjust parameters for second configuration.

5. Repeat steps 3-5 for third and fourth parameter sets.

The parameter sets may be accessed for operation using external switch closures at J1-13 and

J1-14 per the truth table provided in Table 2.3 which follows.

Figure 2-20 Bipolar Speed or Torque Connection Diagram

See Appendix C For Recommended Terminal Tightening Torques

2-36 INSTALLATION

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

SINE +

SINE –

COSINE +

COSINE –

EXCITATION +

COMMON

SHIELD

NOT USED

A

A

B

B

INDEX

INDEX

NOT USED

COMMON

+24V

OPTO IN POWER

OPTO OUT RETURN #1

OPTO OUT RETURN #2

OPTO OUT RETURN #3

OPTO OUT RETURN #4

ENABLE

FORWARD ENABLE

REVERSE ENABLE

CLOSED = ORIENT

OPEN=SPEED, CLOSED=TORQUE

TABLE SELECT

TABLE SELECT

FAULT RESET

EXTERNAL TRIP

INPUT COMMON

PROGRAMMABLE 0-5V OUTPUT (FACTORY PRESET: SPEED)

PROGRAMMABLE 0-5V OUTPUT (FACTORY PRESET: CURRENT)

J1

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

DIFFERENTIAL ± 5VDC, ± 10VDC

OR 4-20 mA

ANALOG GND

ANALOG INPUT 1

POT REFERENCE

ANALOG INPUT +2

ANALOG INPUT -2

ANALOG OUT 1

ANALOG OUT 2

USER COMMON

OPTO OUT #1

OPTO OUT #2

OPTO OUT #3

OPTO OUT #4

5kOhm COMMAND POT

REFER TO POWERING THE

OPTO-ISOLATED OUTPUTS

RESOLVER

INPUT

INCREMENTAL

POSITION

OUTPUT

MN723H-10/95 11/28/95 1:10 AM Page 48 (Black plate)

Page 48

NOTE: FOR 4-20MA INPUT MOVE JUMPER JP1 ON THE MAIN CONTROL BOARD

TO THE LEFT TWO PINS.

J1-8 OPEN disables the control & motor coasts to a stop. CLOSED allows current to flow

in the motor and produce torque.

J1-9 CLOSED to enable operation in the Forward direction. OPEN TO DISABLE Forward

operation (drive will brake to a stop if a Forward command is still present).

J1-10 CLOSED to enable operation in the Reverse direction. OPEN to disable Reverse

operation (drive will brake to a stop if a Reverse command is still present).

J1-11 Causes the motor shaft to orient to the index marker (or home offset).

J1-12 CLOSED puts the control in torque mode.

J1-13 &14 Select from four parameter tables per truth Table 2.3.

J1-15 OPEN to run, CLOSED to reset fault condition.

J1-16 OPEN causes an external trip to be received by the control. Control will disable and

display fault.

Table 2.3 Truth Table for Bipolar Speed or Torque Control Mode

Multiple Parameter Tables

Function J1-13 J1-14

Parameter Table #0 Open Open

Parameter Table #1 Closed Open

Parameter Table #2 Open Closed

Parameter Table #3 Closed Closed

Process Control Mode

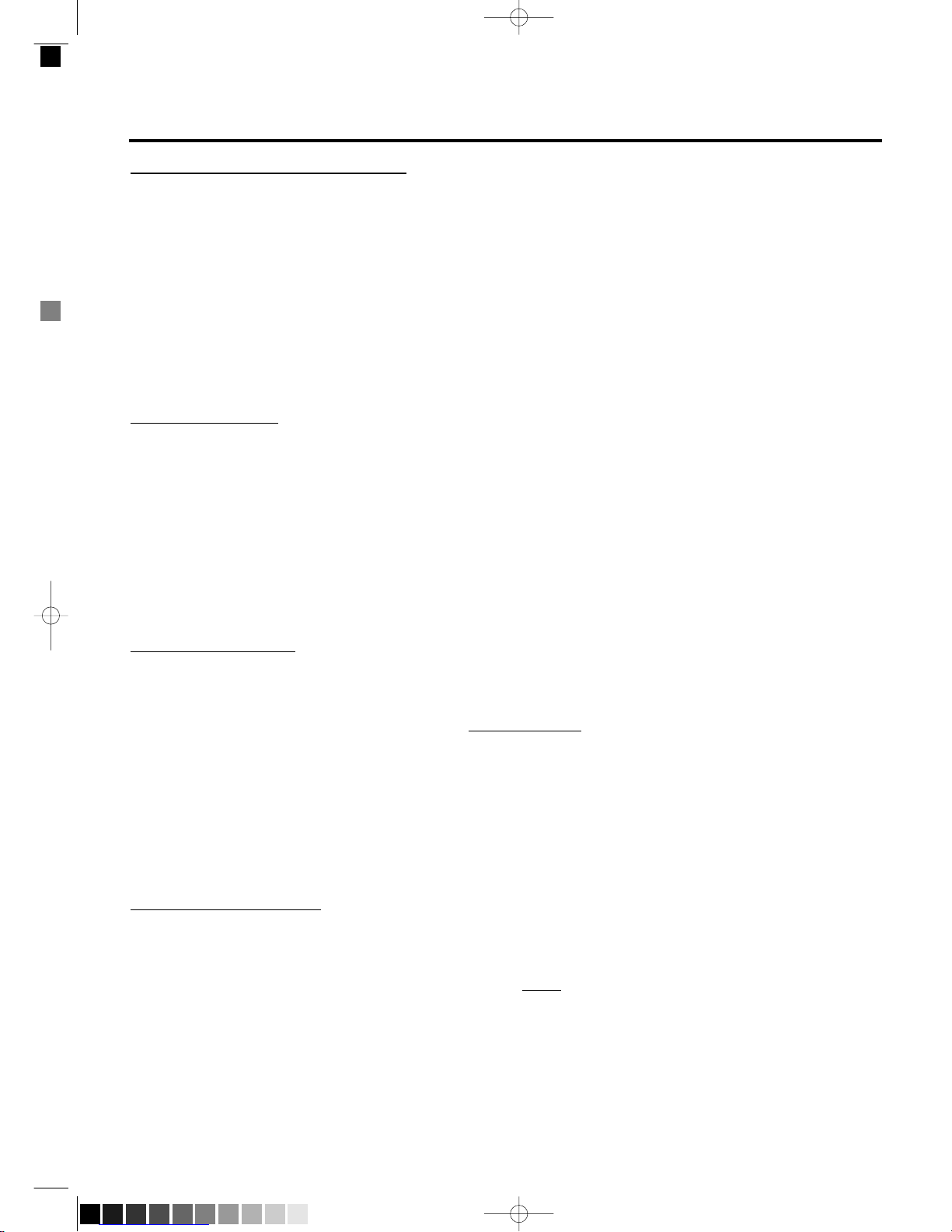

The process control mode is a secondary closed loop system which includes a general purpose set

point PID control. It may be setup in two different ways. One uses a programmable preset set point

and the other uses an external command set point input. In either case a process feedback signal

will be required.

The selection of the set point command and the process feedback signal is located in the Process

Control programming block under the Set point Source Parameter and Process Feedback

Parameter respectively.

The programmable preset set point PID control mode can be used for most general closed loop

systems. This is generally known as feedback control. This method compares the value of the

programmed preset variable with the process variable. The difference between them is the process

error. The process error is then converted to a signal that adjusts the speed or torque of the motor

to eliminate the error. A large process error will result in a large change in the rate of speed or

amount of torque generated by the motor. Likewise, a small error signal will produce a small change

in the rate of speed or amount of torque generated by the motor. The end result is the PID control

2-37INSTALLATION

MN723H-10/95 11/28/95 1:10 AM Page 49 (Black plate)

Page 49

will adjust the motor speed or torque to force the process variable to be as close as possible to the

programmed preset setpoint.

The external command setpoint input PID control mode is used for more complex applications

having a large external disturbance that can affect the process variable. This is useful for processes

that have significant time lag between a process disturbance and the generation of a process error

signal from the process sensor. This mode uses a feedforward command to anticipate changes in

the process. This feedforward signal directly changes the motor speed or torque without having to

develop a process error signal first.

Figure 2-21 shows a block diagram of the Process Mode control system. The user must make the

determination of which technique to implement.

Figure 2-21 Simplified Process Control Feedback System Diagram

NOTE: EXB = OPTIONAL EXPANSION BOARD

2-38 INSTALLATION

∑

∑

∑

∑

PROCESS FEEDBACK

Select The Source Through

Parameter Adjustment.

Available Sources:

POTENTIOMETER

+/-10 VOLTS

+/-5 VOLTS

4 TO 20 mA