Page 1

Page 2

"IMPORTANT SAFETY INSTRUCTIONS"

When using overlock machine, basic safety precautions should always be followed,

including the following.

Read all instructions before using this overlock machine.

DANGER To reduce the risk of electric shock.

1. The overlock machine should never be left unattended when plugged in. Always unplug this overlock machine from

the electrical outlet immediately after using and before cleaning.

2. Always unplug before replacing light bulb. Replace bulb with same type rated 15 watts/110 volts in 110V/120V area.

(15 watts 240 volts in 220V/240V area.)

WARNING To reduce the risk of burns, fire, electric shock, or injury to persons.

1. Do not allow to be used as a toy. Close attention is necessary when the sewing machine is used by or near children.

2. Use this overlock machine only for its intended use as described in this manual. Use only attachments recommend

ed by the manufacturer as contained in this manual.

3. Never operate this overlock machine if it has a damaged cord or plug, if it is not working properly, if it has been

dropped or damaged, or dropped into water. Return the overlock machine to the nearest authorized dealer or serv

ice center for examination, repair, electrical or mechanical adjustment.

4. Never operate the overlock machine with any air openings blocked. Keep ventilation openings of the overlock

machine and foot controller free from the accumulation of lint, dust, and loose cloth.

5. Never drop or insert any object into any opening.

6. Do not use outdoors.

7. Do not operate where aerosol (spray) products are being used or where oxygen is being administered.

8. To disconnect, turn the main switch to the symbol "O" position which represents off, then remove plug from outlet.

9. Do not unplug by pulling on cord. To unplug, grasp the plug, not the cord.

10. Keep fingers away from all moving parts. Special care is required around the overlock machine needle.

11. Always use the proper needle plate. The wrong needle plate can cause the needle to break.

12. Do not use bent needles.

13. Do not pull or push fabric while stitching. It may deflect the needle(s) causing it to break.

14. Switch the overlock machine to the symbol "O" position when making any adjustments in the needle area, such as

threading needle, changing needle, threading looper, or changing presser foot, and the like.

15. Always unplug the overlock machine from the electrical outlet when removing covers, lubricating, or

when making any of the user servicing adjustments mentioned in the instruction manual.

16. Keep fingers away from moving parts, especially the area near the blades.

17. Please note that on disposal, this product must be safely recycled in accordance with

relevant National legislation relating to electrical / electronic products. If in doubt

please contact your retailer for guidance.

18. The appliance is not intended for use by young children or infirm persons without supervision.

19. Young children should be supervised to ensure that they do not play with the appliance.

"SAVE THESE INSTRUCTIONS"

"This overlock machine is intended for household use."

Page 3

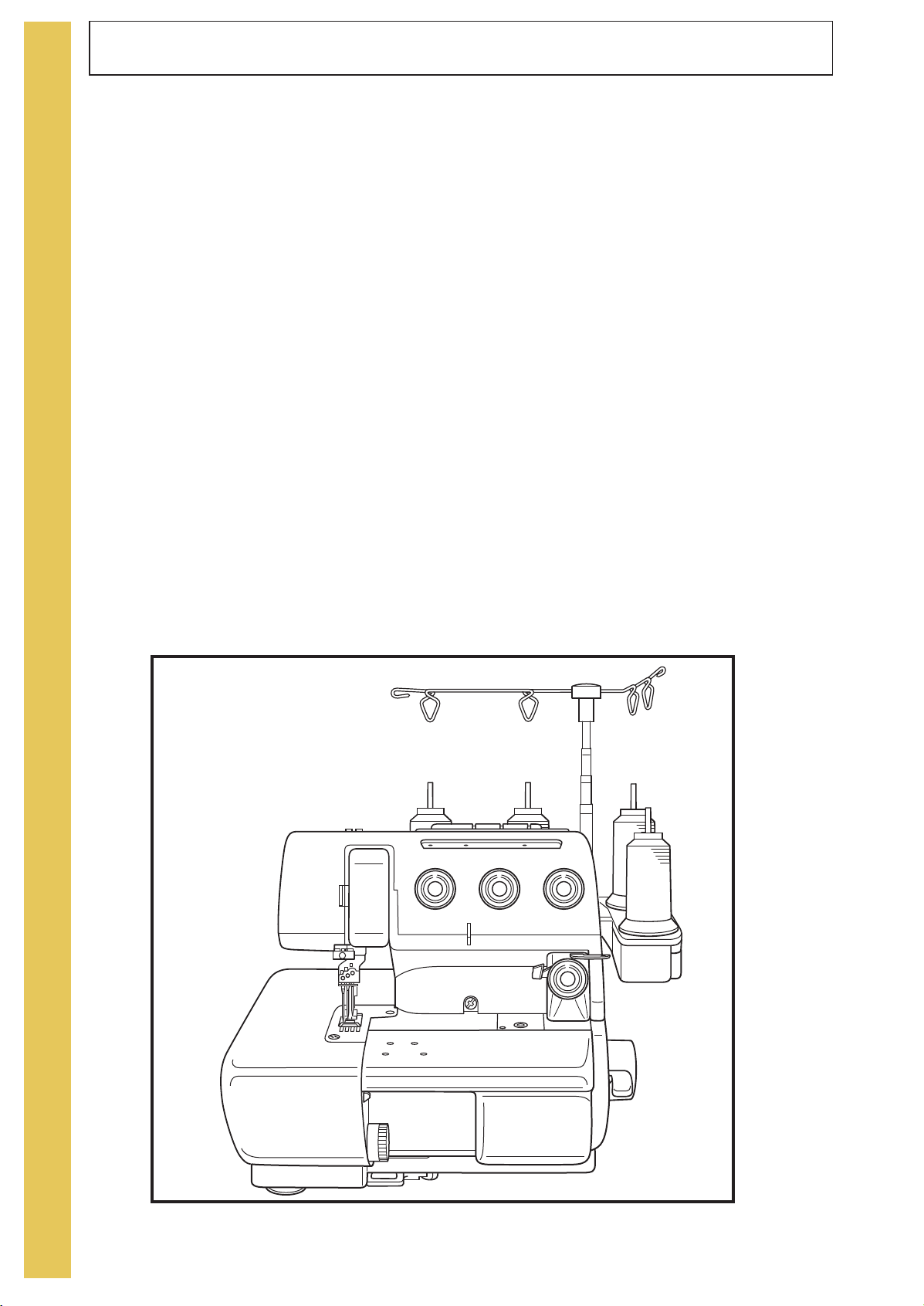

Welcome to the Baby Lock Cover Stitch Machine

Your Baby Lock Cover Stitch machine provides a variety of chain and cover stitches, allowing you to

create professional looking hems just like the readytowear fashions in stores. A variety of stitch

widths and lengths also provide options for creating the look you want.

Your Baby Lock Cover Stitch is a highquality, dependable machine. The patented JetAir Threading

system makes threading the looper a breeze. Speedy at 1300 stitches per minute, BLCS allows you

to complete hems quickly. Other features including differential feed,autotension release when the

presser foot is lifted, and manual tension adjustments put you in control of your project.

With proper care and maintenance, your Baby Lock Cover Stitch machine promises years of high

quality, dependable performance and sewing pleasure. Keep this instruction manual as a stepbystep

guide to become familiar with your Baby Lock.

Happy Sewing!

For additional product information visit our website at

www.babylock.com

1

Page 4

T

A

B

L

E

O

F

C

O

N

T

E

N

T

S

Table of Contents

OVERVIEW ..................................................................................................................4

How Your Machine Operates .................................................................................. 4

Overview of the Baby Lock ..................................................................................... 5

Accessories ............................................................................................................ 6

Needles ..................................................................................................................7

Thread ..................................................................................................................7

Optional Accessories .............................................................................................. 7

Accessory Adapter...................................................................................................8

Setting Up Your Baby Lock .................................................................................. 8/9

Side Cover .............................................................................................................. 9

Thread Cutter........................................................................................................ 10

Presser Foot Pressure Adjustment....................................................................... 10

Snapon Presser Foot........................................................................................... 10

Stitch Length ......................................................................................................... 11

Differential Feed.................................................................................................... 11

Chain/Cover Stitch Tension Dials.......................................................................... 12

Needle Tension Dial ................................................................................ 12

Chain Looper Tension Dial...................................................................... 12

THREADING ................................................................................................................13

Threading Preparation .......................................................................................... 13

Threading Your Baby Lock.................................................................................... 13

Locked Position for Threading .............................................................................. 13

Chain Looper .........................................................................................................14

Chain/Cover Needles............................................................................................ 15

Left Needle C1..................................................................................... 15

Center Needle C2................................................................................ 15

Right Needle C3 .................................................................................. 15

How to Use the Needle Threader ......................................................................... 16

Front Cover Seam Guide...................................................................................... 16

Rethreading Looper..............................................................................................16

Start to Sew .......................................................................................................... 17

To ChainOff of the fabric.......................................................................................17

2

Page 5

Table of Contents (Cont.)

CHAIN/COVER STITCH ............................................................................................... 18

Chain Stitching................................................................................................. 18/19

Chain Stitch Tension Adjustment.......................................................... 19

Cover Stitch Right Narrow 3mm................................................................. 20/21

Cover Stitch Tension Adjustment............................................................. 21

Cover Stitch Left Narrow 3mm .................................................................... 22/23

Cover Stitch Tension Adjustment............................................................. 23

Cover Stitch Wide 6mm............................................................................... 24/25

Cover Stitch Tension Adjustment............................................................. 25

Triple Cover Stitch 6mm ................................................................................ 26/27

Triple Cover Stitch Tension Adjustment................................................... 27

TECHNIQUES.................................................................................................................28

Turning Corners Chain Stitch ............................................................................. 28

Turning Corners Cover Stitch ............................................................................. 28

Flat Hemming Cover Stitch................................................................................. 29

Hemming in the Round Cover Stitch .................................................................. 29

Securing Chain and Cover Stitching..................................................................... 30

SPECIALTY THREADS.................................................................................................. 31

Using Specialty Threads ....................................................................................... 31

Light Weight Threads............................................................................................ 31

Medium Weight Threads....................................................................................... 31

Heavy Weight Threads ......................................................................................... 31

Bypassing the Threading Port .............................................................................. 32

Looper Threading Tool.......................................................................................... 33

Thread Cradle for Looper ..................................................................................... 34

Specialty Thread Guide Chart .............................................................................. 35

MAINTENANCE ............................................................................................................. 36

Troubleshooting............................................................................................... 36/37

Replacing Needles ............................................................................................... 38

Replacing Light Bulb............................................................................................. 39

Cleaning ............................................................................................................... 40

TECHNICAL DATA ......................................................................................................... 41

Technical data....................................................................................................... 41

STITCH SELECTION CHART........................................................................................ 42

Chart for Stitch Selection Setting for Chain/Cover ........................................................ 42

T

A

B

L

E

O

F

C

O

N

T

E

N

T

S

3

Page 6

O

V

How Your Machine Operates

Awareness of its simple operation will enable you to become more proficient in its use. Please read all

instructions before using your new machine.

E

R

V

I

E

W

Use one, two or three chain/cover stitch needles and one looper for a chain or cover stitch.

When forming a chain stitch, the chain needle thread catches the chain looper to form a straight stitch

on the top of your fabric and thread chain loops on the underside. Use 2 or 3 cover stitch needles and

the chain looper to form a double or triple row of straight stitching on the top and a weave of thread on

the underside of your fabric.

After setting up your machine for the first time, take a few moments to learn how it sews. Before your

machine is threaded, turn the handwheel toward you and watch the operation of the various parts.

4

Page 7

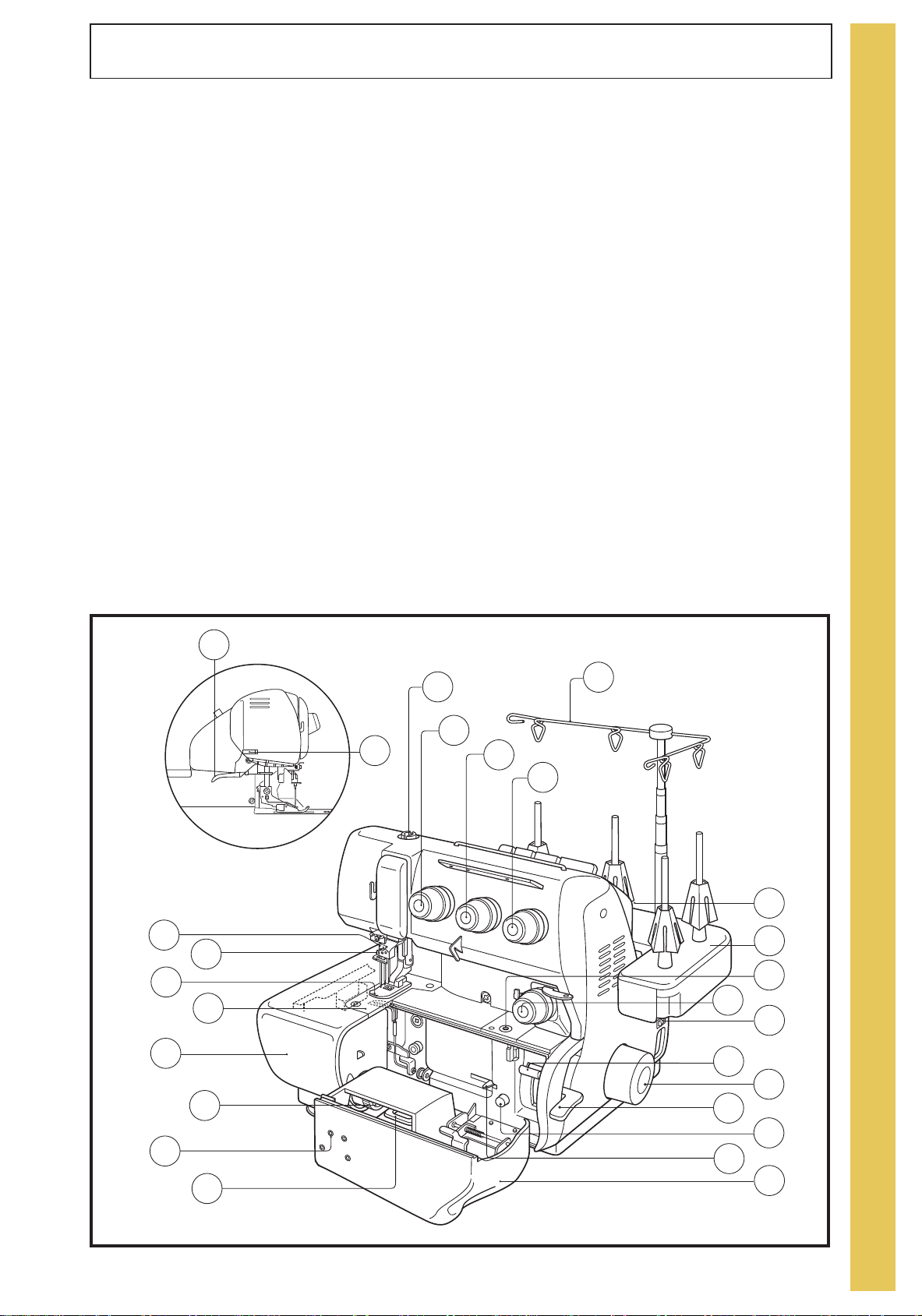

Overview of the Baby Lock

1

18

19

20

24

23

21

25

14

5

17

13

3

2

12

10

9

11

15

26

22

7

8

6

4

16

O

V

1. Presser foot pressure adjusting screw

2. Machine lock button release lever

3. Machine lock button

4. Presser foot thread release lever*

5. Looper threading lever

6. Thread cutter

7. Needle height viewing area

8. Needle clamp screw

9. Needle plate

10. Snapon presser foot

11. Side cover

12. Front table

13. Handwheel

14. Carrying handle

15. Stitch length dial

16. Accessory compartment & spool stand

17. Differential feed adjusting lever

18. Left needle tension dial

19. Center needle tension dial

20. Right needle tension dial

21. Looper tension dial

22. Needle drop drawer

23. Chain looper threading port

24. Telescopic thread guide and antenna

25. Power switch

26. Attachment screw holes

* Raising the presser foot releases needle

threads.

E

R

V

I

E

W

5

Page 8

O

V

E

R

V

I

E

W

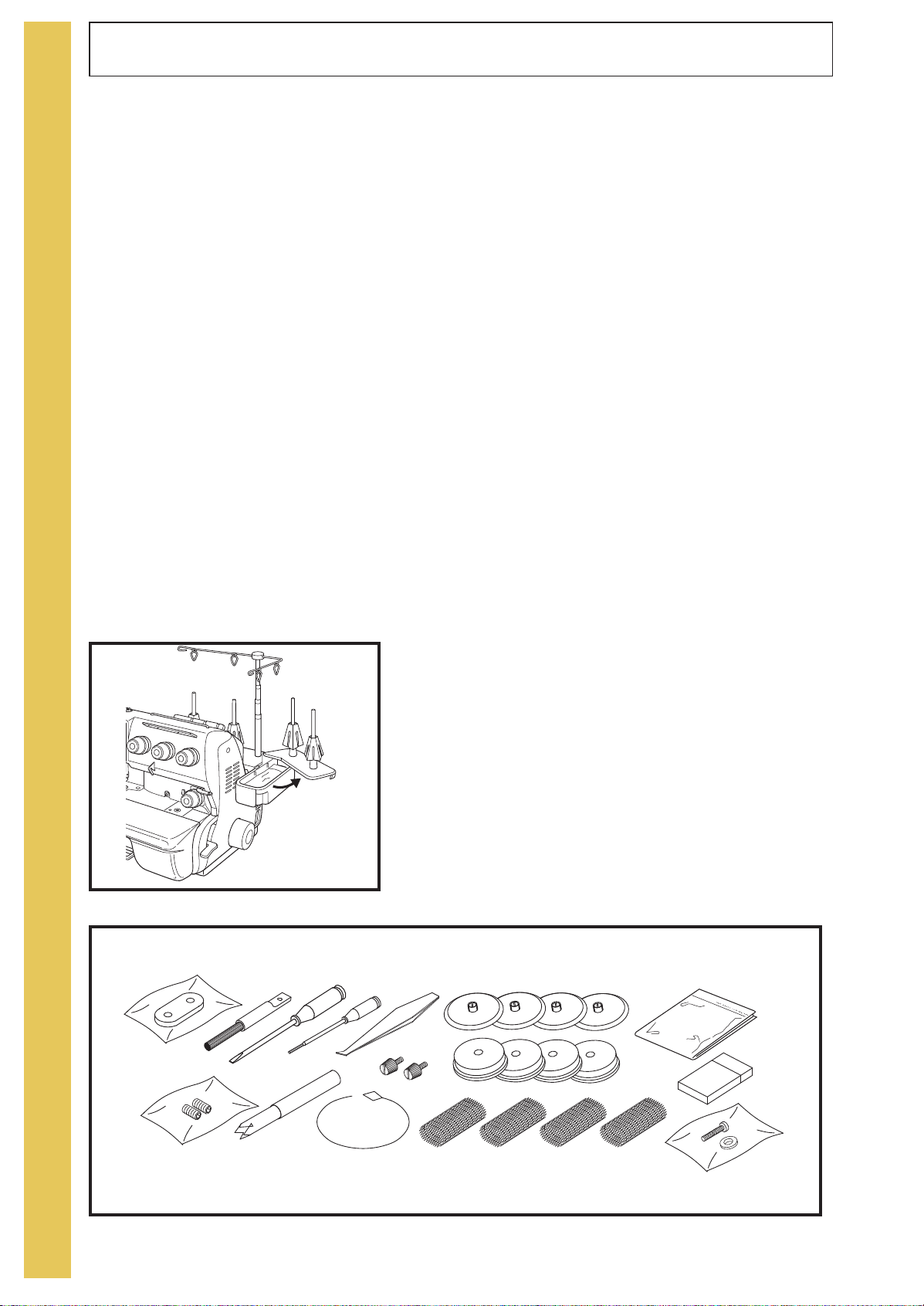

Accessories

Your Baby Lock has a builtin accessory compartment. To open, swing the "lid" on the thread spool

stand to the right to reveal the tray holding some of the accessories listed below. Others may be found

in the machine packing materials.

Accessory Number included Located in

Instruction manual 1 Packing box

Guide fixing screws for table 2 Accessory compartment

Lint brush/needle insert tool 1 Accessory compartment

Package of assorted sized needles 1 Accessory compartment

Organ ELx705CF

Allen screwdriver 1 Accessory compartment

Tweezers 1 Accessory compartment

Needle threader 1 Accessory compartment

Chain/Cover stitch needle screws 2 Accessory compartment

Accessory adapter(for Optional Accessories) 1 Accessory compartment

Looper threading tool 1 Accessory packet

Screwdriver 1 Accessory packet

Machine cover 1 Accessory packet

Mounting bolt with washer(U.S.A. only) 1 Accessory packet

Thread nets 4 Accessory packet

Spool caps 4 Accessory packet

Sponge disks 4 Accessory packet

Cone holders 4 On machine

6

Page 9

Needles

Your Baby Lock is set up with Organ ELx705CF needles size 90/14. This is suitable for most medium

and heavy weight fabrics. For light weight fabrics use size 80/12, ELx705CF needles. The ELx705CF

needle is a semiballpoint design and is suitable for knits and wovens.

O

V

E

Thread

All types of thread may be used on your Baby Lock, but 100% longstaple polyester thread, cross

wound on a cone, consistently provides the best stitch performance. Because the threads must pass

through several thread guides at high speeds, they must be of uniform thickness and high strength

with a minimum amount of linting.

Goodquality cotton or cottoncovered polyester threads sew well, though they produce more lint, cre

ating the need to clean the machine more frequently. Poor grades of thread can result in frequent

fraying, breaking and unbalanced stitches.

Threads of other fiber contents and weights may be used, depending on their strength and thickness.

Testing will help you determine how easily they can pass through the thread guides, thread slots, nee

dles and loopers.

Important Note: For maximum performance of the Baby Lock, it is recommended to use "100% poly

esterlong fiber thread". Recommended brands are MaxiLock and Metrosene. This thread also per

forms best when used with many decorative threads for sewing specialty decorative techniques.

Optional Accessories

R

V

I

E

W

(CHAIN/COVER STITCH OPTIONAL ACCESSORIES)

Belt Loop Folder (3/4", 19mm) ROB0421S12AE (BLE8S12)

Belt Loop Folder (11/2", 38mm) ROB0421S11AE (BLE8S11)

Single Fold Bias Binder (28mm) ROB0421S04AE (BLE8S4)

Single Fold Bias Binder (40mm) ROB0421S05AE (BLE8S5)

Double Fold Bias Binder (11/8", 28mm) ROB0421S03AE (BLE8S3)

Double Fold Bias Binder (13/8), 36mm) ROB0421S02AE (BLE8S2)

Elastic Gatherer Bracket U.S.A. only (BLE8GG)

Elastic Guide for Gatherer Bracket (1/4", 7.5mm) U.S.A. only (BLE8EG7)

Elastic Guide for Gatherer Bracket (3/8", 10mm) U.S.A. only (BLE8EG10)

Elastic Guide for Gatherer Bracket (1/2", 13mm) U.S.A. only (BLE8EG13)

Fabric Guide ROB0420S01AE (BLE8FG)

Plain Hemmer (1/4", 7.5mm) ROB0421S07AE (BLE8S7)

Plain Hemmer (1/2", 13mm) ROB0421S06AE (BLE8S6)

Single Downturn Feller (1/4", 7.5mm) ROB0421S10AE (BLE8S10)

Single Downturn Feller (5/8", 16mm) ROB0421S08AE (BLE8S8)

Single Downturn Feller (1", 25mm) ROB0421S09AE (BLE8S9)

Knit/Woven Double Fold Bias Binder (8mm) ROD13408E (BLCSDFBB8)

Knit/Woven Double Fold Bias Binder (10mm) ROD13410E (BLCSDFBB10)

Knit/Woven Double Fold Bias Binder (15mm) ROD13415E (BLCSDFBB15)

Clear Foot B5002K03AE (BLCSCLF)

Pintuck Foot w/2 Guides ROB500206BCE (BLCSPTF)

NOTE:

・Use the front two Attachment Screw Holes for the Knit / Woven Double Fold Bias Binder.

・Use the back two Attachment Screw Holes with the Accessory Adapter for the Optional

Accessories.

These optional accessories are available at your Baby Lock retailer.

7

Page 10

O

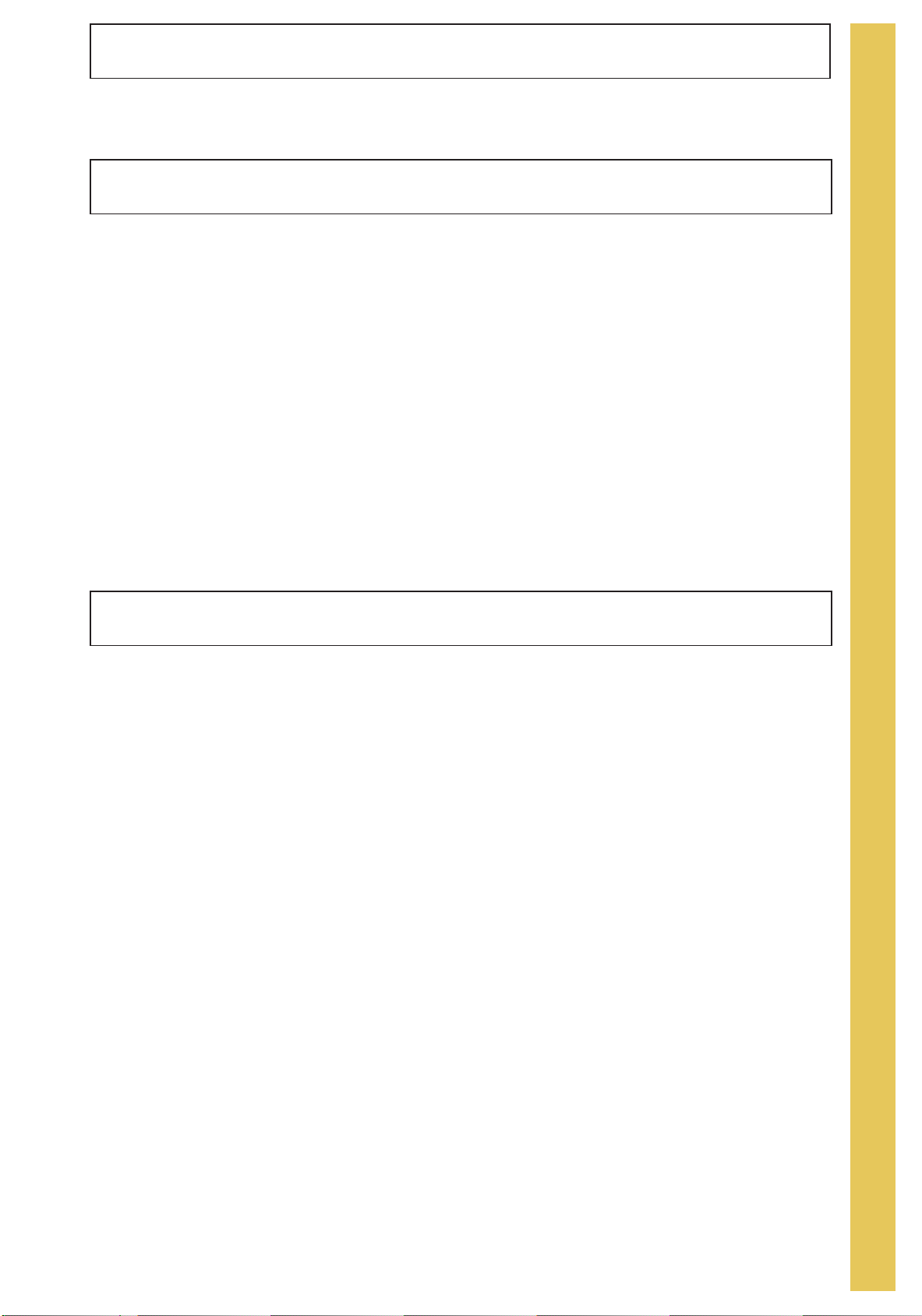

Accessory Adapter

V

E

R

V

I

E

W

・Place Accessory Adapter over the back two holes of the front cover table.

・Place the accessory bracket on top of the Accessory Adapter.

・Insert the Guide Fixing Screws to hold the Accessory Adapter and Accessory in

place.

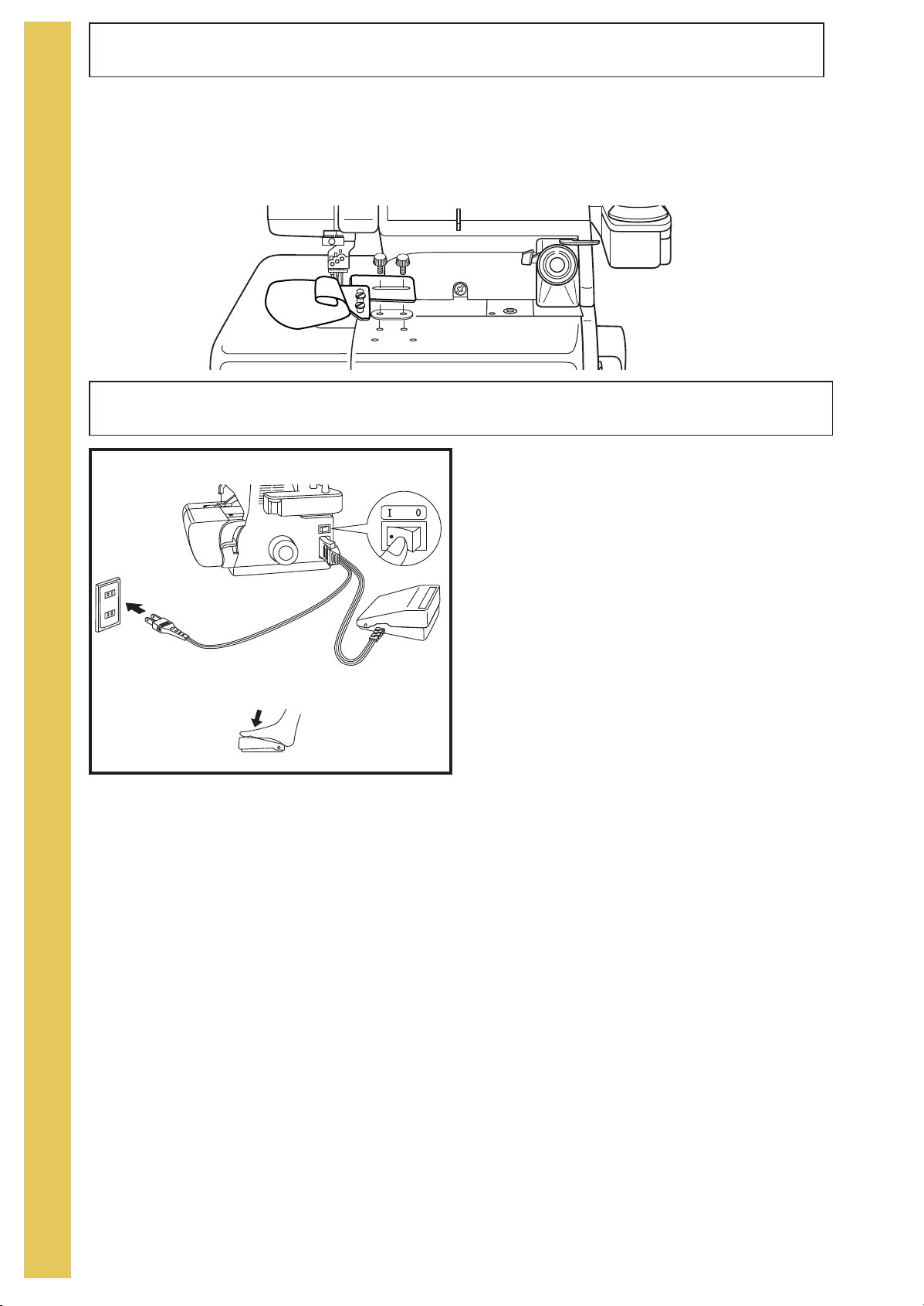

Setting Up Your Baby Lock

1. Remove machine from box

After removing the packing materials from the

box, gently lift your Baby Lock by grasping the

handle provided on the top of the machine.

Place the machine on a sewing table or any

level surface that provides ample work area to

the left. Place the foot controller in a pedal stay,

if desired, and place it under the sewing table.

A

2. Plug in the machine

Plug the power cord into the machine first, then

into a wall outlet. The power switch is located

toward t h e back on t h e ri g h t side of t h e

machine. Always make sure the power is off

when t h e ma c h i n e is not in use ( f i g . A ) .

Available foot controller for U.S.A.: Model YC

482 or YC420W.

3. Polarized plug

This appliance has a polarized plug (one blade

wider than the other). To reduce the risk of

electric shock, this plug is intended to fit in a

polarized outlet only one way. If the plug does

not fit fully in the outlet, reverse the plug. If it

still does not fit, contact a qualified electrician

to install the proper outlet. Do not modify the

plug in any way.

4. Foot controller

The sewing speed of the machine is deter

mined by the amount of pressure applied to the

foot controller. When not in use, do not place

anything on the foot controller, or the machine

could start inadvertently and the controller or

motor could burn out.

8

Page 11

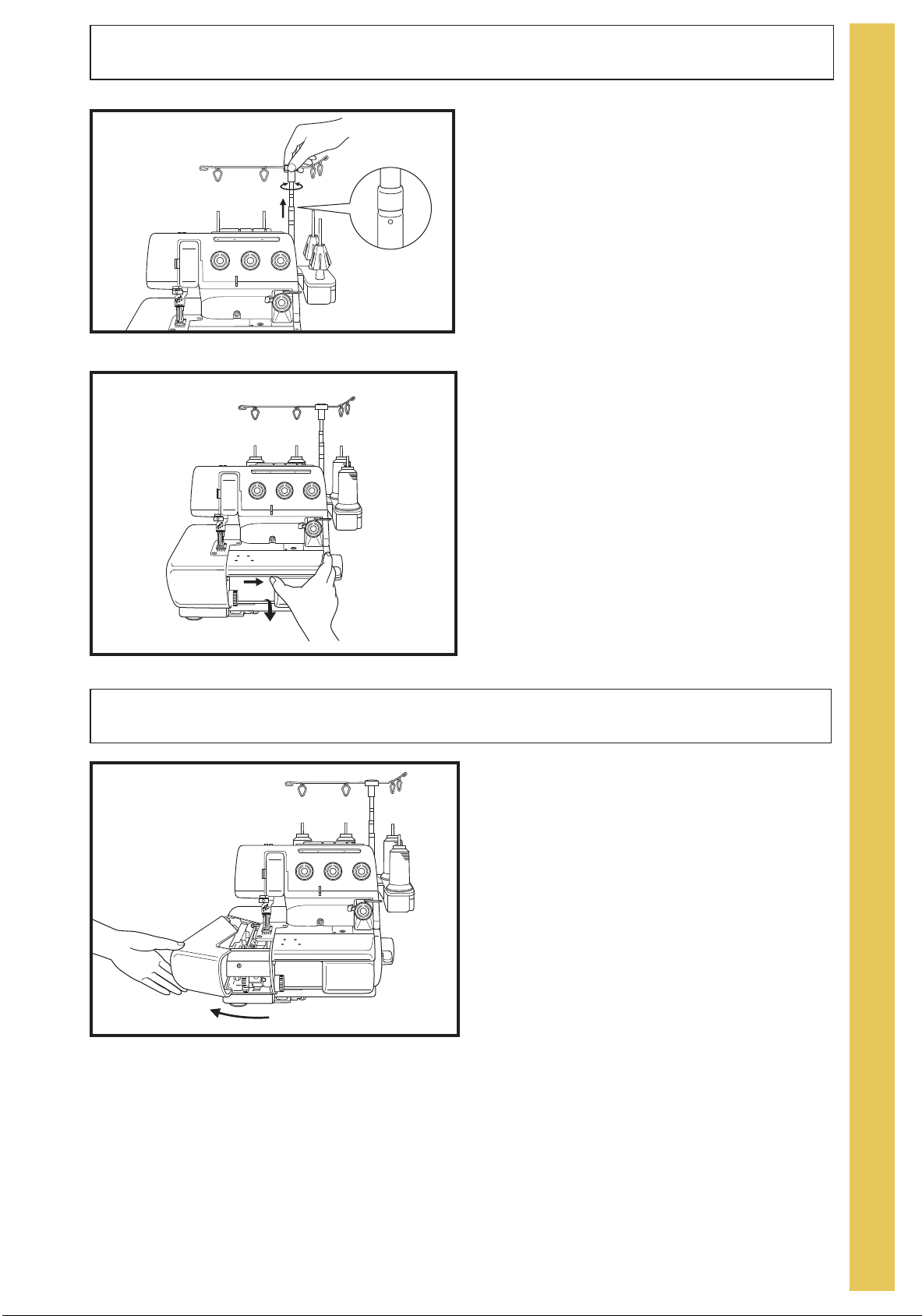

Setting Up Your Baby Lock (Cont.)

O

B

5. Position the telescopic thread guide.

Raise the telescopic thread guide to its high

est position. Rotate the shaft to the left and

right until each section "clicks" into a locked

position (fig. B).

6. Opening Front table

To open the front table, place your thumb

against the tab, and slide the cover to the

right. A slight pull toward you will allow the

cover to swing down, providing access to

the chain looper.

(fig. C).

V

E

R

V

I

E

W

Side Cover

C

Open side door on the left for easy access to

the chain looper thread tray.

Close door before sewing.

9

Page 12

O

Thread Cutter

V

E

R

V

I

E

W

There is a thread cutter located on the left side of your machine. At the

end of a seam, sew off the fabric edge and continue sewing to create a

5 6 inch(12 15cm) thread chain.

Bring the chain of thread up and back and pull forward into the thread

cutter.

Presser Foot Pressure Adjustment

The presser foot pressure has been preset at the factory and rarely

needs adjustment. You may find it necessary, however, to decrease

the pressure for thick fabrics or increase pressure for thin fabrics to

feed more smoothly under the foot. Use a coin to turn the screw on top

of the machine.

To increase pressure, turn the pressure adjusting screw clockwise.

To decrease pressure, turn the screw counter clockwise.

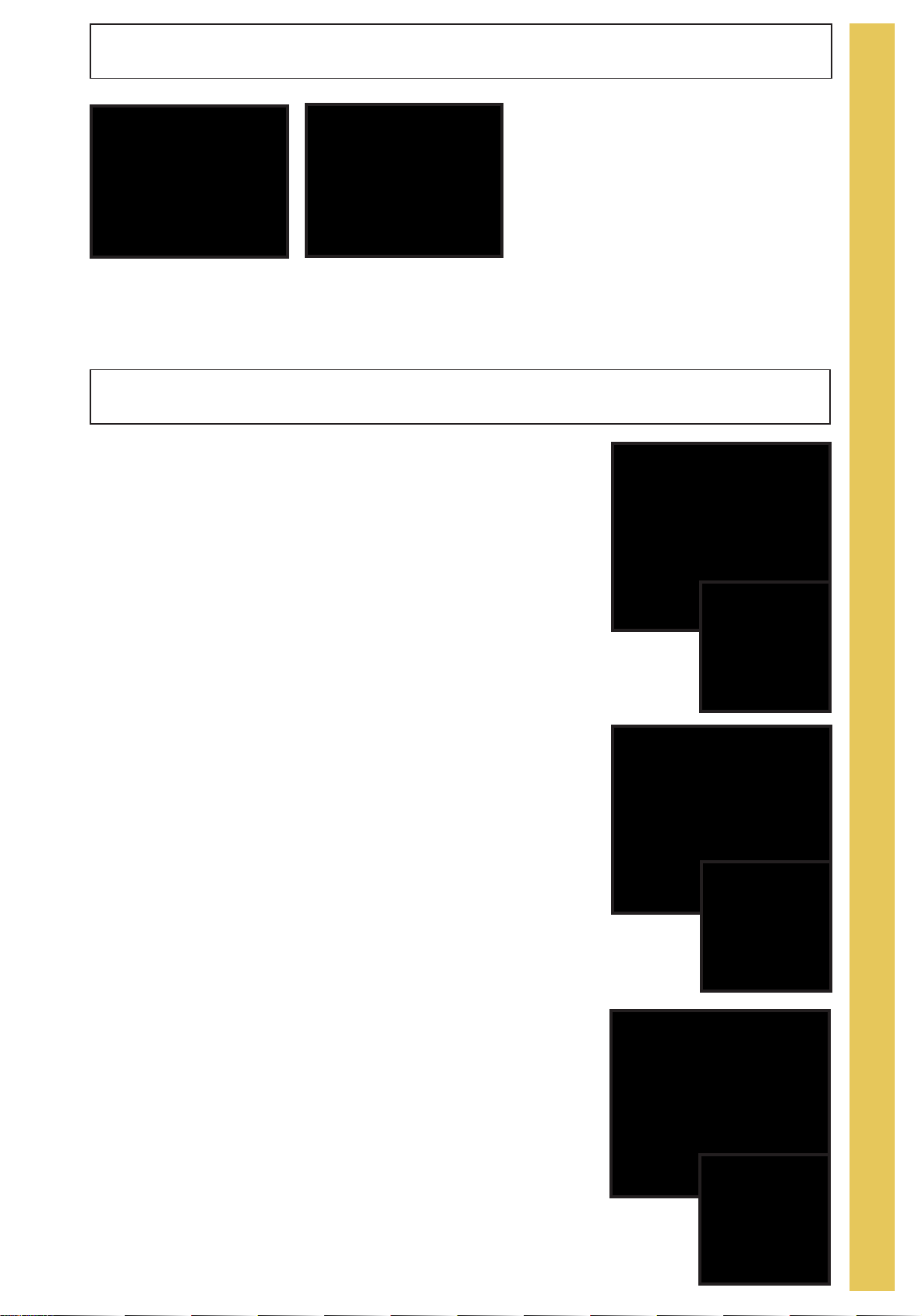

SnapOn Presser Foot

The Baby Lock has the convenience of a snapon presser foot.

To Release:

1. Raise the presser foot lever. This will also lower the feed dogs out of

the way.

2. Raise the needles to the highest position.

3. Push the presser foot release lever located at the back of the presser

foot holder.

4. Slide the presser foot to the left of the needles.

Presser Foot

Release Lever

To Replace:

1. Raise the presser foot lever.This will also lower the feed dogs out of

the way.

2. Raise the needles to the highest position.

3. Slide the foot from the left to right.

4. Align the bar to the foot with the groove in the holder.

5. Lower the presser foot lever to snap into place.

6. Turn the hand wheel counter clockwise to engage the feed dogs in

the up position.

10

The raised markings on the toe of the foot are seam line guides. They indicate the needle positions to

help guide your fabric for accurate seaming.

Page 13

Stitch Length

O

The stitch length adjusting dial is conve

A

B

machine. A stitch length of 3mm, or about 10 stitches per inch is ideal for most fabrics. For seaming

very light weight fabrics, you may prefer a shorter stitch length. When sewing heavier fabrics, you may

choose to lengthen the stitch (fig. B).

niently located just to the left of the front

cover, near the base plate (fig. A). The

dial shows the stitchlength ranging from

1, for the shortest stitch, to 4 for the

longest.

Simply turn the dial aligning the desired

setting with the indicator mark on the

Differential Feed

Your Baby Lock Cover Stitch is equipped with differential feed.The

set of feed dogs work independently in order to ensure smooth

sewing on all fabrics (fig. A)

When the differential feed adjusting lever, located at the machine's

right, front edge is set on "N" for normal feeding, the feed dogs move

the same distance. This is the setting to use for most fabrics and

applications (fig. B).

A

V

E

R

V

I

E

W

When the dial is set above "N", the front feed dog will feed more fab

rics than the back. This is because the front feed dog moves at a

greater distance than the back feed dogs. As a result, the fabric

becomes compressed or eased, as the diagram on the front cover

indicates. This can eliminate wavy seams in stretchy fabrics or those

cut on the bias grain.

At the maximum setting of 2.0 (fig. C), the differential feed can gath

er a lightweight fabric to nearly double fullness (fig. D).

The front feed dog is actually feeding in twice as much fabric as the

back feed dog is feeding out. To maximize the gathering effects, use

the longest stitch length setting. Fabric weight will affect the gather

ing. Test stitch for desired results.

When the differential feed lever is set below "N" (fig. F), the front feed

dog moves less distance than the back feed dog. This adjustment

stretches the fabric slightly as it is sewn. The lower settings prevent

puckers on lightweight fabric (fig. E).

B

D

C

E

F

11

Page 14

O

V

E

Chain/Cover Stitch Tension Dials

R

V

I

E

W

Needle Tension Dials

From left to right the dials are:

Orange for C1 chain needle, Yellow for C2 chain needle and Green for C3 chain needle.

The tension settings range from 0 to 9. The fabric and thread that you are working with will determine

what the tension setting will be. Be sure to sew test after changing the settings.

Chain Looper Tension Dial

The chain looper dial is color coded blue for easy identification. The tension settings range from 0 to 9.

The fabric, thread and stitch that you are working with will determine what the tension setting will be.

Be sure to sew test after changing the settings.

12

Page 15

Threading Preparation

When using overlock threads (cones) place the cone securely over

the spool holder on your machine. The spool holders prevent the

cone from spinning, enabling the thread to feed evenly. (fig. A)

T

H

R

A

Cones with Spool Holder

B

Standard sewing thread with

sponge disks and spool cap.

When using standard sewing thread spools, use the sponge disks

(sponge side up) and spool caps (on top of spool) to prevent the

thread from tangling. (fig. B)

Thread nets can be placed over threads that tend to slip off the

spool during sewing. For example: rayon, silk, nylon, invisible, and

decorative threads. Place the thread net over the spool of thread

and fold net back, (fig. C) Pull thread from the top of spool to enable

the thread to feed evenly. (fig. D)

D

Thread net on thread

C

Pulling thread through net

E

A

D

I

N

G

Threading Your Baby Lock

Your Baby Lock is equipped with an exclusive "Instant JetAir Threading System" for fast, easy

threading of the chain looper.

One push of the "JetAir" threading lever will automatically thread the chain looper. It is no longer nec

essary to use tweezers for threading the thread guides. If a looper thread breaks or runs out, just

rethread it. There is no need to follow threading sequence.

Locked Position for Threading

1. Open the front cover.

2. Raise the presser foot to release all threads.

3. Depress the machine lock button firmly. Rotate

the machine handwheel slowly toward you until

the button "snaps" into the locked position and

the lock button release lever moves to the far

left (fig.A).

Note: The Baby Lock must be in the locked posi

tion when threading the looper unless otherwise

A

indicated.

13

Page 16

T

H

R

E

A

D

I

N

G

Chain Looper

1. With the presser foot up and machine lock button in the locked position, (fig. A pg. 13).

2. Place the thread cone or spool on the "Chain Looper" spool pin. Slip the thread into the telescop

ic antenna thread guide above the thread cone.

3. Insert the thread through the hole of the thread guide above the chain looper tension dial. Bring

the thread under the chain looper tension dial, then up and over the left thread guide,making sure

the thread is in the tension disk. (fig.A).

4. Take the thread down to the chain looper threading port.

5. Pull 18 inches (40cm) of thread and insert 1 inch (10cm) of thread into the chain looper threading

port. Use tweezers if necessary, to insert the thread end. (fig. B).

6. Depress the looper threading lever. (fig. B). If the thread does not go through the chain looper eye

with one push, depress the threading lever again until it does.

7. Open side cover to the left for easy access to the chain looper thread in tray (fig. C).

8. Trim excess thread to 4 inches (2.5cm) from the eye of chain looper and leave it hang.

9. Close side cover.

10. Move the lock button release lever to the right.

A

B

C

14

Page 17

Chain / Cover Needles

Left Needle C-1

1. Raise presser foot and place the thread on the far left spool pin. Slip the thread into the telescopic

antenna thread guide directly above the thread spool. See drawings below for reference.

2. Bring thread down from the telescopic antenna, snap thread into the orange thread guide on the

top of the machine, and then down into the orange hole above the tension dial.

3. Bring the thread down the right side of the orange tension dial, under the dial and back up the left

side, making sure the thread is in the tension disk.

4. Bring the thread through thread guide at top of machine and down to the pretension thread guide

above the needle.

5. Pass the thread from the left side behind the pretension thread guide plate on needle clamp and

into thread guide above the needle. See drawings below for reference.

6. With the needle threader or tweezers in the accessory compartment, thread needle in the left "C1"

needle position.

Center Needle C-2

1. Raise presser foot and place the thread on the second from the left spool pin. Slip the thread into

the telescopic antenna thread guide directly above the thread spool. See drawings below for refer

ence.

2. Bring thread down from the telescopic antenna, snap thread into the yellow thread guide on the top

of the machine, and then down into the yellow hole above the tension dial.

3. Bring the thread down the right side of the yellow tension dial, under the dial and the thread guide

below the dial.

4. Bring the thread through thread guide at top of machine and down to the pretension thread guide

above the needle.

5. Pass the thread from the right side behind the pretension thread guide plate on needle clamp and

into thread guide above the needle. See drawings below for reference.

6. With the needle threader or tweezers in the accessory compartment, thread needle in the center

"C2" needle position.

T

H

R

E

A

D

I

N

G

Right Needle C-3

1. Raise presser foot and place the thread on the back right spool pin. Slip the thread into the tele

scopic antenna thread guide directly above the thread spool. See drawings below for reference.

2. Bring thread down from the telescopic antenna, snap thread into the green thread guide on the top

of the machine, and then down into the green hole above the tension dial.

3. Bring the thread down the right side of the green tension dial, under the green dial and under the

thread guide located below the yellow tension dial.

4. Bring the thread through thread guide at top of machine and down to the pretension thread guide

above the needle.

5. Pass the thread from the right side behind the pretension thread guide plate on needle clamp and

into thread guide above the needle. See drawings below for reference.

6. With the needle threader or tweezers in the accessory compartment, thread needle in the right "C

3" needle position.

NOTE:

After threading the needles, the thread is then place to the left and top of the presser foot.

15

Page 18

T

H

R

E

A

D

I

N

G

How To Use The Needle Threader

1. Hold the needle threader with the arrow mark

on top. Place the thread in the groove of the

needle threader. (fig.A)

2. Push the needle threader against needle and

slide down the groove of the needle to the

eye. Push the thread into the eye of the nee

dle.

A

B

3. With a point of the needle threader or the

tweezers pull the loop of thread from the

back of the needle, under the foot and to the

back left.

Front Cover Seam Guide

There are marks on the bed of the Baby Lock that can be used as a guide while sewing.

It will depend on what cover or chain stitch needle position you will be using as to what the width will

be.

For example, the first mark on the left closest to

the needle plate, C1 needle is 1 inch (2.5cm),

C2 needle is 7/8 inch (2.25cm), and C3 nee

dle is 3/4 inch (2cm).

This guide is great for hemming garments with

cover stitch.

1. Turn under hem and press.

2. Align the raw edge of the hem with the needles

3. Align the folded edge of hem with the correct

guide mark.

16

Rethreading Looper

If a thread breaks, raise the presser foot and pull the broken thread from under the foot. Open the front

table, depress the machine lock button.. Rethread the machine above the threading port, leaving an

18inch (40cm) thread tail. Thread the looper as usual and move lock button release lever to the right.

Close the front cover and sew a test sample.

Note: When rethreading your Baby Lock using the "JetAir Threading" feature, make sure that the

previous thread that was in the looper (tube) is completely removed. This will eliminate any chance of

the previous thread obstructing the flow of the air when rethreading the machine.

Page 19

Start to Sew

When threading is complete, the loose threads should initially interlock on fabric. This is most impor

tant when sewing the chain or cover stitches.

T

H

A

B

C

1. Cut all threads to 4 inch (10cm) in length. All threads should

then be placed over the top and left of the presser foot. The

threads at this time cannot be placed under the presser foot.

2. Place the fabric under the presser foot directly below the

needles (fig. A).

3. Lower the presser foot.

4. Turn the handwheel toward you to form 2 or 3 stitches.

5. Start to sew slowly.

6. After the first few stitches, stop and cut excess threads (fig.

B).

7. Start the next seam at the toe of the presser foot (fig.C).

8.You only need to raise and lower the presser foot when work

ing with thick fabric or when precise position is required.

R

E

A

D

I

N

G

Note: Be careful not to push or pull the fabric. The BLCS will

feed it evenly without help.

To ChainOff of the Fabric

Your BLCS will sew a chain off the edge of the fabric. For best results, we recommend to follow the

instructions below.

1.At the end of the seam, change the stitch length to 4 (fig.A).

2. Let the thread flow from the back of the 24 inches without pulling (figB).

3. Start the seam at the toe of the presser foot (figC).

A

B

C

17

Page 20

C

H

Chain/Cover Stitch

A

I

N

S

T

I

T

C

H

I

N

G

Chain Stitching

The chain stitch is formed using two threads, one thread in the needle and one thread in the chain

looper.

Chain Stitching looks like a straight stitch on the top of the fabric while the chain looper thread forms a

chain on the underside of the fabric. The chain stitch has stretchability that is not found in the conven

tional locked straight stitch from a sewing machine. The chain stitch is used to stabilize seams in

woven fabrics and where needed in knit fabrics. The chain stitch can also be used for sewing wide

elastic in garments and applying bias tape.

For Chain Stitch:

1. Place the machine in locked position to thread the chain looper.

2. Follow the diagram to thread the chain looper, (see pg. 19). Open side cover of machine to make

sure the thread is through the eye of the chain looper. Trim thread to 4 inches (10cm) and lay in tray.

3. Follow the guide to thread the chain/cover stitch needle, (C1, C2, or C3). Place needle thread on

top and to the left of presser foot before sewing.

4. Move the lock button release lever to the right.

5. Set stitch length and other machine adjustments(See chart below).

6. Place the fabric under the needle and turn handwheel toward you two or three stitches in the fabric.

Cut the excess threads and start sewing.

Note: All chain and cover stitches must be started with fabric under the needle.

CHAIN STITCH

Needle Position

C1, C2 or C3

Stitch Length

3,0 4,0

18

Page 21

Chain Stitching (Cont.)

C

H

A

I

N

S

T

I

T

C

H

Chain Stitch Tension Adjustments

Balanced tension

under side

top side

Needle thread is too loose

I

N

G

Balanced tension -

Chain stitch has correct tension when the needle thread sews a

straight seam on the top side and the chain looper thread forms

loops on the under side of the fabric.

Needle thread is too loose -

Increase the chain /cover needle thread tension dial to a higher

number. (Orange, yellow or green)

Or lower the chain looper tension dial to loosen the chain looper

thread. (Blue)

Needle thread is too tight

Needle thread is too tight

Loosen the chain /cover needle thread tension dial to a lower

number. (Orange, yellow or green)

Or increase the chain looper tension dial to a higher number for

tighter tension on the the chain looper thread. (Blue)

19

Page 22

C

O

V

E

R

Cover Stitch Right Narrow 3mm

The narrow cover stitch consists of two rows of straight stitching on the top side of the fabric with an

overlock stitch on the underside of the fabric. This stitch is very common in the garment industry to hem

knit garments. The narrow cover stitch is used on fine knits such as jersey and single knits for hemming

or topstitching. The cover stitch is not limited to knit fabrics. It also works well with woven fabrics.

The Right Narrow cover stitch is formed using two "C" needle positions and the chain looper. The nee

dle positions are C2 and C3. The width of the narrow cover stitch is 3mm.

S

T

I

T

C

H

For Cover Stitch:

1. Place the machine in locked position to thread the chain looper.

2. Follow the diagram to thread the chain looper, (pg. 21). Open the side cover of the machine to make

sure the thread is through the eye of the looper. Trim thread to 4 inches (10cm) and lay in tray.

3. Follow the diagram to thread the chain/cover stitch needles C2 and C3. Place needle threads on

top and to the left of presser foot before sewing.

4. Move the lock button release lever to the right.

5. Set stitch length and other machine adjustments (See chart below).

6. Place the fabric under the needles and turn handwheel toward you two or three stitches into the fab

ric. Cut the excess threads and start sewing.

Note: All chain and cover stitches must be started with fabric under the needle.

COVER STITCH - RIGHT NARROW

20

Needle Position

C2 and C3

Stitch Length

3,0 4,0

Page 23

Cover Stitch Right Narrow (Cont.)

C

O

V

E

R

S

T

I

T

C

H

Cover Stitch - Right Narrow Tension Adjustments

Balanced tension

under side

top side

Needle thread is too loose

Needle thread is too tight

Balanced tension -

Cover stitch has correct tension when the needle thread sews

two rows of straight stitching on the top side and the chain loop

er forms a zig zag on the underside of the fabric.

Needle thread is too loose -

Increase the chain /cover needle thread tension dial to a higher

number. (Orange, yellow or green)

Or decrease the tension on the chain looper tension dial to

loosen the chain looper thread. (Blue)

Needle thread is too tight -

Loosen the tension by turning the chain /cover needle thread ten

sion dial to a lower number. (Orange, yellow or green)

Make sure that the chain looper dial is correctly set for proper

tension (Blue)

21

Page 24

C

O

V

E

R

S

T

I

T

C

H

Cover Stitch Left Narrow 3mm

The narrow cover stitch consists of two rows of straight stitching on the top side of the fabric with the

overlock stitch on the underside of the fabric. This stitch is very common in the garment industry to hem

knit garments. The narrow cover stitch is used on fine knits such as jersey and single knits for hemming

or topstitching. The cover stitch is not limited to knit fabrics. It also works well with woven fabrics.

The Left Narrow cover stitch is formed using two "C" needle positions and the chain looper. The needle

positions are C1 and C2. The width of the narrow cover stitch is 3mm.

For Cover Stitch:

1. Place the machine in locked position to thread the chain looper. (pg.13)

2. Follow the diagram to thread the chain looper, (pg. 23). Open the side cover of the machine to make

sure the thread is through the eye of the looper. Trim the thread to 4 inches (10cm) and lay in tray.

3. Follow the diagram to thread the chain/cover stitch needle positions C1 and C2. Place needle

threads on top and to the left of presser foot before sewing.

4. Move the lock button release lever to the right.

5. Set stitch length and other machine adjustments.(See chart below)

6. Place the fabric under the needles and turn handwheel toward you two or three stitches into the

fabric. Cut the excess threads and start sewing.

Note: All chain and cover stitches must be started with fabric under the needle.

COVER STITCH - LEFT NARROW

Needle Position

C1 and C2

Stitch Length

3,0 4,0

22

Page 25

Cover Stitch Left Narrow (Cont.)

C

O

V

E

R

S

T

I

T

C

H

Cover Stitch - Left Narrow Tension Adjustments

Balanced tension

under side

top side

Needle thread is too loose

Needle thread is too tight

Balanced tension -

Cover stitch has correct tension when the needle threads sew

two rows of straight stitching on the top side and the chain looper

forms a zig zag on the under side of the fabric.

Needle thread is too loose -

Increase the chain /cover needle thread tension dial to a higher

number. (Orange, yellow or green)

Or decrease the tension on the chain looper tension dial to

loosen the chain looper thread. (Blue)

Needle thread is too tight

Loosen the tension by turning the chain /cover needle thread ten

sion dial to a lower number. (Orange, yellow or green)

Make sure that the chain looper dial is correctly set for proper

tension. (Blue)

23

Page 26

C

O

Cover Stitch Wide 6mm

V

E

R

S

T

I

T

C

H

The wide cover stitch consists of two rows of straight stitching on top the fabric with an overlock stitch on

the underside of the fabric. This stitch is very common in the garment industry to hem heavier knit fabrics

such as double knits, sweatshirt fleece, and polar fleece. The wide cover stitch is not limited to knit fab

rics. It also works well with medium to heavy woven fabrics.

The wide cover stitch is formed using two "C" needle positions and the chain looper. The needle posi

tions are C1 and C3. The width of the wide cover stitch is 6mm.

For Cover Stitch:

1. Place the machine in "locked" position to thread the chain looper. (pg.13).

2. Follow the diagram to thread the chain looper, (pg. 25). Open the side cover of the machine to make

sure the thread is through the eye of the looper. Trim the thread to 4 inches (10cm) and lay in tray.

3. Follow the diagram to thread the chain/cover stitch needle positions C1 and C3. Place needle threads

on top and to the left of presser foot before sewing.

4. Move the lock button release lever to the right

5. Set stitch length and other machine adjustments. (See chart below).

6. Place the fabric under the needle and turn handwheel toward you two or three stitches in the

fabric. Cut the excess threads and start sewing.

Note: All chain and cover stitches must be started with fabric under the needle.

COVER STITCH - WIDE

Needle Position

C1 and C3

Stitch Length

3,0 4,0

24

Page 27

Cover StitchWide6mm (Cont.)

C

O

V

E

R

S

T

I

T

C

H

Cover Stitch - Wide Tension Adjustments

Balanced tension

under side

top side

Needle thread is too loose

Needle thread is too tight

Balanced tension -

Cover stitch has correct tension when the needle threads sew

two rows of straight stitching on the topside and the chain looper

forms a zig zag on the underside of the fabric.

Needle thread is too loose -

Increase the chain /cover needle thread tension dial to a higher

number. (Orange, yellow or green)

Or decrease the tension on the chain looper tension dial to

loosen the chain looper thread. (Blue)

Needle thread is too tight

Loosen the tension by turning the chain /cover needle thread ten

sion dial to a lower number. (Orange, yellow or green)

Make sure that the chain looper dial is correctly set for proper

tension. (Blue)

25

Page 28

C

O

Triple Cover Stitch 6mm

V

E

R

S

T

I

T

C

H

The Triple Cover Stitch can be used for topstitching, hemming, and elastic application . The stitch can

also be used as a decorative stitch upside down with the overlock side on the right side of the fabric. The

garment industry uses the Triple Cover Stitch frequently in activewear.

The Triple Cover Stitch is formed using all three "C" needle positions and the chain looper. The Triple

Cover Stitch is made up of three rows of straight stitching on the top of the fabric with the chain looper

forming an overlock stitch on the underside of the fabric.

For Triple Cover Stitch:

1. Place the machine in "locked" position to thread the chain looper. (pg.13)

2. Follow the diagram to thread the chain looper, (pg. 27). Open the side cover of the machine to make

sure the thread is through the eye of the chain looper. Trim thread to 4 inches (10cm) and lay in tray.

3. Follow the diagram to thread the chain/cover stitch needle positions C1, C2 and C3. Place

needle threads on top and to the left of presser foot before sewing.

4. Move the lock button release lever to the right.

5. Set stitch length and other machine adjustments. (See chart below.)

6. Place the fabric under the needles and turn handwheel toward you two or three stitches in the fabric.

Cut the excess threads and start sewing.

Note: All chain and cover stitches must be started with fabric under the needle.

TRIPLE COVER STITCH

Needle Position

C1, C2 and C3

Stitch Length

3,0 4,0

26

Page 29

Triple Cover Stitch (Cont.)

C

O

V

E

R

S

T

I

T

C

H

Triple Cover Stitch Tension Adjustments

Balanced tension

under side

top side

Needle thread is too loose

Needle thread is too tight

Balanced tension -

Triple Cover stitch has correct tension when the needle threads

sew three rows of straight stitching on the topside and the chain

looper forms a zig zag on the underside of the fabric.

Needle thread is too loose -

Increase the chain /cover needle thread tension dial to a higher

number. (Orange, yellow or green)

Or decrease the tension on the chain looper tension dial to

loosen the chain looper thread. (Blue)

Needle thread is too tight

Loosen the tension by turning the chain /cover needle thread ten

sion dial to a lower number. (Orange, yellow or green)

Make sure that the chain looper dial is correctly set for proper

tension. (Blue)

27

Page 30

T

E

C

H

N

I

Q

U

E

S

Turning Corners Chain Stitch

Sew to the point in fabric where you want to turn a corner. Stop the machine. Turn the handwheel

toward you (counter clockwise) by hand, making sure the needle is going down in the fabric. Slowly

start to raise the needle OUT OF FABRIC. Stop when you see the eye of the needle. (The point of the

needle will still be in the fabric.) Raise the presser foot (fig. A), and slowly pivot the fabric (fig. B). Lower

the presser foot and continue to sew (fig. C).

ABC

Turning Corners Cover Stitch

Sew to the point in fabric where you want to turn a corner. Stop the machine. Turn the handwheel

toward you (counter clockwise) until the needles are down in the fabric. Turn the handwheel away from

you (clockwise) until the needles are in the highest position and the needles are out of the fabric. Raise

the presser foot (fig. A) and slowly pivot the fabric. Align the needles with the stitching on the fabric (fig.

B) and lower the presser foot. Continue to sew. (fig. C)

To keep the stitch from unraveling at the corner(s), use a hand needle and thread to complete the cor

ner on the top of the fabric and catch the chain looper thread on the underside.

28

ABC

Page 31

Flat Hemming Cover Stitch

1. Leave one seam on the garment open.

2. Measure, turn up and press hem on garment.

3. On right side of garment mark hem allowance with marking

pen.

4. Place garment right side up under the presser foot, aligning

the marked hem with the needles. Make sure both needles

are positioned on the raw edge of the hem (fig. A).

5. Sew hem.

6. Sew seam on garment.

A

T

E

C

H

N

I

Q

Note: Optional guide or attachments will help with hemming.

(fig.B) Ask your Baby Lock retailer.

B

Hemming in the Round Cover Stitch

1. Sew all seams on the garment.

2. Measure, turn up and press the hem on garment.

3. Stitch around the hem, overlapping the hem approximately

1/2 inch (13mm). (fig.A)

4. Turn the handwheel towards you until the needles are in the

A

B

lowest position in the fabric.

5. Carefully reverse the handwheel until the needles are in the

highest position.

6. Raise the presser foot to release the tension.

7. Carefully and firmly pull fabric and threads to the left. Cut

threads.

8. Pull threads to the back of fabric and tie off or use a seam

sealant to secure the threads at the tie off (fig.B) (fig.C).

U

E

S

C

29

Page 32

T

E

C

Securing Chain and Cover Stitching

The Chain Stitch and Cover Stitch can easily be removed. Trim the chain tail to edge of fabric and the

"end" of the seam and pull on the chain looper thread on underside of the fabric. This will give you the

opportunity to "Unsew" an incorrect seam very easily.

H

N

I

Q

U

E

S

To secure the chain stitch or cover stitch, at the end of the seam, bring the needle thread(s) to the back

of the fabric and tug on the needle threads to secure the seam.

The cover stitch needle threads may also be tied to prevent raveling of the stitch.

To secure the beginning of the Cover stitching the thread tail can be brought around to the front of the

needles and caught into the cover stitching. (This technique is not for chain stitch)

See illustration below.

30

Page 33

Using Specialty Threads

Stitching with specialty threads can form beautiful stitches. These heavy or shiny threads can be used

to enhance the appearance of a stitch and create special effects.

S

P

Some specialty threads work well through the needle and chain looper, while others are too heavy to

be threaded through the needle and are for chain looper use only.

Use the "Specialty Thread Guide Chart" (pg. 35) as a guide for the specialty threads. Keep in mind

that the quality of the thread may vary and tension setting will vary from thread to thread. Make a test

sample before starting on the project.

Lightweight Threads

Lightweight threads such as rayon machineembroidery thread, lingerie thread, can easily be thread

ed on the Baby Lock. Very fine monofilament threads may need threading assistance of a "Threading

Cradle" (pg. 34) or "Looper Threading Tool" (pg 33)

E

C

I

A

L

T

Y

T

H

R

E

A

Medium weight Threads

Medium weight threads, such as topstitching thread, Décor rayon, stretch nylon thread are too bulky

to easily "jetair" through the threading port and looper. By using a "Threading Cradle" (pg.34) or

"Looper Threading Tool" (pg.33), the heavier threads can be threaded easily in the Baby Lock.

Heavy weight Threads

Heavy weight threads such as Pearl Crown Rayon, Décor 6, and Candlelight will need extra atten

tion in the chain looper. Directions for bypassing the threading port (pg. 32) may need to be used for

heavy weight thread.

Please follow the Specialty Thread Guide Chart (pg. 35) for special instructions concerning the use of

these threads.

D

S

31

Page 34

S

P

E

C

I

A

L

T

Y

T

H

R

E

Bypassing the Threading Port

Heavyweight threads can be used through the chain looper thread

paths. Specific techniques may require that the thread bypass the

thread port for the thread pull to be loosened. Start with the

machine threaded with regular serger thread.

1. Open front cover and raise the presser foot.

2. Just above the threading port, clip the chain looper thread. Pull

the thread out of the upper guides and remove the thread cone.

3. Place the specialty thread on the spool pin. Thread it into the

upper guides and tension disk. Bring the thread end through

the hole just left of the jetair threading port. (This will allow the

front door to be closed while sewing. Leave approximately 12

inches (30cm) of thread to be threaded through the chain loop

er. (fig. A).

4. With machine lock button released, use the tweezers to pull the

existing looper thread out of tube extending from the threading

mechanism (fig. B). Leave the thread in the looper arm.

5. Tie the specialty thread onto the regular thread with an over

hand knot (fig. C). Pull on the regular thread from the looper

eye until the specialty thread comes through the looper eye.

6. Lay the thread end in the chain looper tray and close the side

door. (fig.D)

A

B

C

A

D

S

If the thread is heavy and the overhand knot (step #5) is too large

for the looper tube, follow directions #1 thru #6 on page. 34 to

make a thread cradle. Then:

1. Release machine lock button.

2. While holding the loose ends of the thread cradle with one

hand, use the tweezers to pull the cradle loop out of the tube

extending from the threading mechanism with the other hand.

3. Insert 2 inches (5cm) of the decorative thread into the cradle

loop. Pull on the loose ends of the thread cradle from the loop

er eye until the specialty thread comes through the chain looper

eye.Lay in the chain looper tray and close the side door.

D

32

Page 35

Looper Threading Tool

1. Open the front cover and raise the presser foot.

2. At the threading port, cut the chain looper thread. Remove

chain looper thread from under the presser foot and the upper

thread guides. Replace cone of thread with specialty thread.

3. Place the machine in "locked" position to thread the chain

looper.

4. Thread specialty thread into the upper thread guides, leaving

A

B

an 18inch (40cm) tail above the threading port.

5. Place the straight end of the looper threading tool into the

threading port. Push the looper threading tool until the end

comes out of the looper eye. Open side door of machine to

see threading tool come out of the eye of chain looper.

6. Insert the specialty thread tail into the looper threading tool

eye (fig.A). Pull the straight end of the looper threading tool

through the looper eye bringing the specialty thread with it.

(fig.B)

7. Cut chain looper thread to 4 inches (10cm) and place in tray.

Close the side door of the machine.

S

P

E

C

I

A

L

T

Y

T

H

R

E

A

D

S

33

Page 36

S

P

E

C

I

A

L

T

Y

T

H

R

Thread Cradle for Looper

1. Open the front cover and raise the presser foot.

2. At the threading port, cut the chain looper thread. (fig.A)

Remove thread from under the presser foot and the upper

thread guides. Replace cone of thread with specialty thread.

3. Place the machine in "locked" position to thread the chain loop

er.

4. Thread specialty thread into the upper thread guides, leaving an

A

B

18 inch (40cm) tail above the threading port. (fig.C)

5. Cut a 24 inch (55cm) strand of serger thread and fold in half to

form a thread cradle. Insert the loose ends of the thread cradle

into the port about 1 inch (2.5cm).

6. Holding the cradle loop with left hand, depress the threading

lever with your right hand (fig.D) until the thread ends come out

the looper eye. Open side door of machine to make sure

thread is in eye of chain looper.

7. Insert the specialty thread tail into the cradle loop (fig.E), pull

the serger thread ends until the specialty thread comes through

the looper eye (fig.F). Discard or set aside the thread cradle.

8. Cut chain looper thread 4inches (10cm) and place in tray. Close

side door of machine. (fig.G)

E

A

D

S

C

D

34

EFG

Page 37

Specialty Thread Guide Chart

CHAIN/COVER

STITCHES

Topstitching

Buttowhole Twist

(Medium weight)

Wooly Nylon

(Medium weight)

Metallic Threads

(Light weight)

S

P

E

C

I

2-Thread Chain

C-1, C-2, or C-3

Needle Position

3-Thread Cover

Stitch

Left Narrow

Right Narrow Wide

4-Thread Triple

Cover

Stitch

COMMENTS :

CHAIN/COVER

STITCHES

In chain looper only In chain looper only In needles only

In chain looper only

In chain looper only

Not recommended for

needles.

Use in looper only.

Clear Nylon

Filament

(lightweight)

In chain looper only In needles only

In chain looper only

Not recommended for

needles.

Lingerie Thread,

Rayon or Polyester

Machine-embroidery

Thread (lightweight)

In needles only

Sew at a slower

speed

when sewing with

metallic threads.

Decorative Thread:

Décor, Candlelight,

Pearl Crown Rayon

(heavy weight)

A

L

T

Y

T

H

R

E

A

D

S

2-Thread Chain

C-1, C-2, C-3

needle position

3-Thread Cover

Stitch

Left Narrow

Right Narrow

Wide

4-Thread Triple

Cover Stitch

COMMENTS:

Use in needle and chain

looper

Use in needle and chain

looper

Use in needle and chain

looper

Make sure to use soft,

pliable monofilament

thread.

Sew at a slower speed

when sewing with

monofilament thread.

Use in needle and chain

looper

Lingerie thread: Use in

needles and chain looper.

Machine embroidery

thread:Use in needles

only.

Lingerie thread: Use in

needles and chain looper.

Machine embroidery

thread:Use in needles

only.

Use thread nets or

sponge disks to keep

thread from spilling off

spool.

Sew at a slower speed

when sewing with decora

tive thread.

Use in chain looper

only

Use in chain looper

only

Use in chain looper

only

Not recommended

for needles

35

Page 38

M

A

Troubleshooting

Before taking your machine in for service, check the following:

I

N

T

E

N

A

N

C

E

Machine fails to start:

1. Are electrical plugs properly connected?

2. Is the power switch on?

3. Check household circuit breaker or fuse.

4. Is the lock button release lever in the unlocked position?

Thread breaks:

1. Is the machine threaded correctly? Check each thread path carefully.

2. Is the correct needle inserted for the particular stitch? C1, C2, or C3?

3. Is the needle inserted correctly?

4. Is the needle bent and worn?

5. Are you using good quality thread?

6. Is the thread feeding off the cone/spool freely?

7. Is the needle size correct for the type of fabric being used?

8. Are the needles being used the correct Organ ELx705CF system?

Chain or Cover Stitching:

1. Are the tensions too tight on the chain/cover needles or the chain looper?

2. Is the stitch length too short?

3. Did you start the first stitch in the fabric?

Skipped Stitches:

1. Is the needle bent or worn?

2. Is the needle inserted correctly?

3. Is the serger threaded correctly?

4. Is the presser foot pressure right for the fabric?

5. Is the correct needle being used for the particular stitch?

6. Is the correct needle being used for the type of being sewn fabric?

7. Is the fabric being pulled from the rear of the machine while sewing?

Fabric will not feed in machine:

1. Is the machine lock button released?

2. Is the presser foot down?

3. Are the presser foot, and feed dogs free of lint?

4. Is the presser foot pressure right for the fabric?

5. Is the stitch length set properly?

6. Is the needle plate secure on the machine?

36

Page 39

Troubleshooting (Cont.)

M

A

Stitch Unbalanced:

1. Is the machine threaded correctly?

2. Is the proper presser foot on the machine?

3. Is the correct needle inserted and threaded?

4. Is the thread in the tensions?

5. Are the tensions set correctly for the chain/cover needles?

6. Is the tension dial set correctly for the chain looper?

7. Is the chain looper threaded correctly?

8. Is the needle thread(s) in the correct tension disk?

Looper Threading Difficulties:

1. Is the thread end in the threading port correctly?

2. Is at least 1 inch (2.5cm) of the thread end in the threading port?

3. Is there at least 18inches (40cm) of loose thread beyond the thread guide above the threading

port?

4. Is there a kink or twist in the 18 inch (40cm) of thread to restrict the flow into the threading port?

5. Is the thread caught to prevent going through the chain looper?

I

N

T

E

N

A

N

C

E

37

Page 40

M

A

Replacing Needles

Needle Identification (fig. A)-

I

N

T

E

N

A

N

C

E

B

A

The chain/cover stitch needles are on the front portion of the

needle clamp and are identified by C1,C2 and C3.

C1Left chain/cover stitch needle can be used for chain stitch,

left narrow cover stitch, wide cover stitch or triple cover stitch.

C2Center chain/cover stitch needle can be used for a chain

stitch, left narrow cover stitch, right narrow cover stitch or

triple cover stitch.

C3Right chain/cover stitch needle can be used for a chain

stitch, right narrow cover stitch, wide cover stitch, or triple

cover stitch.

To Replace a Needle -

1. Raise the needle to the highest position by turning the hand

wheel toward you.

2. Using the allen screwdriver, loosen the needle screw for the

needle to be changed. Screws are located by sequence as

indicated above.

Note: To prevent the needle from falling into the needle plate,

hold it with the needle insert tool as you loosen the screw (fig.

B).

3. Use the needle insert tool or tweezers to insert the new nee

dle with the flat side to the back. Insert needle as far as it will

go, check the needle viewing window (fig. C).

4. Tighten the needle clamp screw.

C

Note: If you do drop a needle down into the machine just pull out

the needledrop drawer at the bottom of your serger. The

needle will be on the drawer (fig. D).

D

38

Page 41

Replacing Light Bulb

M

1. For safety reasons, unplug main power cord prior of replacing light bulb.

2. Loosen screw on lamp cover and remove.

3. Remove light bulb and replace bulb with the same type rated (15watts/110volts or

15watts/230volts). See below draft for reference.

4 Replace cover and tighten screw.

15W/110V

(Screw Type)

A

I

N

T

E

N

A

N

C

E

15W/230V

(Bayonet Type)

39

Page 42

M

Cleaning

A

I

N

T

E

N

A

N

C

E

Your Baby Lock will operate at best performance if it is kept clean at all times.

Your Baby Lock's major moving parts are well protected and do not need to be oiled.

However, we recommend to use the cleaning brush often during garment construction in order to keep

lint off, the needle bar, the feed dog mechanism and looper. If machine needs to be oiled, check with

your nearest Baby Lock retailer for use of high grade recommended sewing machine oil.

TO REMOVE NEEDLE PLATE PROCEED AS FOLLOW:

1. For safety reasons, unplug main power cord.

2. Raise and remove presser foot.

3. Remove needles from needle clamp.

4. For easy access to the needle plate lock pin set screw, raise needle clamp to its highest position.

(fig. A).

5. Place allen screwdriver (1.5mm) into allen screw and loosen needle plate pin holder screw. See (fig.

B) for location of screw.

6. Remove needle plate lock pin (fig. B) and remove needle plate front screw.

7. Open left side cover of machine and remove needle plate.

8. Clean machine. (fig. C)

9. Place needle plate onto machine and insert needle plate lock pin.

10. Tighten allen screw needle plate lock pin and check and make sure that top needle plate lock pin is

flush with needle plate.

11. Place needle plate front screw and tighten screw.

Note: For better stitch performance, make sure needle C1.C2,and C3 do not touch either side of

needle plate hole.

AB

C

40

Page 43

Technical Data

Looper Threading System: Jet Air Threading for chain looper

Tension Dials: Dials for Chain/Cover stitch needles

Stitch Length Dial: 1.04.0mm

Differential Feed Ratio: 0.6 to 2.0

Presser Foot: Snap On Foot

Looper Chain Looper

Needle System: Organ ELx705CF #80/12 and #90/14

Number of Needles: 3 C1,C2,C3

Sewing Speed: Up to 1500 s.p.m.

Machine Weight: 7.3 kg/16.2bs.

Light Bulb: 15W / 110V or 10W / 230V

Stitch Types: Chain Stitch

Left (C1), Center (C2), Right (C3)

T

E

C

H

N

I

C

A

L

Stitch Width: Cover Stitch

Cover Stitch

Narrow Left

Narrow Right

Wide

Triple

Triple Cover Stitch : 6.0mm

Cover Stitch Wide : 6.0mm

Cover Stitch Narrow : 3.0mm

D

A

T

A

41

Page 44

S

T

I

T

C

H

S

E

L

E

C

T

I

O

N

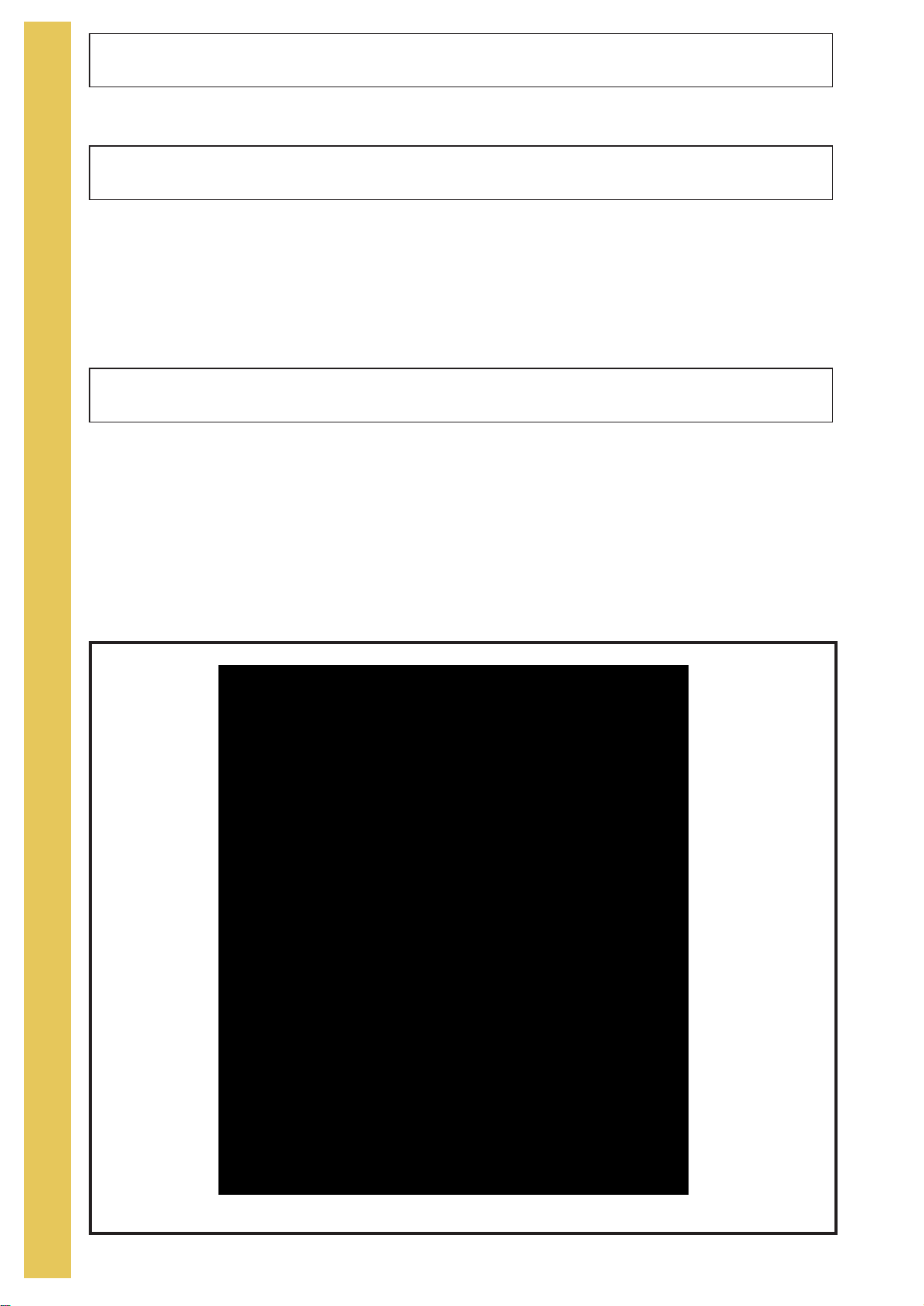

6mm

Seam width

Diff.

Feed

tension dial

Chain looper

tension dial

Right needle

tension dial

Center needle

N

12

46

46

3mm

N

12

46

"

"

12

46

46

6mm

"

12

46

-

N

23

-

"

23

35

-

"

23

35

EI-30(2)-E

IB BLCS-2

Printed in Japan

C

H

A

R

T

46

Left needle

tension dial

L/dial

Stitch

Nb.Needles

& ndle position

3,04,0

C1 / C2 / C3

46

3,04,0

C1C2

46

3,04,0

3,04,0

C2C3

C1C3

35

3,04,0

3,04,0

C1

C2

3,04,0

C3

Chart for stitch selection settings for Chain/Cover

4 Thread

Stitch name

3 Thread

Triple Cover Stitch

Cover St. Narrow

2 Thread

Cover St. Wide

Chain stitch

42 42

BLCS-2 タコニー用

Loading...

Loading...