ARD-A Series

DeviceNet Analog Remote I/O

Features

● Adopts DeviceNet, standard open Network

: Communicates other DeviceNet devices without additional installations

: Configurable power and communication system only with

communication cables

: Connectable max. 63 units per 1 master unit

● Strong against noise and high accuracy (0.3%) measurement with

differential input method (measuring difference between +, - input signal)

● Various I/O range: 0-5VDC, 1-5VDC, 0-10VDC, -5-5VDC,

-10-10VDC, DC4-20mA, DC0-20mA

● Scale function: Settable high/low limit scale value for analog I/O range

(Setting range: -28,000 to 28,000)

● Various functions

: Automatic communication speed recognition, Network voltage monitoring, Input digital filter,

Peak/Bottom Hold, hysteresis, reading model name and number of units, I/O and status flag monitoring

● Built-in surge, ESD protection, Reverse polarity protection circuit

● Mounting DIN rail method and bolt mounting method

Please read “Safety Considerations”

in the instruction manual before using.

Ordering Information

AR D A

Digital/Analog

Network

Item

04I

I/O points

I/O type

(only for ARD-A 04,

other models are compatible)

04 4-point type

I Input type

O Output type

A Analog type

※

1

D

D DeviceNet type

AR Autonics Remote I/O

※

1. For digital type, refer to 'ARD-D Series'.

Digital type

Analog I/O Specications

No. I/O range Max. allowable I/O range

0 0-5VDC -0.25-5.25VDC

1 1-5VDC 0.8-5.2VDC

2 0-10VDC -0.5-10.5VDC

-

5-5VDC -5.5-5.5VDC

3

-

10-10VDC -11-11VDC

4

5 DC4-20mA DC3.2-20.8mA

6 DC0-20mA DC0-21mA

X-24

Autonics

DeviceNet Analog Remote I/O

Specifications

Model ARD-AI04 ARD-AO04

Power supply Rated voltage: 24VDCᜡ, Voltage range: 12-28VDC

Power consumption Max. 3W

I/O points

Volt age

Current DC4-20mA , DC0 -20mA (input impedance: 250Ω) DC4-20mA , DC0-20mA

Control

Max. allowable range

I/O

Resolu ion

Input 4-point

(switchable voltage/current)

0-10VDCᜡ, -10 -10VDCᜡ, 0-5VDCᜡ, 1-5VDCᜡ,

-5-5VDCᜡ

(input impedance: max. 1MΩ)

±5% F.S of rated input range ±5% F.S of rated output range

14bit, 1/16,000

Accuracy ● At room temperature (25±5℃) range: ±0.3% F.S. ● Out of room temperature range: ±0.6% F.S.

Insulation resistance Over 200MΩ (at 50 0VDC megger)

Noise immunity ±240V the square wave noise (pulse width: 1㎲) by the noise simulator

Dielectric strength 500VAC 50/60Hz for 1 min (bet ween external terminals and case, bet ween I/O and power terminals)

Vibration 1.5mm amplitude at frequency of 10 to 55Hz (for 1 min) in each X, Y, Z direction for 2 hours

Shock 500m/s

Ambient

temperature

Environment

Ambient

humidity

2

(approx. 50 G) in each X, Y, Z direction for 3 times

-10 to 50℃, storage: -25 to 75

℃

35 to 85%RH, storage: 35 to 85%RH

Protec ion structure IP20 (IEC standard)

Protec ion circuit Surge, ESD protection, reverse polarity protection circuit

Indicator Network status (NS) LED (green, red), unit status (MS) LED (green, red)

Material Front case, body case: Polycarbonate

Mounting DIN rail or bolt moun ing type

Isolation type I/O and inner circuit: non-insulated, DeviceNet and inner circuit: insulated, power and DeviceNet: insulated

Approval

※

1

Weight

※

Environment resistance is rated at no freezing or condensa ion.

※

1. The weight includes packaging. The weight in parentheses is for unit only.

DeviceNet Communication

00

I

C.

t

Detlfc:eNet

Approx. 210g (approx. 145g)

Item Specications

Communication

I/O Slave messaging (Group 2 Only slave)

● Poll command: Yes ● Bit_strobe command: Yes ● Cyclic command: Yes ● COS command: Yes

Communication distance Max. 500m (125kbps), Max. 250m (250kbps), Max. 100m (500kbps)

NODE ADDRESS setting Max. 64 nodes

Communication speed

※

1

125, 250, 500kbps (automatically set when connecting with Master)

Insulation I/O and inner circuit: Non-insulation, DeviceNetand inner circuit: Insulation, DeviceNet power: Insulation

Approval

※

1. The communication speed is automatically set to the communication speed of the Master (PC, PLC, etc.) When changing the

ODVA Conformance conformance: ARD-AI04

ODVA Conformance compatible : ARD-AO04

communication speed during operation, the network status (NS) LED ashes in red and communication is not possible.

ᜡ

Output 4 -point

(voltage 2CH, current 2CH)

0-10VDCᜡ, -10 -10VDCᜡ, 0-5VDCᜡ, 1-5VDCᜡ,

-5-5VDCᜡ (load resistance: max. 1kΩ)

(load resistance: max. 600Ω)

, DeviceNet compatible

I

C.

t

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

Autonics

X-25

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

ARD-A Series

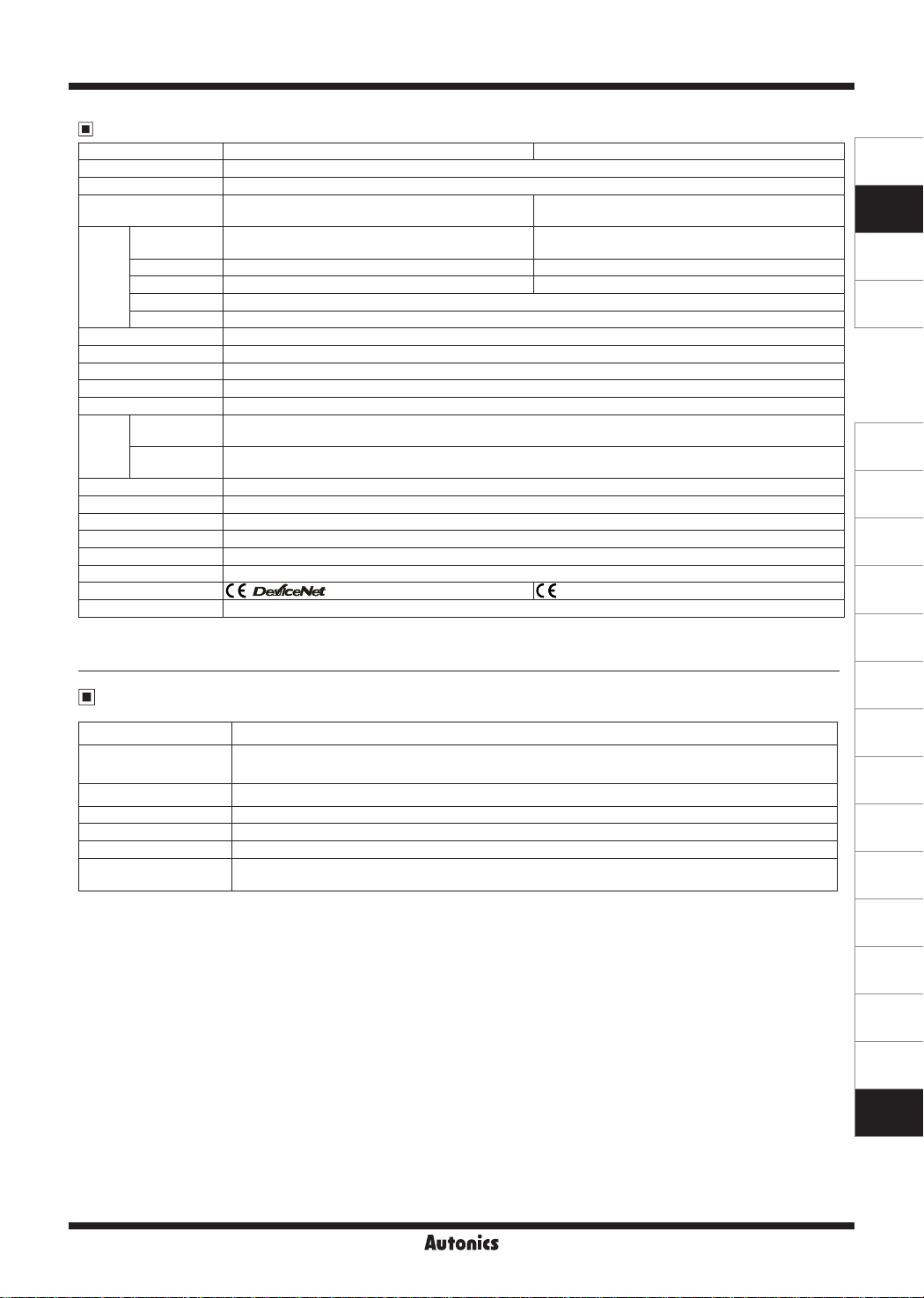

Unit Descriptions

2

3 4

1

1. DeviceNet connector

No.

Color

For Organization

5 Red 24VDC (+)

>----+----+---------<~\

4 White CAN_H

3 None SHIELD

f----+---+---------l

2 Blue CAN_L

>----+----+---------<

1 Black 24VDC (-)

2. Rotary switch for node address

X10 switch represents the 10’s multiplier and X10 switch represents the 1’s multiplier.

3. Status LED: It is LED for displaying Unit status (MS) and Network status (NS).

4. Rail Lock: It is used for mounting DIN rail or with bolt.

5. DIP switch: It is used for set I/O range. (factory default: all switches are OFF)

(●: ON, -: OFF)

~

I/O range SW1 SW2 SW3 SW4 SW5 SW6 SW1 SW2 SW3 SW4 SW5 SW6 SW7 SW8

0-5VDC

1-5VDC

0-10VDC

-5-5VDC

-10-10VDC

DC4-20mA

DC0-20mA

※

1: By turning ON SW8, I/O range is set by DIP switches (SW1 to SW6). By turning OFF SW8, I/O range is set by communication.

When setting I/O range by DIP switches, CH0 and CH1 (CH2 and CH3) cannot be set individually.

When setting it by communication, each channel is set individually.

6. I/O Terminal block: It is terminal block for connec ing external device I/O.

CH0, CH1 CH2, CH3 CH0, CH1 CH2, CH3

- - - - - - - - -

• • •

- - - - - -

• • • • • •

- - - - - -

• • • •

- - - -

-vv:

:\J.

-.

--\~/

ARD-AI04 (Input model) ARD-AO04 (output model)

- - - - - -

• • •

- - -

• • •

- -

• • • • •

V+

□

CAN_H

\D

SHIELD

..

• :

CAN_L

\"

-!

□

■

V-

: Two rotary switches are used for setting node address.

6

Not supported

5

I I

Not supported

- - -

I I

I I

ON

Not

supported

(O Setting)

1 2 3 4 5 6 7 8

ON

Using DIP

switch

OFF

Not using DIP

switch

1

※

X-26

Autonics

DeviceNet Analog Remote I/O

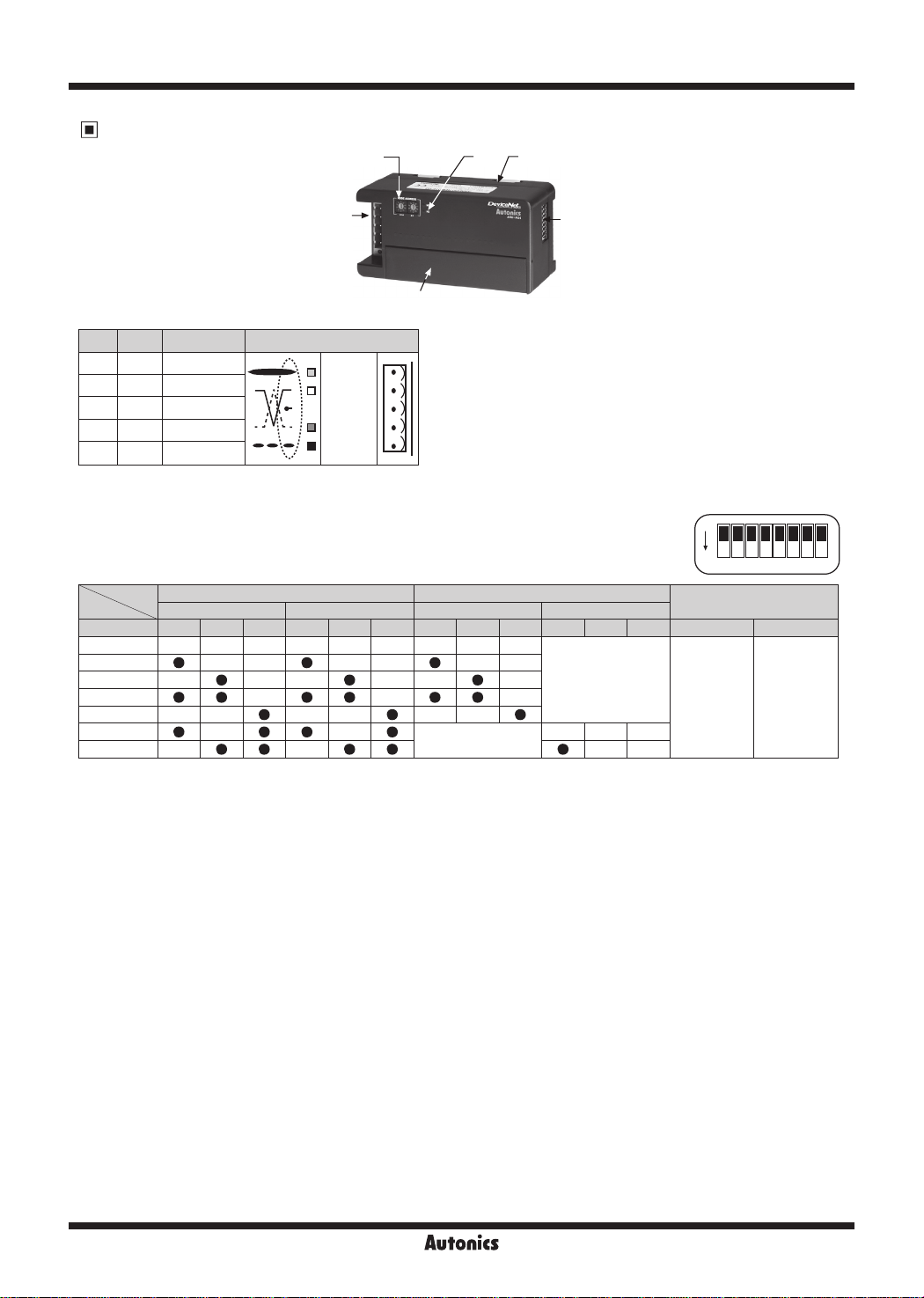

Status LED

~

※

Status of MS LED, NS LED

No. Type LED status Color Descriptions Troubleshooting

MS

1

NS Green

MS

2

NS

MS

3

NS Green

MS

4

NS

MS

5

NS

MS

6

NS

MS

7

NS

MS

8

NS

MS

9

NS

Dimensions

~

~

•

~

~

*

•

*

•

*

105

50

Green

Green

-

Green

Red

-

Red

-

Red

Green

Green

Red

Red

Red

Green

Red

Normal operation

I/O communication or message communication is

working.

Standby of duplicated address

The status of standby for receiving message of

duplicated address check from master unit.

Standby of normal operation

The status of standby for establish connection from

master unit.

Watchdog timer error

The status that DIP switch or another switch

setting is invalid.

Switch setting error

The status that DIP switch or another switch setting

is invalid.

Changed address during normal operation

The status that address is changed during normal

operation.

Invalid address

The status of setting invalid address

Duplicated address

There is duplicated address in the network.

Occuring Bus-O error

Communication is stopped with Bus-O.

I/O Connection time out

●

3-Ø4.5

Panel cut-out

( : ON, : Flash, : OFF)

~

-

-

-

Change the switch with valid

value and re-supply the power.

Change the switch setting to valid value

and re-supply the power.

Change the initial address at the power

applied at rst.

Change the valid address and re-supply

the power.

Change node address not duplicated.

Power on the slave unit again. Check

master unit, communication, cable,

terminating resistance and noise of

network.

Check the master setting and the user

program.

50 3-M4 Tap

i

i

____

_L_

__

_

5238.5

60.5

i

+~

60.5

~

•

(unit: mm)

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

35.3

Autonics

X-27

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

ARD-A Series

I/O Circuit Diagram

Type DeviceNet connector Inner circuit External connections

V

Analog

GND

V

V

V

AG

V.OUT

COM

I.OUT

COM

0

I

0

0

1

I

1

1

•

0

~□

~

Analog

input

Analog

output

CAN H

SHIELD

CAN L

CAN H

SHIELD

CAN L

V+

V-

V+

V-

(Q)

(Q)~~

(Q)~~

(Q)

(Q)

(Q)

(Q)

(Q)

(Q)

(Q)

~----------i

,--------,--------

~~

c---------c-,.--------,

c---------,-,-----,

r------c-1-----,

~-----,

f---------,-J------.-----,

Inner circuit

Power circuit

Inner circuit

Power circuit

Input circuit

Power circuit

Output circuit

Power circuit

Analog

GND

V

mA

Load

Max. 1KΩ

Load

Max. 600Ω

□

Connections

※

When wiring the communication connector, use cable and tap which meet the DeviceNet standard

and tighten the connector screw with a tightening torque of 0.5N.m.

※

When wiring the input/output terminal, tighten the connector screw with a tightening torque of 0.5N.m.

ARD-AI04

l

V

I

0

0

V

AG

0-

~

I I I I I I I I I

V

※

1: For current input, short between V

Terminating Resistance

1

※

Short

V

I

1

V

1-

·5·

mA

I

V

2

1

2

V

AG

AG

2-

111111

I

V

3

3

V

AG

3-

□+

N C

N.C

and I□+.

N C

N.C

ARD-AO04

l

V

V

0

1

COM

COM

·is

I

I I I I I I I I I

V

N.C

I

I

0

1

COM

lY

N C

COM

I I I I I I

mA

N.C

N C

N C

N.C

N C

N C

N C

N C

N.C

N C

Voltage

Current

0-5VDC

1 to 5VDC

-5-5VDC

0-10VDC

-10-10VDC

DC0-20mA

DC4-20mA

● 120Ω ● 1% of metallic lm ● 1/4W

※

Do not install terminating resistance on ARD unit or it may cause network problem (impedance can be too high or low)

or malfunction.

※

Connect terminating resistance on the both ends of the trunk line.

Communication Distance

Baud Rate Max. network length

125kbps 500m 6m 156m

250kbps 250m 6m 78m

500kbps 100m 6m 39m

Max. length of

branch line

Allowable expansion

length of branch line

X-28

Autonics

DeviceNet Analog Remote I/O

Setup and Installation

Node address setup

Two rotary switches are used for setting node address.

①

X10 switch represents the 10’s multiplier and X10 switch represents the 1’s multiplier.

Node address is settable from 0 to 63.

Node address is changed when re-supplying the power to the unit.

②

After changing node address, must re-supply the power.

※

The address of the connected unit must not be duplicated.

When changing the address during operation, the unit status (MS) LED ashes in red and the unit communicates to

the address before the change.

Installation

●

Mounting on panel

Pull Rail Locks (3) on the rear part of a unit,

①

there are xing bolt hole.

Place the unit on a panel to be mounted.

②

Make a hole on a xing bolt position.

③

Fasten the bolt to x the unit tightly.

④

Tightening torque should be below 0.5N.m.

●

Mounting on DIN rail

Pull two Rail Locks on the rear part of unit.

①

Place the unit on DIN rail to be mounted.

②

Press Rail Locks to x the unit tightly.

③

I/O cable connection

Refer to '

Connect a sensor or the signal cable of external I/O device to the terminal block. (tightening torque: 0.5N.m)

I/O circuit diagram and connections'.

DeviceNet cable connection

For stable system, it is recommended to use the DeviceNet dedicated cable.

①

Connect the DeviceNet cable to the DeviceNet connector and tighten the xed bolt of the connector by a driver.

②

(tightening torque: 0.5N.m)

Connect the DeviceNet connector to ARD unit and supply the power to Network.

③

Master unit

PIN No. Signal

5 V+

4 CAN_H

3 SHIELD

2 CAN_L

1 V-

Red

White

None

Blue

Black

ARD unit

PIN No. Signal

5 V+

4 CAN_H

3 SHIELD

2 CAN_L

1 V-

5 (Red): V+

4 (White): CAN_H

3 (None): SHIELD

2 (Blue): CAN_L

1 (Black): V-

E . g . )

The X10 and X1 switches point "3",

the address is "33".

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

Setting of master unit

Check the LED status of ARD unit when power is supplied. Normal operation is below.

①

Type Status LED Status descriptions

Unit status (MS) LED Green LED is ON

Network status (NS) LED Green LED is ON/ashes

Install the software provided by master unit manufacturing company.

②

Set communication speed and address in the software.

③

When master unit status is communication standby: NS LED ashes

When master unit setting is completed: NS LED is ON.

● Baud rate: 125/250/500kbps

● Address of master unit: Usually it is set 00 address.

Register connected unit on Network to the master unit.

④

● There are two ways to register units; automatically register in on-line or manually register in off-line.

(Refer to the manual of master unit.)

● I/O assignment of ARD Series: Usually it is automatically assigned by the setting software.

● Setting of operation mode: Select among Poll, COS, Cyclic, Bit Strobe. (Usually set Poll mode.)

Check operating stauts

When installation and setting are complete, unit status (MS) LED and Network status (NS) LED turn ON green.

(Refer to ' Status LED'.)

Autonics

X-29

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

ARD-A Series

Functions

Model

Com. speed auto-recognition

Network power voltage monitoring

Unit power on total time monitoring

Basic

Unit comment

Last maintenance data stored

Scaling

I/O comment

Adjustment gradient

Adjustment oset

Input conversion points setting

Input digital lter

Analog

Peak/Bottom hold

Disconnected cable detection

Input comparison

Hysteresis

Output setting for error

Communication speed auto-recognition

It recognizes communication speed when connecting

master. Communication speed is able to change only from

master unit.

After changing communication speed, re-supply the

network power to apply the changed communication

speed.

Network power voltage monitoring

● If

network power voltage is lower than the set value, the

network power voltage drop flag bit of Status bit is ON.

It can be read by Configurator or Explicit message.

●

Set monitoring voltage by Explicit message at Network

Power voltage (Set Value) of Application Object.

●

Setting range: 0 to 255

(factory default: 12V, Allowable range: ±1V)

※

Min. supplied power is 12V for ARD unit.

If network voltage is lower than 12V, the contents of

Explicit message reading is not guaranteed.

Unit power on total time monitoring

●

When total time for supplying power to the unit

becomes the SV, Threshold Run Hours Flag bit of

Status Bit turns ON. It can be read by Configurator or

Explicit message.

●

Set the time by Explicit message at Threshold Run

Hour of Application Object.

●

Setting range: 0 to 429,496,729 hours

(factory default: 876,000 hours),

Measured unit: 0.1 hours (6 minutes)

Unit comment

● You can set the comments for the unit (product

description) on network. It can be read by Configurator

or Explicit message.

● Set comment by Explicit message at Unit Comment of

Application Object.

● Setting range: max. 32 characters

ARD-AI04

(input model)

ARD-AO04

(output model)

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

-

Last maintenance date

●

It saves the last date of maintenance. It can be read/

written by Configurator or Explicit message.

●

Set maintenance date by Explicit message at I/O Last

Maintenance Data Setting of Analog Input Point Object.

E.g.) Data: 0x07DB020E→07DB (2011), 02 (Februray),

0E (14th)

Input conversion points setting

● Conversion cycle is changed by the number of points

(point, channel).

(conversion cycle: 1ms/point, when using 4 points,

it is 4ms). It can be read/written by Configurator

or Explicit message. After changing the number of

conversion points, re -supply the network power.

● Set the number of conversion points by Explicit

message at Number of AD Conversion Points Setting

of Analog Input Point Object.

● Setting range: 1 to 4-point (factory default: 4-point),

conversion cycle: 1ms/1-point

Display scale

● Set high/low-limit scale value of analog input or output.

It can be read by Configurator or Explicit message.

It is set as 1,000 per 1V (mA).

In case of 1-5V, 4-20mA, it is

applied from over min. allowable

range 0.8V (800), 3.2 (3,200).

The below input value is break

detec ion. It outputs as min.

allowable range.

It is set as default value 0 to

16000 (-8000 to 8000).

(0-5V, 1-5V, 0-10V, 4-20mA,

0-20mA: 0 to 16000, -5-5V, -1010V: -8,000 to 8,000 )

Set high/low-limit value to apply

at ‘Scaling Point 0%’ and ‘Scaling

Point 100%’.

Setting range: -28,000 to 28,000

Default

Scaling

None

Scaling

User

Scaling

Function Choice

: Scaling Flag bit ON

Scaling Type

: Default Scaling

(factory default)

Function Choice

: Scaling Flag bit

OFF

Scaling Type

: Default Scaling

Function Choice

: Scaling Flag bit ON

Scaling Type

: User Scaling

-

-

-

-

-

-

•

X-30

Autonics

DeviceNet Analog Remote I/O

(Q)

I/O comment

● You can set the comment for I/O. It is able to read/

write by Configurator or Explicit message.

● Set I/O comment by Explicit message at I/O Comment

of Analog Input Point Object, Analog Output Point

Object.

● Setting range: max. 32 characters

(Q)

Gradient adjustment

● It adjusts the gradient of input/output value or scale

value. It is able to read/write by Configurator or Explicit

message.

● It is applied when Adjust Gradient Flag bit is set as ON

at Function Choice of Analog Input Point Object. Set

the range at Adjustment Gradient value.

● Adjustment range: -5 to 5%,

Setting range: -500 to 500 (factory default: 0)

E.g.) When input value is 1000, Adjustment Gradient is

500 (+5%) X’=aX, a=1+Adjustment Gradient (0.05),

X=1000, X’=1.05×1000=1050

(Q)

Oset adjustment

●

This function is to adjust the error occurring from

external analog sensor, etc, not from the unit itself. It is

also applied to analog output. It is able to read/write by

Configurator or Explicit message.

●

It is applied when Adjustment Offset Flag bit is set as

ON at Function Choice of Analog Input Point Object.

Set the value at Adjustment Offset Value.

●

Adjustment range: -5 to 5%,

Setting range: -500 to 500 (factory default: 0)

E.g.) When input range is 0 to 10V, Full Scale 0 to 16000,

input value is 1600 (1V) and Adjustment Gradient

500 (+5%), X’=X+b, X=1600, b=16000×0.05

(added input value and percentage of Full Scale)

X’=1600+800=2400 (1.5V)

(Q)

Input digital lter

●

This function is used when input value vibrates or

repeatedly shake by included noise at input signal.

Accurate control is available by stable input with this

function. It adopts moving average filter method not

to affect sampling cycle. It is able to read/write by

Configurator or Explicit message.

●

It is applied when Moving Average is set as ON at

Function Choice of Analog Input Point. Set the number

of digital filters at Moving Average Filter of Number.

●

Setting range: 0 to 8

(factory default: 3[Moving Average No_8])

Input min./max. value save

● Min./Max. save when power is ON

It saves min./max. input value from power ON the network.

(When network power is OFF, the saved min./max. input

value are cleared.)

It is able to read by Configurator or Explicit message.

When Clear Max, Clear Min Flag bit of is ON at Function

Choice of Analog Output Point Object, the saved values

are cleared and it saves current min./max. value of

current input.

● Min./Max. save when Peak/Bottom Hold signal

is ON

It memorizes the max./min. value while Peak/Bottom

signal is ON. When Peak /Bottom signal is OFF, they are

saved.

It is able to read by Configurator or Explicit message.

It is applied when Peak/Bottom is set as ON at Function

Choice of Analog Input Point Object. You can check the

value of Peak/Bottom at Peak Value and Bottom Value.

Max.

value

Input

Analog

input

Peak/

ON

Bottom

hold signal

OFF

ON

Network

OFF

power

(Q)

Disconnection detection

●

When operating analog input cable (voltage/current

input) is disconnected, Broken Wire Flag Bit turns

ON at Analog Status Flag Read of Analog Input Point

Object. (It operates only for 1-5V, 4-20mA input range.)

It is able to read by Configurator or Explicit message.

●

If this value is below -5%, it recognizes disconnection

and displays ‘32767’ as data value.

(Q)

Input comparison

●

It compares analog input value or the operation value

and alarm set value (HH, H, L, LL) and Analog Status

Bit flag turns ON at Function Choice of Analog Input

Point Object. It is able to read by Congurator or

Explicit message.

●

If the value is within the setting range between ‘H’ and

‘L’, it is available to apply by turning ON Pass Signal

Flag bit at Analog Status Flag Read of Analog Input

Point Object and turning ON/OFF Comparator Flag bit

at Function Choice.

HH

H

L

LL

HH alarm

H alarm

Normal Flag

L alarm

LL alarm

Peak/Bottom Hold value monitoring

Peak Hold value

Bottom Hold value

Min. value

Time

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

Autonics

X-31

ARD-A Series

(Q)

Hysteresis

●

In case of comparison output, this function is to increase

stability of comparison output against v bration of input

signal or chattering.

It is able to read by Congurator or Explicit message.

●

It is applied when Compare Bit flag turns ON at Function

Choice of Analog Input Point Object.

Set the value at Hysteresis Value.

●

Setting range: 0 to 16,383 (factory default: 0)

(Q)

Output value setting for com. error

●

When communication error occurs, this function is to

set output value of output unit by each channel. It is

able to read by Configurator or Explicit message.

●

Set Fault state at Fault Action of Analog Output Point.

●

Setting range: 0 to 3 (factory default: 1)

0: Hold Last State-maintains the last status

2: High Limit-outputs max. value

1: Low Limit-outputs min. value

3: Zero Count-outputs 0%

Assembly Instance ID Assignment

00

(Q)

Produced I/O assignment (Input)

It is available to assign I/O data by the selected data at master. When changing Produced I/O data assignment, re-supply

the network power of ARD unit to apply the changed assignment.

Status ag monitoring

●

When the net work power voltage is lower than the

set value or unit operation time is over the set value,

monitoring is available by Status Bit of Application

Object.

It is able to read by Congurator or Explicit message.

※

Flag Bit

Bit 0: Reserved

Bit 1: Network Power Voltage Drops

(below the set level)

Bit 2: Life State (Unit)

Bit 3: Reserved

Bit 4: Reserved

Bit 5: Reserved

Bit 6: Reserved

Bit 7: Reserved

(Q)

Analog data allotment

●

This function is to allot analog data. Select the desired

data to transmit it to the master unit. It is able to read

by Congurator or Explicit message.

●

Set the allotment at Analog Data 1/2 Allocation

selection of Analog Output Point.

●

Setting range: 0 to 2 (factory default: 0)

0: Analog Input Value

1: Peak Value

2: Bottom Value

1) Analog Data1 (Default I/O Data)

Analog Data 1 is assigned as Produced I/O data by Congurator or Explicit message. By property setting, assignment is

available as Analog Input Value, Peak Value, Bottom Value.

● Assembly Instance ID: 103, ● Default: 0

● Setting range: 0 to 2 (Analog Input Value: 0, Peak Value: 1, Bottom Value: 2)

● Data type: Word, Data size: 4Word

15 0

Assigned value to Analog Data 1 of Input point 0

Assigned value to Analog Data 1 of Input point 1

Assigned value to Analog Data 1 of Input point 2

Assigned value to Analog Data 1 of Input point 3

015

2) Analog Data2

Analog Data 2 is assigned as Produced I/O data by Congurator or Explicit message. By property setting, assignment is

available as Analog Input Value, Peak Value, Bottom Value.

● Assembly Instance ID: 104 ● Default: 0

● Setting range: 0 to 2 (Analog Input Value: 0, Peak Value: 1, Bottom Value: 2)

● Data type: Word, Data size: 4Word

15 15

Assigned value to Analog Data 2 of Input point 0

Assigned value to Analog Data 2 of Input point 1

0 0

Assigned value to Analog Data 2 of Input point 2

Assigned value to Analog Data 2 of Input point 3

3) Generic Status

Generic Status is assigned as Produced I/O data by Congurator or Explicit message.

● Assembly Instance ID: 100 ● Data type: Byte, Data size: 1Byte

● Generic Status

Bit 0: Reserved.

Bit 1: Network Power Voltage Drops.

Bit 2: Life State (Unit)

15

-

X-32

Bit 3: Reserved.

Bit 4: Reserved.

Bit 5: Reserved.

0

Generic Status

Autonics

Bit 6: Reserved.

Bit 7: Reserved.

DeviceNet Analog Remote I/O

4) Analog Status

Analog Status is assigned as Produced I/O data by Congurator or Explicit message.

● Assembly Instance ID: 105 ●Data type: Byte, Data size: 4Byte

● Analog Status

Bit 0: Low Alarm (LL)

Bit 1: Low Warning (L)

Bit 2: Pass Signal (Nomal)

15 0

Analog Status of Input point 1 Analog Status of Input point 0

Analog Status of Input point 3 Analog Status of Input point 2

5) Analog Data1+Analog Data2

Analog Data 1 + Analog Data 2 is assigned as Produced I/O data by Congurator or Explicit message. By property setting,

assignment is available as Analog Input Value, Peak Value, Bottom Value.

● Assembly Instance ID: 106 ● Default: 0

● Setting range: 0 to 2 (Analog Input Value: 0, Peak Value: 1, Bottom Value: 2)

● Data type: Word, Data size: 8Word

15 150 0

Assigned value to Analog Data 1 of Input point 0

Assigned value to Analog Data 2 of Input point 0

Assigned value to Analog Data 1 of Input point 1

Assigned value to Analog Data 2 of Input point 1

6) Analog Status+Generic Status

Analog Status + Generic Status is assigned as Produced I/O data by Congurator or Explicit message.

● Assembly Instance ID: 107 ● Data type: Byte, Data size: 5Byte

15

Analog Status of Input point 1 Analog Status of Input point 0

Analog Status of Input point 3 Analog Status of Input point 2

-

7) Analog Data+Analog Status

Analog Data 1 + Analog Status is assigned as Produced I/O data by Congurator or Explicit message. By property setting,

assignment is available as Analog Input Value, Peak Value, Bottom Value.

● Assembly Instance ID: 108 ● Default: 0

● Setting range: 0 to 2 (Analog Input Value: 0, Peak Value: 1, Bottom Value: 2)

● Data type: Byte, Data size: 12Byte

15 0

Assigned Low Byte at Analog Data 1 of Input point 1 Analog Status of Input point 0

Analog Status of Input point 1 Assigned High Byte at Analog Data 1 of Input point 1

Assigned Low Byte at Analog Data 1 of Input point 3 Analog Status of Input point 2

Analog Status of Input point 3 Assigned High Byte at Analog Data 1 of Input point 3

Cautions during Use

1. Follow instructions in 'Cautions during Use'. Otherwise, it may cause unexpected accidents.

2. 24VDC power supply should be insulated and limited voltage/current or Class 2, SELV power supply device.

3. Keep away from high voltage lines or power lines to prevent inductive noise.

In case installing power line and input signal line closely, use line lter or varistor at power line and shielded wire at input

signal line.

Do not use near the equipment which generates strong magnetic force or high frequency noise.

4. This unit may be used in the following environments.

Indoors (in the environment condition rated in 'Specications')

①

Altitude max. 2,000m

②

Pollution degree 2

③

Installation category II

④

Assigned value to Analog Data 1 of Input point 0

Assigned value to Analog Data 1 of Input point 2

Bit 3: High Warning (H)

Bit 4: High Alarm (HH)

Bit 5: Broken Wire

Assigned value to Analog Data 1 of Input point 2

Assigned value to Analog Data 2 of Input point 2

Assigned value to Analog Data 1 of Input point 3

Assigned value to Analog Data 2 of Input point 3

I

I

I

I

Bit 6: Under Range

Bit 7: Over Range

0

Generic Status

SENSORS

CONTROLLERS

MOTION DEVICES

SOFTWARE

(J)

Temperature

Controllers

(K)

SSRs

(L)

Power

Controllers

(M)

Counters

(N)

Timers

(O)

Digital

Panel Meters

(P)

Indicators

(Q)

Converters

(R)

Digital

Display Units

(S)

Sensor

Controllers

(T)

Switching

Mode Power

Supplies

(U)

Recorders

(V)

HMIs

(W)

Panel PC

(X)

Field Network

Devices

Autonics

X-33

Loading...

Loading...