Page 1

HGM-MZ

Instruction: 3015-9003

Rev: 1

Date: November 2014

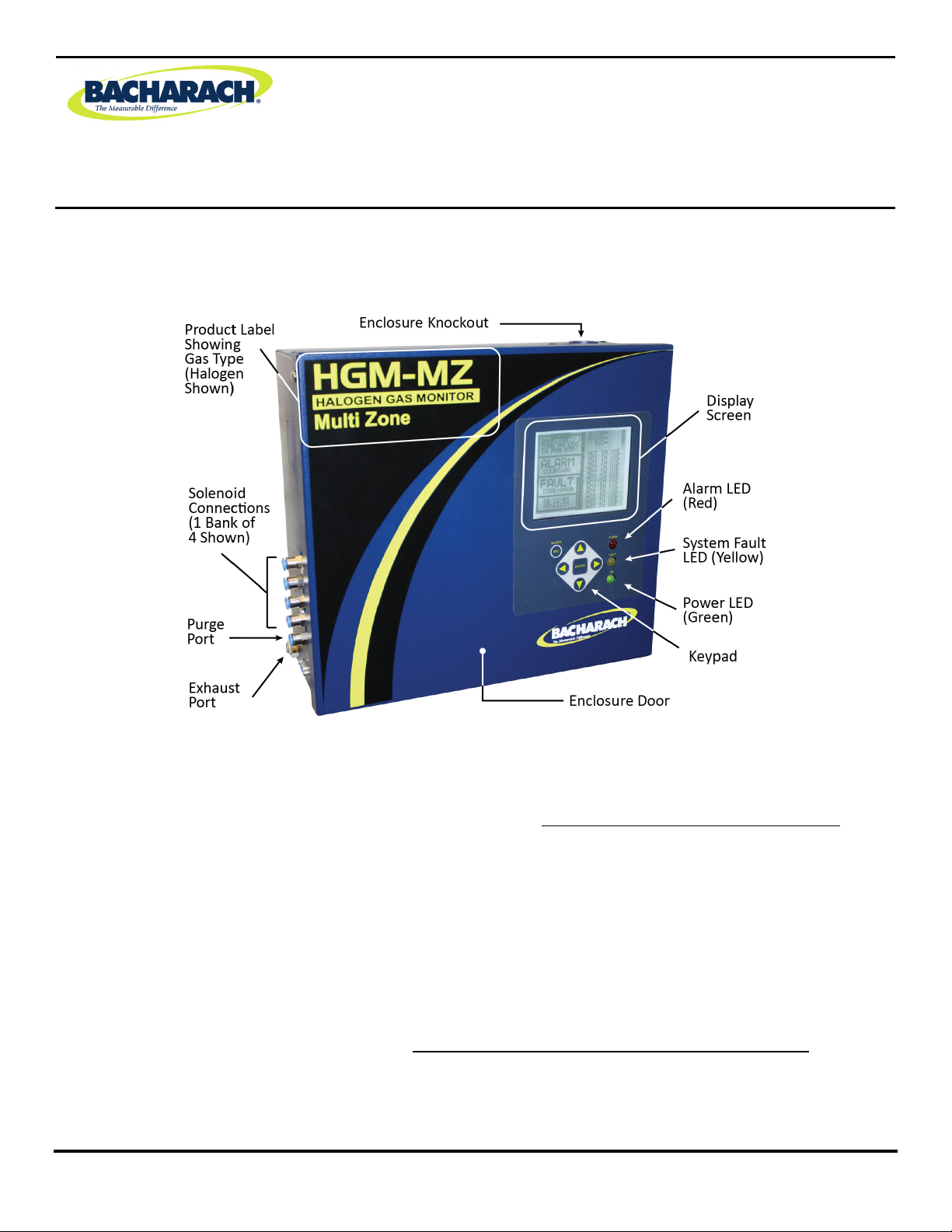

1. VISUAL INSPECTION: Upon opening the box visually inspect exterior of monitor for damage and unpack the

provided Charcoal filter and line end filters.

Quick Start Installation Instructions

Refrigerant Monitor

Figure 1. Refrigerant Leak Monitor Outside View

2. PLACEMENT OF MOUNTING HOLES: Using the supplied template, mark mounting hole locations. Then

drill holes in the wall for installing the monitor to the wall. DO NOT DRILL THROUGH THE MONITOR

will void the warranty.

3. ATTACH TO WALL: Fasten the monitor to the wall securely with appropriate fasteners.

4. REMOVE SHIPPING TIES: Cut the zip ties off the pump inside the monitor. They are only used for shipping

and will cause noise and vibration if left in place.

5. INTERNAL WIRING: With main power off make all internal wiring terminations and connections.

6. RUN SAMPLE TUBING: Locate the positions of remote air sample points and run air sample tubing back to

the monitor making note of the length of the tubing and the sample point location. NOTE: It is a good idea

to make a list of the sample point locations and leave it with the monitor for future reference.

7. PICKUP PLACEMENT AND PROTECTION: Sample point placement is critical for detecting leaks. They

should be located with respect to air currents and proximity to the most likely leak locations.

a. Mount pickup line end filters 6 to 12 inches off the floor for refrigerants.

b. CO

Revision 1 - 1 - P/N: 3015-9003

installations should be mounted 4 to 6 feet off the floor.

2

as this

Page 2

HGM-MZ Refrigerant Monitor Quick Start Installation Instructions

c. If you are placing pickups in a freezer, mount them well away from the door to prevent sensor

freeze up from high humidity near the freezer door. An alternative location is just outside the door

which would pick up refrigerant when the door is opened.

NOTE: Use the worksheet supplied with the monitor to document location and lengths of tubing for later

zone setup information.

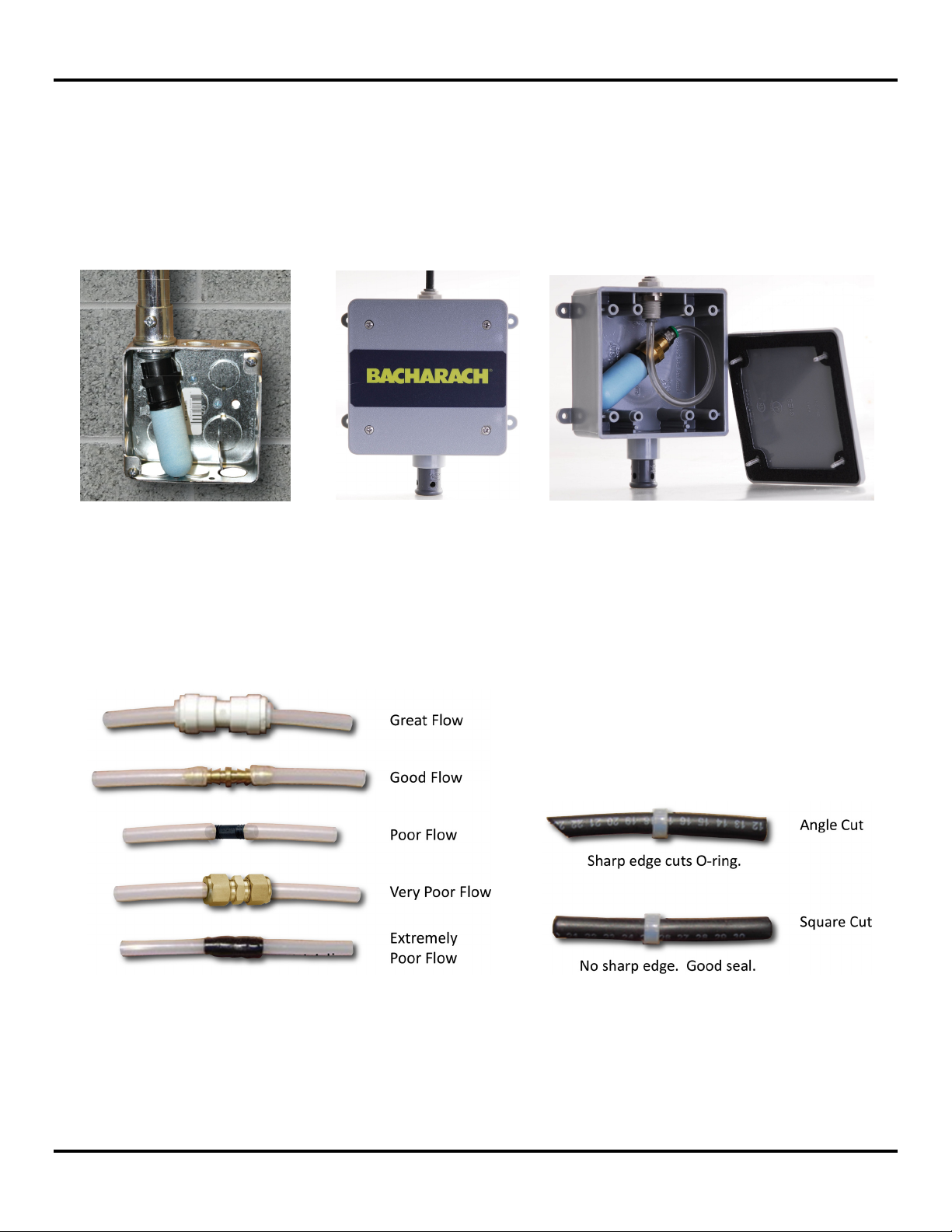

Protect tubing in high traffic areas using conduit and junction boxes. In wet or potential wash down

locations you should use the wet location filter kit p/n 3015-5748. (See end of line Best Practices Below).

Figure 2. Best Practices: End of

Line Filter for Dry Locations

Figure 3. Best Practices: End of Line Filter for Wet Locations

(Splash Guard Accessory Part Number 3015-5748)

8. CONNECT TUBING: Connect tubing to the monitor using best practices for cutting and coupling air sample

tubing (see figures 4 and 5). PTC (push-to-connect) connectors are highly recommended for tubing

connections. In addition, ensure that all tubing cuts are “squared” (perpendicular to the tubing) to avoid

sharp angles that could damage O-rings.

Figure 4. Tubing Connections (Best through Worst) Figure 5. Best Practices: Tubing Cuts

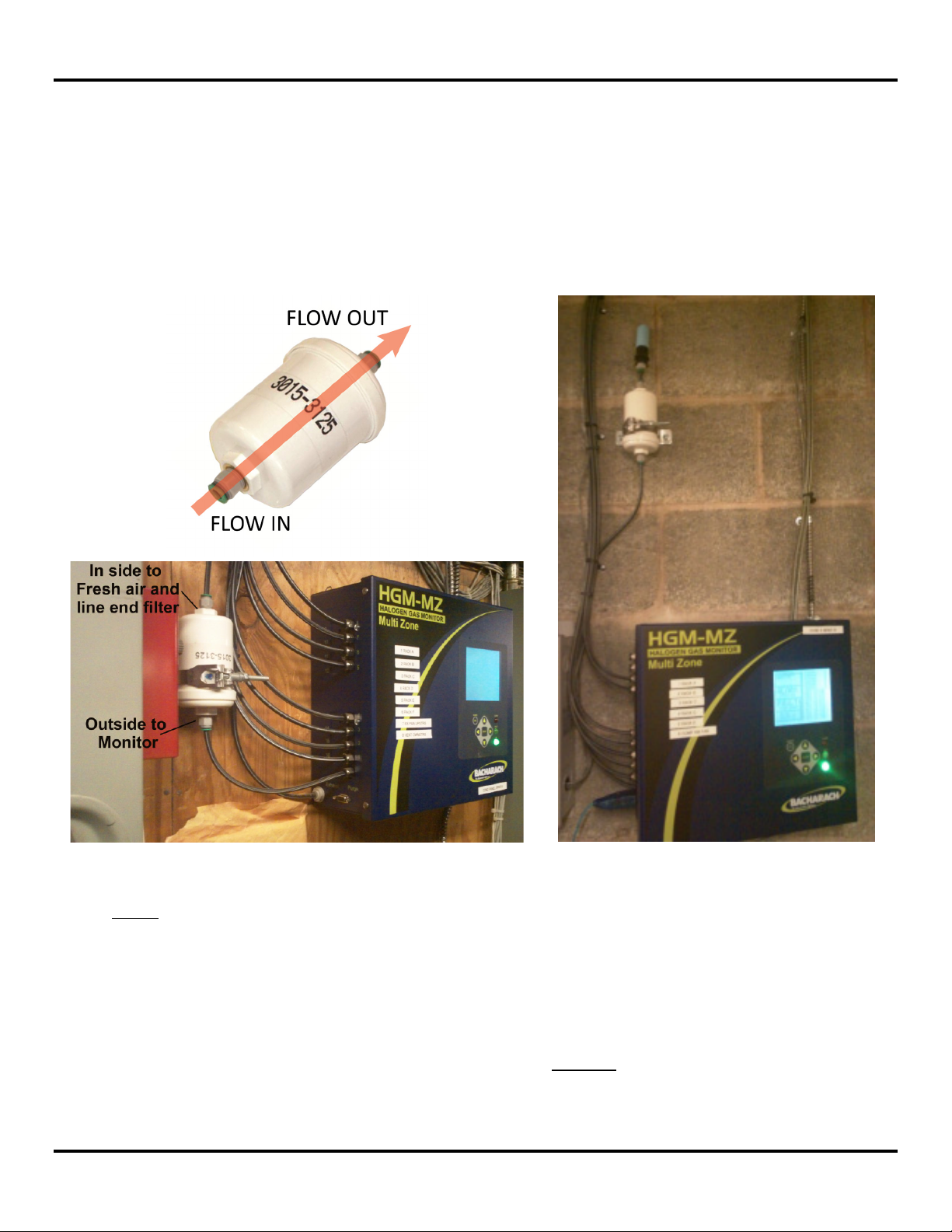

9. MOUNT THE PURGE FILTER: Mount the charcoal purge filter using the supplied bracket. Be sure to mount

the filter near the monitor so that it is accessible when filter replacement is required.

10. CONNECT FILTER’S “FLOW OUT” SIDE: Use appropriate tubing to connect the “OUT” side of the charcoal

filter to the “PURGE port” on the monitor.

Revision 1 - 2 - P/N: 3015-9003

Page 3

HGM-MZ Refrigerant Monitor Quick Start Installation Instructions

11. CONNECT FILTER’S “FLOW IN” SIDE: Run tubing from the “IN side” of the charcoal filter to a location that is

outside of the structure (machinery room). Locate it in an area where the line end filter (a) can be easily

accessed for replacement, and (b) where it will remain dry and free from direct rain or excessive moisture.

This is the optimum installation scenario. See Figure 6.

If this cannot be accomplished, the end of line filter can be mounted inside (near the monitor and charcoal

filter) in an accessible area to allow easy replacement. NOTE: In the case of indoor filter installation, the

monitor must be put in service mode when refrigerant is released (e.g., during maintenance) to prevent

premature purge filter contamination. See Figure 7.

Figure 6. Outdoor Filter Mounting Example (Optimum) Figure 7. Indoor Filter Mounting Example

NOTE:

a. If you are mounting the purge pickup outside the structure, you must place the tubing in an area

away from the elements in a “secure area that is out of the reach of rain and snow” and is

accessible for filter changes.

b. In the case of the CO

monitor, you must mount the pickup away from CO

2

sources (i.e., gas-fired

2

appliance stacks, rack room, store ventilation, truck bays, etc.) which can skew the purge baseline.

c. If mounting a purge pick up inside the structure, you must not have prolonged background ambient

refrigerant contamination as this will cause the charcoal purge filter to fail prematurely (refer to

fault code 0100).

Revision 1 - 3 - P/N: 3015-9003

Page 4

HGM-MZ Refrigerant Monitor Quick Start Installation Instructions

Figure 8. Chiller Installation Example

Figure 9. Typical Refrigeration Rack Installation

Revision 1 - 4 - P/N: 3015-9003

Page 5

HGM-MZ Refrigerant Monitor Quick Start Installation Instructions

Figure 10. Example Grocery Store Installation

12. SUPPLY POWER. Apply power to the monitor. It is universal voltage and accepts 100 to 240 volts AC.

13. CONFIGURE ZONES: Set up all zones based on your application needs. Use the guidelines on the following

pages to set zone names, the number of zones, refrigerant type, alarm limits, and sample lengths for each

zone. If splitters are used on one or more zones:

a. Be sure to keep tubing lengths the same beyond the splitter.

b. DISTANCE (total) for a particular zone using a splitter should equal the tubing length up to the

splitter plus the length of any ONE of the split tubing trunks (not the sum of all split trunks).

c. Note that a leak reading from a zone with split trunks may be lower than a reading from a non-split

trunk due to possible dilution from other pickups (splits) on that trunk. Alarm levels should be

adjusted accordingly.

Revision 1 - 5 - P/N: 3015-9003

Page 6

HGM-MZ Refrigerant Monitor Quick Start Installation Instructions

Figure 11. Configuring the Number of Installed Zones

Figure 12. Accessing the Zone Setup Screen

Revision 1 - 6 - P/N: 3015-9003

Page 7

HGM-MZ Refrigerant Monitor Quick Start Installation Instructions

Best Practice Tip: Press the right arrow button (→) twice to move to the next zone.

Figure 13. Zone Setup Directions

Figure 14. Splitter Example Illustrating Proper Tubing Length Practices for 2-Way and 3-Way Splitters

Figure 15. Disabling One or More Zones

Revision 1 - 7 - P/N: 3015-9003

Page 8

HGM-MZ Refrigerant Monitor Quick Start Installation Instructions

NOTE: To place a zone on hold for testing, start at the Normal Operating Screen. Using the

arrow key, move the cursor to the right to cover the list of zones. Then, using the up and

down arrow keys, select the zone to be put in hold mode. When you have the cursor on

the target zone, press enter until you hear a beep (about 1 second). The zone will remain

on hold for 15 minutes or until you release it using the selection method above to release.

14. PERFORM BUMP TESTS: Gas test (or “bump test”) each zone using the bump gas method described below

to ensure that the monitor is operating properly, the alarms operate, and that each zone’s gas path is clear.

a. This procedure uses “bump gas” (dilurothane) as an inexpensive test gas. Virtually any brand of

keyboard cleaner or “canned air” (readily available at most computer and variety stores) contains

this refrigerant and is sufficient to perform a bump test.

b. Power up the HGM-MZ monitor. The green LED on the monitor will blink until the warmup cycle is

complete.

c. Locate and identify the zone to be checked.

d. Either put the target zone on hold for continuous operation, or wait until the monitor is polling that

specific zone.

e. Have someone view the information at the monitor for the zone to be tested, and at the same time

have a technician dispense the bump gas. The technician should release a 2-second burst of gas

directed at the test zone pickup while the monitor is polling that zone.

f. After a short delay, the monitor will indicate the presence of gas on that zone. The PPM reading

will vary as this is not a regulated gas application.

g. If no refrigerant is detected by the monitor, the tubing needs to be inspected for an open or

blocked pathway. If the tubing was pinched or plugged, the monitor will show a flow fault

(indicating a flow-related problem) in addition to no refrigerant being detected for that zone.

15. FINAL CHECK: Take the monitor in and out of service mode. This will cause a purge and pressure check. It

will also allow the monitor to cycle through all zones for a final check.

16. SAMPLE SCREEN: Finish by putting the monitor into service by returning the display to the sampling screen.

∇ ∇ ∇

Toll Free: 1-800-736-4666 • Tel: +1-724-334-5000 • Fax: +1-724-334-5001

621 Hunt Valley Circle, New Kensington, PA 15068-7074

Website: www.MyBacharach.com • E-mail: help@MyBacharach.com

Printed in U.S.A. ® Registered Trademark of Bacharach Inc.

Revision 1 - 8 - P/N: 3015-9003

Headquarters:

Loading...

Loading...