Autohelm 1000 Manual

Installation and Operating Handbook

ANALOGUE

Autohelm 1000

The Autohelm 1000 is a highly developed autopilot built to operate reliably in exposed marine conditions. When correctly installed it will soon become a vital crew-member giving many years of invaluable service.

The system has been designed for owner installation and aided by the following installation guide, fitting should prove to be a straightforward and enjoyable job.

Cockpit and tiller configurations vary widely, and thus in some cases special attachments may be necessary to effect the neatest possible installation. The attachments available and their

applications are fully described |

|

and are |

stocked |

|||

for immediate supply when required. |

|

|

||||

In cases |

where |

special |

advice is |

needed you are |

||

encouraged |

to |

contact |

our |

Technical |

Sales |

|

Department who will be pleased to assist.

INSTALLATION

The basic actuator unit is a totally self-contained |

The actuator pushrod attaches to the tiller via a |

|

magnetic sensing automatic pilot. The autopilot is |

ball-ended pin situated 18” (460mm) radially |

|

mounted between the tiller and a single attachment |

distant from the rudder stock or rudder pintle |

|

point to the yacht's structure. After connection to |

centreline. |

|

the yacht's 12 volt electrical system the unit |

If the rudder pivot axis is |

sloping, the position |

becomes operational. |

of the ball-ended pin must |

be positioned at a |

|

radius of l8” (460mm) at 90 degrees to the axis of |

|

Since the autopilot incorporates a magnetic sensing |

rudder rotation as shown on the accompanying |

|

device, it is advisable to ensure that the yacht's |

illustration. |

|

steering compass is situated at least 2'6” (750mm) |

|

|

away to avoid deviation. |

|

|

4

Porthand mounting |

|

|

|

Extended pushrods |

|||

In certain instances it may be more convenient to |

In some cases it may not be possible to provide a |

||||||

mount the unit on the porthand side. The standard |

convenient site for the mounting socket at the |

||||||

unit is sensed to operate on the starboard side of |

standard mounting distance of 19" (480mm). In such |

||||||

the |

tiller |

and |

where porthand |

mounting is |

required |

cases the mounting distance can be increased in |

|

a special porthand system must be ordered. |

|

increments of 1" (25mm) to a maximum of 6" (l5Omm) |

|||||

Porthand systems must be fitted with porthand wind |

with the use of special pushrod extensions. The |

||||||

vane attachments. |

|

|

|

pushrod is extended by first unscrewing the pushrod |

|||

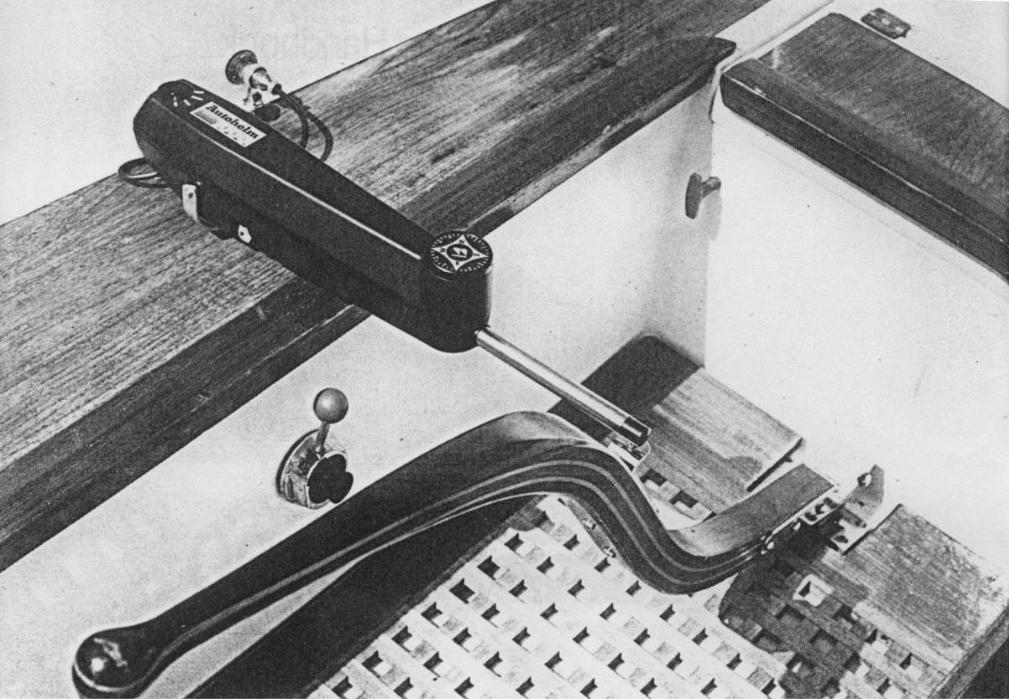

Basic installation method |

|

|

|

end cap and then screwing the pushrod extension |

|||

|

|

|

into position between the pushrod and the end cap. |

||||

When the tiller is positioned |

low |

in the |

cockpit |

This attachment is necessary, for example. When the |

|||

and is adjustable in height, |

the |

mounting socket |

cockpit is unusually wide or when it is convenient |

||||

can |

be |

most |

conveniently |

positioned |

on the |

to mount the unit on the cockpit coaming. |

|

starboard cockpit seat. The pushrod is attached to |

|

||||||

the tiller via the standard ballpin provided which |

|

||||||

is |

inserted directly into the |

top |

of the |

tiller. |

|

||

The ballpin is installed by inserting it into a ¼” (6mm) drilled hole and securing with a good quality two pack epoxy adhesive such as Araldite. The shoulder of the ballpin should be positioned ½” (12.5mm) above the upper surface of the tiller to avoid fouling when the pushrod is fully retracted.

The autopilot mounting socket is installed by inserting it into a 1.2” (12.5mm) drilled hole and permanently bonded with Araldite. It is important to ensure that the mounting socket is securely installed. If the mounting site, for example, consists only of a single glass fibre skin of less thickness than the depth of the socket it will be necessary to provide reinforcement by bonding a plywood strengthening plate to the underside.

The autopilot is capable of generating very high pushrod loads and it must be stressed that in all cases the mounting socket should be very firmly bonded into position.

5

Tiller attachments |

|

|

|

|

|

|

|

The tiller crank attachments are bolted through the |

|||

When the tiller is not adjustable in height or is |

centreline of the tiller, with ¼” (6mm) diameter |

||||||||||

positioned appreciably higher than the most |

bolts and since the bolts through the neutral |

||||||||||

convenient site for the mounting socket. It is |

bending axis, the bending strength of the tiller |

||||||||||

often |

convenient |

to |

lower |

the ballpin |

underneath |

will not be significantly altered. The securing |

|||||

the tiller. Standard tiller cranks are available in |

bolts should be looked into the clearance holes |

||||||||||

a range of sizes to lower the ballpin centre in |

through the tiller with epoxy adhesive to ensure |

||||||||||

increments of 1” (25mm) to a maximum of 5” (125mm) |

that they do not work loose in operation. |

||||||||||

below the underside of the tiller. Since the |

|

||||||||||

pushrod centreline |

is |

positioned |

2” |

(62mm) |

above |

|

|||||

the |

mounting socket, |

these |

attachments |

can |

cater |

|

|||||

for a vertical distance between the mounting socket |

|

||||||||||

and the underside of the tiller of up to a maximum |

|

||||||||||

of |

7" |

(190mm). |

This |

attachment |

is |

particularly |

|

||||

usefulin the case of transom hung rudder configurations (such as the Folkboat) where the tiller passes over an extended counter. In such cases a tiller crank of suitable ballpin off-set will enable the unit to be neatly mounted directly on the surface of the counter or the rear coaming.

6

Loading...

Loading...