DRW180231AB

Autonics

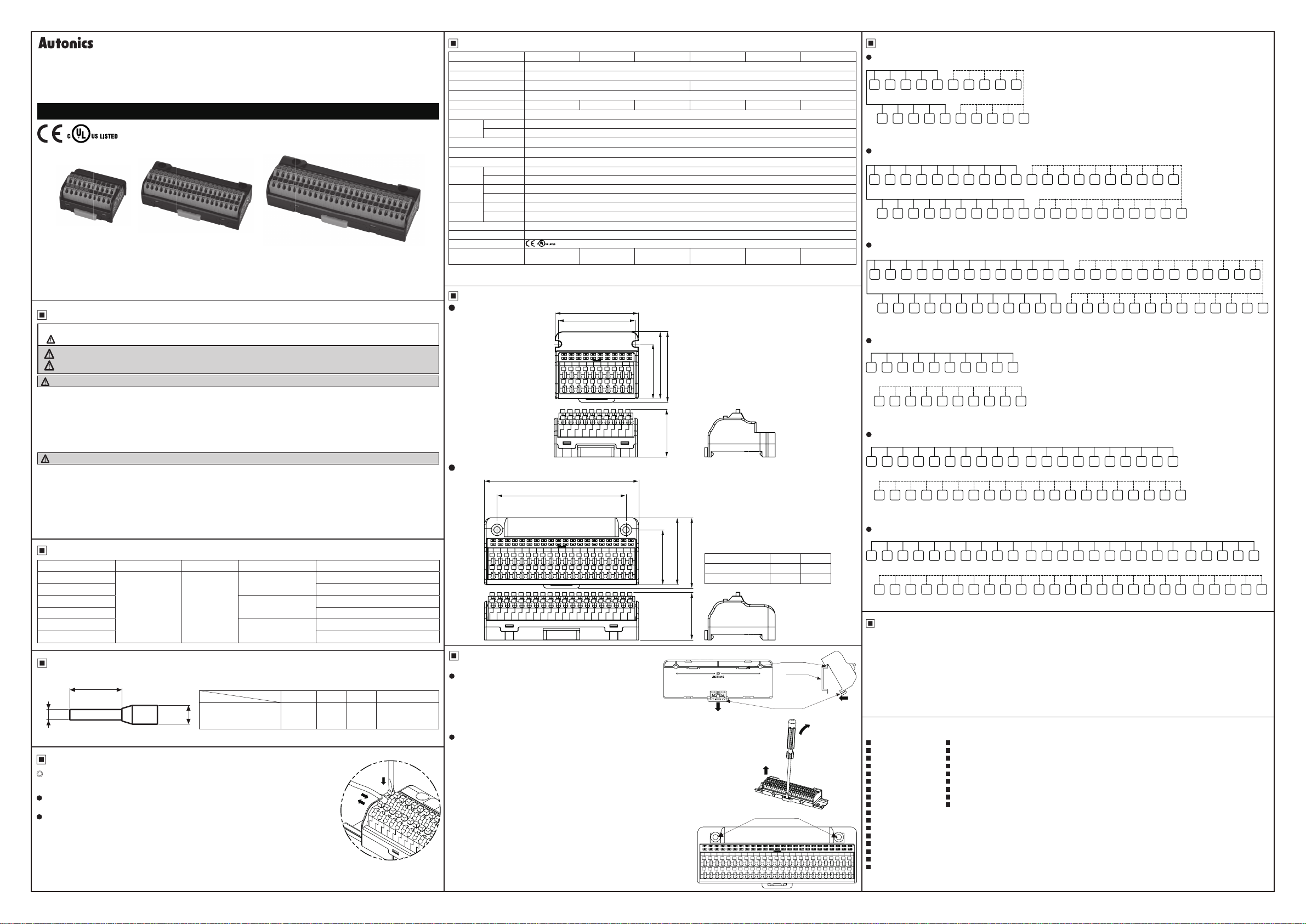

COMMON Terminal Block

(screwless type)

ACL Series

I N S T R U C T I O N M A N U A L

(

E:

c@us

Safety Considerations

Please observe all safety considerations for safe and proper product operation to avoid hazards.

※

symbol represents caution due to special circumstances in which hazards may occur.

※

Warning

Caution

Warning

1. Fail-safe device must be installed when using the unit with machinery that may cause serious injury or substantial economic

loss. (e.g. nuclear power control, medical equipment, ships, vehicles, railways, aircraft, combustion apparatus, safety

equipment, crime/disaster prevention devices, etc.)

Failure to follow this instruction may result in fi re, personal injury, or economic loss.

2. Do not connect, repair, or inspect the unit, or remove connector while connected to a power source.

Failure to follow this instruction may result in electric shock or fi re.

3. Do not disassemble or modify the unit.

Failure to follow this instruction may result in electric shock or fi re.

Caution

1. Use the unit within the rated specifi cations.

Failure to follow this instruction may result in fi re or product damage.

2. Use dry cloth to clean the unit, and do not use water or organic solvent.

Failure to follow this instruction may result in electric shock or fi re.

3. Do not use the unit in the place where fl ammable/explosive/corrosive gas, humidity, direct sunlight, radiant heat, vibration,

impact, or salinity may be present.

Failure to follow this instruction may result in fi re or explosion.

4. Keep metal chip, dust, and wire residue from fl owing into the unit.

Failure to follow this instruction may result in fi re or product damage.

Model

Model Item Terminal type The number of terminal Common type

ACL-20L

ACL-20T Top-Bottom Common

ACL-40L

ACL-40T Top-Bottom Common

ACL-50L

ACL-50T Top-Bottom Common

Crimp Terminal Specifi cations

B

Connecting Crimp Terminals

Connecting and removing end sleeve (ferrule terminal) crimp terminal

at screwless type terminal block

Connecting

•

1) Push the end sleeve (ferrule terminal) crimp terminal towards direction ① to complete the connection.

Removing

•

1) Press and hold the catch above the terminal in direction ② with a fl athead screwdriver.

2) Pull and remove the end sleeve (ferrule terminal) crimp terminal towards direction ③.

The above specifications are subject to change and some models may be discontinued without notice.

※

Be sure to follow cautions written in the instruction manual and the technical descriptions (catalog, homepage).

※

LISTED

[20-pin] [40-pin] [50-pin]

Thank you for choosing our Autonics product.

Please read the following safety considerations before use.

Failure to follow these instructions may result in serious injury or death.

Failure to follow these instructions may result in personal injury or product damage.

Left-Right Common

Left-Right Common

Left-Right Common

I I I

A

Common

terminal block

l..-------,--1

Screwless

End Sleeve

C

---------..1

(Ferrule Terminal) crimp

I

~

terminal

Use the UL certifi ed crimp terminal.

※

20

40

50

A B C Applicable wire

10 to 12.0 ≤ 2 0 ≤ 4.1

I

①

③

(unit: mm)

AWG22-16

(0.30 to 1.25mm

(60℃ only)

②

2

Specifi cations

Model ACL-20L ACL-40L ACL-50L ACL-20T ACL-40T ACL-50T

Rated voltage 250VDCᜡ, 250VACᜠ 50/60Hz

Rated current ≤10A

Common type Left +COM / Right -COM Top +COM / Bottom -COM

Terminal type

The number of terminal

Terminal pitch 5 0mm

Applicable

wires

Stripped wire length 8 to 10mm

Insulation resistance ≥1,000MΩ (at 500VDC megger)

Dielectric strength 3,000VAC 50/60Hz for 1 minute (between open terminals)

Vibration

Shock

Environment

Material Terminal: polyamide 66, conductive plate: copper, tin plated, case: polycarbonate, base: polycarbonate

Protection structure IP20 (IEC standard)

Approval

Weight

※

※

Solid wire Ø0.6 to Ø1 25mm (60℃ only)

Stranded wire

Mechanical 0.75mm amplitude at frequency of 10 to 55Hz (for 1 min) in each X, Y, Z direction for 2 hours

Malfunction 0.75mm amplitude at frequency of 10 to 55Hz (for 1 min) in each X, Y, Z direction for 10 minutes

Mechanical 1,000m/s

Malfunction 100m/s

Ambient temp.

Ambient humi.

1

※

1: The weight includes packaging. The weight in parenthesis is for unit only.

Environment resistance is rated at no freezing or condensation.

Screwless

20 40 50 20 40 50

UL: AWG22-16 (0.30 to 1.25mm2) (60℃ only)

-15 to 55℃, storage: -25 to 65

35 to 85%RH, storage: 35 to 85%RH

(€

,®--

Approx. 71g

(approx. 42g)

I

I

2

(approx. 100G) in each X, Y, Z direction for 3 times

2

(approx. 10G) in each X, Y, Z direction for 3 times

Approx. 146g

(approx. 79g)

I

I I I I

I I I I

℃

Approx. 164g

(approx. 97g)

I I I I

I

Approx. 71g

(approx. 42g)

Approx. 146g

(approx. 79g)

Dimensions

ACL-20L(T)

ACL-40L(T) / ACL-50L(T)

•

'I

i

~~~~~~~~~~~~~~~~~~~=

[:;;;][:;;;][:;;;][:;;;:J[:;;;][:;;;][:;;;][ij][ii]

[ I

i;;

Q[

JJ

1nnu

L ':,'. L

""

I~

LI

L L

, ':,'. L

lrlln

Installation

1. Mounting and removal at DIN rail

Mounting

•

1) Pull the rail lock towards direction ①.

2) Attach the DIN rail connection part onto the DIN rail.

3) Push the unit towards direction ②, then push the rail lock in to lock

toward the unit.

)

Removal

•

1) Insert a screwdriver into the rail lock hole and push it towards direction ③.

2) Remove the unit by pulling the unit towards direction ④.

2. Mounting with screws

1)

The unit can be mounted on panel using the mounting hole.

2)

M4×10mm spring washer screws are recommended for installation. When using

fl at washers, use Ø8mm diameter washers. The tightening torque should be from 1.0

to 1.5N m.

A

B

i]IJ

[ii][ij][ij][ii][ij][ij][ii][ij][ii]

[IC

inn

LIL

n

[ [

LL

57.5

53

I

,i;;

M

I L L L

lnlrl

l\r.t--

lie:~

i;;

i:;

inn

L L

46.5

48.8

38

33.1

46.5

38.1

48.8

Model

ACL-40L(T)

ACL-50L(T)

I I

32.9

①

A B

106 5 89

131 5 102

DIN rail connection part

④

Mounting hole

DIN rail

Rail lock

Approx. 164g

(approx. 97g)

(unit: mm)

(unit: mm)

③

Wire Connections

ACL-20L

-,

B1

B2

B3

B4

B5

B6

B7

B8

B9

000001

-

-

A1

A2

A3

A4

A5

A6

A7

00000

-

-

ACL-40L

•

B1

B2

B3

B4

B5

B6

1c1ic1ic1ic1ic1ic1ic1ic1ic1i2Jooooooooocii

A1

A2

A3

66666666660000000000

ACL-50L

•

B1

B2

A1

ACL-20T

•

B1

B2

A1

A2

0000000000

-

ACL-40T

•

B1

B2

00000000000000000000

A1

A2

00000000000000000006

-

ACL-50T

•

B2

B1

A2

A1

0000000000000000000000000

-

A4

B3

B4

A2

A3

A4

B3

B4

B5

A3

A4

-

-

-

B3

B4

B5

A3

A4

-

-

-

B5

B4

B3

A4

A3

-

-

-

B7

A5

A6

A7

B5

B6

B7

A5

A6

A7

B6

B7

B8

A5

A6

A7

-

-

-

B6

B7

B8

A5

A6

A7

-

-

-

B8

B7

B6

A7

A6

A5

-

-

-

B10

-

-

-

:

:

A8

A9

A10

-

-

-

B15

B16

B17

B18

B19

B8

B9

B10

B11

B12

B13

B14

-

-

-

-

-

-

A8

A9

A10

A11

A12

A13

-

B8

B9

B10

B11

B12

A8

A9

A10

A11

B9

B10

A8

A9

A10

-

-

-

B9

B10

B11

B12

A8

A9

A10

-

B9

A8

-

A11

-

-

-

B12

B11

B10

A11

A10

A9

-

-

-

A14

-

-

-

B13

B14

B15

-

A12

A13

A14

-

-

B13

B14

B15

A12

A13

A14

-

-

-

B15

B14

B13

A14

A13

A12

-

-

-

-

A15

A16

A17

-

-

-

B16

B17

-

-

-

A15

A16

A17

-

-

-

B16

B17

A15

A16

A17

-

-

-

B17

B16

A17

A16

A15

-

-

-

B20

-

-

-

A18

A19

A20

-

-

-

B18

B19

-

A18

-

B18

B19

A18

-

B19

B18

A18

-

B21-B22-B23-B24-B25

B20

-

-

A19

A20

-

-

B20

A19

A20

-

-

B21 B22 B23 B24 B25

B20

A20

A19

-

-

A21-A22-A23-A24-A25

A21-A22-A23-A24-A25

Cautions during Use

1. Follow instructions in 'Cautions during Use'. Otherwise, it may cause unexpected accidents.

2. Keep away from high voltage lines or power lines to prevent inductive noise.

In case installing power line and input signal line closely, use line filter or varistor at power line and shielded wire at input signal line.

Do not use near the equipment which generates strong magnetic force or high frequency noise.

3. This unit may be used in the following environments.

①Indoors (in the environment condition rated in 'Specifications')

②Altitude max. 2,000m

③Pollution degree 2

②

④Installation category II

Major Products

▣

Photoelectric Sensors Temperature Controllers

Fiber Optic Sensors Temperature/Humidity Transducers

Door Sensors SSRs/Power Controllers

Door Side Sensors Counters

Area Sensors Timers

Proximity Sensors Panel Meters

Pressure Sensors Tachometer/Pulse(Rate)Meters

Rotary Encoders Display Units

Connector/Sockets Sensor Controllers

Switching Mode Power Supplies

Control Switches/Lamps/Buzzers

/O Terminal Blocks & Cables

Stepper Motors/Drivers/Motion Controllers

Graphic/Logic Panels

Field Network Devices

Laser Marking System (Fiber, Co₂, Nd:YAG)

Laser Welding/Cutting System

■

■

■

■

■

■

■

■

■

-

-

-

DRW180231AB

Loading...

Loading...